Investigation on microstructure and properties of U71Mn steel joints by Flash-Friction hybrid welding

-

摘要:

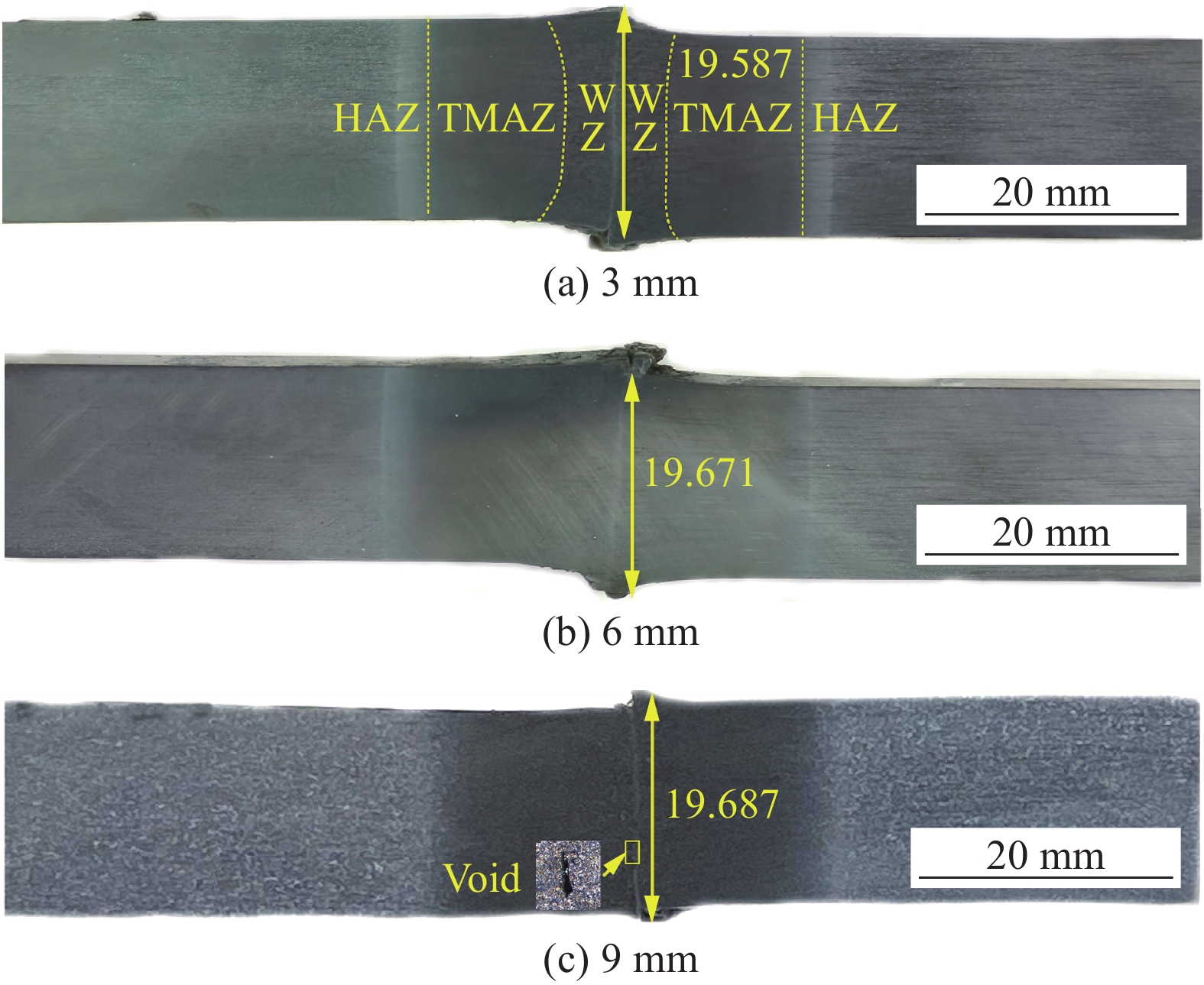

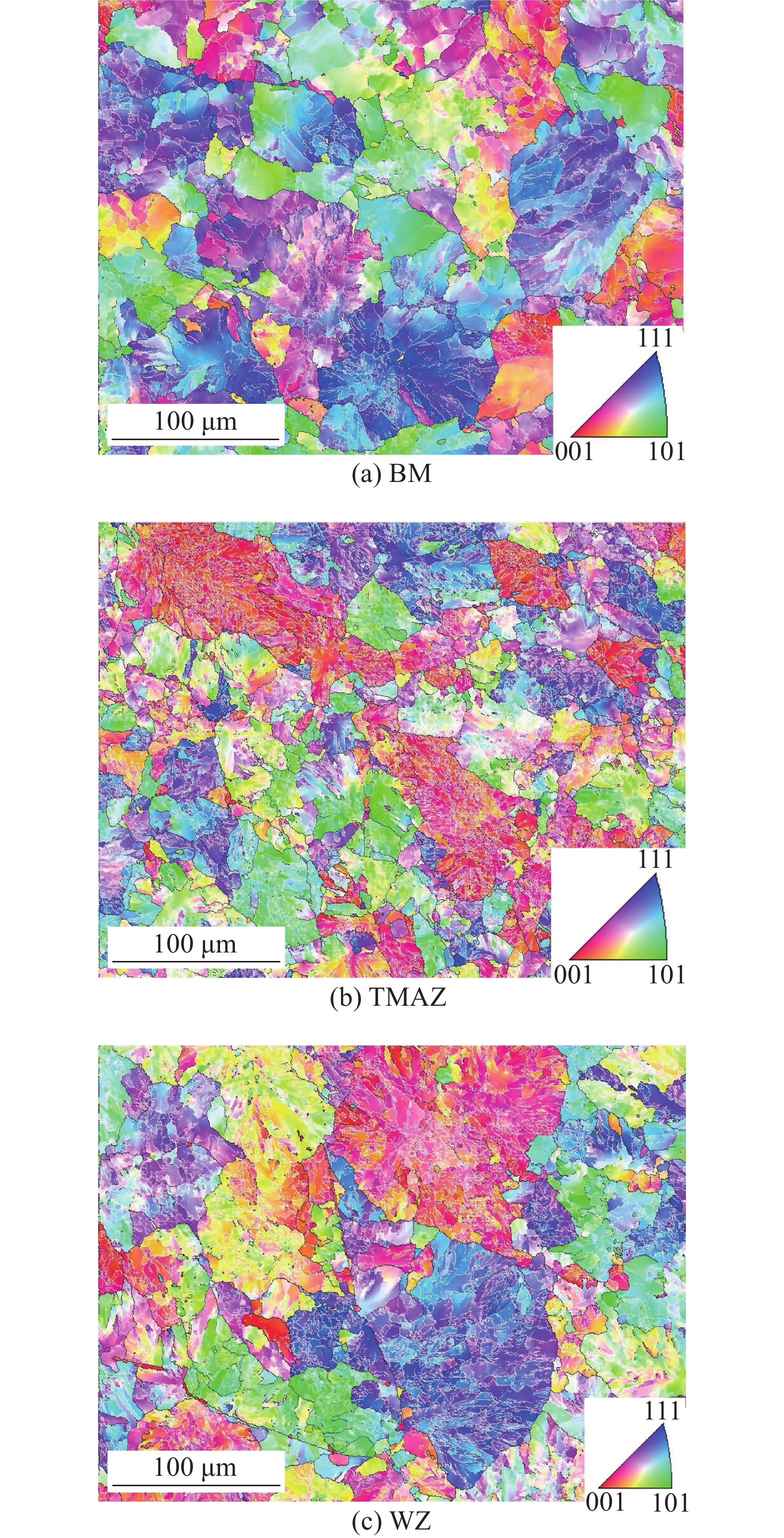

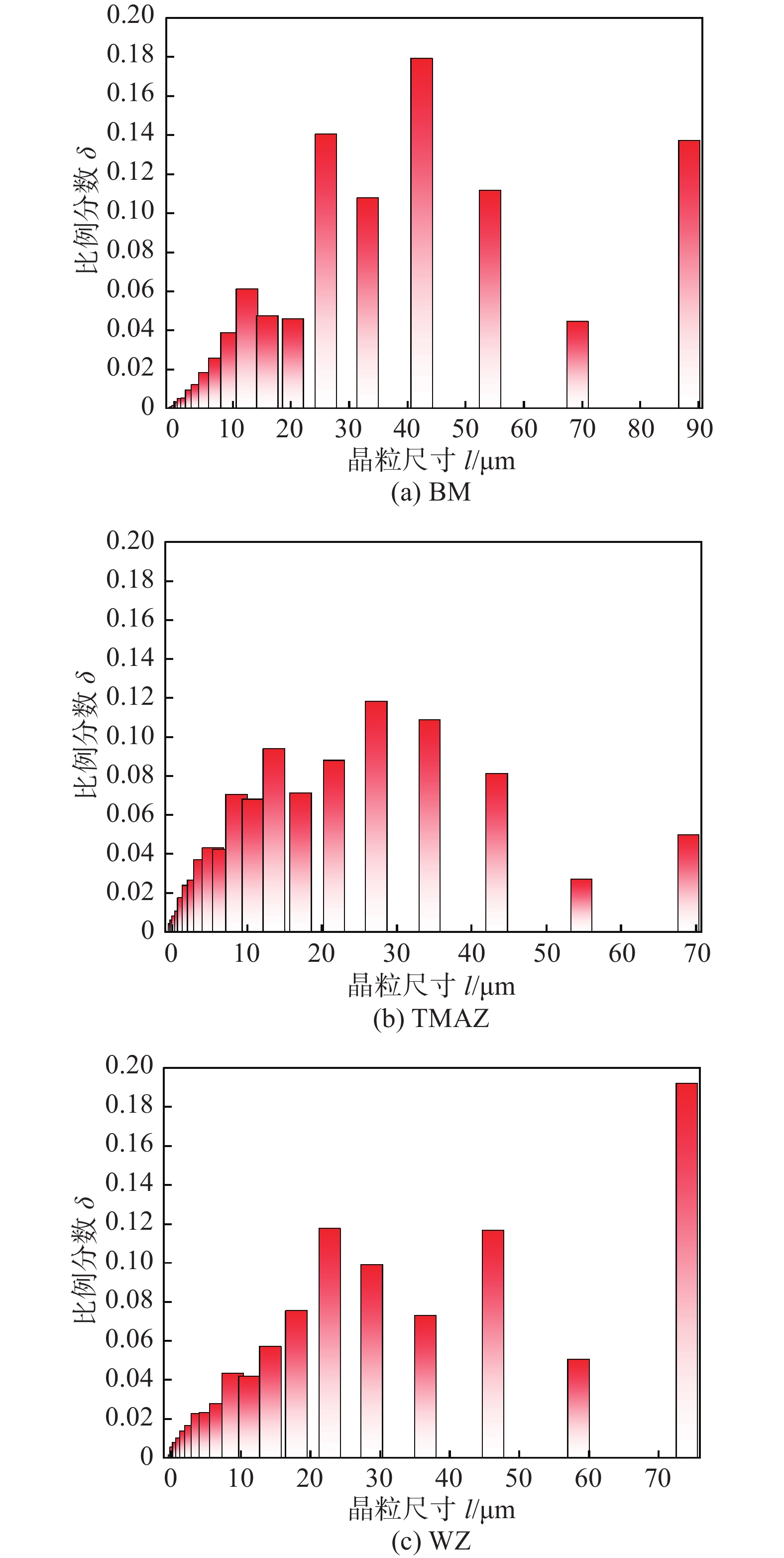

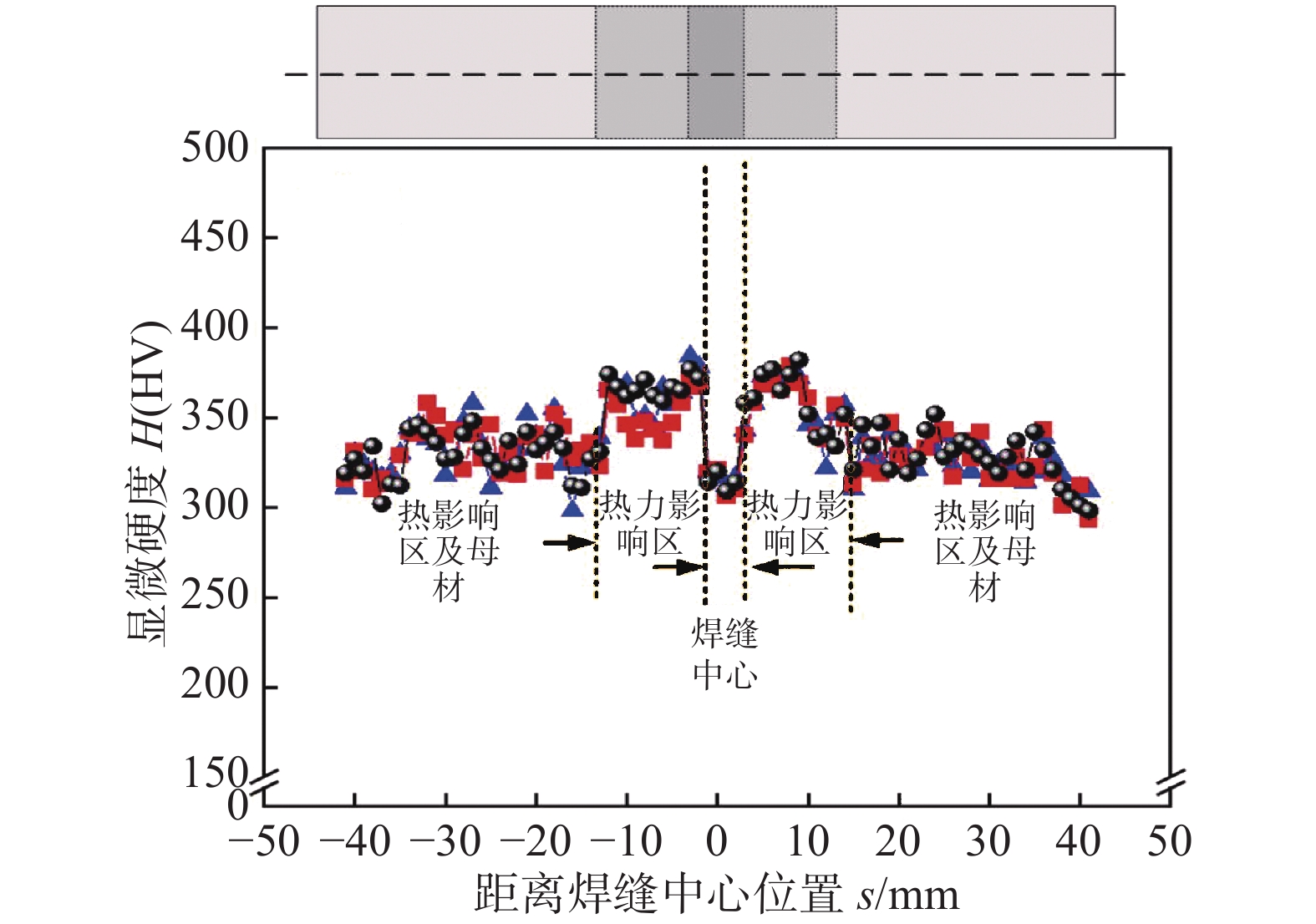

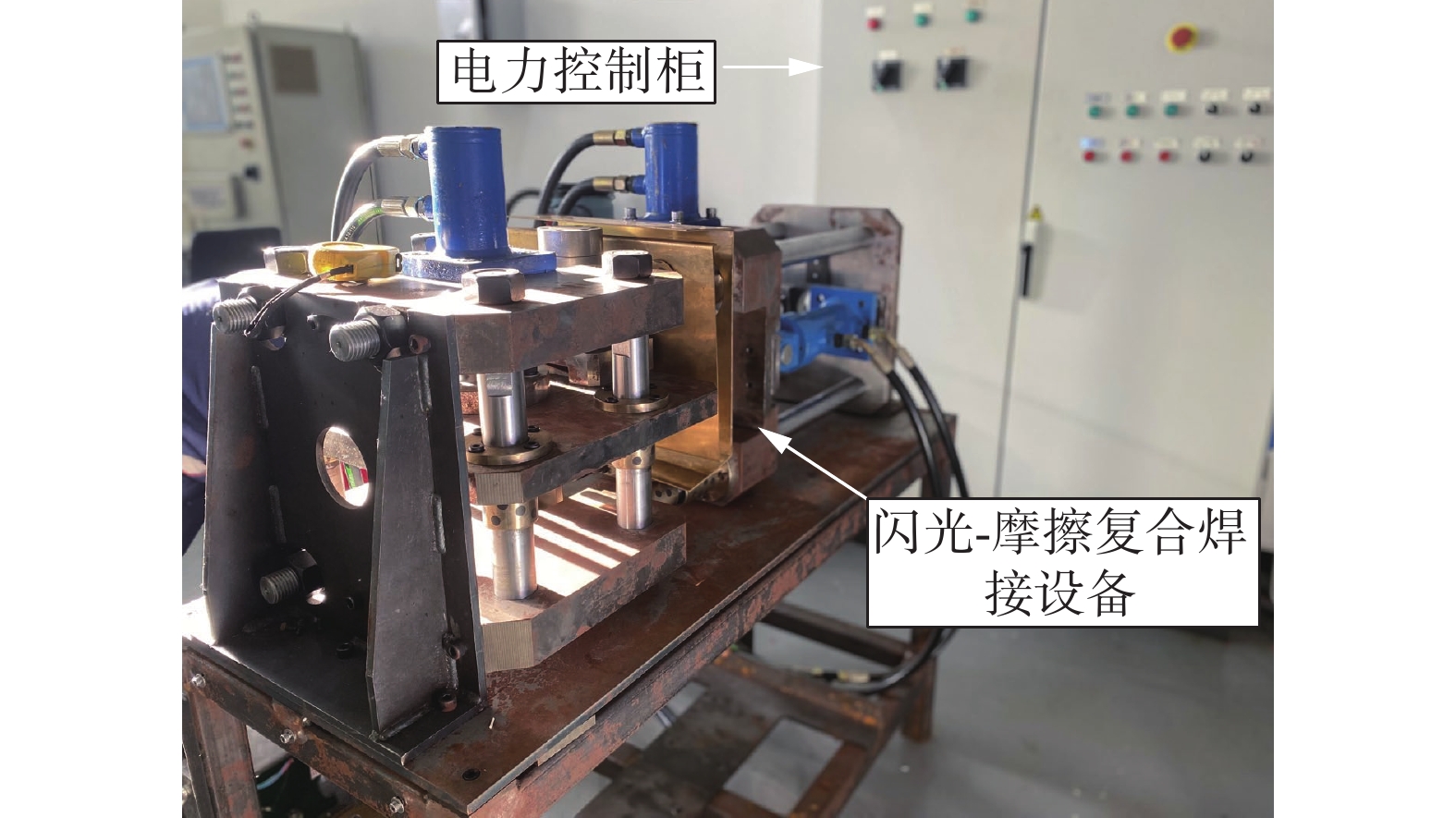

闪光对焊在焊接钢轨时易在焊缝中心产生氧化夹杂缺陷以及软化层,严重降低了接头力学性能,针对上述问题,开发了闪光-摩擦复合焊, 并基于不同的顶锻距离对U71Mn钢进行了焊接工艺研究.结果表明,焊接接头成形良好,接头组织主要分为母材(base material, BM)、热影响区(heat-affected zone, HAZ)、热力影响区(thermo-mechanically affected zone, TMAZ)以及焊核区(weld zone, WZ),其中,在焊接热输入以及摩擦顶锻的作用下,TMAZ及WZ晶粒发生细化,同时,在线性摩擦的作用下,WZ未出现明显的高铁素体含量的软化层组织.接头显微硬度呈M形分布,最高硬度位于TMAZ,接头抗拉强度随顶锻距离的增加呈先上升后下降趋势,最高抗拉强度约为900.3 MPa,达到母材的89.1%,其断裂形式为准解理断裂.

Abstract:Flash butt welding, when applied to rail welding, is prone to the formation of oxidized inclusion defects and softening layers at the weld, significantly impairing the mechanical properties of the joints. To address these issues, this study proposed a novel flash-friction hybrid welding(F-FHW) method and explored the welding process for U71Mn steel based on varying upsetting distances. The results revealed that the welded joint was well formed and the joint structure was mainly divided into base material (BM), thermo-mechanically affected zone (TMAZ), heat-affected zone (HAZ) and weld zone (WZ). Notably, the grains in the TMAZ and WZ were refined under the combined influence of welding heat input and friction upsetting. Additionally, under the action of linear friction, the softening layer with elevated ferrite did not appear in the WZ. The microhardness of the joints displayed an M-shaped distribution, with the highest hardness located at TMAZ. The tensile strength of the joint initially increased and then decreased as the upsetting distance extended. The maximum tensile strength of the joints was approximately 900.3 MPa, achieving 89.1% of the BM, and its fracture form is quasi-cleavage fracture.

-

Keywords:

- flash-friction hybrid welding /

- U71Mn steel /

- microstructures /

- mechanical property

-

-

表 1 U71Mn化学成分(质量分数,%)

Table 1 Chemical compositions of U71Mn

C Si Mn S P V Fe 0.65 0.25 1.2 0.03 0.03 0.03 余量 表 2 EDS点扫描区域元素比例(%)

Table 2 EDS point scanning area element ratio

元素 C Si O Mn Fe A 3.76 0.65 2.8 0.66 92.13 B 3.94 0.82 1.49 0.99 92.76 C 3.09 0.67 2.64 0.80 92.79 D 2.99 0.65 0.96 0.75 94.65 -

[1] 吴越, 韩健, 左齐宇, 等. 钢轨波磨对高速列车车轮多边形磨耗产生与发展的影响[J]. 机械工程学报, 2020, 56(17): 198 − 208. Wu Yue, Han Jian, Zuo Qiyu, et al. Effect of rail corrugation on initiation and development of polygonal wear on high-speed train wheels[J]. Journal of Mechanical Engineering, 2020, 56(17): 198 − 208.

[2] Bešinović N. Resilience in railway transport systems: a literature review and research agenda[J]. Transport Reviews, 2020, 40(4): 457 − 478. doi: 10.1080/01441647.2020.1728419

[3] Ma N, Cai Z, Huang H, et al. Investigation of welding residual stress in flash-butt joint of U71Mn rail steel by numerical simulation and experiment[J]. Materials & Design, 2015, 88: 1296 − 1309.

[4] 王莹莹, 李力, 宋宏图, 等. 钢轨移动闪光焊感应热处理装置及工艺研究[J]. 铁道学报, 2018, 40(3): 120 − 125. doi: 10.3969/j.issn.1001-8360.2018.03.018 Wang Yingying, Li Li, Song Hongtu, et al. Study on induction heat treatment device and technology of rail mobile flash butt welding[J]. Journal of the China Rail Way Society, 2018, 40(3): 120 − 125. doi: 10.3969/j.issn.1001-8360.2018.03.018

[5] 罗欢. U71Mn热处理钢轨焊接工艺参数的调试[J]. 甘肃科技, 2018, 34(5): 47 − 48. doi: 10.3969/j.issn.1000-0952.2018.05.018 Luo Huan. Debugging of welding process parameters for U71Mn heat-treated rails[J]. Gansu Science and Technology, 2018, 34(5): 47 − 48. doi: 10.3969/j.issn.1000-0952.2018.05.018

[6] 于雪梅, 冯立超. U71Mn钢轨气压焊接头断裂分析[J]. 热加工工艺, 2013, 42(19): 215 − 217. Yu Xuemei, Feng Lichao. Analysis on fractured gas pressure welded joint of rail U71Mn[J]. Hot Working Technology, 2013, 42(19): 215 − 217.

[7] 蒋文娟, 向鹏程, 丁昊昊, 等. U71Mn钢轨气压焊焊接接头滚动磨损与损伤性能研究[J]. 摩擦学学报, 2020, 40(5): 579 − 585. Jiang Wenjuan, Xiang Pengcheng, Ding Haohao, et al. Research on rolling wear and damage properties of gas pressure welding joint of U71Mn rail[J]. Tribology, 2020, 40(5): 579 − 585.

[8] Tan J, Gao Z, Ren S, et al. Improving the microstructures and mechanical properties of U71Mn rail steel liner friction welded joint by normalizing treatment[J]. Materials Today Communications, 2024, 38: 107736. doi: 10.1016/j.mtcomm.2023.107736

[9] 王鑫,张福成,吕博,等. 贝氏体钢辙叉与U71Mn钢轨的焊接[J]. 焊接学报, 2009, 30(12): 61 − 64. Wang Xin, Zhang Fucheng, Lü Bo, et al. Flash butt welding of bainite steel crossing with U71Mn steel rail[J]. Transactions of the China Welding Institution, 2009, 30(12): 61 − 64.

[10] Hu J, zhang Q, Yang Q, et al. Cause analysis of surface cracks in flash butt welding joint of high manganese steel frog[J]. Engineering Failure Analysis, 2023, 154: 107683 − 107695. doi: 10.1016/j.engfailanal.2023.107683

[11] You J Q, Zhao Y Q, Dong C L, et al. Improving the microstructure and mechanical properties of Al-Cu dissimilar joints by ultrasonic dynamic-stationary shoulder friction stir welding[J]. Journal of Materials Processing Technology, 2023, 311: 117812. doi: 10.1016/j.jmatprotec.2022.117812

[12] You J Q, Zhao Y Q, Dong C L, et al. Microstructural evolution and mechanical properties of the Al-Cu dissimilar joint enhanced by stationary-dynamic shoulder friction stir welding[J]. Journal of Materials Processing Technology, 2022, 300: 117402

[13] 王恒霖, 曹睿, 李晌, 等. 闪光焊FeCrAl合金管材的接头组织及性能[J]. 焊接学报, 2022, 43(3): 37 − 43. doi: 10.12073/j.hjxb.20210712002 Wang Henglin, Cao Rui, Li Xiang, et al. Microstructure and property of flash welded joint of FeCrAl alloy tube[J]. Transactions of the China Welding Institution, 2022, 43(3): 37 − 43. doi: 10.12073/j.hjxb.20210712002

[14] 文学, 汪宏辉, 李熙岩, 等. X80M钢管道全自动焊接接头裂纹尖端张开位移差异性[J]. 焊接学报, 2024, 45(2): 98 − 104. Wen Xue, Wang Honghui, Li Xiyan, et al. The difference of CTOD of X80M pipeline steel fully auto-matic welded joints[J]. Transactions of the China Welding Institution, 2024, 45(2): 98 − 104.

[15] Li J, Wen K, Sun Q, et al. The comparison of multi-layer narrow-gap laser and arc welding of S32101 duplex stainless steel[J]. China Welding, 2022, 31(4): 37 − 47.

-

期刊类型引用(1)

1. 王守明,高振坤,陈建华,丁韦,许蕊,刘国庆,谭锦红. U71Mn钢闪光-摩擦复合焊接头组织及性能研究. 金属加工(热加工). 2025(04): 67-73+78 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: