Research progress on brazing of advanced functional materials

-

摘要: 以复相陶瓷、纤维增强陶瓷基复合材料以及热电材料为例,从钎料成分设计、钎缝界面组织调控、接头残余应力缓解以及钎焊接头性能评测等角度,讨论了近年来发表的研究成果. 结果表明,在钎料中添加活性元素以及对母材表面改性的方法,能够有效改善钎料润湿性和界面结合强度;对于界面元素扩散以及母材过渡溶解的问题,可以设计制备复合钎料或阻隔层进行解决;接头残余应力的大小受材料热膨胀系数差异的影响较大,目前已提出了多孔中间层、梯度复合层以及母材表面机械加工等多种创新方法,但研究成果的应用仍停留在小尺寸样件,对于缓解大尺寸接头的残余应力问题仍有待解决. 最后对相关研究方向进行了总结和展望,期望推动航空航天构件连接的发展进程.

-

关键词:

- 复相陶瓷 /

- 纤维增强陶瓷基复合材料 /

- 热电材料 /

- 钎焊

Abstract: Taking multiphase ceramics, fiber reinforced ceramic matrix composites and thermoelectric materials as examples, this paper discusses the researches published in recent years which focused on the composition design of filler metals, microstructure controlling of brazed interface, residual stress mitigation of brazed joints and performance evaluation of brazed joints. The results show that the wettability and interfacial bonding strength can be improved effectively by adding active elements to filler metals or modifying the surface of base metal. For the element diffusion of interface and the transitional dissolution of base metal, composite filler metals or barrier layer can be designed and prepared to solve these problems. The residual stress of brazed joint is greatly affected by the difference of thermal expansion coefficient of brazing materials. At present, various novel solutions have been proposed, such as adding porous interlayer, preparing gradient composite layer and machining of base metal surface. However, the application of research results is still limited to small size samples. The problem of relieving the residual stress of large size joints remains to be solved. Ultimately, the prospect of the interest in future research is concluded. It is expected to promote the domestic manufacturing of aerospace and weapons equipment. -

0. 序言

近年来国内交通运输业大幅发展,对大型工程机械的性能及服役寿命提出了更高的要求,提高设备的使用寿命对降低施工成本、缩短施工周期至关重要.硬质合金具有较高的硬度、强度、耐磨性和耐腐蚀性,常被用作大型机械的关键构件,比如捣固车的捣固镐、盾构机的掘进齿等.但硬质合金的韧性较低,常与钢钎焊后使用.这些关键零部件在施工过程中,不仅承受着复合交变载荷的影响,还受到岩石、沙砾等直接接触摩擦和破碎后磨蚀性磨粒的研磨,因此对钎焊接头的质量提出了较高的要求.具有较高强韧性、低应力的钎焊接头才能在遭受巨大冲击时避免发生脱焊、崩刃、塑性变形等,因此,高可靠的硬质合金/钢的连接技术研究一直被国内外学者广泛关注[1-13].

由应力缓释层、钎料合金多层复合而成三明治结构钎料可有效降低钎焊应力,提高钎焊可靠性,被广泛应用于大块硬质合金的钎焊[14-15].在钎焊过程中,多层复合界面处成分、组织形态受钎焊温度、保温时间影响而发生改变,最终影响钎焊接头力学性能.因此厘清三明治复合钎料钎焊过程中界面层组织演变规律、元素扩散特征及其对力学性能的影响,对于调控钎焊工艺至关重要.

1. 试验方法

试验母材为10 mm × 10 mm × 10 mm,Co元素含量为15%的YG15硬质合金和20 mm × 10 mm × 10 mm的42CrMo钢,其化学成分见表1.试验钎料为厚度0.2 mm梯度三明治复合钎料,该钎料是由BAg40CuZnNi,CuMn2和BAg40CuZnNiMnCo复合而成,其结构如图1所示,具体化学成分见表2.

表 1 42CrMo钢的主要化学成分(质量分数,%)Table 1. Chemical composition of 42CrMo steelC Cr Si Mo Mn Fe 0.42 1.05 0.27 0.2 0.65 余量 采用梯度三明治钎料进行YG15硬质合金和42CrMo的炉中钎焊,焊接温度为780 和800 ℃,所用钎剂为FB1206-4,主要由氟硼酸钾、硼砂和硼酸等组成.当箱式电阻炉达到设定温度时,将组装好的试样放入炉内,分别保温2,2.5,3,3.5和4 min后取出(每个保温时间下制备5个平行试样,其中3个样品用于抗剪强度测试),在空气中自然冷. 每个工艺条件下选取其中一个试样进行微观组织分析. 在镶样机中对待测试样进行镶样后,依次采用200,400,600,800,1 000,1 500和2 000目砂纸逐一打磨,并用2 µm氧化铝抛光膏抛光至镜面,用5%FeCl3溶液腐蚀试样5 s,并先后用蒸馏水、酒精浸泡在超声波清洗机中清洗10 min,在烘干箱中40 ℃烘干5 min后备用.

表 2 钎料合金化学成分(质量分数,%)Table 2. Chemical compositions of filler metal材料 Ag Cu Zn Ni Mn Co BAg40CuZnNi 40 30 27.8 2.2 — — CuMn2 — 98 — — 2 — BAg40CuZnNiMnCo 40 30 20.5 4 4.5 1 钎焊接头抗剪强度所用的剪切试验件尺寸如图2所示,试验所用设备为MTS E45.105万能力学试验机,加载速率2 mm/min,每组进行3次平行试验,结果取其平均值.根据GB/T 4340.1—2009《金属材料维氏硬度试验第1部分:试验方法》,采用HV-1000A显微维氏硬度计对经过粗磨、精磨、抛光后的试样进行钎缝显微硬度测试,每个区域取5个平行点测量取平均值.

借助飞纳(Phenom XL)台式扫描电子显微镜(scanning electron microscope,SEM)及自带的能谱仪(energy dispersive spectrometer,EDS)观察剪切试样断口及钎缝界面结合区域形貌、分析梯度钎料界面区域Ag,Cu,Zn,Ni,Mn和Co等元素的分布及化合物相组成.

2. 试验结果与讨论

2.1 保温时间对界面组织形成和生长的影响

780 ℃不同保温时间钎缝微观组织如图3所示,可以看出BAg40CuZnNi/CuMn2/BAg40CuZnNiMnCo复合钎料与钢和硬质合金界面反应分为4个阶段:钎焊过程中界面组织形成、长大、溶合和重排.

第一阶段是界面组织形成,如图3a所示. 钎焊时间为2 min,该工艺条件下,复合钎料中的BAg40CuZnNi和BAg40CuZnNiMnCo合金层为液态,其与硬质合金和钢基体间发生反应,整个钎缝可划分为近硬质合金侧 Ⅰ 区、BAg40CuZnNiMnCo Ⅱ 区、BAg40CuZnNiMnCo与CuMn2过渡 Ⅲ 区、CuMn2 Ⅳ 区(宽度约30 µm)、BAg40CuZnNi与CuMn2过渡Ⅴ 区、BAg40CuZnNi Ⅵ 区和近钢侧Ⅶ 区,钎缝组织主要由深灰色的铜固溶体和浅灰色的银固溶体组成. CuMn2固相线温度约为1065 ℃,在该温度下处于固相,凝固过程中,BAg40CuZnNi和BAg40CuZnNiMnCo合金层中先析出的高熔点铜固溶体相(αCu)分别依附于CuMn2界面层结晶形核长大,形成了过渡Ⅲ 区和Ⅴ 区.

当保温时间为2.5 min时进入第二阶段.此时,钎焊温度为各元素之间的扩散提供驱动力,梯度三明治钎料各层间及其与基体之间相互扩散,界面组织开始长大和粗化. 处于熔融状态的BAg40CuZnNi和BAg40CuZnNiMnCo合金层开始不断溶蚀CuMn2缓释层(Ⅳ区),CuMn2合金层与周围液相发生溶质再分配,不断向BAg40CuZnNi和BAg40CuZnNiMnCo合金层中溶解,致使其厚度不断减小;近硬质合金侧Ⅰ 区和近钢侧Ⅶ 区的铜固溶体不断长大,如图3b所示,此过程受扩散机制的控制[16]. 该阶段界面组织的生长过程可以用菲克定律来描述,随着时间的延长,界面生长变化遵循以下规律,即

$$ X_{{\rm{t}}}=X_{0} + \sqrt{k t} $$ (1) 式中:Xt是不同时间界面层组织的厚度;X0是初始层厚度;t是保温时间;k是扩散系数.界面组织的生长受扩散机制的影响,所以Arrhenius关系是适用的.使晶体原子离开平衡位置迁移到另一个新的平衡或非平更位置所需要的能量即激活能,可以通过Arrhenius关系来计算,即

$$ k=k_{0} \cdot \exp \left(\frac{-Q}{R T}\right) $$ (2) 式中:k0是扩散常数(cm2/s); Q是界面层生长的激活能(kJ/mol);R是气体常数(J/mol·K);T是热力学温度(K).对式(2)两边取对数,得

$$ \ln k=\ln k_{0}-\frac{Q}{R T} $$ (3) 由lnk和1/T的曲线斜率即可求出相应的激活能,激活能越小,则界面反应就越容易进行.

当保温时间延长到3 min时(图3c),CuMn2层已由连续态转变为间断态,继续延长时间至3.5 min,进入第三个阶段,近钢和硬质合金基体侧铜固溶开始长大、相连溶合在一起,钎缝中银铜共晶组织(图3d中B点位置)增多,中间CuMn2层开始变为孤立的小岛(图3d),小岛中心部分仍为CuMn2合金,成分见表3中E点,但已固溶进去少量的Ag,Ni,Co和Zn元素;其周围被低锰铜固溶体包围,成分见表3中D和F点,与E点相比,这两处的Cu和Mn元素含量相对降低,但Ag,Zn,Ni元素的含量相对较高,特别是靠近BAg40CuZnNiMnCo侧的Ni元素含量达到2.84%,Ag元素含量达到10.26%,Zn元素含量达到15.04%.同时,从表3的成分分布可以看出,点F的铜固溶体中未检测到Co元素的存在,可推断在CuMn2固溶体完全溶解之前,Co元素聚集在BAg40CuZnNiMnCo和CuMn2合金侧,其未扩散到BAg40CuZnNi侧. Ⅵ 区的BAg40CuZnNi合金层和Ⅱ 区的BAg40CuZnNiMnCo合金层开始主要以铜固溶体和银固溶体为主,随着保温时间的延长,2种物相的尺寸不断增加,同时开始在其内部析出由αCu和αAg组成的黑白相间层片状共晶组织(图3d中B点位置).

表 3 图3中标识位置能谱分析(质量分数,%)Table 3. Energy spectrum analysis of identified locations in Fig. 3位置 Ag Cu Zn Ni Mn Co 其它 A 6.24 67.04 17.48 4.7 1.74 1.21 余量 B 34.56 38.65 20.26 3.2 1.4 0.8 余量 C 9.67 66.12 17.55 3.67 1.41 0.55 余量 D 10.26 68.02 15.04 2.84 1.50 0.51 余量 E 0.63 94.29 0.57 0.16 2.26 0.13 余量 F 6.49 74.28 14.12 0.47 1.45 — 余量 G 9.26 57.03 19.33 4.06 1.13 — 余量 当保温时间延长至4 min时,进入第四个阶段如图3e所示.整个CuMn2合金层区域消失,其与BAg40CuZnNi和BAg40CuZnNiMnCo 合金层形成统一的整体;近钢和硬质合金基体侧铜固溶体依附于基体,垂直向钎缝中心生长,尺寸达20 μm左右,整个钎缝主要由铜固溶体、银固溶体和银铜共晶组成.

为进一步分析保温过程中元素的扩散情况,选取780 ℃保温2.5,3和3.5 min典型接头区域进行Ag,Cu,Zn,Ni,Mn和Co等元素分析,结果如图4所示.从图4a可以看出,此时的中间CuMn2层部分溶解扩散,宽度由2 min(图3a)时的30 µm减小到20 µm左右;CuMn2合金中的Cu和Mn元素逐渐向两侧扩散,BAg40CuZnNi和BAg40CuZnNiMnCo合金层中的Ni,Co,Zn和Ag等元素逐渐向中间区域扩散,其中Ni和Co等元素聚集在中间层位置. 保温时间延长至3和3.5 min,溶质开始重新分配,两侧相互扩散,其中Cu,Zn,Mn和Co元素的变化最为明显,图4b和4c中能明显看到Cu元素的聚集程度减弱,开始变得间断;原中间Mn和Co元素的聚集情况已变得不再明显,整个界面Zn元素分布变得均匀分散.

2.2 钎焊温度对界面组织形成和生长的影响

800 ℃分别保温2,2.5和3 min不同时间的钎缝界面形貌如图5所示,从图中可以看出与780 ℃工艺条件下的界面组织的形成和长大规律相同. 800 ℃保温2 min条件下的微观形貌与780 ℃保温2.5 min条件下的形貌基本一致,升高温度,原子扩散速率加快,可以在较短时间达到相同的钎缝组织和状态. 800 ℃保温3 min时,钎缝中CuMn2中间层已完全消失,且组织中的长条状共晶相转变为短棒形态,深灰色的铜固溶体含量攀升(图5c).温度越高反应速率越快,界面控制难度加大,且试样钎焊热应力增加,因此在满足工艺条件的情况下选用较低钎焊温度.

2.3 钎焊工艺对性能的影响

不同温度下钎缝组织形成和长大规律相同,因此选取其中一种条件下的试样进行性能测试,分析其对性能的影响.对780 ℃保温2,2.5和4 min的钎焊接头钎缝区域进行显微硬度测试,加载重量为0.025 g,每个区域检测5个数值取平均值结果如图6所示.保温时间2 min时,从左到右硬度依次为138.3,130.5,101.6,147.3和152.8 HV0.025. 随着时间的延长,BAg40CuZnNi和BAg40CuZnNiMnCo侧由于部分中间CuMn2合金的扩散溶解,显微硬度开始降低;中间层CuMn2由于两侧Zn,Ag等元素的溶入,硬度稍有提高;当保温时间延长到4 min时,整个钎缝区域溶为一体,钎缝区域硬度稳定在120 HV0.025左右.

对780 ℃不同保温时间的钎缝抗剪强度进行测试,试样断裂位置均发生在钎缝中间位置,强度结果如图7所示. 伴随保温时间的延长,钎缝抗剪强度由最初的278 MPa升高到285 MPa后开始降低;保温3 min后钎缝强度降低的趋势开始变缓,时间延长至4 min时减小至203 MPa,比保温2 min时降低了26.98%.

为进一步分析钎缝强度变化的原因,对断口形貌进行分析. 保温2.5和4 min时的断口形貌如图8所示,为典型的韧性断裂.从图4a中看出在保温2.5 min时,BAg40CuZnNiMnCo中的Co和Ni元素发生扩散,聚集在中间层CuMn2附近,部分固溶于Cu固溶体中,形成固溶强化,部分形成了Co基第二相强化颗粒,提高CuMn2中间层的整体强韧性,在其断口形貌底部发现存在有该强化相颗粒,此种工艺条件下钎缝强度较高.在断裂发生时,在材料内部第二相颗粒首先发生断裂,分离形成显微空洞;显微空洞的形成使位错受到的排斥力大大降低,从而大量的位错在外力的作用下向新生成的显微空洞运动,使显微空洞逐渐长大.原来存在于位错环后面的位错源,由于原来堆积位错的约束消失而重新活跃起来,产生新的位错环并源源不断地向显微空洞运动,使显微空洞迅速的不稳定扩展及聚合、连接在一起形成韧窝断口,其中空洞聚集形成韧窝而断裂的示意如图9所示.

继续延长保温时间,CuMn2合金层、BAg40CuZnNi和BAg40CuZnNiMnCo合金层元素间不断相互扩散,Co和Ni等元素钎缝强韧化元素开始分散,CuMn2中间层的强度降低,致使钎缝强度开始下降;当继续延长时间到4 min时,钎缝组织粗化,断口韧窝开始变浅和粗大,虽仍为韧性断裂,但整体强韧性下降.由此,钎焊后CuMn2中间层的元素分布和组织形态直接关乎钎缝强度,合理优化控制钎焊温度和保温时间,调控钎缝组织形态是提高钎缝强度的重要手段.

3. 结论

(1)梯度三明治复合钎料与钢和硬质合金界面反应分为4个阶段:钎焊过程中界面组织形成、长大、溶合、重排.

(2)随着保温时间的延长中间CuMn2层开始变为孤立的小岛;继续延长时间至4 min时,整个CuMn2合金区域消失不见,整个钎缝变为近硬质合金过渡层、近钢过渡层和钎缝3个区域.

(3) 780 ℃保温2.5 min时,Co和Ni元素发生长程扩散,聚集在中间层CuMn2附近,钎缝抗剪强度达到285 MPa,在韧窝的根部分布着Co基颗粒强化相,继续延长保温时间,强度开始降低.

-

图 1 经SiO2-BN表面处理后润湿性和接头性能

Figure 1. Wettability and joints performance after surface modification with SiO2-BN ceramic. (a) microstructure of CNTs; (b) Raman spectra; (c) contact angles with different growth times of CNTs; (d) microstructure of VFG; (e) fracture morphologies of the joint with or without VFG

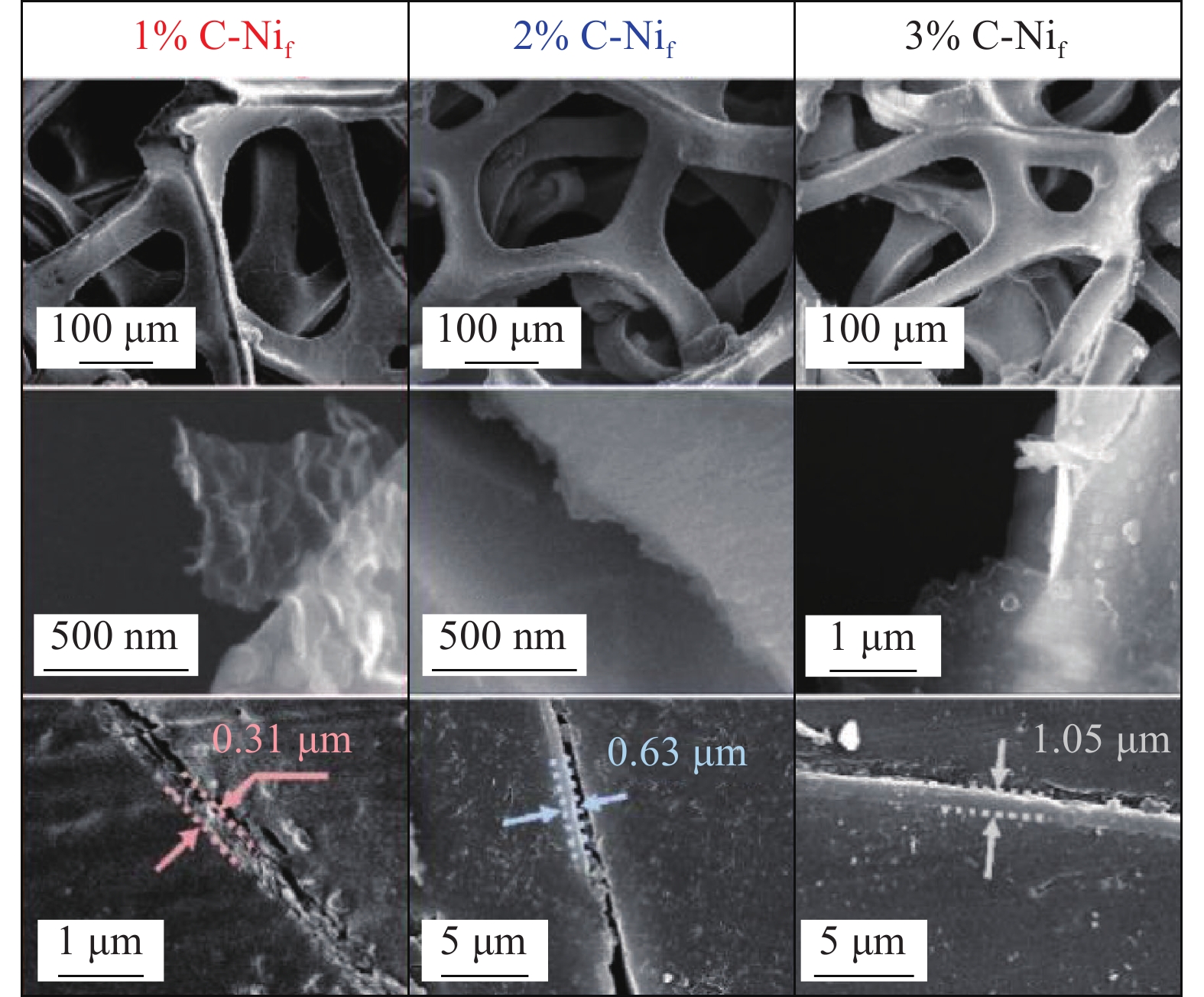

图 5 不同C含量C-Nif中间层显微形貌[42]

Figure 5. Microstructure of C-Nif interlayers with different C content

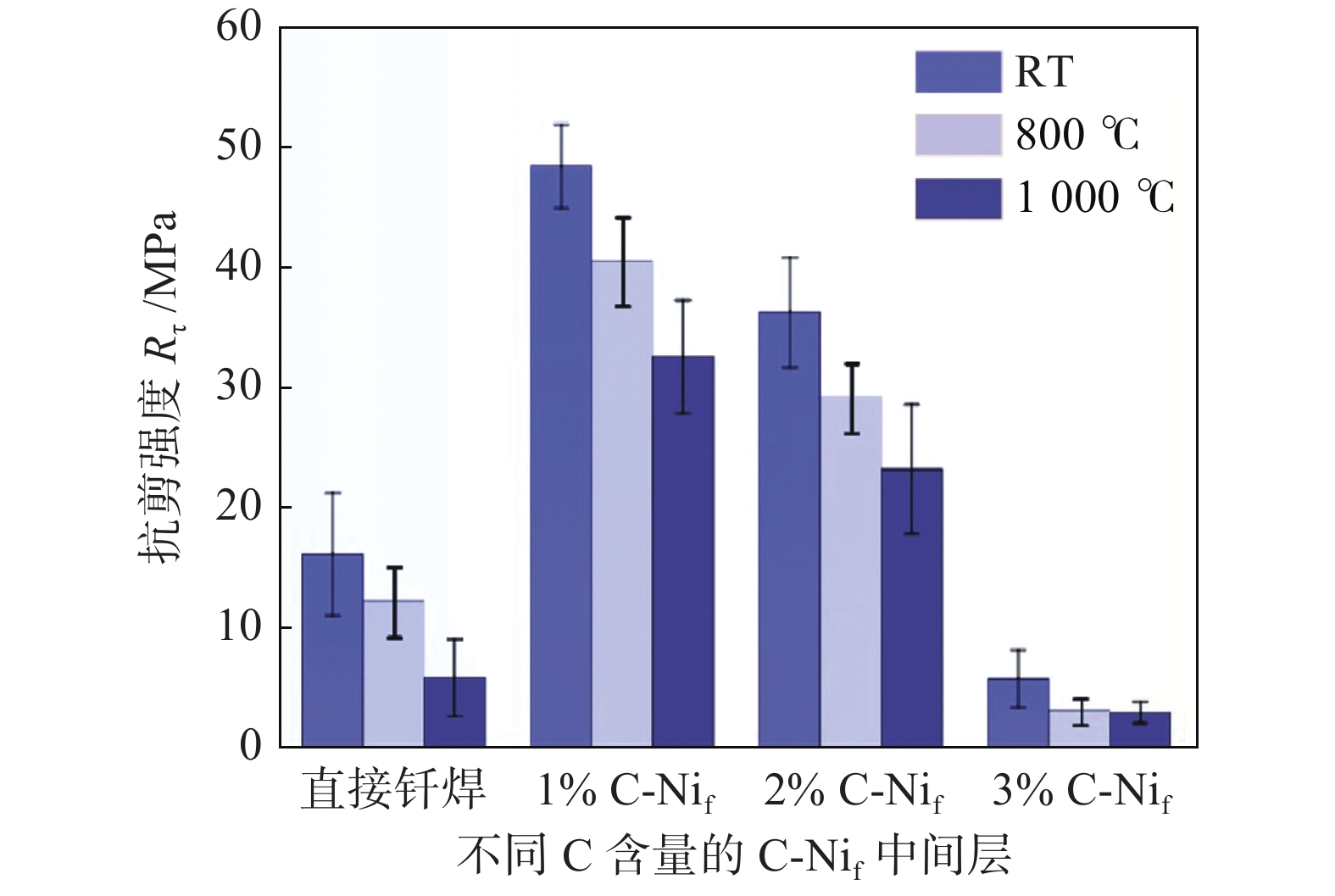

图 6 钎焊接头抗剪强度[42]

Figure 6. Shear strength of brazed joints

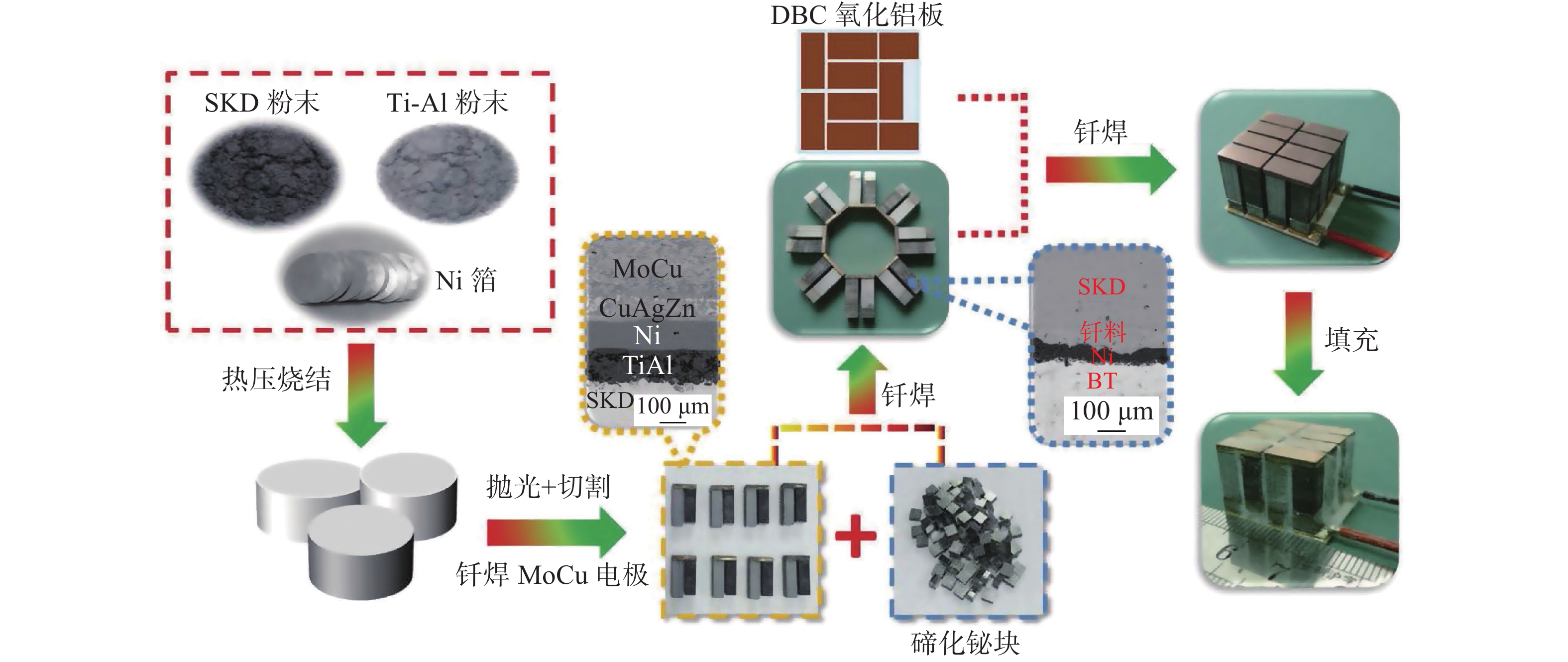

图 7 热电发电器件制备流程[46]

Figure 7. Fabrication flow of thermoelectric generators

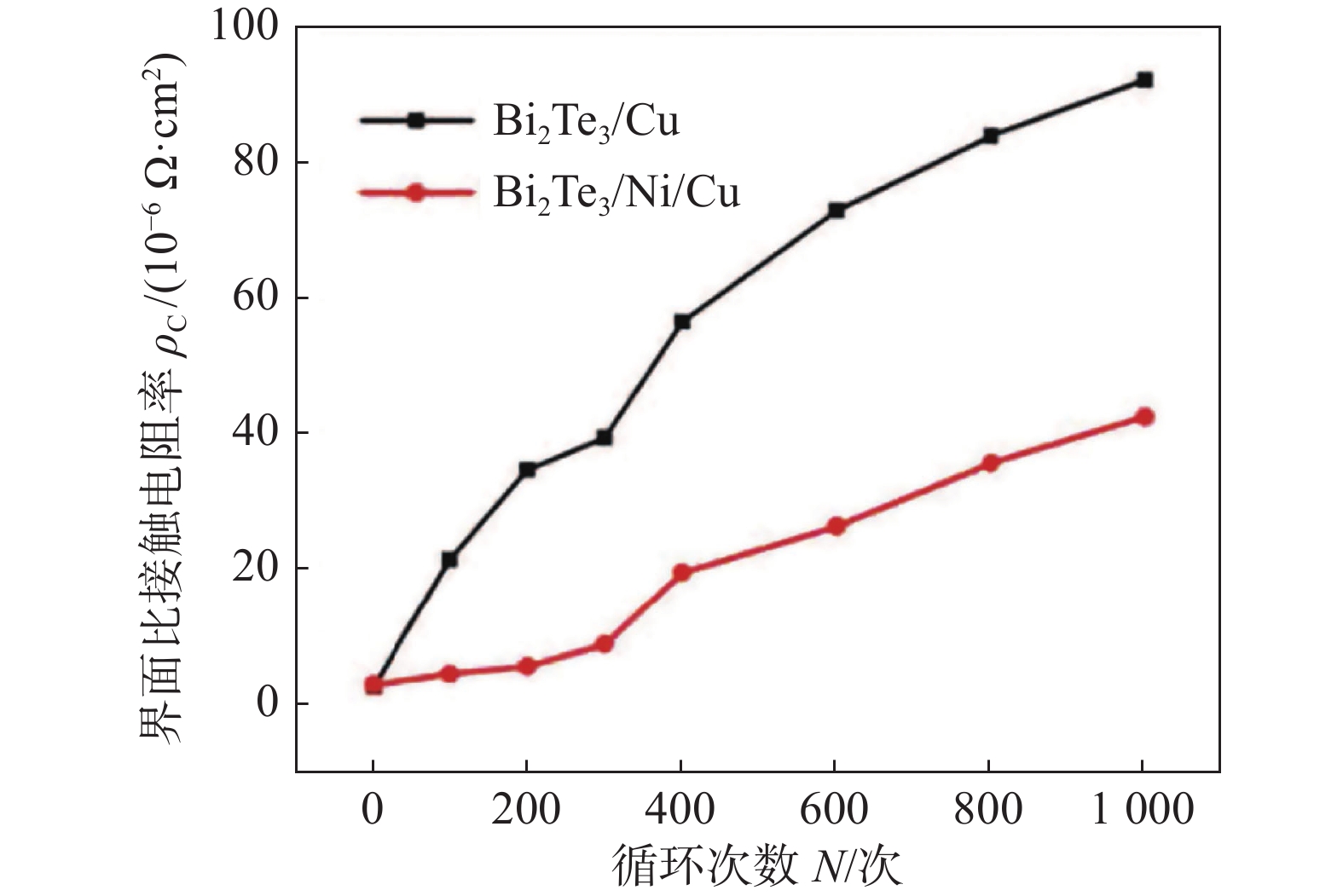

图 8 Bi2Te3/Cu和Bi2Te3/Ni/Cu的界面比接触电阻率对比[52]

Figure 8. Comparison for specific contact resistivity changes between Bi2Te3/Cu and Bi2Te3/Ni/Cu

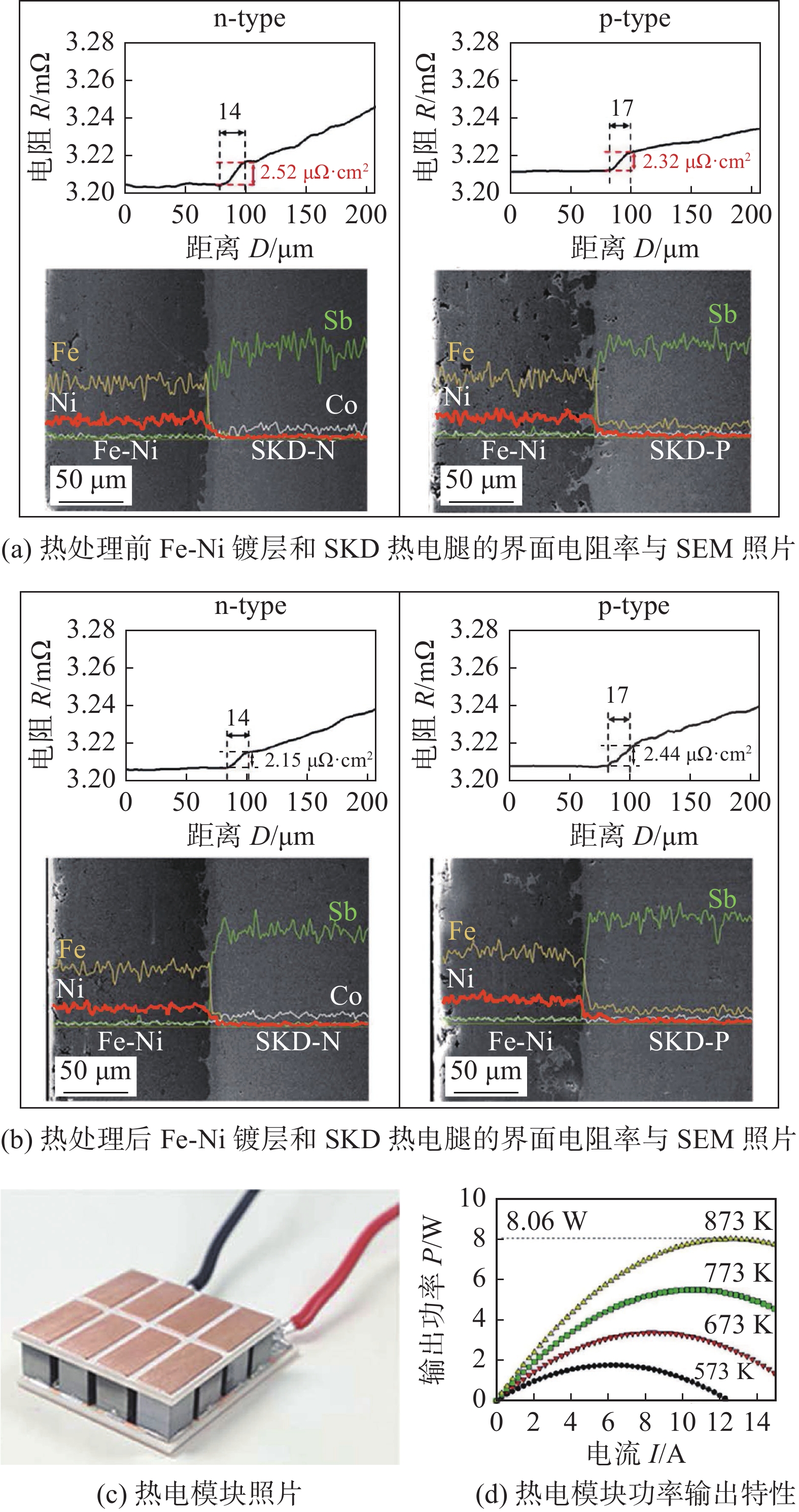

图 9 Fe-Ni合金阻隔层在热电器件中的应用[54]

Figure 9. Application of Fe-Ni barrier layer in thermoelectric devices. (a) electrical resistivity profiles taken on the interface between the Fe-Ni metallization layer and SKD legs, and SEM images before heat treatment; (b) electrical resistivity profiles taken on the interface between the Fe-Ni metallization layer and SKD legs, and SEM images after heat treatment; (c) photograph of the thermoelectric module; (d) output power characteristics of the thermoelectric module

-

[1] 高龙飞, 柴笑笑, 马君毅, 等. 石英纤维增强氮化硼陶瓷基复合材料制备及性能研究[J]. 复合材料科学与工程, 2020(10): 101 − 104. Gao Longfei, Chai Xiaoxiao, Ma Junyi, et al. Preparation and properties of quartz fiber reinforced boron nitride ceramic matrix composites[J]. Composites Science and Engineering, 2020(10): 101 − 104.

[2] 王得盼, 梁森, 周越松, 等. 纤维增强氧化铝陶瓷复合材料工艺及性能研究[J]. 复合材料科学与工程, 2022(4): 45 − 49. Wang Depan, Liang Sen, Zhou Yuesong, et al. Study on the properties and process of fiber reinforced alumina ceramic composites[J]. Composites Science and Engineering, 2022(4): 45 − 49.

[3] 张孟华, 庞梓玄, 贾云祥, 等. 纤维增强陶瓷基复合材料的加工研究进展与发展趋势[J]. 航空材料学报, 2021, 41(5): 14 − 27. doi: 10.11868/j.issn.1005-5053.2021.000033 Zhang Menghua, Pang Zixuan, Jia Yunxiang, et al. Research progress and development trend of fiber-reinforced ceramic matrix composites[J]. Journal of Aeronautical Materials, 2021, 41(5): 14 − 27. doi: 10.11868/j.issn.1005-5053.2021.000033

[4] 李文文, 熊华平, 吴欣, 等. Co-Nb-Pd-Ni-V钎料真空钎焊Cf/SiC复合材料的接头组织与性能[J]. 焊接学报, 2019, 40(9): 128 − 132. Li Wenwen, Xiong Huaping, Wu Xin, et al. Microstructure and strength of the Cf/SiC composite joint brazed with Co-Nb-Pb-Ni-V filler alloy[J]. Transactions of the China Welding Institution, 2019, 40(9): 128 − 132.

[5] 卜静冬. Bi0.5Sb1.5Te3与Cu钎焊工艺与连接机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2019. Bu Jingdong. Soldering technology and joining mechanism of Bi0.5Sb1.5Te3 and Cu[D]. Harbin: Harbin Institute of Technology, 2019.

[6] 毛煜波. Co4Sb12热电材料与Cu电极的连接工艺及机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. Mao Yubo. Research on preparation process and bonding mechanism of Co4Sb12 thermoelectric materials and Cu[D]. Harbin: Harbin Institute of Technology, 2020.

[7] 刘世艳. ZSC陶瓷与GH99合金钎焊工艺及机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. Liu Shiyan. Research on processing and mechanism of brazing ZSC ceramic and GH99 alloy[D]. Harbin: Harbin Institute of Technology, 2016.

[8] 陈勃. ZrC-SiC陶瓷与TC4钛合金的钎焊工艺及机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. Chen Bo. Research on brazing process and mechanism of ZrC-SiC ceramic and TC4 titanium alloy[D]. Harbin: Harbin Institute of Technology, 2020.

[9] 杨景红, 刘甲坤, 付曦, 等. SiO2-BN复相陶瓷润湿性及其接头微观组织[J]. 焊接学报, 2022, 43(10): 31 − 36. doi: 10.12073/j.hjxb.20210908002 Yang Jinghong, Liu Jiakun, Fu Xi, et al. Study on the wettability and the microstructure of SiO2-BN multiphase ceramics[J]. Transactions of the China Welding Institution, 2022, 43(10): 31 − 36. doi: 10.12073/j.hjxb.20210908002

[10] 田晓羽. C/SiC及C/C复合材料与Nb的反应钎焊工艺及机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. Tian Xiaoyu. Research on process and mechanism of reaction brazing of C/SiC and C/C composite to Nb[D]. Harbin: Harbin Institute of Technology, 2018.

[11] 孙湛. SiO2f/SiO2的石墨烯修饰及与Invar钎焊界面结构形成机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. Sun Zhan. Research on decorating the SiO2f/SiO2 composite with graphene and interfacial microstructure formation mechanism for brazing graphene-decorated SiO2f/SiO2 composite and invar alloy[D]. Harbin: Harbin Institute of Technology, 2018.

[12] 常青, 张丽霞, 孙湛, 等. 表面生长碳纳米管对C/C复合材料钎焊接头的影响[J]. 机械工程学报, 2020, 56(8): 20 − 27. doi: 10.3901/JME.2020.08.020 Chang Qing, Zhang Lixia, Sun Zhan, et al. Influence of surface modification by carbon nanotube on C/C composite brazing joints[J]. Journal of Mechanical Engineering, 2020, 56(8): 20 − 27. doi: 10.3901/JME.2020.08.020

[13] 杨振文, 张丽霞, 刘玉章, 等. TiAl合金与C/SiC复合材料钎焊接头界面组织和性能[J]. 焊接学报, 2011, 32(3): 65 − 68. Yang Zhenwen, Zhang Lixia, Liu Yuzhang, et al. Microstructure and mechanical property of vacuum brazed TiAl and C/SiC joint[J]. Transactions of the China Welding Institution, 2011, 32(3): 65 − 68.

[14] 杨景红. 复相陶瓷BN-SiO2与Nb钎焊界面结构及其形成机理[D]. 哈尔滨: 哈尔滨工业大学, 2019. Yang Jinghong. Interfacial structure and formation mechanism of brazed joint of BN-SiO2 ceramic to Nb[D]. Harbin: Harbin Institute of Technology, 2019.

[15] 宋义河. C/C复合材料表面生长CNTs及与Nb钎焊工艺及机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. Song Yihe. Research on the growth of CNTs on C/C composite and the process and mechanism of brazing with Nb[D]. Harbin: Harbin Institute of Technology, 2017.

[16] 曹雨. SiO2f/SiO2复合材料表面碳热还原反应及润湿性提高机制研究[D]. 哈尔滨工业大学, 2019. Cao Yu. Research on the carbothermal reduction reaction of the SiO2f/SiO2 surface and mechanism of the wettability improvement of SiO2f/SiO2[D]. Harbin: Harbin Institute of Technology, 2019.

[17] 郭绍庆, 吴世彪, 熊华平, 等. SiO2f /SiO2复合材料与金属铌环形钎焊接头的残余应力数值模拟[J]. 焊接学报, 2017, 38(3): 67 − 70. Guo Shaoxing, Wu Shibiao, Xiong Huaping, et al. nunerical simulation of residual stresses in brazed ring joint between SiO2f /SiO2 composite and Nb metal[J]. Transactions of the China Welding Institution, 2017, 38(3): 67 − 70.

[18] 李小波. p型方钴矿热电材料及接头的组织结构与性能[D]. 哈尔滨: 哈尔滨工业大学, 2018. Li Xiaobo. Microstructure and properties of the skutterudites thermoelectric materials and joints[D]. Harbin: Harbin Institute of Technology, 2018.

[19] Yang Z W, Zhang L X, Tian X Y, et al. Correlation between microstructure and mechanical properties of active brazed Invar/SiO2–BN joints[J]. Materials Science and Engineering:A, 2012, 556: 722 − 727. doi: 10.1016/j.msea.2012.07.055

[20] Wang W, Liu Y, Wang G, et al. Vacuum brazing ZSCf composite ceramics to TC4 alloy with Ag-Cu filler[J]. Journal of Materials Research and Technology, 2020, 9(4): 8627 − 8635. doi: 10.1016/j.jmrt.2020.05.119

[21] Zhang L X, Zhang B, Sun Z, et al. Brazing of ZrB2-SiC-C and GH99 with AgCuTi/SiC interpenetrating network structural composite as an interlayer[J]. Ceramics International, 2020, 46(8): 10224 − 10232. doi: 10.1016/j.ceramint.2020.01.014

[22] Wang Q, Shi J, Zhang L, et al. Additive manufacturing of a high-strength ZrC-SiC and TC4 gradient structure based on a combination of laser deposition technique and brazing[J]. Journal of Materiomics, 2021, 7(4): 766 − 779. doi: 10.1016/j.jmat.2020.12.019

[23] Zhang L X, Sun Z, Shi J M, et al. Controlling the intermetallics growth in the SiO2-BN/Invar brazed joint by vertical few-layer graphene[J]. Ceramics International, 2018, 44(16): 20012 − 20018. doi: 10.1016/j.ceramint.2018.07.271

[24] Ba J, Li H, Ren B, et al. In situ formation of TiB whiskers to reinforce SiO2-BN/Ti6Al4V brazed joints[J]. Ceramics International, 2019, 45(6): 8054 − 8057. doi: 10.1016/j.ceramint.2019.01.091

[25] Ba J, Zheng X H, Ning R, et al. Brazing of SiO2 -BN modified with in situ synthesized CNTs to Ti6Al4V alloy by TiZrNiCu brazing alloy[J]. Ceramics International, 2018, 44(9): 10210 − 10214. doi: 10.1016/j.ceramint.2018.03.018

[26] Yang Z W, Zhang L X, Ren W, et al. Interfacial microstructure and strengthening mechanism of BN-doped metal brazed Ti/SiO2-BN joints[J]. Journal of the European Ceramic Society, 2013, 33(4): 759 − 768. doi: 10.1016/j.jeurceramsoc.2012.10.017

[27] Yang Z W, Zhang L X, Chen Y C, et al. Interlayer design to control interfacial microstructure and improve mechanical properties of active brazed Invar/SiO2-BN joint[J]. Materials Science and Engineering:A, 2013, 575: 199 − 205. doi: 10.1016/j.msea.2013.03.055

[28] Pan R, Kovacevic S, Lin T, et al. Control of residual stresses in 2Si-B-3C-N and Nb joints by the Ag-Cu-Ti + Mo composite interlayer[J]. Materials & Design, 2016, 99: 193 − 200.

[29] He Z, Li C, Yang B, et al. Interfacial reaction and brazing behaviour of SiCf/SiC with Cf/C composites using Si-10Zr alloy at high temperatures[J]. Journal of the European Ceramic Society, 2021, 41(2): 1142 − 1150. doi: 10.1016/j.jeurceramsoc.2020.09.057

[30] Sun Z, Zhang L X, Hao T D, et al. Brazing of SiO2f/SiO2 composite to Invar using a graphene-modified Cu-23Ti braze filler[J]. Ceramics International, 2018, 44(13): 15809 − 15816. doi: 10.1016/j.ceramint.2018.05.259

[31] Guo X, Si X, Li C, et al. Active brazing of C/C composites and single crystal Ni-based superalloy: Interfacial microstructure and formation mechanism[J]. Journal of Alloys and Compounds, 2021, 886: 161183. doi: 10.1016/j.jallcom.2021.161183

[32] Lin J, Ba J, Cai Y, et al. Brazing SiO2f /SiO2 with TC4 alloy with the help of coating graphene[J]. Vacuum, 2017, 145: 241 − 244. doi: 10.1016/j.vacuum.2017.09.010

[33] Yang Z W, Wang C L, Han Y, et al. Design of reinforced interfacial structure in brazed joints of C/C composites and Nb by pre-oxidation surface treatment combined with in situ growth of CNTs[J]. Carbon, 2019, 143: 494 − 506. doi: 10.1016/j.carbon.2018.11.047

[34] 霸金, 亓钧雷, 李航, 等. 表面金属热渗辅助钎焊C/SiC-Nb接头界面增强机制[J]. 科学通报, 2021, 66(1): 118 − 127. doi: 10.1360/TB-2020-0952 Ba Jin, Qi Junlei, Li Hang, et al. Brazing mechanism of C/SiC-Nb joint interface reinforced by surface metal heat infiltration[J]. Chinese Science Bulletin, 2021, 66(1): 118 − 127. doi: 10.1360/TB-2020-0952

[35] Ba J, Li H, Lin J, et al. Magnesiothermic reduction of SiO2f/SiO2 composites for brazing with Nb using AgCuTi[J]. Journal of Manufacturing Processes, 2019, 46: 26 − 33. doi: 10.1016/j.jmapro.2019.08.024

[36] Sun Z, Cao Y, Zhang L, et al. Carbothermal reduction reaction enhanced wettability and brazing strength of AgCuTi-SiO2f/SiO2 system[J]. Journal of the European Ceramic Society, 2020, 40(4): 1488 − 1495. doi: 10.1016/j.jeurceramsoc.2019.11.067

[37] Wang Y, Wang W, Ye Z, et al. Reactive composite-diffusing brazing of Cf/SiC composite and stainless steel with (Cu-15Ti) + C filler material[J]. Materials Science and Engineering:A, 2020, 788: 139582. doi: 10.1016/j.msea.2020.139582

[38] Wang Y, Wang W, Huang J, et al. Composite brazing of C/C composite and Ni-based superalloy using (Ag-10Ti) + TiC filler material[J]. Journal of Materials Processing Technology, 2021, 288: 116886. doi: 10.1016/j.jmatprotec.2020.116886

[39] Ba J, Zheng X H, Ning R, et al. C/SiC composite-Ti6Al4V joints brazed with negative thermal expansion ZrP2WO12 nanoparticle reinforced AgCu alloy[J]. Journal of the European Ceramic Society, 2019, 39(4): 755 − 761. doi: 10.1016/j.jeurceramsoc.2018.12.028

[40] Zhang L X, Sun Z, Chang Q, et al. Brazing SiO2f/SiO2 composite to Invar alloy using a novel TiO2 particle-modified composite braze filler[J]. Ceramics International, 2019, 45(2): 1698 − 1709. doi: 10.1016/j.ceramint.2018.10.052

[41] Sun Z, Zhang L X, Chang Q, et al. Active brazed Invar-SiO2f/SiO2 joint using a low-expansion composite interlayer[J]. Journal of Materials Processing Technology, 2018, 255: 8 − 16. doi: 10.1016/j.jmatprotec.2017.11.058

[42] Wang Z, Butt H A, Ma Q, et al. The use of a carbonized phenolic formaldehyde resin coated Ni foam as an interlayer to increase the high-temperature strength of C/C composite-Nb brazed joints[J]. Ceramics International, 2022, 48(6): 7584 − 7592. doi: 10.1016/j.ceramint.2021.11.302

[43] Dresselhaus M S, Chen G, Tang M Y, et al. New directions for low-dimensional thermoelectric materials[J]. Advanced Materials, 2007, 19(8): 1043 − 1053. doi: 10.1002/adma.200600527

[44] Liu W, Hu J, Zhang S, et al. New trends, strategies and opportunities in thermoelectric materials: A perspective[J]. Materials Today Physics, 2017, 1: 50 − 60. doi: 10.1016/j.mtphys.2017.06.001

[45] Heremans J P, Thrush C M, Morelli D T, et al. Thermoelectric power of bismuth nanocomposites[J]. Physical Review Letters, 2002, 88(21): 6801.

[46] Zhang Q, Liao J, Tang Y, et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration[J]. Energy & Environmental Science, 2017, 10(4): 956 − 963.

[47] Salvador J R, Cho J Y, Ye Z, et al. Conversion efficiency of skutterudite-based thermoelectric modules[J]. Physical Chemistry Chemical Physics, 2014, 16(24): 12510 − 12520. doi: 10.1039/C4CP01582G

[48] Fan X C, Gu M, Shi X, et al. Fabrication and reliability evaluation of Yb0.3Co4Sb12/Mo-Ti/Mo-Cu/Ni thermoelectric joints[J]. Ceramics International, 2015, 41(6): 7590 − 7595. doi: 10.1016/j.ceramint.2015.02.083

[49] 赵德刚, 李小亚, 江莞, 等. CoSb3/MoCu热电接头的一步SPS法制备及性能评价[J]. 无机材料学报, 2009, 24(3): 545 − 548. doi: 10.3724/SP.J.1077.2009.00545 Zhao Degang, Li Xiaoya, Jiang Wan, et al. Fabrication of CoSb3/MoCu thermoelectric joint by one-step SPS and evaluation[J]. Journal of Inorganic Materials, 2009, 24(3): 545 − 548. doi: 10.3724/SP.J.1077.2009.00545

[50] Zhao D, Geng H, Teng X. Fabrication and reliability evaluation of CoSb3/W–Cu thermoelectric element[J]. Journal of Alloys and Compounds, 2012, 517: 198 − 203. doi: 10.1016/j.jallcom.2011.12.130

[51] Chen S W, Chu A H, Wong D S H. Interfacial reactions at the joints of CoSb3-based thermoelectric devices[J]. Journal of Alloys and Compounds, 2017, 699: 448 − 454. doi: 10.1016/j.jallcom.2016.12.386

[52] Zhu X, Cao L, Zhu W, et al. Enhanced interfacial adhesion and thermal stability in bismuth telluride/nickel/copper multilayer films with low electrical contact resistance[J]. Advanced Materials Interfaces, 2018, 5(23): 1801279. doi: 10.1002/admi.201801279

[53] Zhou H, Mu X, Zhao W, et al. Low interface resistance and excellent anti-oxidation of Al/Cu/Ni multilayer thin-film electrodes for Bi2Te3-based modules[J]. Nano Energy, 2017, 40: 274 − 281. doi: 10.1016/j.nanoen.2017.08.034

[54] Park S H, Jin Y, Cha J, et al. High-power-density skutterudite-based thermoelectric modules with ultralow contact resistivity using Fe-Ni metallization layers[J]. ACS Applied Energy Materials, 2018, 1(4): 1603 − 1611. doi: 10.1021/acsaem.8b00064

[55] Zhang Q, Zhou Z, Dylla M, et al. Realizing high-performance thermoelectric power generation through grain boundary engineering of skutterudite-based nanocomposites[J]. Nano Energy, 2017, 41: 501 − 510. doi: 10.1016/j.nanoen.2017.10.003

[56] Zong Pan, Hanus R, Dylla M, et al. Skutterudite with graphene-modified grain-boundary complexion enhances zT enabling high-efficiency thermoelectric device[J]. Energy & Environmental Science, 2017, 10(1): 183 − 191.

-

期刊类型引用(4)

1. 李国坤,杨梦颖,潘远樵,冯鑫鑫,王怡如,王泽宇. “芯—鞘”结构强化C_f/SiC-Nb钎焊接头成形机理. 焊接学报. 2025(02): 80-86 .  本站查看

本站查看

2. 龙伟民,乔瑞林,秦建,宋晓国,李鹏远,樊喜刚,刘代军. 异质材料钎焊技术与应用研究进展. 焊接学报. 2025(04): 1-21 .  本站查看

本站查看

3. 龙伟民. 钎焊材料成分设计准则及典型组织演变机制(英文). 稀有金属材料与工程. 2025(04): 837-853 .  百度学术

百度学术

4. 丁天然,路全彬,张陕南,杨骄. 盾构刀具高性能钎焊技术研究进展. 矿山机械. 2024(02): 53-63 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: