Microstructural evolution and corrosion property of Al-Mg alloy friction stir welding joint

-

摘要:

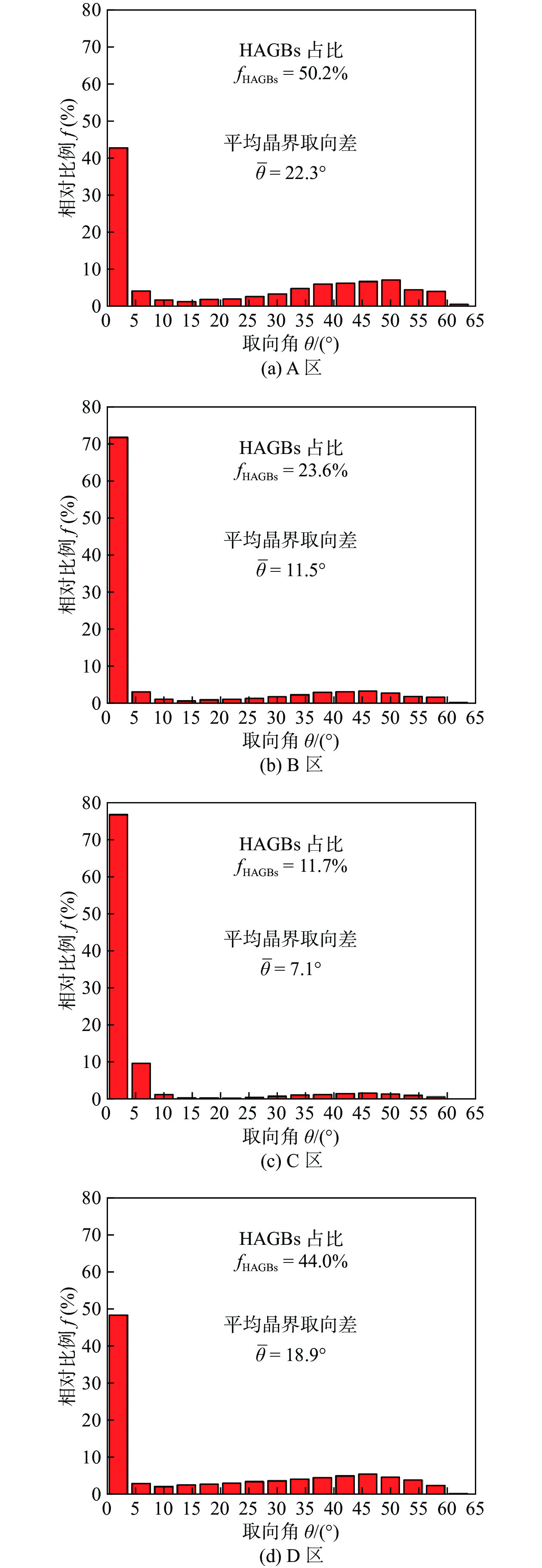

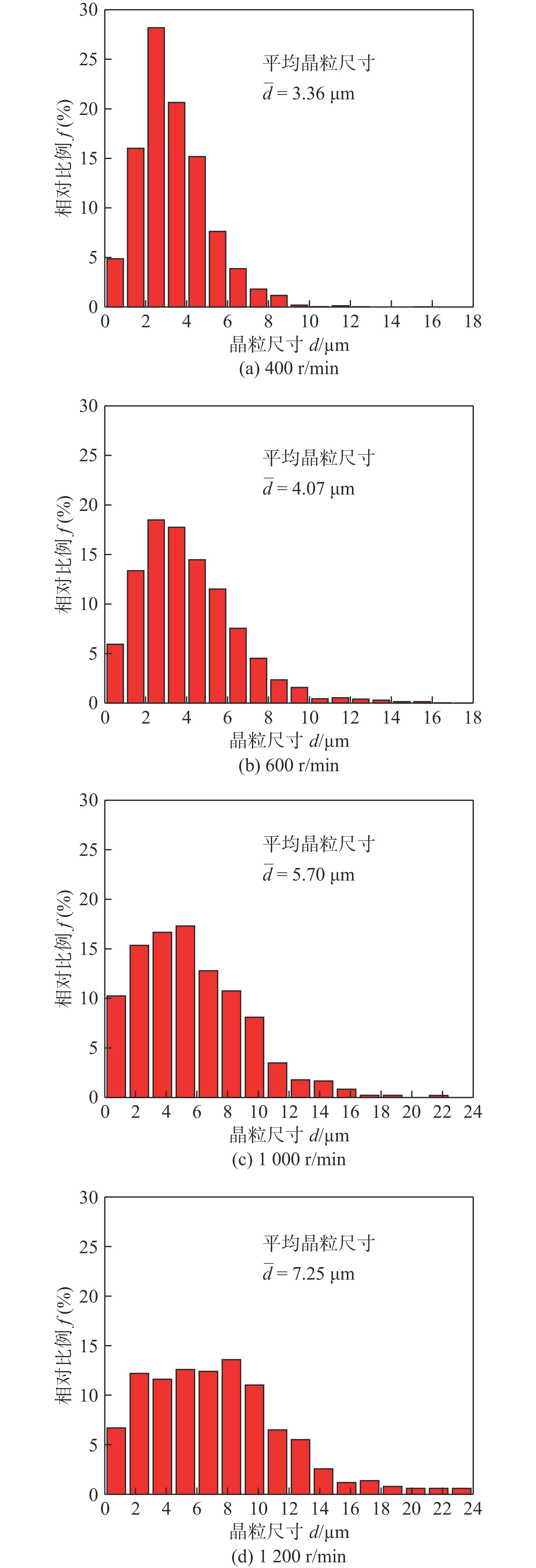

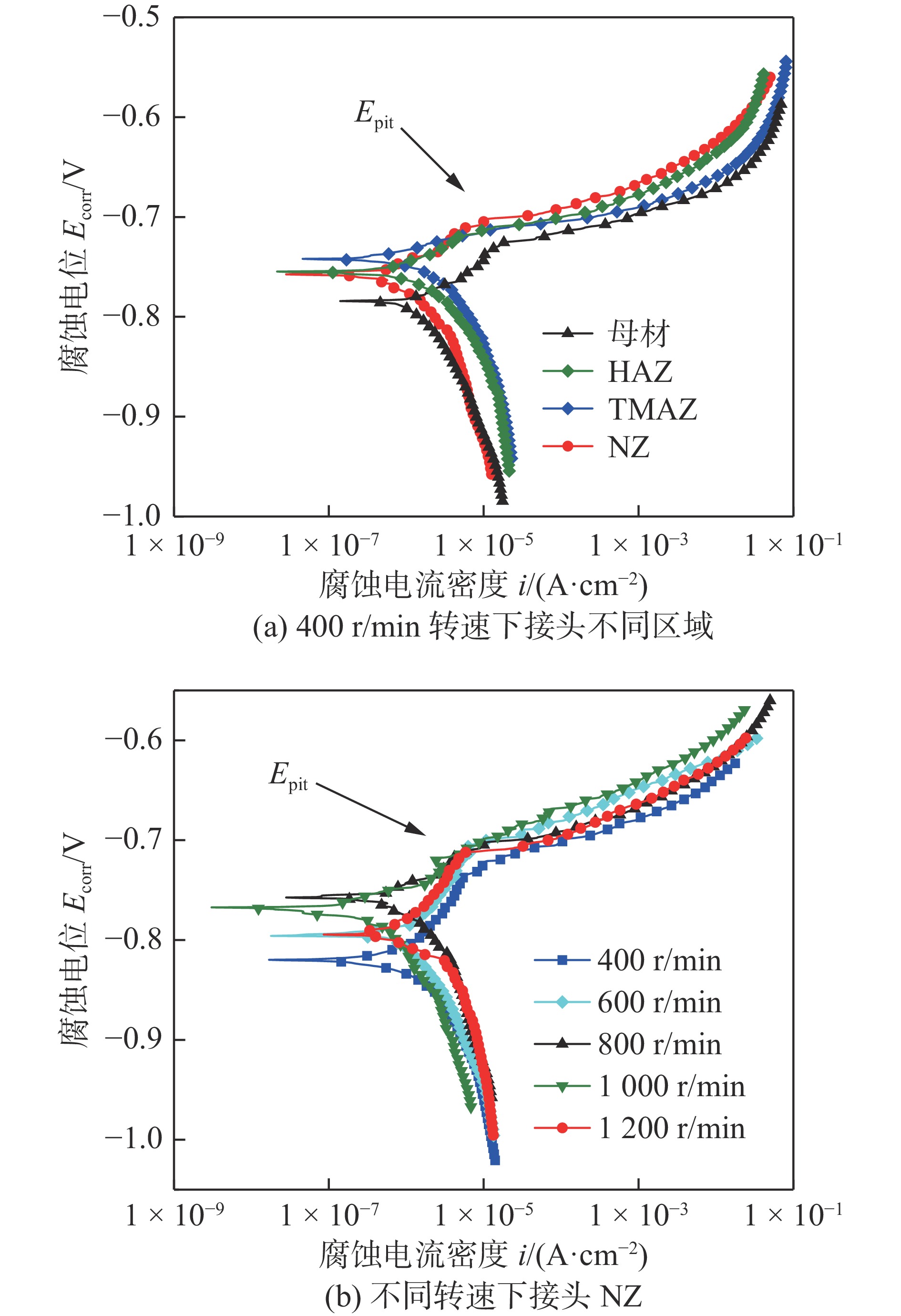

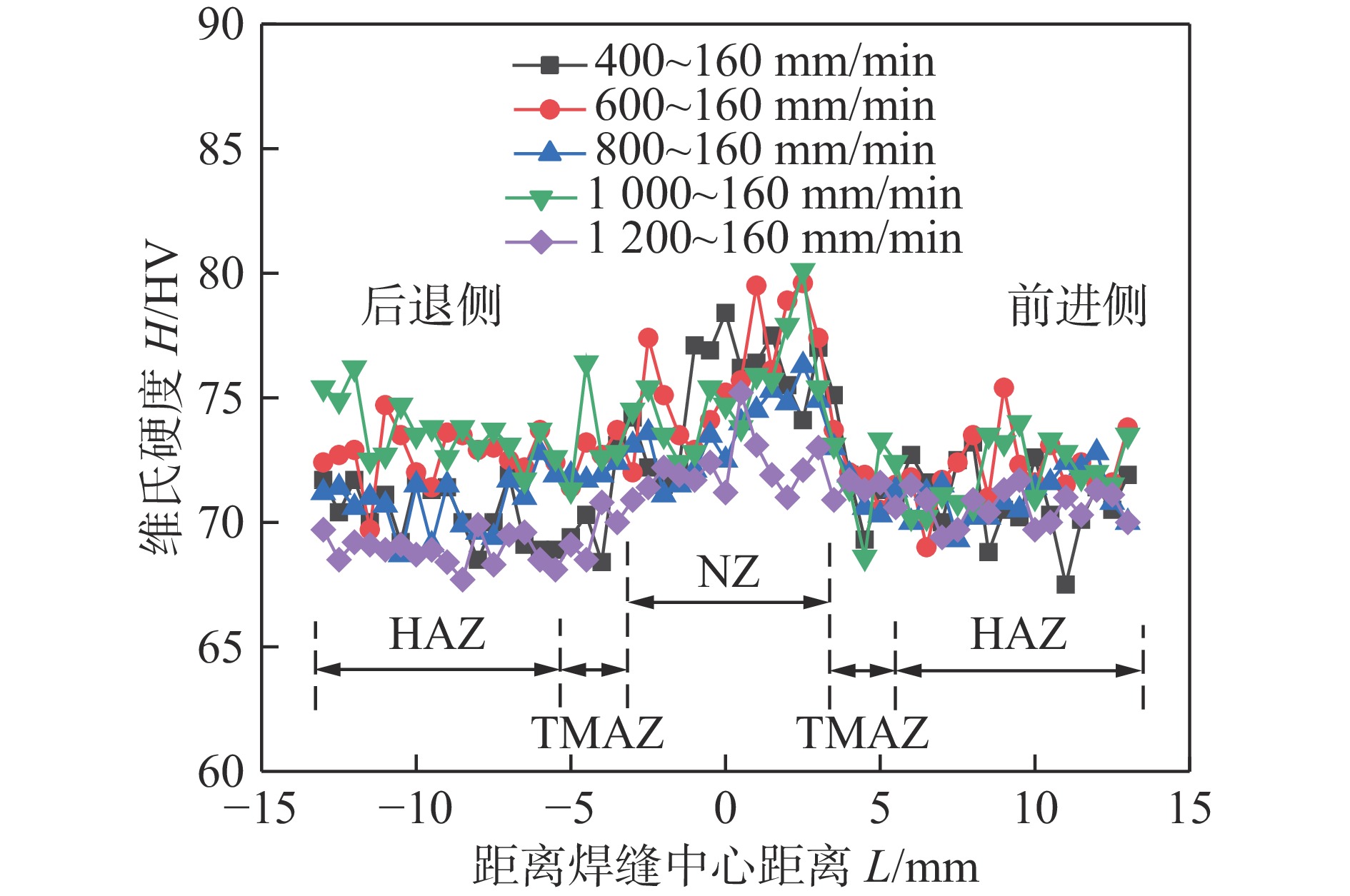

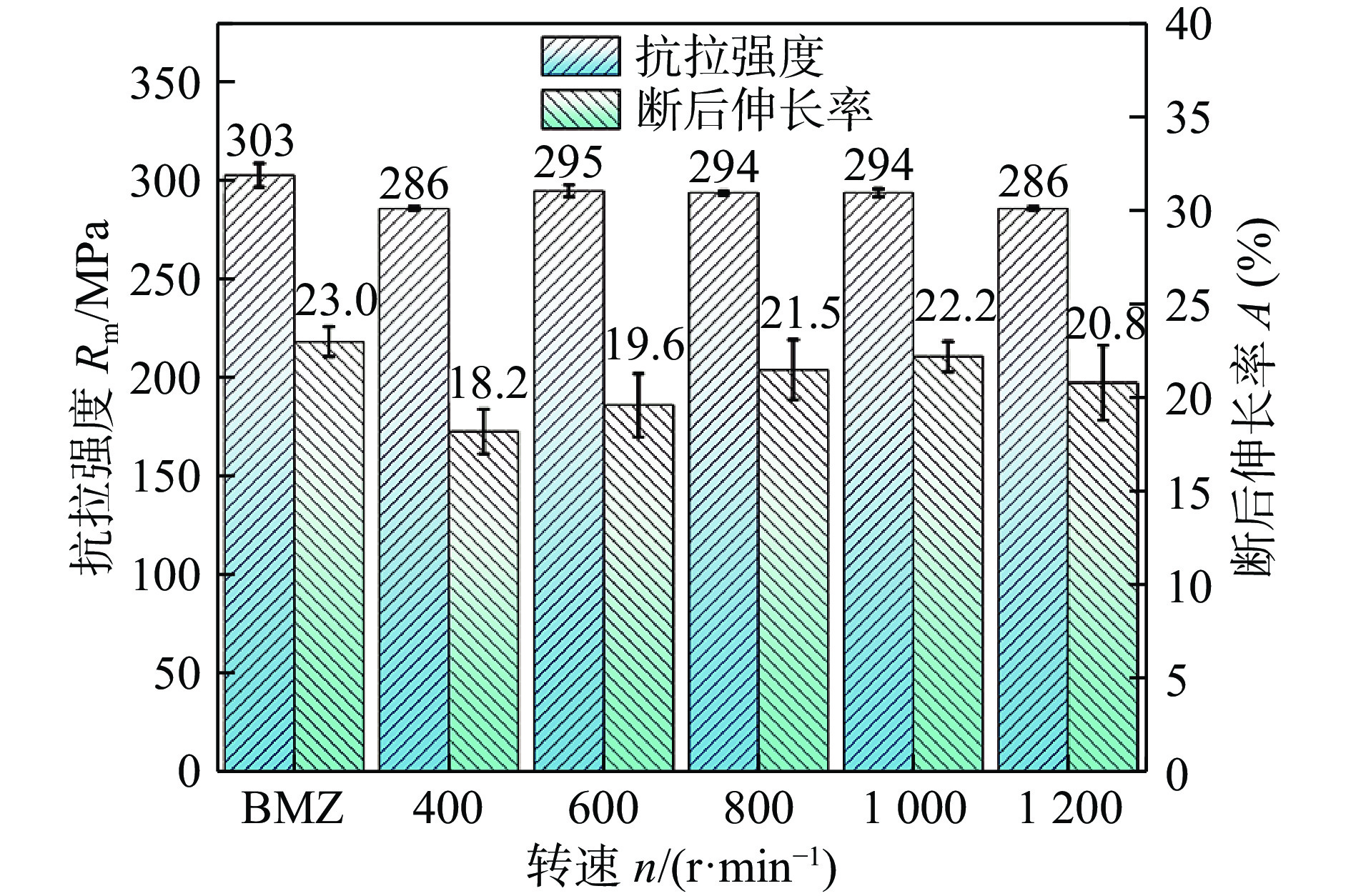

文中基于电子背散射衍射(electron backscatter diffraction, EBSD)和动电位极化等方法,探索了Al-Mg系合金AA5083-H112搅拌摩擦焊(friction stir welding, FSW)接头的微观组织、腐蚀性能和力学性能,揭示了Al-Mg系合金搅拌摩擦焊接头微观组织的演变机理,明确了微观组织对其腐蚀性能和力学性能的影响规律.结果表明,5083-H112铝合金搅拌摩擦焊接头从母材区(base metal zone, BMZ)到焊核区(nugget zone, NZ)的组织演变规律符合连续动态再结晶机制. 800 r/min下接头从BMZ到NZ的平均晶粒尺寸先增大后减小,大角度晶界(high angle grain boundaries, HAGBs)占比先减小后增加. 随转速的升高,NZ的平均晶粒尺寸逐渐增大,HAGBs占比受焊接热输入及焊后冷却时间的影响先减小后增大. 同转速下接头不同区域和不同转速下接头NZ的腐蚀倾向均呈现出与HAGBs占比正相关的规律,腐蚀部位主要在晶界,腐蚀形貌呈现出晶间腐蚀和剥落腐蚀的特征. 接头各区域的硬度与微观组织相符,但对转速的变化不敏感. 在600 r/min和

1000 r/min转速范围内接头抗拉强度达母材的97%以上,同时断后伸长率与母材接近.Abstract:Based on electron backscatter diffraction (EBSD) and potentiodynamic polarization, the paper explores the microstructure, corrosion property and mechanical property of Al-Mg alloy AA5083-H112 friction stir welding (FSW) joint, reveals the evolution mechanism of the microstructure of Al-Mg alloy FSW joint, and clarifies the influence of microstructure on its corrosion property and mechanical property. The results show that the microstructure evolution of 5083-H112 aluminum alloy FSW joint from base metal zone (BMZ) to nugget zone (NZ) conforms to the mechanism of continuous dynamic recrystallization. The average grain size of the joint from the BMZ to the NZ at 800 r/min increases and then decreases, and the fraction of high angle grain boundaries (HAGBs) decreases and then increases. With the increasing of rotating rate, the average grain size in the NZ increases gradually, and the fraction of HAGBs decreases at first and then increases due to the influence of welding heat input and post-welding cooling time. The corrosion tendency in different zones of the joint at the same rotating rate and in the NZ of the joints with different rotating rates show a positive correlation with the fraction of HAGBs, and the corrosion site is mainly in the grain boundaries, and the corrosion morphology is characterized by intergranular corrosion and exfoliation corrosion. The hardness of each zone of the joint is consistent with the microstructure, but is insensitive to changes in rotating rate. The tensile strength of the joints reached more than 97% of the base metal in the range of 600 r/min and

1000 r/min, while the elongation is close to that of the base metal. -

-

表 1 5083-H112铝合金化学成分(质量分数, %)

Table 1 Composition of 5083-H112 aluminum alloy

Mg Si Fe Mn Cu Cr Zn Ti Al 4.15 0.09 0.25 0.67 0.04 0.10 0.02 0.02 余量 表 2 EDS分析结果(原子分数,%)

Table 2 Results of EDS analysis

特征点 Al Mg Si Fe Mn 1 48.74 27.77 23.39 0.01 0.09 2 85.77 0.18 0.02 8.78 5.25 -

[1] Ma Y T, Dong H G, Li P, et al. A novel corrosion transformation process in aluminum alloy/galvanized steel welded joint[J]. Corrosion Science, 2022, 194: 109936. doi: 10.1016/j.corsci.2021.109936

[2] 陈兴惠, 张洪申. 基于主成分及灰色关联度分析的5083铝合金FSW接头工艺参数优化[J]. 焊接学报, 2023, 44(5): 62 − 69. Chen Xinghui, Zhang Hongshen. Process parameters optimization of 5083 aluminum alloy FSW joint based on principal component analysis and grey correlation analysis[J]. Transactions of the China Welding Institution, 2023, 44(5): 62 − 69.

[3] Han R H, Ren D X, Song G, et al. Research on friction stir welding of 5754 aluminum alloy with unequal thickness[J]. China Welding, 2023, 32(3): 1 − 9.

[4] Zamrudi F H, Setiawan A R. Effect of friction stir welding parameters on corrosion behaviour of aluminium alloys: an overview[J]. Corrosion Engineering, Science and Technology, 2022, 57(7): 696 − 707. doi: 10.1080/1478422X.2022.2116185

[5] Li Y L, Xia W J, Yan H G, et al. Microstructure and mechanical properties of friction-stir-welded high-Mg-alloyed Al-Mg alloy plates at different rotating rates[J]. Rare Metals, 2021, 40(8): 2167 − 2178. doi: 10.1007/s12598-020-01558-3

[6] 李莹莉. 5A12铝合金搅拌摩擦焊接头组织与力学性能的研究[D]. 长沙: 湖南大学, 2020. Li Yingli. Research on microstructure and mechanical properties of friction stir welded joint of 5A12 aluminum alloy[D]. Changsha: Hunan University, 2020.

[7] Yadav R, Kumar A, Chaudhari G P, et al. Mechanical and stress corrosion cracking behavior of welded 5059H116 alloy[J]. Corrosion Science, 2022, 206: 110528. doi: 10.1016/j.corsci.2022.110528

[8] Fan L T, Ma J J, Zou C X, et al. Revealing foundations of the intergranular corrosion of 5XXX and 6XXX Al alloys[J]. Materials Letters, 2020, 271: 127767. doi: 10.1016/j.matlet.2020.127767

[9] Qin J, Li Z, Ma M Y, et al. Diversity of intergranular corrosion and stress corrosion cracking for 5083 Al alloy with different grain sizes[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(3): 765 − 777. doi: 10.1016/S1003-6326(22)65831-X

[10] Hu Z L, Pang Q, Dai M L. Microstructure and mechanical properties of friction stir welding joint during post weld heat treatment with different zigzag lines[J]. Rare Metals, 2019, 38(11): 1070 − 1077. doi: 10.1007/s12598-018-1179-7

[11] Etter A L, Baudin T, Fredj N, et al. Recrystallization mechanisms in 5251 H14 and 5251 O aluminum friction stir welds[J]. Materials Science & Engineering A, 2007, 445: 94 − 99.

[12] Hu Y Y, Liu H J, Li S, et al. Improving mechanical properties of a joint through tilt probe penetrating friction stir welding[J]. Materials Science & Engineering A, 2018, 731: 107 − 118.

[13] 郭幼节, 李劲风, 刘丹阳, 等. 铝锂合金动态再结晶行为的研究进展[J]. 航空材料学报, 2022, 42(5): 15 − 31. Guo Youjie, Li Jinfeng, Liu Danyang, et al. Research progress on dynamic recrystallization behavior of Al-Li alloy[J]. Journal of Aeronautical Materials, 2022, 42(5): 15 − 31.

[14] Engler O, Miller-jupp S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083[J]. Journal of Alloys and Compounds, 2016, 689: 998 − 1010. doi: 10.1016/j.jallcom.2016.08.070

[15] Chen Y C, Huang Y Y, Chang C P, et al. The effect of extrusion temperature on the development of deformation microstructures in 5052 aluminium alloy processed by equal channel angular extrusion[J]. Acta Materialia, 2003, 51(7): 2005 − 2015. doi: 10.1016/S1359-6454(02)00607-9

[16] 张成聪, 常保华, 陶军, 等. 2024铝合金搅拌摩擦焊过程组织演化分析[J]. 焊接学报, 2013(3): 57 − 60. Zhang Chengcong, Chang Baohua, Tao Jun, et al. Microstructure evolution during friction stir welding of 2024 aluminum alloy[J]. Transactions of the China Welding Institution, 2013(3): 57 − 60.

[17] 李芳草. 5083-H112铝合金FSW接头的敏化行为[D]. 沈阳: 东北大学, 2018. Li Fangcao. Sensitization behavior of 5083-H112 aluminum alloy friction stir welded joint[D]. Shenyang: Northeastern University, 2018.

[18] D'Antuono D S, Gaies J, Golumbfskie W, et al. Direct measurement of the effect of cold rolling on β phase precipitation kinetics in 5xxx series aluminum alloys[J]. Acta Materialia, 2017, 123: 264 − 271. doi: 10.1016/j.actamat.2016.10.060

-

期刊类型引用(12)

1. 邹阳,魏巍,范悦,王泽震,王强,赵亮. 铝合金搅拌摩擦焊工艺研究进展. 热加工工艺. 2024(03): 7-13 .  百度学术

百度学术

2. 陈平. 2系铝合金的搅拌摩擦焊接接头微观组织与力学性能研究. 北京印刷学院学报. 2024(03): 32-37 .  百度学术

百度学术

3. 王浡婳,张立杰. 铝合金搅拌摩擦焊接头微观组织和力学性能分析. 精密成形工程. 2023(01): 94-100 .  百度学术

百度学术

4. 许辉,刘宽,徐耀钟,于文凯,刘婷,王笑含,徐雪华. 2A14铝合金FSW焊缝背部线状缺陷返修工艺. 电焊机. 2023(03): 117-123 .  百度学术

百度学术

5. 马领航,李波,赵彦广,宋建岭,高世康,李雨,许子彦,周利. 火箭贮箱焊接缺陷修复技术研究现状. 电焊机. 2023(03): 31-45 .  百度学术

百度学术

6. 李晓华,齐影,郑瑞娟,武媛,祝弘滨,崔雷. QT400球墨铸铁摩擦塞焊接头的微观组织和力学性能研究. 热加工工艺. 2023(05): 141-144 .  百度学术

百度学术

7. 鲁克锋,殷凤仕,王文宇,滕涛,樊世冲,刘亚凡,王鸿琪,朱建,任智强. 铝合金搅拌摩擦焊接头缺陷及焊件结构问题控制策略的研究进展. 表面技术. 2023(07): 55-79 .  百度学术

百度学术

8. 丁清伟,汪春能,眭怀明,赵引红,陈冬梅. 铝合金机匣预埋管处渗漏机理分析及解决措施. 铸造技术. 2023(09): 873-876 .  百度学术

百度学术

9. 李德福,王希靖. 6082铝合金摩擦塞补焊接头焊核区晶体特征. 兰州理工大学学报. 2022(03): 7-12 .  百度学术

百度学术

10. 高彦军,刘西伟,刘旭升,邵震,崔雷. 2060-T8铝锂合金顶锻式摩擦塞补焊接头组织性能研究. 电焊机. 2022(07): 69-75+99 .  百度学术

百度学术

11. 赵慧慧,高焓,胡蓝,董吉义,尹玉环,崔雷. 2219铝合金薄板拉拔式摩擦塞焊工艺及力学性能优化. 焊接. 2021(06): 48-55+64 .  百度学术

百度学术

12. 胡永鹅,龙琼,韩兴科,何波,王尧,杨秀芳. 铝合金材料焊接方法研究进展. 贵州农机化. 2020(03): 15-19 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: