Defect identification algorithm for weld X-ray imagesbased on the CCBFE-RCNN model

-

摘要:

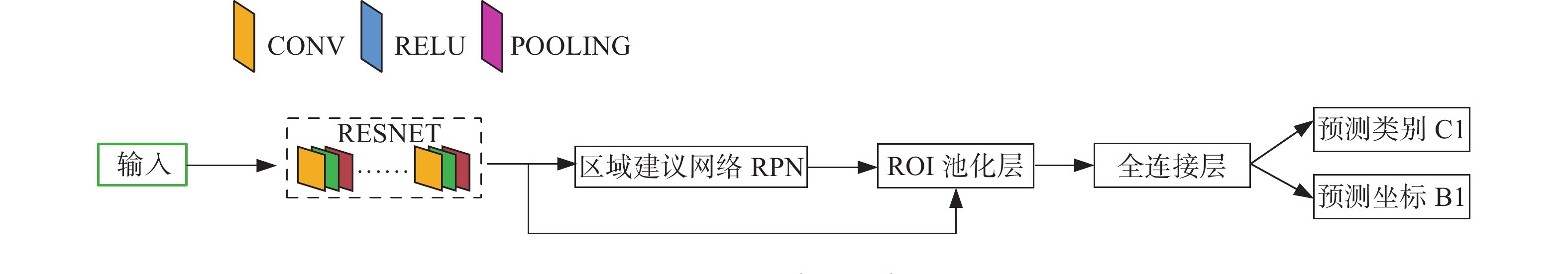

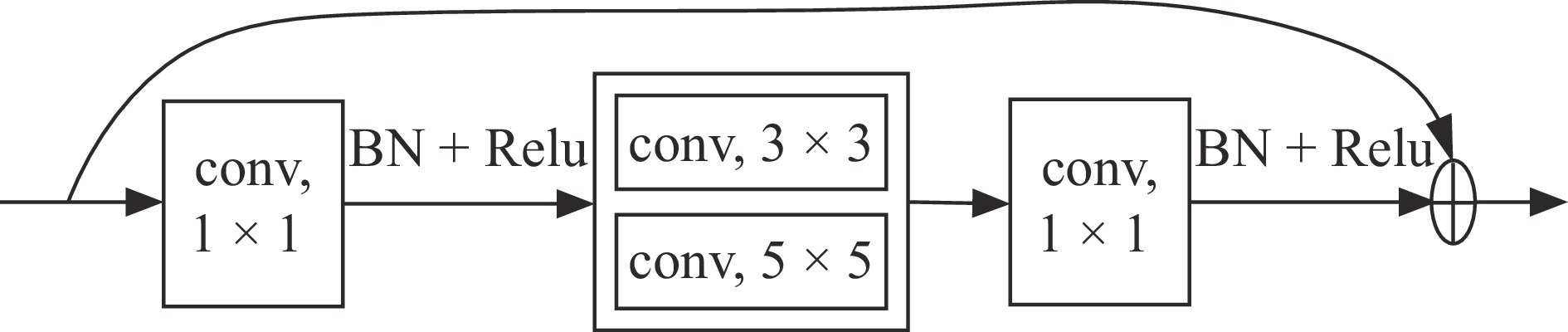

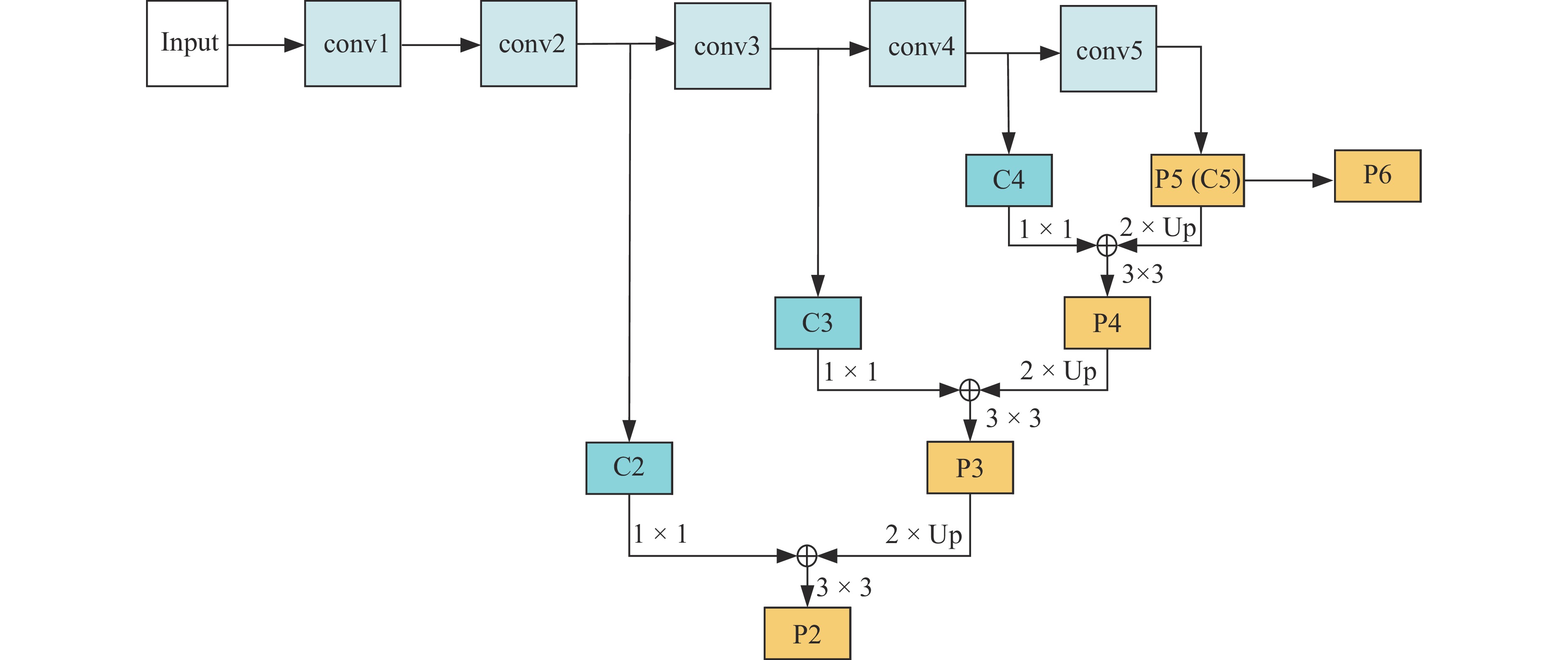

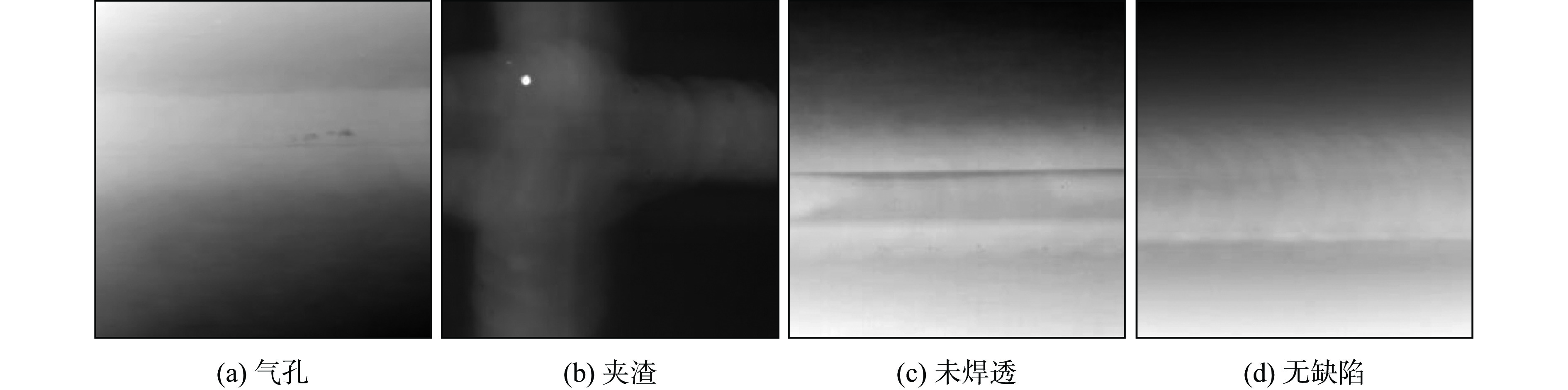

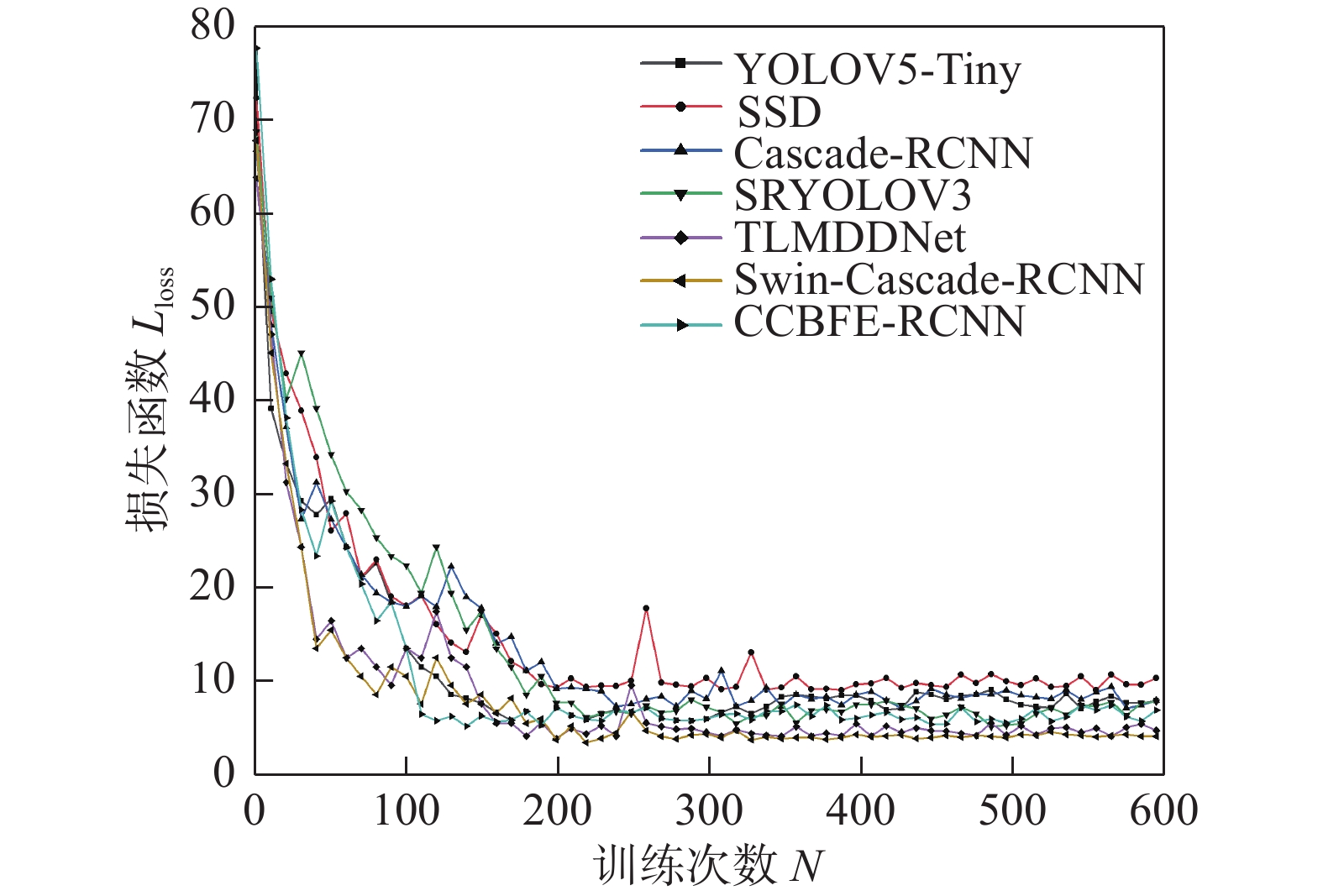

针对X射线图像人工评定过程中存在劳动强度大、检测效率低等问题,提出一种基于Cascade-RCNN网络改进的多尺度目标检测网络CCBFE-RCNN模型,采用合并卷积层结构和FPN特征金字塔网络提升模型特征提取的尺度范围,增强了模型对于多尺度特征的提取能力;使用BFE特征批量消除网络,随机消除特征图区域,避免多次训练过程中的过拟合问题并强化了特征区域表达,同时对损失函数进行改进,对模型没有准确识别出含缺陷图像加大惩罚. 通过构建并扩充熔焊焊缝X射线图像数据集,对模型进行测试. 结果表明,CCBFE-RCNN缺陷检测模型全类别召回率均值、全类别精确率均值为93.09%和91.92%,与Cascade-RCNN网络模型相比平均召回率提升5.16%,平均精确率提升5.27%. 并使用工业缺陷检测数据集对CCBFE-RCNN模型进行测试,验证了模型的泛化能力,可为焊缝缺陷智能化识别提供算法支撑.

Abstract:In view of the problems of high labor intensity and low detection efficiency in the manual evaluation process of X-ray images, a multi-scale object detection network CCBFE-RCNN model based on the improved Cascade-RCNN network is proposed. The combined convolutional layer structure and FPN feature pyramid network are used to enhance the scale range of model feature extraction, and the model's ability to extract multi-scale features is enhanced; Use BFE features to batch eliminate networks, randomly eliminate feature map regions, avoid overfitting problems during multiple training processes, and enhance feature region expression. At the same time, improve the loss function to increase penalties for models that do not accurately identify images containing defects. The model was tested by constructing and expanding a dataset of X-ray images of fusion welds The results show that the CCBFE-RCNN defect detection model has an average recall rate of 93.09% and an average precision rate of 91.92% across all categories, which is 5.16% higher than the average recall rate and 5.27% higher than the average precision rate of the Cascade-RCNN network model. The CCBFE-RCNN model is tested using an industrial defect detection dataset to verify its generalization ability, which can provide algorithm support for intelligent recognition of weld defects.

-

Keywords:

- defect identification /

- concatnated convolution /

- loss function /

- recall /

- precision

-

0. 序言

随着新兴的物联网、人工智能、5G通信等技术的发展,人们对电子元器件的需求日益增加[1,2]. 电子市场朝着更快、更轻、更小、更低成本的方向发展发展也促使电子元器件也不断追求轻量化的设计,以满足日益增长的便携需求[2]. 传统凸点的节距通常超过150 μm,这不符合对细节距和极细节距芯片对于凸点节距的要求. 同时,随着凸点尺寸的减小,尤其是针对无铅焊点,电迁移成为一项严重的可靠性问题[3]. 在这个基础上,铜柱凸点技术应运而生,并于21世纪处开始蓬勃发展. 铜柱凸点(copper pillar bump,CPB)由铜柱和焊帽两部分组成,通过独特的结构设计,不仅实现了更小尺寸、更细节距、更高密度的电连接,而且具备了优异的抗电迁移性能,从而满足了电子器件向小型化方向发展的需求[4,5]. 同时,更细的节距增加了芯片与基板之间的接触面积,并且得益于铜的卓越的导热性能,CPB技术能够有效地提升电子器件的传热效率. 除此以外,铜柱具有比传统凸点更高的屈服应力,使用CPB技术连接能为芯片与基板之间的连接提供了更强的机械可靠性. 铜柱凸点技术成为电子行业中重要的封装技术之一,其应用使电子元器件更加可靠、具备更高的性能.

本文详细叙述了CPB技术的结构与性能的特点,对比分析了CPB与C4凸点的优缺点. 讨论了电镀制备CPB的工艺流程和影响因素. 对铜柱凸点结构在热载荷和电载荷下的可靠性服役情况进行了归纳总结. 最后对CPB技术的应用及未来发展方向进行了展望,指出了在实际应用中的潜在挑战和改进机会,展示了这一技术在微电子封装领域中的广阔前景.

1. 铜柱凸点的特点

电子封装行业中主要有三个层次,分别为芯片与芯片、基板之间连接的一级封装、基板与印刷电路板之间连接的二级封装、将二级封装的组件连接在同一块母板上的三级封装. 倒装芯片键合技术主要应用于一级封装中,利用凸点来实现芯片之间以及芯片与基板之间的电气和物理连接. 常见的凸点结构为C4凸点和CPB,如图1所示[6,7]. CPB作为一种更可靠、更高性能的新一代凸点技术,在电性能、热性能、力学性能以及成本效益等方面具有一定的优势.

CPB技术通过铜柱—焊帽的特殊结构,实现了细节距连接. 在回流过程中,凸点的焊帽部分会熔化. 当凸点的节距较小时,可能会导致凸点坍塌和桥接现象,进而引发可靠性问题. 然而,CPB的铜柱部分在回流过程中不会发生太大的形貌改变,焊帽部分则会受限制于表面张力的作用[8]. 因此,CPB可以实现更细节距的连接,通常在20-150 μm之间[9,10]. 由于CPB在顶部使用少量焊料即可形成完整的凸点结构,因此在更小的节距、较小的直径条件下也能保持较高的凸点高度,同时扩大了底部填充胶的流动空间,提高了可靠性[11]. 与此同时,CPB的特殊结构使得铜柱的直径和高度的选择具有灵活性,为电子元器件的设计和封装提供了更多的方案.

相比传统的焊料凸点,CPB技术不仅仅实现了更小节距、更高密度的互连,同时具备优异的热学、电学和机械性能,能有效提升电子器件的可靠性. 从热学性能来看,铜的热导率远高于焊料的热导率,同时,拥有更低节距的CPB提高了芯片与基板之间的接触面积,因此,CPB的应用可以很好地提高传热效率. 除此以外,由于CPB具有较大的高宽比,因此在设计凸点时,可以使凸点的高度高于传统的C4凸点. 这样做可以减小基板与芯片或芯片与芯片之间因热膨胀系数(Coefficient of thermal expansion,CTE)失配而产生的应变,从而提高连接的可靠性[12].

针对电学性能,铜的导电性能也优于绝大多数焊料[13]. 与铜柱凸点相比,传统的焊料凸点温升效应会更加剧烈,因此使用铜连接时,凸点的抗电迀移性能更好,在相同电流密度下,铜柱凸点相比C4凸点需要更长时间才会发生失效[14]. 此外,柱形凸点的结构使得电流塞积发生的区域位于铜柱,远离焊料帽,从而减小电迁移对器件的影响[10,15]. 由于CPB的细节距和其本身的尺寸优势,可以在芯片与基板之间形成更多凸点,从而实现更高的I/O密度,这使得CPB技术更适用于高频信号的传输需求.

在力学性能方面,铜的屈服应力比传统凸点采用的焊料更高,这使得使用CPB连接可以为芯片与基板之间的连接提供更好的机械性能[16]. 同时,由于铜的强度通常高于普通软钎料,只需在铜柱顶部放置少量的焊料即可形成牢固的焊点,这也进一步提高了更细节距连接的可能性.

尽管如此,CPB技术仍然存在一些问题与挑战. 首先,C4凸点焊球在回流焊的过程会熔化,该过程有自对准作用,从而也降低了贴装的精度要求. 然而铜柱凸点的焊帽中焊料较少,且随着铜柱尺寸进一步的减小,凸点中有限的焊料体积将导致自对准效应被大幅度削弱,这可能会导致可靠性问题[17]. 此外,铜柱相比普通的焊球硬度更高,但这也可能使其更易受到外部冲击而产生脆性断裂. 另外,铜柱的制备过程相比传统的C4凸点会更为复杂,这可能会导致生产成本的增加和技术难度的增加.

表1将C4凸点和CPB的特点进行了比较,CPB技术在提高电子器件连接的可靠性、性能方面具有明显优势,但也需要注意自对准效应被削弱可能带来的贴装精度和硬度更高的铜柱的脆性断裂问题. 因此,应进一步提高CPB的可靠性、精度和应用范围. 首先可以改进焊帽设计,提高自对准效应,确保凸点的精确定位;其次可以优化铜柱材料的硬度,找到合适的平衡点,使其既具备足够的强度又能抵御外部冲击;最后降低CPB技术的生产成本并简化制造流程,能更大范围拓展其应用前景.

表 1 C4凸点和CPB的比较Table 1. Comparison between C4 bump and CPB性能对比 C4凸点 铜柱凸点 电阻率(μΩ m) 0.12-0.14 0.0172 热导率(μΩ m) 55-60 400 屈服强度 低 高 凸点节距(μm) 50-200 20-150 凸点高度(μm) 50-70 30-80 制备难度 容易 复杂 结构设计 固定 灵活 I/O密度 低 高 自对准效应 强 弱 2. 铜柱凸点的制备

凸点的制备方式有多种选择,通常包括蒸发凸点法、植球法、丝网印刷凸点法、钉头凸点法和电镀凸点法等[18]. 早期凸点主要由蒸发法制备,生产过程简单,但是具有其生产成本极高、生产效率低、图形精度差等缺点;植球法大幅度提高了生产效率,但是也不具备生产成本优势,并且精度控制不足;而丝网印刷凸点法则降低了沉积凸点的成本,但是凸点的直径和均匀性均会受限制于丝网,同样不能适用于细节距铜柱凸点的制备;钉头凸点法材料使用受限制,可能会导致凸点一致性较差[19-21]. 而电镀凸点法依托光刻技术定位的精确性,可控制凸点的节距和直径最小,同时电镀凸点材料的适用范围很广,因此电镀凸点法被认为是制造CPB的最理想方法[19].

电镀制备CPB的核心工艺包括光刻技术和电镀技术,其主要步骤如图2所示. 首先,需要对凸点下的金属表面进行金属化处理,以提供良好的异质材料结合力以及电连接的稳定性. 凸点下金属化(under bump metallization,UBM)技术可通过磁控溅射、电镀或化学镀等方法实现[22-24]. 在晶圆的表面进行钝化和金属化处理,以满足后续工艺的基础条件. 随后,在晶圆表面通过溅射技术或者化学气相沉积技术等沉积一层Ti/TiW层作为黏附层、一层铜种子层作为导电层. 接着,在铜种子层上涂覆一层光刻胶,并根据铜柱所需的直径,利用光刻技术进行曝光和显影,以形成开口. 在这些开口中电镀铜,形成铜柱. 随后,在铜柱上电镀一层锡基焊料,通过蚀刻等步骤去除光刻胶,并选择性地蚀刻掉种子层. 最后,在焊料层上涂覆一层助焊剂,并通过回流工艺形成具有焊料帽的铜柱凸点.

在电镀制备工艺流程中,电镀体的微观组织结构直接影响到铜柱凸点的服役可靠性. 影响电镀制备的CPB的质量的因素有很多,简要概括为镀液成分、电镀参数两部分,同时,考虑到生产成本与时间成本,电镀速率也是满足高生产效率的重要参数.

电镀CPB的镀液主要分为硫酸铜体系和甲基磺酸铜体系两大类. 相对于昂贵的甲基磺酸铜镀液来说,硫酸铜镀液体系因为电流效率高、沉积速度快、价格便宜、光亮性好而被更为广泛的使用于工艺生产中. 镀液成分中,添加剂的选择将会极大影响电镀后CPB的质量,添加剂有Cl-离子、抑制剂、加速剂和整平剂四类. Cl-离子在加速镀液中铜沉积的同时,防止阳极铜钝化[25];抑制剂在铜的电沉积过程中吸附于铜表面,从而控制铜的沉积速率,并且促使加速剂在电镀表面的移动;加速剂的作用是促进铜的沉积;整平剂则通过吸附在电镀体表面抑制高电流密度区的沉积,从而实现对铜柱表面的整平作用. 表2选取了部分学者[26-31]在电镀CPB时通过改变添加剂的浓度后选择的最佳镀液配比以及其特点.

表 2 电镀CPB方法对比Table 2. Comparison of electroplating CPB methods基础镀液 Cl- 抑制剂 加速剂 整平剂 电流密度 特点 参考文献 0.40 mol/L CuSO4

1.80 mol/L H2SO460 ppm 20mg/L EO/PO 0.7mg/L

SPS-- 18∼20 mA/cm2 通过提高Cl-浓度,加快了铜离子的还原反应,形成了致密的铜结构 [26] 0.26 M CuSO4

2 M H2SO41.13 mM 0. 02mM

PEG0.01 mM

SPS-- 20 mA/cm2 同时使用PEG和SPS可以很好降低沉积铜的间隙 [27] 0.6MCuSO4·5H2O

1.2 M H2SO460 ppm 600ppm

PEG9 ppm

SPS-- 5 A/dm2 该浓度下PEG和SPS可以获得具有细小晶粒的铜层且铜柱光洁性好 [28] 0.88MCuSO4·5H2O

0.54 M H2SO450 ppm 200ppm

PEG-branch1 ppm

SPS-- 30 mA/cm2 PEG-Branch具有较强的抑制能力,使得铜柱表面呈现平整度较高的外凸型 [29] 200 g/L CuSO4⋅5H2O

50 g/L H2SO460 ppm 200ppm

PEG5 ppm

SPSmST 2 A/dm2 PEG-mST-SPS体系所需的电镀效率高于PEG-JGB-SPS体系 [30] 140 g/L H2SO4

120 g/L CuSO4⋅5H2O50 mg/L 100ppm

PEG8 ppm

SPSKunyuan

Chemical3∼7 A/dm2 整平剂沉积速率快,同时,在大电流密度下,铜柱表面平整度最好 [31] 较高的电流密度下,可能会导致铜柱表面呈现凸状,严重影响CPB制作的后续工艺,因此,一般来说,降低电流密度可以获得更好的铜柱凸点形貌[32]. 同时,有研究表明,通过脉冲电镀的方式改变电流的方向、波形形状获得了更加均匀的铜柱表面[33]. 然而,降低电流密度会需要更长的时间,而脉冲电镀同样也是一种十分耗时且生产效率低的工艺,这也限制了其在尤其重视成本和效率驱动的IC制造中的应用. 在这个基础上,Luo等人[34]提出了梯度速率电镀工艺,在沉积初期采用小电流密度形成一层较薄的铜层,之后再加大电流密度. 图3比较了不同电流密度下凸点表面形貌,使用梯度速率电镀法在大幅提高了电镀效率的同时,凸点表面较为平整,且凸点高度具有较好的一致性.

![]() 图 3 不同电流密度下凸点形貌对比[34]Figure 3. Comparison of bump morphology at different current densities.

图 3 不同电流密度下凸点形貌对比[34]Figure 3. Comparison of bump morphology at different current densities.3. 铜柱凸点的可靠性

铜柱凸点作为应用于细节距互连的关键技术,其失效可能会导致电子元器件寿命缩短甚至失效,因此,对CPB的可靠性表征十分重要. CPB技术在热学可靠性方面表现出色,这得益于凸点形状、高度的设计,表面处理和底部填充的合理选择等. 此外,CPB还展现出出色的抗电迁移能力和电迁移可靠性,这些性能受到内在设计因素如凸点形状、焊帽设计和表面处理方法的影响,同时也受到电流分布等外在载荷的影响.

3.1 铜柱凸点的热循环可靠性表征

传统的铜柱凸点焊点由凸点下金属层、焊球和基板组成,在回流过程中会生成层状金属间化合物(intermetallic compounds,IMCs),一般情况下主要为Cu6Sn5和Cu3Sn. 在回流过程中,界面形成的IMCs通常较薄,随后的IMCs生长主要通过固相互扩散来进行. 但是,在IMCs和界面处或者IMCs中容易产生kirkendall空洞,这会导致芯片焊点出现失效[35]. 而在器件工作时产生的热量会加速空洞的生长,这将会导致焊点出现严重的可靠性问题[36,37]. 同时,由于不同材料之间存在热膨胀系数差异,焊点可能会产生热机械应力,进而引发蠕变和疲劳失效. 研究中表明[38],CPB在热老化试验中,IMCs生长模式与普通Sn钎料凸点IMCs相似,但与传统凸点相比,CPB构成的倒装芯片结中焊球变成了铜柱和焊帽两部分. 因此,CPB的热循环可靠性分析结果会因其特殊的结构而与C4凸点有所不同.

将CPB应用在电子封装领域后,系统在温度循环下最为常见的失效的模式有很多种,最常见的是由于热失配导致焊点非弹性应变过大而导致的疲劳失效[39]. 除此以外,失效的模式还有因应力集中导致的低介电层断裂[40]和因金属疲劳而导致的焊盘开裂等[41],如图4所示. 这些应力应变的集中受影响于封装材料和封装几何形状与尺寸等的设置上[42],因此封装材料的选择和封装的设计对于系统整体的可靠性起到重大的作用.

改变凸点的形状可以调整应力分布,从而提高CPB在热应力下的可靠性. Pang等人[43]采用有限元分析的方法,模拟了热循环条件下不同形状,即圆柱形和板状铜柱对铜柱的应力分布和服役寿命的影响. 实验结果显示,圆柱形铜柱焊点疲劳寿命更长,因此其设计优于板状铜柱. Park等人[44]则模拟了五种不同铜柱表面的CPB在热循环作用下的应力分布,如图5所示. 铜柱表面呈现外凸型的凸点具有更优良的性质. 而适当增加凸点的高度则有利于降低焊点整的剪切应变,因此拥有更好的可靠性. Sun等人[45]将凸点高度分为铜柱、焊帽两部分,发现通过适当降低铜柱高度、提高焊帽高度和采用具有更低塑性应变的凸点焊帽材料,可以提高凸点的热疲劳寿命. 其中,焊帽高度对凸点的可靠性影响最大.

![]() 图 5 不同形状铜柱凸点对应力分布影响[44]Figure 5. The influence of different CPB types on stress characteristics. (a) plate type; (b) pin type; (c) conical frustum type; (d) skirt type; (e) zigzag type; (f) equivalent stress characteristics

图 5 不同形状铜柱凸点对应力分布影响[44]Figure 5. The influence of different CPB types on stress characteristics. (a) plate type; (b) pin type; (c) conical frustum type; (d) skirt type; (e) zigzag type; (f) equivalent stress characteristics焊点的可靠性除了受到凸点形状的影响,同时也受到表面处理工艺的影响. 常见的表面处理技术包括化学镍金(Electroless Nickel/Immersion Gold,ENIG)、有机可焊性保护(Organic Solderability Preservative,OSP)、沉锡、沉银等. 在ENIG工艺中,Ni 层和 Au 层分别充当扩散阻挡层和氧化阻挡层,降低了工艺成本,并且具有良好的可焊性. 然而,由于镍层的存在,ENIG工艺在一些特殊环境下可能会出现镍腐蚀,导致焊点质量下降甚至失效[46-48]. OSP涂覆工艺则将薄的有机层涂覆在铜电极表面,它可以保护铜表面免受氧化,其平整度好、成本低,且与铜焊盘之间不会形成IMCs[49]. 沉锡则可以在没有引入任何新的元素的同时在长时间高温储存中依旧可以保持铜柱的可焊性,但在长时间高温环境下容易发生锡须生长,可能会对焊点可靠性产生影响[50]. 沉银则也具有优异的可焊性和耐腐蚀性,工艺流程方便,与铜基板的接触电阻非常低,但银层容易与硫化物发生反应,可能引起银硫化物的形成,进而导致焊点质量下降[51]. 表3总结了不同表面处理方法对CPB热循环可靠性的影响[6,52].

表 3 不同表面处理后CPB热循环可靠性分析Table 3. the influence of different surface finishes on the thermal reliability of CPB表面处理

方法温度循环

试验高温蒸煮

试验高温储存

试验温度冲击

试验ENIG 失效 较差 失效 良好 Sn 良好 良好 优秀 非常优秀 Sn/Ag 较差 良好 失效 较差 OSP 良好 非常优秀 失效 非常优秀 针对具体CPB结构的封装器件而言,选择更薄的芯片可以降低开裂风险并提高封装的可靠性[53]. 而针对芯片中其他可能产生严重可靠性问题的部位,为了减小聚酰亚胺层开裂的风险,Ning等人[54]通过加速热循环试验分析了CPB技术制备的芯片的可靠性. 聚酰亚胺层开窗越大、铝垫尺寸越大、凸点直径越小越有利于提高聚酰亚胺层的热循环可靠性. 除此以外,通过填充与焊点CTE相匹配的树脂或聚合物作为底部填充层,可以明显提高CPB焊点的寿命. Li等人[55]探讨了底部填充对CPB热循环可靠性的影响,如图6所示,2000次温度循环后,无颗粒底部填充的凸点已出现Cu6Sn5/Cu3Sn界面处脆性断裂,而有颗粒底部填充的凸点仅观察到微孔洞的出现. 这是由于底部填充后焊点应力减小,防止了脆性断裂的发生,并提供更好的热循环可靠性.

![]() 图 6 底部填充对于铜柱凸点影响[55]Figure 6. The influence of underfill on CPB (a) without underfill; (b) with underfill

图 6 底部填充对于铜柱凸点影响[55]Figure 6. The influence of underfill on CPB (a) without underfill; (b) with underfill3.2 铜柱凸点的电迁移可靠性表征

随着芯片尺寸的不断减小以及I/O接口的不断增多,凸点尺寸也在逐渐缩小,这会导致电流密度显着增加,因此互连焊点的电迁移已经成为电子封装领域一个重要的可靠性问题[56-58]. 通常情况下,倒装芯片的电迁移失效来源于电流拥挤效应导致的凸点下金属层快速消耗[59]. 而有研究证明[60],使用CPB技术之后,铜柱结构具有优越的散热能力同时内部没有出现电流拥挤效应,可以承受更大的电流密度,因此可以很好提高芯片的电迁移性能[61,62]. 与SnAg凸点相比,CPB的寿命几乎提高了两个数量级,这证明了CPB结构具有优越的抗电迁移性能[63,64]. Syed等人[65]则进一步比较高铅钎料凸点、SnPb共晶钎料凸点、SnAg钎料凸点和CPB下焊点的抗电迁移性能. 在145 °C和700 mA条件下,对焊点的电迁移性能进行了比较,如图7所示,这些凸点的抗电迁移性能从小到大排序为高铅钎料凸点< SnPb共晶钎料凸点< SnAg钎料凸点< CPB,这表明CPB具有更好的抗电迁移性能.

![]() 图 7 不同凸点的电迁移性能比较 (145°C,700mA)[67]Figure 7. Comparison of different bumps EM performance.

图 7 不同凸点的电迁移性能比较 (145°C,700mA)[67]Figure 7. Comparison of different bumps EM performance.铜柱凸点互连焊点的电迁移失效机理从UBM层消耗转变为了在Cu/Cu3Sn以及Cu6Sn5/焊料界面处产生的孔洞和裂纹引起的失效[4,66,67]. CPB在电流作用下失效一般分为两个阶段,第一阶段为IMCs的生成,而在第二个阶段下,Kirkendall空洞在电子风力的作用下萌生并合并产生裂纹,这个阶段下焊点会迅速失效[68]. Ma等人[69]分析出在电流应力作用下Sn焊帽的CPB焊点存在三种不同的破坏模式,如图8所示. 这些模式包括阴极侧铜/Cu3Sn、阳极侧铜/Cu3Sn的界面破坏以及IMCs的脆性断裂. 阴极侧铜/Cu3Sn界面破坏是在电迁移和热应力共同作用下Cu3Sn/Cu界面会形成大量的Kirkendall空洞并沿着界面扩展形成裂纹. 而阳极侧铜/Cu3Sn界面破坏主要是Cu和Sn界面互扩散引起的,但电迁移效应会减少阳极上Kirkendall空洞的形成,因此阳极上的空洞量会明显小于阴极上的空洞量. IMCs发生脆性断裂则是由锡焊料在耗尽之前会产生电迁移效应造成. 在阴极侧的Cu6Sn5/Sn界面上形成了一些较大的孔洞,这些孔洞会随着应力的增大而逐渐扩大. 当钎料Sn转变为Cu6Sn5相后,Cu与基板CTE不同也将会产生热应力,宏观裂纹在Cu6Sn5/钎料界面产生并导致IMCs脆性断裂.如果能对铜柱或者基板进行表面化处理,抑制Cu/Sn界面间的扩散,能够很好地抑制后两者破坏模式,从而减缓CPB在电流作用下的失效.

![]() 图 8 铜柱凸点的断裂模式 (197°C , 29. 8 kA cm−2) [69]Figure 8. SEM images of the CPB with a current density of 29. 8 kA cm−2 at 197 °C. (a)500h; (b) 870h

图 8 铜柱凸点的断裂模式 (197°C , 29. 8 kA cm−2) [69]Figure 8. SEM images of the CPB with a current density of 29. 8 kA cm−2 at 197 °C. (a)500h; (b) 870h适当的表面处理同样可以增加CPB的电迁移可靠性. 因为Ni-Sn反应比Cu-Sn反应需要更高的活化能[70],所以镍层可以为铜柱提供足够的保护,同时,Ni阻挡层可以通过阻挡Cu扩散使Cu3Sn的生长速率减慢从而减少Kirkendall空洞的生成. 所以,适当增加镍层厚度将有效延长Cu柱的腐蚀时间,提高互连的使用寿命. 但若仅仅对铜柱侧进行表面化处理,缺陷仍然会出现在铜基板一侧,因此也需要对铜基板一侧进行表面化处理[71]. 有研究表明[72],铜柱和铜基板均进行化学镍金处理后,焊点的寿命反而低于仅仅对单侧进行化学镍金处理,这是因为Ni也可能会扩散到焊料中形成Ni3P层导致焊点失效. 因此,Hsiao等人[73]通过对铜基板采用OSP进行处理,表现出比镀镍基板更好的寿命结果.

除了表面化处理,凸点在电流应力的作用下受到很多其他因素的共同作用,如铜柱凸点的形貌、高度以及钎料的体积. Fan等人[74]对沙漏型、圆柱形、桶形三种不同凸点形状下的焊点进行电迁移试验,如图9所示,根据模拟结果计算得出柱状焊点具有最长的平均失效时间. 因此,柱状凸点是铜柱互连结构提高电迁移电阻的最优选择. 铜柱的高度则通过影响电流拥挤效应的位置也会对CPB的电迁移性能产生影响,一般而言,更高的铜柱高度可以有效缓解电流拥挤效应,使最大电流密度减小[71]. 然而,随着铜柱高度的进一步增加,电流从凸点周围朝着凸点中央转移,反而会导致最大电流密度/平均电流密度比例增加,同时更高的铜柱会引入更大的应力,因此,给出了35 μm作为同时兼顾电迁移和机械可靠性的铜柱高度[67].

![]() 图 9 不同形状凸点的电迁移微观图像[68]Figure 9. SEM images of different shapes under electromigration test. (a) hourglass-shaped; (b) cylinder-shaped, (c) barrel-shaped

图 9 不同形状凸点的电迁移微观图像[68]Figure 9. SEM images of different shapes under electromigration test. (a) hourglass-shaped; (b) cylinder-shaped, (c) barrel-shaped采用钎料体积更小的CPB对IMCs的形成有较强的限制作用,从而提高了焊点的抗电迁移能力. 这是因为当CPB的焊帽部分体积较大时,由于钎料的体积足以与镍阻挡层反应,这可能会导致镍阻挡层被完全消耗. 有研究表明[76],在电流作用下,焊帽中Sn晶粒的取向也会影响电迁移失效机制的改变,Cu原子晶粒的c轴与电流平行时,Cu会快速扩散导致IMCs迅速增长. 因此,焊帽使用具有大α角的Sn晶粒的钎料,能够有效抑制Cu的扩散和IMCs的生长,从而表现出优异的抗电迁移性能. 图10是表征的IMCs取向,靠近铜柱一侧的Cu6Sn5表现出与电流相关的优先取向,从而影响电迁移失效机制.

![]() 图 10 铜柱凸点在电流作用下的微观结构(197°C , 29. 8 kA cm−2 ,600 h) [76]Figure 10. Microstructure of CPB after current stressing at 1. 5 × 104 A/cm2 at 125 °C for 600 h. (a) SEM image; (b) EBSD image

图 10 铜柱凸点在电流作用下的微观结构(197°C , 29. 8 kA cm−2 ,600 h) [76]Figure 10. Microstructure of CPB after current stressing at 1. 5 × 104 A/cm2 at 125 °C for 600 h. (a) SEM image; (b) EBSD image与直流电流相比,CPB在脉冲电流变化下的金属原子迁移规存在明显不同,相应的破坏机理也截然不同. Xu等人[77]在温度为125 ℃、电流密度为3.5 × 104 A/cm2条件下,研究了CPB分别通过直流和脉冲电流下的电迁移行为. 相较于直流电流,试样在脉冲电流作用下的电阻变化率显著降低,大约只有直流电流作用时的五分之一. 这一差异的原因是在直流电流作用下,如果阴极一侧是铜柱,则镍层会被部分消耗形成凹槽,因此将会有大量IMCs在其上生长;若阴极一侧为铜焊盘,尽管镍层此时能很好的保护铜柱,但阴极Cu焊盘会被快速消耗,并产生大量空洞. 而双向脉冲电流作用下,持续的双向电流改变了铜、镍原子原有的迁移机制,导致IMCs的生长速度减慢. Fu等人[78]则在温度为125 ℃,电流密度为3.5 × 104 A/cm2条件下进一步研究了电流方向和时间比例对铜柱镀镍后的CPB的影响,研究中Sn原子同样主要与Cu焊盘发生反应,Cu3Sn层的生长主要集中在Cu焊盘两侧. 在双向脉冲电流下,电迁移通量会减小,凸点完全转化为Cu-Sn化合物的时间延长,而当正向电流时间占比总电流时间的70 %时,结构演化将不再表现出明显的极性差异.

4. 总结和展望

(1) 对比了CPB技术和传统C4凸点技术的差异,并指出CPB利用铜柱-焊帽的特殊结构实现了更小尺寸、更细节距、更大密度的连接,并提高了电子器件的灵活性和可靠性,同时在热、电、力学性能上更加优越. 然而,CPB技术也面临自对准效应减弱、脆性断裂风险和制备过程更加复杂等挑战.

(2) 在多种凸点制备方法中,电镀法被认为是制备CPB的最理想方法,而电镀铜柱则一般采用硫酸铜镀液. 可以通过改变镀液成分和电镀的参数获得质量更优、平整度更好的CPB. 而在未来的铜柱凸点的研究与应用中,通过优化电镀参数、改变镀液成分可以获得更为均匀、性能更好的铜柱凸点.

(3) CPB拥有卓越的热循环可靠性和电迁移可靠性,这使得其在电子封装领域拥有更广阔的前景,其可靠性与凸点形状和高度、不同表面处理工艺、底部填充和电流等因素有关. 通过优化凸点的结构与设计,如形状和高度、表面处理工艺和底部填充等可以更好地提高铜柱凸点服役时的可靠性.

(4) 目前电镀制备铜柱凸点的表征多停留于铜柱的顶端分析,需要进一步进行对铜柱凸点的侧面和电镀焊帽后完整的凸点进行实验验证和理论分析. 除此以外,对铜柱凸点的力学可靠性的表征还较少,仍然需进一步明晰铜柱凸点在振动、冲击等条件下的可靠性与失效模式.

-

表 1 Resnet101网络

Table 1 Resnet101 network

卷积层 Resnet101 conv1 conv,7 × 7,64,stride 2

max pool,3 × 3, stride 2conv2 $ \left[ {\begin{array}{*{20}{l}} {{\text{conv}},1 \times 1,64} \\ {{\text{conv}},3 \times 3,64} \\ {{\text{conv}},1 \times 1,256} \end{array}} \right] \times 3 $ conv3 $ \left[ {\begin{array}{*{20}{l}} {{\text{conv}},1 \times 1,128} \\ {{\text{conv}},3 \times 3,128} \\ {{\text{conv}},1 \times 1,512} \end{array}} \right] \times 4 $ conv4 $ \left[ {\begin{array}{*{20}{l}} {{\text{conv}},1 \times 1,256} \\ {{\text{conv}},3 \times 3,256} \\ {{\text{conv}},1 \times 1,1024} \end{array}} \right] \times 23 $ conv5 $ \left[ {\begin{array}{*{20}{l}} {{\text{conv}},1 \times 1,512} \\ {{\text{conv}},3 \times 3,512} \\ {{\text{conv}},1 \times 1,2048} \end{array}} \right] \times 3 $ 表 2 指标计算公式

Table 2 Calculation formula

评价指标 公式 召回率R $ \dfrac{{TP}}{{TP + FN}} $ 精确率P $ \dfrac{{TP}}{{TP + FP}} $ 全类别召回率均值RmAR@0.5 $\dfrac{ {\displaystyle\sum\limits_{j = 1}^c {\sum\limits_{i = 1}^x {R_i} } } }{ {cx} }$ 全类别精确率均值PmAP@0.5 $\dfrac{ {\displaystyle\sum\limits_{j = 1}^c {\displaystyle\sum\limits_{i = 1}^x {P_i} } } }{ {cx} }$ 表 3 不同模型测试结果

Table 3 Results of different models

模型 夹渣 未焊透 气孔 全类别召回率

均值

RmAR@0.5(%)全类别精确率

均值

PmAP@0.5(%)频率

f/(帧·s−1)召回率R(%) 精确率P(%) 召回率R(%) 精确率P(%) 召回率R(%) 精确率P(%) YOLOV5-Tiny 90.23 89.60 83.68 88.71 89.65 86.32 87.85 88.21 61 SSD 85.98 86.33 80.24 85.13 85.07 86.68 83.76 86.05 56 Cascade-RCNN 89.20 87.11 85.26 87.92 89.33 84.92 87.93 86.65 27 SRYOLOV3 88.27 86.99 84.47 87.82 88.67 86.81 87.14 87.21 51 TLMDDNet 92.13 90.45 88.11 90.18 92.67 90.73 90.97 90.45 19 Swin-Cascade-RCNN 93.15 88.42 86.79 88.48 90.26 88.98 90.07 88.99 29 CCBFE-RCNN 93.69 90.63 90.40 93.01 95.20 92.13 93.09 91.92 22 表 4 不同数据集测试结果

Table 4 Test results for different datasets

数据集 全类别召回率均值

RmAR@0.5(%)全类别精确率均值

PmAP@0.5(%)DAGM 92.56 91.84 NEU 95.68 93.58 AITEX 89.34 87.59 -

[1] Li Y W. Research progress of aluminum alloy welding technology[J]. The International Journal of Advanced Manufacturing Technology, 2020, 109(1): 1207 − 1218.

[2] Chen S B. On intelligentized welding manufacturing. In: Robotic welding[C]//Intelligence and Automation: RWIA’2014. Springer International Publishing, 2015: 3 − 34.

[3] Ahmed, Mohamed M Z. Friction stir welding of aluminum in the aerospace industry: the current progress and state-of-the-art review[J]. Materials, 2023, 16(8): 2971. doi: 10.3390/ma16082971

[4] Mohandas T. Welding technologies in aerospace applications[J]. Aerospace Materials and Material Technologies, 2017, 2(1): 65 − 83.

[5] Wang G, Liao T W. Automatic identification of different types of welding defects in radiographic images[J]. Ndt & E International, 2002, 35(8): 519 − 528.

[6] Madhvacharyula, Anirudh Sampath, Pavan, et al. In situ detection of welding defects: a review[J]. Welding in the World, 2022, 66(4): 611 − 628. doi: 10.1007/s40194-021-01229-6

[7] Andrew G, Vignesh S, Sooyoung L, et al. Applications of deep learning for fault detection in industrial cold forging[J]. International Journal of Production Reseach, 2021, 59(16): 4826 − 4835.

[8] Lenka L, Jan S, Renata W. The learning path to neural network industrial application in distributed envisonment[J]. Processes, 2021, 9(12): 2247. doi: 10.3390/pr9122247

[9] Dutta, Sourav. An overview on the evolution and adoption of deep learning applications used in the industry[J]. Wiley Interdisciplinary Reviews:Data Mining and Knowledge Discovery, 2018, 8(4): 1257. doi: 10.1002/widm.1257

[10] 王睿, 胡云雷, 刘卫朋, 等. 基于边缘AI的焊缝X射线图像缺陷检测[J]. 焊接学报, 2022, 43(1): 79 − 84. Wang Rui, Hu Yunlei, Liu Weipeng, et al. Defect detection of weld X-ray image based on edge AI[J]. Transactions of the China Welding Institution, 2022, 43(1): 79 − 84.

[11] 刘欢, 刘骁佳, 王宇斐, 等. 基于复合卷积层神经网络结构的焊缝缺陷分类技术[J]. 航空学报, 2022, 43(S1): 165 − 172. Liu Huan, Liu Xiaojia, Wang Yufei, et al. Weld defect classification technology based on compound convolution neural network structure[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(S1): 165 − 172.

[12] 任文坚, 王永红, 李春凯, 等. 液体火箭发动机推力室熔焊缝数字化胶片图像缺陷识别方法研究[J]. 电焊机, 2023, 53(1): 9 − 14. Ren Wenjian, Wang Yonghong, Li Chunkai, et al. Research on automatic detection method of DR digital imaging for brazing seam defects of thrust chamber body[J]. Electric Welding Machine, 2023, 53(1): 9 − 14.

[13] 程松, 杨洪刚, 徐学谦, 等. 基于YOLOv5的改进轻量型X射线铝合金焊缝缺陷检测算法[J]. 中国激光, 2022, 49(21): 136 − 144. Cheng Song, Yang Honggang, Xu Xueqian, et al. Improved lightweight X-ray aluminum alloy weld defects detection algorithm basedon YOLOv5[J]. Chinese Journal of Lasers, 2022, 49(21): 136 − 144.

[14] 杨会敏, 李春棚, 袁新安, 等. 基于SSD的交流电磁场缺陷智能识别方法[J]. 无损检测, 2022, 44(8): 25 − 30. Yang Huimin, Li Chunpeng, Yuan Xin’an, et al. Defects intelligent recognition method of ACFM based on SSD[J]. Nondestructive Testing, 2022, 44(8): 25 − 30.

[15] Zhang Z, Zhang Y, Wen Y, et al. Intelligent defect detection method for additive manufactured lattice structures based on a modified YOLOv3 model[J]. Journal of Nondestructive Evaluation, 2022, 41(1): 1 − 14. doi: 10.1007/s10921-021-00836-z

[16] Wei X, Wei D, Suo D, et al. Multi-target defect identification for railway track line based on image processing and improved YOLOv3 model[J]. IEEE Access, 2020, 8(1): 973 − 988.

[17] Dong C, Zhang K, Xie Z, et al. An improved cascade RCNN detection method for key components and defects of transmission lines[J]. IET Generation, Transmission Distribution, 2023, 17(19): 4277 − 4292. doi: 10.1049/gtd2.12948

[18] Redmon J, Divvala S, Girshick R, et al. You only look once: unified, realtime object detection[J]. Computer Vision and Pattern Recognition, 2016, 91(1): 779 − 788.

[19] Bhavya Sree B, Yashwanth Bharadwaj V, Neelima N. An inter-comparative survey on state-of-the-art detectors—R-CNN, YOLO and SSD[C]//Intelligent Manufacturing and Energy Sustainability: Proceedings of ICIMES 2020. Springer Singapore, 2021: 475 − 483.

[20] Cao C Q. An improved faster R-CNN for small object detection[J]. Ieee Access, 2019, 7(1): 106838 − 106846.

[21] Bharati P, Pramanik A. Deep learning techniques—R-CNN to mask R-CNN: a survey[J]. Computational Intelligence in Pattern Recognition:Proceedings of CIPR 2019, 2020(1): 657 − 668.

[22] Cai Z W, Vasconcelos N. Cascade R-CNN: delving into high quality object detection[C]//Proceedings of the IEEE Conference on Computer Vision and Pattern Recongnition, 2018: 6165 − 6162.

[23] Sun C Y, Hong X J, Shi S, et al. Cascade faster R-CNN detection for vulnerable plaques in OCT images[J]. IEEE Access, 2021(9): 24697 − 24704.

[24] Cai Z W, Vasconcelos Nuno. Cascade R-CNN: high quality object detection and instance segmentation[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2019, 43(5): 1483 − 1498.

[25] Feng T, Liu J G, Xia F, et al. A double-branch surface detection system for armatures in vibration motors with miniature volume based on ResNet-101 and FPN[J]. Sensors, 2020, 20(8): 1 − 16. doi: 10.1109/JSEN.2020.2978309

[26] Alshammari A, Chabaan R C. Sppn-Rn101: spatial pyramid pooling network with resnet 101-Based foreign object debris detection in airports[J]. Mathematics, 2023, 11(4): 841. doi: 10.3390/math11040841

[27] Ren K, Huang L, Fan C Q, et al. Real-time traffic sign detection network using DS-DetNet and lite fusion FPN[J]. Journal of Real-Time Image Processing, 2021, 18(6): 1 − 11.

[28] Li Y C, Zhou S L, Chen H, et al. Attention-based fusion factor in FPN for object detection[J]. Applied Intelligence, 2022, 1(1): 1 − 10.

[29] Chen J Y, Liu S P, Zhao L. Small object detection combining attention mechanism and a novel FPN[J]. Journal of Intelligent Fuzzy Systems, 2022, 42(4): 3691 − 3703.

[30] Dai Z Z, Chen M Q, Gu X D, et al. Batch drop block network for person re-identification and beyond [C]// Proceedings of the IEEE Conference on Computer Vision, 2019: 3690 − 3700.

[31] Ye J. Single valued neutrosophic cross-entropy for multicriteria decision making problems[J]. Applied Mathematical Modelling, 2014, 38(3): 1170 − 1175. doi: 10.1016/j.apm.2013.07.020

[32] Chen Y P, Xu K, Zhou P, et al. Improved cross entropy loss for noisy labels in vision leaf disease classification[J]. IET Image Processing, 2022, 16(6): 1511 − 1519. doi: 10.1049/ipr2.12402

[33] 程松, 戴金涛, 杨洪刚, 等. 基于改进型YOLOv4的焊缝图像检测与识别[J]. 激光与光电子学进展, 2022, 59(16): 105 − 111. Cheng Song, Dai Jintao, Yang Honggang, et al. Weld Image detection and recognition based on improved YOLOv4[J]. Laser & Optoelectronics Progress, 2022, 59(16): 105 − 111.

下载:

下载: