Effect of welding speed on microstructure and mechanical properties of electron beam welded joints of 12Cr heat-resistant steel

-

摘要:

新型耐热钢12Cr是汽轮机高温转子部件的重要材料,对20 mm厚12Cr耐热钢进行了电子束焊接试验,系统研究了电子束焊接速度对12Cr耐热钢接头微观组织与力学性能的影响.结果表明,焊缝组织主要由马氏体板条构成,其尺寸相比于母材更加细小均匀,随着焊接速度的增加,热输入减小,焊缝和热影响区的晶粒尺寸趋于细化.基于Kurdjumov-Sachs取向关系,将马氏体组织重构为原奥氏体晶粒(proto austenitic grain, PAG),证明焊接速度对原奥氏体晶粒尺寸影响较小,不同参数下焊接接头均具有较弱立方织构.力学性能结果表明,焊缝区的显微硬度显著高于母材,在厚度方向上焊缝平均硬度随着焊接速度的增加有所提高.接头焊缝的抗拉性能有所提升,所有拉伸试样均断裂于母材处,平均抗拉强度为968 MPa,断口有韧窝,断裂机制为韧脆混合断裂.

Abstract:The 12Cr alloy represents a significant advancement in materials for high-temperature rotor components used in steam turbines. A systematic investigation was conducted through an electron beam welding experiment on 20 mm thick 12Cr heat-resistant steel, focusing on the influence of welding speed on the microstructural characteristics and mechanical properties of the welded joints. The findings reveal that the microstructure of the weld predominantly consists of martensitic lath, characterized by a finer and more uniform grain size compared to the base material. An increase in welding speed correlates with a reduction in heat input, resulting in a refinement of the grain size within both the weld and the heat-affected zone. Utilizing the Kurdjumov-Sachs orientation relationship, it was observed that the martensitic structure was reconstructed from the PAG, indicating that the welding speed has a negligible impact on the dimensions of the original austenite grains. Furthermore, the welded joints displayed a weak cubic texture across varying parameters. Mechanical property assessments demonstrated that the microhardness within the weld zone significantly exceeds that of the base material, with the average hardness value in the thickness direction of the weld increasing in conjunction with the welding speed. The tensile properties of the welded joints exhibited enhancement, as all tensile specimens failed within the base material, yielding an average tensile strength of 968 MPa. The fracture surfaces revealed a dimpled morphology, suggesting a mixed ductile-brittle fracture mechanism.

-

Keywords:

- electron beam welding /

- heat-resistant steel /

- microstructure /

- mechanical property

-

0. 序言

12Cr耐热钢与传统CrMoV钢相比,具有更高的高温蠕变强度和使用寿命,是制造新一代燃气轮机压气机高温转子的重要材料[1],压气机转子结构复杂,根据形状大小,常用的转子尺寸厚度多在10 ~ 30 mm之间,采用分段制造后焊接而成[2],在使用过程中,焊接结构要经历循环动载荷[3],要求焊接接头具有优异的综合力学性能.

对于厚板耐热钢的焊接主要采用多层多道电弧焊,其生产效率低,工艺稳定性差[4-5],此外,多层多道焊过程中,反复热循环会导致热影响区韧性显著降低[6],主要是大量的碳氮化合物重新固溶于奥氏体晶粒内部,形成过饱和的马氏体,从而导致热影响区组织脆化[7].电子束焊具有能量密度高、焊接热影响区小、真空保护气氛等优点,焊接钢材时可以有效避免残余应力的聚集[8],在焊接厚板耐热钢材料中无需多次焊接,可以避免层间热作用,提高焊缝组织均匀性[9],其产生的韧性降低问题可以通过焊后热处理得到有效改善[10].

文中研究了20 mm厚12Cr耐热钢的电子束焊,分析了焊接速度对电子束焊接接头微观组织与力学性能的影响.

1. 试验方法

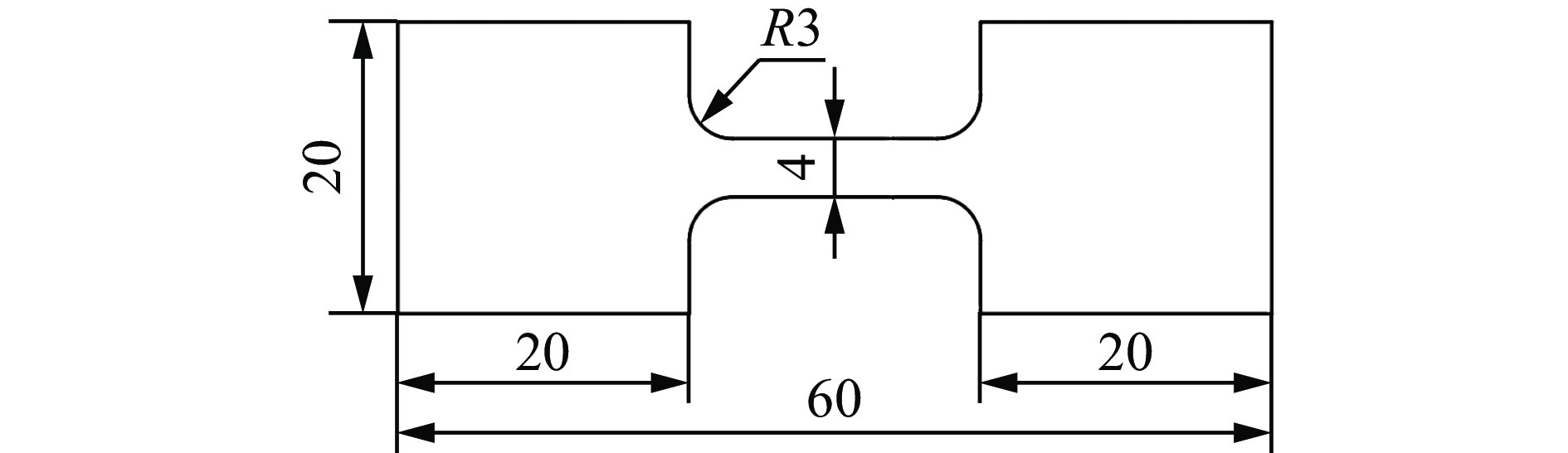

试验采用的材料为新型马氏体耐热钢,牌号为1Cr10Mo1NiWVNbN,其成分组成见表1,力学性能见表2,所采用设备是THDW-15真空电子束焊机,焊接板材长宽高尺寸为100 mm × 37.5 mm × 20 mm,分别利用酒精与丙酮对焊接区域进行擦拭,去除油脂与水分.焊接接头采用对接形式,对接间隙不大于0.1 mm,在试板下方加入长宽高为100 mm × 10 mm × 10 mm的衬板并进行点固,点固束流采用正式焊接束流的1/3,装配示意图如图1所示,焊接参数见表3.

表 1 12Cr耐热钢化学成分(质量分数,%)Table 1. Chemical composition of 12Cr heat resistant steelC Mn P S Si Cr 0.09 ~ 0.14 0.40 ~ 0.70 0.02(max) 0.02(max) ≤0.30 10 ~ 11 Mo V Nb Ni N W 1.0 ~ 1.3 0.15 ~ 0.25 0.04 ~ 0.08 0.4 ~ 0.7 0.03 ~ 0.07 0.20 ~ 0.30 表 2 12Cr耐热钢常温力学性能Table 2. Room temperature mechanical properties of 12Cr heat-resistant steel抗拉强度

Rm/MPa屈服强度

Rel/MPa断后伸长率

A(%)断面收缩率

Z(%)冲击吸收能量

Akv/J硬度

H/HV0.2≥690 490 ≥35 ≥13 ≥40 185 ~ 260 表 3 焊接工艺参数Table 3. Welding parameters试样

编号加速电压

U/kV聚焦电流

If/mA焊接速度

v/(mm·min−1)焊接束流

I/mA1 85 386 200 65 2 85 386 300 65 3 85 386 400 65 电子束焊接完成后,对接头进行XRD射线衍射分析,衍射角为20° ~ 100°,测试标靶为Cu靶,探究工艺参数对组成相的影响,在焊缝成形稳定部位截取金相试样及拉伸性能测试试样,通过Olympus光学显微镜及Merlin Compact扫描电子显微镜对焊缝微观组织进行分析,观察特征组织和鉴定相成分.采用Instron 5967 型万能试验机对接头进行拉伸试验,拉伸速率1 mm/min,拉伸试样尺寸如图2所示.采用FY-HV-100S显微硬度计测量横截面硬度,载荷3N,保持15s,厚度方向上两点间距离1 mm,宽度方向上两点间距离0.2 mm.

2. 试验结果及讨论

2.1 微观组织

耐热钢电子束焊缝表面及横截面形貌,如图3所示,焊缝表面成形良好,焊缝截面呈钉形,无明显焊接缺陷.焊接接头由焊缝等轴晶区和柱状晶区、热影响区粗晶区和细晶区、母材组成.焊缝部分属于典型的电子束焊接头形貌,可以看到,焊接速度为200和300 mm/min时,焊缝完全熔透试板,焊接速度为400 mm/min时,由于热输入较小,试板未完全熔透.

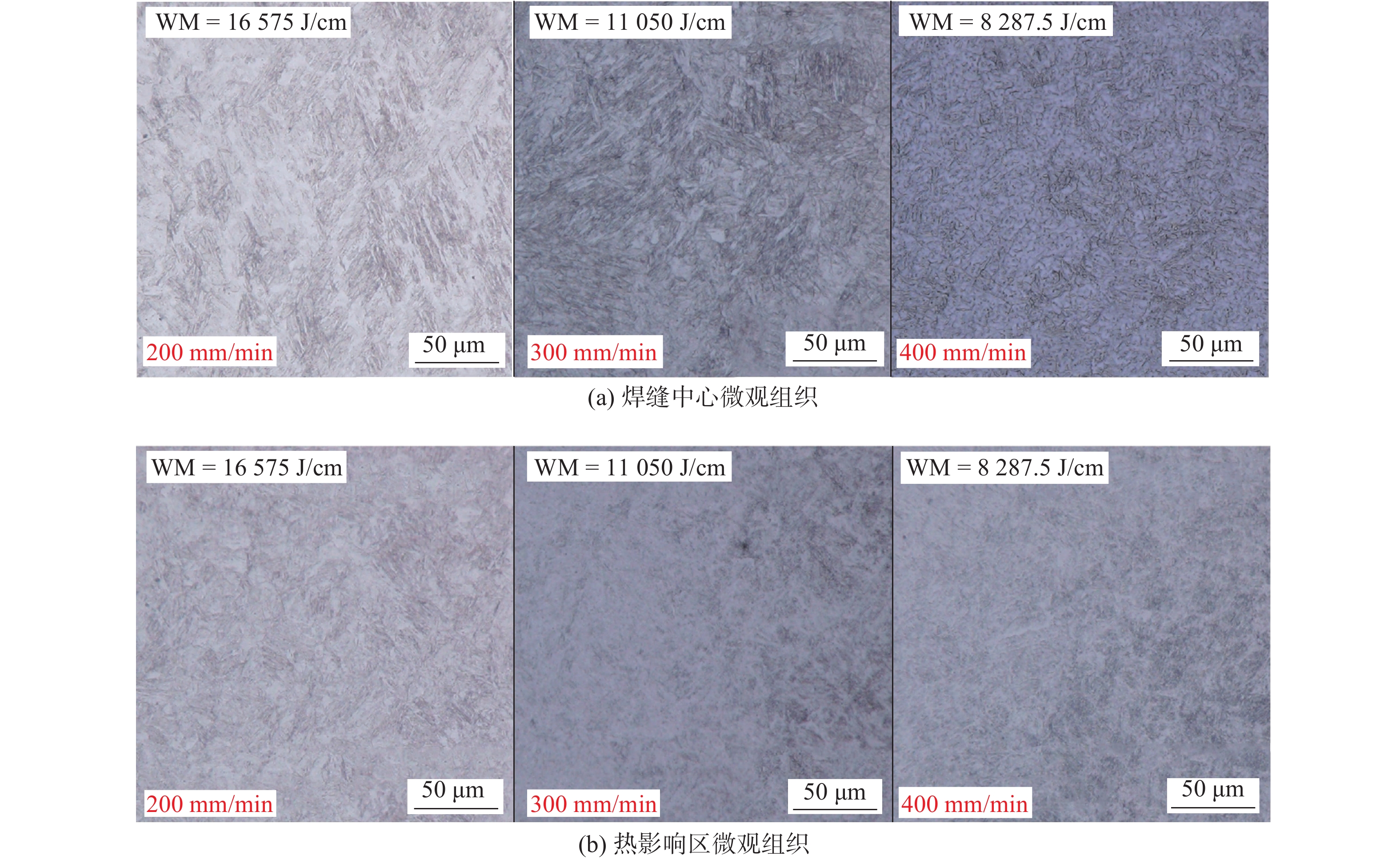

为了更加深入地探究焊接接头晶粒形态,使用场发射扫描电子显微镜对接头微观组织进行分析,如图4所示.可以发现焊缝金属仍然是典型的板条马氏体组织,相比于母材金属来说,焊缝金属的板条马氏体更为细小,且原奥氏体晶界已经消失,这是因为焊缝金属经历了较高的热输入,其组织转变更加完全. 热影响区中可见不均匀生长的马氏体板条,由于试验采用电子束焊接方法产生的热影响区宽度较窄,在放大的热影响区图像中观察到2个不同的微区.细晶区由于加热温度高于Ac3见图4(d),先前的马氏体组织完全奥氏体化,与粗晶区相比,焊接产生的热输入更少,细晶区中新形成的奥氏体晶粒更小更均匀.

对焊缝区域进行XRD分析,如图5所示.从图中可以看到在衍射角度内共有4个衍射峰,通过对比标准PDF卡片,其与Fe-Cr标准衍射峰匹配较好,分别为(110)(200)(210)(220)面.改变焊接速度,接头的4个衍射峰的衍射角基本相等,表明他们的晶格常数相同,晶体结构也相同,工艺参数并不改变组织相组成.由于焊接参数对晶粒结晶度有所影响,因此较高的衍射峰通常意味着在(110)(200)(210)(220)晶面上具有较强的择优取向.在XRD结果中并未发现焊缝金属中的析出相的特征匹配峰,可能由于析出相在焊缝金属的比重较少以及析出相本身较小而并未被检测到.

在马氏体钢的焊接过程中,焊缝金属被加热到很高的温度,在之后的冷却过程中,熔池首先从液体凝固成δ-铁素体,然后进一步转化成奥氏体相.在足够快的冷却速率下,原奥氏体相将会发生相变转变成马氏体相,在高温条件下热影响区的晶粒长大,在晶界附近形成了马氏体,容易造成焊缝金属的韧性降低,冷却速率与焊接热输入直接相关,因此分别计算了每道焊缝的热输入值,随焊接速度的升高分别为

16575 、11050 、8287.5 J/cm.$$ E = \frac{{IU\eta }}{v} $$ (1) 式中:E为热输入;I为焊接束流;U为加速电压;η为能量转换效率;v为焊接速度.

不同焊接速度下接头焊缝及热影响区的微观组织,如图6所示,热输入的降低提高了熔池中的冷却速度,较快的焊接速度下,奥氏体向马氏体的转变并不完全,板条没有足够的时间长大,因此焊接速度下焊缝的热输入值WM中马氏体板条尺寸明显减小,马氏体板条束分布更加密集.对于热输入较大的焊缝,其焊接速度较慢,奥氏体完全转变为马氏体组织,马氏体在高温下停留时间长,有足够的时间长大.此外,由于热影响区的热循环温度较低,晶粒尺寸没有有明显长大的趋势,热影响区为均匀且致密的马氏体组织.

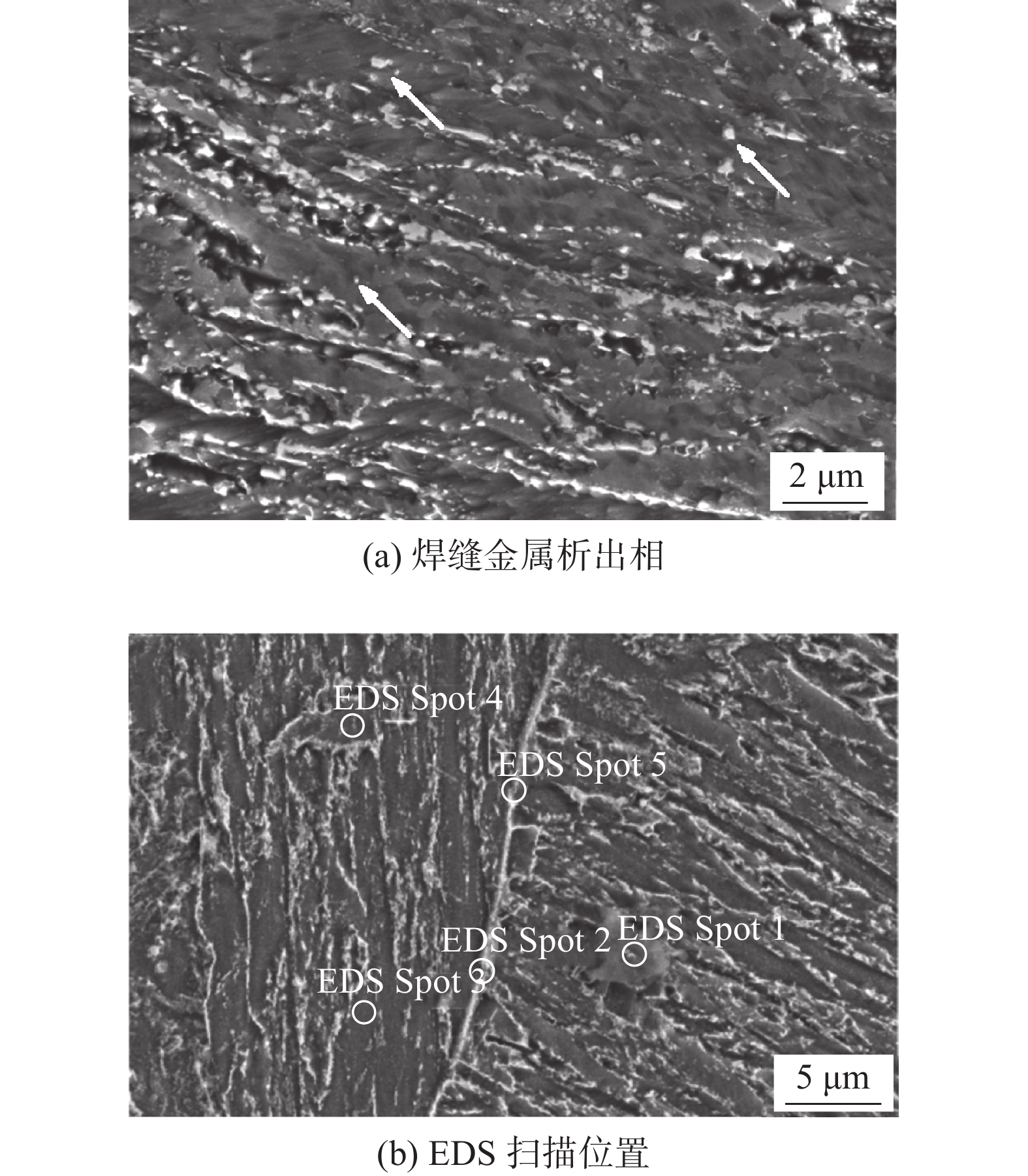

在12Cr耐热钢的焊接过程中,经历较大焊接热输入后的焊缝,其显微组织中存在着大量纳米级弥散分布的析出相,主要沿奥氏体晶粒和马氏体板条束边界析出,如图7所示,析出相分布在基体及晶界上,由于晶界具有较低的扩散激活能,相对疏松的组织降低了应变能,溶质易富集,晶界形核功低,析出相易在此区域形核,对晶界处的细小析出相进行EDS扫描得出的结果见表4.EDS能谱分析结果表明,主要分布在晶界及板条束边界的颗粒析出相为M23C6碳化物(主要为Cr23C6),其主要位于原奥氏体晶界、板条束界、块界及板条界,富含Cr元素,有棒状和球状两种不同的形态.

表 4 析出相化学成分(原子分数,%)Table 4. Chemical composition of precipitated pases能谱位置 Fe Cr C Si Mo Nb W 1 54.76 10.07 32.53 1.78 0.76 0.01 0.09 2 80.21 13.69 5.28 — 0.48 — 0.33 3 81.85 12.28 5.34 — 0.32 0.01 0.19 4 82.53 11.61 5.36 — 0.42 0.02 0.06 5 78.91 15.66 4.28 — 0.75 0.05 0.35 随着电子束焊的进行,当马氏体钢的焊接温度超过奥氏体开始形成温度Ac1时,发生马氏体向奥氏体的转变,在随后的冷却过程中,马氏体钢焊缝金属经历了奥氏体向马氏体的转变,组织变得难以分辨.马氏体和奥氏体在转变过程中具有特定的取向关系,根据马氏体和奥氏体之间的取向关系重建EBSD表征结果,以获得原奥氏体晶粒的相关信息,在重建过程中,马氏体和奥氏体遵循Kurdjumov-Sachs({011}M//{111}γ,<-1-11>M//<-101>γ)取向关系,基于KS关系,使用AZtecCrystal软件中的母相晶粒重构功能,将成形质量最优的1号件马氏体子相重构为母相奥氏体晶粒.

不同焊接速度下的IPF反极图及重构后的晶粒图以及从IPF图中提取出的极(PF)图,如图8所示,可以明显看到,材料在焊接期间经历了完全奥氏体化,同一晶粒内的马氏体取向基本一致, 奥氏体晶界清晰可见,最终形成了由完全细马氏体组成的显微组织,将图中未识别和尺寸过小的晶粒去除后,测得焊缝中心PAG的平均尺寸分别为12.88, 13.71 μm,表明降低焊接速度对晶粒尺寸有较弱的影响,其PF图的织构强度分别为3.414,3.003,具有较弱的立方织构.

![]() 图 8 不同焊接速度下焊缝区域的EBSDFigure 8. EBSD of weld area at different welding speeds. (a) weld microstructure at 300 mm/min; (b) weld microstructure at 200 mm/min; (c) reconstructed weld microstructure at 300 mm/min; (d) reconstructed weld microstructure at 200 mm/min; (e) weld PF diagram at 300 mm/min; (f) weld PF diagram at 200 mm/min

图 8 不同焊接速度下焊缝区域的EBSDFigure 8. EBSD of weld area at different welding speeds. (a) weld microstructure at 300 mm/min; (b) weld microstructure at 200 mm/min; (c) reconstructed weld microstructure at 300 mm/min; (d) reconstructed weld microstructure at 200 mm/min; (e) weld PF diagram at 300 mm/min; (f) weld PF diagram at 200 mm/min2.2 力学性能

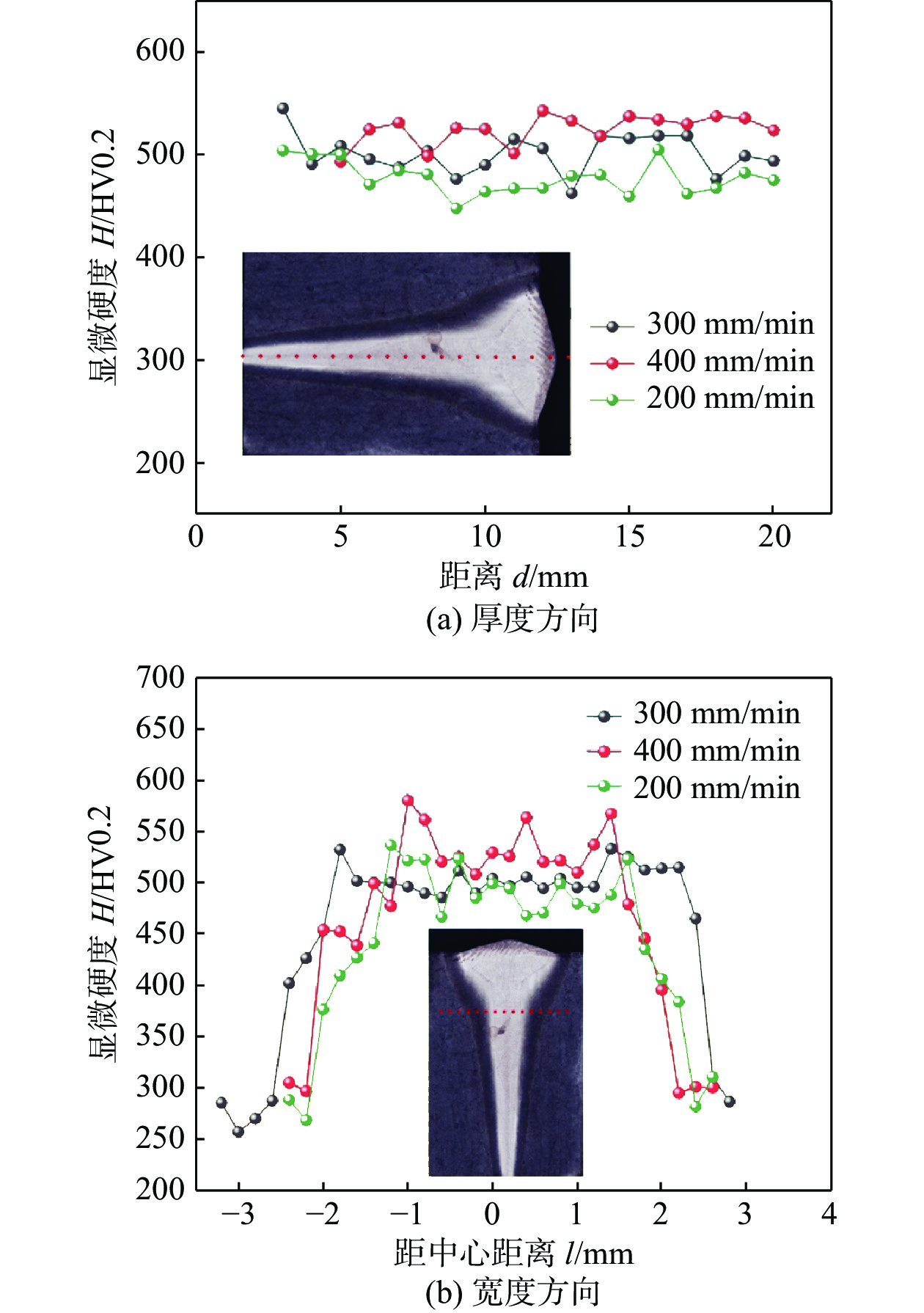

张西雷等人[11]使用电弧焊焊接了12Cr型钢材,焊接后焊缝平均硬度为200 HV0.2,如图9所示,由图9(a)可知,在沿焊缝厚度方向上,使用电子束焊接时,不同焊接速度下对焊接接头硬度的影响较小,硬度变化在430 ~ 550 HV0.2,随着焊接速度的提高,焊缝硬度平均值也提高,分别为477,501,524 HV0.2,焊缝中心的整体硬度主要与碳含量、马氏体含量和晶粒尺寸有关,这与显微组织观察结果一致.

在焊缝横截面宽度方向测量其硬度,其硬度变化见图9(b),焊缝区的硬度明显高于母材金属,从焊缝中心到母材区,硬度呈现逐渐下降的趋势,焊缝和热影响区的显微硬度分布与加热和冷却过程中的组织转变有关,由于电子束焊接的冷却速度快,相当于淬火,因此拥有细马氏体组织的焊缝硬度显著提高.随着焊接速度的降低,焊缝中心的热输入也升高,马氏体组织较厚,板条数量减少,Cr,W和Mo等合金元素溶解程度有一定程度的升高,沿着原奥氏体晶界和板条束边界形成的碳化物逐渐增加,析出相数量逐渐增加,因此,马氏体板条和固溶强化的效果降低,而沉淀强化的效果增加.

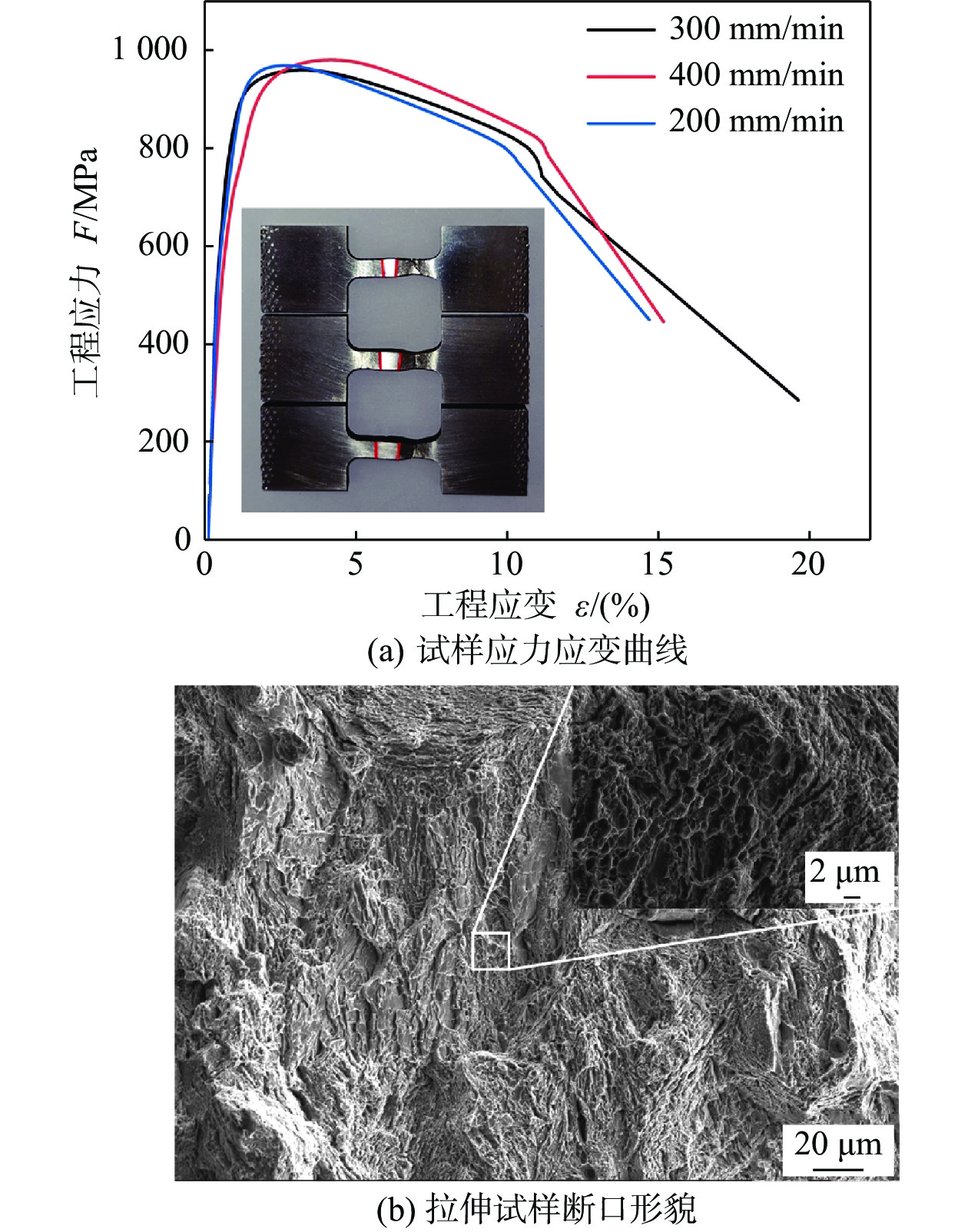

在3组试样中心位置取拉伸试样,保证焊缝在拉伸试样中心位置,每个接头取3组拉伸试样计算平均值,使用万能材料试验机对试样进行抗拉强度测试,如图10所示,拉伸曲线见图10(a),测试结果表明3组拉伸试样均断裂于母材靠近热影响区处,平均抗拉强度分别955,980,969 MPa,证明焊缝金属的拉伸力学性能要优于母材金属.力学性能测试结果表明,焊接后的马氏体组织提高了焊缝区域的硬度和抗拉强度,这是因为随着金属经历了较高的热循环,马氏体是一种硬脆相,相比于母材,焊缝的马氏体组织更加的均匀密集.

拉伸试样在室温下的断裂面形貌见图10(b),可以看到,接头断口处存在表征延性的韧窝和表征脆性的解理面和解理台阶,并未发现明显的河流纹特征,说明其断裂机制为以韧性断裂为主的韧脆混合断裂,形成断裂机制主要与试样微观组织特征的不均匀性有关,这种深韧窝形貌通常与应力集中和M23C6析出相有关.

3. 结 论

(1)使用电子束焊得到了成形良好、无焊接缺陷的12Cr耐热钢电子束焊焊缝,焊缝和热影响区组织为马氏体组织.

(2)提高焊接速度,焊缝区马氏体板条尺寸有所减小,经历高热输入后焊缝马氏体的尺寸相比于母材来说更加细小,析出相主要为纳米级的M23C6相.

(3)焊接后焊缝硬度提高,焊缝区硬度在430 ~ 550 HV,热影响区硬度在400 HV左右.随着焊接速度提高,焊缝平均硬度值有所升高,接头拉伸试样断裂于母材,3组不同焊接速度下试样断裂的平均抗拉强度为968 MPa,断口断裂机制为韧脆混合断裂模式.

-

图 8 不同焊接速度下焊缝区域的EBSD

Figure 8. EBSD of weld area at different welding speeds. (a) weld microstructure at 300 mm/min; (b) weld microstructure at 200 mm/min; (c) reconstructed weld microstructure at 300 mm/min; (d) reconstructed weld microstructure at 200 mm/min; (e) weld PF diagram at 300 mm/min; (f) weld PF diagram at 200 mm/min

表 1 12Cr耐热钢化学成分(质量分数,%)

Table 1 Chemical composition of 12Cr heat resistant steel

C Mn P S Si Cr 0.09 ~ 0.14 0.40 ~ 0.70 0.02(max) 0.02(max) ≤0.30 10 ~ 11 Mo V Nb Ni N W 1.0 ~ 1.3 0.15 ~ 0.25 0.04 ~ 0.08 0.4 ~ 0.7 0.03 ~ 0.07 0.20 ~ 0.30 表 2 12Cr耐热钢常温力学性能

Table 2 Room temperature mechanical properties of 12Cr heat-resistant steel

抗拉强度

Rm/MPa屈服强度

Rel/MPa断后伸长率

A(%)断面收缩率

Z(%)冲击吸收能量

Akv/J硬度

H/HV0.2≥690 490 ≥35 ≥13 ≥40 185 ~ 260 表 3 焊接工艺参数

Table 3 Welding parameters

试样

编号加速电压

U/kV聚焦电流

If/mA焊接速度

v/(mm·min−1)焊接束流

I/mA1 85 386 200 65 2 85 386 300 65 3 85 386 400 65 表 4 析出相化学成分(原子分数,%)

Table 4 Chemical composition of precipitated pases

能谱位置 Fe Cr C Si Mo Nb W 1 54.76 10.07 32.53 1.78 0.76 0.01 0.09 2 80.21 13.69 5.28 — 0.48 — 0.33 3 81.85 12.28 5.34 — 0.32 0.01 0.19 4 82.53 11.61 5.36 — 0.42 0.02 0.06 5 78.91 15.66 4.28 — 0.75 0.05 0.35 -

[1] 吕振家, 彭建强, 周立艳, 等. 汽轮机转子用9-12%Cr钢发展情况综述[J]. 大型铸锻件, 2019(2): 1 − 5. Lü Zhenjia, Peng Jianqiang, Zhou Liyan, et al. Development status summarization of 9-12%Cr steel used for steam turbine rotor[J]. Heavy Castings and Forgings, 2019(2): 1 − 5.

[2] 李轶非, 蔡志鹏, 潘际銮, 等. NiCrMoV耐热钢汽轮机转子焊缝韧性薄弱区的成因[J]. 焊接学报, 2014, 35(10): 73 − 76 Li Yifei, Cai Zhipeng, Pan Jiluan, et al. Research on toughness weak points of joints of NiCrMoV refractory steel for manufacturing steam turbine rotor[J]. Transactions of the China Welding Institution, 2014, 35(10): 73 − 76.

[3] Wang S Q, Li W Y, Zhou Y, et al. Tensile and fatigue behavior of electron beam welded dissimilar joints of Ti–6Al–4V and IMI834 titanium alloys[J]. Materials Science & Engineering: A, 2016, 649: 146 − 152. doi: 10.1016/j.msea.2015.09.107

[4] Li Y J, Zhou B, Feng T, et al. Microstructure and fracture morphology in the welding zone of T91 heat-resisting steel used in power station[J]. Journal of Materials Science & Technology, 2002, 18(5): 427 − 430.

[5] Chellapandi P, Chetal S C. Influence of mis-match of weld and base material creep properties on elevated temperature design of pressure vessels and piping[J]. Nuclear Engineering and Design, 2000, 195(2): 189 − 196. doi: 10.1016/S0029-5493(99)00247-2

[6] Shiue R K, Lan K C, Chen C. Toughness and austenite stability of modified 9Cr–1Mo welds after tempering[J]. Materials Science & Engineering A, 2000, 287(1): 10 − 16. doi: 10.1016/S0921-5093(00)00831-5

[7] 李晓泉, 滕亚兰, 初雅杰, 等. 焊接热循环对T92钢组织脆化的影响[J]. 焊接学报, 2010, 31(3): 9 − 12. Li Xiaoquan, Teng Yalan, Chu Yajie, et al. Influence of welding thermal cycle on micro-structural brittleness of T92 steel[J]. Transactions of the China Welding Institution, 2010, 31(3): 9 − 12.

[8] Naveed N. Characterisation of short-length scale residual stress variations within an electron beam welded P91 ferritic–martensitic steel plate[J]. Heliyon, 2021, 7(5): e7045.

[9] 冯吉才, 王廷, 张秉刚, 等. 异种材料真空电子束焊接研究现状分析[J]. 焊接学报, 2009, 30(10): 108 − 112. Feng Jicai, Wang Ting, Zhang Binggang, et al. Research status analysis of electron beam welding for joining of dissimilar materials[J]. Transactions of the China Welding Institution, 2009, 30(10): 108 − 112.

[10] Manugula V L, Rajulapati K V, Reddy G M, et al. Role of evolving microstructure on the mechanical properties of electron beam welded ferritic-martensitic steel in the as-welded and post weld heat-treated states[J]. Materials Science & Engineering: A, 2017, 698: 36 − 45. doi: 10.1016/j.msea.2017.05.036

[11] 张西雷, 王强, 刘彦青. 12Cr5Mo耐热合金钢焊接工艺[J]. 石油工程建设, 2019, 45(3): 44 − 47 doi: 10.3969/j.issn.1001-2206.2019.03.010 Zhang Xilei, Wang Qiang, Liu Yanqing. Welding process for heat-resistant alloy steel 12Cr5Mo[J]. Petroleum Engineering Construction, 2019, 45(3): 44 − 47. doi: 10.3969/j.issn.1001-2206.2019.03.010

下载:

下载: