Process parameters analysis of coaxial powder feeding argon arc cladding based on RSM and NSGA-II algorithm

-

摘要:

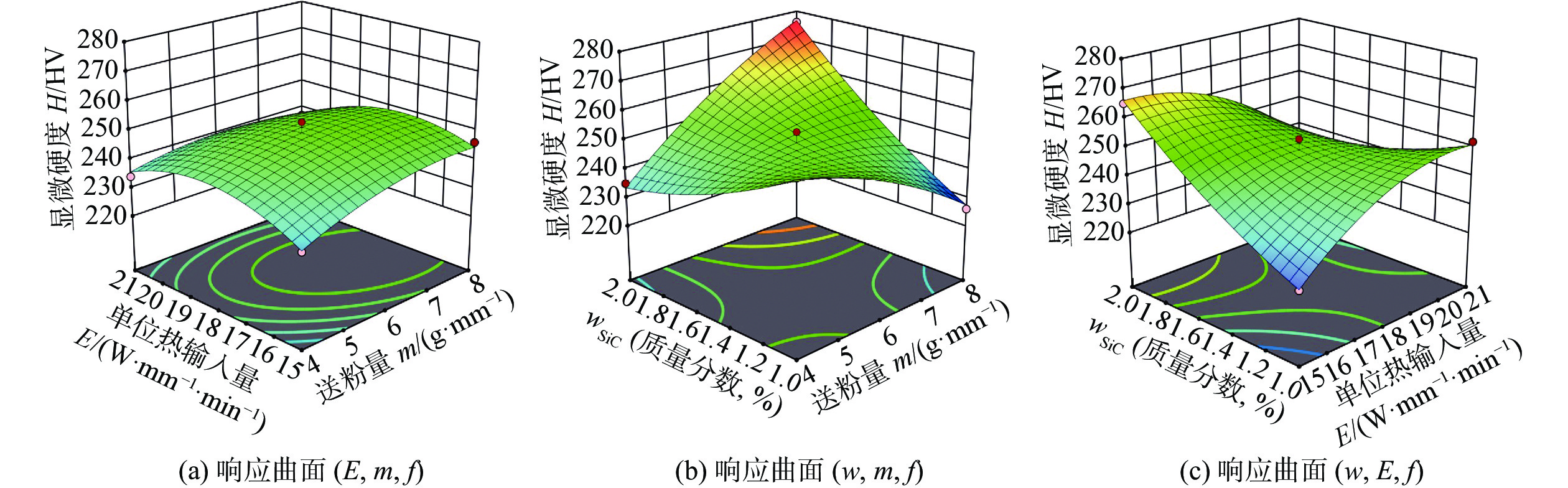

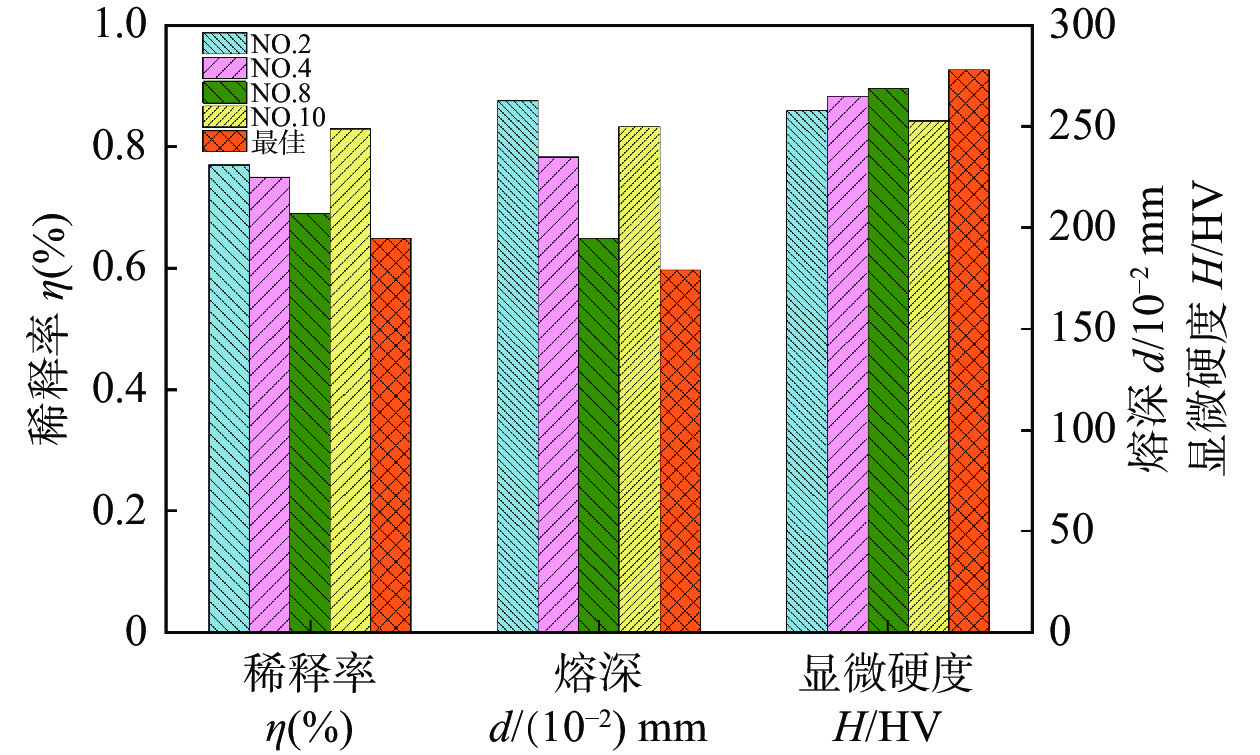

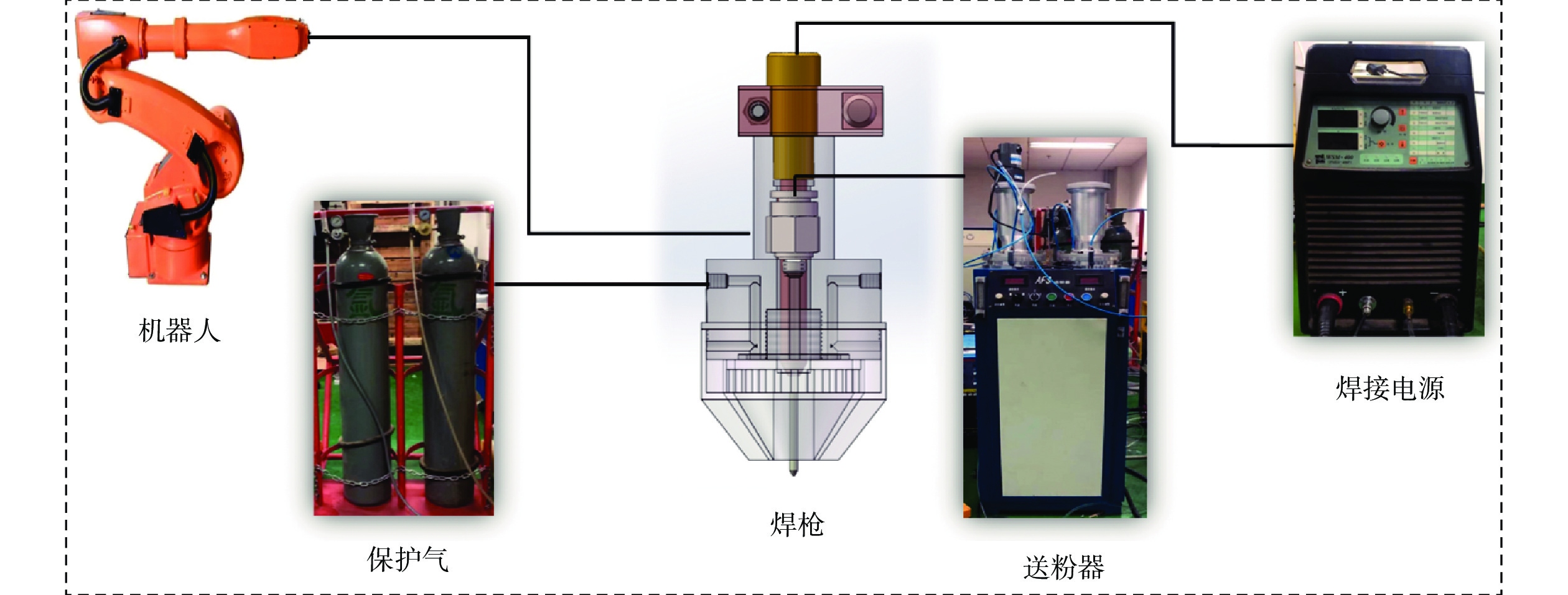

为提高再修复工件表面熔覆层的质量与性能,采用自主研发的同轴送粉钨极氩弧熔覆系统,在316L不锈钢表面进行了纳米SiC增强耐磨涂层的氩弧熔覆试验,针对多因素交互影响作用下,工艺参数难以寻优的问题,提出了一种RSM与NSGA-II算法集成的工艺参数多目标优化方法.该方法以单位热输入量、送粉量和SiC质量分数为输入因素,显微硬度、熔深和稀释率为响应指标,通过响应曲面法建立熔覆层质量与工艺参数之间的回归模型,探究工艺参数对熔覆层质量的交互影响,使用NSGA-II算法寻得最优工艺参数组合,对最优工艺参数条件下制备的试样进行熔覆层质量对比与组织形貌观察.结果表明,最优参数组合为单位热输入量17.82 W/(mm·min−1),送粉量8 g/mm,SiC质量分数2%,该条件下的试样显微硬度增大了9.9%,熔深降低了31.9%,稀释率降低了22.4%,熔覆层形貌良好无缺陷,顶部区域为均匀细小的等轴状晶粒.

Abstract:In order to improve the quality and performance of the cladding layer on the surface of the re-repaired workpiece, the argon arc cladding experiment of Nano-SiC reinforced wear-resistant coating was carried out on the surface of 316 L stainless steel by using the self-developed coaxial powder feeding tungsten argon arc cladding system. Aiming at the problem that the process parameters are difficult to optimize under the interaction of multiple factors, a multi-objective optimization method of process parameters integrated with RSM and NSGA-II algorithm is proposed. In this method, the welding unit heat input, powder feeding amount and SiC quality fraction were taken as input factors, and the microhardness, penetration depth and dilution rate were taken as response indexes. The regression model between the quality of cladding layer and process parameters was established by response surface method, and the interaction effect of process parameters on the quality of cladding layer was explored. Then, the NSGA-II algorithm was used to find the optimal combination of process parameters. Finally, the quality comparison and microstructure observation of cladding layer were carried out on the samples prepared under the optimal process parameters. The results show that the optimal parameter combination is unit heat input is 17.82 W/(mm·min−1), powder feeding amount 8g/mm and SiC quality fraction 2%. The microhardness of the specimens under these conditions increased by 9.9%, the depth of fusion decreased by 31.9%, the dilution rate decreased by 22.4%. The morphology of the cladding layer is good without defects, and the top area is uniform and fine equiaxed grains.

-

-

图 15 最优参数下熔覆层截面显微组织图

Figure 15. Microstructure of the cross-section of the cladding layer under the optimum parameters. (a) microstructure of the cross-section of the cladding layer; (b) partial enlargement of the lower part of Fig.15(a); (c) partial enlargement of the middle part of Fig.15(a); (d) partial enlargement of the upper part of Fig.15(a)

表 1 316L不锈钢化学成分(质量分数,%)

Table 1 Chemical composition of 316L stainless steel

C Si Mn S P Cr Ni Mo Fe ≤0.03 ≤1.00 ≤2.00 ≤0.03 ≤0.045 16.0 ~ 18.0 10.00 ~ 14.00 2.00 ~ 3.00 余量 表 2 工艺参数水平编码表

Table 2 Process parameter level coding table

水平 单位热输入量

E/(W·mm−1·min−1)送粉量

m/(g·mm−1)SiC含量

wSiC(质量分数,%)−1 15 4 1 0 18 6 1.5 1 21 8 2 表 3 试验方案及对应的响应值

Table 3 Test scheme and the corresponding response value

序号 单位热输入量

E/(W·mm−1·min−1)送粉量

m/(g·mm−1)SiC含量

wSiC(质量分数,%)显微硬度

H/HV熔深

d/mm稀释率

η(%)S1 21 4 1.5 234 2.63 77.47 S2 18 4 1 258 1.80 66.35 S3 15 8 1.5 246 1.40 78.35 S4 15 6 2 265 2.34 75.94 S5 18 6 1.5 249 2.80 80.40 S6 21 6 2 236 3.20 65.10 S7 15 6 1 225 2.70 79.83 S8 18 8 2 269 1.98 69.73 S9 15 4 1.5 232 1.95 63.62 S10 18 6 1.5 253 2.5 83.77 S11 18 4 2 235 1.72 74.56 S12 21 6 1 252 3.07 84.76 S13 18 6 1.5 247 2.71 81.24 S14 18 8 1 226 1.36 71.91 S15 21 8 1.5 237 3.25 70.05 S16 18 6 1.5 248 2.65 85.23 表 4 响应指标的回归模型方差分析

Table 4 Regression model analysis of variance of response indicators

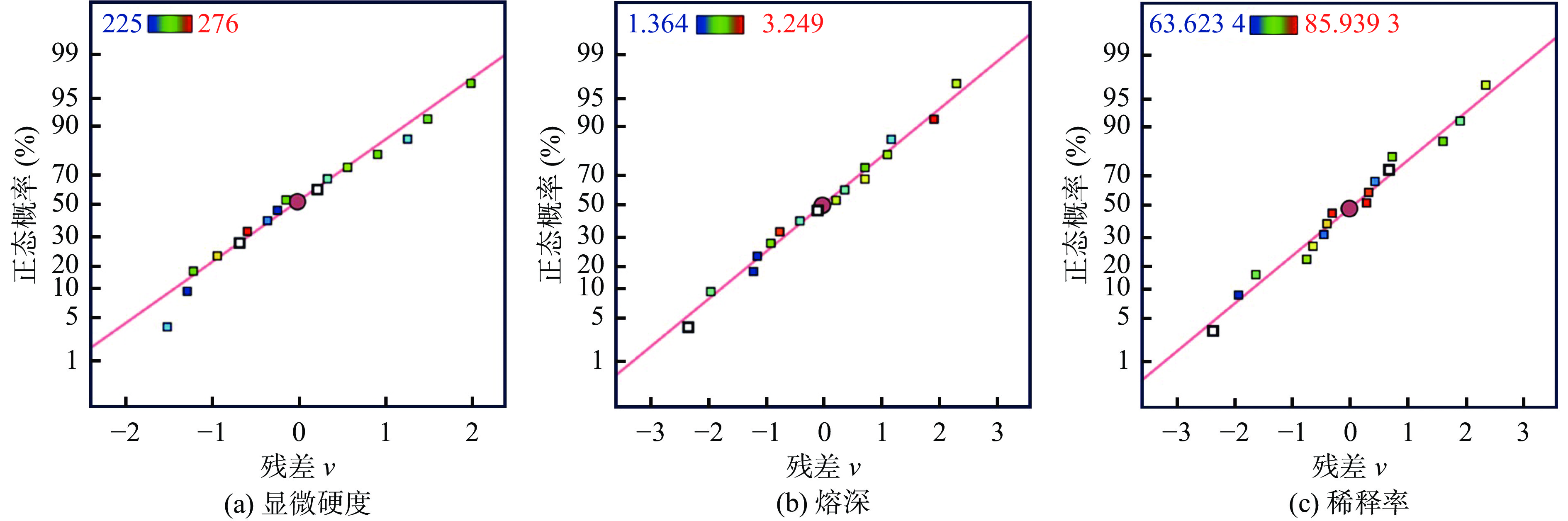

来源 平方和 均方差 F值 P值 显微硬度 熔深 稀释率 显微硬度 熔深 稀释率 显微硬度 熔深 稀释率 显微硬度 熔深 稀释率 模型 2935.94 5.3100 776.10 326.22 0.5903 86.23 59.31 10.74 4.39 < 0.0001 0.0046 0.0428 m 84.50 0.0053 3.10 84.50 0.0053 3.10 15.36 0.10 0.16 0.0078 0.7666 0.7048 E 10.13 1.7700 13.81 10.13 1.7700 13.81 1.84 32.14 0.70 0.2237 0.0013 0.4338 w 325.13 0.0056 14.08 325.13 0.0056 14.08 59.11 0.10 0.72 0.0003 0.7601 0.4296 E·m 30.25 0.3422 123.19 30.25 0.3422 123.19 5.50 6.22 6.27 0.0574 0.0468 0.0462 m·w 1332.25 0.0864 44.78 1332.25 0.0864 44.78 242.23 1.57 2.28 < 0.0001 0.2565 0.1818 E·w 784.00 0.0610 167.27 784.00 0.0610 167.27 142.55 1.11 8.52 < 0.0001 0.3327 0.0267 m2 60.06 2.2300 369.97 60.06 2.2300 369.97 10.92 40.58 18.84 0.0163 0.0007 0.0049 E2 264.06 0.6072 1.55 264.06 0.6072 1.55 48.01 11.04 0.08 0.0004 0.0159 0.7881 w2 45.56 0.2068 38.33 45.56 0.2068 38.33 8.28 3.76 1.95 0.0281 0.1005 0.2119 残差 33.00 0.3299 117.84 5.50 0.0550 19.64 — — — — — — 失拟项 12.25 0.2823 104.01 4.08 0.0941 34.67 0.59 5.94 7.52 0.6621 0.0888 0.6580 纯误差 2.75 0.0476 13.82 0.91 0.0159 4.61 — — — — — — 总离差 2950.94 5.64 893.94 — — — — — — — — — -

[1] 朱明冬, 吴冰洁, 曹立彦, 等. 304LN不锈钢表面激光熔覆钴基合金组织和性能[J]. 焊接学报, 2022, 43(8): 48 − 53. doi: 10.12073/j.hjxb.20220508001 Zhu Mingdong, Wu Bingjie, Cao Liyan, et al. The microstructure and properties of laser cladding cobalt-based alloy on the surface of 304LN stainless steel[J]. Transactions of the China Welding Institution, 2022, 43(8): 48 − 53. doi: 10.12073/j.hjxb.20220508001

[2] 郗文超, 宋博学, 王钊, 等. 表面熔覆工艺的成形特征及粉末有效利用率研究[J]. 表面技术, 2019, 48(3): 211 − 218. Xi Wenchao, Song Boxue, Wang Zhao, et al. Study on the forming characteristics and effective utilization rate of powder of surface cladding process[J]. Surface Technology, 2019, 48(3): 211 − 218.

[3] Raghavendra C R, Satyappa Basavarajappa, Irappa Sogalad, et al. Study on Ni composite coating on Al6061 substrate material with different nano particle reinforcement by electrodeposition process[J]. Materials Today: Proceedings, 2020, 24(Part2): 1680 − 1685.

[4] 王子龙, 秦建, 路全彬, 等. 焊接方法对 S22053 双相钢焊接接头组织和性能的影响[J]. 焊接, 2018(8): 21 − 27. Wang Zilong, Qin Jian, Lu Quanbin, et al. Effects of welding methods on microstructure and properties of welded joints of S22053 dual phase steel[J]. Welding & Joining, 2018(8): 21 − 27.

[5] 王金凤, 井子润, 杨伟, 等. 激光熔覆与等离子熔覆的镍基合金熔覆层组织和性能对比[J]. 材料保护, 2020, 53(1): 80 − 83. Wang Jinfeng, Jing Zirun, Yang Wei, et al. Comparison of microstructure and properties of Ni-based alloy cladding layer by laser cladding and plasma cladding[J]. Materials Protection, 2020, 53(1): 80 − 83.

[6] Rajeev R, Kumar A D. Recent advancements in surface modification by gas tungsten arc cladding technique: a review[J]. Advanced Materials Research, 2022, 6608: 113 − 122.

[7] 王浡婳, 张立杰. AZ91D镁合金表面氩弧熔覆Nd/TiC耐磨涂层的特性研究[J]. 粉末冶金工业, 2021, 31(3): 63 − 67. Wang Bohua, Zhang Lijie. Study on the characteristics of Nd / TiC wear-resistant coating on AZ91D magnesium alloy by argon arc cladding[J]. Powder Metallurgy Industry, 2021, 31(3): 63 − 67.

[8] Kumar P, Sinha N A, Hirwani K C, et al. Investigation of TIG cladding of NiTi wire on substrate 304L to study the effect of applied current on microstructure and mechanical properties[J]. Transactions of the Indian Institute of Metals, 2021, 74(6): 1333 − 1348. doi: 10.1007/s12666-021-02213-w

[9] 王婉婉, 高辉, 周灿丰, 等. 同轴送粉TIG熔覆过程数值模拟与试验研究[J]. 兵器材料科学与工程, 2023, 46(5): 70 − 75. Wang Wanwan, Gao Hui, Zhou Canfeng, et al. Numerical simulation and experimental study on coaxial powder feeding TIG cladding process[J]. Ordnance Material Science and Engineering, 2023, 46(5): 70 − 75.

[10] Fesharaki N M , Shoja Razavi R , Mansouri A H, et al. Microstructure investigation of Inconel 625 coating obtained by laser cladding and TIG cladding methods[J]. Surface & Coatings Technolog, 2018: 35325 − 35331.

[11] 胡言峰, 杜彦斌, 许磊, 等. 响应面法与粒子群算法集成的激光熔覆工艺参数优化方法[J]. 机械科学与技术, 2023, 42(4): 629 − 637. Hu Yanfeng, Du Yanbin, Xu Lei, et al. Optimization method of laser cladding process parameters based on response surface method and particle swarm optimization algorithm[J]. Mechanical Science and Technology for Aerospace Engineering, 2023, 42(4): 629 − 637.

[12] 马小英, 孙志礼, 张毅博, 等. 基于Kriging-PSO智能算法优化焊接工艺参数[J]. 东北大学学报(自然科学版), 2019, 40(3): 370 − 374. doi: 10.12068/j.issn.1005-3026.2019.03.013 Ma Xiaoying, Sun Zhili, Zhang Yibo, et al. Optimization of welding process parameters based on Kriging-PSO intelligent algorithm[J]. Journal of Northeastern University (Natural Science), 2019, 40(3): 370 − 374. doi: 10.12068/j.issn.1005-3026.2019.03.013

[13] Deb K, Pratap A, Agarwal S, et al. A fast and elitist multiobjective genetic algorithm: NSGA-Ⅱ[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2): 182 − 197. doi: 10.1109/4235.996017

[14] Acherjee B, Kuar A S, Mitra S, et al. Effect of carbon black on temperature field and weld profile during laser transmission welding of polymers: a FEM study[J]. Optics & Laser Technology, 2012, 44(3): 514 − 521. doi: 10.1016/j.optlastec.2011.08.008

[15] 王群, 余洋, 钱志强. 基于响应面法的HR-2抗氢钢电子束插接焊工艺参数优化[J]. 焊接学报, 2023, 44(4): 50 − 57. doi: 10.12073/j.hjxb.20220522001 Wang Qun, Yu Yang, Qian Zhiqiang. Optimization of electron beam welding process parameters of HR-2 hydrogen resistant steel based on response surface method[J]. Transactions of the China Welding Institution, 2023, 44(4): 50 − 57. doi: 10.12073/j.hjxb.20220522001

[16] Mohammed J K Bashir, Hamidi Abdul Aziz, Yusoff Mohd Suffian, et al. Application of response surface methodology (RSM) for optimization of ammoniacal nitrogen removal from semi-aerobic landfill leachate using ion exchange resin[J]. Desalination, 2010, 254(1-3): 154 − 161. doi: 10.1016/j.desal.2009.12.002

[17] Dikshit Mithilesh K, Suryansh Singh, Pathak V, et al. Surface characteristics optimization of biocompatible Ti6Al4V with RCCD and NSGA II using die sinking EDM[J]. Journal of Materials Research and Technology, 2023, 24: 223 − 235. doi: 10.1016/j.jmrt.2023.03.005

[18] Ma S M, Zhang A H, Gu J J. Multi-objective optimization of process parameters for ultra-narrow gap welding based on Universal Kriging and NSGA Ⅱ[J]. China Welding, 2023, 32(3): 28 − 35.

-

期刊类型引用(11)

1. 陈翔,朱桂春,张程娇,罗宁,胡建华,王新欢,梁国峰. 夹层爆炸焊接高强度铝合金与钛合金的界面特性和力学性能研究. 金属加工(热加工). 2025(04): 102-110 .  百度学术

百度学术

2. 尚永鹏,王呼和,乔岳云,刘倩. 炸药爆速对钛/铝爆炸焊接界面显微组织及性能的影响. 兵器材料科学与工程. 2025(03): 36-41 .  百度学术

百度学术

3. 李军,蒋晓博,任江毅,赵亮. 爆炸焊接制备铝-钛复合板工艺研究. 新技术新工艺. 2024(01): 19-23 .  百度学术

百度学术

4. 吕琪,丁旭,罗海龙,张振,田晓东,代闯. 轧制对爆炸焊接TA1/5052与TA1/1060/5052复合板组织与性能的影响. 材料热处理学报. 2024(06): 202-211 .  百度学术

百度学术

5. 李文轩,戴美想,吴晓明,孙泽瑞,房中行. 异种金属爆炸焊接窗口分析与应用. 焊接学报. 2022(03): 68-73+86+117 .  本站查看

本站查看

6. 李岩,李艳彪,刘翠荣,吴志生,任金锁,张卫国. 双金属复合板爆炸焊接参数选择窗口开发. 压力容器. 2021(05): 72-79 .  百度学术

百度学术

7. 王小伟,杨东青,李晓鹏,王磊,王克鸿. AZ31Mg/2A12Al爆炸复合板界面组织与性能. 焊接学报. 2021(05): 14-17+98 .  本站查看

本站查看

8. 田启超,马宏昊,沈兆武,陈子俊,赵凯,赵阳. Al_(0.1)CoCrFeNi高熵合金/TA2钛复合板爆炸焊接试验及性能测试. 焊接学报. 2021(06): 22-29+98 .  本站查看

本站查看

9. 李岩,陈闯,李艳彪,刘翠荣,赵瑞,周印梅,任金锁. 钛/铝爆炸焊接复合板界面表征及冶金连接机制. 压力容器. 2021(07): 9-16 .  百度学术

百度学术

10. 裴龙基,胡志月,瞿龙,蒋淑英,张军利. TA2/Co_(13)Cr_(28)Cu_(31)Ni_(28)/Q235脉冲TIG焊接头组织与性能. 焊接学报. 2021(11): 90-96+102 .  本站查看

本站查看

11. 田晓东,王小苗,丁旭,彭艺杰,周仁健,罗海龙. 钛/铝复合板爆炸焊接技术研究进展. 钛工业进展. 2020(06): 34-40 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: