Experiment welding of Al/Cu dissimilar metals with infrared-blue hybrid laser welding for power battery

-

摘要:

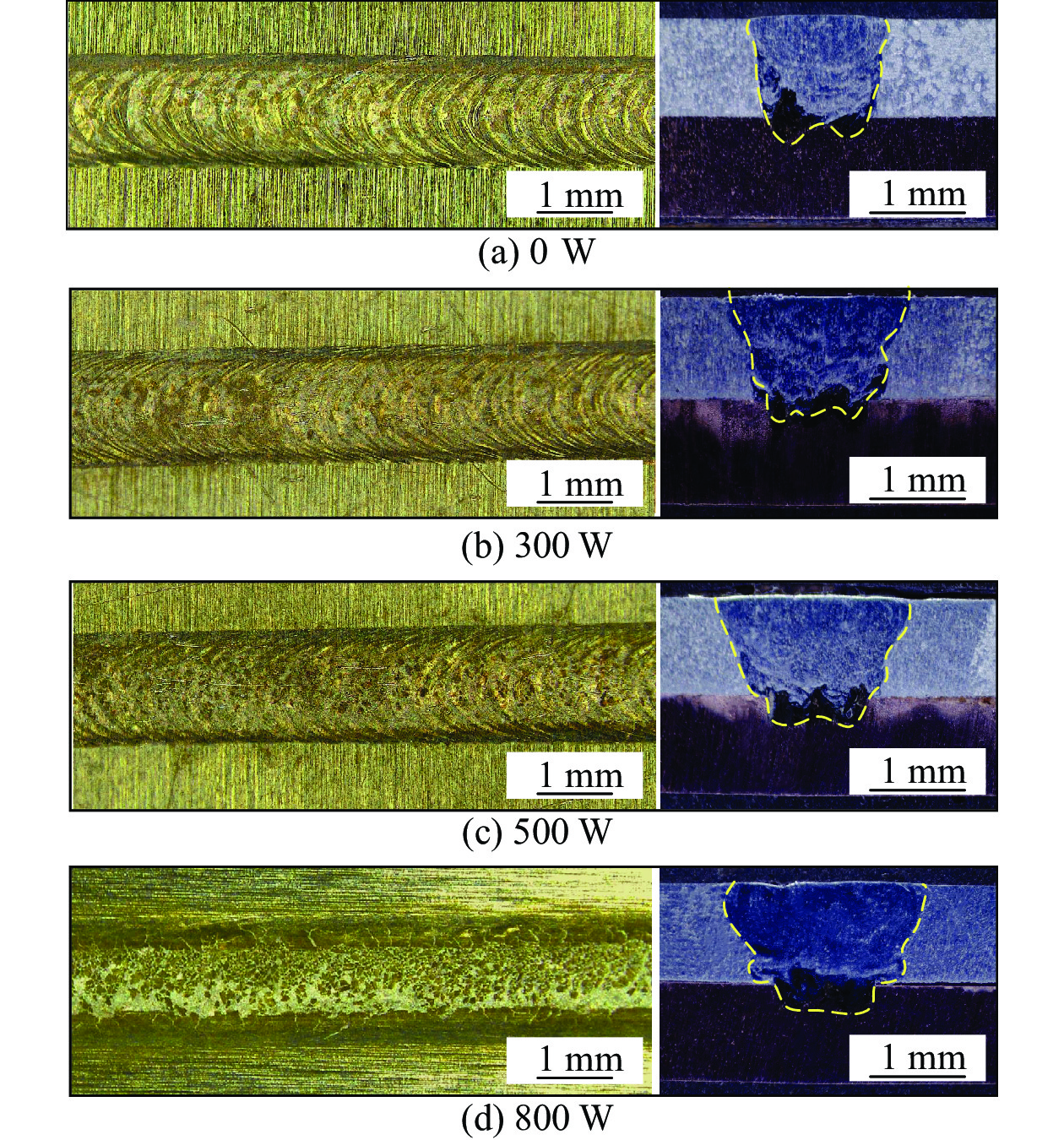

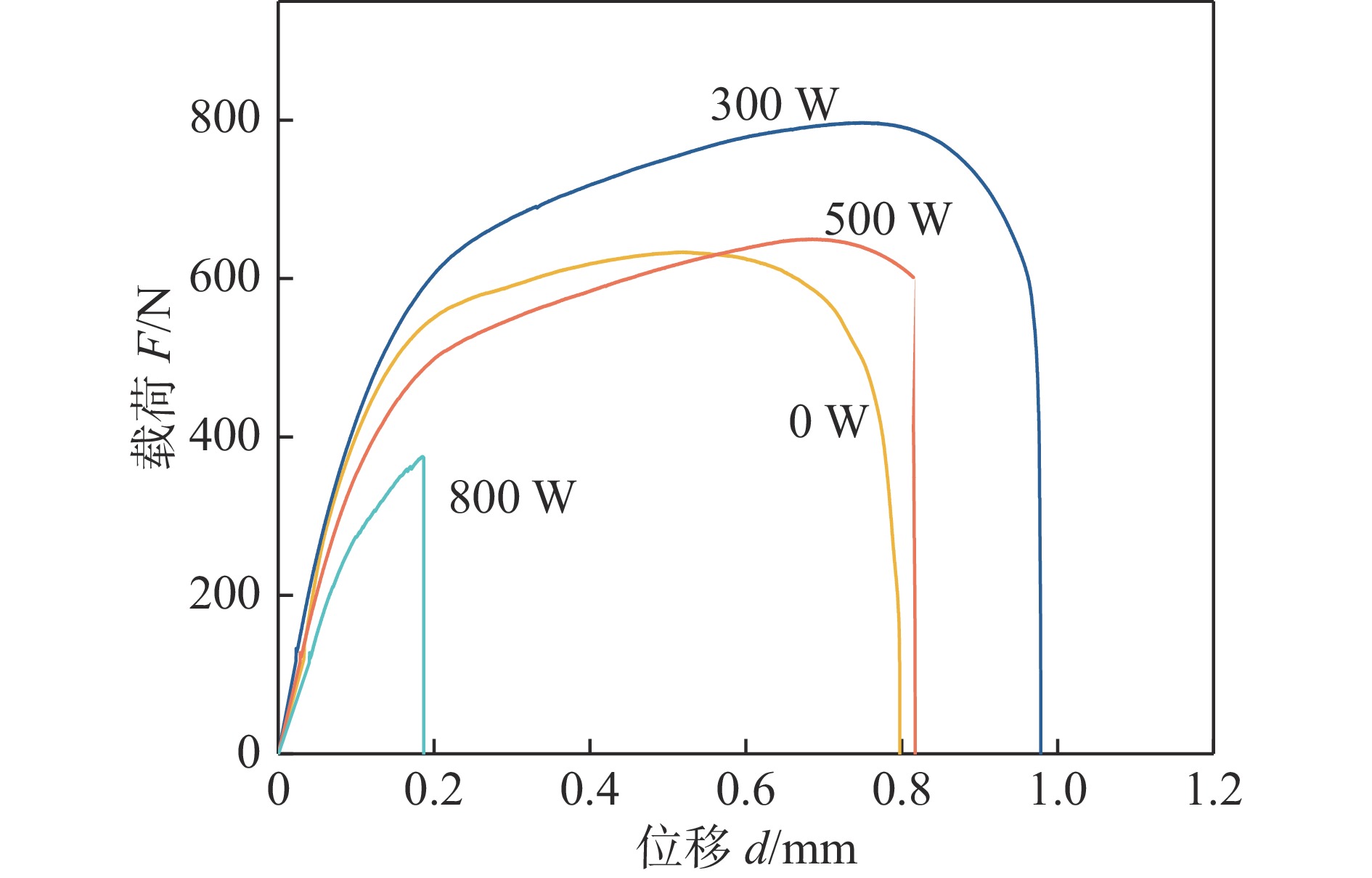

针对铝/铜搭接焊接的技术难点,提出了一种红外—蓝激光复合焊接新工艺. 对厚度为1 mm的5052铝合金和T2紫铜搭接接头进行焊接试验,研究了不同蓝激光功率对接头焊缝成形、显微组织以和力学性能的影响规律. 结果表明,在0 ~ 500 W的蓝激光功率范围内,红外—蓝激光复合焊可以有效减缓下方铜板的铜元素向上方铝板的对流扩散,而进一步增大蓝激光功率则会导致激光总功率增加,发生过焊现象,进而生成更多脆性Al-Cu金属间化合物(intermetallic compound,IMC). 在接头界面层,沿着铜侧到铝侧方向依次生成ϒ2-Al4Cu9相、AlCu相、θ-Al2Cu相、α-Al + Al2Cu共晶组织和Al/Cu共晶组织,其中,Al2Cu相是接头界面层中的主要IMC相. 当红外激光功率为

1050 W,蓝激光功率为300 W时,接头抗剪切力达到最大值795.51 N,断裂发生在铝侧热影响区(heat affected zone,HAZ)处,呈韧性断裂模式.Abstract:Aiming at the technical difficulties of laser overlap welding of Al/Cu dissimilar metals, a new infrared-blue hybrid laser welding process was proposed. Laser welding of the overlap joints of 5052 aluminum alloy and T2 copper with thickness of 1 mm was carried out. The effects of different blue laser powers on the weld appearance, microstructure and mechanical properties of the joints were investigated. The results showed that the convection diffusion of copper elements from the lower copper plate to the upper aluminum plate could be weakened by using infrared-blue laser hybrid welding process with a blue laser power in the range of 0 ~ 500 W. With the increase of blue laser power, the mixing degree of molten copper and aluminum was increased, resulting in more brittle Al-Cu intermetallic compound (IMC) phases. Generates the following phases in the order from the copper side to the aluminum side, ϒ2-Al4Cu9, AlCu, θ-Al2Cu, α-Al + Al2Cu eutectic structure and Al/Cu eutectic structure. Among these, Al2Cu was the primary IMC phase at the interface layer of the joints. When the infrared laser power was

1050 W and the blue laser power was 300 W, the shear resistance of the joint reached up to 795.51 N. The joint was broken at the heat affected zone (HAZ) of the upper aluminum plate with a ductile fracture mode. -

-

表 1 5052铝合金和T2紫铜化学成分(质量分数,%)

Table 1 Chemical compositions of 5052 aluminum and T2 copper

Si Fe Bi Mn Mg Ni Cr Zn Cu Al 0.2500 0.4300 0.0009 0.1300 2.5100 0.0013 0.2100 0.1100 0.12 余量 0.0043 0.0032 0.0008 0.0016 0.0019 0.0028 0.0036 0.0054 余量 0.0094 表 2 激光焊接工艺参数

Table 2 Parameters for laser welding

红外激光功率

PR/W蓝激光功率

PB/W焊接速度

v/(m·min−1)离焦量

Df /mm1050 0 3.6 −1 1050 300 3.6 −1 1050 500 3.6 −1 1050 800 3.6 −1 表 3 图5中标记区域的EDS分析结果

Table 3 EDS analysis results of the marked region in Fig.5

测量点 元素含量(原子分数, %) 物相 Al Cu 1 95.65 4.35 Al/Cu共晶组织 2 82.34 17.66 α-Al + Al2Cu 3 69.01 30.99 θ-Al2Cu 4 34.43 65.57 ϒ2-Al4Cu9 5 6.70 93.30 Cu 6 90.14 9.86 Al/Cu共晶组织 7 82.59 17.41 α-Al + Al2Cu 8 65.27 34.73 θ-Al2Cu 9 54.78 45.21 AlCu 10 20.69 79.30 ϒ2-Al4Cu9 11 15.26 84.73 Cu 12 94.56 5.44 Al/Cu共晶组织 13 82.28 17.20 α-Al + Al2Cu 14 76.51 23.49 α-Al + Al2Cu 15 59.39 40.61 θ-Al2Cu 16 33.97 66.03 ϒ2-Al4Cu9 17 5.30 94.70 Cu 18 73.00 27.00 α-Al + Al2Cu 19 58.67 41.33 θ-Al2Cu 20 29.78 70.22 ϒ2-Al4Cu9 21 20.40 79.60 Cu -

[1] Dhara S, Finuf M, Zediker M, et al. Utilising blue laser over infrared laser to enhance control of penetration depth and weld strength for producing electric vehicle battery interconnects[J]. Journal of Materials Processing Technology, 2023, 317: 117989. doi: 10.1016/j.jmatprotec.2023.117989

[2] Tian S K, Zhao F, Liu X H. Clarification of the solid-state diffusion behavior of a copper alloy/aluminum alloy composite interface assisted by position marking of the second phases[J]. Materials Characterization, 2022, 192: 112173. doi: 10.1016/j.matchar.2022.112173

[3] Zwicker M F, Moghadam M, Zhang W, et al. Automotive battery pack manufacturing-a review of battery to tab joining[J]. Journal of Advanced Joining Processes, 2020, 1: 100017. doi: 10.1016/j.jajp.2020.100017

[4] Ma B, Gao X D, Huang Y J, et al. A review of laser welding for aluminium and copper dissimilar metals[J]. Optics & Laser Technology, 2023, 167: 109721.

[5] 王秋影, 邱培现, 孙进发, 等. 超声振动辅助铝/钢激光-MIG熔钎焊外观成形、组织以及拉伸性能研究[J]. 精密成形工程, 2023, 15(5): 123 − 130. Wang Qiuying, Qiu Peixing, Sun Jinfa, et al. Forming, microstructure and tensile properties of aluminum/steel joint by ultrasonic vibration assisted laser-MIG welding-brazing[J]. Journal of Netshape Forming Engineering, 2023, 15(5): 123 − 130.

[6] Ali S, Shin J. In-depth characterization of laser-welded aluminum-and-copper dissimilar joint for electric vehicle battery connections[J]. Materials, 2022, 15(21): 7463. doi: 10.3390/ma15217463

[7] Lerra F, Ascari A, Fortunato A. The influence of laser pulse shape and separation distance on dissimilar welding of Al and Cu films[J]. Journal of Manufacturing Processes, 2019, 45: 331 − 339. doi: 10.1016/j.jmapro.2019.07.015

[8] Dimatteo V, Ascari A, Liverani E, et al. Experimental investigation on the effect of spot diameter on continuous-wave laser welding of copper and aluminum thin sheets for battery manufacturing[J]. Optics & Laser Technology, 2022, 145: 107495.

[9] Li W C, Dong H, Zhang B, et al. The influence of adjustable ring-mode laser on the formation of intermetallic compounds and mechanical properties of ultra-thin Al-Cu lap welded joints[J]. Journal of Materials Processing Technology, 2024, 332: 118537. doi: 10.1016/j.jmatprotec.2024.118537

[10] Du W Z, Huang X T, Zheng M, et al. Hybrid laser welding and brazing for controlling intermetallic compounds in Al/Cu dissimilar joint[J]. Optics & Laser Technology, 2025, 180: 111559.

[11] Song Y X, Xiao M Z, Huang D C, et al. Effect of process parameters on the morphology of aluminum/copper alloy lap joints by red and blue hybrid laser welding[J]. China Welding, 2024, 33(2): 23 − 30.

[12] Zhou J, Xia G J, Zhou Z K, et al. Comparison study of 6082 Al alloy laser welding using 455 nm blue laser and 1080 nm near-infrared laser[J]. Optik, 2023, 272: 170224. doi: 10.1016/j.ijleo.2022.170224

[13] Zapico E P, Ascari A, Fortunato A, et al. Influence of process parameters in blue laser welding of copper and aluminum thin sheets[J]. Journal of Laser Applications, 2022, 34(4): 042039. doi: 10.2351/7.0000836

[14] Tang Z J, Wan L, Yang H H, et al. Stable conduction mode welding of conventional high-reflectivity metals with

2000 W blue laser[J]. Optics & Laser Technology, 2024, 168: 109971.[15] Maina M R, Okamoto Y, Hamada K, et al. Effects of superposition of 532 nm and

1064 nm wavelengths in copper micro-welding by pulsed Nd: YAG laser[J]. Journal of Materials Processing Technology, 2022, 299: 117388. doi: 10.1016/j.jmatprotec.2021.117388[16] Yang H, Tang X H, Hu C, et al. Study on laser welding of copper material by hybrid light source of blue diode laser and fiber laser[J] Journal of Laser Applications, 2021, 33(3): 032018.

[17] Wu D S, Sun J H, Li Z G, et al. Molten pool behaviors and energy absorption in coaxial hybrid blue-IR lasers welding of a copper material[J]. International Journal of Thermal Sciences, 2023, 184: 107945. doi: 10.1016/j.ijthermalsci.2022.107945

[18] Dimatteo V, Ascari A, Fortunato A. Dissimilar laser welding of copper and aluminum alloys in multilayer configuration for battery applications[J]. Journal of Laser Applications, 2021, 33(4): 042028. doi: 10.2351/7.0000476

[19] 尹驰, 郭永环, 范希营, 等. 基于BKA-GBRT与MOSPO的铝/铜激光焊接参数多目标优化[J]. 焊接学报, 2024, 45(11): 140 − 144. Yin Chi, Guo Yonghuan, Fan Xiying, et al. Multi-objective optimization of aluminum copper laser welding parameters based on BKA-GBRT and MOSPO[J]. Transactions of the China Welding Institution, 2024, 45(11): 140 − 144.

[20] 徐旭, 刘玉龙, 宿再春, 等. 添加SiO2纳米粉末AC辅助Al/Cu等离子弧熔钎焊接头组织及性能分析[J]. 材料导报, 2023, 37(11): 171 − 177. Xu Xu, Liu Yulong, Su Zaichun, et al. Microstructure and properties analysis of AC assisted Al/Cu plasma arcbrazing joint by adding SiO2 nano-powder[J]. Materials Reports, 2023, 37(11): 171 − 177.

[21] Yan S H, Shi Y. Influence of Ni interlayer on microstructure and mechanical properties of laser welded joint of Al/Cu bimetal[J]. Journal of Manufacturing Processes, 2020, 59: 343 − 354. doi: 10.1016/j.jmapro.2020.09.078

[22] 邓呈敏, 程东海, 张华, 等. 焊丝成分对铝/铜激光熔钎焊接头组织和性能的影响[J]. 焊接学报, 2022, 43(1): 16 − 21. Deng Chengmin, Cheng Donghai, Zhang Hua, et al. Effect of welding wire composition on microstucture and properties on Al/Cu laser welding-brazing joints[J]. Transactions of the China Welding Institution, 2022, 43(1): 16 − 21.

[23] 周惦武, 姜德福, 刘金水, 等. 铝/钢表面预置粉末激光焊接头的组织与性能[J]. 中国有色金属学报, 2019, 29(5): 942 − 953. Zhou Dianwu, Jiang Defu, Liu Jinshui, et al. Microstructure and mechanical properties of laser welding joint with aluminum/steel surface preset filler powder addition[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(5): 942 − 953.

-

期刊类型引用(2)

1. 田君,戴品强,李小军,王海燕. 稀土对Zn20Sn高温无铅钎料组织与性能的影响. 电子元件与材料. 2017(03): 59-62 .  百度学术

百度学术

2. 殷祚炷,孙凤莲. 铜铝钎焊接头腐蚀机理分析. 焊接学报. 2017(10): 121-124+134 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: