Analysis of dynamic stress-strain characteristics of AH36 steel welded joint

-

摘要:

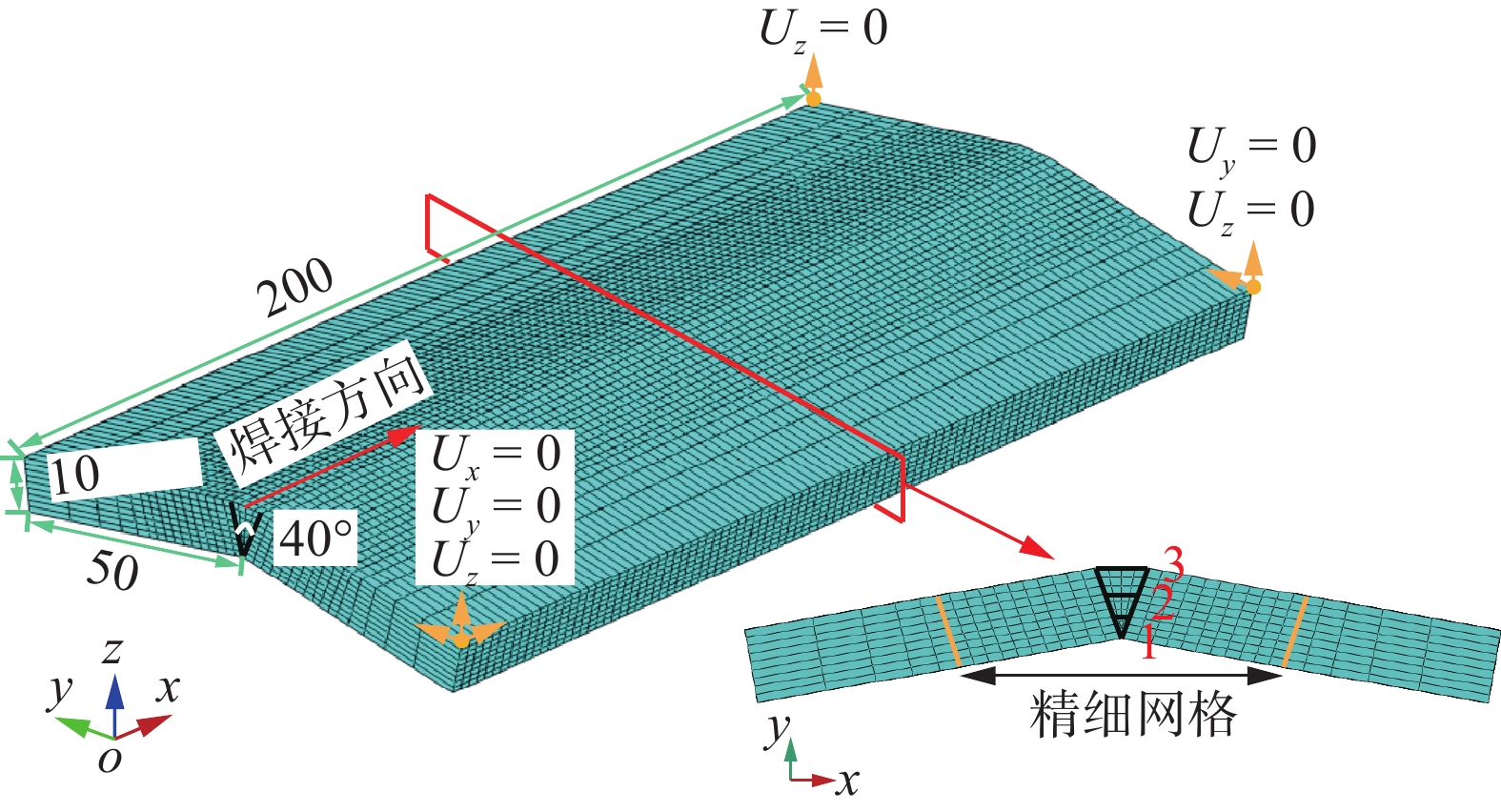

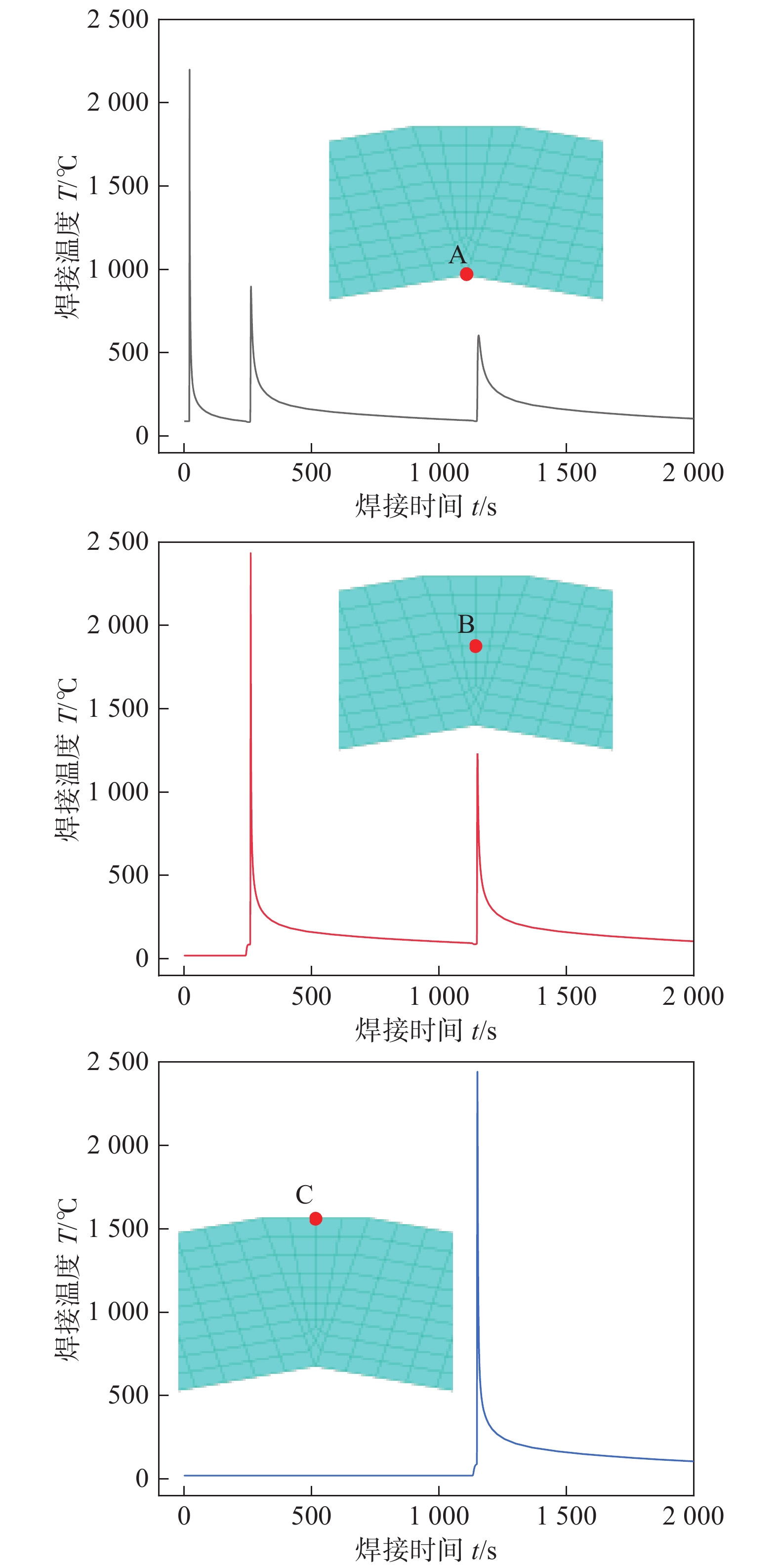

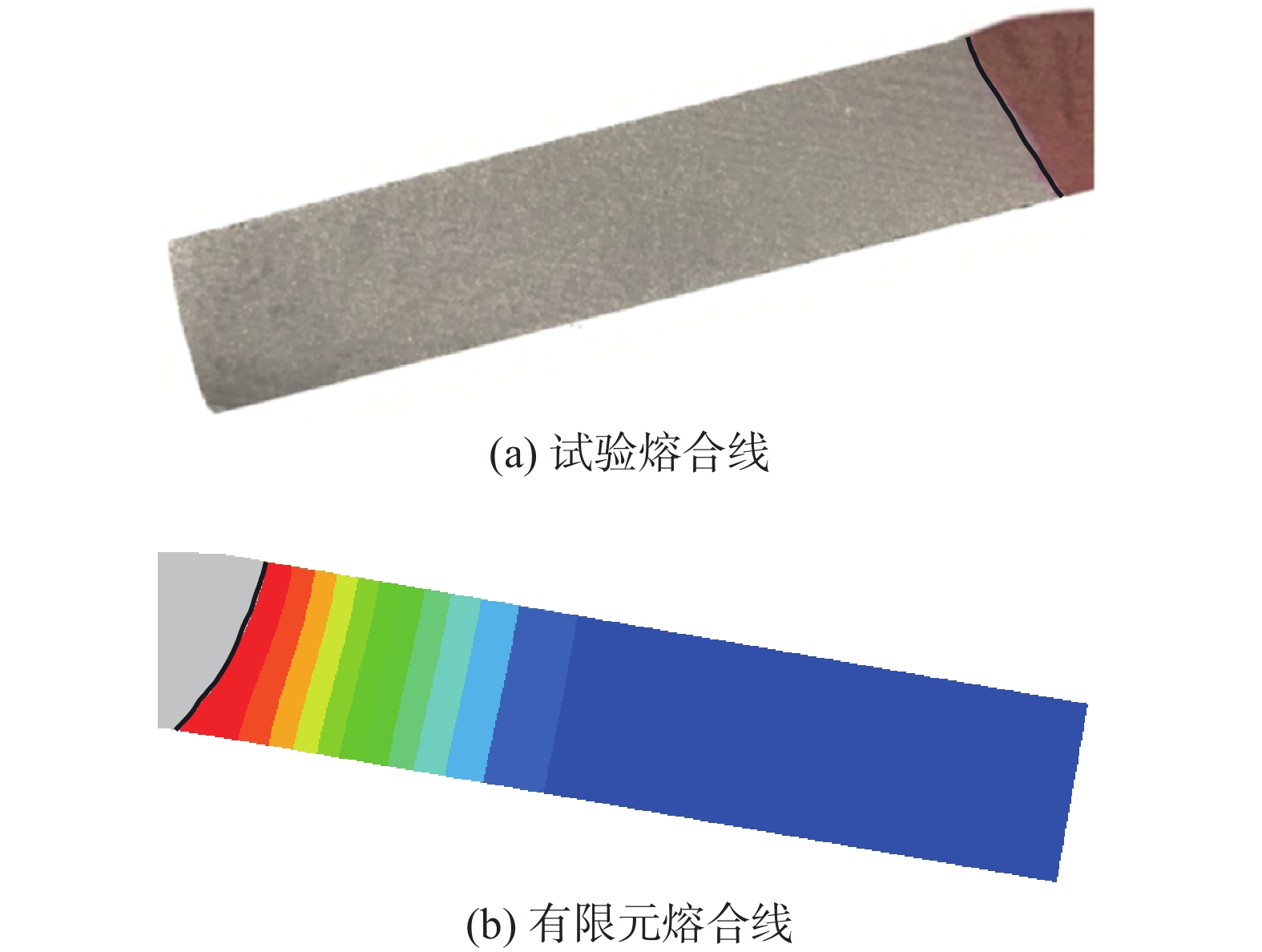

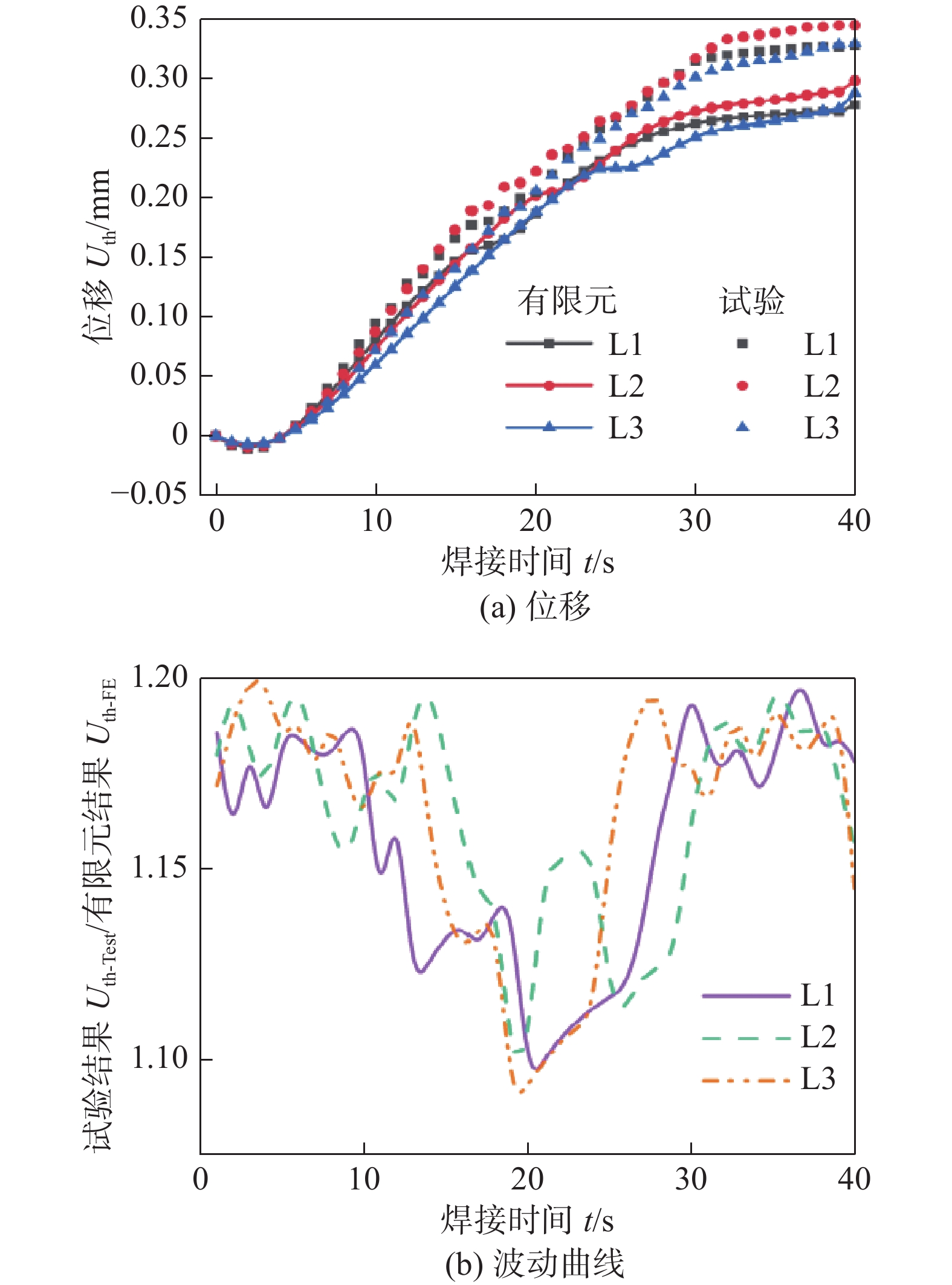

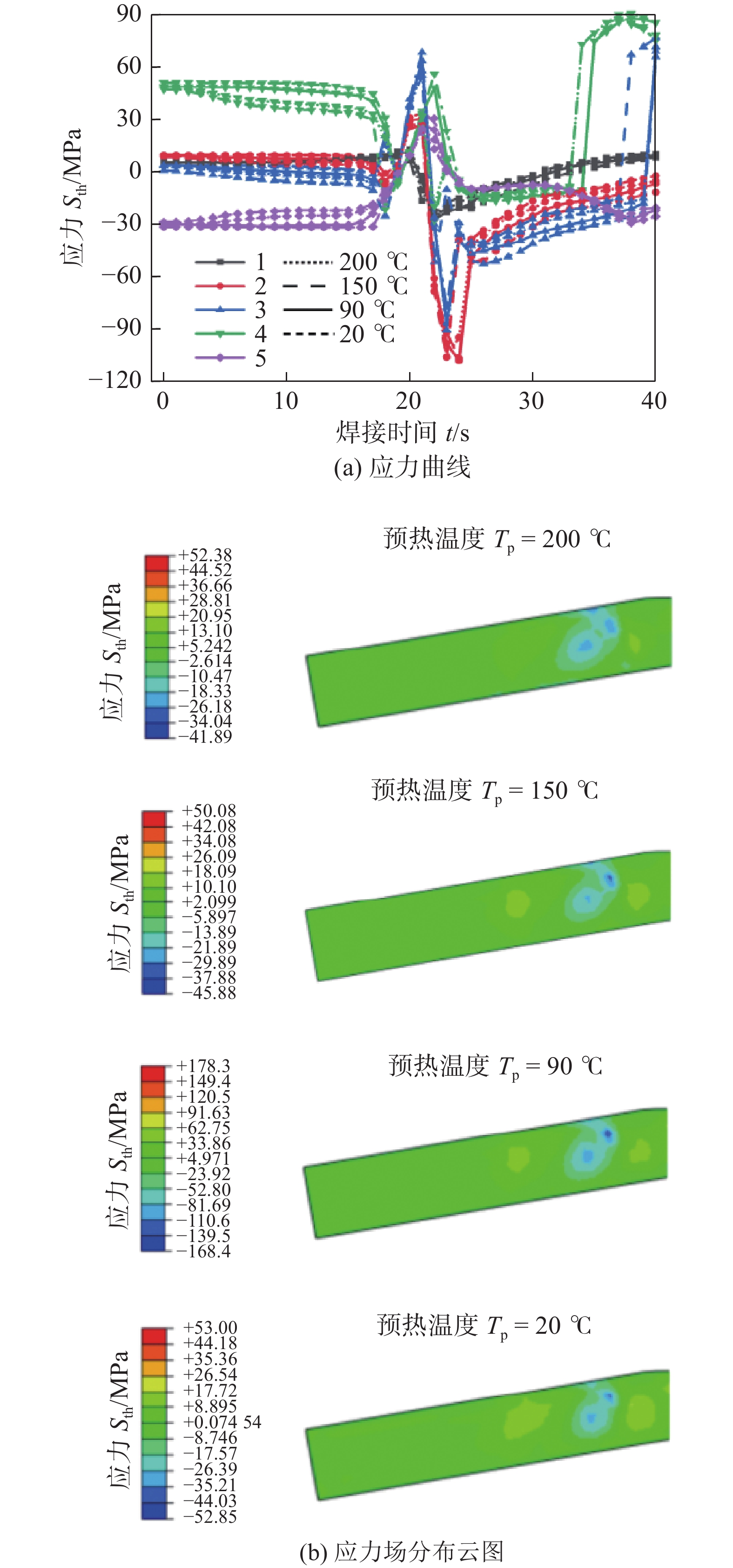

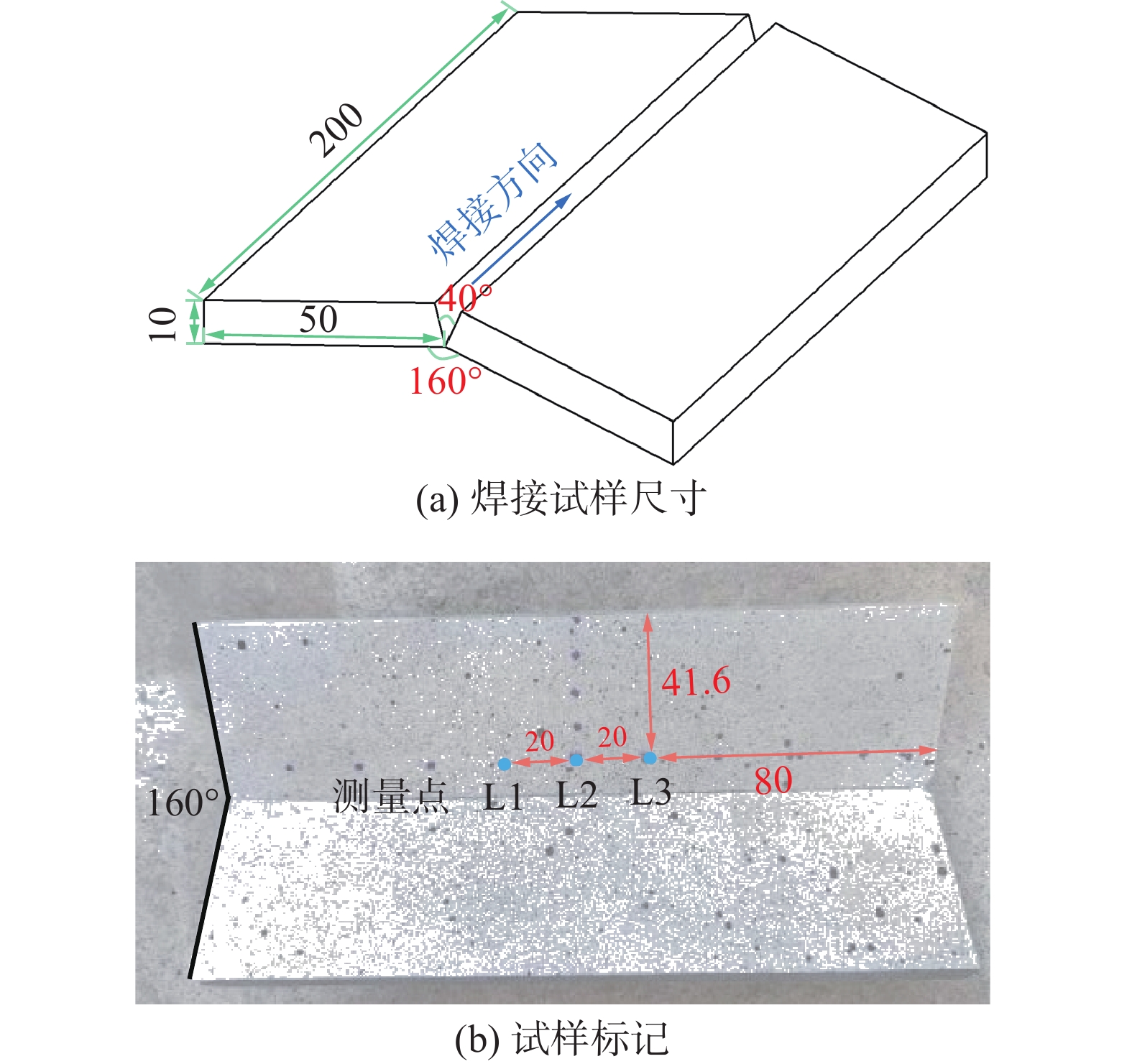

基于热弹塑性法研究了160°对接AH36钢焊接接头动态应力应变过程,同时制作试样,利用三维全场应变测量分析系统记录焊接应变的动态变化,验证了焊接有限元结果的准确性. 分析了预热温度和焊接速度对动态应力应变的影响. 研究结果表明,随着预热温度的增加,焊接变形逐渐减小. 预热温度为200 ℃时的平均焊接变形量比未预热时的平均焊接变形量降低了34.6%,同时改善了焊接应力场的分布情况,增加焊缝及热影响区的压应力分布区域,但应力幅值对预热温度的改变不敏感. 焊接变形随焊接速度增大而增大,当焊接速度大于5 mm/s时,增长趋势逐渐平缓,焊接变形场等势分布面积减小. 随着焊接速度的增加,焊接压应力场分布区域减小,焊接拉应力场分布区域增大,焊接速度的改变还会造成平板厚度方向中间层厚度处的应力出现波动.

Abstract:Based on the thermal elastic-plastic method, the dynamic stress-strain deformation process of AH36 steel welded joint with 160° butt joint was studied. At the same time, the sample was made, and the dynamic change of welding strain was recorded by three-dimensional full-field strain measurement and analysis system, which verified the accuracy of welding finite element results. The effects of preheating temperature and welding velocity on dynamic stress and strain were analyzed. The results show that with the increase of preheating temperature, the welding deformation decreases gradually. When the preheating temperature is 200 ℃, the average welding deformation is reduced by 34.6% compared with the average welding deformation without preheating. At the same time, the distribution of welding stress field is improved, and the compressive stress distribution area of weld and heat affected zone is increased, but the stress amplitude is not sensitive to the change of preheating temperature. The welding deformation increases with the increase of welding velocity. When the welding velocity is greater than 5 mm/s, the growth trend gradually slows down, and the equipotential distribution area of the welding deformation field decreases. With the increase of welding velocity, the distribution area of welding compressive stress field decreases, and the distribution area of welding tensile stress field increases. The change of welding velocity will also cause the stress of middle layer thickness to fluctuate.

-

-

表 1 焊接参数

Table 1 Welding parameters

焊缝深度

h / mm电压

V / V电流

I / A焊接速度

v / (mm·s−1)热输入

q / (J·mm−1)3 18 80 5 230.4 3 21 110 5 369.6 3.5 23 130 5 478.4 表 2 AH36钢的高温属性

Table 2 High temperature properties of AH36 steel

温度

T / ℃热膨胀系数

α / (10−5·K−1)屈服强度

ReL / MPa弹性模量

E / GPa泊松比

μ密度

ρ / (g·cm−3)比热

C / (J·kg−1·K−1)导热系数

λ / (W·m−1·K−1)20 1.67 265 200 0.29 7.80 465 15.0 100 1.70 237 190 0.30 7.79 500 15.1 300 1.83 170 168 0.31 7.75 512 18.0 500 1.95 142 157 0.32 7.65 546 20.4 700 2.00 122 151 0.33 7.57 589 22.9 900 2.02 68 120 0.33 7.50 615 25.5 1100 2.03 36 76 0.33 7.47 647 29.5 1300 2.10 17 20 0.34 7.35 697 33.0 1500 2.13 8 10 0.39 7.33 704 32.0 表 3 不同预热温度下各节点的位移

Table 3 Displacement of points under different preheat temperatures

节点 20 ℃ 90 ℃ 150 ℃ 200 ℃ 位移峰值

Umax / mm最终位移

U / mm位移峰值

Umax / mm最终位移

U / mm位移峰值

Umax / mm最终位移

U / mm位移峰值

Umax / mm最终位移

U / mm1 −0.475 −0.690 −0.438 −0.651 −0.386 −0.600 −0.262 −0.486 2 −0.432 −0.650 −0.391 −0.608 −0.336 −0.554 −0.211 −0.439 3 −0.405 −0.624 −0.361 −0.579 −0.305 −0.524 −0.179 −0.408 4 −0.378 −0.597 −0.332 −0.550 −0.274 −0.493 −0.149 −0.376 5 −0.354 −0.572 −0.305 −0.522 −0.258 −0.464 −0.116 −0.348 表 4 不同预热温度下各节点的应力

Table 4 Stress of points under different preheat temperatures

节点 20 ℃ 90 ℃ 最大应力

σmax / MPa最终应力

σ / MPa最大应力

σmax / MPa最终应力

σ / MPa1 −24.01 8.01 −27.39 9.11 2 −107.29 −11.93 −108.46 −6.98 3 −77.97 65.77 −87.05 68.99 4 86.66 75.19 87.91 85.44 5 32.89 −20.70 −31.42 −22.27 节点 150 ℃ 200 ℃ 最大应力

σmax / MPa最终应力

σ / MPa最大应力

σmax / MPa最终应力

σ / MPa1 −26.41 9.59 −26.03 10.17 2 −106.42 −6.45 −106.57 −2.44 3 −90.92 71.39 76.84 76.84 4 90.37 85.31 87.43 77.99 5 −27.60 −25.62 −29.57 −25.71 表 5 不同焊接速度下各节点的位移

Table 5 Displacement of points under different welding velocities

节

点2 mm/s 5 mm/s 10 mm/s 位移峰值

Umax / mm最终位移

U / mm位移峰值

Umax / mm最终位移

U / mm位移峰值

Umax / mm最终位移

U / mm1 0.087 −0.423 −0.438 −0.651 −0.509 −0.643 2 0.177 −0.352 −0.391 −0.608 −0.488 −0.618 3 0.223 −0.317 −0.361 −0.579 −0.473 −0.599 4 0.268 −0.283 −0.332 −0.550 −0.456 −0.579 5 0.314 −0.247 −0.305 −0.522 −0.442 −0.560 表 6 不同焊接速度下各节点的应力

Table 6 Stress of points under different welding velocities

节

点2 mm/s 5 mm/s 10 mm/s 最大应力

σmax / MPa最终应力

σ / MPa最大应力

σmax / MPa最终应力

σ / MPa最大应力

σmax / MPa最终应力

σ / MPa1 −21.94 1.94 −27.39 9.11 11.77 −9.07 2 70.79 4.78 −108.46 −6.98 38.15 −12.05 3 103.43 7.11 −87.05 68.99 56.86 −9.64 4 63.13 3.71 47.99 85.44 49.68 10.67 5 19.73 −8.42 27.44 −22.27 35.22 −6.84 -

[1] 段斌, 马德志. 现代焊接工程手册(基础卷)[M]. 北京: 化学工业出版社, 2016. Duan Bin, Ma Dezhi. Modern welding engineering handbook (basic) [M]. Beijing: Chemical Industry Press, 2016.

[2] 陈祝年, 陈茂爱. 焊接工程师手册(第三版)[M]. 北京: 机械工业出版社, 2019. Chen Zhunian, Chen Maoai. Handbook for welding engineer [M]. Beijing: China Machine Press, 2019.

[3] Ghafouri M, Ahola A, Ahn J, et al. Numerical and experimental investigations on the welding residual stresses and distortions of the short fillet welds in high strength steel plates[J]. Engineering Structures, 2022, 260: 114269. doi: 10.1016/j.engstruct.2022.114269

[4] Barsoum Z, Barsoum I. Residual stress effects on fatigue life of welded structures using LEFM[J]. Engineering Failure Analysis, 2009, 16(1): 449 − 467. doi: 10.1016/j.engfailanal.2008.06.017

[5] Cui C, Zhang Q, Bao Y, et al. Fatigue life evaluation of welded joints in steel bridge considering residual stress[J]. Journal of Constructional Steel Research, 2019, 153: 509 − 518. doi: 10.1016/j.jcsr.2018.11.003

[6] Jiang W, Xie X, Wang T, et al. Fatigue life prediction of 316L stainless steel weld joint including the role of residual stress and its evolution: Experimental and modelling[J]. International Journal of Fatigue, 2021, 143: 105997. doi: 10.1016/j.ijfatigue.2020.105997

[7] Shajan N, Kumar R, Manik R, et al. Role of residual stress in the failure of HF-ERW welded tubes[J]. Engineering Failure Analysis, 2024, 161: 108342. doi: 10.1016/j.engfailanal.2024.108342

[8] Ghafouri M, Ahola A, Ahn J, et al. Welding-induced stresses and distortion in high-strength steel T-joints: Numerical and experimental study[J]. Journal of Constructional Steel Research, 2022, 189: 107088. doi: 10.1016/j.jcsr.2021.107088

[9] Keränen L, Pylvänäinen M, Kaijalainen A, et al. Residual stresses of MAG-welded ultrahigh-strength steel rectangular hollow sections[J]. Engineering Structures, 2024, 305: 117719. doi: 10.1016/j.engstruct.2024.117719

[10] 朴东光, 潘乾刚, 储继君. 气焊、焊条电弧焊、气体保护焊和高能束焊的推荐坡口[S]. 北京: 中国质检出版社, 2008. Piao Dongguang, Pan Qiangang, Chu Jijun. Recommended joint preparation for gas welding, manual metal arc welding, gas-shield arc welding and beam welding[s]. Beijing: China Quality Inspection Press, 2008.

[11] Zhu Z K, Han Y, Zhang Z, et al. Numerical simulation of residual stress and deformation for submerged arc welding of Q690D high strength low alloy steel thick plate[J]. China Welding, 2021, 30(3): 49 − 58.

[12] 金希红, 曾燕军, 刘恒, 等. 不同残余应力测试方法与数值模拟对比研究[J]. 焊接技术, 2022, 51(1): 24 − 27,113-114. Jin Xihong, Zeng Yanjun, Liu Heng, et al. Comparative study of different residual stress testing methods and numerical simulation[J]. Welding Technology, 2022, 51(1): 24 − 27,113-114.

[13] 乔瑞林, 龙伟民, 秦建, 等. YG8/GH4169异种材料钎焊接头残余应力的数值模拟[J]. 焊接学报, 2024, 45(3): 68 − 74. Qiao Ruilin, Long Weimin, Qin Jian, et al. Numerical simulation of residual stress in YG8/GH4169 dissimilar material brazed joints[J]. Transaction of the China Welding Institution, 2024, 45(3): 68 − 74.

[14] Pavan A R, Arivazhagan B, Vasudevan M, et al. Numerical simulation and validation of residual stresses and distortion in type 316L(N) stainless steel weld joints fabricated by advanced welding techniques[J]. CIRP Journal of Manufacturing Science and Technology, 2022, 39: 294 − 307. doi: 10.1016/j.cirpj.2022.08.010

[15] Goldak J, Chakravarti A, Bibby M. A new finite element model for welding heat sources[J]. Metallurgical Transactions B, 1984, 15(2): 299 − 305. doi: 10.1007/BF02667333

[16] Wang Y F, Feng G J, Pu X W, et al. Influence of welding sequence on residual stress distribution and deformation in Q345 steel H-section butt-welded joint[J]. Journal of Materials Research and Technology, 2021, 13: 144 − 153. doi: 10.1016/j.jmrt.2021.04.059

[17] 王阳. 大型复杂船体结构焊接变形分析方法的研究及应用[D]. 上海: 上海交通大学, 2015. Wang Yang. Investigation and application on the analysis methods of welding distortion in large-scale and complex marine structures[D]. Shanghai: Shanghai Jiao Tong University, 2015.

[18] Wang B, Zhou L, Du J G, et al. Analysis of residual stresses in electron beam welding with filler wire of Ti62A alloy[J]. Journal of Materials Research and Technology, 2023, 23: 985 − 997. doi: 10.1016/j.jmrt.2023.01.081

[19] Sun J M, Liu X Z, Tong Y G, et al. A comparative study on welding temperature fields, residual stress distributions and deformations induced by laser beam welding and CO2 gas arc welding[J]. Materials & Design, 2014, 63: 519 − 530.

[20] Ahn J, He E, Chen L, et al. Prediction and measurement of residual stresses and distortions in fibre laser welded Ti-6Al-4V considering phase transformation[J]. Materials & Design, 2017, 115: 441 − 457.

下载:

下载: