Study on the longitudinal superplastic properties of TC4 titanium alloy laser welded joint with rare earth elements

-

摘要:

针对钛合金激光焊接接头超塑性能低的难题,提出在焊缝中以Yb2O3的方式添加稀土Yb元素,分析Yb2O3含量对TC4钛合金激光焊接头高温拉伸峰值流变应力、断后伸长率及组织的影响.结果表明,Yb2O3能够促进变形过程的组织等轴化进程,减小焊缝β晶粒尺寸和接头超塑性变形流变应力,并提高断后伸长率.随着Yb2O3含量增加,接头应力应变曲线下移,峰值流变应力呈先降低后升高的趋势,而断后伸长率则为先增大后减小.在超塑性变形过程中,Yb2O3含量6%时峰值流变应力最低为11.9 MPa,断后伸长率为572.3%;焊缝中心β晶粒尺寸最小为127 μm,相较于未添加Yb2O3时β晶粒尺寸的337 μm细化了62.3%.此时,马氏体组织发生相变,形态转变成片层,焊缝区域组织等轴化程度最高,焊缝的超塑性能最好.

Abstract:Aiming at the problem of low superplasticity of titanium alloy laser welded joints, this paper proposes to add rare earth Yb element in the form of Yb2O3 in the weld, and analyzes the effects of Yb2O3 content on the peak flow stress, elongation and microstructure of laser welded joint of TC4 titanium alloy at high temperature. The results show that Yb2O3 can reduce the β grain size of the weld and the superplastic deformation flow stress of the joint, increase the elongation, to promote the equiaxed process of the deformation process. With the increase of Yb2O3 content, the stress-strain curve of the joint moves down, the peak flow stress decreases first and then increases, while the elongation increases first and then decreases. In the process of superplastic deformation the lowest peak flow stress is 11.9 MPa and the elongation is 572.3% when the content of Yb2O3 is 6%. The minimum grain size of β in the weld center is 127 μm, which is 62.3 % finer than the 337 μm of the β grain size without Yb2O3. At this time, the martensitic structure undergoes phase transformation, the morphology changes into lamellar, the degree of equiaxed structure in the weld area is the highest, and the superplasticity of the weld is the best.

-

Keywords:

- Yb2O3 content /

- laser welding /

- TC4 titanium alloy /

- superplastic properties

-

0. 序言

钛合金焊接/超塑成形组合技术能够一次成形轻量化空心结构,在航空航天领域具有广泛应用,目前应用主要在扩散焊接/超塑成形技术上,而激光焊/超塑成形技术具有效率高、加工灵活、无需真空等优势,具有很大的应用潜力[1-5].然而,TC4钛合金激光焊缝组织为针状马氏体组成的网篮组织,其强度高、塑性低,尤其是在超塑性成形时,焊缝变形所需应力大,变形小,难以满足加工和设计需要.

针对TC4钛合金激光焊缝超塑性能的调控主要包括热处理、置氢处理等方法,这些方法均是通过焊后处理调节母材的变形能力,达到和焊缝变形相协调的目的.关于TC4钛合金焊缝组织性能调控的研究很少.添加稀土元素是调控合金组织性能的一种可行方法,稀土元素以单质、氧化物或金属间化合物形态出现在合金组织中,起到净化、改性和微合金化作用[6-10].Castro等人[11]通过在锻造状态下的CP-Ti(商用纯钛)中添加不同含量的Yb2O3来探究稀土氧化物对钛的弥散效果.发现Yb2O3在CP-Ti中表现出明显的弥散强化特征,Y2O3阻碍了位错的滑移,使得峰值强度大幅上升.因此,稀土Yb能够在不同的铝、镁合金中生成金属间化合物,这些化合物的析出能起到钉扎阻碍作用,进而限制动态再结晶行为达到细化晶粒的作用,提升材料的塑性和强度[12-16].

稀土元素Yb由于其经济性在铝、镁等合金中应用较为广泛,但鲜少有报道Yb元素对钛合金的影响.本文以Yb2O3的方式添加Yb元素,分析Yb2O3的含量对TC4钛合金激光焊接接头超塑性变形能力的影响,并观察组织结构,为钛合金激光焊/超塑成形技术的实际应用提供理论依据.

1. 试验方法

试验材料为2 mm厚退火态TC4钛合金板,填充粉末为TC4钛合金与Yb2O3混合粉末,其中TC4钛合金粉末粒径为35 μm,纯度为99.9%;Yb2O3粉末粒径为10 μm,纯度为99.98%.

采用德国IPG Photonics公司制造的IPG YLS-6000系列光纤激光器进行焊接,焊接工艺参数为2000 W,焊接速度2.2 m/min.

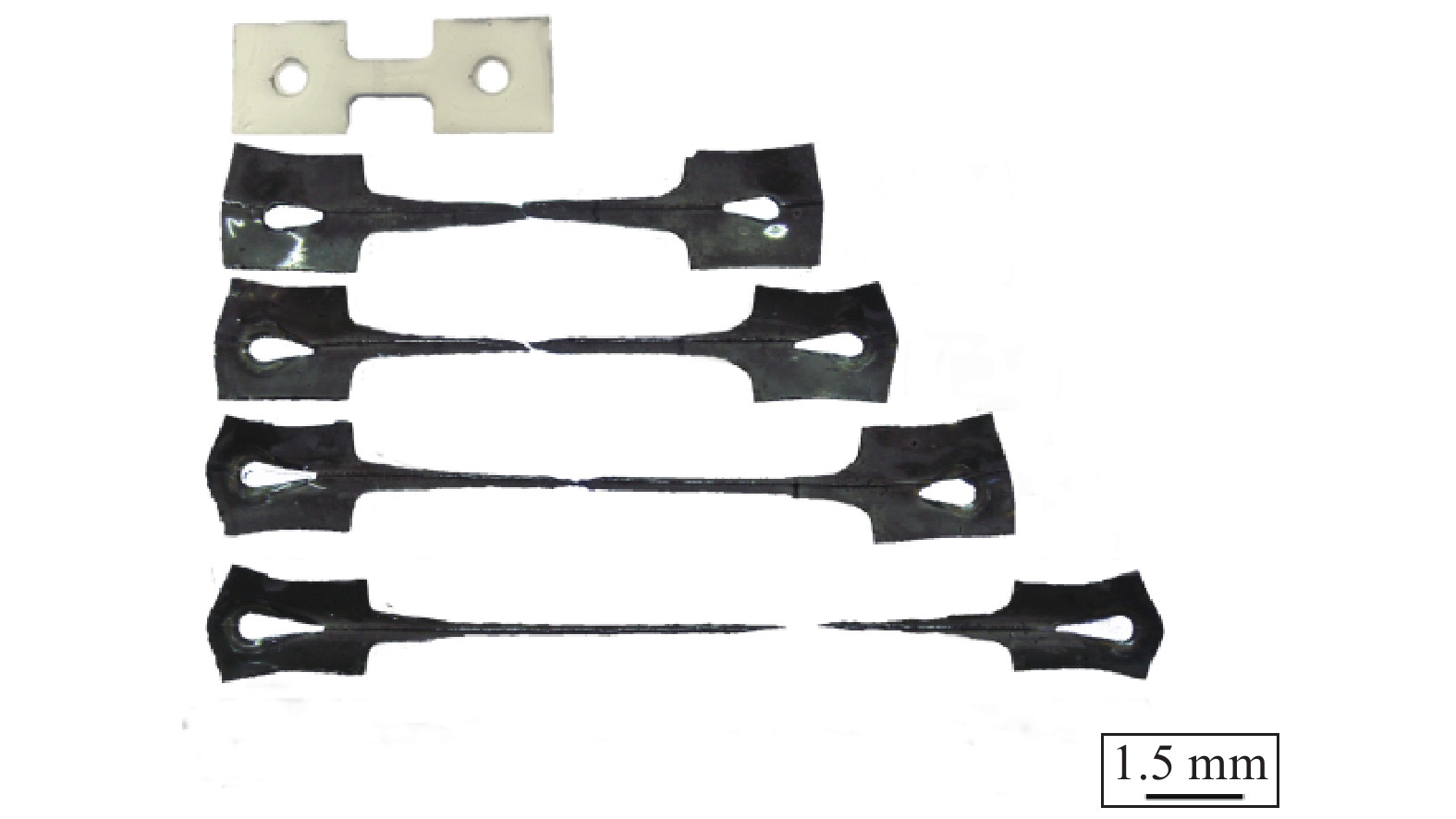

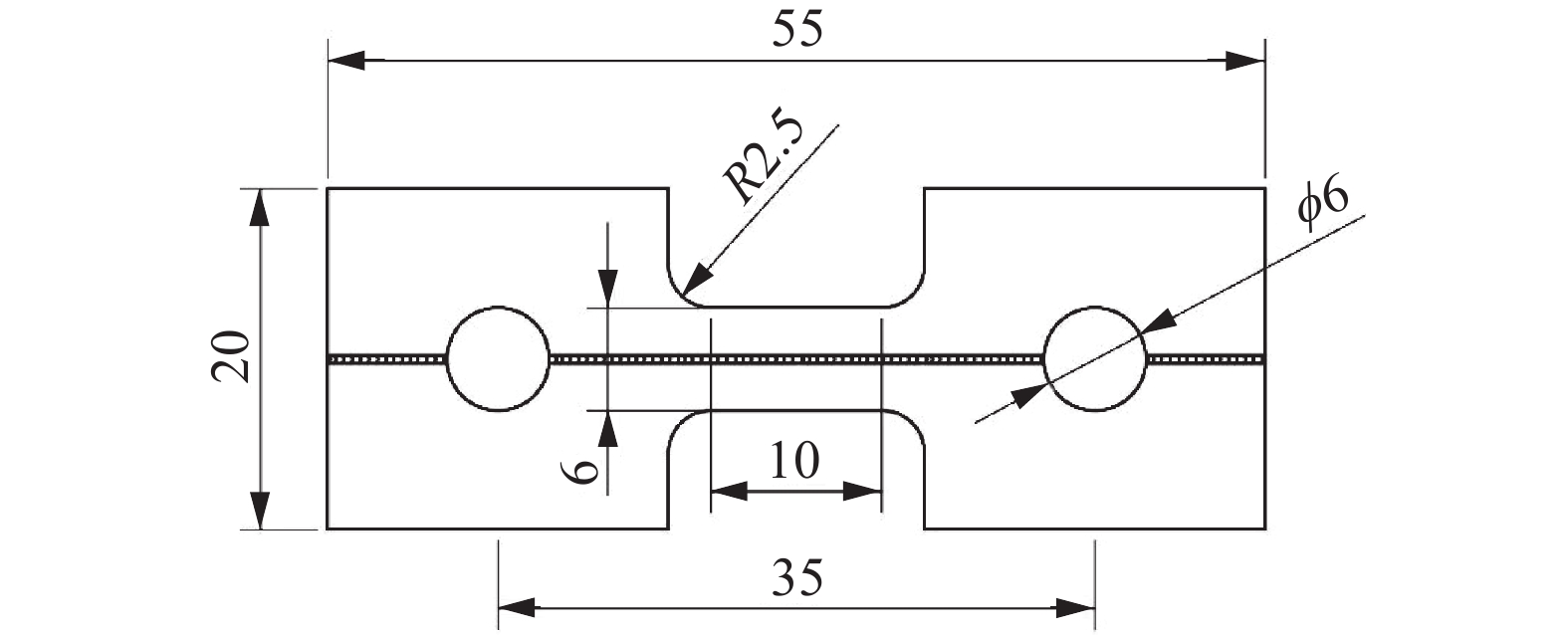

超塑变形试验在CMT4104型高温拉伸机上进行,图1为高温拉伸试样尺寸.超塑性变形中高温变形温度880-920 ℃,初始应变速率分别为1 × 10−2 s−1和1 × 10−3 s−1.采用接头纵向高温试样研究添加Yb2O3对接头变形能力的影响.采用金相显微镜、扫描电子显微镜观察焊缝组织分布规律及形态变化,采用Image J软件计算晶粒尺寸.

2. 试验结果与讨论

2.1 接头纵向超塑性能研究

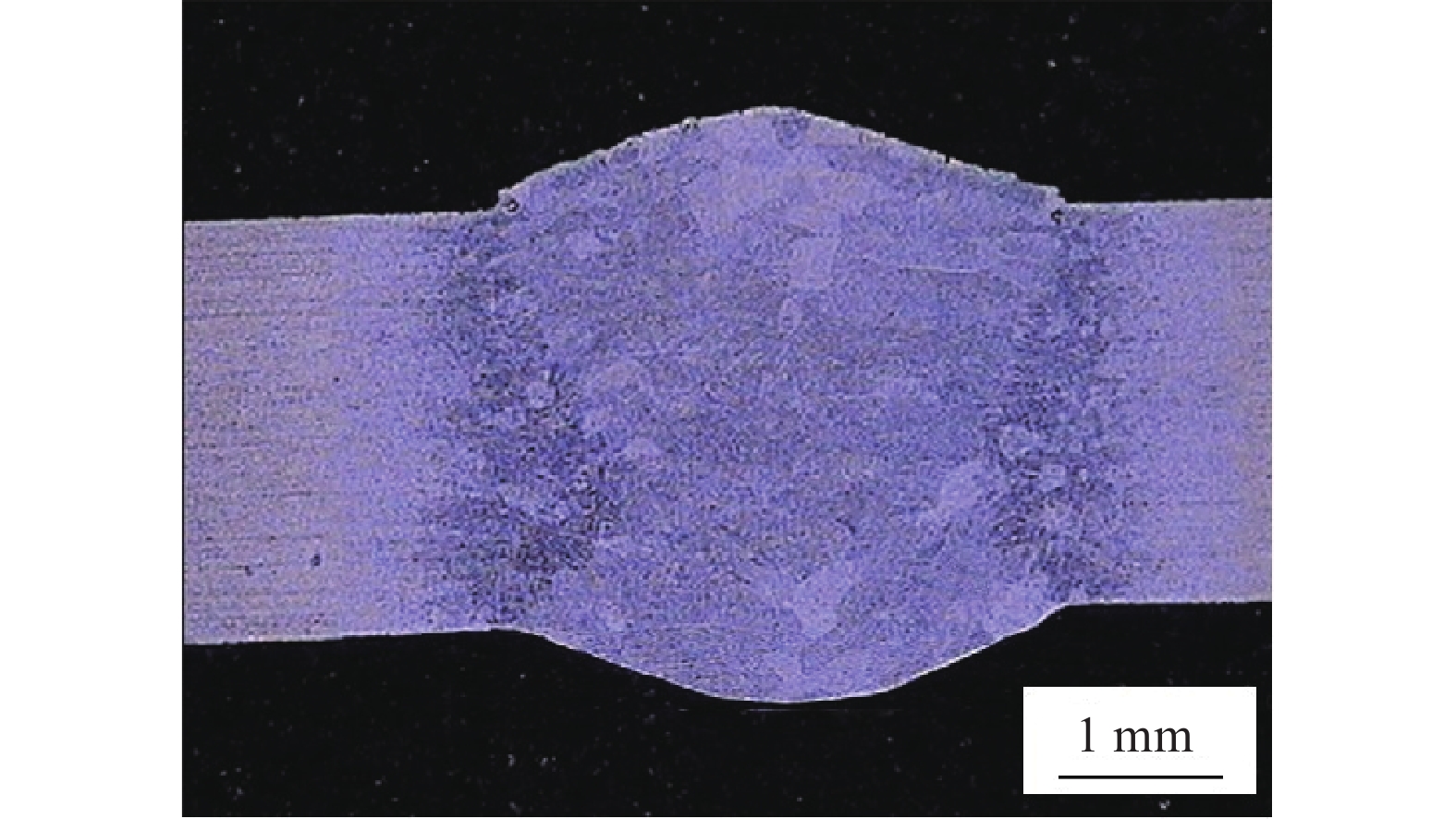

图2是未添加Yb2O3,焊接功率2000 W,焊接速度2.2 m/min时获得的接头宏观形貌.焊缝表面成形良好,无明显缺陷和烧损氧化现象.为单独分析Yb2O3添加对钛合金激光焊接头组织的作用排除了其他缺陷对接头组织性能造成的影响.

图3为纵向接头试样高温拉伸宏观断裂图.接头纵向超塑性变形过程变形均匀,未出现突然颈缩断裂,这也保证了纵向接头试样在超塑变形过程能获得较大的断后延伸率,呈现了超塑性变形能力.

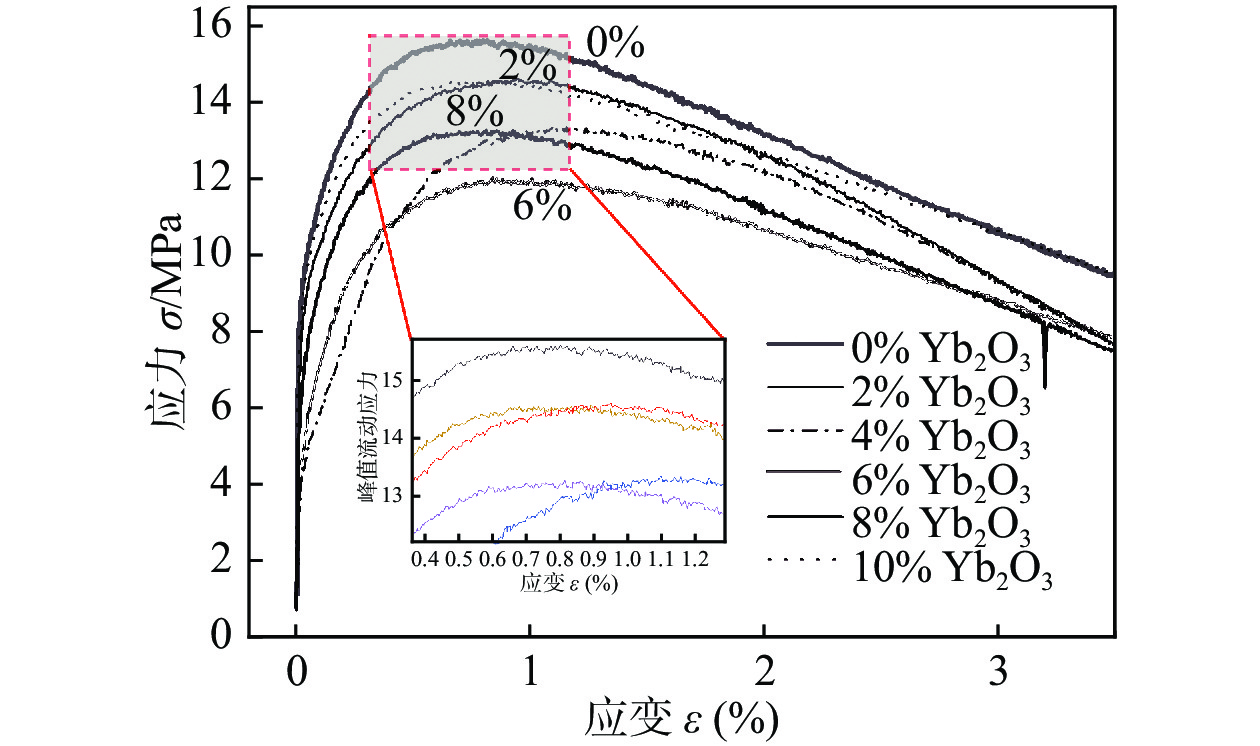

图4是变形温度为920 ℃,应变速率为1 × 10−3 s−1条件下不同Yb2O3含量的接头纵向变形应力应变曲线.随着应变的增加应力迅速升高到最大值,而后缓慢平稳降低直到断裂.从曲线局部放大可看到线条并不平滑,呈现明显的抖动,说明在拉伸过程中应力正在迅速发生变化,呈现颈缩与抗颈缩的自适应超塑性变形特征.这都表明试样具有良好的超塑性变形能力.另外,加入Yb2O3后的试样应力应变曲线下移、低于未加试样的曲线,且应力下降趋势更平缓.说明Yb2O3的加入提高了接头的超塑性能,使得试样流变应力降低,超塑变形更平稳.这主要是因为Yb2O3的加入能够细化焊缝晶粒,并且调控焊缝中的马氏体分布,使其更容易在超塑性变形过程中发生滑移运动,进而超塑性能提高.

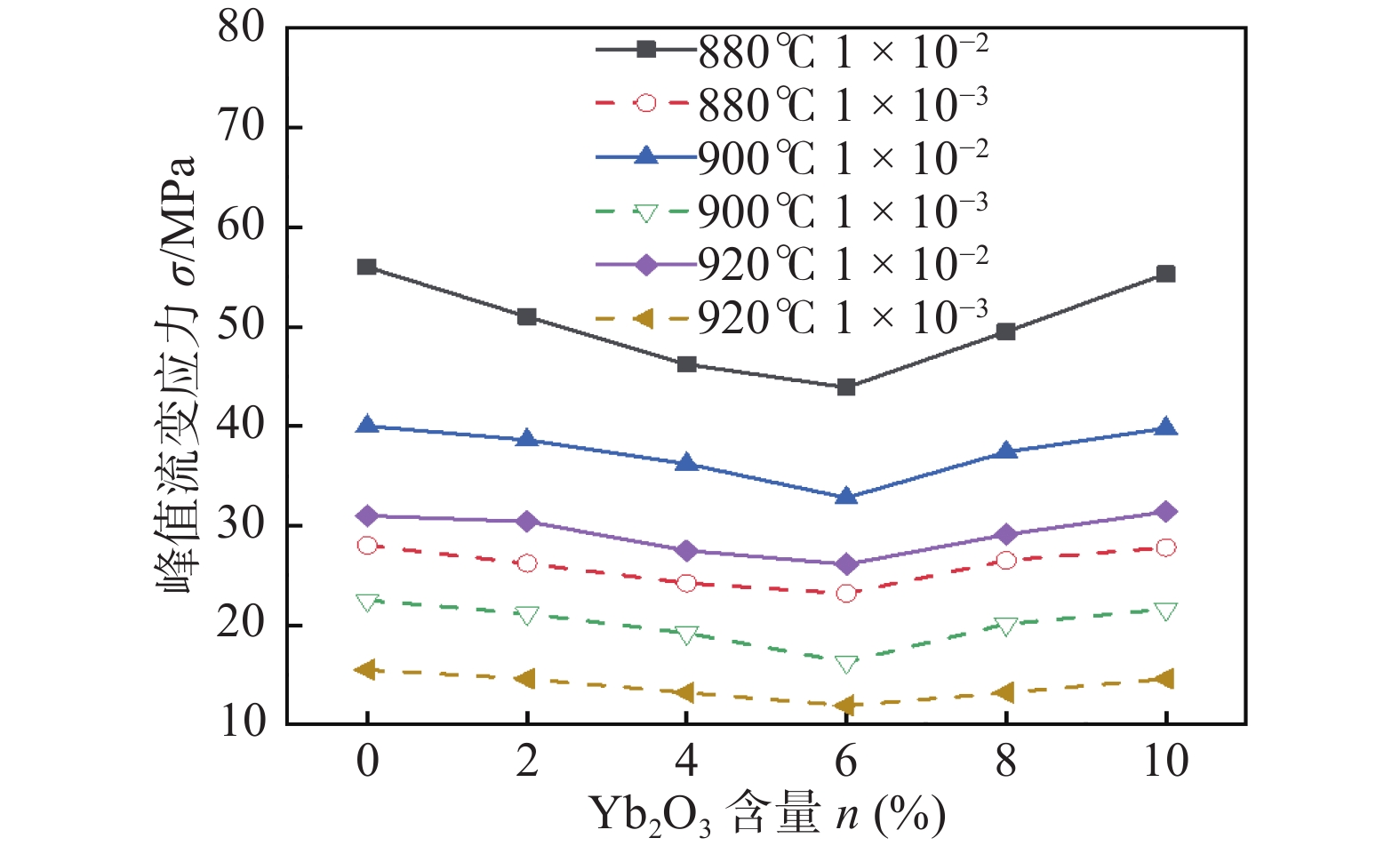

图5为Yb2O3含量对接头变形峰值流动应力的影响.添加Yb2O3的试样其峰值流变应力均低于未添加Yb2O3的试样,而试样的断后延伸率均大于未添加Yb2O3的高温拉伸试样,这说明Yb2O3的加入能够提高接头超塑变形能力.由变形温度880 ℃,应变速率1 × 10−2 s−1的峰值流变应力变化趋势可知,接头超塑变形能力对Yb2O3的含量较为敏感.试样的峰值流变应力随着Yb2O3含量的增加先下降后增加,当接头中Yb2O3的含量为6%(质量分数)时,Yb2O3对纵向接头高温试样超塑性能影响最为显著.此时试样的峰值流变应力最小为43.9 MPa,相对于未添加Yb2O3的焊接试样,峰值流变应力减小了21.6%.

超塑变形机制主要是晶界滑移,晶体中的原子通过沿着晶面的滑移面滑动,实现材料超塑性变形.Yb2O3的适量增加一方面对焊缝晶粒产生了积极的晶粒细化作用,α晶粒形态也由片层状趋向于等轴球化,更利于晶界的滑动转动;另一方面有效促进了焊缝晶粒的动态再结晶,生成细小的等轴晶粒.这些细小的等轴化晶粒为焊缝提供了较多的晶界面积,进而有效增加了焊缝区域的滑移系数量.在热与力的相互作用下,这些数量较大的短小晶界能够促进位错的滑移,大幅缓解焊缝变形过程的应力集中,进而软化了纵向接头高温试样高温变形抗力.随着接头中Yb2O3含量持续上升,纵向接头试样的超塑性能开始逐步下降.当焊缝中Yb2O3含量为10%时,试样的峰值流变应力为55.3 MPa,相对于焊缝中Yb2O3的含量为6%时的焊接试样,峰值流变应力增加了26%. 这表明过量的添加会降低试样的超塑变形能力,Yb2O3的含量需要得到有效地控制.同时,变形温度和应变速率对接头峰值流动应力也有一定的影响,随着变形温度的升高和应变速率的下降,接头峰值流动应力降低,这主要是因为变形温度的提高和应变速率的降低都有利于材料的软化变形,峰值流动应力整体下降,但Yb2O3含量的影响趋势更加平缓.当变形温度提高到920 ℃、1 × 10−3s−1后,Yb2O3的含量为6%时接头峰值流动应力最低为11.9 MPa.

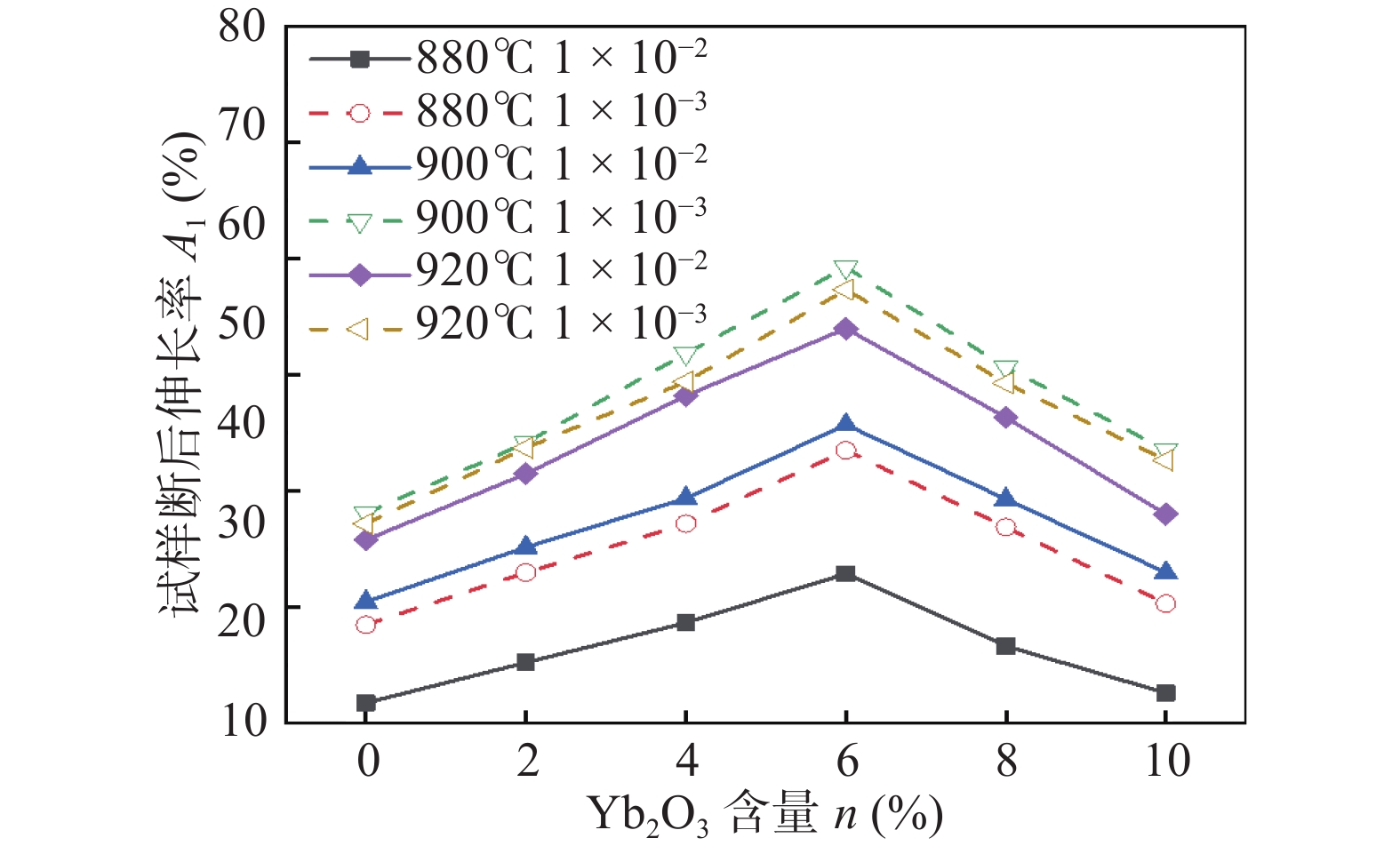

图6是Yb2O3含量对接头延伸率的影响.随着Yb2O3含量的升高接头断后伸长率先升高再降低,当含量为6%的时候断后伸长率达到最高.Yb2O3含量、变形温度、应变速率三个因素均能对接头的超塑性变形产生影响.适量Yb2O3能调控焊缝晶粒大小以及马氏体分布,使得接头组织更容易发生滑移,改善焊缝超塑性变形能力,提高接头断后伸长率.随着应变速率的降低,接头断后伸长率升高.焊缝在超塑性变形过程中马氏体组织要发生相变转变成α + β相,且形态从针状长大为片层状,继而片层断裂进行等轴化.这些变化均需要时间完成,当应变速率越低时,焊缝更容易适应组织的转变,变形也能持续进行更充分,超塑性能也就更强,断后伸长率更大.随着变形温度升高,断后伸长率总体是升高的趋势,因为变形温度越高,材料内能量越高,活性越强,晶粒发生相变、晶界滑移、动态再结晶等也越容易,超塑性进行更充分,断后伸长率越大.然而图6显示在6%的Yb2O3含量、应变速率1 × 10−3 s−1时,900 ℃的断后伸长率为592.2%大于920 ℃时的572.3%,一方面900 ℃、920 ℃时温度较高,对接头的软化促进效果难以大幅度提升,在此两温度下断后伸长率变化不明显,仅有20%左右的差异;另一方面,900 ℃时试样的流变应力大于920 ℃的试样,为协调颈缩与抗颈缩的过程,900 ℃时试样的流变应力变化更剧烈,在最后颈缩断裂时,可能同时多个颈缩有较大量的变形,进而提高了试样断后伸长率.

2.2 组织分析

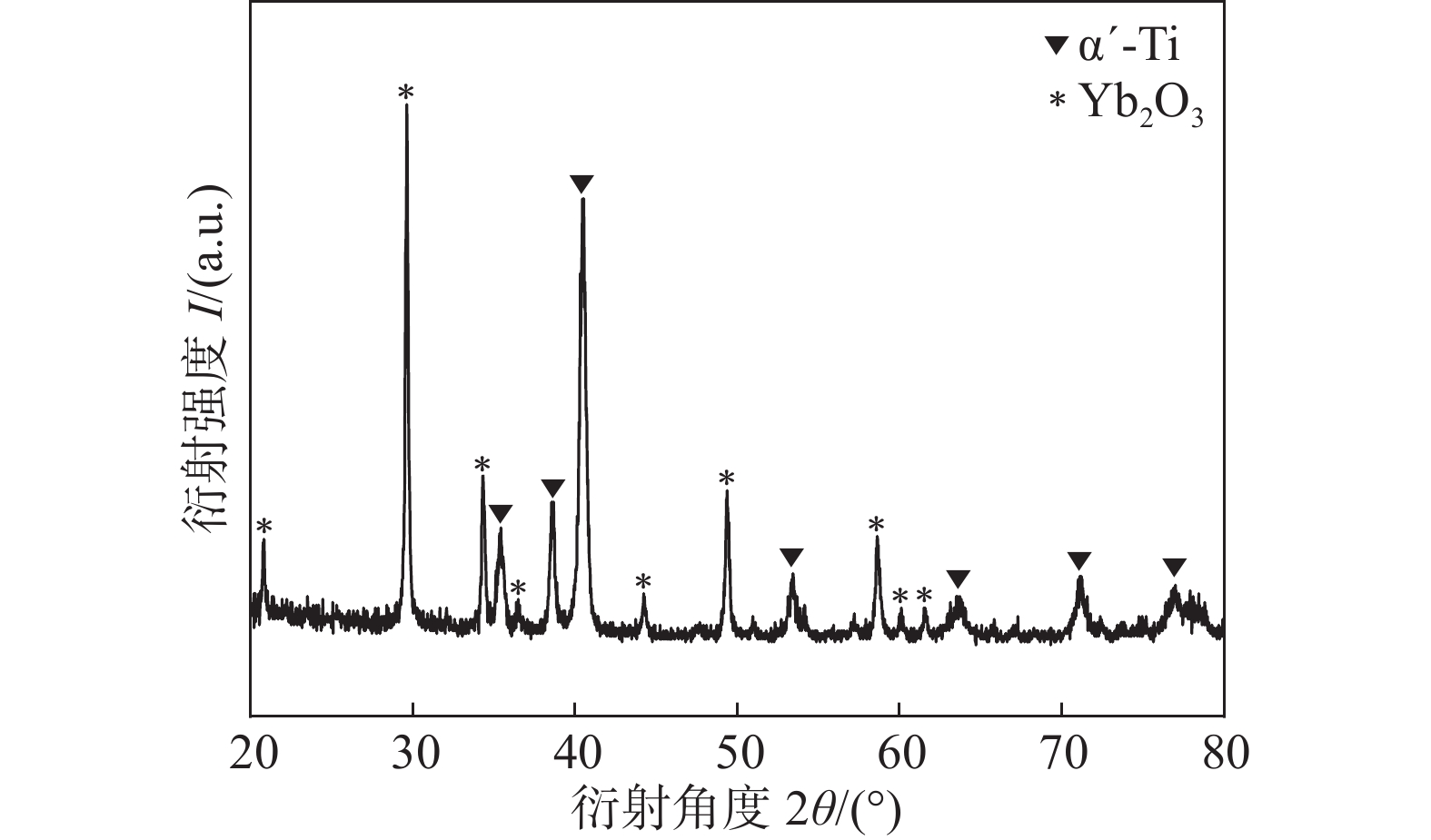

图7是Yb2O3添加含量为6%时的钛合金接头X衍射图.由图可知,焊缝中存在α′马氏体及Yb2O3化合物.

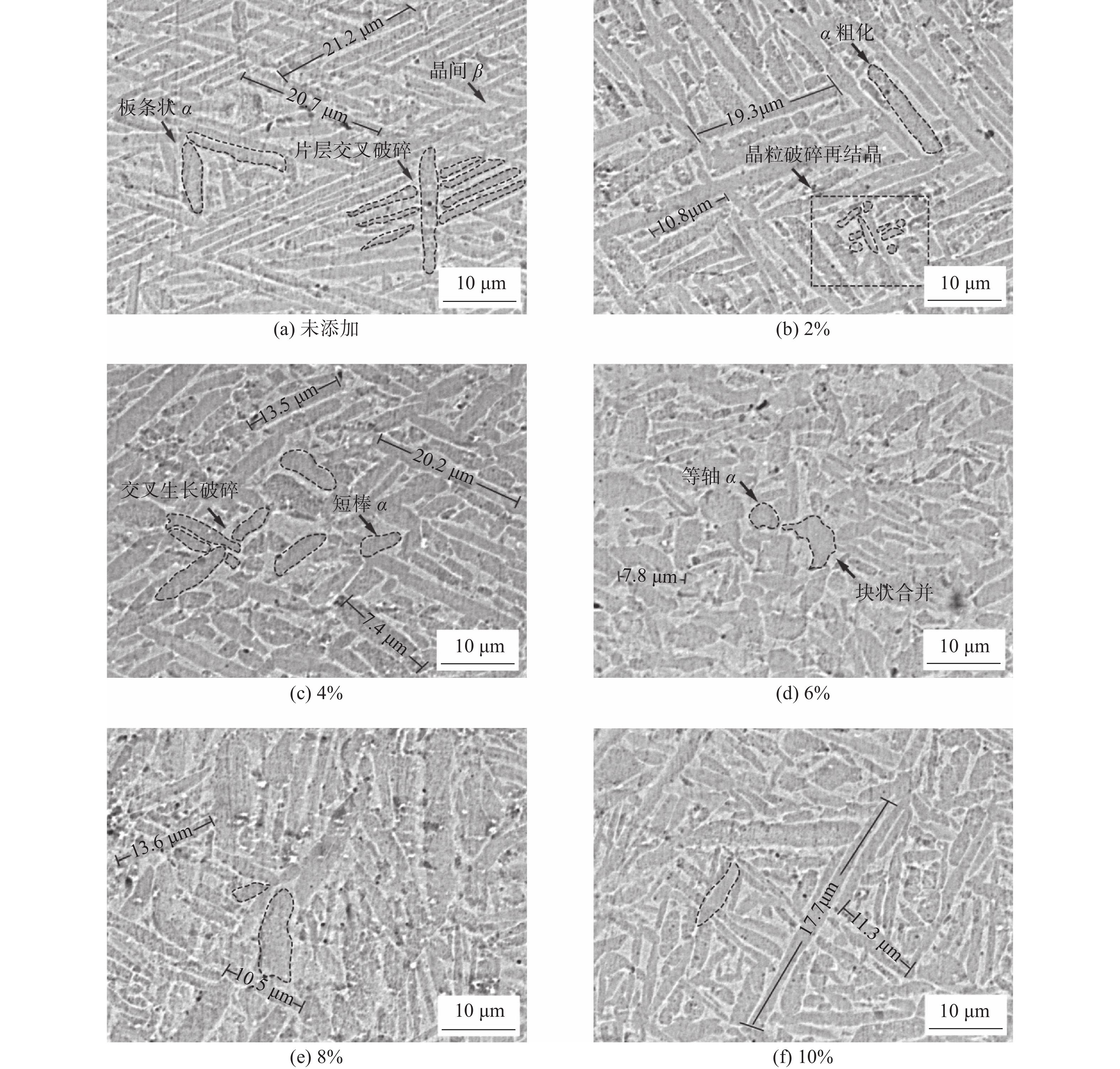

图8为不同Yb2O3含量时TC4钛合金焊缝中心区域金相组织.可以看到,焊缝由外延生长的粗大原始β柱状晶组成,β晶粒内部由针状马氏体α′组成,这些马氏体有序排列且分布贯穿整个β晶粒,最终形成典型的网篮组织,这种组织导致了焊缝相对于母材而言强度、硬度高而塑性低的特征.相比于未添加Yb2O3的TC4钛合金焊缝组织图8(a),加入Yb2O3后(图8(b-f))后晶粒总体有所细化,且当含量为6%时,细化效果最好.

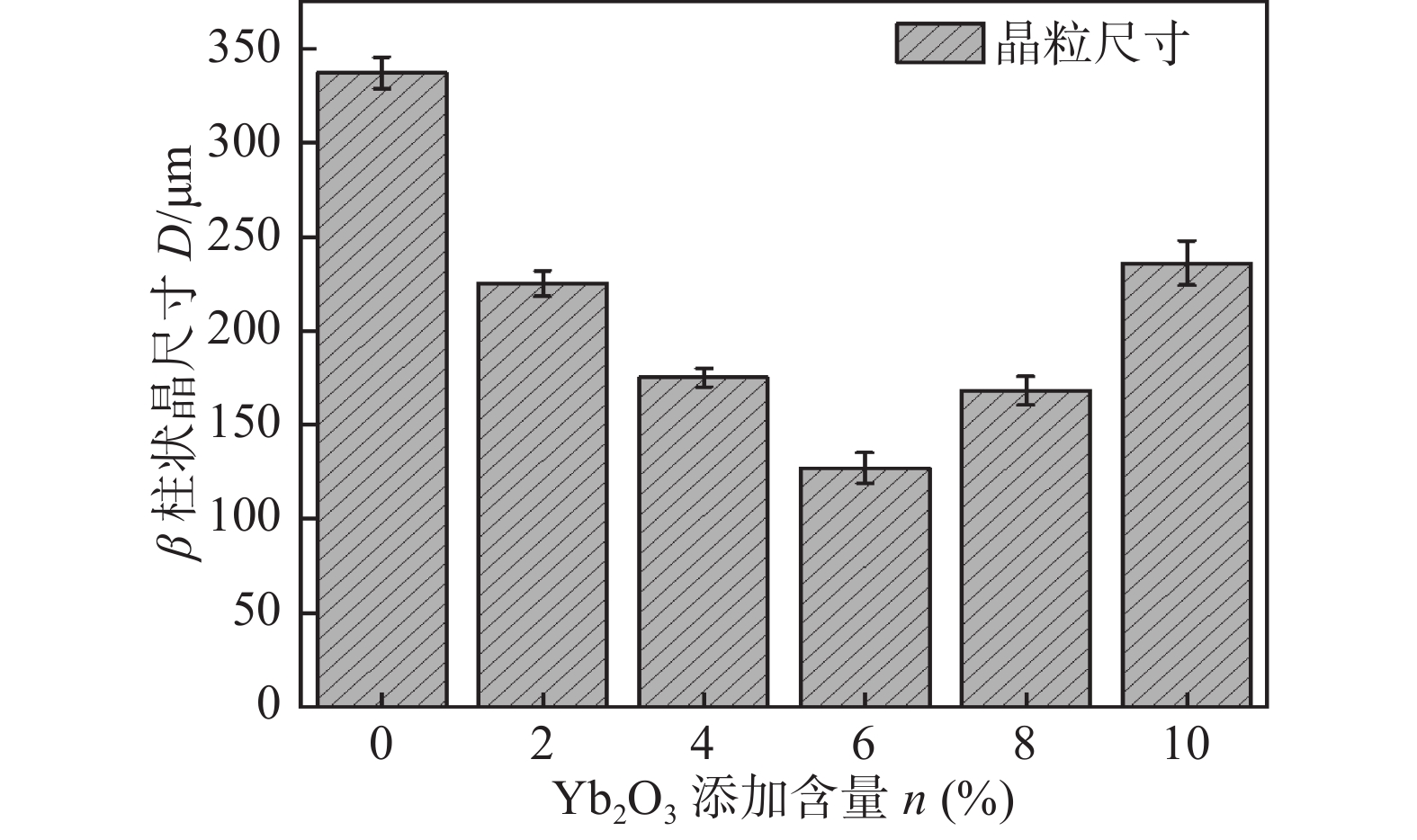

图9为Yb2O3含量晶粒尺寸的影响.由图可知,在合适的添加量下,焊缝β晶粒尺寸随着Yb2O3含量不断减.当添加Yb2O3含量为6%时,Yb2O3对焊缝中心β晶粒尺寸的影响最为显著,此时β晶粒尺寸最小为127 μm,相较于未添加Yb2O3时β晶粒尺寸的337 μm细化了62.3%.这是因为Yb2O3的加入为焊缝提供了更多的异质形核核心,使得晶粒形核需要的过冷度大幅下降.在焊缝成型过程中,虽然晶粒生长方向仍然由熔合区往焊缝中心生长,但核心更多,因此晶粒数量增加,导致晶粒尺寸细化,使得β晶粒在形态上开始出现明显等轴化的趋势.但是随着Yb2O3的继续加入,晶粒尺寸反而升高,当Yb2O3的含量为10%时,焊缝晶粒尺寸为236 μm,这是因为随着焊缝中稀土氧化物的增加,容易聚集成较大的夹渣物,对晶粒的细化产生不利影响.

图10为不同Yb2O3含量下的α′马氏体组织生长形态.由图10(a)和(b)可知,焊缝中α′马氏体组织呈现细针状,其长宽比大于10∶1,这主要是钛合金熔池冷却速率极快导致的.通常在焊接过程中,焊缝区的温度远远高于α + β→β相转变温度,在冷却过程中,焊缝生成的β相组织中的合金元素来不及发生充分扩散,只能以近程迁移的方式以一种非平衡扩散状态实现切变相变,最终得到了细针状的α′马氏体.而这些针状α′马氏体通常以原始β晶界形核长大,首先平行生长直至贯穿整个β晶粒,其次在平行的初生α′之间生成细小的次生α′,两者互相交叉生长,最终形成图中所示的网篮组织.随着焊缝中Yb2O3含量的增加,针状α′马氏体大小出现的细化,其针间间距也出现逐渐变窄现象(图9(d-f)).Yb2O3的加入使得原始β晶粒的大小得到细化,而针状马氏体相的生长被原始β晶界所限制,使得生长受限;其次稀土Yb元素对TC4钛合金相变温度发生变化,减小α相区区间,使得针状α′马氏体在降温过程长大时间缩短,最终导致了针状α′马氏体的细化现象.随着焊缝中Yb2O3含量的进一步增加,β晶粒尺寸开始粗化,针状α′马氏体大小及晶间间距也随之发生改变.

图11为变形温度900 ℃、变形速率1 × 10−2s−1条件下,Yb2O3含量对焊缝变形后显微组织的影响.由图11(a)可知,未添加Yb2O3情况下焊缝区由板条状α相和晶间β相构成,相对于变形前呈垂直分布的针状马氏体α′,超塑变形后的α晶粒在拉应力的作用下取向发生了变化,由垂直的90 °角沿拉伸轴方向出现角度上的偏转,这表明在超塑变形过程中,针状马氏体α′不但发生了α′→α + β相变,其相变后的板条α相在高温及拉应力下还可能出现了晶界滑移,造成了形态上的晶粒滑动旋转,这也从侧面证明激光焊接头在组织特征上具备一定程度的塑性变形能力.随着焊缝中Yb2O3的加入(图11(b-f)),焊缝中的板条α晶粒出现了区域性的晶粒破碎再结晶的特征,在该区域短棒状的α相周围出现了细小的等轴α相,说明此时焊缝区域出现了动态再结晶.一般来说动态再结晶出现在具有较高畸变能的区域,而板条α相垂直交叉生长导致的晶粒破碎正好满足了这一内在要求[17].与此同时,Yb2O3的加入在晶界和晶内的聚集分布能有效细化晶粒,导致单位区域内晶界的增加,促进了动态再结晶的形核和晶界滑移,提高了焊缝组织的超塑变形能力(图11(b-d)).

随着焊缝中Yb2O3含量的不断增加,片层组织逐渐开始变宽变短,焊缝中晶粒的取向开始杂乱.当焊缝中Yb2O3含量为6%时(图11(d)),焊缝区域不再存在具有织构特性的片层组织,而是出现了较多短棒状α晶粒以及再结晶生成的细小等轴α晶粒.焊缝中形变组织的细小主要是其原始焊缝组织导致的,原始焊缝组织越细小,相变生成的α相也就趋于等轴化,相对于片层组织,这些细小的等轴晶具有良好的滑动和转动特性,能有效缓解拉应力造成的位错塞积,进而获得较大的断后延伸率.

为直观比较不同状态下组织的超塑变形能力,特以焊缝组织中α晶粒的平均宽度和长度比作为焊缝组织等轴化系数(J),J值越趋近于1,等轴化程度越高.表1为不同Yb2O3含量焊缝组织的等轴化系数.焊缝组织中Yb2O3的加入能有效提高焊缝组织的等轴化系数,随着焊缝中Yb2O3含量的增加,焊缝区域组织的等轴化系数呈先增加后下降的趋势.当焊缝中Yb2O3含量为6%时,此时焊缝组织的等轴化系数达到最高值的0.26,是未添加Yb2O3焊缝区域的5.2倍.随着Yb2O3含量的继续升高,此时原始焊缝组织的细化作用减小,这导致超塑性变形焊缝区域的晶粒又开始呈现板条化趋势,焊缝超塑性变形能力下降.

表 1 不同Yb2O3含量焊缝组织的等轴化系数Table 1. Isoaxial coefficient of weld microstructure with different content of Yb2O3Yb2O3含量

n(质量分数, %)平均宽度

W/μm平均长度

L/μm等轴化系数

J0 1.17 22.3 0.05 2 2.05 18.6 0.11 4 2.12 15.6 0.14 6 1.94 7.5 0.26 8 2.51 14.7 0.17 10 2.13 16.3 0.13 3. 结论

(1)随着Yb2O3的加入,接头应力应变曲线下移,接头峰值流变应力先降低后升高,断后伸长率先增大后减小. 在920 ℃应变速率1 × 10−3 s−1条件下Yb2O3含量6%时,峰值流变应力最低为11.9 MPa,断后伸长率为572.3%.

(2) Yb2O3能够降低焊缝β晶粒尺寸. 当添加Yb2O3含量为6%时,Yb2O3对焊缝中心β晶粒尺寸的影响最为显著,此时β晶粒尺寸最小为127 μm,相较于未添加Yb2O3时β晶粒尺寸的337 μm细化了62.3%.

(3)在超塑性变形过程中,焊缝马氏体组织发生相变,形态转变成片层,而后等轴化.Yb2O3的含量升高,等轴化程度先升高后降低,含量6%时等轴化系数达到最大0.26.

-

表 1 不同Yb2O3含量焊缝组织的等轴化系数

Table 1 Isoaxial coefficient of weld microstructure with different content of Yb2O3

Yb2O3含量

n(质量分数, %)平均宽度

W/μm平均长度

L/μm等轴化系数

J0 1.17 22.3 0.05 2 2.05 18.6 0.11 4 2.12 15.6 0.14 6 1.94 7.5 0.26 8 2.51 14.7 0.17 10 2.13 16.3 0.13 -

[1] 许良, 苏居季, 周松, 等. TC4 钛合金激光双光束焊T形接头疲劳性能及断裂机理[J]. 中国有色金属学报, 2019, 29(7): 1408 − 1416. Xu Liang, Su Juji, Zhou Song, et al. Fatigue performance and fracture mechanism of dual-beam laser welded T-joints of TC4 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(7): 1408 − 1416.

[2] Zhou X, Xu D, Geng S, et al. Mechanical properties, corrosion behavior and cytotoxicity of Ti-6Al-4V alloy fabricated by laser metal deposition[J]. Materials Characterization, 2021, 179: 111302.

[3] Cooke K O, Atieh A M. Current trends in dissimilar diffusion bonding of titanium alloys to stainless steels, aluminium and magnesium[J]. Journal of Manufacturing and Materials Processing, 2020, 4(2): 39.

[4] Cotton J D, Clark L P, Phelps H R. Titanium alloys on the F-22 fighter airframe[J]. Advanced Materials & Processes, 2002, 160(5): 25 − 29.

[5] 付明杰, 陈俐, 曾元松. 激光焊接Ti-45Al-3V-2Fe-2Mo合金的超塑成形组织及性能[J]. 稀有金属材料与工程, 2018, 47(8): 2555 − 2560. Fu Mingjie, Chen Li, Zeng Yuansong. Superplastic deformation microstructure and property of laser welded Ti-4.5Al-3V-2Fe-2Mo Alloy[J]. Rare Metal Materials and Engineering, 2018, 47(8): 2555 − 2560.

[6] 曹泽安, 程东海, 胡德安, 等. 氢热处理对钛合金激光焊接接头超塑性变形的影响[J]. 材料热处理学报, 2018, 39(12): 129 − 134. Cao Zean, Cheng Donghai, Hu Dean, et al. Effect of hydrogen heat treatment on superplastic deformation of laser welded joints of titanium alloy[J]. Transactions of Materials and Heat Treatment, 2018, 39(12): 129 − 134.

[7] Li B, Shi Y, Lei Y, et al. Effect of rare earth element addition on the microstructure of Sn-Ag-Cu solder joint[J]. Journal of Electronic Materials, 2005, 34: 217 − 224.

[8] Dudek M A, Chawla N. Effect of rare-earth (La, Ce, and Y) additions on the microstructure and mechanical behavior of Sn-39Ag-07Cu solder alloy[J]. Metallurgical and Materials Transactions A, 2010, 41: 610 − 620.

[9] Cai Y C, Liu R P, Wei Y H, et al. Influence of Y on microstructures and mechanical properties of high strength steel weld metal[J]. Materials & Design (1980-2015), 2014, 62: 83 − 90.

[10] Fang H C, Chen K H, Zhang Z, et al. Effect of Yb additions on microstructures and properties of 7A60 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 28 − 32.

[11] Castro V De, Leguey T, Muñoz A, et al. Microstructure and tensile properties of Y2O3-dispersed titanium produced by arc melting[J]. Materials Science and Engineering: A, 2006, 422(1-2): 189 − 197.

[12] 吴文远. 稀土冶金学[M]. 北京: 化学工业出版社, 2005. Wu Wenyuan. Rare earth metallurgy[M]. Beijing: Chemical Industry Press, 2005.

[13] 邓炬, 杨冠军. 稀土元素在钛及钛合金中的作用[J]. 稀有金属材料与工程, 1993(5): 1 − 11. Deng Ju, Yang Guanjun. The role of rare earth elements in titanium and its alloys[J]. Rare Metal Materials and Engineering, 1993(5): 1 − 11.

[14] Alabort E, Kontis P, Barba D, et al. On the mechanisms of superplasticity in Ti-6Al-4V[J]. Acta Materialia, 2016, 105: 449 − 463.

[15] Zhang H X, Dai J J, Ma Z W, et al. Effect of Y2O3 on microstructures and wear resistance of TiC reinforced Ti-Al-Si coating by laser cladding on TC4 alloy[J]. Surface Review and Letters, 2019, 26(10): 1950077.

[16] Jin S, Liu H, Wu R, et al. Combination effects of Yb addition and cryogenic-rolling on microstructure and mechanical properties of LA141 alloy[J]. Materials Science and Engineering: A, 2020, 788: 139611.

[17] 朱堂葵, 王柯. TA19钛合金高温变形热加工图构建和微观组织演变[J]. 钛工业进展, 2021, 38(2): 1 − 6. Zhu Tangkui, Wang Ke. Processing map establishiment and microstructure evolution during hot deformation of TA19 titanium alloy[J]. Titanium Industry Progress, 2021, 38(2): 1 − 6.

-

期刊类型引用(2)

1. 李传胜,王雷,郭糠,杨祥帆,于文晶,王利忠,王洪宝,张怀强,张英波. Mo对钛合金激光焊接接头组织性能影响研究. 电焊机. 2025(01): 73-79 .  百度学术

百度学术

2. 李海英,熊淑秋. 船用耐蚀材料激光焊接技术分析. 舰船科学技术. 2024(21): 67-70 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: