Development on improving fatigue life of high strength steel welded joints

-

摘要:

随着人们对装备性能和环保的追求高强钢被越来越多地应用,对于高强钢而言焊接作为一种重要的材料连接方法应用非常广泛,然而接头疲劳性能并不随着钢材强度升高而提高,因此提高焊接接头的疲劳寿命对于高强钢的应用具有重要意义.基于近年来国内外相关研究,总结了影响高强钢焊接接头疲劳性能的因素,包括应力集中、焊接残余应力、焊接方法和焊材选择等因素. 综述了多种提高高强钢焊接接头疲劳寿命的方法,根据其对接头疲劳性能改善机理进行分类,第1类方法主要基于对焊缝几何形貌的改进,通过降低应力集中系数减缓疲劳裂纹的萌生提高寿命.如TIG熔修、激光熔修、喷涂沉积和仿形加工和打磨等方法. 其中一些方法在改进焊缝几何形貌的同时还引入对疲劳寿命有益的残余压应力. 第2类寿命提高方法主要基于对焊缝残余应力进行调整,通过减小残余拉应力或引入残余压应力减缓裂纹扩展速度. 如焊后热处理(post-weld heat treatment, PWHT)、高频机械冲击(high frequency mechanical impact,HFMI)、激光冲击强化(laser shock processing,LSP)、滚压和搅拌摩擦等方法,其中一些方法同时还会改善接头表面硬度和晶粒尺寸从而影响疲劳裂纹萌生. 并对这些方法的使用提出建议和展望.

Abstract:With the increasing application of high-strength steel in people's pursuit of equipment performance and environmental protectio, welding, as an important material joining method, is essential in the application of high-strength steel. However, the fatigue performance of welded joints does not improve with the increase of steel strength level. So how to improve the fatigue life of the welded joints is of great significance to the application of high-strength steel. Based on the relevant research results at home and abroad in recent years, this paper summarizes the factors affecting the fatigue performance of high-strength steel welded joints, including stress concentration, welding residual stress, welding method and welding material. A variety of methods to improve the fatigue life of high strength steel welded joints are reviewed, and they are classified according to the mechanism of improving the fatigue performance of joints. The first type of life improvement method is mainly based on the improvement of the geometric morphology of the joint, and the life is improved by reducing the stress concentration factor to slow down the initiation of fatigue cracks, such as TIG dressing, laser dressing, spray deposition, profiling and grinding methods. Some of these methods improve the weld morphology and lead-in residual compressive stress that is beneficial to fatigue life. The second type of life improvement method is mainly based on the adjustment of the residual stress of the joint. The crack growth rate is slowed down by reducing the residual tensile stress or introducing the residual compressive stress, such as post-weld heat treatment (PWHT), high frequency mechanical shock (HFMI), laser shock processing (LSP), rolling and friction stir. Some of which also improve the surface hardness and grain size of the joint to affect the fatigue crack initiation. Suggestions and prospects for the use of these methods are put forward.

-

Keywords:

- fatigue /

- high strength steel /

- welded joint /

- residual stress /

- improving fatigue life

-

0. 序言

随着工业化的持续发展,人们在追求装备性能的同时也开始注意其对环境造成的影响. 高强钢的使用在提高了构件的强度及其他力学性能的情况下,降低了钢材的用量从而减轻了构件重量,实现轻量化,这有利于装备向节材减重、降耗减排的方向发展. 目前高强钢已广泛应用于工程机械、海洋结构、建筑结构和军用机械装备等方面[1-2]. 而在高强钢应用过程中,焊接是一种常用的连接方式,但是焊接后高强钢接头常常存在成形不良、偏析、气孔或裂纹等缺陷,容易在接头表面和焊趾处造成局部应力集中以及残余应力场. 这些对于接头的疲劳性能是不利的,常常成为疲劳断裂失效的薄弱位置[3-5]. 对于承受交变载荷的焊接零部件来说,这些位置容易过早发生疲劳破坏,从而严重影响装备使役安全[6]. 高强钢的使用虽然提高了母材强度,但母材强度的提升与接头疲劳强度并不是正相关,在工程实践中已发生多起焊接接头疲劳断裂失效而影响构件正常运行的事故[7-8],严重制约了高强钢的应用,因此如何提高高强钢焊接接头疲劳性能对高强钢的应用具有重要意义.

近年来,随着对焊接接头疲劳断裂机理和疲劳寿命影响因素的认识不断加深,国内外科技工作者基于此采用多种方法提高金属焊接接头的疲劳寿命.但一些传统的疲劳寿命提高方法已不能适用于强度较高的高强钢焊接接头,因此文中介绍了高强钢焊接接头疲劳寿命的影响因素,概述了可以适用于提高高强钢焊接接头疲劳寿命的一些方法及其改善效果,并根据其原理对这些方法进行分类.

1. 高强钢焊接接头疲劳寿命影响因素

1.1 应力集中

高强钢焊接接头在承受循环载荷时由于焊趾常常存在几何过渡不均匀、焊接缺陷或夹杂和焊缝组织的不均匀分布导致应力集中. 在承受交变载荷的过程中疲劳裂纹容易在此形核使得疲劳裂纹过早萌生[9-10]. 一般T形接头相比对接接头具有更高的应力集中和应力梯度效应,导致较低的疲劳寿命及较高分散性. 此外接头的焊趾半径在0.16 ~ 0.36 mm之间,而最大的应力集中取决于最小的焊趾半径,因此导致了较差的接头疲劳裂纹萌生寿命,故可将焊趾进行机械加工. 焊趾半径对应力集中和疲劳性能的影响,如图1所示[11]. 图1(a)中相比焊态,不同的焊趾加工半径均可减少应力集中,并随着焊趾半径增大,应力集中逐渐减小. 图1(b)中S-N曲线可以看到即使半径为0.5 mm疲劳性能也显著提高[11].另外降低焊缝余高也可以减小应力集中从而提高焊接接头的疲劳寿命[12].

当应力集中区域的组织存在弹塑性不匹配时,在疲劳载荷作用下,疲劳裂纹容易在弹塑性失配界面萌生. 王晓南等人[13]通过对800 MPa级高强钢光纤激光焊接接头的疲劳裂纹扩展研究发现,由于铁素体和马氏体强度的差异,应变容易在铁素体侧集中,导致裂纹容易在铁素体和马氏体相界面形成. Wang等人[14]发现CrMoV/NiCrMoV异种钢焊接接头热影响区与焊缝的界面由于碳迁移容易形成一条贫碳的铁素体层,界面两侧的组织硬度均高于界面处,造成界面处力学性能严重失配,在循环载荷下应变优先集中于此造成疲劳裂纹在界面处萌生并沿着界面扩展,故导致了较差的疲劳寿命.

1.2 残余应力

在焊接过程中,由于接头加热时的不均匀温度场和急速冷却过程中的相变,导致接头内产生残余应力,焊接接头中的残余应力分为直接应力、间接应力和组织应力3类,即使进行PWHT也不能将其完全消除[14-16]. 残余应力在焊接件截面上是一个分布值,如X80管线钢对接板焊接接头纵向应力和等效应力最大值在焊缝附近出现,横向应力峰值集中在熔合线位置,而厚度方向应力峰值则位于结构内部,其中横向残余应力的存在对疲劳裂纹的扩展存在较大的影响[17]. 一些接头处理技术通过在接头表面引入一层残余压应力以减缓裂纹的萌生和扩展. 如通过激光冲击处理(laser shock peening,LSP)使得电弧增材制造低合金钢构件顶部垂直方向的残余拉应力较大区域的裂纹尖端残余应力由150 MPa降低至−260 MPa,并且在距离裂纹尖端1.5 mm至9.5 mm内引入压应力,降低了疲劳裂纹扩展速率[18]. 构件在承受交变载荷时,残余应力间接改变了循环应力幅值,存在的残余拉应力使得局部应力集中倾向增大和形核位置增多,造成疲劳裂纹提前萌生和加速扩展,导致疲劳寿命降低[19]. 因此以通过调整焊接接头的残余拉应力变为残余压应力来提高焊接接头疲劳性能.

1.3 焊接工艺

1.3.1 焊接方法

高强钢在焊接之后存在组织不均匀、几何不连续、内部缺陷和残余应力等造成焊接结构过早发生疲劳破坏的问题[3,20-21]. 不同的焊接工艺诸如焊接方法、热输入和填充材料等,会获得不同疲劳性能的焊接接头. 其中焊接方法对接头疲劳寿命影响尤为明显. Ceferino等人[22]采用熔化极气体保护焊(gas metal arc welding,GMAW)、激光复合焊(laser hybrid welding,LHW)和电子束焊(electron beam welding,EBW)等3种不同焊接方法分别对S960 MC和S960QL钢进行焊接. 不同焊接方法接头的横截面和疲劳S-N曲线[22],如图2所示. 图2(a)为接头横截面,图2(b)为进行相同载荷条件下的四点弯曲疲劳实验结果,GMAW接头疲劳强度最高,EBW接头疲劳强度次之,LHW接头最低. 其原因在于LHW和EBW工艺制造的焊缝中缺陷较多,且硬度较高,焊趾处应力集中程度较高,另外采用不同焊接方式的热输入与冷却速度不同,造成不同的热影响区状态.

较小的热输入、焊前预热和多层多道细窄焊接道次可使得t8/5延长、冷却速度降低,有助于降低热影响区的硬度和裂纹敏感性,同时增加氢渗出的窗口,提高接头性能[23-24]. Hariprasath等人[25]对比了焊条电弧焊(shielded metal arc welding,SMAW)和GMAW两种方法焊接的DMR249A钢焊接接头疲劳性能,GMAW接头中针状铁素体体积分数比SMAW高,使得 GMAW工艺制备的接头疲劳强度更好,原因为针状铁素体具有细小的晶粒尺寸和大量的大角度晶界,有助于降低焊件疲劳裂纹萌生的应力强度因子[26-28]. 在实际施工时焊接方法及工艺要结合材料、工况和成本等进行选择,以达到更好的效果.

1.3.2 填充材料

填充材料的选择对高强钢焊接接头疲劳性能也有很大的影响,一般来说,根据其相对于母材的强度水平可以分为低强匹配、等强匹配和高强匹配[29]. Adam等人[30]对两种强度等级的高强钢(S690和S960)焊接接头在不同强度匹配等级下的疲劳性能进行研究发现,焊接填充材料的选择要考虑钢材的强度等级. 对于强度较低的S690钢在较高疲劳载荷下,由于高强匹配接头焊缝脆性开裂使其疲劳寿命低于等强匹配接头,但在较低疲劳载荷下具有较高的寿命;对于强度较高的S960高强钢采用低强匹配方式具有更好的疲劳裂纹抵抗能力. 同时Ravi等人[31-33]研究了低合金高强钢接头的中心裂纹试件强度匹配对疲劳强度和裂纹扩展速率的影响后发现,低匹配接头的变形和屈服主要集中在焊缝区域,裂纹很难扩展到熔合线以外. 而高匹配接头,除焊缝金属本身具有更高的断裂抗力外,裂纹尖端塑性区容易延伸到强度更低的母材当中,另外由于变形和屈服发生在母材和焊缝两者之中,裂纹尖端区域容易应力松弛,裂纹扩展需要更大的驱动力.

此外采用低相变温度焊接材料进行焊接时熔池在冷却至接近室温时才发生马氏体相变,导致相变膨胀量和残余压应力较大,对疲劳性能具有一定改善效果. Shiga等人[34]采用一种低相变温度焊接材料对AH40高强钢进行角焊焊接,随着焊缝贝氏体转变开始温度(Ms温度)降低,焊缝金属及其焊趾的残余应力由拉应力转变为压应力,并且减小了应力集中,接头疲劳寿命提高7 ~ 10倍. 故合适的焊缝匹配等级和焊接材料可以有效提高接头的疲劳性能.

2. 焊接接头疲劳寿命的提高方法

2.1 焊后热处理

焊接之后的接头存在着一些较大的残余拉应力和组织不均匀,这对接头疲劳寿命具有不良影响. 采用PWHT可以降低焊接过程中的残余拉应力和对组织不均匀进行改善[35]. Feng等人[36]通过PWHT处理正交异性钢桥面板纵肋与顶板焊接接头后发现残余应力降低了76% ~ 78%.由于残余应力的减小,裂纹扩展速率显著降低,2 × 106次寿命的疲劳强度提高了23%~33%. Selvamani等人[37]研究了PWHT对AISI 1020级低碳钢焊接接头疲劳性能的影响,焊态AISI 1020焊接接头的疲劳强度为170 MPa,经过PWHT后由于接头硬度降低最高达220 HV并且铁素体分布变多,将疲劳强度提高到185 MPa. Ravi等人[32]研究了热处理对HSLA-80 钢焊接接头疲劳性能的影响,经过实验发现一方面通过热处理降低了焊缝区和热影响区的拉伸残余应力,提高了接头的疲劳性能. 另外PWHT后对裂纹的扩展具有阻碍作用的针状铁素体含量增多对疲劳性能的提升也有一定的帮助. 因此对焊接接头进行PWHT处理降低焊接接头残余拉应力,增加针状铁素体含量阻碍疲劳裂纹萌生与扩展. PWHT对焊件的疲劳性能影响取决于钢的成分、焊接工艺以及PWHT工艺,对不同接头选择合适的PWHT工艺将有助于疲劳性能的提高.

2.2 高频机械冲击

2.2.1 喷丸强化技术

喷丸强化(shot peening,SP)是一种材料表面冷加工工艺,具有操作简单、成本低、适应性强和强化效果好等优点. 其原理是利用高速运动的介质(弹丸、水流等)冲击工件,使得工件表面产生塑性变形,产生有益的残余压应力场和形变组织强化,改变工件表面性能,从而提高受喷工件的疲劳强度[38-39]. 基于此开发出一些新型的喷丸技术,例如高能喷丸、超声喷丸、预应力喷丸和二次喷丸[40]等. 但这些方法的强化机理是相似的,主要通过应力强化和组织强化[41-43]. SP机制示意图,如图3所示[43]. 图3(a)为喷丸后接头表面引入残余压应力场, 残余压应力分布先逐渐增大后逐渐减小,如图3 (b)所示. 喷丸后表层组织内亚晶粒尺寸变小、位错密度增大. 但喷丸后组织表面粗糙度增加,可能导致微裂纹的形成或应力集中,对接头疲劳寿命有不利影响.

李丰博等人[44]对X70管线钢焊接接头进行了不同时长的SP处理,发现随着SP时间延长残余压应力持续提高,而表面粗糙度先增大后减小. 并在SP后消除了表层拉伸残余应力,引入的残余压应力提高了疲劳强度. 此外表层晶粒较基体明显细化. 门延会等人[45]指出细晶可以抑制裂纹萌生,但不利于抑制疲劳裂纹的扩展,而与之相反的是粗晶不利于阻碍裂纹萌生,但可以降低疲劳裂纹的扩展速率,因此SP后表层产生的细晶可以提高疲劳裂纹萌生的寿命,表层以下的粗晶可以提高裂纹扩展阶段的寿命. 激光喷丸处理不仅可以对接头表面引入残余压应力,还可以减少HT780焊接接头焊趾处含有的0.2 mm深以内半圆形缺陷的影响,将疲劳极限提高45 %[46].

Yamaguchi等人[47]提出一种微针喷丸(micro-needle peening,MNP)方法并对980 MPa级别高强钢弧焊接头进行强化. 不同强化方式性能对比,如图4所示[47]. 图4 (a)中 MNP方法比其他方法引入更多的残余压应力,除此之外还提高接头局部硬度,这有利于抑制疲劳裂纹的萌生. 另外MNP还避免了常规针击喷丸(needle peening,NP)造成的裂纹状缺陷,使得图4 (b)中3 × 106周次的疲劳强度由未喷丸的275 MPa提高到600 MPa,而NP处理则只能提高到300 MPa,还可以看到常规SP处理也具有较好的改善效果. 目前SP处理形式较多,但其工艺参数优化也制约着焊接接头疲劳寿命提高的效果,还需要进一步探索.

2.2.2 超声冲击处理

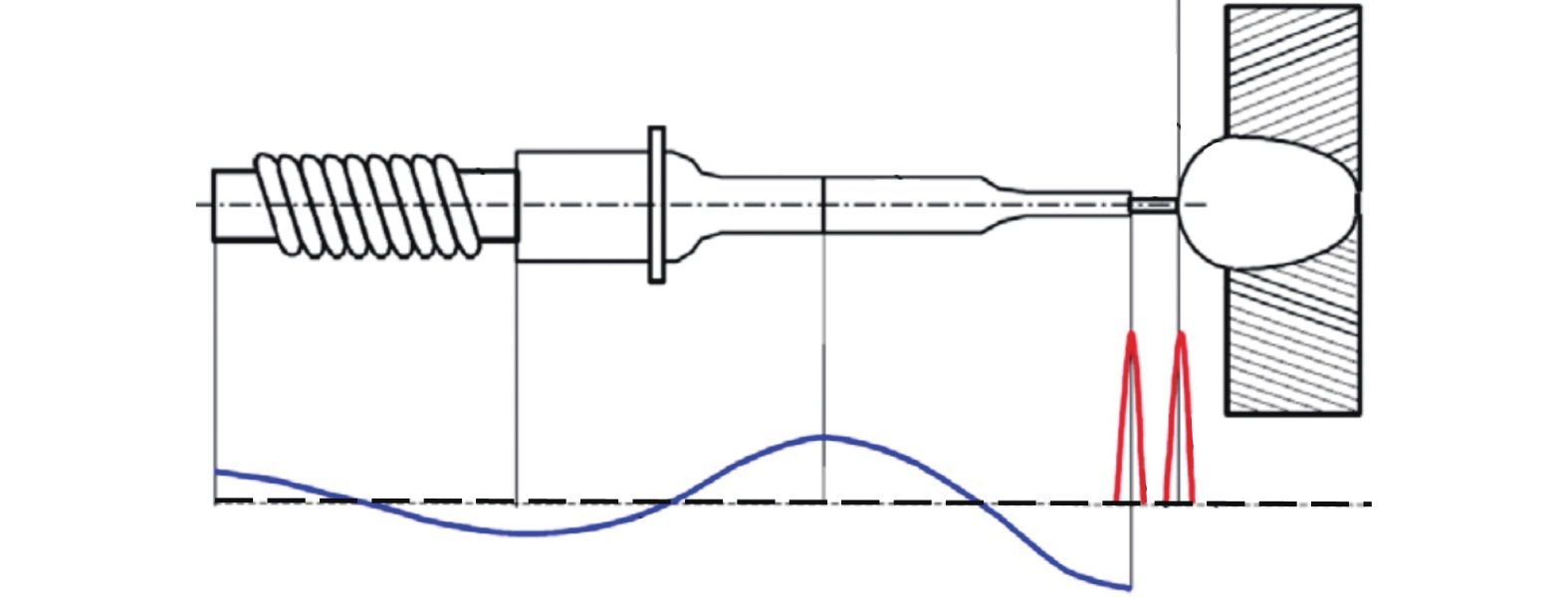

超声冲击处理(ultrasonic impact treatment,UIT)技术是一种具有效率高、成本低和灵活度高等优点的表面强化方法[48]. 在一定的静压力、振幅及进给速度等参数下,超声冲击针对材料表面进行高频冲击,材料表面经受每秒上万次的接触冲击从而形成严重的塑性变形层,其原理如图5所示[49]. 与SP处理效果类似,接头表层引入残余压应力并且表层晶粒组织细化并且沿厚度方向呈梯度变化,由于应力平衡使得次表层的应力调整为残余拉应力[50-52]. 超声冲击对焊接接头疲劳性能主要的影响为,调整接头表层残余应力场,引入残余压应力;剧烈的塑性变形使表层位错密度增加,晶粒尺寸减小,形成细晶强化层;可以改善焊接接头的表面形貌,从而降低应力集中[53-55].

Lago等人[56]对Strenx 700 MC低合金高强钢焊接接头进行接触力为85N的二次UIT,通过对UIT前后残余应力进行测量,结果如图6所示. 发现接头表面有效深度1 mm内的残余拉应力转换为残余压应力. 此外由于四点弯曲疲劳实验试样表层受力最大,而经过UIT的试样表层位错密度增加,疲劳裂纹形核所需要的进一步位错滑移受到限制,因而增加了疲劳裂纹萌生所需要的循环次数. 随着循环应力继续加载,次表层内的气孔和夹杂物等各种缺陷将作为疲劳裂纹的形核点,这使得疲劳次数N为108次时的疲劳强度最高从370 MPa增加至410 MPa. 刘博洋[57]对UIT前后30CrMnSi钢焊接接头试样的疲劳性能进行对比,结果显示处理后试样的疲劳强度提高了26.45%左右,达到300 MPa. 分析发现UIT除了在表面引入残余压应力、增加表面位错密度和细化晶粒之外,还改善焊趾处的表面形貌降低了应力集中,这些因素共同改善了接头疲劳性能.

Zhang等人[58]通过UIT对存在裂纹的S690QL钢焊接接头进改善,并使用有限元分析了UIT对不同初始裂纹深度接头疲劳寿命的影响. 当初始裂纹深度低于10 μm时,UIT可得到与无裂纹接头相同的改善效果. 当裂纹深度超过10 μm时,随着裂纹深度增加UIT后引入的残余压应力减小,对疲劳寿命的改善效果减弱,另外塑性变形使得疲劳裂纹发生偏转,减缓了疲劳裂纹的扩展. 随着裂纹深度继续增加,使得裂纹偏转的效果也随之减小,对疲劳寿命改善幅度持续减弱. 对于已经存在的浅裂纹或飞溅等焊接缺陷的焊接接头,通过UIT同样也可以改善其疲劳性能,这对于已经服役的构件的疲劳寿命改善具有实践意义.

SP处理、UIT和高频冲击处理等都属于HFMI范畴[59]. 其利用超声、气动或其他技术将压头进行高频(>90 Hz)加速的部件或结构进行冲击,被冲击材料发生高度塑性变形,导致焊趾局部区域几形貌状发生变化,并改变冲击区域的残余应力状态,此外还会使得局部硬度增大,角变形减小以及改善缺陷等[60]. HFMI处理的效果取决于许多参数,如压头半径、冲击加速度、压头数量、施加的载荷水平、被处理的材料质量、几何形状和现有的裂纹尺寸等[61].此外对于屈服强度较高的材料,HFMI诱导产生的残余压应力也会更大[62].

2.3 激光冲击强化

LSP是一种无污染、高效率的强化手段,通过高能量激光束实现对金属构件表面改性[63]. 在进行LSP加工过程中,高功率密度、短脉冲的激光束穿过材料表面的透明约束层,在吸收层表面迅速加热,发生电离气化形成等离子体,并在约束层作用下形成高幅值,短持续时间的压力脉冲后以冲击波形式传递到金属材料内部,当冲击波压力超过材料动态屈服强度时,就在材料表面产生塑性变形,引起位错,细化表面晶粒. 并在表面以下引入残余压应力,接头表面硬度显著增加[64-66].

许多学者对LSP改善高强钢焊接接头疲劳性能进行研究. 符素宁等人[67]对比分析了不同的LSP参数对1Cr14Ni3 W2VB/1Cr18Ni9 Ti异种钢TIG对接接头振动疲劳性能的影响,不同LSP功率对接头的强化效果,如图7所示. 从图7(a)中残余应力趋势可以看到,未经处理的焊接接头表面有较小残余压应力,次表面为残余拉应力,LSP处理之后在1 mm深度范围内将残余应力场调整为压应力,且改善效果随着激光功率增大而增大. 从图7(b)可以看到8J激光能量LSP后的试样振动疲劳寿命较未强化试样提高2.57倍. Ma等人[68]研究了LSP对U75VG钢轨闪光焊焊接接头三点弯曲疲劳性能的影响,发现经过LSP处理的接头诱导形成1.5 mm深度残余压应力层,改善了表面形貌从而降低了接头表面应力的集中,使得焊接接头疲劳极限提高了近7%. 冲击后晶粒内部高密度位错线相互缠结,形成亚晶界,并最终形成晶界,细化了晶粒. 另外随着LSP能量的增加,残余应力改善程度与晶粒细化程度也随之提高. 但接头表面随着冲击次数的增多而变得粗糙,粗糙度的增加有利于疲劳裂纹从表面萌生[69]. 因此疲劳性能的提高严重依赖于工艺参数,合理的激光参数可以显著提高疲劳寿命[70]. 疲劳裂纹萌生与扩展是多项因素相互作用的结果,需要结合接头类型、焊接方法、热处理方式和温度等外部因素选择合适的工艺,形成复合强化处理的方法,达到更优良的强化效果.

2.4 焊缝几何形状修整

焊接接头焊趾与焊缝表面由于几何不连续和组织不均匀容易形成应力集中,在焊接接头在承受交变载荷的过程中,疲劳载荷与应力集中叠加,疲劳裂纹非常容易在这些位置形核并萌生. 近年来改变焊趾处残余应力状态的方法在许多研究项目和工业实践中得到了广泛关注,然而焊缝几何形状改进技术同样应用广泛[71-73]. 焊接后可以通过将焊缝易产生应力集中的位置进行修整,去除焊趾表面缺陷增大过渡半径以降低应力集中来延缓疲劳裂纹的形核与萌生[74]. 目前对高强钢焊缝进行修整以提高焊缝疲劳性能的方法有打磨、焊缝仿形加工[75-76]、TIG熔修[77]和激光熔修[78]等方法,其主要原理就是焊后修整焊缝几何形状以及消除表面缺陷,以改善焊缝质量并降低应力集中,获得了更好的疲劳性能.

Moritz等人[75-76]分析了打磨和仿形加工对焊接接头疲劳强度的影响,指出磨削可适用于对接和角接焊接接头,在较低的应力范围内可以提高疲劳性能. 仿形加工对疲劳性能改善的效果,如图8所示[75]. 焊缝仿形加工比焊趾磨削对疲劳强度的提升更大,图8(a)中经过焊缝仿形加工的S690钢焊接接头的疲劳极限较焊态提高了284.7 %,图8(b)将仿形加工处理过的S355接头与经过HFMI处理的焊接接头疲劳性能进行对比,发现前者疲劳性能要略好于经过HFMI处理的接头,表明通过仿形加工和HFMI处理具有相近的疲劳性能改善效果.

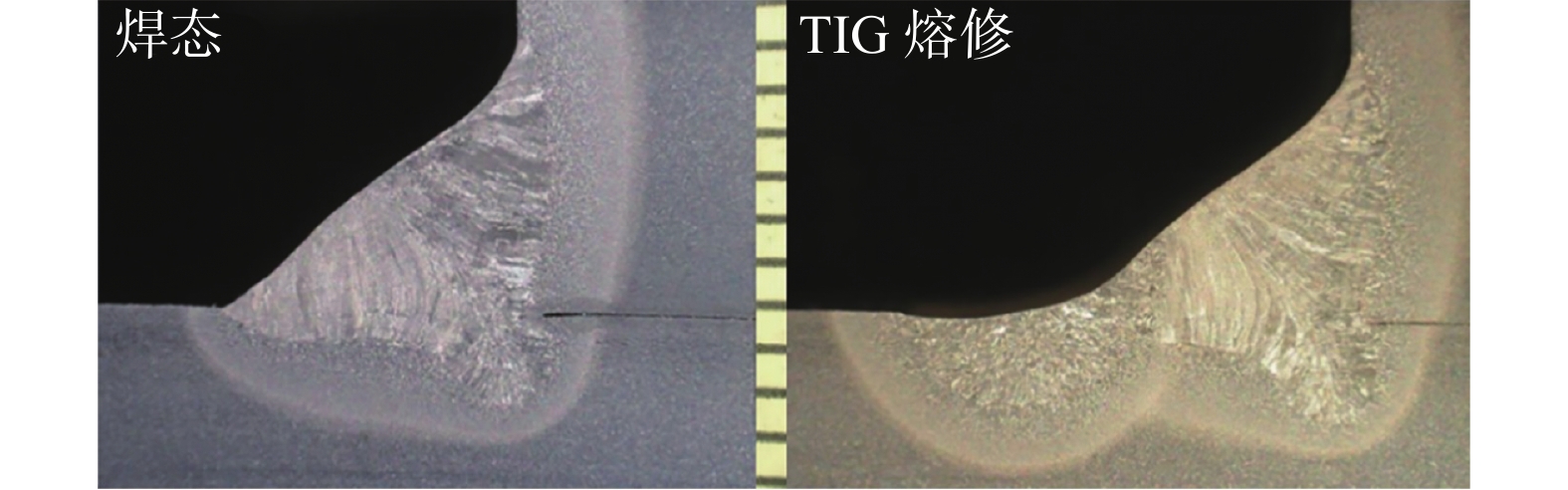

Mettanen等人[77]和Tuomas等人[78]分别对淬火S960钢非承载角焊缝焊接十字接头进行TIG熔修和激光熔修处理,TIG熔修处理前后接头横截面,如图9所示. 进行疲劳实验发现两种方法均增大了焊趾半径减小了应力集中系数,疲劳寿命均产生一定程度提高. 而TIG熔修对接头熔敷区引入较大残余压应力,激光熔修对残余应力场改善较小,使得TIG熔修接头疲劳性能要略好于激光熔修接头. Tobias等人[79]对Strenx® 1100Plus钢焊接接头进行TIG熔修处理将接头疲劳FAT等级提高到200 MPa,同样对比发现通过改善焊缝表面形貌,降低应力集中可达到与机械冲击强化相同的疲劳性能改善效果.

2.5 表面塑性加工

2.5.1 表面滚压

对表面进行滚压从而产生表面塑性变形是一种可以提高材料表面和亚表面磨损性能和疲劳强度的方法,其在一定接触力下,压头通过单次或多次滚动在表层和次表层产生连续的塑性变形,从而在表面和亚表面产生残余压应力和加工硬化,对于高强钢焊接接头焊趾位置存在的残余应力和局部组织软化等具有改进作用[80-81]. 对X30 MnCrN16-14合金钢焊接接头深滚之后发现,接头表面硬度显著提高,焊缝热影响区和熔合区的硬度均达到母材硬度之上,如图10所示,DP-A为低接触力、DP-B为高接触力,随着接触力增加焊趾残余应力由拉伸转为压缩,并且几何粗糙度大幅减小;随着接触力增加,残余应力改善程度增加,但接触力大小对几何粗糙度影响较小[82]. Danekas等人[83]对S355钢焊接接头进行深滚处理后发现接头表面变得平滑,接头表面残余压应力达到800 MPa和表面硬度提高是疲劳裂纹萌生寿命显著提高的主要原因.利用深滚方法提高接头疲劳性能时,随着滚珠直径增大接触力越大,在接头表面产生的残余压应力越大,其疲劳寿命越高.

焊趾作为焊接接头薄弱部位半径小且不规则,其对疲劳性能有较大影响. 较小直径的滚珠对焊接接头焊趾根部具有较好的可达性,有利于对焊趾部位的性能改善. 此外还有重叠因子和线间距等参数对疲劳性能的提高也有一定影响,表面粗糙度的增加对疲劳寿命也有一定的不利影响. 目前由于对滚压设备和工艺要求较高,采用滚压提高高强钢焊接接头的应用研究较少,阻碍了滚压在高强钢接头上的应用,但其为提高高强钢焊接接头疲劳性能提供了一种思路.

2.5.2 搅拌摩擦处理

采用搅拌摩擦处理(friction stir processing,FSP)对高强钢焊接接头表面实现塑性变形是一种可行的方法,利用搅拌头的旋转摩擦可以细化和均匀化金属材料微观组织,使得搅拌区强度、延展性和断裂韧性等力学性能提高. 同时有助于消除焊接接头内部缺陷,减少疲劳裂纹形核点[84-85]. FSP对高强钢焊接接头的疲劳性能提升效果依赖于处理工艺,行进速度过快容易造成接头表面粗糙度增加而有利于疲劳裂纹萌生,适当的行进速度可以更大程度改善高强钢焊接接头表面质量从而提高疲劳性能.

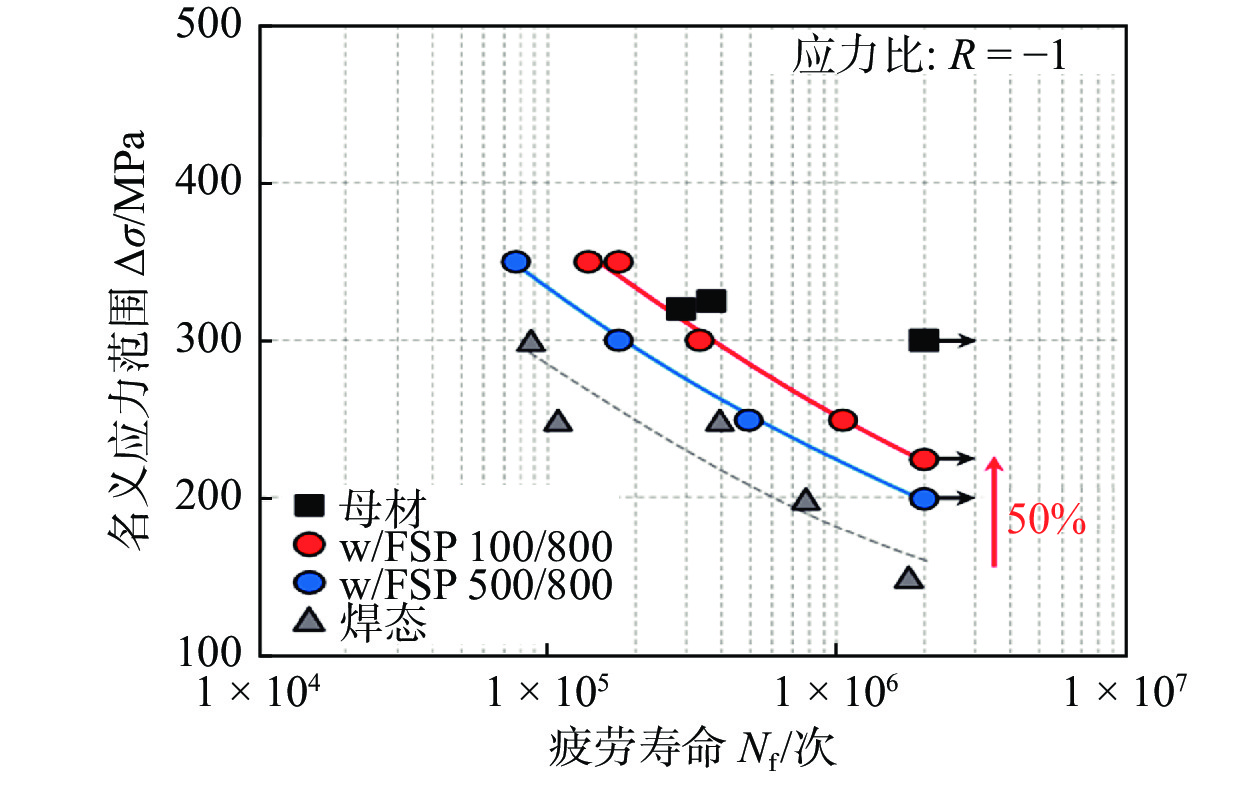

Yamamoto等人[86-87]使用球形搅拌头对低合金超高强钢焊接接头在转速下进行不同行程速度的FSP. 发现两种FSP接头不仅没有形成缺陷并且改善了焊趾位置的几何形状从而降低了应力集中系数,焊趾处的晶粒得到细化的同时提高硬度. FSP对接头疲劳性能的影响[86],如图11 所示. 低行程速度(100/800 mm/r/min)将焊趾处残余应力由27 MPa降低到−214 MPa,疲劳强度最大提升50%;而高行程速度(500/800 mm/r/min)反而提高了残余应力. 但是由于高行程速度FSP对焊趾应力集中和组织进行了改善,使得接头的疲劳强度也得到提高. 另外由于搅拌头材料成分中添加了大量W元素以提高硬度,在摩擦时搅拌头表面磨损的W元素混入接头表面组织,使得焊接接头表面局部硬度较高,有助于阻碍裂纹萌生,从而提高焊接接头的疲劳性能[87]. 因此FSP对于高强钢焊接接头疲劳性能的提升具有较好前景.

2.6 喷涂沉积

喷涂沉积是一种增材制造技术,其原理是预热的压缩气体(氦气/氮气)通过缩放喷嘴将固体状态粒子加速至超音速(300 ~

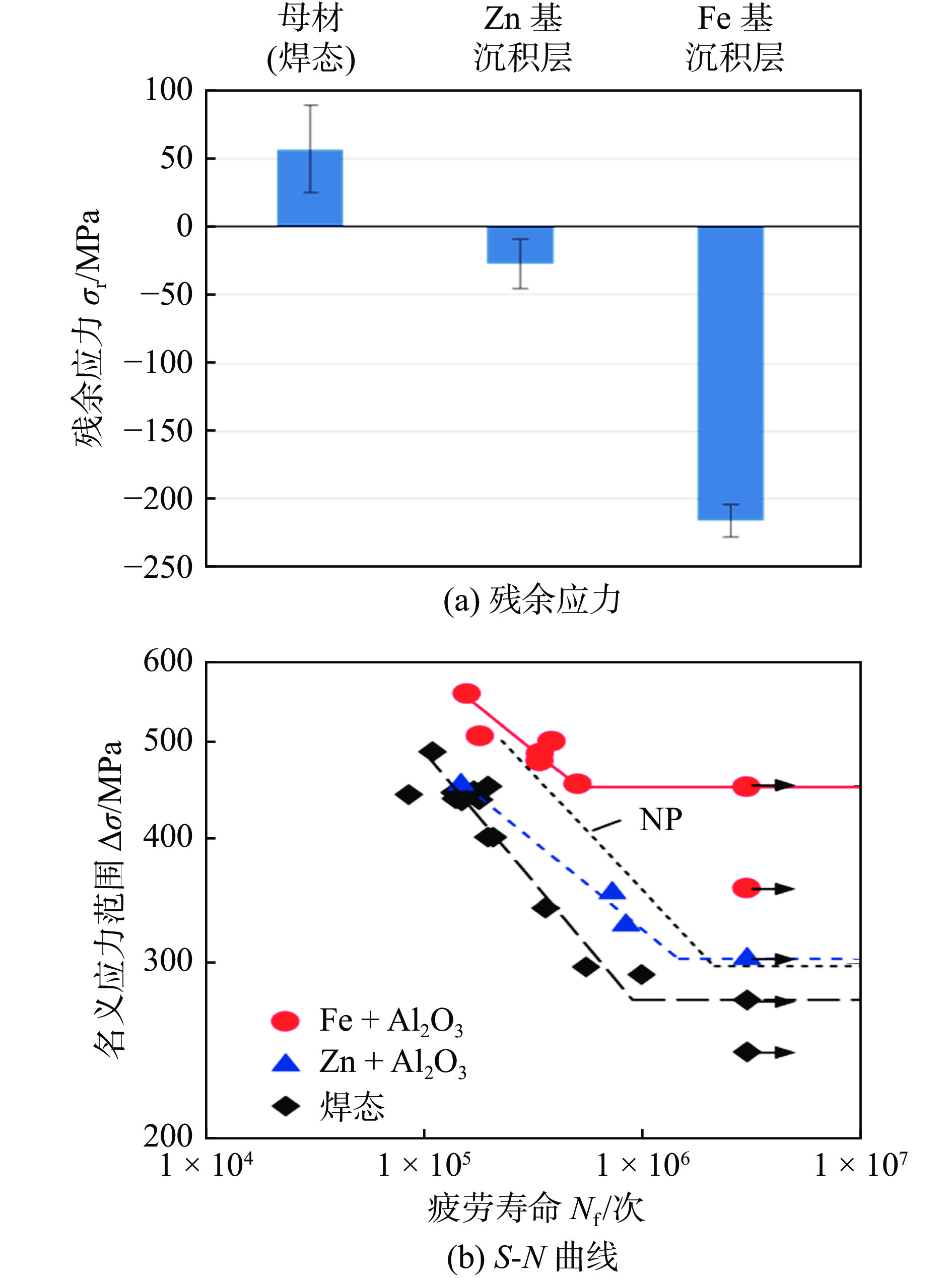

1200 m/s),从而在材料表面获得厚沉积层,许多学者通过喷涂沉积缓解或改善在焊缝表面以及焊趾位置的应力集中、残余应力和微观组织[88-89]. Naoki等人[89]对抗拉强度等级为980 MPa的超高强度钢搭接角焊缝使用两种不同沉积物进行喷涂,沉积层不仅降低了焊趾处的应力集中系数阻碍疲劳裂纹萌生,并且引入了残余压应力阻碍疲劳裂纹扩展. 喷涂沉积对接头残余应力和疲劳性能的影响[89],如图12所示. 图12(a)为对焊趾残余应力测量,发现两种沉积层均引入了残余压应力,但由于Zn质量比Fe小且热膨胀系数大导致收缩应力较大,抵消了更多的压应力使得Zn基沉积层残余压应力较Fe基沉积层小,从图12(b)可以看到,两种喷涂材料均提高了疲劳强度,但Fe基沉积层将接头3 × 106周次的疲劳强度从275 MPa提高到450 MPa,高于NP处理和Zn基喷涂沉积对疲劳性能的提升. 沉积层的组织性能如喷射颗粒间结合程度、沉积层力学性能对疲劳性能的提升也具有显著影响,若沉积层力学性能较低且表面较粗糙,则较基体更有利于裂纹萌生与扩展,从而降低接头的疲劳性能[90]. 此外沉积层与基体之间结合的紧密程度也是影响喷涂沉积对疲劳性能提升的重要因素,当沉积层与基体结合力较强不过早分层时,残余压应力具有降低载荷作用,当结合力较弱时,界面是裂纹容易萌生的薄弱位置[91]. 除此之外沉积层孔隙率、焊接缺陷敏感程度和形成的表面几何形状等对焊接接头疲劳性能都有着重要影响[91-92].文中将目前文献中报道的高强钢焊接接头疲劳寿命提高方法进行概述,将其进行总结归纳,如图13所示. 根据其作用机理,将这些方法分为两类,即基于几何形貌改进的方法和基于残余应力状态改进的方法.

3. 结论与展望

(1)文中讨论了影响高强钢焊缝疲劳性能的因素,焊缝中存在组织不均匀与应力集中造成疲劳裂纹过早萌生,焊接残余应力对接头疲劳裂纹扩展有显著的影响,引入残余压应力可以提高接头疲劳寿命.不同的焊接方法与填充材料等工艺会形成不同组织和强度以及焊缝形貌和残余应力状态,选择合适的焊接方法、焊材与工艺是可以获得较好疲劳性能的前提.

(2)高强钢焊接接头疲劳寿命的提高方法主要分为,基于焊缝几何形貌的改进,主要降低应力集中系数减缓疲劳裂纹的萌生.如TIG熔修、激光熔修、喷涂沉积、仿形加工和打磨等方法.其中TIG熔修、激光熔修和喷涂沉积也对残余应力状态有所调整,共同改善接头疲劳寿命;基于焊缝表面残余应力状态调整,主要以引入残余压应力减缓裂纹扩展速度.如PWHT、HFMI、LSP、滚压和搅拌摩擦等方法.这些方法除了调整残余应力外,还会提高接头表面硬度和细化表层晶粒从而阻碍疲劳裂纹萌生.

(3)目前这些提高高强钢焊接接头疲劳寿命方法已得到工业界的广泛认可,但还存在着一定局限性,后续研究需要注意的是由于高强钢焊接接头强度较高,传统的锤击和滚压在使用时对处理设备要求较高;使用TIG熔修、激光熔修和FSP对接头进行处理工艺不当时会造成表面粗糙度增加,对疲劳寿命提高不利;改善喷涂沉积后强化层抗裂纹能力和强化层与基体间结合力可以更好地提高接头疲劳寿命,HFMI或LSP后疲劳裂纹将偏向于在接头次表面萌生,因此如何减少次表面缺陷和优化组织对延长疲劳裂纹萌生寿命对更大程度提高接头疲劳寿命具有重要意义;对已经在表面产生的较小长度的疲劳裂纹可以对其进行修复,提高在役构件使用寿命从而降低运行成本;提高延寿设备的可达性、便携性和自动化程度以方便在焊接现场使用,大批量生产时需要提高设备生产效率.

-

-

[1] 帅朋, 高珊, 吴志生, 等. 高强钢焊接研究现状[J]. 焊接技术, 2016, 45(6): 1 − 4. Shuai Peng, Gao Shan, Wu Zhisheng, et al. Research status of high strength steel welding[J]. Welding Technology, 2016, 45(6): 1 − 4.

[2] 张伟. 第三代高强钢激光点焊接头成形机理及断裂行为研究[D]. 合肥: 中国科学院大学, 2021. Zhang Wei. Formation mechanism and fracture behavior of laser spot welded third generation high-strength steel [ D ]. Hefei: University of Chinese Academy of Sciences , 2021.

[3] 胡银辉. DP1000高强钢点焊工艺及接头组织与性能[D]. 长春: 吉林大学, 2013. Hu Yinhui. Resistance spot welding process and the microstructures and properties of DP1000 high strength steel joints [D]. Changchun: Jilin University, 2013.

[4] Ohnishi, Kawahito, Mizutani, et al. Butt welding of thick, high strength steel plate with a high power laser and hot wire to improve tolerance to gap variance and control weld metal oxygen content[J]. Science and Technology of Welding and Joining, 2013, 18(4): 314 − 322. doi: 10.1179/1362171813Y.0000000108

[5] Katayama S, Kawahito Y, Mizutani M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects[J]. Physics Procedia, 2010, 5(2): 9 − 17.

[6] Otegui J L, Kerr H W, Burns D J, et al. Fatigue crack initiation from defects at weld toes in steel[J]. International Journal of Pressure Vessels and Piping, 1989, 38(5): 385 − 417. doi: 10.1016/0308-0161(89)90048-3

[7] 李进. 大港电厂1号汽轮机喷嘴室断裂事故金属分析[J]. 华北电力技术, 1991(8): 7 − 12. Li Jin. Metal analysis of No. 1 steam turbine nozzle chamber fracture accident in dagang power plant[J]. North China Electric Power Technology, 1991(8): 7 − 12.

[8] 叶华文, 黄若森, 周渝, 等. 澳大利亚焊接工字钢梁桥疲劳断裂事故分析[J]. 建筑结构, 2022, 52,(S1): 1251 − 1255. Ye Huawen, Huang Ruosen, Zhou Yu, et al. Fatigue fracture failure analysis of a welded I-beam steel bridge in Australia[J]. Building Structure, 2022, 52,(S1): 1251 − 1255.

[9] Chapetti M D, Otegui J L. Controlled toe waviness as a means to increase fatigue resistance of automatic welds in transverse loading[J]. International Journal of Fatigue, 1997, 19(10): 667 − 675. doi: 10.1016/S0142-1123(97)00061-3

[10] Ahiale K G, Oh Y, Choi W, et al. Microstructure and fatigue resistance of high strength dual phase steel welded with gas metal arc welding and plasma arc welding processes[J]. Metals and Materials International, 2013, 19(5): 933 − 939. doi: 10.1007/s12540-013-5005-3

[11] Tsuyoshi S, Naoki Y, Yoshikiyo T, et al. Effect of weld toe geometry on fatigue life of lap fillet welded ultra-high strength steel joints[J]. International Journal of Fatigue, 2018, 116: 409 − 420. doi: 10.1016/j.ijfatigue.2018.06.050

[12] 张晨星. 焊缝形貌对焊接强度的影响研究[D]. 秦皇岛: 燕山大学, 2022. Zhang Chenxing. Study on the influence of weld morphology on welding strength[D]. Qinhuangdao: Yanshan University, 2022.

[13] 王晓南, 郑知, 曾盼林, 等. 800 MPa级高强钢光纤激光焊接接头微观结构对硬度及疲劳性能的影响[J]. 中国激光, 2016, 43(12): 115 − 124. Wang Xiaonan, Zheng Zhi, Zeng Panlin, et al. Effects of microstructure on hardness and fatigue properties of 800 MPa high strength steel fiber laser welded joints[J]. Chinese Journal of Lasers, 2016, 43(12): 115 − 124.

[14] Wang W K, Liu Y, Guo Y, et al. High cycle fatigue and fracture behaviors of CrMoV/NiCrMoV dissimilar rotor welded joint at 280 ℃[J]. Materials Science & Engineering A, 2020: 139473.

[15] 镇顺利. 焊接T形接头疲劳寿命及残余应力释放研究[D]. 石家庄铁道大学, 2022. Zheng Shunli. Research on fatigue life and residual stress release of welded T-joints[D]. Shijiazhuang Tiedao University, 2022.

[16] 苗玉刚, 刘吉, 李小旭, 等. BC-MIG丝材电弧增材制造NAB/钢复合结构的微观组织与力学性能[J]. 焊接学报, 2023, 44(7): 56 − 62. Miao Yugang, Liu Ji, Li Xiaoxu. Microstructure and mechanical properties of NAB/steel composite structures by additive manufacturing with BC-MIG wire arc[J]. Transactions of the China Welding Institution, 2023, 44(7): 56 − 62.

[17] 苟川东. X80管道焊接残余应力及结构疲劳寿命数值分析[D]. 西安理工大学, 2022. Gou Chuandong. Numerical analysis of welding residual stress and structural fatigue life of X80 pipeline[D]. Xi 'an University of Technology, 2022.

[18] Anna E, Javad R, Sandra C, et al. The effect of surface treatment and orientation on fatigue crack growth rate and residual stress distribution of wire arc additively manufactured low carbon steel components[J]. Journal of Materials Research and Technology, 2023, 24: 2988 − 3004. doi: 10.1016/j.jmrt.2023.03.227

[19] 熊祥. 残余应力场对超高强钢焊接接头疲劳裂纹扩展行为的影响[D]. 哈尔滨工业大学, 2014. Xiong Xiang. Effect of residual stress field on fatigue crack propagation behavior at welded joints of ultra-high strength steel[D]. Harbin Institute of Technology, 2014.

[20] Leitner M , Mossler W, Putz A, et al. Effect of post-weld heat treatment on the fatigue strength of HFMI-treated mild steel joints[J]. Welding in the World, 2015, 59(6): 861 − 873.

[21] 宋威, 满铮, 徐杰, 等. 含错位效应十字焊接接头疲劳可靠性评估[J]. 焊接学报, 2023, 44(6): 20 − 26 + 34. doi: 10.12073/j.hjxb.20220629001 Song Wei, Man Zheng, Xu Jie, et al. Fatigue reliability analysis of load-carrying cruciform joints with misalignment effects[J]. Transactions of the China Welding Institution, 2023, 44(6): 20 − 26 + 34. doi: 10.12073/j.hjxb.20220629001

[22] Ceferino S, Nenad G, Tomaz V, et al. Effect of welding processes on the fatigue behaviour of ultra-high strength steel butt-welded joints[J]. Engineering Fracture Mechanics, 2022, 275: 108845. doi: 10.1016/j.engfracmech.2022.108845

[23] Tumer M, Schneider-Broskamp C, Enzinger N. Fusion welding of ultra-high strength structural steels-a review[J]. Journal of Manufacturing Processes, 2022, 82: 203 − 229. doi: 10.1016/j.jmapro.2022.07.049

[24] Dzioba I, Pala T. Influence of LWE on strength of welded joints of HSS S960-experimental and numerical analysis[J]. Materials, 2020, 13(3): 747 − 747. doi: 10.3390/ma13030747

[25] Hariprasath P, Sivaraj P, Balasubramanian V, et al. Effect of welding processes on high cycle fatigue behavior for naval grade HSLA joints: a fatigue strength prediction[J]. Engineering Failure Analysis, 2022, 142: 106783. doi: 10.1016/j.engfailanal.2022.106783

[26] Ravi S, Balasubramanian V, Babu S, et al. Assessment of some factors influencing the fatigue life of strength mis-matched HSLA steel weldments[J]. Materials & Design, 2004, 25(2): 125 − 135.

[27] Liu Y, Tsang K S, Subramaniam N A, et al. Structural fatigue investigation of thermite welded rail joints considering weld-induced residual stress and stress relaxation by cyclic load[J]. Engineering Structures, 2021, 235: 112033. doi: 10.1016/j.engstruct.2021.112033

[28] Ngoula T D, Beier H, Vormwald M. Fatigue crack growth in cruciform welded joints: influence of residual stresses and of the weld toe geometry[J]. International Journal of Fatigue, 2017, 101: 253 − 262.

[29] 赵智力, 杨建国, 刘雪松等. 10CrNi3MoV钢低匹配对接接头的拉伸疲劳性能[J]. 焊接学报, 2010, 31(3): 89 − 92. Zhao Zhili, Yang Jianguo, Liu Xuesong, et al. Mechanical and fatigue properties of undermatching butt joints of 10CrNi3MoV steel[J]. Transactions of the China Welding Institution, 2010, 31(3): 89 − 92 .

[30] Adam D, Marcell G, Janos L. The influence of mismatch effect on the high cycle fatigue resistance of high strength steel welded joints[J]. Advanced Materials Research, 2018, 1146: 73 − 83.

[31] Ravi S, Balasubramanian V, Nasser N S. Effect of mis-match ratio (MMR) on fatigue crack growth behaviour of HSLA steel welds[J]. Engineering Failure Analysis, 2003, 11(3): 413 − 428.

[32] Ravi S, Balasubramanian V, Nasser N S. Influences of Post Weld heat treatment on fatigue life prediction of gtrength mis-matched HSLA steel welds[J]. International Journal of Fatigue, 2005(27): 547 − 553

[33] Ravi S, Balasubramanian V, Nasser S N. Fatigue life prediction of strength mis-matched high strength low alloy steel welds[J]. Materials & Design, 2006, 27(4): 278 − 286.

[34] Shiga C, Murakawa H, Hiraoka K, et al. Elongated bead weld method for improvement of fatigue properties in welded joints of ship hull structures using low transformation temperature welding materials[J]. Welding in the World, 2017, 61(4): 769 − 788. doi: 10.1007/s40194-017-0439-8

[35] Smith C, Pistorius P G. The effect of a long post weld heat treatment on the integrity of a welded joint in a pressure vessel steel[J]. International Journal of Pressure Vessels and Piping, 1997, 70(3): 183 − 195. doi: 10.1016/S0308-0161(96)00029-4

[36] Feng X Y, Zheng K F, Heng J L, et al. Fatigue performance of rib-to-deck joints in orthotropic steel deck with PWHT[J]. Journal of Constructional Steel Research, 2022, 196: 107420. doi: 10.1016/j.jcsr.2022.107420

[37] Selvamani S, Vigneshwar M, Nikhil M, et al. Enhancing the fatigue properties of friction welded AISI 1020 grade steel joints using post weld heat treatment process in optimized condition[J]. Materials Today, 2019, 16(P2): 1251 − 1258.

[38] Yildirim C H, Marquis B G. Overview of fatigue data for high frequency mechanical impact treated welded joints[J]. Welding in the World, 2012, 56(7-8): 82 − 96. doi: 10.1007/BF03321368

[39] 朱鹏飞, 严宏志, 陈志, 等. 齿轮齿面喷丸强化研究现状与展望[J]. 表面技术, 2020, 49(4): 113 − 131. Zhu Pengfei, Yan Hongzhi, Chen Zhi, et al. Research status and prospect of shot peening of gear tooth flanks[J]. Surface Technology, 2020, 49(4): 113 − 131

[40] Malaki M, Ding H. A review of ultrasonic peening treatment[J]. Materials & Design, 2015, 87: 1072 − 1086.

[41] Zhan K, Jiang C H, Ji V. Effect of prestress state on surface layer characteristic of S30432 austenitic stainless steel in shot peening process[J]. Materials & Design, 2012, 42: 89 − 93.

[42] Scuracchio G B, Lima D B, Schon G C. Role of residual stresses induced by double peening on fatigue durability of automotive leaf springs[J]. Materials & Design, 2013, 47: 672 − 676.

[43] 王成. 喷丸强化过程的数值模拟与疲劳裂纹扩展行为研究[D]. 浙江工业大学, 2016. Wang Cheng. Study of shot peening simulation and fatigue crack growth behavior[D]. Zhejiang University of Technology, 2016.

[44] 李丰博, 肖桂枝. 喷丸对X70管线钢焊接接头组织与性能的影响[J]. 金属热处理, 2017, 42(9): 178 − 182. Li Fengbo, Xiao Guizhi. Effect of shot peening on microstructure and properties of pipeline steel welded joint[J]. Heat Treatment of Metals, 2017, 42(9): 178 − 182.

[45] 门延会, 王强, 严瑞强, 等. 喷丸对小型船舶钢板焊接接头的腐蚀和疲劳影响[J]. 船舶工程, 2021, 43(9): 101 − 104 + 110. Men Yanhui, Wang Qiang, Yan Ruiqiang, et al. Effects of shot blasting on corrosion and fatigue properties of welded joint of ship steel sheets[J]. Ship Engineering, 2021, 43(9): 101 − 104 + 110.

[46] Fueki R, Takahashi K. Improving the fatigue limit and rendering a defect harmless by laser peening for a high strength steel welded joint[J]. Optics & Laser Technology, 2021, 134: 106605.

[47] Yamaguchi N, Shiozaki T, Tamai Y. Micro-needle peening method to improve fatigue strength of arc-welded ultra-high strength steel joints[J]. Journal of Materials Processing Technology, 2021, 288: 116894. doi: 10.1016/j.jmatprotec.2020.116894

[48] 李东东, 郑云, 初明进, 等. 超声冲击强化技术处理焊接结构的研究进展[J]. 材料保护, 2019, 52(11): 139 − 145 + 150. Li Dongdong, Zheng Yun, Chu Mingjin, et al. Research progress of ultrasonic impact strengthening technology for welded structures[J]. Material protection, 2019, 52(11): 139 − 145 + 150.

[49] Abdullah A, Malaki M, Eskandari A. Strength enhancement of the welded structures by ultrasonic peening[J]. Materials & Design, 2012, 38: 7 − 18.

[50] 朱有利, 王燕礼, 边飞龙, 等. 金属材料超声表面强化技术的研究与应用进展[J]. 机械工程学报, 2014, 50(20): 35 − 45. doi: 10.3901/JME.2014.20.035 Zhu Youli, Wang Yanli, Bian Feilong, et al. Progresses on research and application of metal ultrasonic surface enhancement technologies[J]. Journal of Mechanical Engineering, 2014, 50(20): 35 − 45. doi: 10.3901/JME.2014.20.035

[51] 白易立, 王东坡, 邓彩艳, 等. 超声冲击强度对焊接接头疲劳寿命的影响[J]. 焊接学报, 2019, 40(12): 149 − 153. Bai Yili, Wang Dongpo, Deng Caiyan, et al. Effect of ultrasonic impact strength on fatigue life of welded joints[J]. Transactions of the China Welding Institution, 2019, 40(12): 149 − 153.

[52] Huang S, Qi Z J, Zhang A F, et al. Reducing the anisotropy of the mechanical properties of directed energy deposited Ti6Al4V alloy with inter-layer ultrasonic impact peening and heat treatment[J]. Materials Science & Engineering A, 2022, 857: 144123.

[53] 邓海鹏, 于影霞. 超声冲击对焊接接头表面质量的影响[J]. 表面技术, 2017, 46(2): 208 − 213. Deng Haipeng, Yu Yingxia. Effect of ultrasonic impact on the surface quality of welded joint[J]. Surface Technology, 2017, 46(2): 208 − 213.

[54] Haagensen P J, Statnikov E S, Lopezmartinez L. Introductory fatigue tests on welded joints in high strength steel and aluminum improved by various methods including ultrasonic impact treatment (UIT)[R]. Oslo, Norway: International Institute of Welding, 2008.

[55] 叶雄林, 朱有利. 超声冲击细化22SiMn2TiB超高强钢焊接接头晶粒研究[J]. 热加工工艺, 2006(6): 12 − 14. doi: 10.3969/j.issn.1001-3814.2006.06.006 Ye Xionglin, ZhuYouli. Investigation on fining grain of ultrahigh strength steel welding joint by ultrasonic impact treatment[J]. Hot Working Technology, 2006(6): 12 − 14. doi: 10.3969/j.issn.1001-3814.2006.06.006

[56] Lago J, Trsko L, Jambor M, et al. Fatigue life improvement of the high strength steel welded joints by ultrasonic impact peening[J]. Metals, 2019, 9(6): 618. doi: 10.3390/met9060618

[57] 刘博洋. 超声冲击处理对30CrMnSi钢焊接接头腐蚀和疲劳性能的影响[D]. 吉林大学, 2022. Liu Boyang. Effect of ultrasonic impact treatment on corrosion and fatigue properties of 30CrMnSi steel welded joint[D]. Changchun: Jilin University, 2022.

[58] Zhang H, Wang D P, Xia L Q, et al. Effects of ultrasonic impact treatment on pre-fatigue loaded high-strength steel welded joints[J]. International Journal of Fatigue, 2015, 80: 278 − 287. doi: 10.1016/j.ijfatigue.2015.06.017

[59] Hassan A , Franz U, Mohammad A. Fatigue life extension of existing welded structures via high frequency mechanical impact (HFMI) treatment[J]. Engineering Structures, 2021, 239: 112234.

[60] Yildirim C H, Marquis B G. Fatigue strength improvement factors for high strength steel welded joints treated by high frequency mechanical impact[J]. International Journal of Fatigue, 2012, 44: 168 − 176. doi: 10.1016/j.ijfatigue.2012.05.002

[61] Leitner M, Khurshid M, Barsoum Z. Stability of high frequency mechanical impact (HFMI) post-treatment induced residual stress states under cyclic loading of welded steel joints[J]. Engineering Structures, 2017, 143: 589 − 602. doi: 10.1016/j.engstruct.2017.04.046

[62] Shams-Hakimi P, Zamiri F, Al-Emrani M, et al. Experimental study of transverse attachment joints with 40 and 60 mm thick main plates, improved by high-frequency mechanical impact treatment (HFMI)[J]. Engineering Structures, 2018, 155: 251 − 266. doi: 10.1016/j.engstruct.2017.11.035

[63] 何兆儒, 沈一洲, 周晋, 等. 激光冲击强化的微观组织演变与性能研究进展[J]. 航空制造技术, 2021, 64(19): 48 − 58. He Zhaoru, Shen Yizhou, Zhou Jin, et al. Microstructure evolution and performant enhancement of laser shock peening[J]. Aeronautical Manufacturing Technology, 2021, 64(19): 48 − 58.

[64] Charles S, Wei T, YeL, et al. Laser shock processing and its effects on microstructure and properties of metal alloys: a review[J]. International Journal of Fatigue, 2002, 24(10): 1021 − 1036. doi: 10.1016/S0142-1123(02)00022-1

[65] 舒坤, 乔红超, 赵吉宾, 等. 激光冲击强化对焊缝组织性能影响的研究进展[J]. 表面技术, 2023, 52(7): 41 − 54. Shu Kun, Qiao Hongchao, Zhao Jibin, et al. Research progress on the effect of laser shock processing on the properties of weld[J]. Surface Technology, 2023, 52(7): 41 − 54.

[66] Yuji S, Tomoharu K, Yoshio M, et al. Development of a portable laser peening device and its effect on the fatigue properties of HT780 butt-welded joints[J]. Forces in Mechanics, 2022, 7: 100080. doi: 10.1016/j.finmec.2022.100080

[67] 符素宁, 武德安, 赵静, 等. 激光冲击强化对异种不锈钢焊接接头振动疲劳性能影响的分析[J]. 热加工工艺, 2023, 52(9): 56 − 60. Fu Suning, Wu Dean, Zhao Jing, et al. Analysis of the effect of laser shock peening on the vibration fatigue properties of dissimilar stainless steel welded joints[J]. Hot Working Technology, 2023, 52(9): 56 − 60.

[68] Ma R, Huang D, Zhang J, et al. Effects of rail flash-butt welding and post-weld heat treatment processes meeting different national standards on residual stresses of welded joints[J]. International Journal of Materials Research, 2020, 111(9): 780 − 787. doi: 10.3139/146.111935

[69] Dhakal B, Swaroop S. Review: laser shock peening as post welding treatment technique[J]. Journal of Manufacturing Processes, 2018, 32: 721 − 733. doi: 10.1016/j.jmapro.2018.04.006

[70] Zhang X S, Ma Y, Yang M, et al. A comprehensive review of fatigue behavior of laser shock peened metallic materials[J]. Theoretical and Applied Fracture Mechanics, 2022, 122: 103642. doi: 10.1016/j.tafmec.2022.103642

[71] Leitner M, Simunek D, Shah F S, et al. Numerical fatigue assessment of welded and HFMI-treated joints by notch stress/strain and fracture mechanical approaches[J]. Advances in Engineering Software, 2018, 120: 96 − 106. doi: 10.1016/j.advengsoft.2016.01.022

[72] Schubnell J, Pontner P, Wimpory R, et al. The influence of work hardening and residual stresses on the fatigue behavior of high frequency mechanical impact treated surface layers[J]. International Journal of Fatigue, 2020, 134: 105450. doi: 10.1016/j.ijfatigue.2019.105450

[73] Baumgartner J, Yildirim C H, Barsoum Z. Fatigue strength assessment of TIG-dressed welded steel joints by local approaches[J]. International Journal of Fatigue, 2019, 126: 72 − 78. doi: 10.1016/j.ijfatigue.2019.04.038

[74] Al-Karawi H, Polach U B, Al-Emrani M. Fatigue crack repair in welded structures via tungsten inert gas remelting and high frequency mechanical impact[J]. Journal of Constructional Steel Research, 2020, 172: 106200. doi: 10.1016/j.jcsr.2020.106200

[75] Moritz B, Jonas H, Shi S , et al. Fatigue strength of normal and high strength steel joints improved by weld profiling[J]. Engineering Structures, 2021, 246: 113030.

[76] Moritz B, Wang X R. A review of fatigue test data on weld toe grinding and weld profiling[J]. International Journal of Fatigue, 2021, 145: 106073.

[77] Mettanen H, Nykanen T, Skriko T, et al. Fatigue strength assessment of TIG-dressed ultra-high-strength steel fillet weld joints using the 4R method[J]. International Journal of Fatigue, 2020, 139: 105745. doi: 10.1016/j.ijfatigue.2020.105745

[78] Tuomas S, Antti A, Ilkka P, et al. Fatigue strength of laser-dressed non-load-carrying fillet weld joints made of ultra-high-strength steel[J]. Procedia Structural Integrity, 2022, 38: 393 − 400. doi: 10.1016/j.prostr.2022.03.040

[79] Tobias J, Torbjorn N, Zuheir B. Fatigue and ultimate strength assessment of post weld treated strenx® 1100 plus butt welds[J]. Procedia Structural Integrity, 2022, 38: 414 − 417.

[80] 王佳杰, 杨建国, 张敬强, 等. 随焊冲击碾压整形新方法及等承载接头拉伸与疲劳性能[J]. 焊接学报, 2012, 33(11): 35 − 38. Wang Jiajie, Yang Jianguo, Zhang Jingqiang, et al. A new weld shaping method with trailing impact rolling and of tensile and fatigue properties of equal load-carry capacity joints[J]. Transactions of the China Welding Institution, 2012, 33(11): 35 − 38.

[81] Maximilian K H, Steffen H, Christian D, et al. Automated geometry measurement and deep rolling of butt welds[J]. Welding in the World, 2022, 66(12): 2533 − 2547. doi: 10.1007/s40194-022-01346-w

[82] Jan S, Martin D, Michael L. Strength improvement of laser beam welded joints in cold worked high-manganese-steel by means of deep rolling[J]. Procedia CIRP, 2022, 111: 457 − 461. doi: 10.1016/j.procir.2022.08.065

[83] Danekas C, Heikebrugge S, Schubnell J, et al. Influence of deep rolling on surface layer condition and fatigue life of steel welded joints[J]. International Journal of Fatigue, 2022, 162: 106694.

[84] Sekban D, Aktarer S, Xue P, et al. Impact toughness of friction stir processed low carbon steel used in shipbuilding[J]. Materials Science & Engineering A, 2016, 672: 40 − 48.

[85] Xue P, Wang B B, Chen F F, et al. Microstructure and mechanical properties of friction stir processed Cu with an ideal ultrafine-grained structure[J]. Materials Characterization, 2016, 121: 187 − 194.

[86] Yamamoto H, Danno Y, Ito K, et al. Weld toe modification using spherical-tip WC tool FSP in fatigue strength improvement of high-strength low-alloy steel joints[J]. Materials & Design, 2018, 160: 1019 − 1028.

[87] Yamamoto H, Koga S, Ito K, et al. Fatigue strength improvement due to alloying steel weld toes with WC tool constituent elements through friction stir processing[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(9): 6203 − 6213.

[88] Assadi H, Kreye H, Gärtner F , et al. Cold spraying−a materials perspective[J]. Acta Materialia, 2016, 116: 382 − 407.

[89] Naoki Y , Tsuyoshi S , Yoshikiyo T , et al. Effect of cold spray deposition on fatigue strength of arc-welded ultra-high strength steel sheet[J]. International Journal of Fatigue, 2022, 161: 106876.

[90] Bagherifard S, Guagliano M. Fatigue performance of cold spray deposits: coating, repair and additive manufacturing cases[J]. International Journal of Fatigue, 2020, 139: 105744. doi: 10.1016/j.ijfatigue.2020.105744

[91] Xiong Y M, Zhang M X. The effect of cold sprayed coatings on the mechanical properties of AZ91D magnesium alloys[J]. Surface & Coatings Technology, 2014, 253: 89 − 95.

[92] Cavaliere P, Perrone A, Silvello A. Fatigue behaviour of Inconel 625 cold spray coatings[J]. Surface Engineering, 2018, 34(5): 380 − 391. doi: 10.1080/02670844.2017.1371872

-

期刊类型引用(1)

1. 孙立成,毛泓霖,明驰,卫星. 承载型60°斜十字全熔透焊接接头疲劳寿命评估. 焊接学报. 2025(01): 137-144 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: