Multi-channel multi-frequency eddy current detection of lithium battery welds in aviation field

-

摘要:

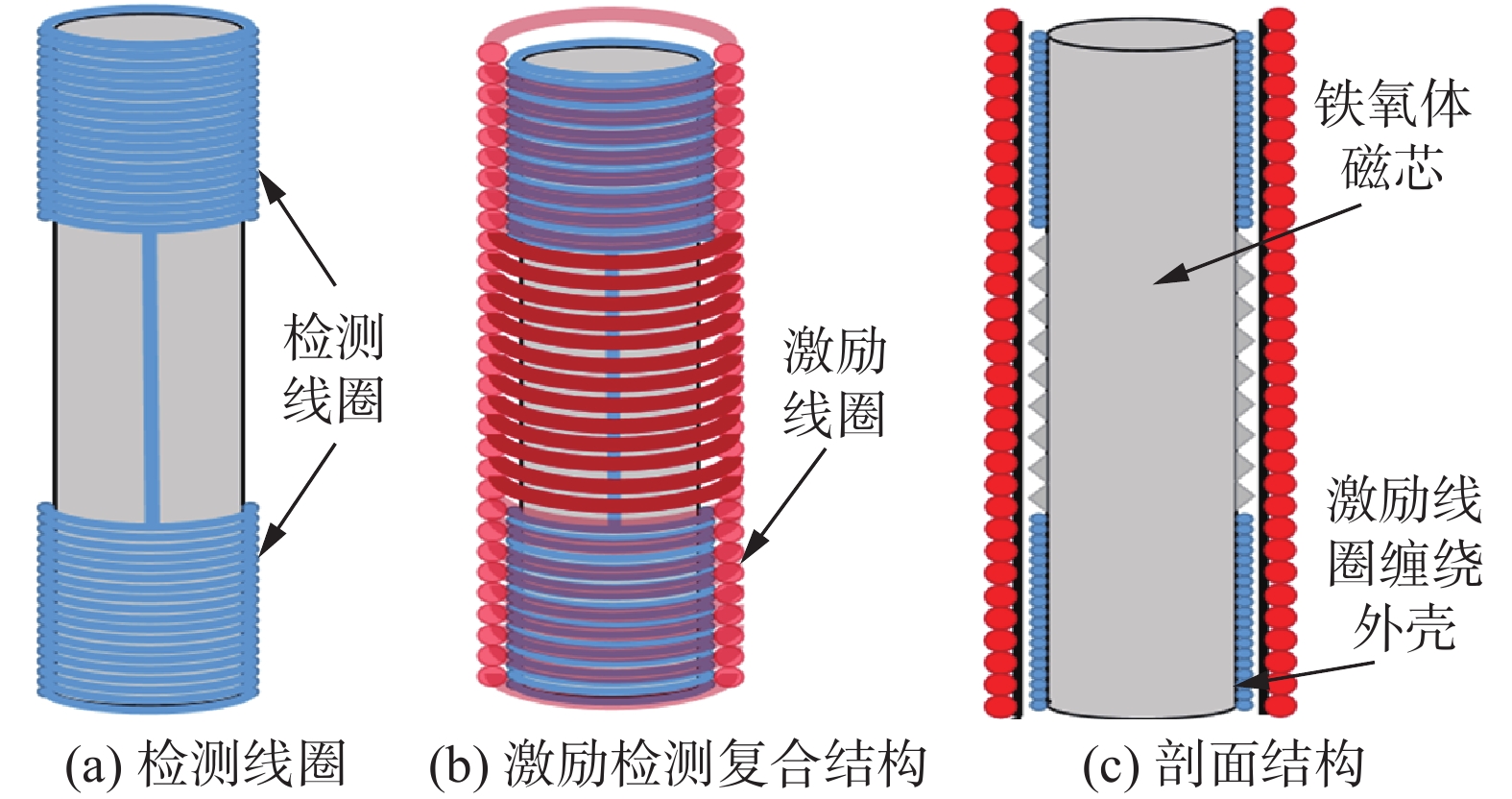

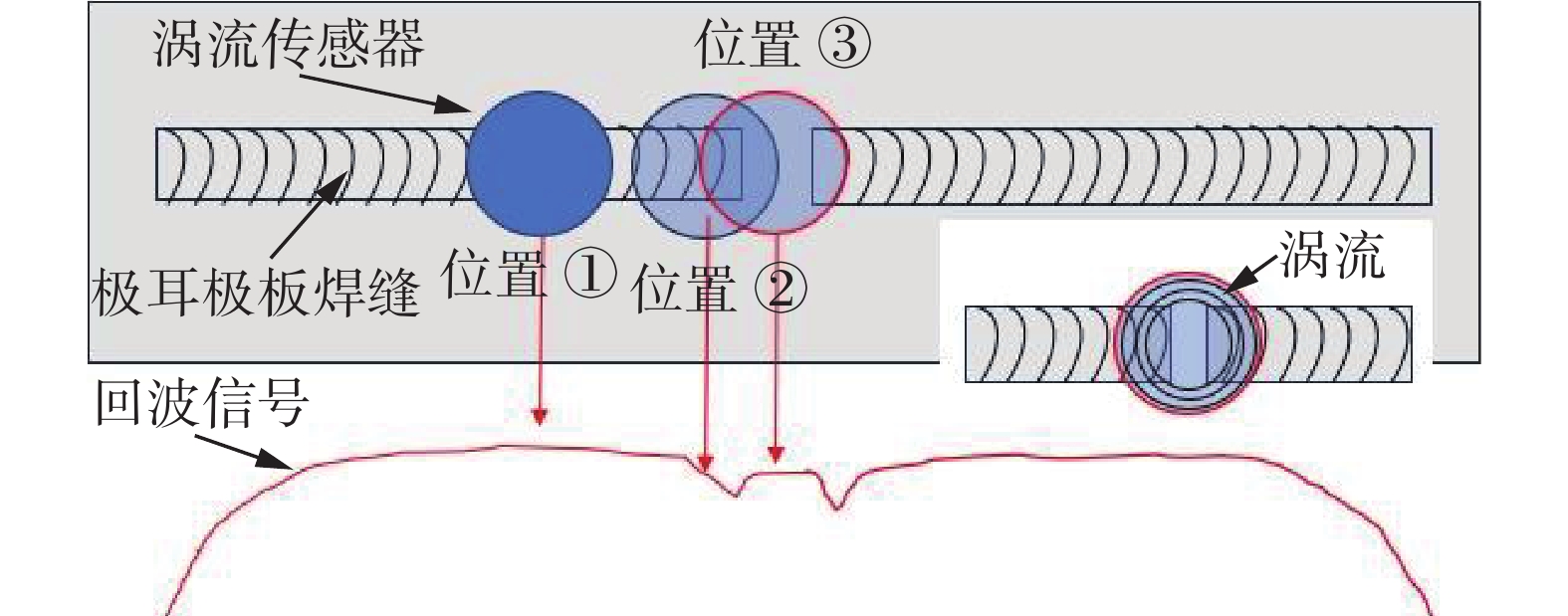

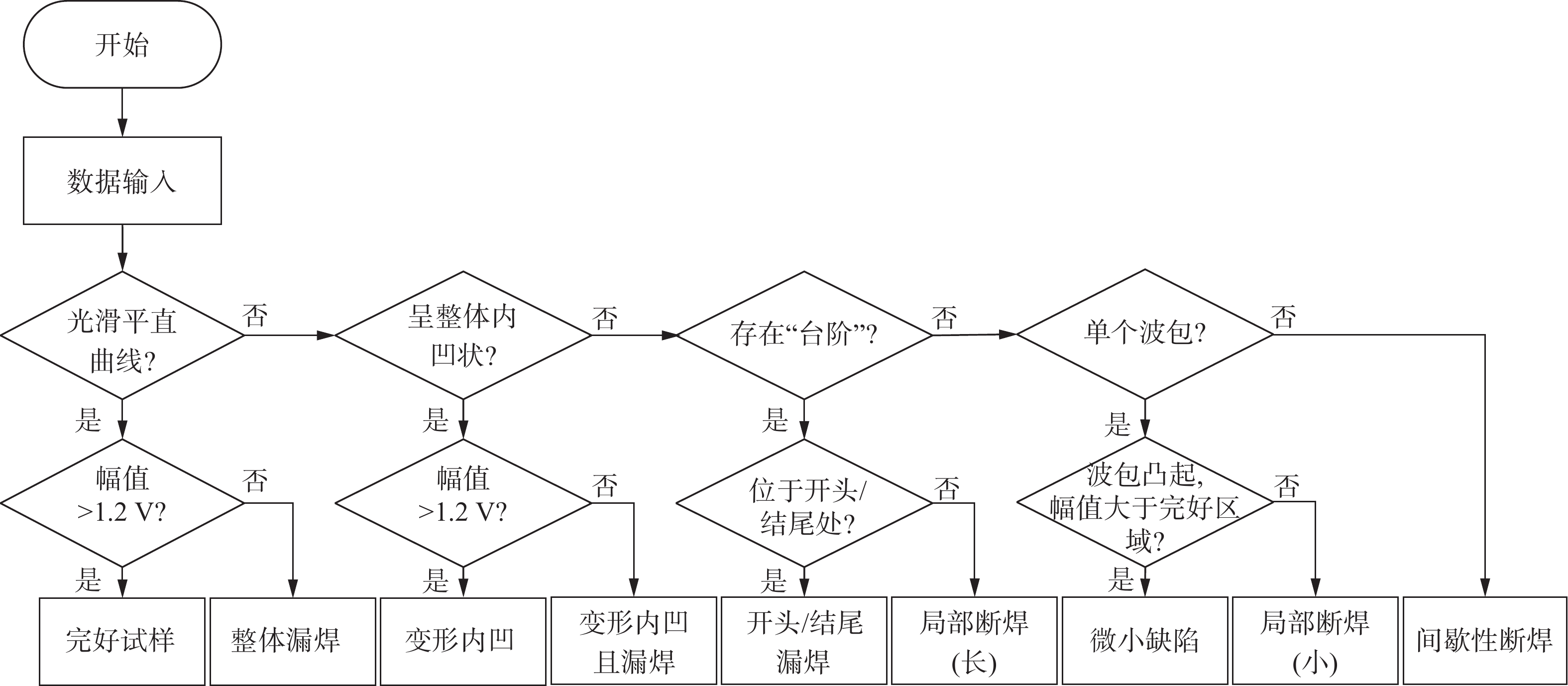

为了实现航空锂电池极耳极板激光焊缝的高效准确检测,设计制作了带有层析成像功能的多通道多频涡流检测系统. 采用该系统及5通道防干扰差分结构涡流传感器对极耳极板焊缝中的局部断焊、整体漏焊、焊缝变形内凹、微小缺陷等典型缺陷进行检测,并基于趋肤效应原理,采用层析成像技术对焊瘤缺陷进行扫查成像. 结果表明,研发的带有层析成像功能的多通道多频涡流检测系统可有效检测出锂电池极耳极板焊缝中的多种典型缺陷,最小可检测$\phi $1 mm的缺陷,层析成像技术可实现不同深度下缺陷的形貌观测. 通过对大量检测结果的对比分析,总结了缺陷种类、位置及长度的判别方法,提出了一套缺陷判别流程与评定准则,为实现锂电池极耳极板焊缝检测的工程化奠定了良好的基础.

Abstract:In order to realize the efficient and accurate detection of laser welds of aviation lithium battery, a multi-channel multi-frequency eddy current detection system with the function of tomographic imaging was designed and developed. The system and the 5-channel anti-interference differential structure eddy current sensor were used to detect the typical defects in the tab polar plate weld, such as local incomplete welding, overall missing welding, weld deformation and concave, and micro defect. Based on the principle of skin effect, tomographic imaging technology was used to scan and image the overlap. The results show that the developed multi-channel multi-frequency eddy current detection system with the function of tomographic imaging can effectively detect a variety of typical defects in the tab polar plate weld of lithium batteries, and the smallest defects can be detected at $\phi $1 mm. The tomographic imaging technology enables the observation of defect morphology at different depths. Through the comparative analysis of a large number of test results, the identification methods of defect type, location and length were summarized, and a set of defect identification process and evaluation criteria were proposed, which laid a good foundation for the engineering realization of the lithium battery weld detection.

-

0. 序言

NiCrMoV低合金钢作为一种超高强钢,综合性能良好,在船舶、压力容器等领域应用广泛[1-2]. 但由于此类高强钢具有较大的淬硬倾向,焊接时容易产生冷裂纹. 且随着强度的提高,其焊接冷裂敏感性就越大,还易导致焊接接头脆化[3-5].

对于NiCrMoV低合金高强钢焊接,除了采用预热措施之外,往往采用奥氏体焊材低强匹配接头抑制冷裂纹的产生,但是会大幅降低高强钢接头强度. 现有的奥氏体焊丝如316L或304不锈钢焊材,得到的焊缝接头强度仅为500 ~ 600 MPa. 因此采用高强度奥氏体焊材焊接超高强钢意义重大. 李大用等人[6]采用高铬镍奥氏体焊丝焊接低合金高强钢,其中氮含量约为0.1%,焊缝主要由树枝状奥氏体组成,无裂纹,接头强度可达800 MPa. 在抑制裂纹的同时可保证强度.

在奥氏体不锈钢体系中,高氮钢以氮部分或全部代替镍合金而形成固溶强化的奥氏体不锈钢,强度可达1 000 MPa[7]. 因此文中拟采用高氮奥氏体焊丝作为填充材料进行超高强钢熔化极气体保护焊(gas metal arc welding, GMAW). 目前对于此类焊丝GMAW工艺研究较少. 针对8 mm厚超高强钢板对接,初步探索了利用高氮钢焊丝GMAW工艺,分析在60°和90°不同的坡口角度下接头组织和力学性能,为超高强钢焊接提供了新思路.

1. 试验方法

试验使用直径1.0 mm的高氮奥氏体钢焊丝作为填充材料,超高强钢板为母材,试板尺寸300 mm × 200 mm × 8 mm. 所用焊丝和母材成分如表1所示.

表 1 焊丝与母材化学元素组成(质量分数,%)Table 1. Chemical component of wire and substrate材料 C Ni Cr Mo Mn Si N 焊丝 0.071 2.32 21.59 1.21 16.95 — 0.79 母材 0.32 1.8 1.0 0.7 1.2 0.4 — 采用CMT + P焊接模式,先正面焊一道,然后背部清根,反面焊一道. 工艺参数为正面送丝速度10 m/min,反面送丝速度9.5 m/min,焊接速度4 mm/s. 保护气体为93.5% Ar + 1.5% O2 + 5% N2,气体流量20 L/min. 坡口形式分别为60°和90°坡口,上下深度比为5∶3. 考虑到焊枪的可达性及减少侧壁未熔合,间隙为3 mm. 拉伸试件按国家标准GBT 2651—2008《焊接接头拉伸试验方法》加工.

2. 试验结果分析

2.1 焊缝宏观形貌

图1是超高强钢高氮奥氏体焊丝熔化极电弧焊接的焊缝宏观形貌和接头纵向截面宏观形貌. 接头成形良好,焊材与母材之间形成冶金结合,接头纵向截面未见气孔、裂纹等缺陷.

2.2 显微组织分析

图2~图4为不同坡口焊缝与热影响区组织形貌. 热影响区可分为明显的粗晶区和细晶区,均为马氏体组织,如图2a,2b,3a,3b所示,对硬度影响较大. 焊缝的组织主要是被奥氏体基体所包围的铁素体树枝晶,且铁素体枝晶很密集. 除此之外,在枝晶中间还有一些“粒状”铁素体散乱的分布在整个金相中,被奥氏体基体所包围,如图2c,3c所示. 两种坡口的焊缝金属和母材金属在结合处的“白亮带”区域有着明显的模糊状态,有相互渗透的现象,并观察到该区是奥氏体与马氏体的混合组织,如图4所示.

两种坡口接头熔合线附近热影响区组织和焊缝组织基本一致. 不同的是,90°坡口焊缝附近热影响区马氏体组织较60°的更细小,同时90°坡口热影响区马氏体和奥氏体的混合组织区的范围比60°的小. 在相同的热输入参数下90°坡口相比60°坡口,不仅能让电弧充分达到焊缝底部,且在相同的深度下,90°坡口与电弧的接触面积更大,熔池凝固快. 60°坡口情况则相反,熔池存在时间更长,这个过程提供了晶粒继续长大的条件,因此60°坡口热影响区马氏体和奥氏体混合组织区较90°的大,相应的马氏体组织也较为粗大. 同时,60°坡口焊缝区也受到影响,组织相对粗大.

如图5所示,在200 ~ 240 μm的热影响区到焊缝的过渡区,核心元素都有一个线性变化的过程,过渡区的存在说明焊缝金属和母材金属有着充分的冶金结合. 但如图4所示,90°坡口的渗透区域相对60°坡口的更大,且相对更均匀.

2.3 显微硬度

如图6所示1和2分别为60°坡口和90°坡口的硬度分布,硬度取样区域线见图1,两种硬度分布是一致的. 硬度按从母材-热影响区-焊缝的顺序依次测量,经过的组织依次为母材马氏体组织-马氏体细晶组织-混合组织-奥氏体组织. 根据图6各组试样的横向硬度分布可知,硬度最高区域主要集中在2.5 ~ 4 mm和7.5 ~ 9 mm的区域内,该区域的维氏硬度在450 ~ 590 HV之间,60°坡口该区硬度平均值为508 HV,90°坡口该区硬度平均值为536 HV. 在硬度显微镜下观测该硬度较高的区域主要为马氏体细晶区. 其中马氏体细晶区的硬度值均在500 HV及以上,平均可达530 HV;在热影响区到焊缝区的过渡区(3.5 ~ 4 mm),该区组织硬度相对马氏体细晶区有一个下降过程,主要是因为该区是马氏体组织和奥氏体组织的混合组织,该区组织相对不均匀,所以该区域的硬度有个下降过程. 由图6可知,硬度最低的区域主要为4.5 ~ 7 mm区域,均在300 HV以下,平均硬度仅在275 HV左右. 该区域是焊缝区,其组织主要以奥氏体为基体的树枝状铁素体晶粒组织,故硬度较低,两种坡口在该区硬度值相差不大.

2.4 拉伸试验

从图7可以看出,60°坡口试样主要是从焊缝位置断裂,部分沿熔合线附近位置断裂,90°坡口试样主要沿熔合线附近位置断裂. 每个试样均有颈缩现象发生. 如表2所示,采用高氮奥氏体钢焊丝获得的接头平均抗拉强度可达850 MPa,该强度是在90°坡口下获得的. 60°坡口接头的抗拉强度则与之相差较大,仅为690 MPa. 对于不同坡口接头的拉伸力学性能变化与微观组织的某些区域的大小以及晶粒的大小有关. 在相同的坡口深度下,60°坡口侧壁与电弧的接触面积更小,其熔池存在时间更长,该过程为焊缝组织晶粒继续长大提供了条件,因此60°坡口焊缝区组织晶粒更粗大,其拉伸性能较低. 对于90°坡口其与电弧的接触面积更大,其熔池凝固快,晶粒相对较小,因此强度更高,并且由于混合组织区较宽,该区域成分介于母材和焊丝之间,得到的性能相对较低,所以90°坡口多断在此处.

表 2 接头抗拉强度 (MPa)Table 2. Tensile strength of joint坡口角度 试样1 试样2 试样3 平均抗拉强度 60° 720 678 672 690 90° 887 834 829 850 3. 结论

(1) 采用高氮奥氏体丝材进行超高强钢GMAW工艺,可以获得成形良好的焊接接头.

(2) 高氮钢焊缝金属和超高强钢母材金属在接头熔合线处有着明显的“白亮带”存在,有相互渗透的现象,说明焊材和母材有着充分的冶金结合.

(3) 采用上述工艺中60°坡口进行焊接,接头热影响区马氏体组织晶粒较大,且马氏体、奥氏体混合组织过渡区小;而90°坡口焊接接头热影响区马氏体组织晶粒更细小,且马氏体、奥氏体混合组织过渡区较大.

(4) 采用高氮奥氏体焊丝进行GMAW焊接,90°坡口可获得接头抗拉强度(850 MPa)高于60°坡口接头抗拉强度(690 MPa). 90°坡口试样马氏体细晶区硬度平均值为536 HV,高于60°坡口试样(508 HV).

-

图 5 多通道多频涡流检测人工试样实物图

Figure 5. Multi-channel multi-frequency eddy current testing manual sample. (a) weld sample without defect; (b) weld sample with local incomplete welding (2 mm); (c) weld sample with intermittent incomplete welding; (d) weld sample with overall missing welding; (e) weld sample with missing weld at the beginning/end; (f) weld sample with deformation and concave; (g) weld sample with local micro defect ($\phi $1 mm)

图 6 自制涡流检测系统对典型缺陷人工试样检测结果

Figure 6. Test results of manual samples with typical defects by self-made eddy current test system. (a) echo signals of no defect and overall missing weld specimen; (b) echo signals of localized incomplete weld (2 mm) and intermittent incomplete weld specimen; (c) echo signals of beginning/end missing weld specimen; (d) echo signals of weld deformation concavity and localized micro defect

表 1 不同频率对应的电池极板趋肤深度

Table 1 Different frequencies correspond to the skin depth of the battery plate

激励频率f /kHz 趋肤深度δ/mm 激励频率f /kHz 趋肤深度δ/mm 1 3.00 6 1.22 2 2.12 7 1.13 3 1.73 8 1.06 4 1.50 9 1.00 5 1.34 10 0.95 -

[1] 贾志杰, 高峰, 杜世伟, 等. 磷酸铁锂电池不同应用场景的生命周期评价[J]. 中国环境科学, 2022, 42(4): 1975 − 1984. doi: 10.3969/j.issn.1000-6923.2022.04.055 Jia Zhijie, Gao Feng, Du Shiwei, et al. Life cycle assessment of lithium iron phosphate battery in different utilization scenarios[J]. Chinese Environmental Science, 2022, 42(4): 1975 − 1984. doi: 10.3969/j.issn.1000-6923.2022.04.055

[2] 刘国刚, 陈龙, 黄昊鹏, 等. 锂电池高纯氧化铝的制备及应用研究进展[J]. 电源技术, 2023, 47(4): 421 − 425. Liu Guogang, Chen Long, Huang Haopeng, et al. Research progress on preparation of high purity alumina and its application in lithium battery[J]. Power Technology, 2023, 47(4): 421 − 425.

[3] 张世超, 沈泽宇, 陆盈盈. 金属锂电池的热失控与安全性研究进展[J]. 物理化学学报, 2021, 37(1): 55 − 72. Zhang Shichao, Shen Zeyu, Lu Yingying. Research progress of thermal runaway and safety for lithium metal batteries[J]. Journal of Physical Chemistry, 2021, 37(1): 55 − 72.

[4] Feng X N, Zheng S Q, Ren D S, et al. Key characteristics for thermal runaway of Li-ion batteries[J]. Energy Procedia, 2019, 158: 4684 − 4689.

[5] Wang Q S, Mao B B, Stoliarov S I, et al. A review of lithium- ion battery failure mechanisms and fire prevention strategies[J]. Prog Energy Combust Science, 2019, 73: 95 − 131. doi: 10.1016/j.pecs.2019.03.002

[6] 杨传礼, 张修庆. 基于机器视觉和深度学习的材料缺陷检测应用综述[J]. 材料导报, 2022, 36(16): 222 − 230. doi: 10.11896/cldb.20070136 Yang Chuanli, Zhang Xiuqing. Survey of applications of material defect detection based on machine vision and deep learning[J]. Material Guide, 2022, 36(16): 222 − 230. doi: 10.11896/cldb.20070136

[7] 王露. 基于机器视觉的锂电池极片缺陷检测与分类系统 [D]. 西安: 西安科技大学, 2020. Wang Lu. Defect detecting and classification system of the lithium battery pole piece based on machine vision[D]. Xi 'an: Xi 'an University of Science and Technology, 2020.

[8] 王诗文. 锂电池极耳焊接缺陷的自动光学检测研究 [D]. 哈尔滨: 哈尔滨工业大学, 2017. Wang Shiwen. Automated optical inspection of tabs welding defects in lithium batteries[D]. Harbin: Harbin Institute of Technology, 2017.

[9] 黄锴. 基于超声波成像技术的锂离子电池电解液浸润性研究 [D]. 武汉: 华中科技大学, 2019. Huang Kai. Study on filling process of lithium-ion battery electrolyte based on ltrasonic imaging[D]. Wuhan: Huazhong University of Science and Technology, 2019.

[10] 邓哲. 锂电池超声扫描成像技术及其应用 [D]. 武汉: 华中科技大学, 2021. Deng Zhe. A thesis submitted in partial fulfillment of the requirements for the degree of doctor of philosophy in engineering[D]. Wuhan: Huazhong University of Science and Technology, 2021.

[11] 邬冠华, 熊鸿建. 中国射线检测技术现状及研究进展[J]. 仪器仪表学报, 2016(8): 1683 − 1695. doi: 10.3969/j.issn.0254-3087.2016.08.001 Wu Guanhua, Xiong Hongjian. Radiography testing in China[J]. Chinese Journal of Instrument, 2016(8): 1683 − 1695. doi: 10.3969/j.issn.0254-3087.2016.08.001

[12] 马天翼, 苏素, 张宗, 等. 计算机断层扫描技术在锂离子电池检测中的应用研究[J]. 重庆理工大学学报, 2020, 34(2): 133 − 139. doi: 10.3969/j.issn.1674-8425(z).2020.02.019 Ma Tianyi, Su Su, Zhang Zong, et al. Application of computed tomography in lithiumion battery detection[J]. Journal of Chongqing University of Technology, 2020, 34(2): 133 − 139. doi: 10.3969/j.issn.1674-8425(z).2020.02.019

[13] Zhang Kai, Ren Fang, Wang Xuelong, et al. Finding a needle in the haystack: Identification of functionally important minority phases in an operating battery[J]. Nano letters, 2017, 17(12): 7782 − 7788. doi: 10.1021/acs.nanolett.7b03985

[14] 南京奥科特创智能科技有限公司. 一种基于超声和红外探伤对锂电池的检测方法: CN202111090945.3[P]. 2022-01-07. Nanjing Aoke Chuang Intelligent Technology Co. , LTD. The invention relates to a detection method for lithium battery based on ultrasonic and infrared flaw detection: CN202111090945.3[P]. 2022-01-07.

[15] 王伟, 黄平, 周家宁, 等. 航空锂电池极耳焊缝微缺陷检测系统研究[J]. 无损探伤, 2023, 47(2): 4. Wang Wei, Huang Ping, Zhou Jianing, et al. Research on micro-defect detection system of tab welding seam of aviation lithium battery[J]. Non-destructive Testing, 2023, 47(2): 4.

[16] 周兆逸, 张亚南, 王肖锋, 等. 基于改正二维主成分分析的焊缝表面缺陷检测[J]. 焊接学报, 2021, 42(11): 70 − 76. doi: 10.12073/j.hjxb.20210412001 Zhou Zhaoyi, Zhang Ya’nan, Wang Xiaofeng, et al. Weld surface defect detection based on improved twodimensional principal component analysis[J]. Transactions of the China Welding Institution, 2021, 42(11): 70 − 76. doi: 10.12073/j.hjxb.20210412001

下载:

下载: