Microstructure and mechanical properties of DP-MIG welding-rolling composite forming joints of 6061-T6 aluminum alloy

-

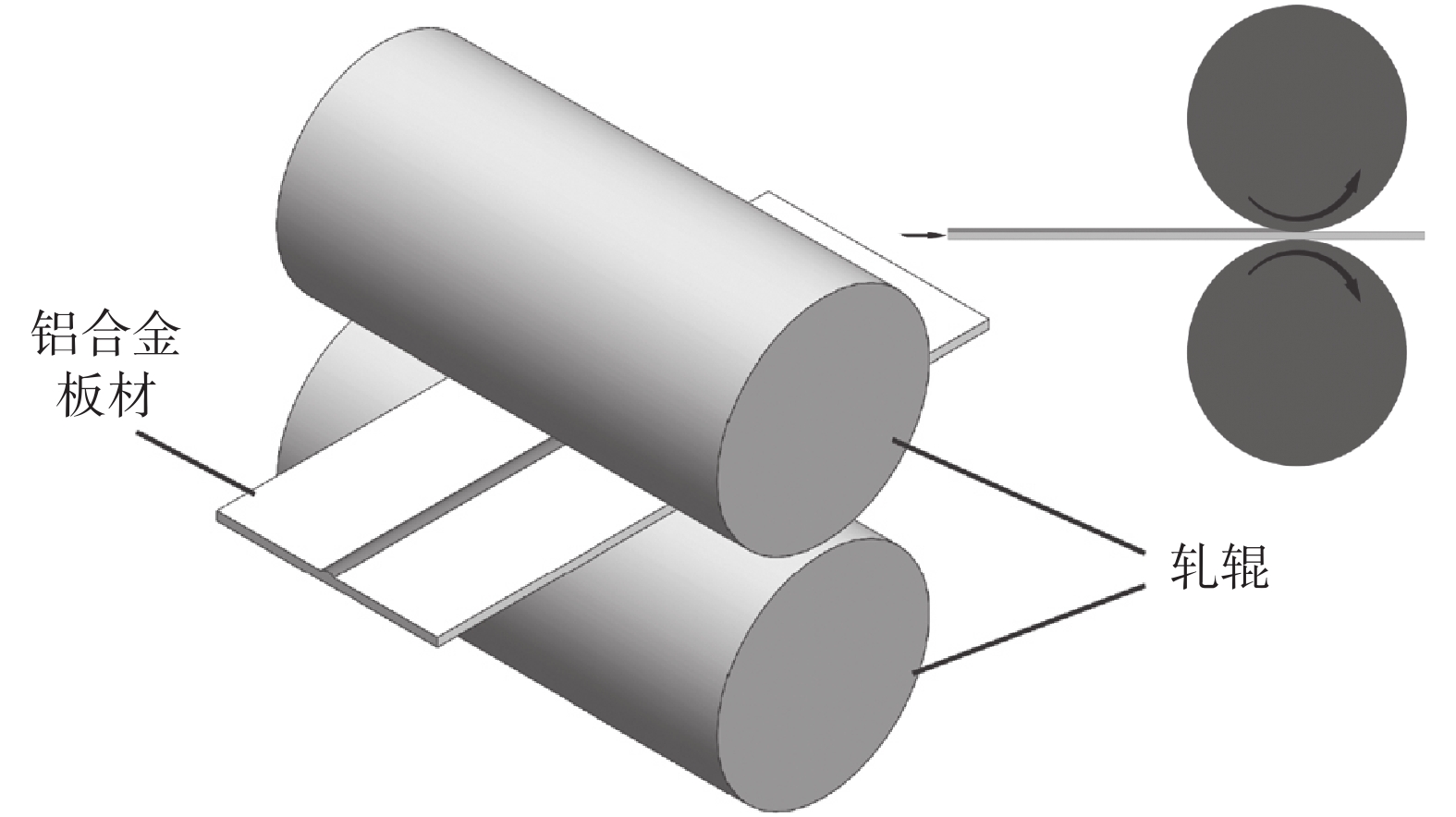

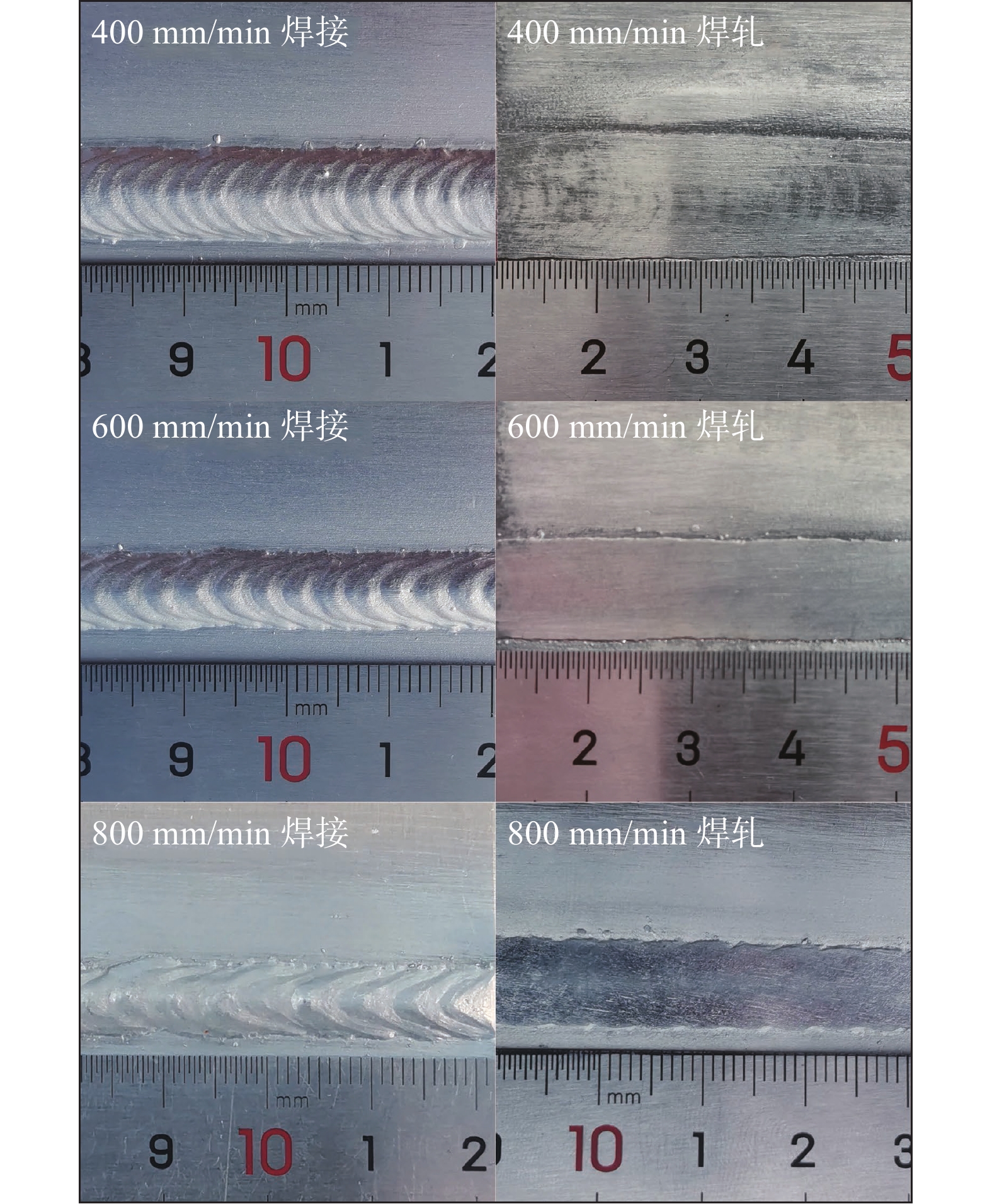

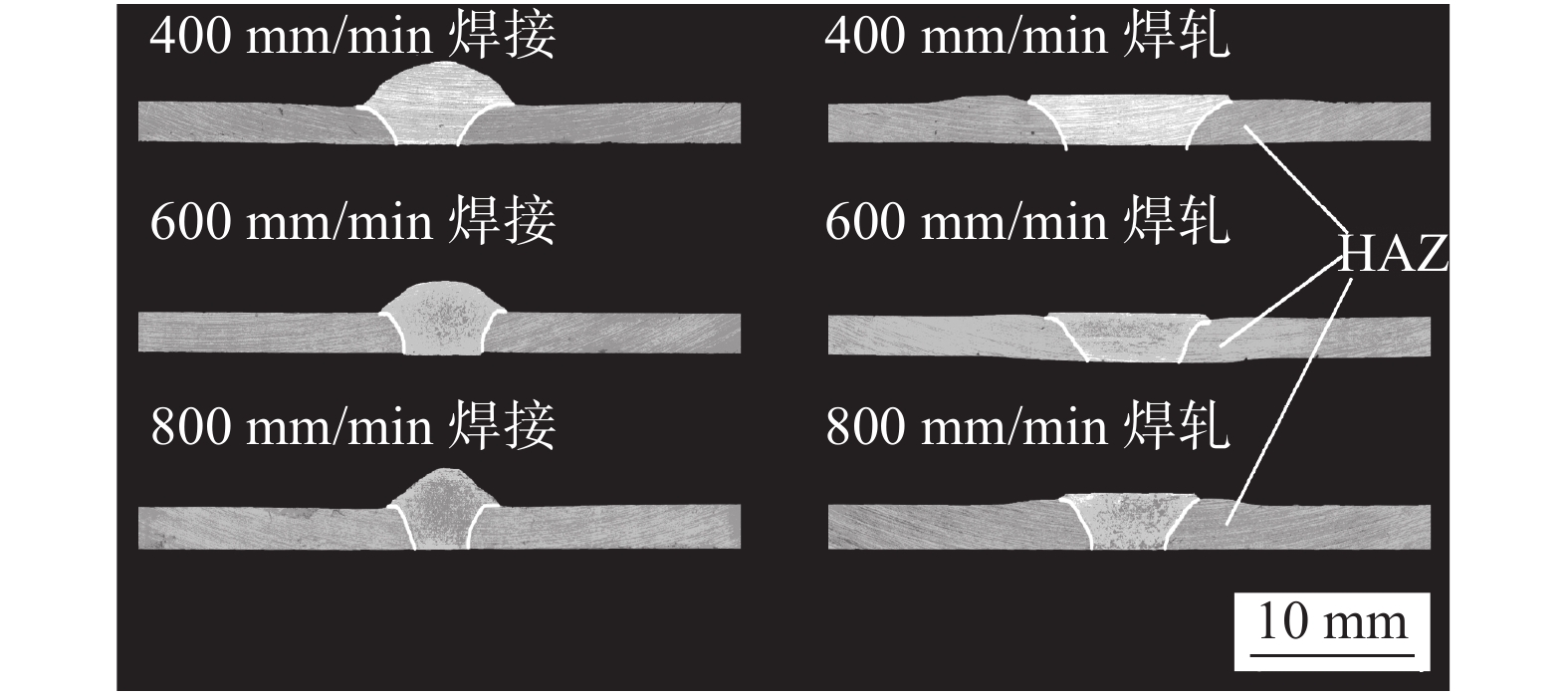

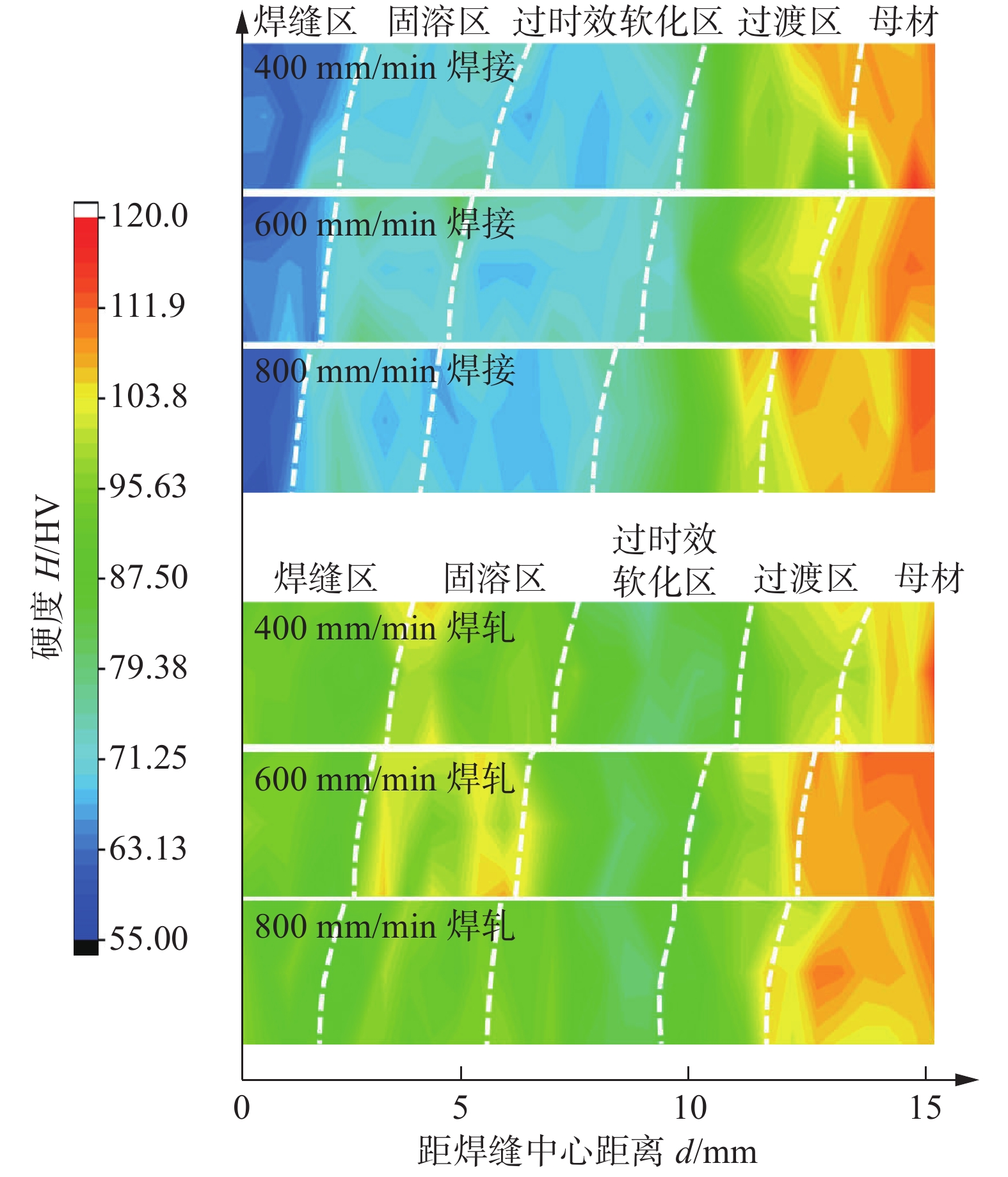

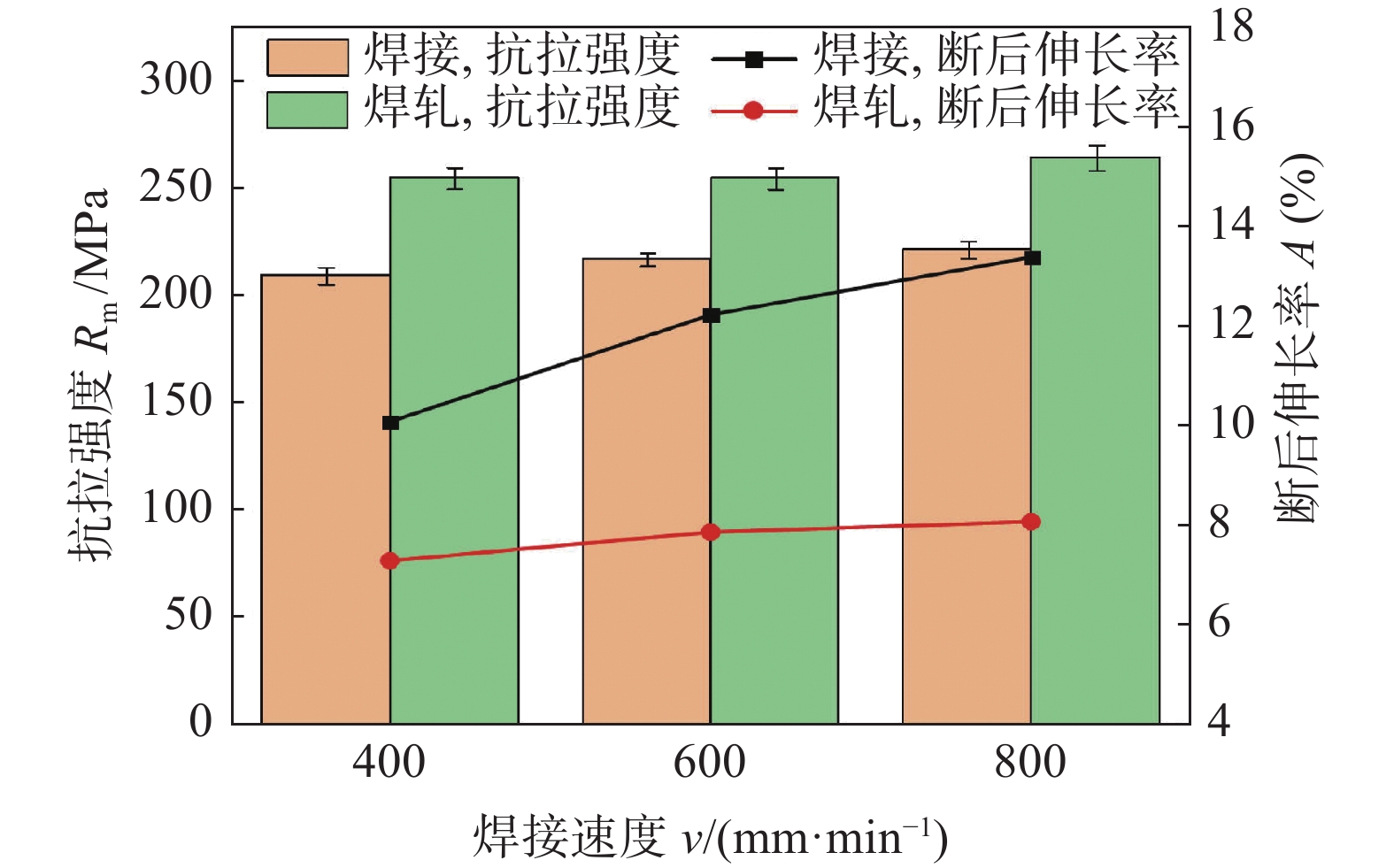

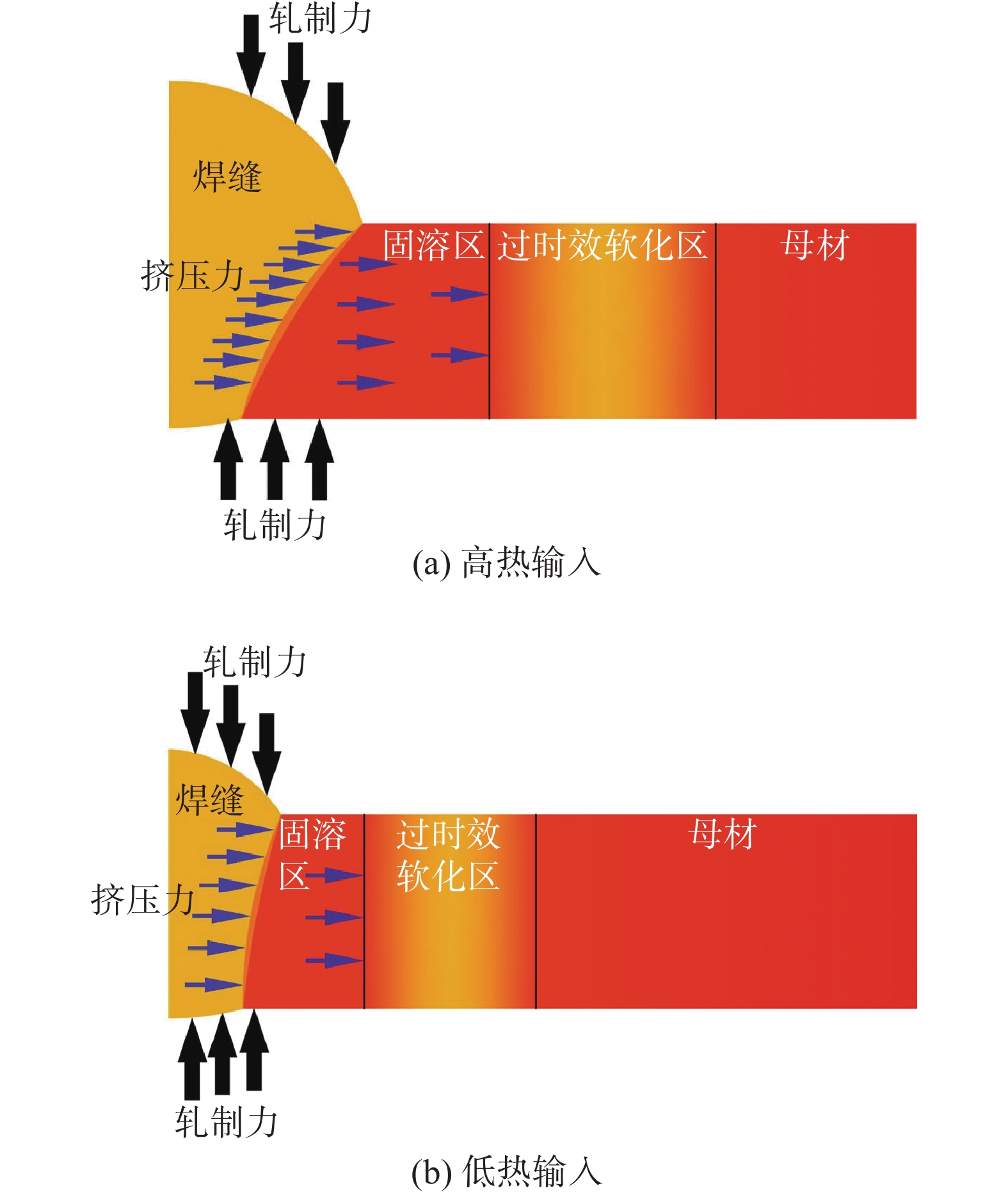

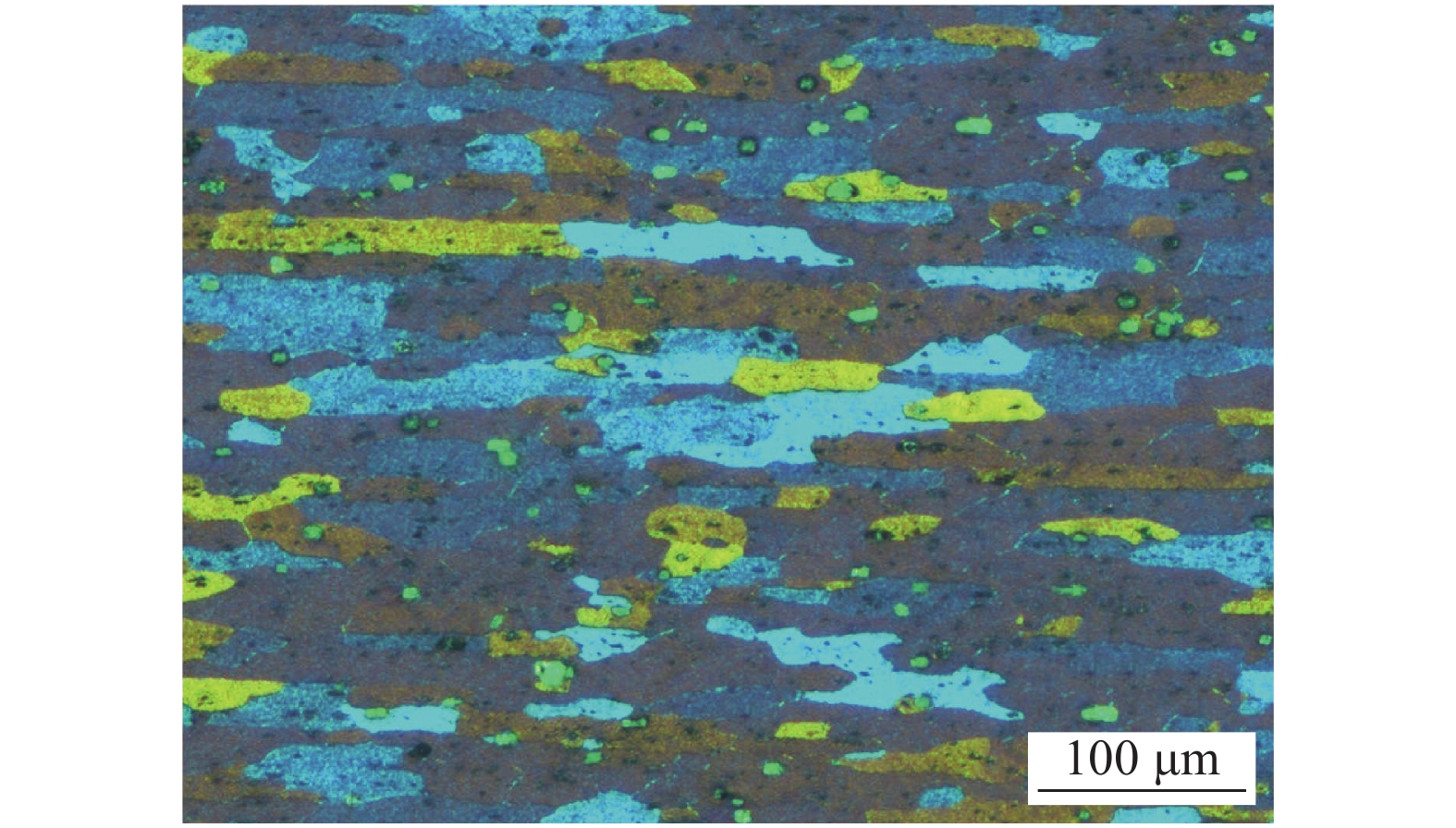

摘要: 为解决6061-T6铝合金焊后热影响区软化导致力学性能下降的问题,基于焊接接头余高大变形强化过时效软化区的思想,采用双轧辊系统对6061-T6薄板铝合金直流双脉冲熔化极气体保护焊(DC double pulse metal inert gas welding,DP-MIG焊)接头进行同步双面轧制,并分析了焊轧复合成形接头组织与力学性能. 结果表明,焊缝晶粒受到竖直方向的轧制力发生大塑性变形,内部气孔消失,焊缝区域变宽,邻近焊缝的热影响区受到来自焊缝的挤压力发生协同宏观变形,远离焊缝的过时效软化区组织受到来自焊缝处的压应力,从沿垂直焊缝方向产生部分协同形变强化;接头的硬度明显提升,过时效软化区的硬度由60 ~ 70 HV提升至80 ~ 90 HV,过时效软化区的拉伸性能也有所提升,当焊接速度为800 mm/min时,抗拉强度最佳可达到母材的83.6%,相较于焊接接头提升19.4%,进而实现了对过时效软化区的强化效果.

-

关键词:

- 铝合金 /

- 热影响区软化 /

- 直流双脉冲熔化极气体保护焊 /

- 焊轧复合成形

Abstract: To solve the problem of degrading of mechanical properties of as welded 6061-T6 aluminum alloy joint caused by softening of the heat-affected zone, this study applied a double-roller system to perform simultaneous double-sided rolling on 6061-T6 thin aluminum alloy DC double pulse metal inert gas (DP-MIG) welded joints, based on the idea of utilizing welding residual height and large deformation to strengthen the over-aging softened zone. The microstructure and mechanical properties of the welding-rolling composite forming joints were analyzed. The results are as follows: the weld grain is subjected to large plastic deformation by the vertical rolling force; The internal pores disappear, thus the weld area widens. The heat-affected zone adjacent to the weld is subjected to co-macro deformation by the extrusion force from the weld, and the over-aging softened zone far from the weld is subjected to compressive stress from the weld, resulting in partial co-deformation strengthening along the vertical weld direction. The overall hardness of the joints is significantly improved with the hardness of the over-aging softened zone, which increased from 60 − 70 HV to 80 − 90 HV. The tensile properties of the over-aging softened zone are improved. When the welding speed is 800 mm/min, the best tensile strength can reach 83.6% of that of the base metal, 19.4% higher than that of the welded joint, which is a notable improvement to the over-aging softened zone. -

-

表 1 母材与焊丝的化学成分(质量分数,%)

Table 1 Chemical compositions of base metal and welding wire

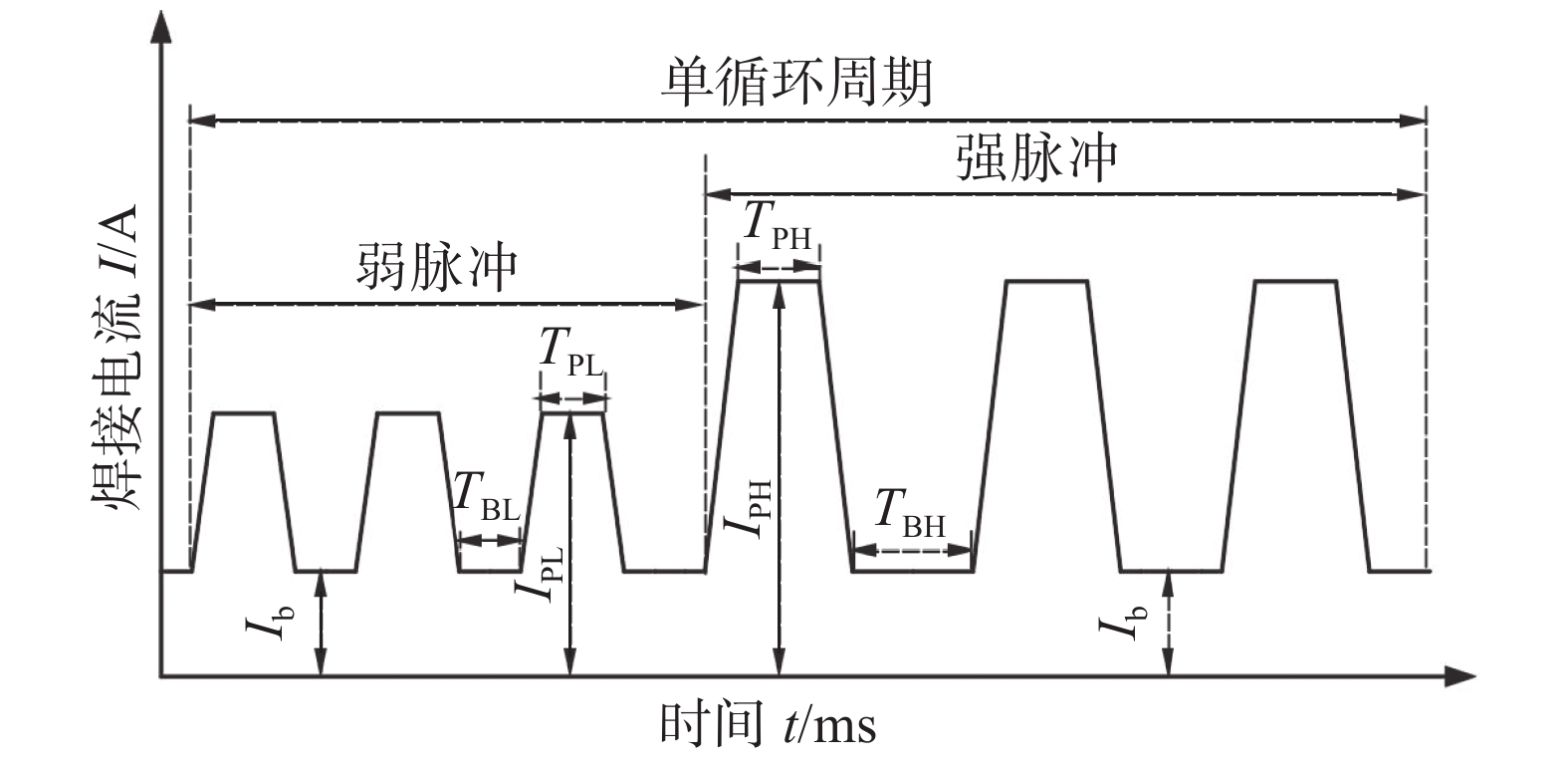

材料 Mg Si Fe Cu Mn Cr Zn Ti Al 6061-T6 1.074 0.635 0.397 0.268 0.082 0.205 0.003 0.003 余量 ER5356 4.900 0.050 0.120 0.005 0.120 0.120 0.090 0.090 余量 表 2 DP-MIG焊焊接电流波形基本参数

Table 2 Corresponding parameters of DP-MIG welding current waveform

平均焊接电流

I/A基值电流

Ib /A峰值电流 IP /A 基值时间 tb /ms 峰值时间 tP /ms 弱脉冲 强脉冲 弱脉冲 强脉冲 弱脉冲 强脉冲 80 28 310 336 0.8 0.6 1.0 0.8 表 3 焊接工艺参数

Table 3 Welding parameters

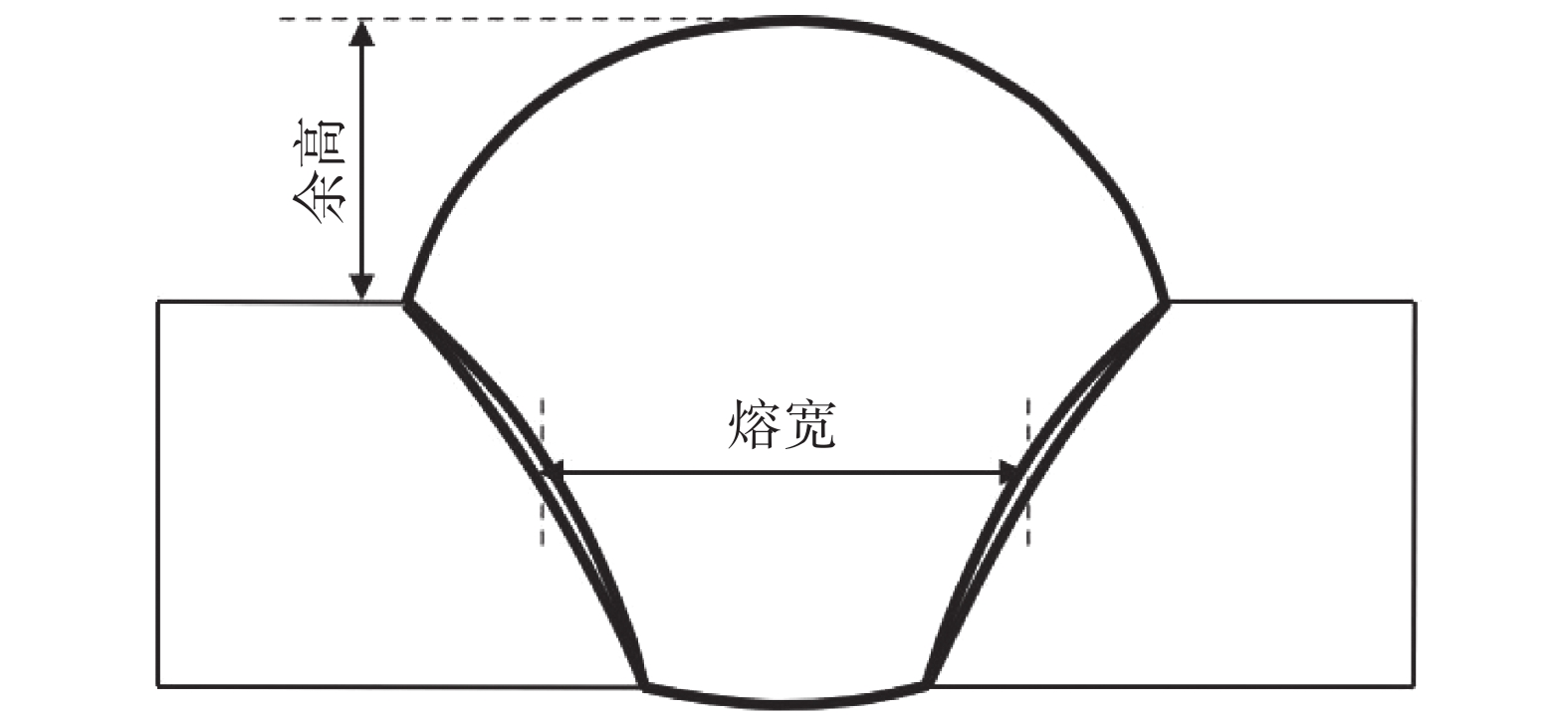

焊接电流I/A 焊接速度v/(mm·min−1) 脉冲频率f/Hz 热输入E/(kJ·mm−1) 焊丝伸出长度l/mm 保护气体流量Q/(L·min−1) 80 400 3 1.78 15 16 80 600 3 1.19 15 16 80 800 3 0.90 15 16 表 4 不同焊接速度下焊缝尺寸

Table 4 Weld size at different welding speeds

焊接速度v/(mm·min−1) 余高h/mm 熔宽w/mm 400 2.88 8.54 600 1.98 7.80 800 1.52 6.16 -

[1] Yan S, Chen H, Zhu Z, et al. Hybrid laser-metal inert gas welding of Al-Mg-Si alloy joints: microstructure and mechanical properties[J]. Materials & Design, 2014, 61: 160 − 167.

[2] 林相远, 张威, 王利, 等. 6xxx系铝合金弧焊与高功率激光焊组织性能对比[J]. 有色金属加工, 2020, 49(2): 16 − 19. Lin Xiangyuan, Zhang Wei, Wang Li, et al. Comparative study on mechanical properties of 6xxx aluminum alloy high power laser welding and arc welding welded joint[J]. Nonferrous Metals Processing, 2020, 49(2): 16 − 19.

[3] Rekik W, Ancelet O, Gardin C. Identification of the gradient of mechanical properties in electron beam welded joints of thick Al6061-T6 plate[C]//ASME 2016 Pressure Vessels and Piping Conference. Vancouver, Canada, 2016, 50411: V005T09A014.

[4] 春兰, 韩永全, 陈芙蓉, 等. 铝合金脉冲变极性等离子弧焊接工艺[J]. 焊接学报, 2016, 37(1): 29 − 32. Chun Lan, Han Yongquan, Chen Furong, et al. Pulse variable polarity plasma arc welding technology of aluminum alloy[J]. Transactions of the China Welding Institution, 2016, 37(1): 29 − 32.

[5] Maneiah D, Mishra D, Rao K P, et al. Process parameters optimization of friction stir welding for optimum tensile strength in Al 6061-T6 alloy butt welded joints[J]. Materials Today: Proceedings, 2020, 27: 904 − 908. doi: 10.1016/j.matpr.2020.01.215

[6] 王强, 霍文涛, 恒俊楠. 汽车铝合金薄板 CMT 和 MIG 对比焊接工艺研究[J]. 有色金属加工, 2022, 51(3): 16 − 20. Wang Qiang, Huo Wentao, Heng Junnan, et al. Research on comparative welding process of CMT and MIG for automotive aluminum alloy sheet[J]. Nonferrous Metals Processing, 2022, 51(3): 16 − 20.

[7] Kolubaev E, Kolubaev A, Sizova O, et al. Ultrasonic impact treatment of the welded joint of aluminum-magnesium alloy produced by friction stir welding[C]//AIP Conference Proceedings. American Institute of Physics, Tomsk, Russia, 2014, 1623(1): 271 − 274.

[8] Zhang H, Zhao X, Liu Y. Effect of high frequency impacting and rolling on fatigue crack growth of 2A12 aluminum alloy welded joint[J]. International Journal of Fatigue, 2021, 147: 106172. doi: 10.1016/j.ijfatigue.2021.106172

[9] 王佳杰, 杨建国, 张敬强, 等. 随焊冲击碾压整形新方法及等承载接头拉伸与疲劳性能[J]. 焊接学报, 2012, 33(11): 35 − 38. Wang Jiajie, Yang Jianguo, Zhang Jingqiang, et al. A new weld shaping method with trailing impact rolling and tensile and fatigue properties for equal load-carrying capacity joints[J]. Transactions of the China Welding Institution, 2012, 33(11): 35 − 38.

[10] Chai S, D Zhang, Dong Y, et al. Effect of partial rolling on the microstructure, mechanical properties and fracture behavior of AZ31 Mg alloy joints[J]. Materials Science & Engineering: A, 2015, 620: 1 − 9.

[11] 宋刚, 程继文, 刘振夫. 基于“热导拘束 + 局部变形强化”的铝合金焊轧复合成形方法[J]. 机械工程学报, 2020, 56(8): 85 − 91. doi: 10.3901/JME.2020.08.085 Song Gang, Cheng Jiwen, Liu Zhenfu. Compound technique of welding and rolling for aluminum alloy based on thermal conductivity constraint and local deformation strengthening[J]. Journal of Mechanical Engineering, 2020, 56(8): 85 − 91. doi: 10.3901/JME.2020.08.085

[12] 孔祥玉. 铝、镁合金双脉冲 MIG 焊接研究[D]. 大连: 大连理工大学, 2011. Kong Xiangyu. Study on double pulse MIG welding process of aluminum alloy and magnesium alloy[D]. Dalian: Dalian University of Technology, 2011.

[13] Nowacki J, Rybicki P. The influence of welding heat input on submerged arc welded duplex steel joints imperfections[J]. Journal of Materials Processing Technology, 2005, 164: 1082 − 1088.

[14] Steinmetz D R, Jäpel T, Wietbrock B, et al. Revealing the strain-hardening behavior of twinning-induced plasticity steels: Theory, simulations, experiments[J]. Acta Materialia, 2013, 61(2): 494 − 510. doi: 10.1016/j.actamat.2012.09.064

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: