Forming behavior of friction pull plug welding for 2219 aluminum alloy and its effect on interfacial bonding quality

-

摘要:

针对2219铝合金拉拔式摩擦塞补焊(friction pull plug welding, FPPW)接头界面结合质量提升的问题,基于FPPW试验和仿真分析了接头成形过程中温度场、应变场和正应力场演变规律,及这些因素对界面结合质量的影响. 结果表明,在焊接过程中,当塞棒旋转进给时,摩擦界面上的峰值温度可达到约525 ℃,周围材料产生剧烈的塑性变形. 分析界面上的正应力场可知,沿板厚方向正应力的分布不均匀,呈现先上升后下降的趋势;当塞棒停转后,界面上的温度降低,塑性变形没有明显增加,上部界面的正应力增加,显著大于下部界面的正应力. 分析认为,相对于温度和塑性应变,正应力对界面结合质量的影响更加显著. 通过调整界面附近发生塑性流动的材料体积,可以增大正应力并改善其分布均匀性,将更多新鲜金属挤入氧化膜破碎的区域,增加新鲜金属实际接触面积,进而显著提高界面结合质量和接头拉伸性能.

Abstract:Aiming at improving the interfacial bonding quality of friction pull plug welding (FPPW) joints for 2219 aluminum alloy, the evolutions of temperature, plastic strain, and normal stress field during forming of joints were investigated on the basis of both experimental and simulation results, as well as their influence on interfacial bonding quality. The results indicate that during the welding process, when the rotating plug rotates and feeds, the interfacial temperature increases to about 525 ℃, and the material around the interface experiences severe plastic deformation. It can be analyzed that the interfacial normal stress shows non-uniformity throughout the thickness of the plate, exhibiting an initial increase followed by a subsequent decrease. When the plug stops rotating, the interfacial temperature decreases and plastic strain shows no obvious increase. The normal stress at the upper interface increases and exceeds that at the lower interface. It can be analyzed that the normal stress shows more obvious effect on the interfacial bonding quality compared with temperature and plastic strain. By adjusting the volume of plastic flow material near the interface, the normal stress increases and exhibits uniform, resulting in more fresh metal being extruded into the broken area of oxide film, and increasing the real contact area of fresh metal. The interfacial bonding quality and tensile property of joints can be effectively improved.

-

Keywords:

- friction pull plug welding /

- aluminum alloy /

- joint forming /

- tensile property

-

0. 序言

Fe-Mn-Si-Cr-Ni合金是一类利用应力诱发的Shockley不完全位错的可逆移动,进而诱发 γ (fcc)奥氏体→ ε (hcp)马氏体正逆相变,从而实现形状记忆效应的耐蚀型铁基形状记忆合金[1-4]. Fe-Mn-Si-Cr-Ni合金具有成本低、强度高、相变温度接近室温、耐腐蚀性好等优点,同时其在摩擦磨损过程中还会表现出特有的减摩抗磨特性[5-6]. 减摩方面,摩擦磨损过程中的接触应力,会使Fe-Mn-Si-Cr-Ni形状记忆合金产生应力诱发马氏体,即一部分作用力充当了 γ (fcc)奥氏体→ ε (hcp)马氏体相变的驱动力,进而降低了作用在合金摩擦时的接触应力;抗磨方面, ε (hcp)马氏体较 γ (fcc)奥氏体具有更高的硬度和更低测粘附系数[7]. 尽管Fe-Mn-Si-Cr-Ni合金具备独特的减摩耐磨特性,但其本身相对较低的硬度仍制约了其在工业领域的应用范围[8]. 为了解决这一问题,强化Fe-Mn-Si-Cr-Ni合金以期提高其硬度,并拓宽其工业应用范围是非常具有意义的.

陶瓷颗粒因其显著提升合金硬度和耐磨性而广泛应用于合金强化[9],其中WC以其高硬度(2 800 ~ 3 500 HV)、低热膨胀系数(3.84 × 10−6 ~ 5.96 × 10−6 K−1)、高熔点(2 870 ℃)和良好的热稳定性及耐磨性,在如合金化等应用中展现出卓越的性能[10-13]. 例如,在LIU等人[14]的研究中,通过在304不锈钢表面使用激光熔覆技术,成功制备了含有WC的Fe-Mn-Si形状记忆合金(SMA/WC)涂层.

WC的引入显著提升了涂层的性能,涂层的显微硬度增加了两倍以上,而其摩擦系数和磨损损失分别减少了约25%和67%. 此外,袁晓波等人[15]通过堆焊技术研究发现,WC可以增强相对位错运动的阻碍作用,从而显著的提升材料的强度、硬度和耐磨性. 然而,目前对WC提升铁基记忆合金耐磨性能的研究较少,对其机制的研究也尚不清晰.

值得进一步指出的是,铁基形状记忆合金的加工成形性较差,难以使用传统工艺成形复杂精密部件[16]. 增材制造在加工具有形状记忆功能的复杂形状金属制件上具有传统工艺所不具备的优势,可以为拓展铁基形状记忆合金的应用提供新思路[17-19].

选取Fe-17Mn-6Si-9Cr-5Ni合金作为研究对象,以WC作为添加材料,采用激光熔丝沉积增材制造技术制备了添加不同含量WC的Fe-17Mn-6Si-9Cr-5Ni合金,考察了其在油润滑条件下的摩擦磨损行为,分析并初步讨论了WC的添加量对合金耐磨机制的影响,旨在为颗粒增强铁基记忆合金的研究提供参考.

1. 试验方法

按照Fe-17Mn-6Si-9Cr-5Ni-xWC合金(x = 0,0.25,0.5,1,2,4;WC为微米级)的化学成分,选择合适管径和壁厚的304不锈钢管(其主要成分为Fe,Cr和Ni)作为外皮,并按照“同成分、等体积”原则配置填充粉末(Fe,Mn,Si,Cr,Ni和WC粉),配好的粉末通过充分研磨后利用震动灌装装置将其填入不锈钢管中,保证粉芯丝材成分与合金设计成分一致,利用课题组定制的轧尖拉拔一体化装置,采用“圆管法”制备增材制造用粉芯丝材[20-22],其主要工艺流程如图1所示. 该粉芯丝材具有典型的“皮包粉”抗损结构,能够抑制合金中元素的不均匀烧损,而且其便于对成分进行调控. 使用以HWS2000型激光焊机为主体的增材制造平台,将粉芯丝材以2 mm/s的送丝速度、1 500 W的激光功率,在304不锈钢基板上逐层堆积成约75 mm(长) × 10 mm(宽) × 10 mm(高)的薄壁墙试样,沉积完成后使用NSC-M332/W6型电火花线切割机对合金进行取样,截取尺寸为10 mm(长) × 10 mm(宽) × 5 mm(高)的摩擦磨损试样和沉积态组织观察用试样.

摩擦磨损试验前,使用400目砂纸将试样表面打磨至平整. 随后,在MGW-01往复式摩擦磨损机进行摩擦磨损试验. 在试验过程中,将试样固定在装置上,并在试样表面添加RHY型润滑油,采用直径为2.1 mm的GCr15钢球作为对磨件,施加载荷为7 N,往复摩擦频率为30 Hz,行程为6 mm,试验时间为60 min,试验过程中自动动态采集摩擦系数. 此外,采用体积磨损率作为耐磨性指标,体积磨损率Ws=V/d,其中,V为磨损体积损失,d为滑动行程距离. 采用VHX-2000型共聚焦显微镜测量体积磨损率,测量磨痕左侧、中间和右侧3个位置的磨痕深度、宽度与磨痕横切面面积,以磨痕横切面面积的平均值作为体积磨损率.

摩擦磨损试验后,沿磨痕中间部位截取横切面制备金相试样,以观察磨痕次表层形貌. 沉积态组织观察用试样和磨痕次表层形貌观察试样均制备成金相试样,经过腐蚀液(3 g CuSO4 + 10 mL HCl + 30 mL H2O)浸蚀处理后,采用CMY210型光学显微镜和S-3400N型扫描电子显微镜进行微观组织形貌观察.

采用HXD-1000TMB显微硬度计测量增材制造合金硬度,载荷0.1 kg,取3处不同区域硬度的平均值作为试验结果. 采用弯曲变形法(图2)测定合金的形状回复特性,按式(1)计算形状回复率 η,其中$ {\theta _{\text{m}}} $为记忆条的回复角度,$ {\theta _{\text{e}}} $为压力卸载后记忆条的回弹角度.

$$ \eta = \frac{{{\theta _{\mathrm{m}}}}}{{{{180}^ \circ } - {\theta _{\mathrm{e}}}}} \times 100\% $$ (1) 试样的预变形量 ε 可根据公式(2)计算,文中用于测定形状回复率的长条试样厚度t 为1 mm,采用模具直径D为25 mm,故其预变形量 ε 为4%.

$$ \varepsilon = \frac{{\text{t}}}{D} \times 100\% $$ (2) 2. 试验结果与分析

2.1 合金沉积态形貌

图3为增材制造Fe-Mn-Si-Cr-Ni-xWC(x = 0,0.25,0.5,1,2,4)合金沉积态的OM图像,如图3(b)所示,当WC添加量为0.25%时,在合金中未观察到明显的WC陶瓷颗粒,这可能是因为WC在加热过程中完全分解,其W和C元素进入晶格间隙,从而通过固溶强化增强合金;随着WC含量的提高,由于激光参数(如功率、扫描速度、离焦量、送粉速度)保持不变,导致作用于合金粉末的平均能量密度固定,所以随着加入的WC硬质颗粒比例增大,过多的WC硬质颗粒并没有熔化,在合金中起到弥散强化的作用[23];如图3 (c)和图3(d)所示,由于WC添加量较少,合金中未熔的WC硬质颗粒密度变化并不明显,导致弥散强化现象并不显著;随着WC添加量的增加,如图3 (e)和图3(f)所示,未熔化的WC颗粒密度随之增加,WC颗粒的弥散强化现象开始能够显著观察并逐渐增强.

图4为Fe-Mn-Si-Cr-Ni-xWC合金(x = 0,0.25,0.5,4)合金沉积态下的XRD,可以观察到Fe6W6C相的出现(用♦表示). 分析认为,WC在熔覆过程中会分解,释放出的W元素一部分固溶于合金中,但是由于W 元素在合金中的固溶度有限,所以大部分的 W 元素与 Fe和C元素结合,形成Fe6W6C型碳化物[24]. 而在FeMnSi形状记忆合金中,Fe6W6C颗粒能够限制堆积断层的运动,进而抑制马氏体的形成,导致部分奥氏体难以转变为马氏体[14]. 因此,随着WC含量增加,Fe6W6C相的特征峰显现并增强,同时降温马氏体的峰值开始减弱.

2.2 合金摩擦磨损后次表层形貌

图5展示了合金摩擦磨损后次表层的电镜(SEM)图像,对比图5 (a)和图5 (b),可以看到添加0.5% WC的合金相较于未添加WC的合金,其马氏体板条的数量减少,且马氏体间距增加;当WC含量增加为2%时,如图5 (c)所示,马氏体板条数量急剧减少,已无法在图5 (c)中明显观察到马氏体板条. 分析认为,随着WC含量的增加,合金中形成更多的Fe6W6C颗粒,Fe6W6C颗粒能够限制堆积断层的运动,导致冷却过程中合金形成的降温马氏体含量减少,这些降温马氏体,可以为合金在变形时提供更多的形核点. 因此,随着降温马氏体的减少,合金的形核点数量大幅减低,从而使得应力诱导的马氏体相变过程变得更为困难. 这种现象最终导致马氏体板条数量的显著减少,增加了塑性变形所承担的比重,进而对合金的形状记忆性能产生了不利影响[25-27]. 此外,在摩擦磨损过程中,Fe6W6C颗粒同样限制了堆积断层的运动,进一步限制应力诱发马氏体的形成,使得磨损时次表层中应力诱发马氏体含量进一步降低.

2.3 合金的记忆性能

图6为不同WC添加量Fe-Mn-Si-Cr-Ni合金在4%预变形下回复率,随着WC含量的增加,合金的记忆性能逐渐降低.

未添加WC的Fe-Mn-Si-Cr-Ni合金回复率为68.5%;当WC添加量为0.25 w%,0.5%,1%,2%和4%合金,形状回复率为68.3%,59.8%,50.1%,43.0%和38.8%. 其中,当WC添加量为0.25%时,记忆性能的下降幅度相对较小,分析认为,当WC添加量为0.25%时,合金中WC含量较少,合金中超出固溶限度的W元素有限,导致生成的Fe6W6C颗粒较少,可以看到在该条件下的XRD图中几乎观察不到Fe6W6C相的峰. 因此,在图6中看到,0.25% WC的添加量对合金的形状回复率影响小.

2.4 硬度和体积磨损率

图7是增材制造Fe-17Mn-6Si-9Cr-5Ni-xWC合金(x = 0,0.25,0.5,1,2,4)的体积磨损率及硬度曲线.

从图7可以看出,随着WC硬质颗粒添加量的增加,合金的硬度呈现出上升的趋势,其中,不添加WC的合金的硬度在290 HV 左右;添加量分别为 0.25%. 0.5%,1%,2%和4%的WC硬质颗粒时,合金的平均硬度分别提升到401 HV,410 HV,418 HV,459 HV和458 HV,相比于原始基体硬度分别增加了1.38倍、1.41倍、1.44倍、1.58倍和1.57倍. 此外,当WC的添加量从2%增加为4%时,合金的硬度并未继续提升,这种现象的原因在于,在给定的激光功率、扫描速度、离焦量和送粉速度条件下,激光在铁基合金粉末上的平均能量密度是固定的. 因此,随着WC硬质颗粒添加量的进一步增加,超出了熔化能力范围的WC硬质颗粒无法被有效熔化,这些WC硬质颗粒容易引发应力集中增加,增加合金的开裂可能,使合金内部出现缺陷[23],最终导致合金硬度的增长受到限制.

从图7中可以看出,未添加WC和添加0.25%,0.5%,1%,2%和4% WC试样合金的体积磨损率分别为24 444 × 10−6 mm2,19 875 × 10−6 mm2,34 761 × 10−6 mm2,48 160 × 10−6 mm2,35 138 × 10−6 mm2和28 710 × 10−6 mm2. 根据上述体积磨损率,相对于未添加WC的合金,添加0.25% WC合金的耐磨性提高了23.1%,添加0.5% WC合金的耐磨性下降了29.7%,添加1% WC合金的耐磨性下降了49.2%,添加2% WC合金的耐磨性下降了30.4%,添加4% WC合金的耐磨性下降了14.8%. 可见,合金的体积磨损率呈现出先降低后升高再降低的趋势,且在添加0.25% WC时达到最低点.

3. 分析讨论

在外力作用时,铁基记忆合金有两种变形方式,一种是 γ → ε 相变,另一种则是普通塑性滑移,二者呈现出竞争关系. 若要获得优异的形状记忆效应,则需要让变形更多的以马氏体相变承担而非塑性变形[16]. 在相同的摩擦磨损条件下,形状记忆效应回复率可以一定程度体现合金 γ → ε 相变的程度. 铁基记忆合金在摩擦磨损过程中具有减摩抗磨特性[6],减摩方面,摩擦磨损过程中的接触应力,会使Fe-Mn-Si-Cr-Ni形状记忆合金产生应力诱发马氏体,即一部分作用力充当了 γ(fcc)奥氏体→ ε (hcp)马氏体相变的驱动力,进而降低了作用在合金摩擦时的接触应力;抗磨方面,ε(hcp)马氏体较 γ(fcc)奥氏体具有更高的硬度和更低测粘附系数. 因此,形状记忆效应的表现在一定程度上反映了铁基形状记忆合金特有的减摩抗磨特性的效能.

一般来说,合金的硬度越高其耐磨性越好. 在文中试验条件下,当添加0.25%,0.5%和1% WC时,合金硬度提高其耐磨性却随之下降. 这是由于合金的磨损机制可以分为两个主要阶段,首先,在添加0.25%,0.5%和1%WC的情况下,磨损主要由Fe-Mn-Si-Cr-Ni合金固有的减摩和抗磨特性主导. 在此过程中,加入的WC会发生分解,释放出的W元素部分固溶于合金基体中. 然而,鉴于W元素在合金中的有限固溶度,大量的W元素与Fe和C元素反应,形成Fe6W6C型碳化物. 在FeMnSi形状记忆合金中,这些Fe6W6C碳化物粒子能够阻碍滑移带的移动,从而抑制马氏体相的形成,使得一部分奥氏体难以转换为马氏体. 当WC的添加量为0.25%时,由于添加的WC含量较少,超出固溶度限度的W元素相对较少,导致形成的Fe6W6C碳化物粒子数量有限,合金的形状记忆效应变化不显著,但硬度得到提升,从而增强了耐磨性. 然而,随着WC含量从0.25%增为1%,形成的Fe6W6C碳化物粒子数量开始增多,合金的形状记忆效应逐渐减弱,摩擦磨损过程中次表层马氏体含量的减少,导致铁基形状记忆合金特有的减磨抗磨特性减弱,耐磨性逐步降低.

在第二阶段,随着WC添加量的增加为2%和4% 时,磨损机制转变,主要由WC颗粒的弥散强化效应主导. 此阶段下,已无法在次表层观察到应力诱发的马氏体. 在试验设定的激光功率、扫描速度、离焦量及送粉速度条件下,激光在铁基合金粉末上的平均能量密度保持恒定,这超出了WC硬质颗粒的熔化能力范围. 因此,随着WC含量的进一步增加,合金中未溶解的WC硬质颗粒密度增加,这些WC颗粒的弥散强化效应变得更加明显,从而导致耐磨性的提升.

4. 结论

(1) 随着WC颗粒添加量的增加,Fe-Mn-Si-Cr-Ni合金的耐磨性能呈现出先升后降再升的趋势,且在添加0.25% WC时达到最高点(其体积磨损率最小).

(2) 在添加0.25%,0.5%和1%WC的情况下,磨损机制主要由Fe-Mn-Si-Cr-Ni合金特有的减摩抗磨特性主导. 当添加0.25% WC时,由于合金的记忆效应变化不大且硬度增加,其耐磨性得以提升. 然而,随着WC含量从0.25%增加为1%,合金的记忆效应逐渐降低,摩擦磨损中次表层中应力诱发的马氏体含量减少,铁基记忆合金合金特有的减摩抗磨特性发挥变弱,导致耐磨性逐步下降.

(3) 当WC添加量为2%和4% 时,磨损机制转变以WC颗粒的弥散强化作用为主. 由于激光参数保持不变,导致作用于合金粉末的平均能量密度固定. 因此,随着WC含量的提高,未熔化的WC颗粒的密度随之增加,WC颗粒的弥散强化作用开始显著,从而导致耐磨性的提升.

-

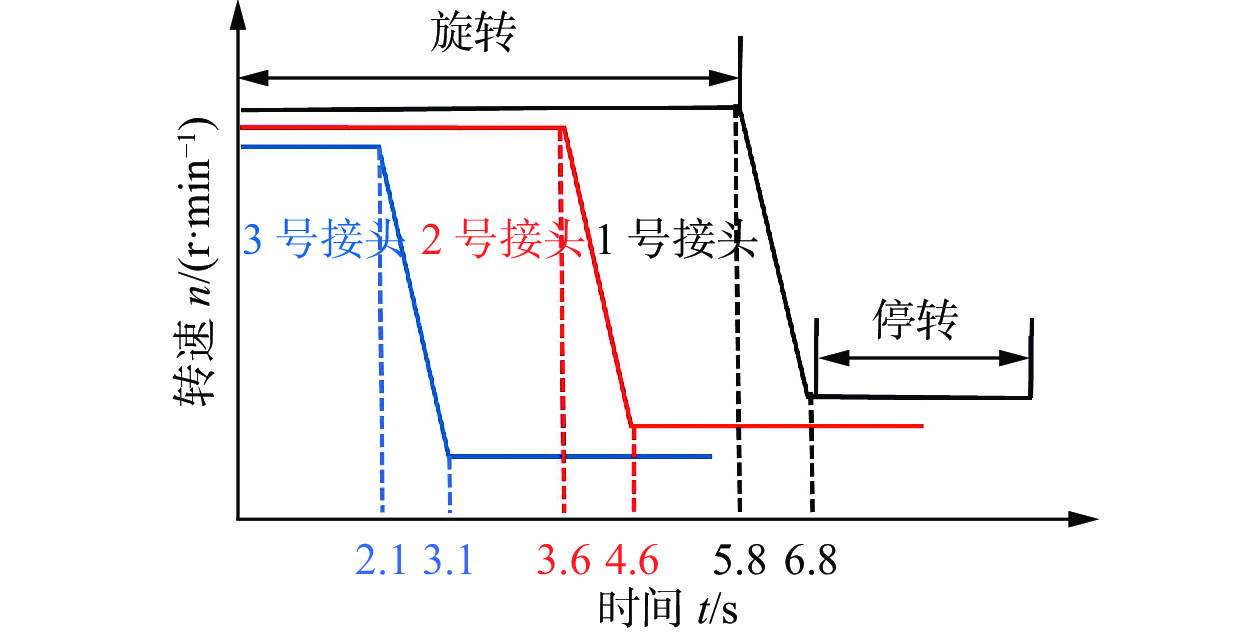

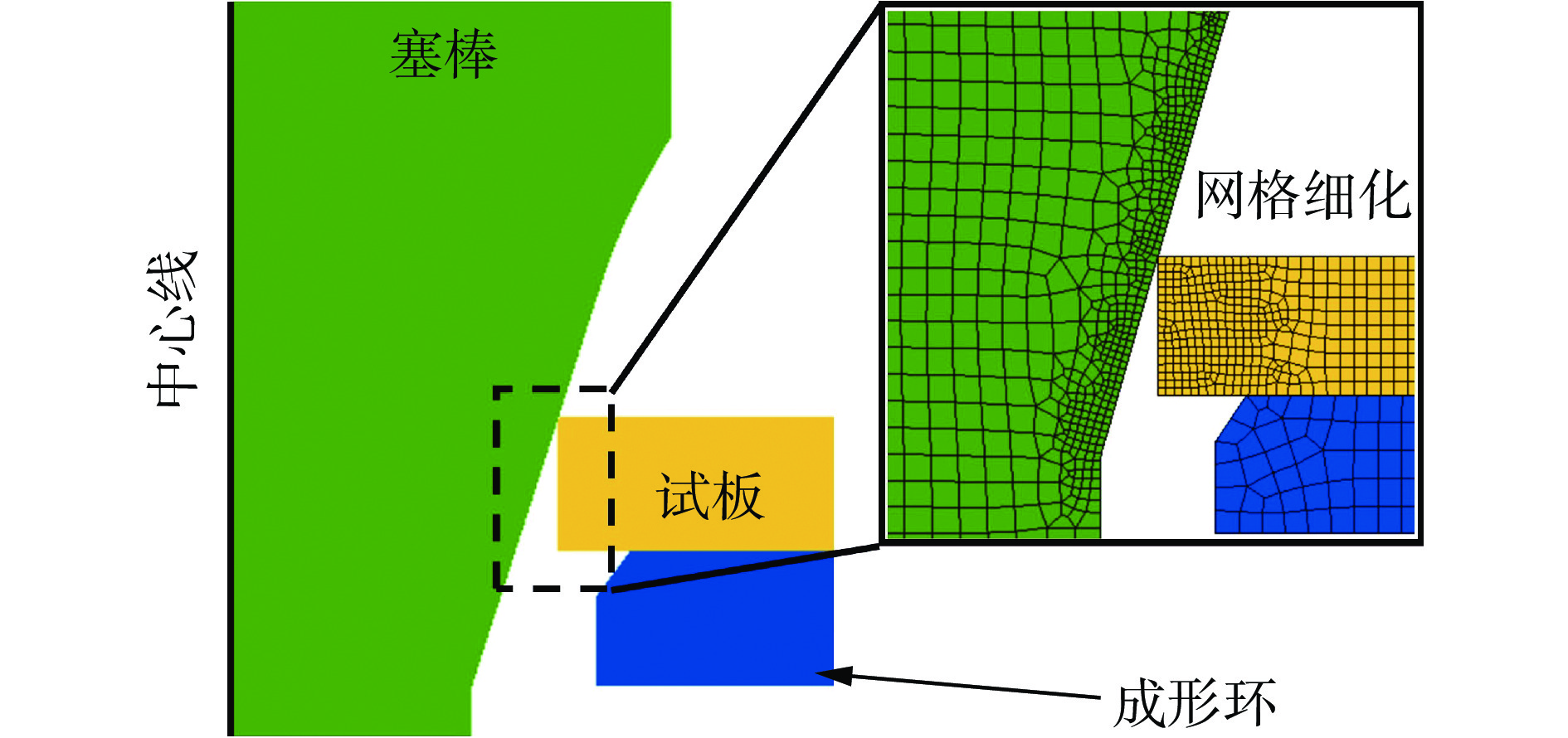

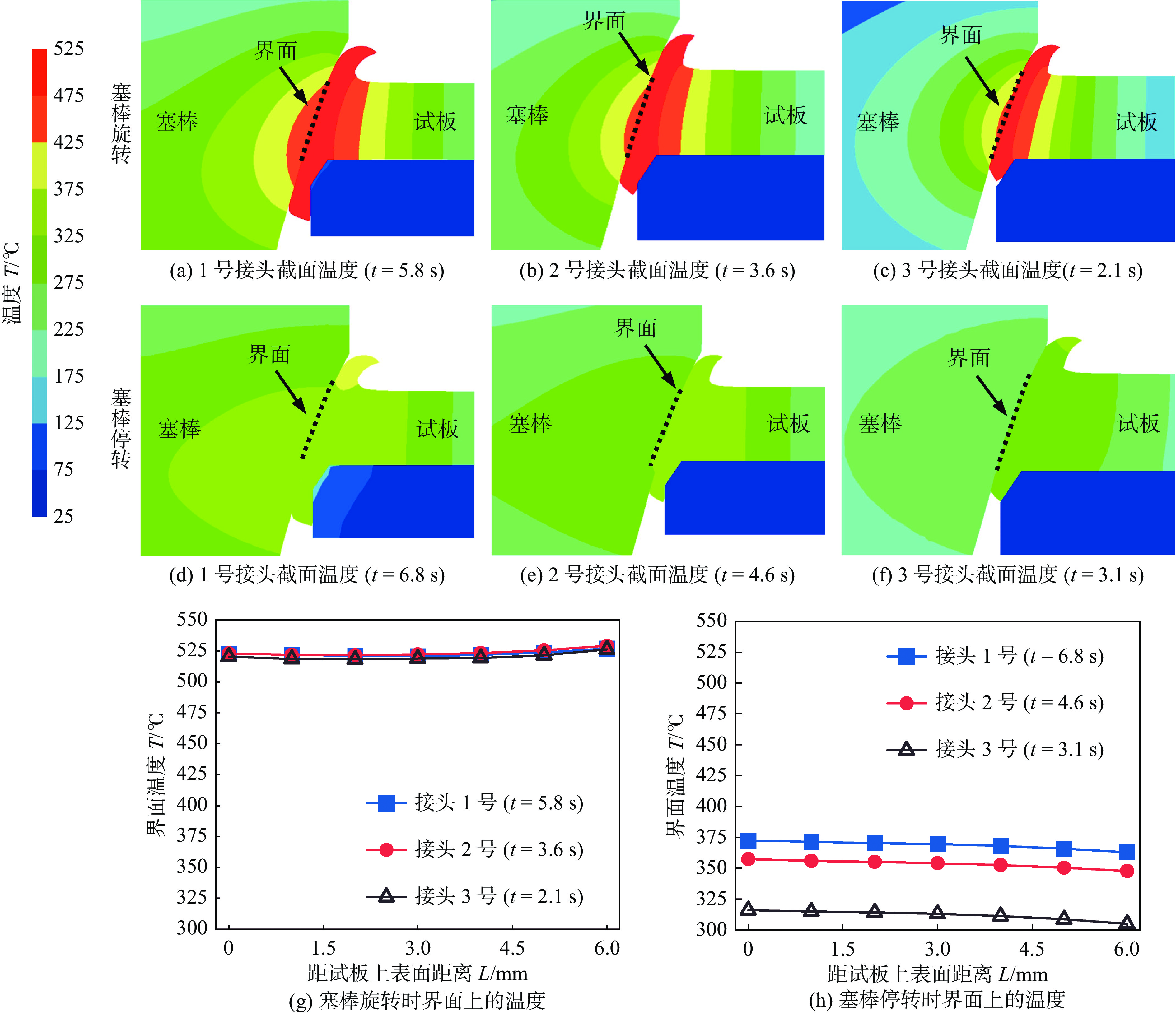

图 7 不同时刻下FPPW接头的温度场分布

Figure 7. Distribution of temperature field at different instances in FPPW joints. (a) cross-sectional temperature in joint 1(t = 5.8 s); (b) cross-sectional temperature in joint 2(t = 3.6 s);(c) cross-sectional temperature in joint 3(t = 2.1 s);(d)cross-sectional temperature in joint 1(t = 6.8 s);(e)cross-sectional temperature in joint 2(t = 4.6 s);(f) cross-sectional temperature in joint 3(t = 3.1 s);(g) interfacial temperature when the plug is rotating; (h) interfacial temperature when the plug stops rotating

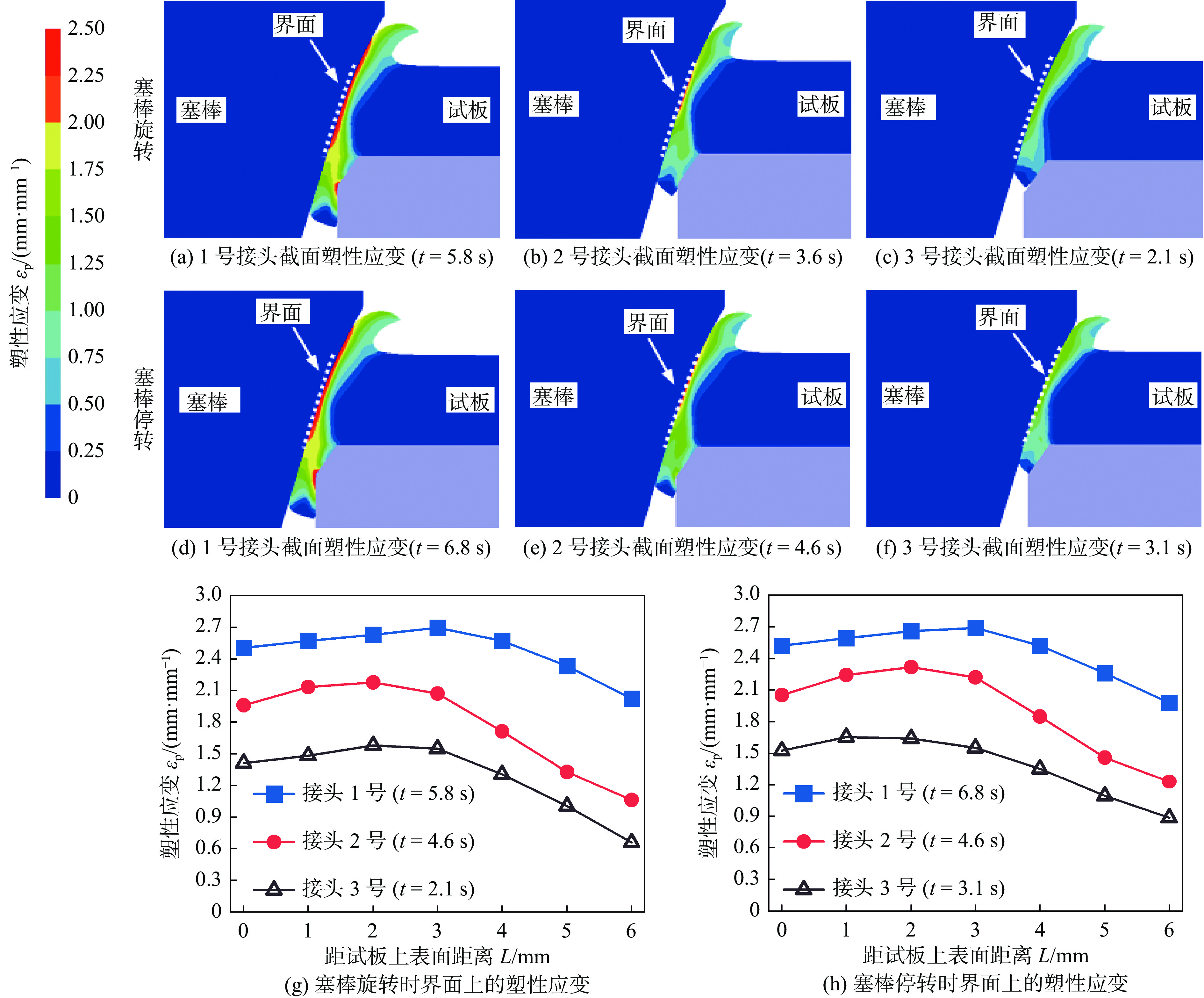

图 8 不同时刻下FPPW接头的塑性应变场分布

Figure 8. Distribution of plastic strain field at different instances in FPPW joints. (a) cross-sectional plastic strain in joint 1(t = 5.8 s); (b)cross-sectional plastic strain in joint 2(t = 3.6 s); (c)cross-sectional plastic strain in joint 3(t = 2.1 s); (d) cross-sectional plastic strain in joint 1(t = 6.8 s);(e)cross-sectional plastic strain in joint 2(t = 4.6 s);(f)cross-sectional plastic strain in joint 3(t = 3.1 s);(g) interfacial plastic strain when the plug is rotating; (h) interfacial plastic strain when the plug stops rotating

图 9 不同时刻下FPPW接头的正应力场分布

Figure 9. Distribution of normal stress field at different instances in FPPW joints. (a) cross-sectional normal stress in joint 1(t = 5.8 s); (b)cross-sectional normal stress in joint 2(t = 3.6 s); (c)cross-sectional normal stress in joint 3(t = 2.1 s); (d) cross-sectional normal stress in joint 1(t = 6.8 s);(e)cross-sectional normal stress in joint 2(t = 4.6 s);(f)cross-sectional normal stress in joint 3(t = 3.1 s);(g) interfacial normal stress when the plug is rotating; (h) interfacial normal stress when the plug stops rotating

图 10 不同时刻下FPPW接头的材料流动速度分布

Figure 10. Distribution of material flow velocity field at different instances in FPPW joints. (a) cross-sectional material flow velocity in joint 1(t = 5.8 s); (b) cross-sectional material flow velocity in joint 2(t = 3.6 s); (c) cross-sectional material flow velocity in joint 3(t = 2.1 s); (d) cross-sectional material flow velocity in joint 1(t = 6.8 s);(e) cross-sectional material flow velocity in joint 2(t = 4.6 s);(f) cross-sectional material flow velocity in joint 3(t = 3.1 s);(g) interfacial material flow velocity when the plug is rotating; (h) interfacial material flow velocity when the plug stops rotating

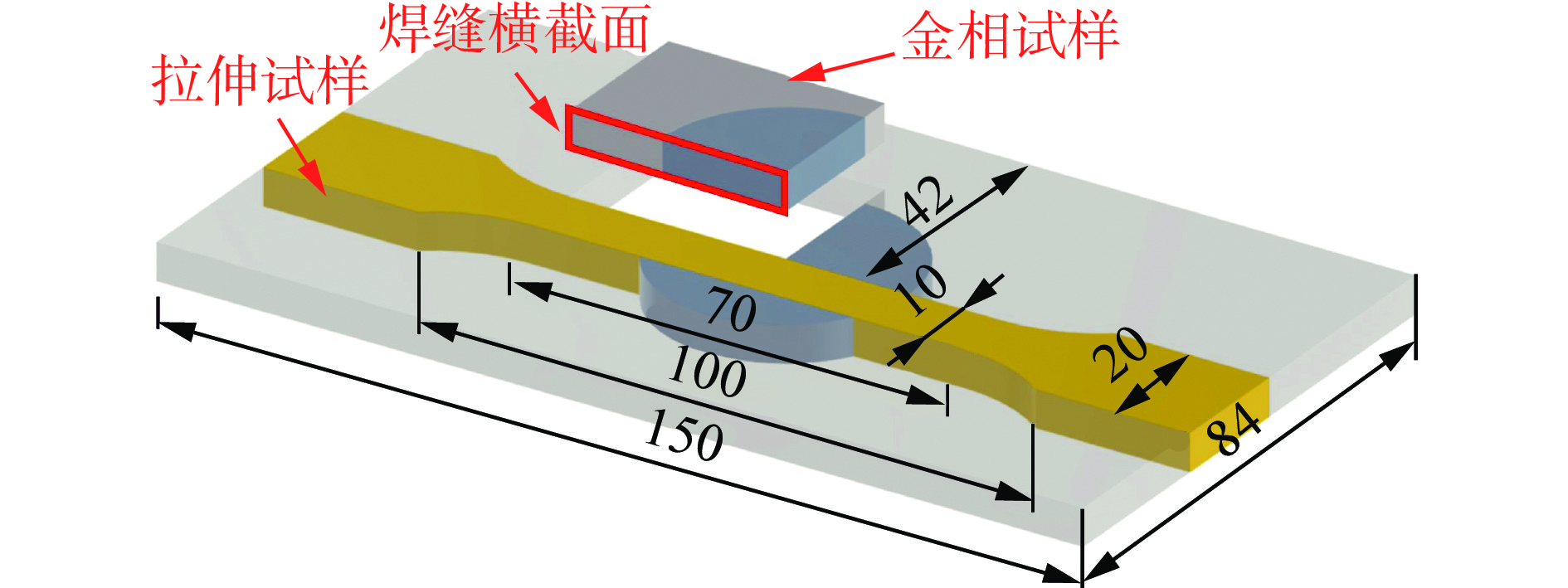

图 11 FPPW接头结合界面附近宏观形貌与微观组织

Figure 11. Macro-morphology and micro-morphology of bonding interface in FPPW joints. (a) macro-morphology of joint 1; (b) macro-morphology of joint 2; (c) macro-morphology of joint 3; (d) micro-morphology of joint 1 in region Ⅰ; (e) micro-morphology of joint 2 in region Ⅰ; (f) micro-morphology of joint 3 in region Ⅰ; (g) micro-morphology of joint 1 in region Ⅱ; (h) micro-morphology of joint 2 in region Ⅱ; (i) micro-morphology of joint 3 in region Ⅱ

表 1 2219铝合金热物理参数[16]

Table 1 Thermo-physical properties of 2219 aluminum alloy

温度

T /K密度

ρ/(kg·m−3)比热容

c/(J·kg−1·K−1)热导率

λ/(W·m−1·K−1)298 2 840 726.3 138.6 373 2 840 801.3 142.7 573 2 840 957.3 154.2 773 2 840 1 049.0 166.6 表 2 Arrhenius模型多项式系数取值

Table 2 Coefficients of polynomial function of Arrhenius model

α Q n lnA B0 = 0.0196 C0 = 2.94 × 105 D0 = 5.61 E0 = 49.4 B1 = − 0.0776 C1 = −6.81 × 105 D1 = −4.44 E1 = −128.04 B2 = 0.458 C2 = 3.21 × 106 D2 = 30.7 E2 = 613.59 B3 = −0.920 C3 = −6.56 × 106 D3 = −73.31 E3 = − 1226 B4 = 0.652 C4 = 4.81 × 106 D4 = 57.95 E4 = 846.21 表 3 FPPW模型中摩擦系数[18]

Table 3 Friction coefficient in FPPW model

温度 T /K 摩擦系数μ 298 0.3 673 0.25 793 0.2 816 0.01 -

[1] 李德福, 王希靖, 赵早龙, 等. 轴肩辅助加热6082铝合金摩擦塞补焊接头组织及力学性能[J]. 焊接学报, 2022, 43(1): 36 − 41. Li Defu, Wang Xijing, Zhao Zaolong, et al. Microstructure and mechanical properties of friction plug repair welding joint by shoulder auxiliary heating for 6082 aluminum alloy[J]. Transactions of the China Welding Institution, 2022, 43(1): 36 − 41.

[2] Dong J H, Huang Y M, Zhu J L, et al. Quality assessment of friction-stir-welded aluminum alloy welds via three-dimensional force signals[J]. Advances in Manufacturing, 2024, 12(1): 61 − 75. doi: 10.1007/s40436-023-00452-2

[3] 李书新, 孙转平, 刘旭, 等. 7075-T651铝合金摩擦塞补焊接头的组织与性能[J]. 焊接学报, 2023, 44(7): 95 − 101. Li Shuxin, Sun Zhuanping, Liu Xu, et al. Microstructure and properties of 7075-T651 aluminum alloy friction plug welding joint[J]. Transactions of the China Welding Institution, 2023, 44(7): 95 − 101.

[4] Cui L, Lu P, Li W K, et al. Influence of axial force parameters to the quality of friction pull plug welding for 2219-T87 aluminum alloy sheets[J]. Science and Technology of Welding and Joining, 2018, 24(1): 27 − 35.

[5] Du B, Sun Z P, Yang X, et al. Characteristics of friction plug welding to 10 mm thick AA2219-T87 sheet: weld formation, microstructure and mechanical property[J]. Material Science and Engineering A, 2016, 654: 21 − 29. doi: 10.1016/j.msea.2015.12.019

[6] 蒋常铭. 6082-T6铝合金摩擦塞补焊工艺优化及数值模拟[D]. 兰州: 兰州理工大学, 2023. Jiang Changming. Optimization and numerical simulation of welding process for 6082-T6 aluminum alloy friction plug welding[D]. Lanzhou : Lanzhou University of Technology, 2023.

[7] Du B, Yang X Q, Tang WS, et al. Numerical analyses of material flows and thermal processes during friction plug welding for AA2219 aluminum alloy[J]. Journal of Materials Processing Technology, 2020, 278: 116466. doi: 10.1016/j.jmatprotec.2019.116466

[8] Du B, Cui L, Yang X Q, et al. Weakening mechanism and tensile fracture behavior of AA 2219-T87 friction plug welds[J]. Materials Science and Engineering A, 2017, 693: 129 − 135. doi: 10.1016/j.msea.2017.03.093

[9] Gao J Y, Yang L J, Cui L, et al. Improving the weld formation and mechanical properties of the AA-5A06 friction pull plug welds by axial force control[J]. Acta Metallurgica Sinica (English letters), 2020, 33: 828 − 838. doi: 10.1007/s40195-020-01015-1

[10] 卢鹏, 崔雷, 王惠苗, 等. 2219铝合金拉锻式摩擦塞补焊工艺研究[J]. 航空制造技术, 2019, 62(12): 55 − 64. Lu Peng, Cui Lei, Wang Huimiao, et al. Friction pull plug welding process of 2219 aluminum alloy[J]. Aeronautical Manufacturing Technology, 2019, 62(12): 55 − 64.

[11] 邵震, 崔雷, 王东坡, 等. 轴向拉力对铝合金拉拔式摩擦塞焊接头组织及力学性能的影响[J]. 机械工程学报, 2021, 57(20): 117 − 125. doi: 10.3901/JME.2021.20.117 Shao Zhen, Cui Lei, Wang Dongpo, et al. Influence of axial force on the microstructure and mechanical properties of 2A70 aluminum alloy friction pull plug welding[J]. Journal of Mechanical Engineering, 2021, 57(20): 117 − 125. doi: 10.3901/JME.2021.20.117

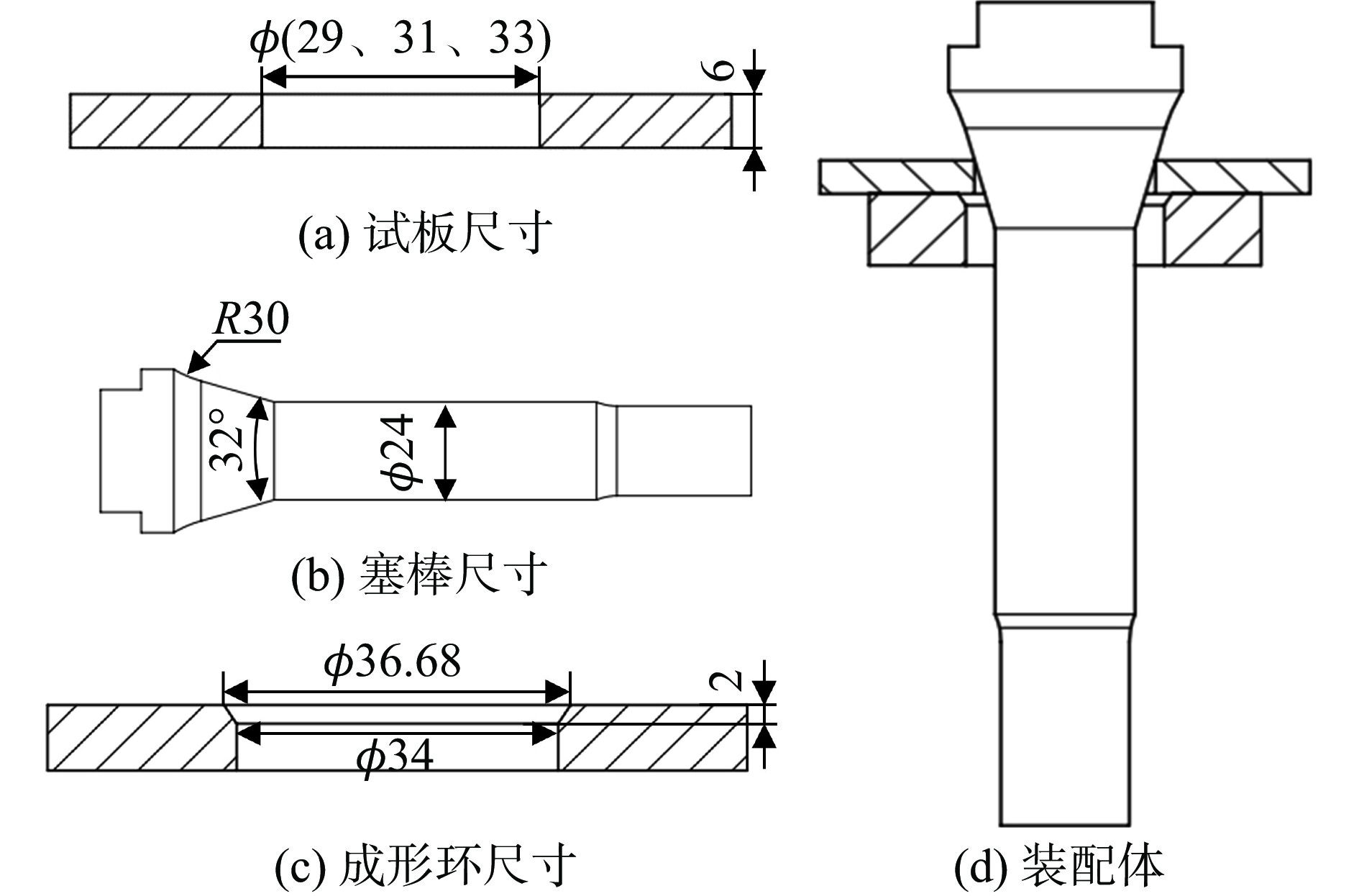

[12] 邵震, 崔雷, 王东坡, 等. 几何参数对2219铝合金拉拔式摩擦塞补焊接头微观组织及力学性能的影响[J]. 材料工程, 2022, 50(1): 25 − 32. Shao Zhen, Cui Lei, Wang Dongpo, et al. Influence of geometric parameters on microstructure and mechanical properties of friction pull plug welding joints for 2219 aluminum alloy[J]. Journal of Materials Engineering, 2022, 50(1): 25 − 32.

[13] 梁鑫裕. 大厚度2219铝合金拉拔式摩擦塞补焊工艺优化[D]. 天津: 天津大学, 2023. Liang Xinyu. The friction pull plug welding process optimization of AA2219 with large thickness[D]. Tianjin : Tianjin University, 2023.

[14] 邓越, 崔雷, 王东坡, 等. 铝合金拉拔式摩擦塞补焊成形及其对界面结合行为的影响[J]. 中国有色金属学报, 2023, 33(9): 2825 − 2838. Deng Yue, Cui Lei, Wang Dongpo, et al. Forming of aluminum alloy friction pull plug welding and its influence on interfacial bonding behavior[J]. The Chinese Journal of Nonferrous Metals, 2023, 33(9): 2825 − 2838.

[15] 邓越, 刘正武, 浦岩昊, 等. 2219铝合金拉拔式摩擦塞补焊接头界面缺陷研究[J]. 航天制造技术, 2023(4): 30 − 35. Deng Yue, Liu Zhengwu, Pu Yanhao, et al. Study on interfacial defects of 2219 aluminum alloy friction pull plug welding[J]. Aerospace Manufacturing Technology, 2023(4): 30 − 35.

[16] Wang H X, Wei Y H, Yang C L. Numerical calculation of variable polarity keyhole plasma arc welding process for aluminum alloys based on finite difference method[J]. Computational Materials Science, 2007, 40(2): 213 − 225. doi: 10.1016/j.commatsci.2006.12.006

[17] Geng P H, Qin G L, Chen L, et al. Effect of tool revolutionary pitch on heat transfer and material flow in Al/steel friction stir lap welding[J]. Journal of Materials Processing Technology, 2024, 325: 118306. doi: 10.1016/j.jmatprotec.2024.118306

[18] Saad B Aziz, Mohammad W Dewan, Daniel J Huggett, et al. A fully coupled thermomechanical model of friction stir welding (FSW) and numerical studies on process parameters of lightweight aluminum alloy joints[J]. Acta Metallurgica Sinica (English letters), 2018, 31: 1 − 18. doi: 10.1007/s40195-017-0658-4

[19] 陈永亮, 杨子超, 林恒利, 等. 拉锻式摩擦塞焊的热力耦合解析模型和试验验证[J]. 中国机械工程, 2020, 31(17): 2118 − 2127. Chen Yongliang, Yang Zichao, Lin Hengli, et al. Analytical model of thermo-mechanics coupling and experimental verification for friction pull plug welding[J]. China Mechanical Engineering, 2020, 31(17): 2118 − 2127.

[20] Xu S B, Zhao G Q, Ren G. Numerical simulation and experimental investigation of pure copper deformation behavior for equal channel angular pressing/extrusion process[J]. Computational Materials. Science, 2008, 44(2): 247 − 252. doi: 10.1016/j.commatsci.2008.03.032

[21] Chen H, Zhao G Q, Zhang C S, et al. Numerical simulation of extrusion process and die structure optimization for a complex aluminum multicavity wallboard of high-speed train[J]. Materials and Manufacturing Processes, 2011, 26(12): 1530 − 1538. doi: 10.1080/10426914.2011.551950

[22] Yu J Q, Zhao G Q. Interfacial structure and bonding mechanism of weld seams during porthole die extrusion of aluminum alloy profiles[J]. Materials Characterization, 2018, 138: 56 − 66. doi: 10.1016/j.matchar.2018.01.052

[23] Chen H Y, Fu L, Zhang W Y, et al. Radial distribution characteristics of microstructure and mechanical properties of Ti-6Al-4V butt joint by rotary friction welding[J]. Acta Metallurgica Sinica (English letters), 2015, 28(10): 1291 − 1298. doi: 10.1007/s40195-015-0325-6

[24] Cui D C, Wu Q F, Jin F, et al. Heterogeneous deformation behaviors of an inertia friction welded Ti2AlNb joint: an in-situ study[J]. Acta Metallurgica Sinica (English letters), 2023, 36: 611 − 622. doi: 10.1007/s40195-022-01477-5

[25] 杜随更, 王喜锋, 高漫. 单晶DD3与细晶GH4169高温合金摩擦焊接界面表征[J]. 金属学报, 2015, 51(8): 951 − 956. Du Suigeng, Wang Xifeng, Gao Man. Characteristics of the friction welding interface between single crystal super alloy DD3 and fine grained superalloy GH4169[J]. Acta Metallurgica Sinica, 2015, 51(8): 951 − 956.

[26] Cooper D R, Allwood J M. The influence of deformation conditions in solid-state aluminium welding processes on the resulting weld strength[J]. Journal of Materials Processing Technology, 2014, 214(11): 2576 − 2592. doi: 10.1016/j.jmatprotec.2014.04.018

[27] Shao Z, Cui L, Yang L J, et al. Microstructure and mechanical properties of friction pull plug welding for 2219-T87 aluminum alloy with tungsten inert gas weld[J]. International Journal of Minerals, Metallurgy and Materials, 2022, 29(6): 1216 − 1224. doi: 10.1007/s12613-020-2222-x

[28] Liang X Y, Wang Z J, Cui L, et al. High-quality friction pull plug welding of AA2219-T87 plate with a thickness of 18 mm: experimental characterization on shaping, microstructure and mechanical properties[J]. Materials Characterization, 2022, 194: 112448. doi: 10.1016/j.matchar.2022.112448

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: