-

摘要: 纳米铜基导电薄膜具有高导电、高性价比且易与柔性基材结合等优点,在下一代柔性电子产品领域具有广泛的应用前景. 然而,纳米铜基导电薄膜在制备的过程中易被氧化,成为制备高导电纳米铜基导电薄膜的难题. 文中从油墨配方、印刷方法、烧结方法等方面系统的介绍了纳米铜基柔性导电薄膜的制造方法,着重介绍了目前抗氧化油墨的设计思路,阐明了目前柔性电子先进微纳连接技术的工艺流程,对比了其优缺点及适用范围,并列举了纳米铜基导电薄膜在下一代柔性电子产品领域的典型应用. 在此基础上,对纳米铜柔性导电薄膜制造尚存的主要问题进行了总结,并对其未来发展趋势进行了展望.

-

0. 序言

随着纳米材料的广泛应用,以印刷电子为代表的增材制造技术已成为制造电子产品的高效新型技术. 与光刻[1-2]、真空沉积[3-4]和化学镀[5-6]等传统减材制造技术相比,具有低成本、生产效率高、产生废弃物少和环境友好等优点[7-8]. 通过将电子元件集成于柔性基板表面,可赋予电子产品重量轻、可弯曲、灵活、甚至可折叠等特性,使其在下一代柔性电子产品领域具有广泛的应用前景[9].

典型情况下,首先将功能性纳米材料制备成导电油墨,然后将其在柔性基板上结构化,并对所得结构进行固化烧结处理,形成具有电气互联的导电薄膜. 目前常用的导电油墨主要包含纳米金属[10-15, 21]、导电聚合物[16-18]及碳基纳米材料等[19-20]. 其中,纳米金属油墨因其优异的导电性,成为近年来的研究热点. 与其他纳米金属相比(如金[13-14]、铝[15]、镍[21]等),纳米银(Ag)不仅导电性高(电阻率仅约1.59 μΩ·cm),且其化学性质稳定[22],已广泛应用于柔性电子器件的设计及制造中. 然而,高昂的价格及有限的储量限制了Ag导电薄膜的大规模应用[23].

相比而言,铜(Cu)具有与Ag相当的导电性(电阻率为1.68 μΩ·cm),而成本极低,仅为Ag的1%,且储量丰富[24],被认为是银基导电薄膜的良好替代品. 但纳米铜材料的稳定性较差,容易在储存及加工过程中被氧化为氧化亚铜(Cu2O)或氧化铜(CuO),导致所得导电结构的电阻率升高[25]. 为克服这一科学难题,研究人员对其制造、加工方法开展了大量研究.

文中从油墨配方、印刷方法、烧结方法等方面系统地介绍了铜基柔性导电薄膜的制造方法,着重介绍了不同成分油墨的抗氧化策略、不同的烧结方法烧结原理及减少氧化物的原理. 还介绍了铜基柔性导电薄膜在下一代柔性电子产品领域的应用,最后对纳米铜柔性导电薄膜制造尚存的主要问题进行了总结,并对其未来发展趋势进行了展望. 旨在全面而深入地概述铜基柔性导电薄膜,促进铜基柔性导电薄膜的研究和应用.

1. 纳米铜基导电油墨

导电油墨是构建导电结构的基础,与不会被氧化的银纳米粒子油墨不同,铜纳米粒子油墨在空气中极易被氧化,很难稳定存在. 为获得在空气中不易被氧化的铜基导电油墨,目前已开发的铜基导电油墨主要包括纳米铜基粒子油墨、铜氧化物油墨及铜离子前驱体油墨.

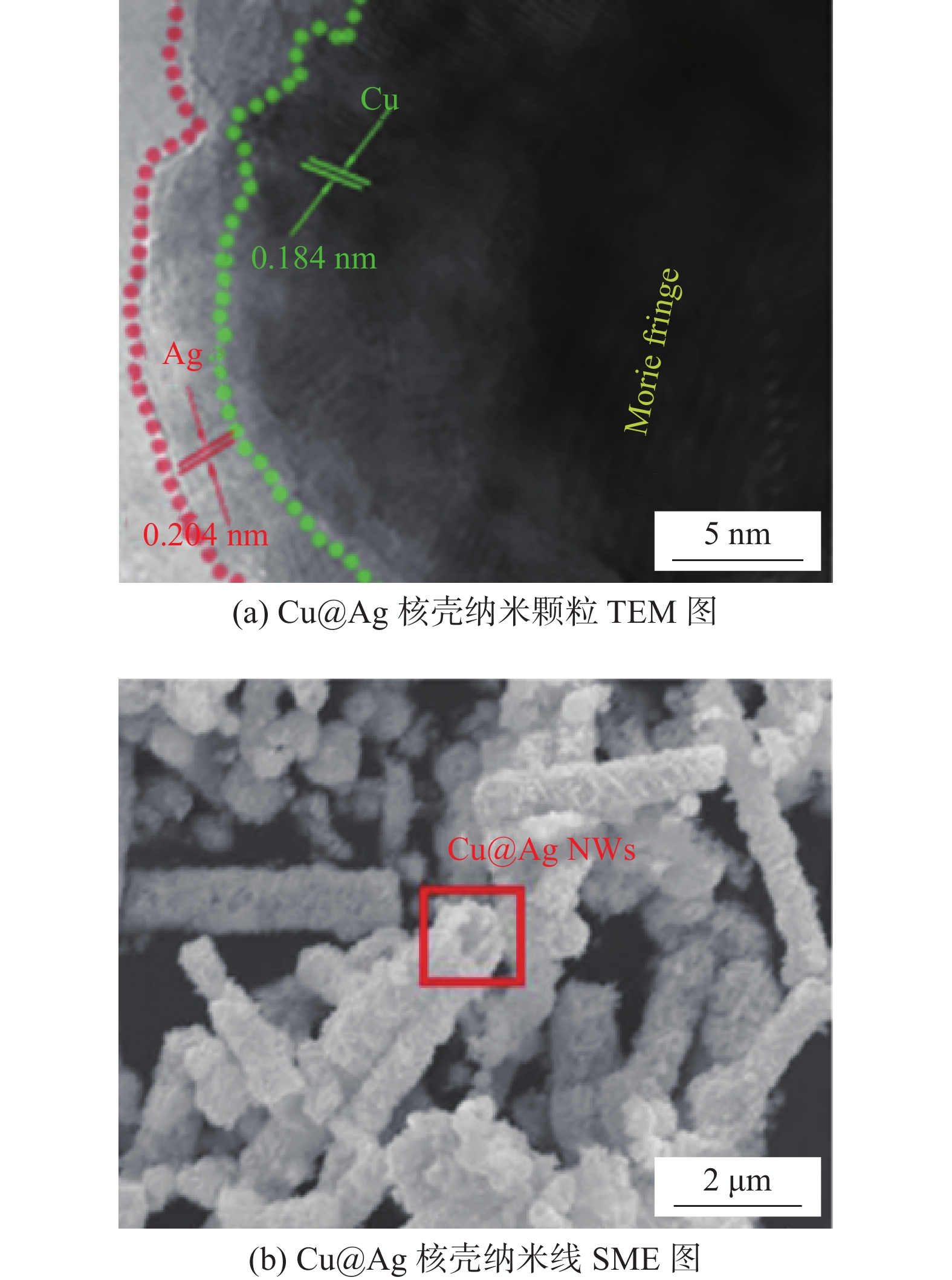

纳米铜基粒子通常采用湿化学法(如水热法等[26])合成,通过改变合成过程中反应温度、有机物(如还原剂、封端剂等)种类、有机物浓度等工艺参数,可实现不同性状纳米材料的合成,如纳米颗粒、纳米线等[27]. 然而,铜纳米粒子易在储存过程中发生氧化,其表面形成的氧化物(氧化亚铜及氧化铜)将劣化其电学性能. 研究人员开发了抗氧化纳米铜基粒子的制造方法,以为提高其储存过程中的稳定性. 典型的抗氧化纳米粒子为核壳结构,可采用聚合物、碳材料、贵金属材料等作为壳结构,用以阻挡纳米铜粒子与外界有氧环境的接触,达到抗氧化的目的. 由于聚合物较不稳定、碳材料的引入易对最终结构的导电性能产生负面影响,以银为代表的铜@银核壳结构被认为是最佳选择. Zhang等人[28]采用多元醇法制备铜纳米颗粒后,利用铜纳米颗粒与硫酸银间的置换反应制备了铜@银纳米颗粒(如图1a所示),所得纳米颗粒在156 ℃条件下存放40天后未出现氧化. 类似地,Zhao等人[29]通过水热法合成铜纳米线后,添加硝酸银制备了铜@银纳米线(如图1b所示),该纳米线在140 ℃大气环境条件下保持500小时未发现被氧化. 可以看出,铜@银核壳结构可大幅提高纳米粒子的稳定性,但需精确的调控合成过程中的工艺参数,避免出现铜纳米粒子未被银壳完全包覆的情况. 此外,由于铜、银为不混熔的二元体系,在后续加工过程中极易出现相分离,Zhang等人[28]的研究结果表明:铜@银纳米颗粒表面的银纳米壳在扩散的驱动力低于铜纳米核,纳米铜还未开始扩散时,铜@银纳米颗粒表面的银纳米壳之间已经发生了扩散和相互连接,导致出现大量的裸漏的纳米铜核,破坏预制的核壳结构,导致结构在服役中抗氧化性能的下降.

利用铜纳米粒子的易氧化特性,基于氧化铜/氧化亚铜纳米粒子所开发的氧化物纳米油墨可规避其储存过程中的稳定性问题. 通过在预合成的氧化物纳米粒子中添加还原剂等配体,可经由后续的工艺步骤将其还原为铜纳米粒子,实现导电薄膜的制造. 例如,Kang等人[30]在预合成的氧化铜纳米颗粒中添加乙二醇,通过辐照激光所产生的光-热作用将乙二醇分解为甲酸,在还原性羧基(-COOH)的作用下将CuO还原Cu,最后形成铜导电薄膜. 纳米铜基粒子和氧化物纳米铜基导电油墨基板、方法、导电性和稳定性如表1所示[28, 30-41].

表 1 不同前驱体纳米铜基导电油墨工艺、方法和稳定性Table 1. Processes, methods and stability of copper nanobased conductive inks with different precursors前驱体 基板 印刷—烧结方法 方阻/电阻率 温度—时间 参考文献 铜@银纳米颗粒 玻璃 丝网印刷—热烧结 113 mΩ·sq−1 室温—三周 [31] 铜@银纳米颗粒 玻璃 旋转丝网印刷—热烧结 0.60 Ω·sq−1 室温-两个月 [32] 铜@银纳米颗粒 聚酰亚胺(PI) 喷墨打印—热烧结 3.21 μΩ·cm 156 ℃-40 d [28] 铜@银纳米颗粒 玻璃 喷墨打印—热烧结 11 μΩ·cm NA [33] 铜@银纳米颗粒 玻璃 平面丝网印刷—热烧结 0.18 Ω·sq−1 室温-六个月 [34] 铜@银纳米颗粒 PI 旋转丝网印刷—激光烧结 28.5 μΩ·cm NA [35] 铜@银纳米颗粒 玻璃 旋转丝网印刷—热烧结 13.7 μΩ·cm NA [36] 铜@银纳米线 聚氨基甲酸酯(PU) 喷墨打印—热烧结 35 Ω·sq−1 140 ℃-500 h [37] 铜@金纳米线 玻璃 NA—热烧结 35 Ω·sq−1 80 ℃-700 h [38] 氧化铜纳米颗粒 PI NA—激光烧结 31 μΩ·cm NA [30] 氧化铜纳米颗粒 玻璃 旋转丝网印刷—激光烧结 9.5 μΩ·cm NA [39] 氧化铜纳米颗粒 聚乙烯(PE) 喷墨打印—强脉冲光烧结 3.1 μΩ·cm NA [40] 氧化铜纳米颗粒 聚对苯二甲酸乙二醇酯(PET) 喷墨打印—强脉冲光烧结 9 μΩ·cm NA [41] 由于上述结构均采用预合成的纳米结构进行后续加工,具有较为复杂的工艺步骤. 为简化工艺流程,近年来铜离子前驱体油墨受到广大研究人员的青睐. 典型的前驱体油墨由铜盐与还原剂等其他配体混合而成,由于铜盐的形式存在,如Draper等人[44]将硝酸铜氢化物和果糖在水中混合制备铜的前驱体油墨,因此它们可以在大气环境条件下保持长期稳定性. 然而,与前述两种油墨相比,铜驱前体油墨中需要的还原剂等配体相对含量较高,在后续加工中易引入孔洞,导致印刷后薄膜的致密度较低,电阻率大,在某些要求高导电的应用中需要进行繁琐的多次涂层才能达到所期望的导电性.

2. 柔性导电薄膜印刷方法

合成导电油墨后,通常需通过印刷步骤将其在目标基板上结构化. 目前用于制造柔性印刷电子设备的印刷方法可分为接触印刷和非接触印刷[45-47]. 接触式印刷技术包括凹版印刷[48]、凹版胶印 [49]、柔版印刷[50]等. 相比而言,非接触式印刷具有操作简单、效率高、对制造过程的适应性强等优点,是目前最常用的柔性印刷电子技术. 典型的非接触式印刷技术包括丝网印刷、喷墨印刷等.

丝网印刷可分为平面丝网印刷和旋转丝网印刷两种类型[51]. 图2a为平面丝网印刷的加工过程示意,印刷设备通常由刮刀、基板、丝网印版和印刷台组成. 印刷时,在丝网印版的一端倒入油墨,用刮刀对丝网印版上的油墨部位施加一定压力,同时朝丝网印版另一端匀速移动,油墨在移动中被刮板从丝网印版的网孔中挤压到基材上,形成特定的图案. 丝网印版可采用薄片材料、精细多孔织物网和合成纤维/丝绸制成,不仅价格高昂,且针对不同图形化需求时需予以更换. 图2b为旋转丝网印刷(即卷对卷印刷技术),只需要将导电油墨放置在圆筒内,随着两个圆筒的不断转动,内部固定的刮板不断的将油墨挤压流过滚轮上的网孔,印刷在基板上,同时基板也随着滚轮的转动不断地移动,形成特定的图案. 与平面丝网印刷相比,自动化程度高,同时无需每印刷一次就换一次基材,极大的提高了印刷速率,但仍然需要针对不同结构调整印版.

相对于丝网印刷技术,喷墨打印技术的印刷精度可控性高(可达500 nm),且无需印版的参与,有利于降低制造成本. 印刷过程中,通过压电机、电流机、或加热油墨所产生的体积压力对喷嘴中的油墨施压,微小尺寸的液滴通过喷墨喷嘴头中的热或压电驱动器产生的相应脉冲喷射出来,利用计算机设计喷嘴移动轨迹,可实现油墨在目标基板上的图形化. 图2c, d所示为压电和电流体动力驱动液滴进行印刷的工作机理[52-53]. 其中,压电喷墨是在电压的作用下油墨以墨滴的形式沉积在基板表面,电流体动力喷墨是导电油墨受静电场力的作用下,以连续的墨滴流形式沉积在基板. 与压电喷墨相比,电流体驱动喷墨具有喷射速度快、打印效率高等优点,但电流体驱动喷墨对墨滴的控制程度低于压电喷墨,因此打印出图案的精度也低于压电喷墨. 在喷墨印刷中导电油墨的成分和粘度影响图案的质量,是获得均匀、连续、无缺陷薄膜的关键因素. Gu等人[54]将甘油作为增稠剂加入到铜油墨中,增加油墨粘度而获得均匀、连续和无缺陷的薄膜图案.

然而,与丝网印刷相比,受喷嘴出墨速率的限制,其印刷效率较低. 此外,纳米铜基粒子和铜氧化物油墨在喷嘴中长时间停留时,油墨中溶剂的挥发易造成纳米粒子的团聚,导致喷嘴间歇性堵塞,降低设备的使用寿命,无颗粒的铜基离子前驱体墨水开发是喷墨印刷技术发展的未来方向[55].

3. 柔性导电薄膜烧结方法

3.1 热烧结

将导电油墨结构化后,通常需要烧结步骤提高其电学性能. 目前典型的烧结方法有热烧结、光子烧结、等离子烧结、电烧结、化学烧结等.

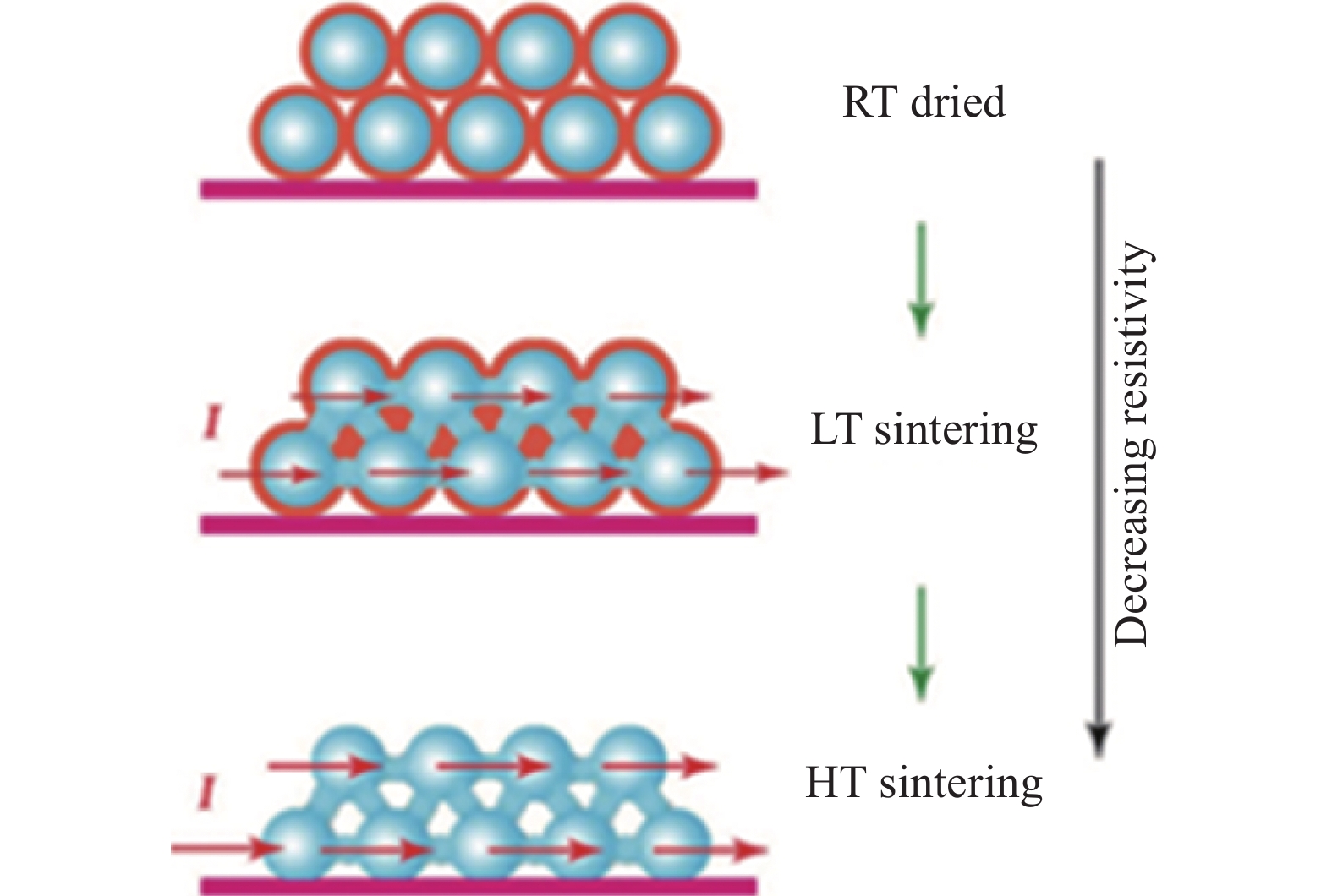

热烧结[56] (如图3所示)通常利用管式炉或烘箱实现,利用整体的温升将铜纳米材料相互连接,形成电气互联的纳米铜导电薄膜,是目前应用最广的烧结方法之一. 对于预合成纳米铜基离子,其烧结过程所需的温升主要由取决于油墨中纳米铜的粒径大小[57],而铜前体油墨的烧结温度主要由还原剂分解温度决定[58]. 由于铜的易氧化特性,需要在惰性气氛、还原气氛或真空下进行热烧结. 其中,还原气氛不仅可以防止铜的氧化,且可促进铜氧化物的还原及封端剂等配体有机物的分解,从而降低铜油墨的烧结温度. 例如,Kim等人[59]以甲酸为还原性气体,在200 °C热烧结铜纳米颗粒油墨1小时后,独立的铜纳米颗粒连接为连续的网状结构,所得薄膜的电阻率可达4.0 μΩ·cm,而在真空条件下325 ℃烧结1小时后,获得铜基导电薄膜电阻率仅达17.2 μΩ·cm[60]. 然而,由于热烧结过程中整体加热的特性,将造成能量的浪费,而200 ℃以上长时间的烧结将易造成热敏性基板的翘曲变形.

![]() 图 3 热烧结工艺示意图(RT表示室温,LT表示低温,HT表示高温)[56]Figure 3. Schematic diagram of the thermal sintering process (RT indicates room temperature, LT indicates low temperature, and HT indicates high temperature)

图 3 热烧结工艺示意图(RT表示室温,LT表示低温,HT表示高温)[56]Figure 3. Schematic diagram of the thermal sintering process (RT indicates room temperature, LT indicates low temperature, and HT indicates high temperature)3.2 光子烧结

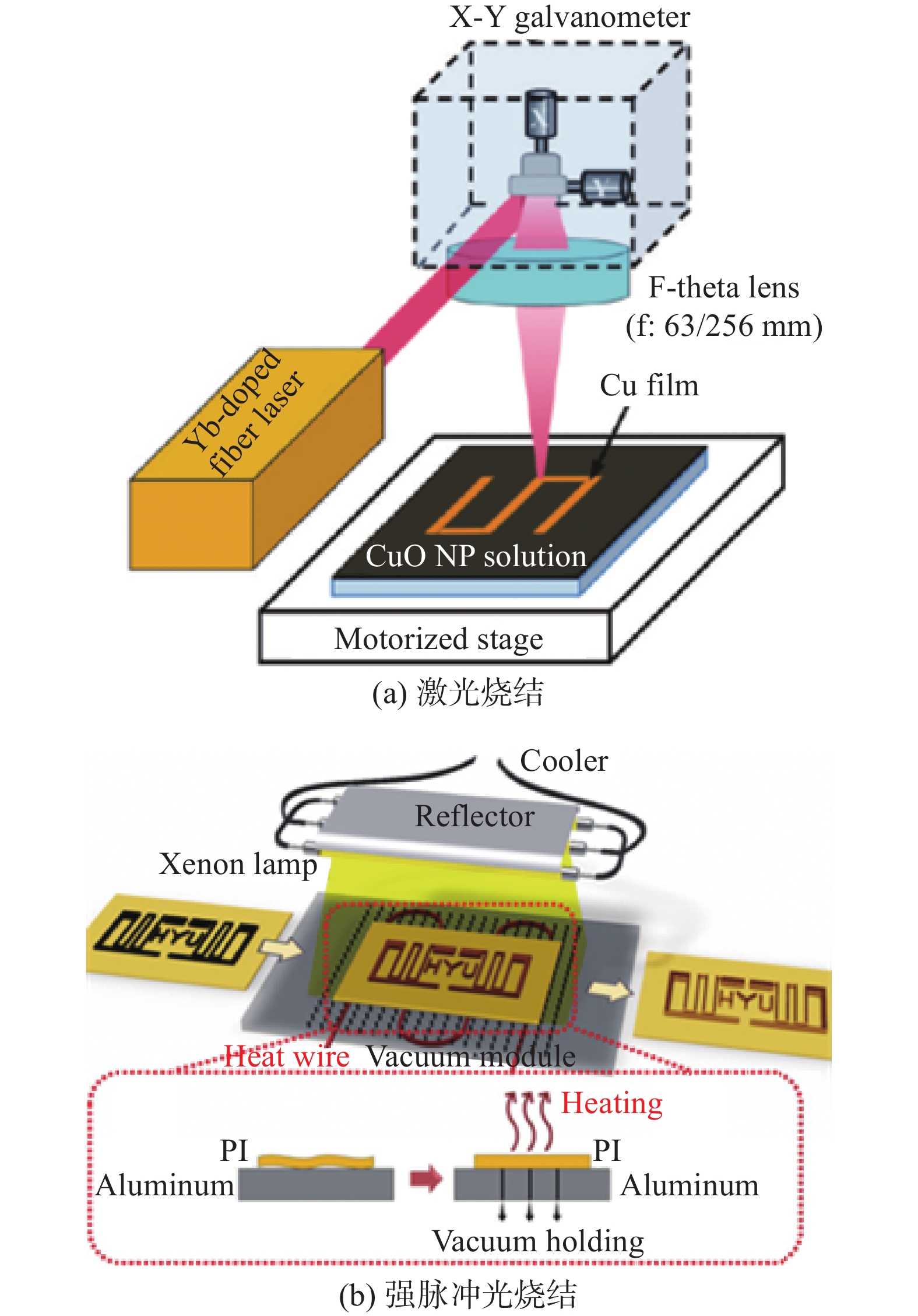

光子烧结是近年来广受关注的先进连接技术,可在短时间内实现纳米材料的连接. 由于高温历时短,在加工铜纳米材料时可避免其氧化,在大气环境下即可进行烧结;且由于能量主要由铜油墨吸收,有利于减少能源的浪费及基板的热损伤,具有广泛的应用前景. 光子烧结据光源类型可划分为激光烧结和强脉冲光(IPL)烧结[61-63].

IPL烧结(如图4b所示)通常采用氙灯作为光源(波长通常为200 ~ 1 000 nm),其烧结规模取决于氙灯的尺寸. Kim等人[64]首次使用IPL烧结铜纳米颗粒油墨,发现仅需照射约2 ms即可完成5 nm铜纳米颗粒的连接,所得薄膜的电阻率低至5.0 μΩ·cm,是在真空中热烧结铜纳米颗粒油墨的三分之一[60]. 在还原剂的辅助下,IPL烧结可实现CuO纳米粒子的还原及烧结. 据Öhlund等人[65]报道,基于CuO纳米粒子油墨,IPL可在5 ms内完成电阻率3.1 μΩ·cm的导电薄膜制备,仅约铜块材电导率的50%. Wang等人[66]对结构化后的氢氧化铜基油进行IPL烧结,所得薄膜电阻率仅5.27 μΩ·cm. Chung等人[67]对比了多种铜离子油墨(氯化铜、三水硝酸铜、五水硫酸铜、三氟乙酰丙酮)的IPL烧结特性,发现不同的前驱体吸收不同的光波区域,分解温度也根据前驱体的种类而改变. 进一步地,Paglia等人[68]通过调控IPL的能量输入控制CuO纳米颗粒的还原程度,进而控制铜基薄膜中CuO和Cu2O的含量,实现了多价态导电薄膜的制造,有望扩展其应用范围.

区别于IPL烧结,激光烧结(如图4a所示)所采用的光源具有固定的波长,据报道紫外至红外区域的激光均可实现铜基纳米粒子的烧结. 例如,Yu等人[69]使用532 nm波长的激光烧结铜纳米颗粒油墨,图案电阻率低至5.3 μΩ·cm,与在真空中热烧结325 ℃持续1 h相比,烧结时间更短,获得的铜基柔性薄膜图案电阻率更低[60]. 在这一过程中,光诱导的等离子基元(SPR)效应仅在纳米结构的结节处引起局部温升,可有效避免整体加热引起的铜结构氧化[70]. 激光也可用于还原-烧结铜氧化物油墨,据Kang等人[71]研究结果显示,在激光诱导所引起的光-热-化学作用下,乙二醇可脱水生成乙醛,所含的还原性羟基(-OH)可以将CuO纳米颗粒还原为Cu纳米颗粒,并原位连接为导电结构. 针对铜离子前驱体油墨,激光提供的高能和热量可以快速分解有机铜盐或无机铜盐基油墨,并且原位形成的小尺寸铜纳米颗粒将在短时间内互连形成稳定的导电结构[72]. 此外,在激光烧结中,也可以通过改变激光的功率调控所得薄膜中铜结构的价态及含量. 本团队Zhou等人[73]基于硝酸铜前驱体油墨进行激光烧结,发现在低能量输入下所得结构表面含有大量铜氧化物纳米颗粒,随着激光功率的升高,铜氧化物还原程度提高,所得结构以铜为主. 相比于强光烧结,由于激光光斑较小,激光烧结适用于制备高精度的导电结构,但在大面积薄膜结构加工中效率低于强脉冲光烧结.

3.3 其他烧结方法

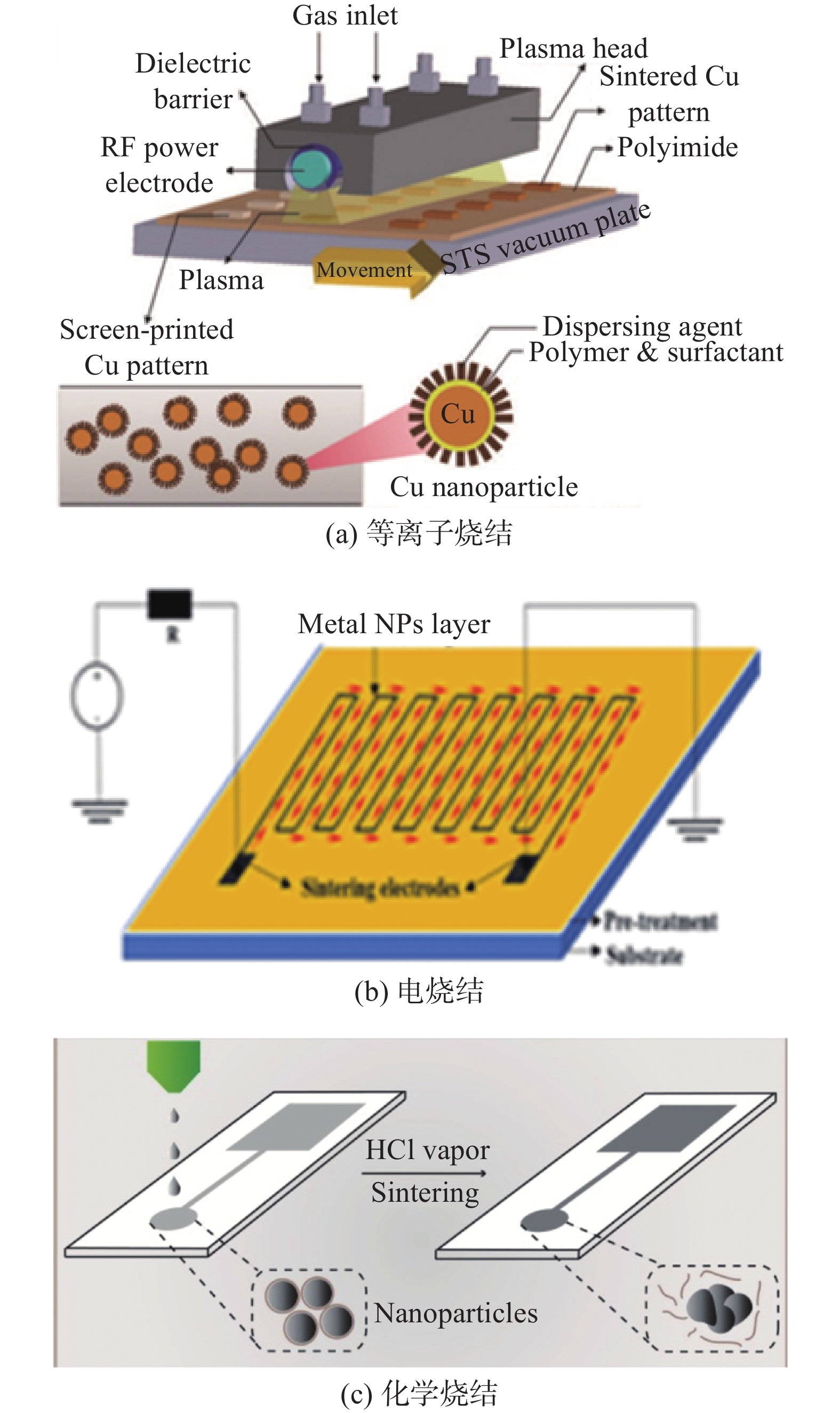

等离子烧结是利用基态和激发态的电子、离子和中性粒子组成的电离气体轰击可打印材料,实现铜基油墨在低温下的烧结,工艺示意图如图5a所示[74]. 虽然等离子烧结可以实现各种铜油墨的低温连接,但由于基材在加工过程中也受到离子的轰击,容易发生损伤.

电烧结是另一种快速烧结技术,它在整个印刷区域施加电压,产生的电阻热可以让油墨中的有机溶剂蒸发,同时将纳米铜粒子连接为致密的铜基导电薄膜,工艺示意图如图5b所示[75]. 但由于电烧结要求结构在烧结前具有一定导电性,应用场景受到限制;此外,由于通电过程需要与结构相接触,可能造成结构的物理损伤.

化学烧结通过向油墨材料中添加化学介质(如氯离子,图5c),来分解其表面包裹的有机物,使裸露的纳米铜粒子直接接触或将前驱体油墨还原生成纳米铜粒子,通过扩散形成电气互联的导电结构[76-77]. 目前化学烧结所得结构导电性较差,仅达铜块材的3.3%[77].

4. 纳米铜基柔性导电薄膜典型应用

近年来,纳米铜基柔性导电薄膜已应用于多种电子产品的开发[78-84]. 柔性天线是航空航天、移动通信、遥测、医疗、射频识别标签等无线传感器应用的重要组成部分. 随着无线传感器系统的应用不断扩展(如飞机监控系统、汽车碰撞警告、远程患者监控系统等),人们对无线传输速度的要求不断提高,导电性良好的铜结构被认为是传统铝制天线的替代品. 如今,在塑料基板上已经实现将铜基柔性导电薄膜作为柔性天线使用. 例如,Li等人[78]采用IPL烧结甲酸铜油墨,在PI、聚萘二甲酸乙二醇酯(PEN)和PET基板上制备的V形偶极子铜基柔性薄膜天线图案(如图6a所示). Cu天线长30 mm,宽5 mm,角度约为30°,PI、PEN和PET基板上铜天线的回波损耗(S11)分别为52,35,18 dB,满足实际应用的敏感度.

超级电容器(SCs)具有体积小、薄、灵活、易于集成等优点,已经是日常便携式、可穿戴电子设备中重要的储能单元. SCs由活性电极、电解质、集流体及封装材料组成. 纳米铜基导电薄膜可用于其中集流体的制造,例如,Zhang等人[28]制备的Cu@Ag合金电极具有高电导率(3.21 μΩ·cm)和抗弯折性能,在10 mm半径弯曲2000次后,Cu@Ag的电阻率仅增加33%,Cu@Ag的电阻率仅增加33%. 此外,利用铜基材料的赝电容特性,可实现活性电极的制造,例如,本团队Liao等人[79]基于铜离子油墨,采用聚焦激光对其进行选区扫描,制备了铜-石墨烯导电薄膜,所制备的铜-石墨烯复合结构不仅导电性优良(方阻约0.57 Ω·sq−1),且具有较高的电化学活性,进一步组装所得准固态电容器(如图6b所示)的比电容高达13.2 mF·cm−2.

电容屏又称电容式触摸屏,是一种利用电容触控技术来工作的四层复合玻璃屏,广泛地应用于工业、医疗、通信领域的控制、信息查询等方面. Walia等人[80]利用裂纹模板法完成了柔性电容式触摸屏的制造(如图6c所示). 首先通过墨粉打印配合旋涂的前驱体完成了菱形网格模板的制造,随后将导电Cu热沉积于模板的目标区域,将30 μm的薄层聚二甲基硅氧烷(PDMS)作为介电层,完成了触摸屏的组装. 电容屏不仅透光率高达90%,可以检测手指的接近(量程约20 cm)、触摸、下压(180 kPa以下)及温度(50 ℃以下),且可在弯曲半径2 cm的状态下工作.

集成式柔性葡萄糖电化学传感器具有无痛、重量轻和便携等优点,有望通过体液检测实现人体葡萄糖含量的实时监控. 该类传感器通常由共平面的工作电极、对电极和参比电极组成,传统的工作电极需要葡萄糖氧化酶的活化,可实现葡萄糖的准确测量,但氧化酶的不稳定性影响了器件的稳定性. 本团队Zhou等人[81]基于铜离子前驱体,采用激光直写技术低成本在PI基底上实现了Cu2O/Cu的高效制造. 通过前驱体比例的调控优化了所得结构的成分,所得结构不仅具有低至1.3 Ω·sq−1的方阻,且具有优良的葡萄糖检测活性(如图6d所示),因此可同时用作集流体及工作电极. 与商用的印刷参比电极、对电极配合后,实现了集成式柔性葡萄糖传感器的设计及制造. 所得器件在低至0.3 V的检测电位下的检测限可达0.34 μM,且具有优良的抗干扰性及可弯折性,有望进一步开发为可穿戴葡萄糖传感器.

散热效率是保证电子器件运行速度和可靠性的关键因素,随着电子器件的小型化及高度集成,其热管理面临着越来越大的挑战. 本团队Yao等人[82]采用激光对涂敷于PI表面的铜离子前驱体进行选区辐照,制备了均匀的铜—碳(Cu-C)导热薄(如图6e所示),其导热系数可达2.25 W·m−1·K−1,显著高于PI的导热系数(0.1 ~ 0.4 W·m−1·K−1).

5. 总结

综上所述,成本低、性能优良的纳米铜基材料已广泛地应用于柔性导电薄膜制造. 基于油墨性状的调控已开发出数种抗氧化纳米铜基油墨,可有效地提高其稳定性. 通过高效、快速的先进连接技术开发,已实现薄膜成分、结构的调控,可获得高导电性铜基柔性导电薄膜. 然而,核壳铜纳米粒子在连接过程中易发生不期望的结构变化,而基于铜离子油墨所制造薄膜的导电性仍低于预合成纳米粒子,且所得薄膜在长期服役过程中仍存在稳定性欠佳等问题,未来仍需针对油墨组分的优化开展大量研究工作. 此外,先进的烧结技术中所涉的结构连接机理、结构调控机理尚有待进一步深入,且其控制精度尚需进一步提高. 目前,虽已开发出多种柔性电子原型器件,但尚处起步阶段,集成化、小型化的高性能多功能柔性电子系统开发是未来研究的发展方向之一.

-

图 3 热烧结工艺示意图(RT表示室温,LT表示低温,HT表示高温)[56]

Figure 3. Schematic diagram of the thermal sintering process (RT indicates room temperature, LT indicates low temperature, and HT indicates high temperature)

表 1 不同前驱体纳米铜基导电油墨工艺、方法和稳定性

Table 1 Processes, methods and stability of copper nanobased conductive inks with different precursors

前驱体 基板 印刷—烧结方法 方阻/电阻率 温度—时间 参考文献 铜@银纳米颗粒 玻璃 丝网印刷—热烧结 113 mΩ·sq−1 室温—三周 [31] 铜@银纳米颗粒 玻璃 旋转丝网印刷—热烧结 0.60 Ω·sq−1 室温-两个月 [32] 铜@银纳米颗粒 聚酰亚胺(PI) 喷墨打印—热烧结 3.21 μΩ·cm 156 ℃-40 d [28] 铜@银纳米颗粒 玻璃 喷墨打印—热烧结 11 μΩ·cm NA [33] 铜@银纳米颗粒 玻璃 平面丝网印刷—热烧结 0.18 Ω·sq−1 室温-六个月 [34] 铜@银纳米颗粒 PI 旋转丝网印刷—激光烧结 28.5 μΩ·cm NA [35] 铜@银纳米颗粒 玻璃 旋转丝网印刷—热烧结 13.7 μΩ·cm NA [36] 铜@银纳米线 聚氨基甲酸酯(PU) 喷墨打印—热烧结 35 Ω·sq−1 140 ℃-500 h [37] 铜@金纳米线 玻璃 NA—热烧结 35 Ω·sq−1 80 ℃-700 h [38] 氧化铜纳米颗粒 PI NA—激光烧结 31 μΩ·cm NA [30] 氧化铜纳米颗粒 玻璃 旋转丝网印刷—激光烧结 9.5 μΩ·cm NA [39] 氧化铜纳米颗粒 聚乙烯(PE) 喷墨打印—强脉冲光烧结 3.1 μΩ·cm NA [40] 氧化铜纳米颗粒 聚对苯二甲酸乙二醇酯(PET) 喷墨打印—强脉冲光烧结 9 μΩ·cm NA [41] -

[1] Lee H B, Bae C W, Duy L T, et al. Mogul-patterned elastomeric substrate for stretchable electronics[J]. Advanced Materials, 2016, 28(16): 3069 − 3077. doi: 10.1002/adma.201505218

[2] Wang Z, Xing R, Yu X, et al. Adhesive lithography for fabricating organic electronic and optoelectronics devices[J]. Nanoscale, 2011, 3(7): 2663 − 2678. doi: 10.1039/c1nr10039d

[3] Chen C W, Kang H W, Hsiao S Y, et al. Efficient and uniform planar-type perovskite solar cells by simple sequential vacuum deposition[J]. Advanced Materials, 2014, 26(38): 6647 − 6652. doi: 10.1002/adma.201402461

[4] Parashkov R, Becker E, Riedl T, et al. Large area electronics using printing methods[J]. Proceedings of the IEEE, 2005, 93(7): 1321 − 1329. doi: 10.1109/JPROC.2005.850304

[5] Cai J, Zhang C, Khan A, et al. Selective electroless metallization of micro-and nanopatterns via poly (dopamine) modification and palladium nanoparticle catalysis for flexible and stretchable electronic applications[J]. ACS applied materials & interfaces, 2018, 10(34): 28754 − 28763.

[6] Li J, Zhang X, Liu X, et al. Conductivity and foldability enhancement of Ag patterns formed by PVAc modified Ag complex inks with low-temperature and rapid sintering[J]. Materials & Design, 2020, 185: 108255.

[7] Cui Z. Printed electronics: materials, technologies and applications[M]. New Jersey: John Wiley & Sons, 2016.

[8] Nguyen P Q M, Yeo L P, Lok B K, et al. Patterned surface with controllable wettability for inkjet printing of flexible printed electronics[J]. ACS Applied Materials and Interfaces, 2014, 6(6): 4011 − 4016. doi: 10.1021/am4054546

[9] Nathan A, Ahnood A, Cole M T, et al. Flexible electronics: the next ubiquitous platform[J]. Proceedings of the IEEE, 2012, 100(Special Centennial Issue): 1486-1517.

[10] Magdassi S, Grouchko M, Kamyshny A. Copper nanoparticles for printed electronics: routes towards achieving oxidation stability[J]. Materials, 2010, 3(9): 4626 − 4638. doi: 10.3390/ma3094626

[11] 姜皎洁, 刘文涛, 黄灵阁, 等. 无线射频识别技术用导电油墨的研究[J]. 材料导报, 2015, 29(1): 121 − 126. doi: 10.11896/j.issn.1005-023X.2015.01.021 Jiang Jiaojie, Liu Wentao, Huang Lingge, et al. Research on conductive inks for radio frequency identification technology[J]. Materials Guide, 2015, 29(1): 121 − 126. doi: 10.11896/j.issn.1005-023X.2015.01.021

[12] 李金焕, 陆建辉, 王玉丰, 等. 金属银导电油墨的研究进展[J]. 电子元件与材料, 2014, 33(11): 14 − 17. doi: 10.14106/j.cnki.1001-2028.2014.11.004 Li Jinhuan, Lu Jianhui, Wang Yufeng, et al. Research progress of metallic silver conductive inks[J]. Electronic Components and Materials, 2014, 33(11): 14 − 17. doi: 10.14106/j.cnki.1001-2028.2014.11.004

[13] Bacalzo N P, Go L P, Querebillo C J, et al. Controlled microwave-hydrolyzed starch as a stabilizer for green formulation of aqueous gold nanoparticle ink for flexible printed electronics[J]. ACS Applied Nano Materials, 2018, 1(3): 1247 − 1256. doi: 10.1021/acsanm.7b00379

[14] Liu X, Kanehara M, Liu C, et al. Spontaneous patterning of high-resolution electronics via parallel vacuum ultraviolet[J]. Advanced Materials, 2016, 28(31): 6568 − 6573. doi: 10.1002/adma.201506151

[15] Guo Rumeng, Xiao Yubo, Gao Ye et al. Interfacial enhancement of Ag and Cu particles sintering using(111)-oriented nanotwinned Cu as substrate for die-attachment[J]. China Welding, 2022, 31(1): 22 − 28.

[16] Wang X, Guo W, Zhu Y, et al. Electrical and mechanical properties of ink printed composite electrodes on plastic substrates[J]. Applied Sciences, 2018, 8(11): 2101. doi: 10.3390/app8112101

[17] Stempien Z, Rybicki T, Rybicki E, et al. In-situ deposition of polyaniline and polypyrrole electroconductive layers on textile surfaces by the reactive ink-jet printing technique[J]. Synthetic Metals, 2015, 202: 49 − 62. doi: 10.1016/j.synthmet.2015.01.027

[18] Zhao P, Zhang R, Tong Y, et al. All-paper, all-organic, cuttable, and foldable pressure sensor with tuneable conductivity polypyrrole[J]. Advanced Electronic Materials, 2020, 6(8): 1 − 10.

[19] Htwe Y Z N, Mariatti M. Surfactant-assisted water-based graphene conductive inks for flexible electronic applications[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 125: 402 − 412. doi: 10.1016/j.jtice.2021.06.022

[20] Aziz A, Bazbouz M B, Welland M E. Double-walled carbon nanotubes ink for high-conductivity flexible electrodes[J]. ACS Applied Nano Materials, 2020, 3(9): 9385 − 9392. doi: 10.1021/acsanm.0c02013

[21] 杨婉春, 王帅, 祝温泊, 等. 低温烧结纳米铜焊膏的制备及其连接性能分析[J]. 焊接学报, 2018, 39(6): 72 − 76. doi: 10.12073/j.hjxb.2018390152 Yang Wanchun, Wang Shuai, Zhu Wenbo, et al. Preparation of low-temperature sintered nano-copper solder paste and its connection performance analysis[J]. Transactions of the China Welding Institution, 2018, 39(6): 72 − 76. doi: 10.12073/j.hjxb.2018390152

[22] Nie X, Wang H, Zou J. Inkjet printing of silver citrate conductive ink on PET substrate[J]. Applied Surface Science, 2012, 261: 554 − 560. doi: 10.1016/j.apsusc.2012.08.054

[23] 奚甡. 中外银矿资源现状分析[J]. 世界有色金属, 2012, 6: 60 − 63. Xi Shen. Analysis of the current situation of silver resources in China and abroad[J]. World Non-ferrous Metals, 2012, 6: 60 − 63.

[24] 罗晓玲. 国内外铜矿资源分析[J]. 世界有色金属, 2000, 4(4): 4 − 10. Luo Xiaoling. Analysis of domestic and foreign copper ore resources[J]. World Non-ferrous Metals, 2000, 4(4): 4 − 10.

[25] Zhou X, Guo W, Zhu Y, et al. The laser writing of highly conductive and anti-oxidative copper structures in liquid[J]. Nanoscale, 2020, 12(2): 563 − 571. doi: 10.1039/C9NR07248A

[26] Chen H, Lee J H, Kim Y H, et al. Metallic copper nanostructures synthesized by a facile hydrothermal method[J]. Journal of Nanoscience and Nanotechnology, 2010, 10(1): 629 − 636. doi: 10.1166/jnn.2010.1739

[27] Zhang B, Li W, Jiu J, et al. Large-scale and galvanic replacement free synthesis of Cu@Ag core-shell nanowires for flexible electronics[J]. Inorganic Chemistry, 2019, 58(5): 3374 − 3381. doi: 10.1021/acs.inorgchem.8b03460

[28] Zhang W, Zhou Y, Ding Y, et al. Sintering mechanism of size-controllable Cu-Ag core-shell nanoparticles for flexible conductive film with high conductivity, antioxidation, and electrochemical migration resistance[J]. Applied Surface Science, 2022, 586: 152691. doi: 10.1016/j.apsusc.2022.152691

[29] Zhao J, Zhang D, Zhang X. Preparation and characterization of copper/silver bimetallic nanowires with core-shell structure[J]. Surface and Interface Analysis, 2015, 47(4): 529 − 534. doi: 10.1002/sia.5743

[30] Kang B, Han S, Kim J, et al. One-step fabrication of copper electrode by laser-induced direct local reduction and agglomeration of copper oxide nanoparticle[J]. The Journal of Physical Chemistry C, 2011, 115(48): 23664 − 23670. doi: 10.1021/jp205281a

[31] Yu X, Li J, Shi T, et al. A green approach of synthesizing of Cu-Ag core-shell nanoparticles and their sintering behavior for printed electronics[J]. Journal of Alloys and Compounds, 2017, 724: 365 − 372. doi: 10.1016/j.jallcom.2017.07.045

[32] Lee C, Kim N R, Koo J, et al. Cu-Ag core-shell nanoparticles with enhanced oxidation stability for printed electronics[J]. Nanotechnology, 2015, 26(45): 455601. doi: 10.1088/0957-4484/26/45/455601

[33] Grouchko M, Kamyshny A, Magdassi S. Formation of air-stable copper-silver core-shell nanoparticles for inkjet printing[J]. Journal of Materials Chemistry, 2009, 19(19): 3057 − 3062. doi: 10.1039/b821327e

[34] Pajor-Świerzy A, Farraj Y, Kamyshny A, et al. Air stable copper-silver core-shell submicron particles: Synthesis and conductive ink formulation[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2017, 521: 272 − 280.

[35] Titkov A I, Logutenko O A, Vorobyev A M, et al. Laser sintering of Cu@Ag core-shell nanoparticles for printed electronics applications[J]. Materials Today:Proceedings, 2020, 25: 447 − 450. doi: 10.1016/j.matpr.2019.12.163

[36] Kim N R, Lee Y J, Lee C, et al. Surface modification of oleylamine-capped Ag-Cu nanoparticles to fabricate low-temperature-sinterable Ag-Cu nanoink[J]. Nanotechnology, 2016, 27(34): 345706. doi: 10.1088/0957-4484/27/34/345706

[37] Zhang B, Li W, Nogi M, et al. Alloying and embedding of Cu-core/Ag-shell nanowires for ultrastable stretchable and transparent electrodes[J]. ACS Applied Materials & Interfaces, 2019, 11(20): 18540 − 18547.

[38] Niu Z, Cui F, Yu Y, et al. Ultrathin epitaxial Cu@Au core-shell nanowires for stable transparent conductors[J]. Journal of the American Chemical Society, 2017, 139(21): 7348 − 7354. doi: 10.1021/jacs.7b02884

[39] Rahman M K, Lu Z, Kwon K S. Green laser sintering of copper oxide (CuO) nano particle (NP) film to form Cu conductive lines[J]. AIP Advances, 2018, 8(9): 095008. doi: 10.1063/1.5047562

[40] Öhlund T, Schuppert A K, Hummelgard M, et al. Inkjet fabrication of copper patterns for flexible electronics: using paper with active precoatings[J]. ACS Applied Materials & Interfaces, 2015, 7(33): 18273 − 18282.

[41] Paquet C, James R, Kell A J, et al. Photosintering and electrical performance of CuO nanoparticle inks[J]. Organic Electronics, 2014, 15(8): 1836 − 1842. doi: 10.1016/j.orgel.2014.05.014

[42] Zhang B, Li W, Jiu J, et al. Large-scale and galvanic replacement free synthesis of Cu@Ag core-shell nanowires for flexible electronics[J]. Inorganic Chemistry, 2019, 58(5): 3374 − 3381. doi: 10.1021/acs.inorgchem.8b03460

[43] Dai X, Xu W, Zhang T, et al. Room temperature sintering of Cu-Ag core-shell nanoparticles conductive inks for printed electronics[J]. Chemical Engineering Journal, 2019, 364: 310 − 319. doi: 10.1016/j.cej.2019.01.186

[44] Draper G L, Dharmadasa R, Staats M E, et al. Fabrication of elemental copper by intense pulsed light processing of a copper nitrate hydroxide ink[J]. ACS Applied Materials & Interfaces, 2015, 7(30): 16478 − 16485.

[45] Son S G, Park H J, Kim Y K, et al. Fabrication of low-cost and flexible potassium ion sensors based on screen printing and their electrochemical characteristics[J]. Applied Chemistry for Engineering, 2019, 30(6): 737 − 741.

[46] Lee H, Lee D, Hwang J, et al. Silver nanoparticle piezoresistive sensors fabricated by roll-to-roll slot-die coating and laser direct writing[J]. Optics Express, 2014, 22(8): 8919 − 8927. doi: 10.1364/OE.22.008919

[47] Zhu D, Wang Z, Zhu D. Highly conductive graphene electronics by inkjet printing[J]. Journal of Electronic Materials, 2020, 49(3): 1765 − 1776. doi: 10.1007/s11664-019-07920-1

[48] Secor E B, Lim S, Zhang H, et al. Gravure printing of graphene for large-area flexible electronics[J]. Advanced Materials, 2014, 26(26): 4533 − 4538. doi: 10.1002/adma.201401052

[49] Lau P H, Takei K, Wang C, et al. Fully printed, high performance carbon nanotube thin-film transistors on flexible substrates[J]. Nano Letters, 2013, 13(8): 3864 − 3869. doi: 10.1021/nl401934a

[50] Mariappan D D. Nanoporous flexographic printing: fundamentals, applications and scale-up[D]. Massachusetts Institute of Technology, 2019.

[51] Søndergaard R R, Hösel M, Krebs F C. Roll-to-Roll fabrication of large area functional organic materials[J]. Journal of Polymer Science, Part B:Polymer Physics, 2013, 51(1): 16 − 34. doi: 10.1002/polb.23192

[52] Singh M, Haverinen H M, Dhagat P, et al. Inkjet printing-process and its applications[J]. Advanced Materials, 2010, 22(6): 673 − 685. doi: 10.1002/adma.200901141

[53] Khan S, Doh Y H, Khan A, et al. Direct patterning and electrospray deposition through EHD for fabrication of printed thin film transistors[J]. Current Applied Physics, 2011, 11(1): S271 − S279. doi: 10.1016/j.cap.2010.11.044

[54] Gu Y, Wu A, Federici J F, et al. Inkjet printable constantan ink for the fabrication of flexible and conductive film[J]. Chemical Engineering Journal, 2017, 313: 27 − 36. doi: 10.1016/j.cej.2016.12.071

[55] Choi Y, Seong K, Piao Y. Metal-organic decomposition ink for printed electronics[J]. Advanced Materials Interfaces, 2019, 6(20): 1901002. doi: 10.1002/admi.201901002

[56] Sugiyama T, Kanzaki M, Arakawa R, et al. Low-temperature sintering of metallacyclic stabilized copper nanoparticles and adhesion enhancement of conductive copper film to a polyimide substrate[J]. Journal of Materials Science:Materials in Electronics, 2016, 27(7): 7540 − 7547. doi: 10.1007/s10854-016-4734-8

[57] 李俊龙, 徐杨, 赵雪龙, 等. 铜颗粒低温烧结技术的研究进展[J]. 焊接学报, 2022, 43(3): 13 − 24. doi: 10.12073/j.hjxb.20210225002 Li Junlong, Xu Yang, Zhao Xuelong, et al. Research progress of low-temperature sintering technology for copper particles[J]. Transactions of the China Welding Institution, 2022, 43(3): 13 − 24. doi: 10.12073/j.hjxb.20210225002

[58] Kim I, Kim J. The effect of reduction atmospheres on the sintering behaviors of inkjet-printed Cu interconnectors[J]. Journal of Applied Physics, 2010, 108(10): 102807. doi: 10.1063/1.3511688

[59] Gu W, Yuan W, Zhong T, et al. Fast near infrared sintering of silver nanoparticle ink and applications for flexible hybrid circuits[J]. RSC Advances, 2018, 8(53): 30215 − 30222. doi: 10.1039/C8RA04468F

[60] Park B K, Kim D, Jeong S, et al. Direct writing of copper conductive patterns by ink-jet printing[J]. Thin solid films, 2007, 515(19): 7706 − 7711. doi: 10.1016/j.tsf.2006.11.142

[61] Zhai D, Zhang T, Guo J, et al. Water-based ultraviolet curable conductive inkjet ink containing silver nano-colloids for flexible electronics[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2013, 424: 1 − 9.

[62] MacNeill W, Choi C-H, Chang C-H, et al. On the self-damping nature of densification in photonic sintering of nanoparticles[J]. Scientific Reports, 2015, 5(1): 1 − 13. doi: 10.9734/JSRR/2015/14076

[63] Ryu C H, Joo S J, Kim H S. Intense pulsed light sintering of Cu nano particles/micro particles-ink assisted with heating and vacuum holding of substrate for warpage free printed electronic circuit[J]. Thin Solid Films, 2019, 675: 23 − 33. doi: 10.1016/j.tsf.2019.02.020

[64] Kim H S, Dhage S R, Shim D E, et al. Intense pulsed light sintering of copper nanoink for printed electronics[J]. Applied Physics A, 2009, 97(4): 791 − 798. doi: 10.1007/s00339-009-5360-6

[65] Öhlund T, Schuppert A K, Hummelgard M, et al. Inkjet fabrication of copper patterns for flexible electronics: using paper with active precoatings[J]. ACS Applied Materials & Interfaces, 2015, 7(33): 18273 − 18282.

[66] Wang B Y, Yoo T H, Song Y W, et al. Cu ion ink for a flexible substrate and highly conductive patterning by intensive pulsed light sintering[J]. ACS Applied Materials & Interfaces, 2013, 5(10): 4113 − 4119.

[67] Chung W H, Hwang H J, Kim H S. Flash light sintered copper precursor/nanoparticle pattern with high electrical conductivity and low porosity for printed electronics[J]. Thin Solid Films, 2015, 580: 61 − 70. doi: 10.1016/j.tsf.2015.03.004

[68] Paglia F, Vak D, Van Embden J, et al. Photonic sintering of copper through the controlled reduction of printed CuO nanocrystals[J]. ACS Applied Materials & Interfaces, 2015, 7(45): 25473 − 25478.

[69] Yu J H, Kang K T, Hwang J Y, et al. Rapid sintering of copper nano ink using a laser in air[J]. International Journal of Precision Engineering and Manufacturing, 2014, 15(6): 1051 − 1054. doi: 10.1007/s12541-014-0435-5

[70] 周兴汶, 廖嘉宁, 姚煜, 等. 铜微纳结构的激光直写及其应用研究进展[J]. 中国激光, 2021, 48(8): 141 − 153. Zhou Xingwen, Liao Jianing, Yao Yi, et al. Progress of laser direct writing of copper micro-nano structures and its application[J]. China Laser, 2021, 48(8): 141 − 153.

[71] Kang B, Han S, Kim J, et al. One-step fabrication of copper electrode by laser-induced direct local reduction and agglomeration of copper oxide nanoparticle[J]. The Journal of Physical Chemistry C, 2011, 115(48): 23664 − 23670. doi: 10.1021/jp205281a

[72] Ohishi T, Takahashi N. Preparation and properties of copper fine wire on polyimide film in air by laser irradiation and mixed-copper-complex solution containing glyoxylic acid copper complex and methylamine copper complex[J]. Materials Sciences and Applications, 2018, 9(11): 859. doi: 10.4236/msa.2018.911062

[73] Zhou X, Guo W, Fu J, et al. Laser writing of Cu/CuxO integrated structure on flexible substrate for humidity sensing[J]. Applied Surface Science, 2019, 494: 684 − 690. doi: 10.1016/j.apsusc.2019.07.159

[74] Kim K S, Bang J O, Choa Y H, et al. The characteristics of Cu nanopaste sintered by atmospheric-pressure plasma[J]. Microelectronic Engineering, 2013, 107: 121 − 124. doi: 10.1016/j.mee.2012.08.019

[75] Gao Y, Zhang H, Jiu J, et al. Fabrication of a flexible copper pattern based on a sub-micro copper paste by a low temperature plasma technique[J]. RSC Advances, 2015, 5(109): 90202 − 90208. doi: 10.1039/C5RA18583A

[76] Shi L, Layani M, Cai X, et al. An inkjet printed Ag electrode fabricated on plastic substrate with a chemical sintering approach for the electrochemical sensing of hydrogen peroxide[J]. Sensors and Actuators B:Chemical, 2018, 256: 938 − 945. doi: 10.1016/j.snb.2017.10.035

[77] Li D, Sutton D, Burgess A, et al. Conductive copper and nickel lines via reactive inkjet printing[J]. Journal of Materials Chemistry, 2009, 19(22): 3719 − 3724. doi: 10.1039/b820459d

[78] Li W, Zhang H, Gao Y, et al. Highly reliable and highly conductive submicron Cu particle patterns fabricated by low temperature heat-welding and subsequent flash light sinter-reinforcement[J]. Journal of Materials Chemistry C, 2017, 5(5): 1155 − 1164. doi: 10.1039/C6TC04892G

[79] Liao J, Guo W, Peng P. Direct laser writing of copper-graphene composites for flexible electronics[J]. Optics and Lasers in Engineering, 2021, 142: 106605. doi: 10.1016/j.optlaseng.2021.106605

[80] Walia S, Mondal I, Kulkarni G U. Patterned Cu-Mesh-based transparent and wearable touch panel for tactile, proximity, pressure, and temperature sensing[J]. ACS Applied Electronic Materials, 2019, 1(8): 1597 − 1604. doi: 10.1021/acsaelm.9b00330

[81] Zhou X, Guo W, Yao Y, et al. Flexible nonenzymatic glucose sensing with one-step laser-fabricated Cu2O/Cu porous structure[J]. Advanced Engineering Materials, 2021, 23(6): 2100192. doi: 10.1002/adem.202100192

[82] Yao Y, Guo W, Zhou X, et al. Thermal properties of laser-fabricated copper-carbon composite films on polyimide substrate[J]. Advanced Engineering Materials, 2021: 2100623.

[83] Peng Z, Lin J, Ye R, et al. Flexible and stackable laser-induced graphene supercapacitors[J]. ACS Applied Materials & Interfaces, 2015, 7(5): 3414 − 3419.

[84] Liu H, Liu Y, Guo W, et al. Laser assisted ink-printing of copper oxide nanoplates for memory device[J]. Materials Letters, 2020, 261: 127097. doi: 10.1016/j.matlet.2019.127097

-

期刊类型引用(5)

1. 张仁航,李帅贞,汪认,何建英,许骏,孙晓红,冷康龙. 全熔透与部分熔透十字接头疲劳性能对比分析. 金属加工(热加工). 2021(03): 45-48 .  百度学术

百度学术

2. 周松,查涛,黄研清,安金岚,回丽,王磊. 典型高速列车用6N01铝合金焊接接头的微观组织及疲劳性能. 中国有色金属学报. 2021(05): 1253-1260 .  百度学术

百度学术

3. 杜亚芳,王东坡,刘秀国,龚宝明,邓彩艳. T形接头承载角焊缝根部裂纹扩展角度. 焊接学报. 2021(09): 21-27+98 .  本站查看

本站查看

4. 张军,张凤梅,周韶泽. 惯性载荷作用下结构应力法焊接结构抗疲劳性能研究. 大连交通大学学报. 2019(01): 40-45 .  百度学术

百度学术

5. 王苹,米莉艳,于谊飞,董平沙. 7N01铝合金十字接头抗疲劳设计. 焊接学报. 2019(10): 20-24+161-162 .  本站查看

本站查看

其他类型引用(5)

下载:

下载: