On-line monitoring of TIG welding quality of nuclear power plug tube based on arc spectrum

-

摘要:

为了实现受操作空间限制和辐射环境下,高温气冷堆蒸汽发生器传热管道堵管钨极惰性气体保护电弧焊(tungsten inert gas welding, TIG)的质量监测,搭建了一套基于光纤光谱仪的 TIG 焊接过程实时监测系统,用于核电传热管道堵管TIG 焊接熔深监测.试验研究采用该系统采集电弧光谱,利用主成分分析法获取不同焊缝熔深的光谱主成分特征,创新性提出了一种 ATT-L2R-BiLSTM 深度学习模型,实现了堵管TIG焊接过程中焊缝熔深的分类识别. 结果表明,实验室条件下模型准确率可达92.61%,比Bi-LSTM网络准确率提高5.11%,该模型在核电蒸汽发生器堵管验证平台进行了测试和验证,准确率达到99.26%,最终,实现了光谱信息不完备下TIG 焊接质量特征深度挖掘,以及TIG焊接熔深的精准评估.

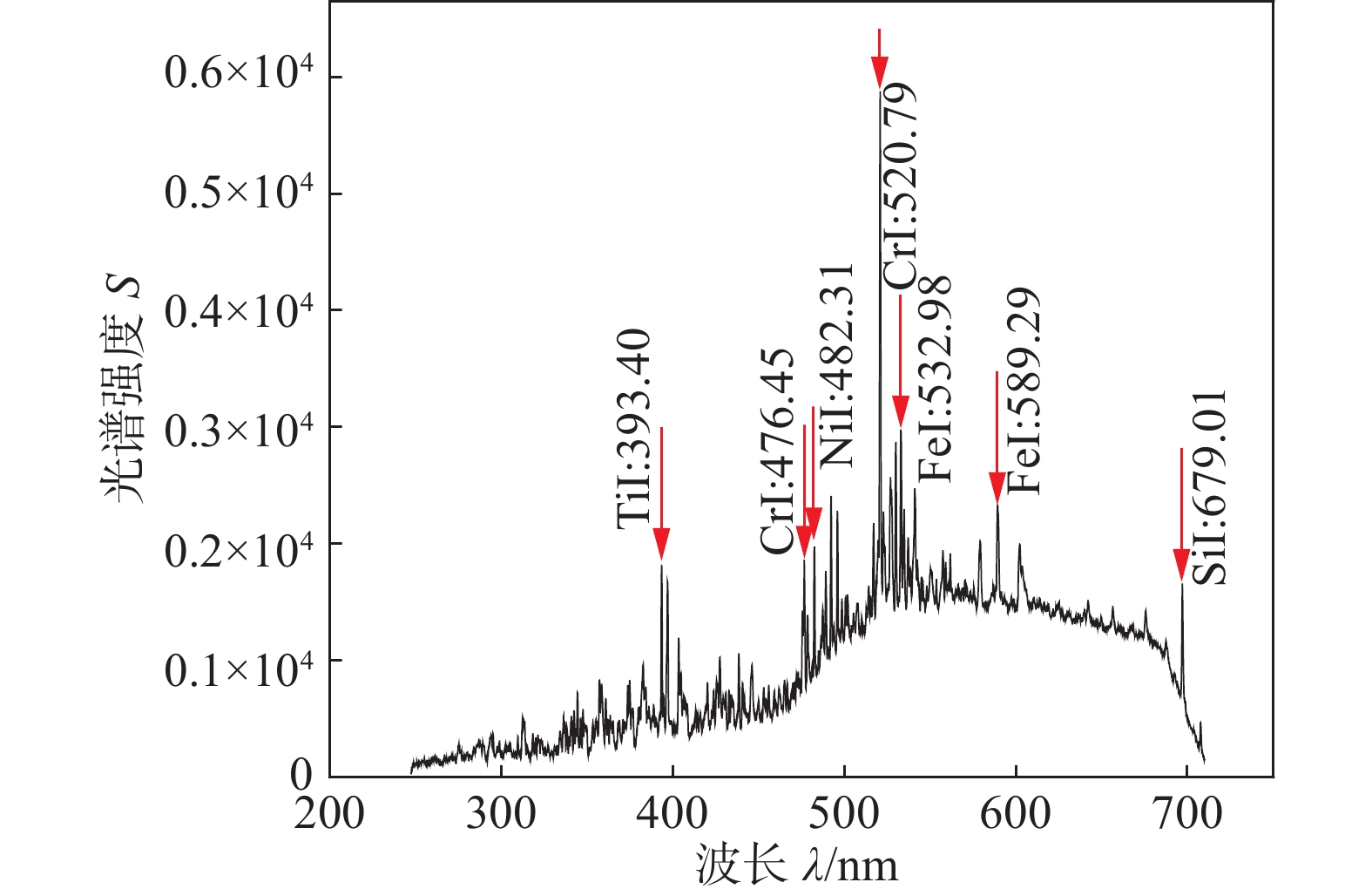

Abstract:In order to monitor the quality of TIG welding for blocked tube welding of high-temperature gas-cooled reactor steam generators under the constraints of operation space and radiation environment, a real-time monitoring system based on a fiber optic spectrometer for TIG welding process was developed for monitoring the depth of penetration during welding. This study used the system to collect arc spectra and utilized Principal Component Analysis to obtain the spectral principal components of different weld penetration depths. An innovative ATT-L2R-BiLSTM deep learning model was proposed to achieve classification and recognition of weld penetration depth during blocked tube TIG welding. The results show that the model achieved an accuracy of 92.61% under laboratory conditions, which is 5.11% higher than that of the Bi-LSTM network. The model was tested and verified on a blocked tube verification platform for nuclear power steam generators, achieving an accuracy of 99.26%. Finally, deep mining of welding quality features and precise evaluation of weld penetration depth during TIG welding were achieved under incomplete spectral information.

-

-

表 1 TIG堆焊试验工艺参数

Table 1 Experimental process parameters of TIG surfacing

焊接速度

v/(cm·min−1)频率

f/Hz氩气流量

q/(L·min−1)焊接层数 填丝情况 15 2.3 15 1 不填丝 表 2 Incoloy 800H化学成分(质量分数,%)

Table 2 Incoloy 800H chemical components

C Si Cr Ni Fe Al Ti S 其他 0.05 ~ 0.10 ≤1.0 19.0 ~ 23.0 30.0 ~ 35.0 ≥39.5 0.15 ~ 0.6 0.15 ~ 0.6 ≤0.015 ≤0.015 表 3 焊接熔深和对应标签

Table 3 Welding depth and its corresponding labeling

试验编号 焊接电流

I/A熔深

d1/μm标签 1 110 636.83 0 2 140 754.79 1 3 155 878.22 2 4 170 954.17 3 表 4 网络模型参数

Table 4 Network model parameters

学习率 批训练大小 训练周期T/周次 网络层数 N1 隐藏层数 N2 L2正则化权重衰减 0.000 15 50 200 3 80 0.002 表 5 TIG焊800H焊接过程质量评估结果对比

Table 5 Comparison of quality assessment results of 800H TIG welding process

网络 平均train

准确率Ata(%)平均test

准确率Ate(%)RNN 100 79.55 LSTM 100 81.82 GRU 100 81.53 Bi-LSTM 100 87.50 ATT-L2R-BiLSTM 100 92.61 表 6 圆弧焊接试验固定工艺参数

Table 6 Fixed experimental parameter of circular arc welding

焊接速度

v/(cm·min−1)频率

f/Hz氩气流量

q/(L·min−1)焊接

层数填丝

情况17 2.3 15 1 填丝 表 7 填充焊丝化学成分(质量分数,%)

Table 7 Filler wire chemical components

C Si Cr Ni Fe Al Ta + Nb S Mn Cu Ti 其他 ≤0.1 ≤0.5 18 ~ 22 ≥67 ≤2 0.15 ~ 0.6 2 ~ 3 ≤0.015 2.5 ~ 3.5 ≤0.5 ≤0.75 ≤0.5 表 8 焊接和光谱监测系统动态变化参数

Table 8 Welding and spectral monitoring system dynamic change parameters

试验

编号积分时间

t/ms焊接电流

I/A光谱探头与焊点

间距L/cm1 15 130 35 2 4 120 40 3 10 120 40 4 40 120 40 表 9 堵管焊接熔深和对应标签

Table 9 Pipe plug welding depth and corresponding label

试验编号 熔深d1/mm 标签 数据量 1 1.66 0 2 131 2 2.58 1 2 977 3 1.44 2 2 356 4 1.67 0 1 107 -

[1] 欧清扬. 核电蒸汽发生器换热管内壁残余应力测试技术应用研究[D]. 广州: 华南理工大学, 2019. Ou Qingyang, Application of residual stress test technology on inner wall of heat exchange tube of nuclear power steam generator [D]. Guangzhou: South China University of Technology, 2019.

[2] 刘冀. 表面状态对蒸汽发生器传热管材高温高压水腐蚀行为的影响[D]. 合肥: 中国科学技术大学, 2021. Liu Ji. Influence of surface state on high temperature and high pressure water corrosion behavior of steam generator heat transfer pipe [D]. Hefei: University of Science and Technology of China, 2021.

[3] 齐欣. 5A06铝合金变动送气TIG焊焊缝性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2021. Qi Xin. Study on weld properties of 5A06 aluminum alloy with variable gas injection TIG welding [D]. Harbin: Harbin University of Science and Technology, 2021.

[4] 李振华. 核电蒸汽发生器传热管疲劳行为及损伤机理研究[D]. 北京: 北京科技大学, 2022. Li Zhenhua. Study on fatigue behavior and damage mechanism of heat transfer tube of nuclear power steam generator [D]. Beijing: University of Science and Technology Beijing, 2022.

[5] 李春凯, 席保龙, 石玗, 等. 氟化物活性TIG焊电弧特征的光谱分析[J]. 焊接学报, 2021(42): 54 − 58. doi: 10.12073/j.hjxb.20210201002 Li Chunkai, Xi Baolong, Shi Yu, et al. Spectroscopic analysis of arc characteristics in fluoride-activated TIG welding[J]. Transactions of the China Welding Institution, 2021(42): 54 − 58. doi: 10.12073/j.hjxb.20210201002

[6] 熊俊, 郑森木, 陈辉, 等. 电弧增材制造成形在线监测与控制研究进展及展望[J]. 电焊机, 2021, 51(8): 70 − 78. doi: 10.7512/j.issn.1001-2303.2021.07.13 Xiong Jun, Zheng Senmu, Chen Hui, et al. Research progress and prospect of on-line monitoring and control of arc additive manufacturing[J]. Electric Welding Machine, 2021, 51(8): 70 − 78. doi: 10.7512/j.issn.1001-2303.2021.07.13

[7] Xia C, Pan Z, Fei Z, et al. Vision based defects detection for Keyhole TIG welding using deep learning with visual explanation[J]. Journal of Manufacturing Processes, 2020, 56: 845 − 855. doi: 10.1016/j.jmapro.2020.05.033

[8] 卢振洋, 宫兆辉, 闫志鸿, 等. 基于深度学习的TIG焊背部熔池检测和熔宽提取[J]. 北京工业大学学报, 2019, 46(9): 988 − 996. doi: 10.11936/bjutxb2018070033 Lu Zhenyang, Gong Zhaohui, Yan Zhihong, et al. Deep learning based weld pool detection and weld width extraction for TIG welding back[J]. Journal of Beijing University of Technology, 2019, 46(9): 988 − 996. doi: 10.11936/bjutxb2018070033

[9] 王良瑞. 核电厚壁管道全位置TIG焊熔透状态监测及视觉信息表征[D]. 上海: 上海交通大学, 2020. Wang Liangrui. Penetration state monitoring and visual information characterization of full-position TIG welding for thick-wall nuclear power pipeline [D]. Shanghai: Shanghai Jiao Tong University, 2020.

[10] Górka J, Jamrozik W. Enhancement of imperfection detection capabilities in TIG welding of the infrared monitoring system[J]. Metals, 2021, 11: 41 − 42.

[11] Zhang Z F, Wen G R, Chen S B. Weld image deep learning-based on-line defects detection using convolutional neural networks for Al alloy in robotic arc welding[J]. Journal of Manufacturing Processes, 2019, 45: 208 − 216. doi: 10.1016/j.jmapro.2019.06.023

[12] Ren W, Wen G, Xu B, et al. A novel convolutional neural network based on time–frequency spectrogram of arc sound and its application on GTAW penetration classification[J]. IEEE Transactions on Industrial Informatics, 2020, 17(2): 809 − 819.

[13] Madhvacharyula A S, Pavan A V S, Gorthi S, et al. In situ detection of welding defects: a review[J]. Welding in the World, 2022, 66(4): 611 − 628. doi: 10.1007/s40194-021-01229-6

[14] 张晋, 袁召, 陈立学, 等. 离子体发射光谱诊断[J]. 强激光与粒子束, 2021, 33(6): 120 − 125. Zhang Jin, Yuan Zhao, Chen Lixue, et al. Ion emission spectroscopy diagnosis[J]. High Power Laser and Particle Beams, 2021, 33(6): 120 − 125.

[15] 刘莹, 杨立军, 何天玺, 等. 药芯焊丝TIG焊电弧特性的光谱分析[J]. 光谱学与光谱分析, 2017, 37(7): 2171 − 2176. Liu Ying, Yang Lijun, He Tianxi, et al. Spectral analysis of TIG welding arc characteristics of flux-cored wire[J]. Spectroscopy and Spectral Analysis, 2017, 37(7): 2171 − 2176.

[16] 刘自刚, 梅亚泽, 张建峰, 等. 深熔TIG焊研究现状与展望[J]. 热加工工艺, 2023, 52(1): 6 − 11. Liu Zigang, Mei Yaze, Zhang Jianfeng, et al. Research status and prospect of deep penetration TIG welding[J]. Hot Working Technology, 2023, 52(1): 6 − 11.

[17] Mirapeix J, Vila E, Valdiande J J, et al. Real-time detection of the aluminium contribution during laser welding of Usibor1500 tailor-welded blanks[J]. Journal of Materials Processing Technology, 2016, 235(9): 106 − 113.

[18] Zhang Z, Chen H, Xu Y, et al. Multisensor-based real-time quality monitoring by means of feature extraction, selection and modeling for Al alloy in arc welding[J]. Mechanical Systems & Signal Processing, 2015, 60: 151 − 165.

[19] Palanco S, Klassen M, Skupin J, et al. Spectroscopic diagnostics on CW-laser welding plasmas of aluminum alloys[J]. Spectrochim Acta Part B At Spectrosc, 2001, 56: 651 − 659.

[20] Nomura K, Yoshii K, Toda K, et al. 3D measurement of temperature and metal vapor concentration in MIG arc plasma using a multi-directional spectroscopic method [J]. Journal of Physics, D. Applied Physics: A Europhysics Journal, 2017, 42: 425205.

[21] Song Lijun,Huang Wenkang,Han Xu,et al. Real-time composition monitoring using support vector regression of laser-induced plasma for laser additive manufacturing[J]. IEEE Transactions on Industrial Electronics, 2016, 64(1): 633 − 642.

[22] Zhang Linjie, Bai Qinglin, Ning Jie, et al. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding[J]. Materials & Design, 2016, 110(15): 35 − 50.

[23] Huang Y, Wu D, Lü N, et al. Investigation of porosity in pulsed GTAW of aluminum alloys based on spectral and X-ray image analyses[J]. Journal of Materials Processing Technology, 2017, 243: 365 − 373. doi: 10.1016/j.jmatprotec.2016.12.026

[24] 叶昕. 基于光谱分析的电弧焊接在线检测与评估方法研究[D]. 镇江: 江苏大学, 2020. Ye Xin. Research on online detection and evaluation method of arc welding based on spectral analysis [D]. Zhenjiang: Jiangsu University, 2020.

[25] Zhang Z, Yang Z, Ren W, et al. Random forest-based real-time defect detection of Al alloy in robotic arc welding using optical spectrum[J]. Journal of Manufacturing Processes, 2019, 42: 51 − 59. doi: 10.1016/j.jmapro.2019.04.023

[26] Huang Y, Zhao D, Chen H, et al. Porosity detection in pulsed GTA welding of 5A06 Al alloy through spectral analysis[J]. Journal of Materials Processing Technology, 2018, 259: 332 − 340. doi: 10.1016/j.jmatprotec.2018.05.006

[27] 张志芬, 杨哲, 任文静, 等. 电弧光谱深度挖掘下的铝合金焊接过程状态检测[J]. 焊接学报, 2019, 40(1): 12 − 25. doi: 10.12073/j.hjxb.2019400005 Zhang Zhifen, Yang Zhe, Ren Wenjing, et al. Welding state detection of aluminum alloy by arc spectral deep mining[J]. Transactions of the China Welding Institution, 2019, 40(1): 12 − 25. doi: 10.12073/j.hjxb.2019400005

[28] 张萌. 基于AM_BiLSTM的在线评论质量分类研究[D]. 北京: 北京交通大学, 2021. Zhang Meng. Research on quality classification of online reviews based on AM_BiLSTM [D]. Beijing: Beijing Jiaotong University, 2021.

-

期刊类型引用(2)

1. 陈昕航,徐新胜,曹立,吴松泽,陆弘毅. 基于残差修正的产品质量预测方法. 制造技术与机床. 2025(02): 177-184 .  百度学术

百度学术

2. 沈植诚,王宾,程军辉. 基于SMA-BP算法的焊件动态电阻预测. 中国新技术新产品. 2024(21): 18-20 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: