Prediction model of multiaxial fatigue life of circular weld of GH4169 casing mounting seat

-

摘要:

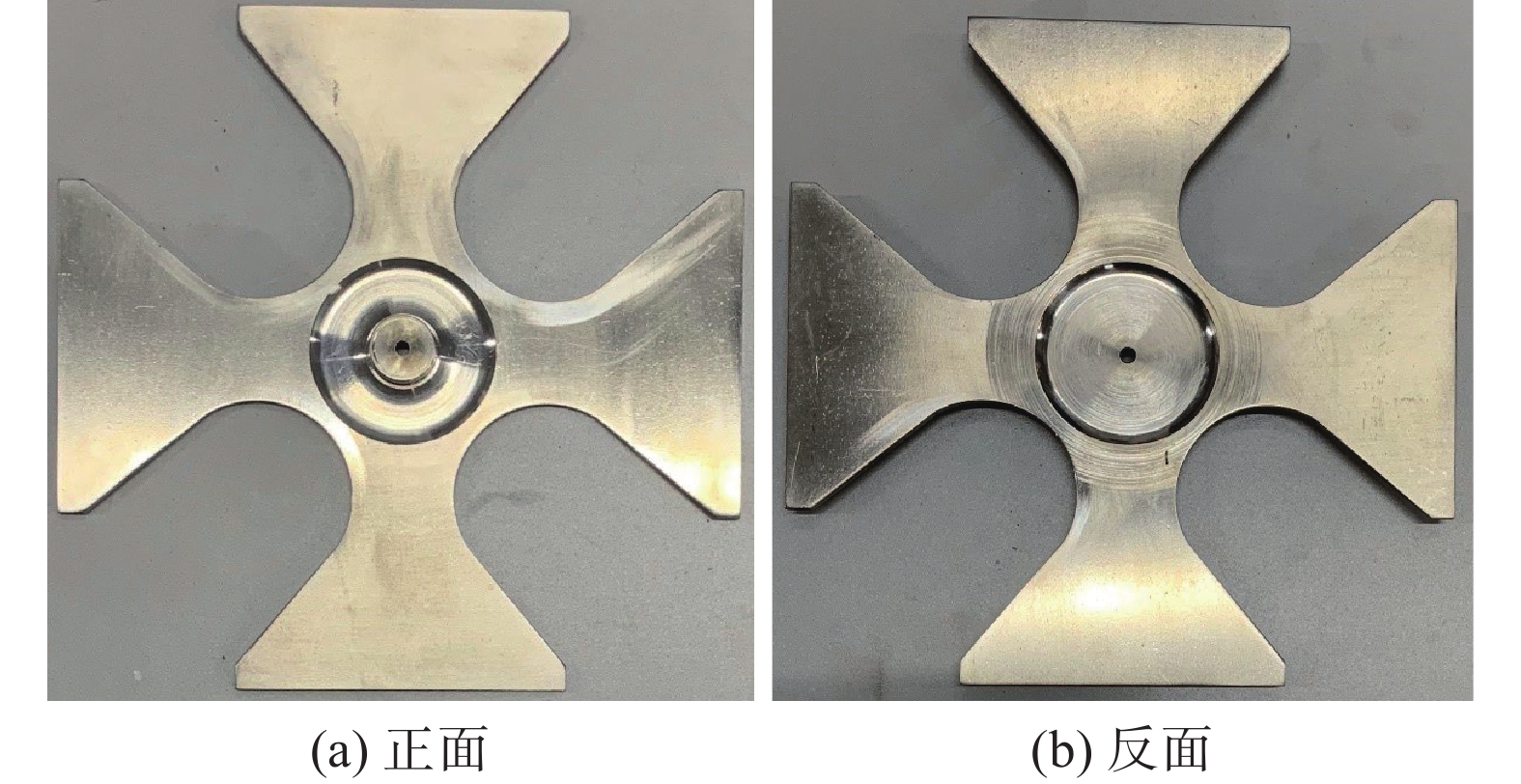

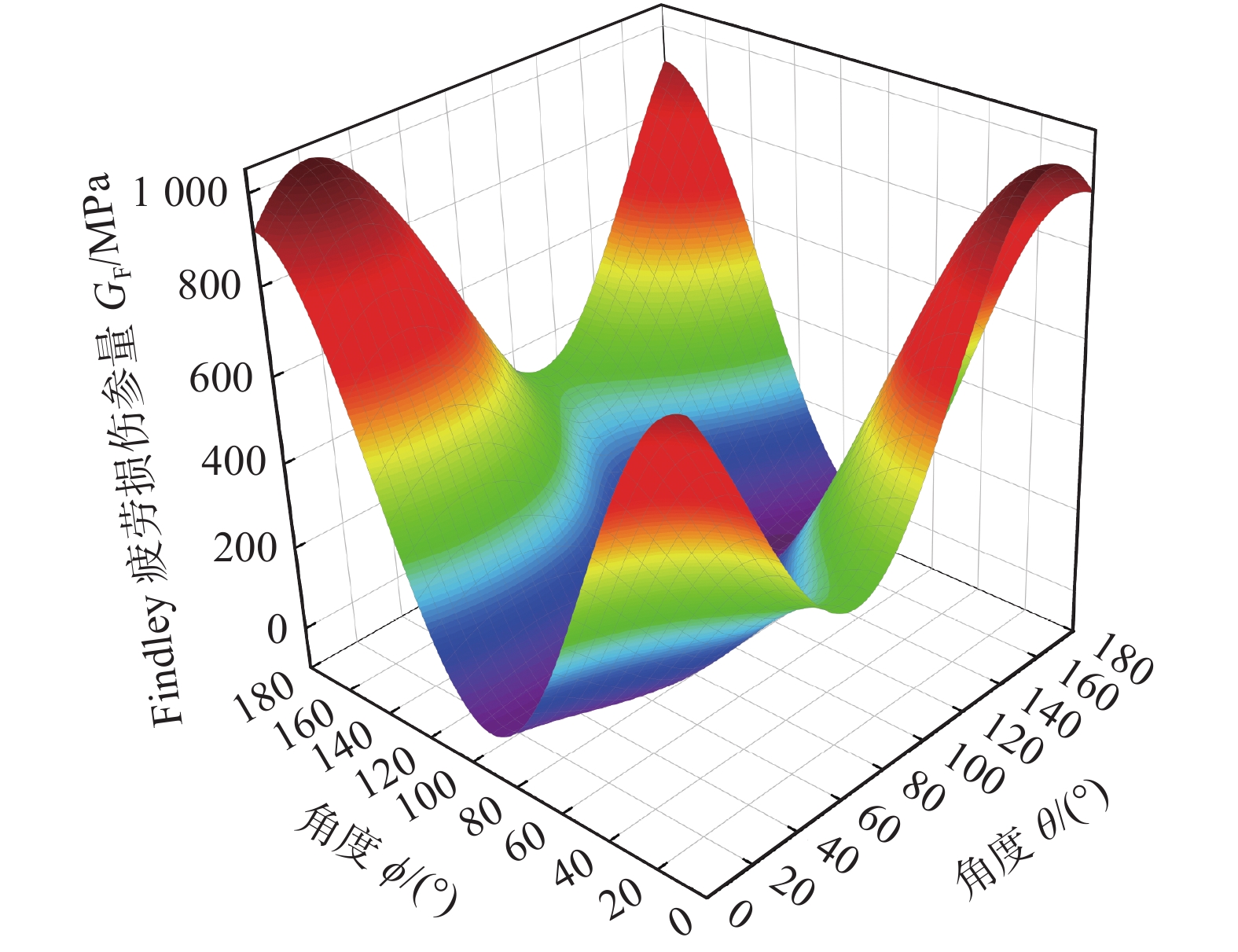

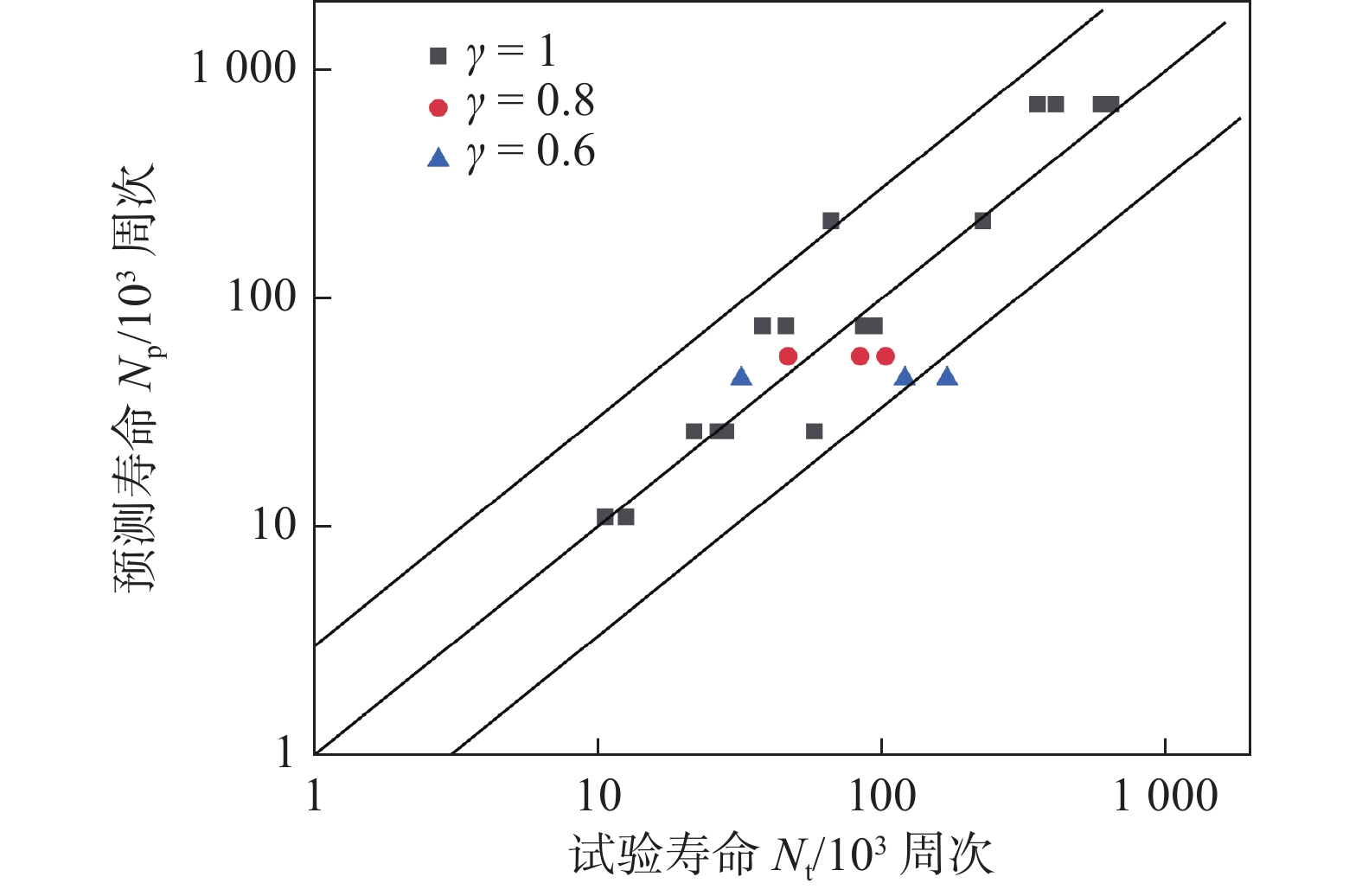

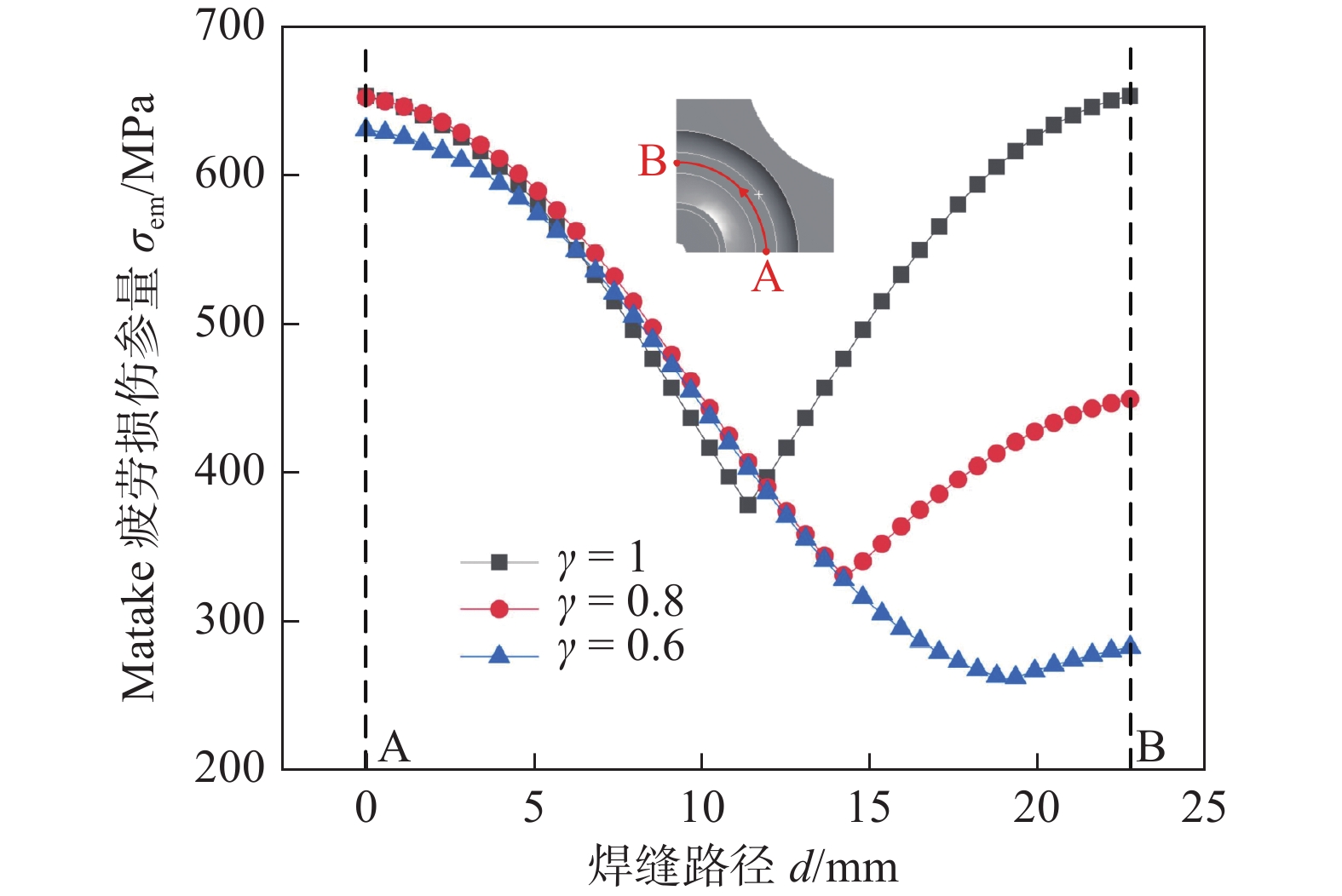

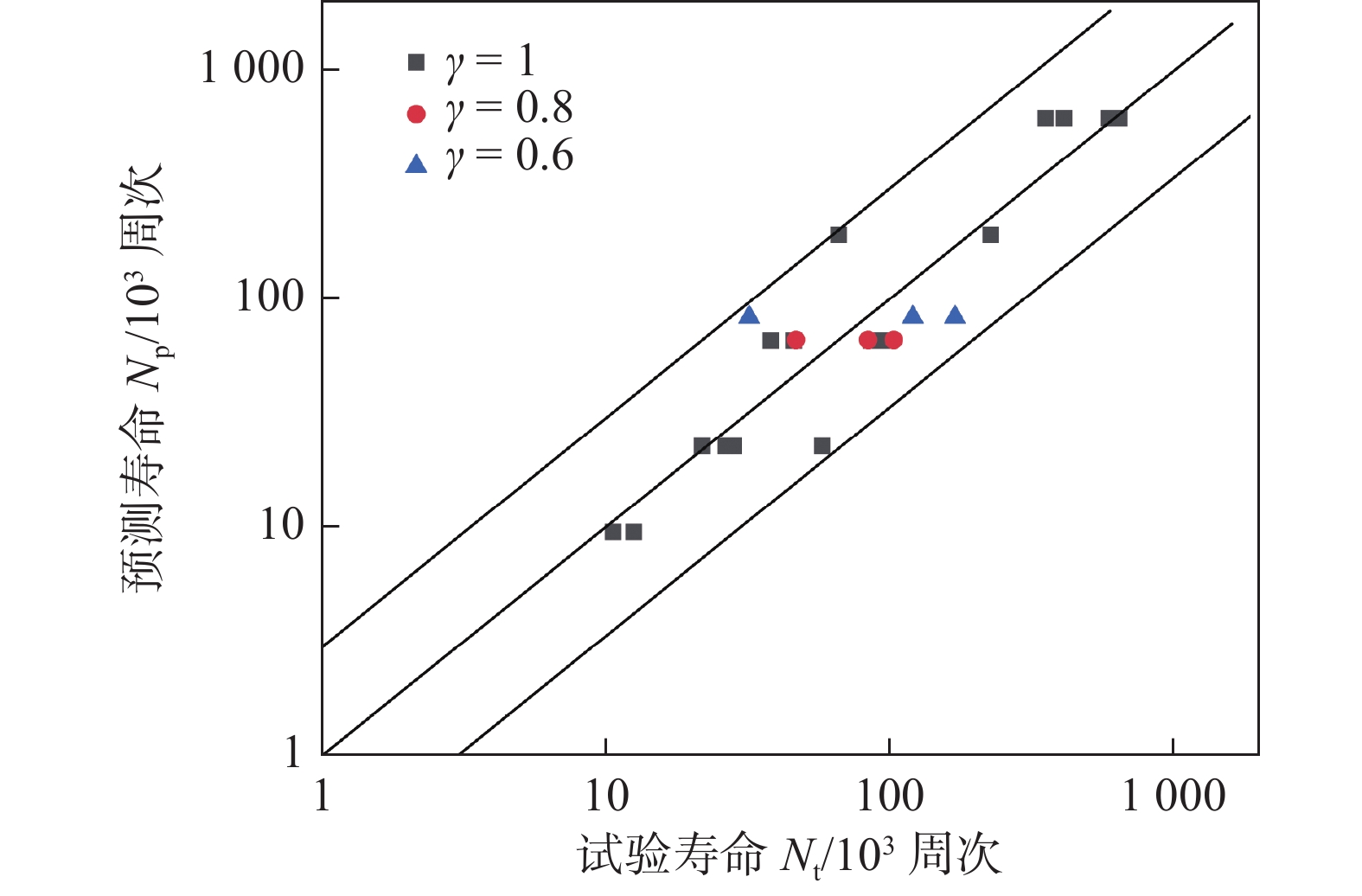

针对航空发动机机匣安装座焊接结构在复杂载荷作用下的多轴疲劳寿命研究,提出了一种基于临界平面法的多轴疲劳寿命预测模型研究方法. 首先,根据机匣安装座环形焊缝的结构特征,设计了一种可以实现双轴拉伸的疲劳试验件,分别在不同载荷级和双轴比下进行双轴拉伸疲劳试验,然后,基于临界平面法的Findley和Matake准则下分别预测疲劳寿命. 结果表明,两种准则并不能很好地预测不同双轴比下的机匣安装座环形焊缝疲劳寿命,通过对Matake准则下的疲劳寿命预测模型进行调整,引入双轴比γ对其进行修正,最终建立了能综合考虑不同双轴比影响的双轴拉伸疲劳寿命预测模型,预测结果均在3倍分散带以内.

Abstract:Aming at multiaxial fatigue life prediction model research on the welded structure of aviation engine casing mounting seat under complex loads, a fatigue life prediction model based on critical plane method is proposed. Firstly, based on the structural characteristics of circular weld of the casing mounting seat, a fatigue biaxial tensile specimen was designed, and biaxial tension fatigue tests were conducted at different load levels and biaxial ratios. Then, based on the critical plane method of Findely and Matake criteria, the fatigue life was predicted separately, and the results showed that the two criteria could not effectively predict the fatigue life of circular weld of the casing mounting seat under different biaxial ratios, by introducing the biaxial ratio γ to adjust the fatigue life prediction model under the Matake criterion, a biaxial tensile fatigue life prediction model was established that can comprehensively consider the effects of different biaxial ratios, and the predicted results are within a 3-fold dispersion band.

-

Keywords:

- casing mounting seat /

- circular weld /

- multiaxial fatigue /

- critical plane method

-

-

-

[1] 管德清, 易伟建. 焊接钢结构疲劳强度预测的应力场强模型研究[J]. 电力科学与技术学报, 2004, 19(3): 59 − 62. Guan Deqing, Yi Weijian. Research of stress field intensity model on the fatigue strength prediction for welded steel structures[J]. Journal of Electric Power Science and Technology, 2004, 19(3): 59 − 62.

[2] 黄如旭, 刘刚, 黄进浩. 等效热点应力法结合临界面法评估焊接接头多轴疲劳强度研究[J]. 船海工程, 2014, 43(4): 38 − 46. Huang Ruxu, Liu Gang, Huang Jinhao. Multi-axial fatigue strength assessment of welded joints based on equivalent hot spot stress approach and critical plane method[J]. Marine Engineering, 2014, 43 (4): 38 − 46.

[3] 耿立艳, 杨新岐, 许海生. 铝合金焊接接头疲劳评定的应力平均法[J]. 机械强度, 2006, 28(2): 266 − 270. Geng Liyan, Yang Xinqi, Xu Haisheng. Fatigue assessment of aluminium welded joints by the stress averaging approach[J]. Mechanical Strength, 2006, 28 (2): 266 − 270.

[4] 程艳艳. 点焊接头疲劳评估方法研究[J]. 南方农机, 2020, 51(18): 182 − 183. Chen Yanyan. Research on fatigue assessment methods for spot welded joints[J]. Southern Agricultural Machinery, 2020, 51 (18): 182 − 183.

[5] Brown M W, Miller K J. A theory for fatigue failure under multiaxial stress-strain conditions[J]. Proceedings of the Institution of Mechanical Engineers, 1973, 187(1): 745 − 755. doi: 10.1243/PIME_PROC_1973_187_161_02

[6] 王霄翔. TC17钛合金电子束焊接接头多轴疲劳寿命研究[D]. 南京: 南京航空航天大学, 2012. Wang Xiaoxiang. Multiaxial fatigue life evaluation of TC17 titanium alloy electron beam welded joints[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012.

[7] 顾明恒. 钛合金真空电子束焊焊接接头多轴疲劳寿命研究[D]. 南京: 南京航空航天大学, 2014. Gu Mingheng. Multiaxial fatigue life evaluation of titanium alloy electron beam welded joints[D] Nanjing: Nanjing University of Aeronautics and Astronautics, 2014.

[8] 刘亮. Ti60-TC17异种钛合金电子束焊接头的多轴疲劳寿命研究[D]. 南京: 南京航空航天大学, 2015. Liu Liang. Multiaxial fatigue life evaluation of Ti60-TC17 dissimilar titanium alloy electron beam welded joints[D] Nanjing: Nanjing University of Aeronautics and Astronautics, 2015.

[9] 赵一阳. 基于临界面法的焊接结构多轴疲劳强度研究[D]. 大连: 大连理工大学, 2010. Zhao Yiyang. Study on multiaxial fatigue strength of welded structures based on critical plane method[D]. Dalian: Dalian University of Technology, 2010.

[10] 邬婷. 基于临界面法的焊接结构多轴疲劳寿命预测方法[D]. 大连: 大连理工大学, 2013. Wu Ting. Method of multiaxial fatigue life estimation of welded structures based on critical plane method[D] Dalian: Dalian University of Technology, 2013.

[11] 刘健. 考虑复杂应力状态的焊接结构疲劳寿命估算研究[D]. 南京: 南京航空航天大学, 2009. Liu Jian. Fatigue life evaluation of welded components in condition of complex stress[D] Nanjing: Nanjing University of Aeronautics and Astronautics, 2009.

[12] Abecassis M, Köster A, Esin V A, et al. Crack growth behavior in dissimilar welded Ti based alloys under biaxial fatigue loading[J]. International Journal of Fatigue, 2018, 118(6): 209 − 224.

[13] Koji G, Toshio N, Yosuke A. Fatigue crack growth behaviour of an out-of-plane gusset welded joints under biaxial tensile loadings with different phases[J]. European Conference on Frature, Trondheim, 2014(3): 1536 − 1541.

[14] Shanyavskiy A. Fatigue cracking simulation based on crack closure effects in Al-based sheet materials subjected to biaxial cyclic loads[J]. Engineering Fracture Mechanics, 2011, 78(8): 1 − 8.

[15] Ruiz C, Boddington P H B, Chen K C. An investigation of fatigue and fretting in a dovetail joint[J]. Experimental Mechanics, 1984, 24(3): 208 − 217. doi: 10.1007/BF02323167

[16] 郑小梅, 孙燕涛, 杨兴宇, 等. 某涡扇发动机高压涡轮盘螺栓孔低循环疲劳模拟件设计[J]. 航空动力学报, 2018, 33(10): 2351 − 2358. Zheng Xiaomei, Sun Yantao, Yang Xingyu, et al. Design of low cycle fatigue simulating specimen for bolt holes of a turbofan engine high pressure turbine disc[J]. Journal of Aerodynamics, 2018, 33 (10): 2351 − 2358.

[17] 丁继伟, 李岩, 姜东坡. 某型透平叶片叶根疲劳试验模拟件设计[J]. 科学技术创新, 2020(6): 11 − 14. Ding Jiwei, Li Yan, Jiang Dongpo. Design of fatigue test simulating specimen for a certain type of turbine blade root[J]. Science and Technology Innovation, 2020(6): 11 − 14.

[18] 郭海丁, 武奇. 基于场强法的平板法兰角焊缝接头的疲劳寿命估算方法[J]. 航空动力学报, 2008(6): 128 − 132. Guo Haidong, Wu Qi. Way to evaluate fatigue life of fillet weld of plate with flange based on stress field intensity[J]. Journal of Aerodynamics, 2008(6): 128 − 132.

[19] 吴振豪, 刘鹏飞. 安装座焊接结构双轴拉伸模拟件设计[J]. 焊接, 2023(9): 40 − 47. Wu Zhenhao, Liu Pengfei. Design of biaxial tensile simulating specimen for welding structure of mounting seat[J]. Welding & Joining, 2023(9): 40 − 47.

[20] Findley W N. A theory for the effect of mean stress on fatigue of metals under combined torsion and axial load or bending[J]. Journal of Engineering for Industry, 1959, 81(4): 301 − 305. doi: 10.1115/1.4008327

[21] Matake Tomokazu. An explanation on fatigue limit under combined stress[J]. JSME International Journal, 1977, 20(141): 257 − 263. doi: 10.1299/jsme1958.20.257

-

期刊类型引用(1)

1. 李劲风,李昊然,王正安. 铝锂合金组织-性能相关性及新型铝锂合金设计. 中国材料进展. 2022(10): 796-807 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: