Tailored deformation and properties of cast aluminum alloy ZL114A repaired by laser deposition

-

摘要:

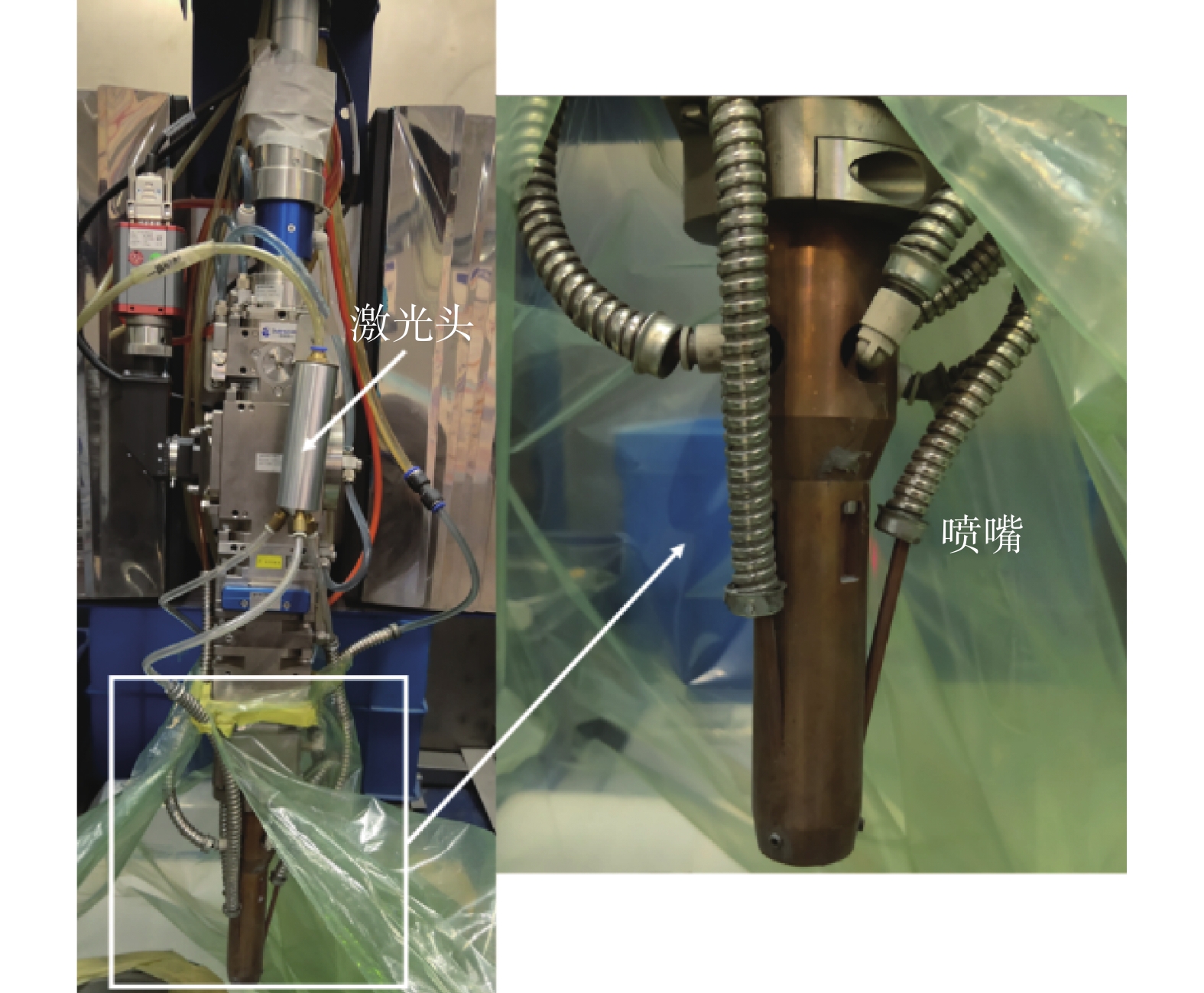

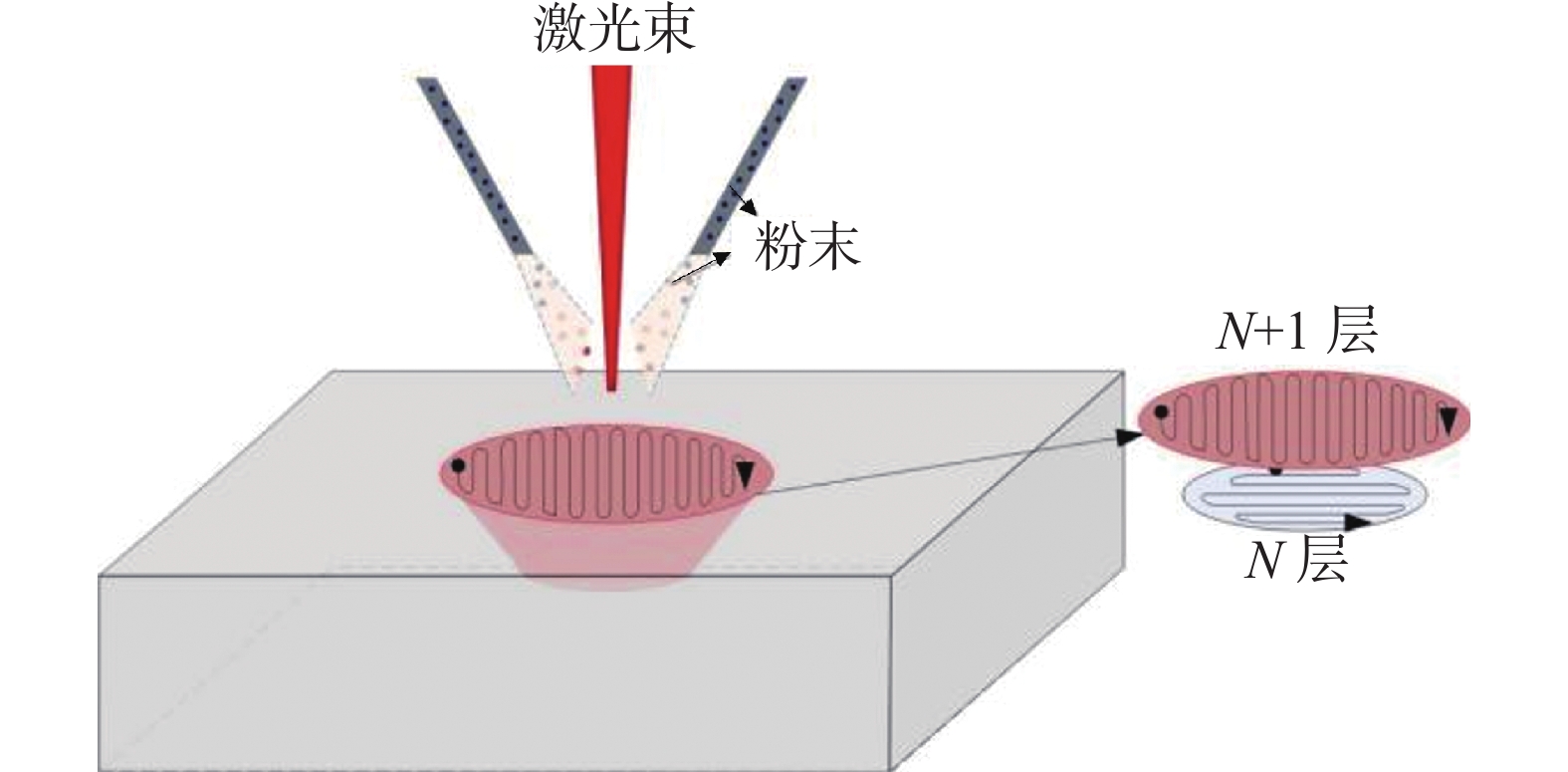

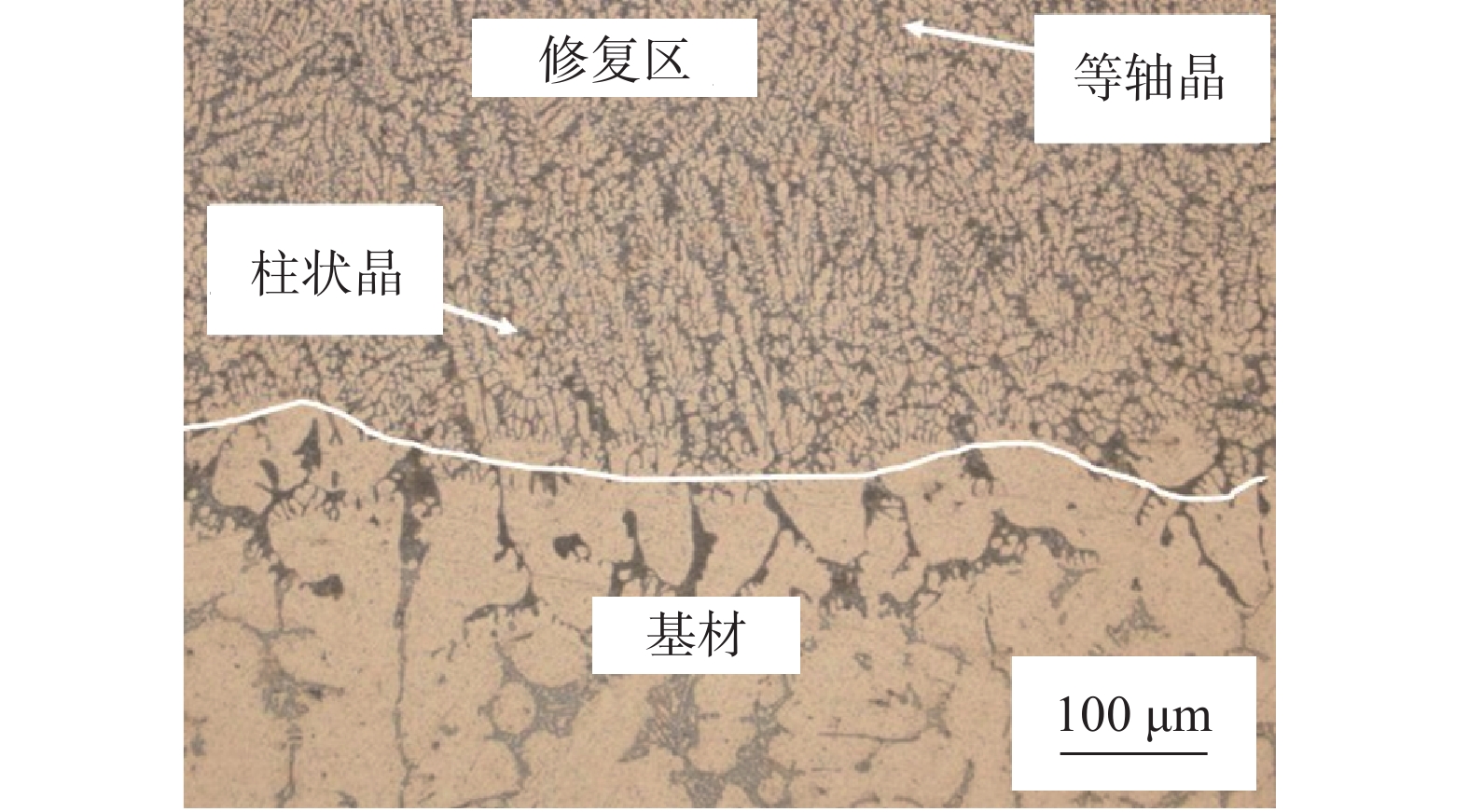

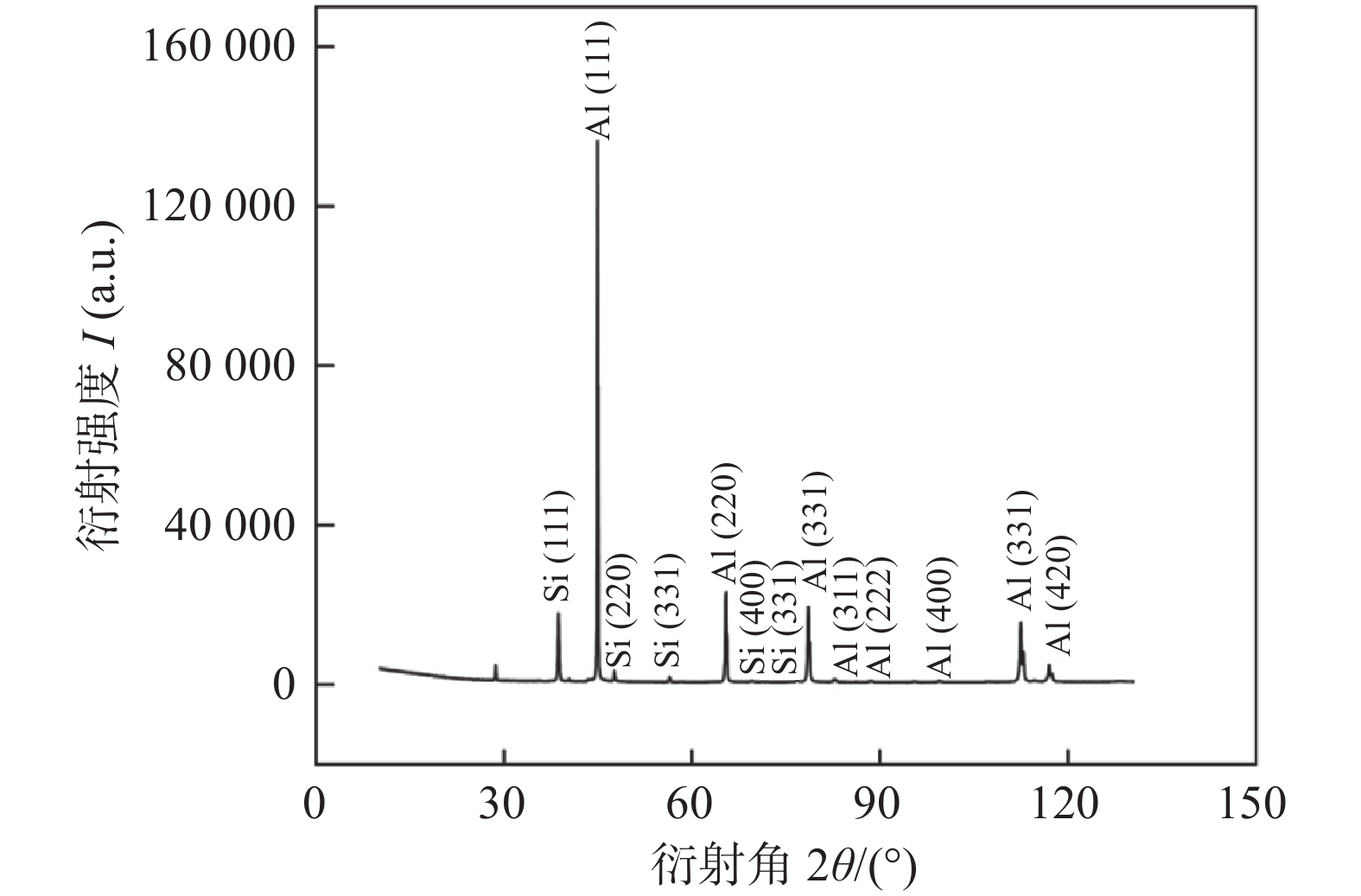

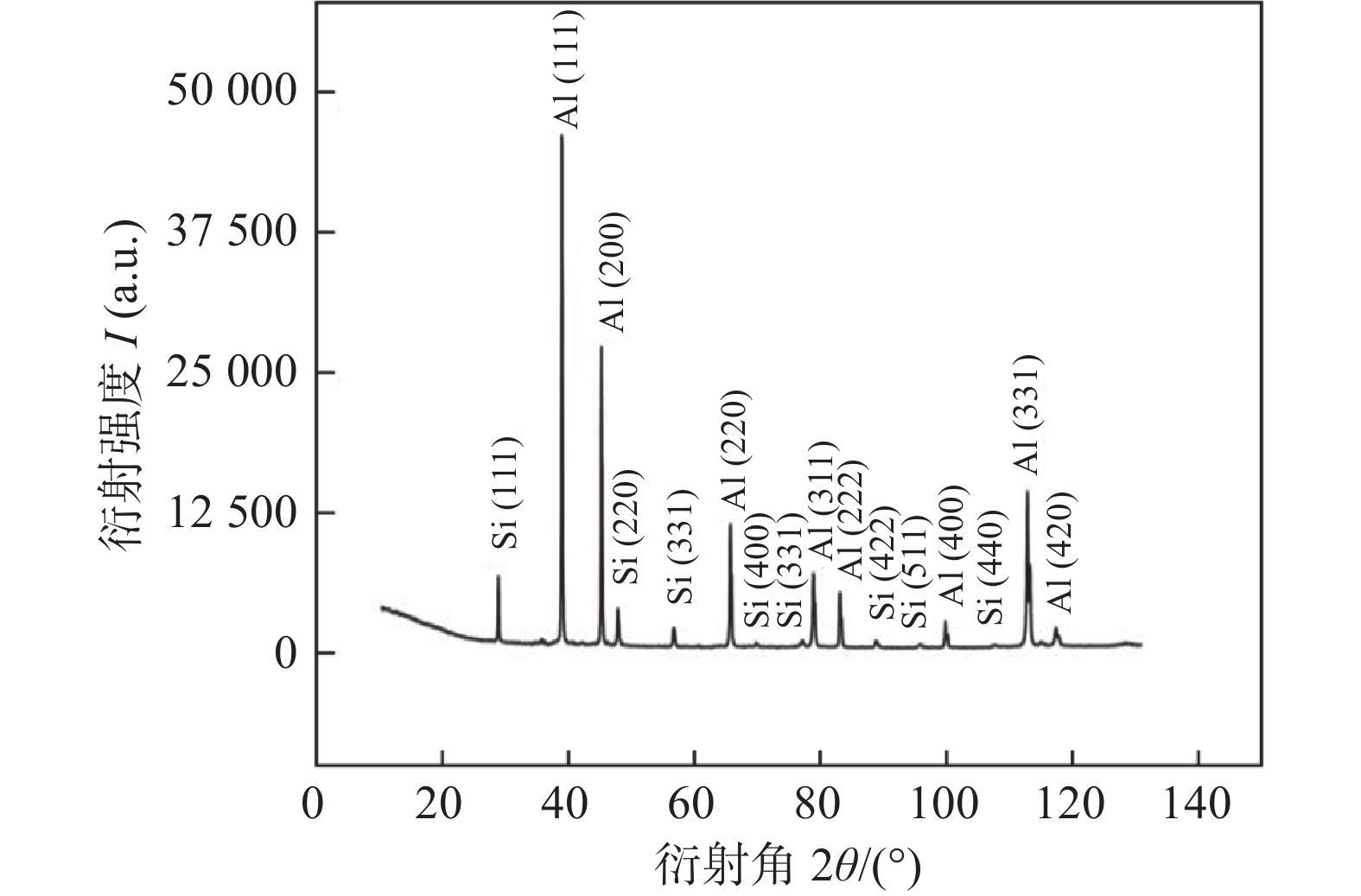

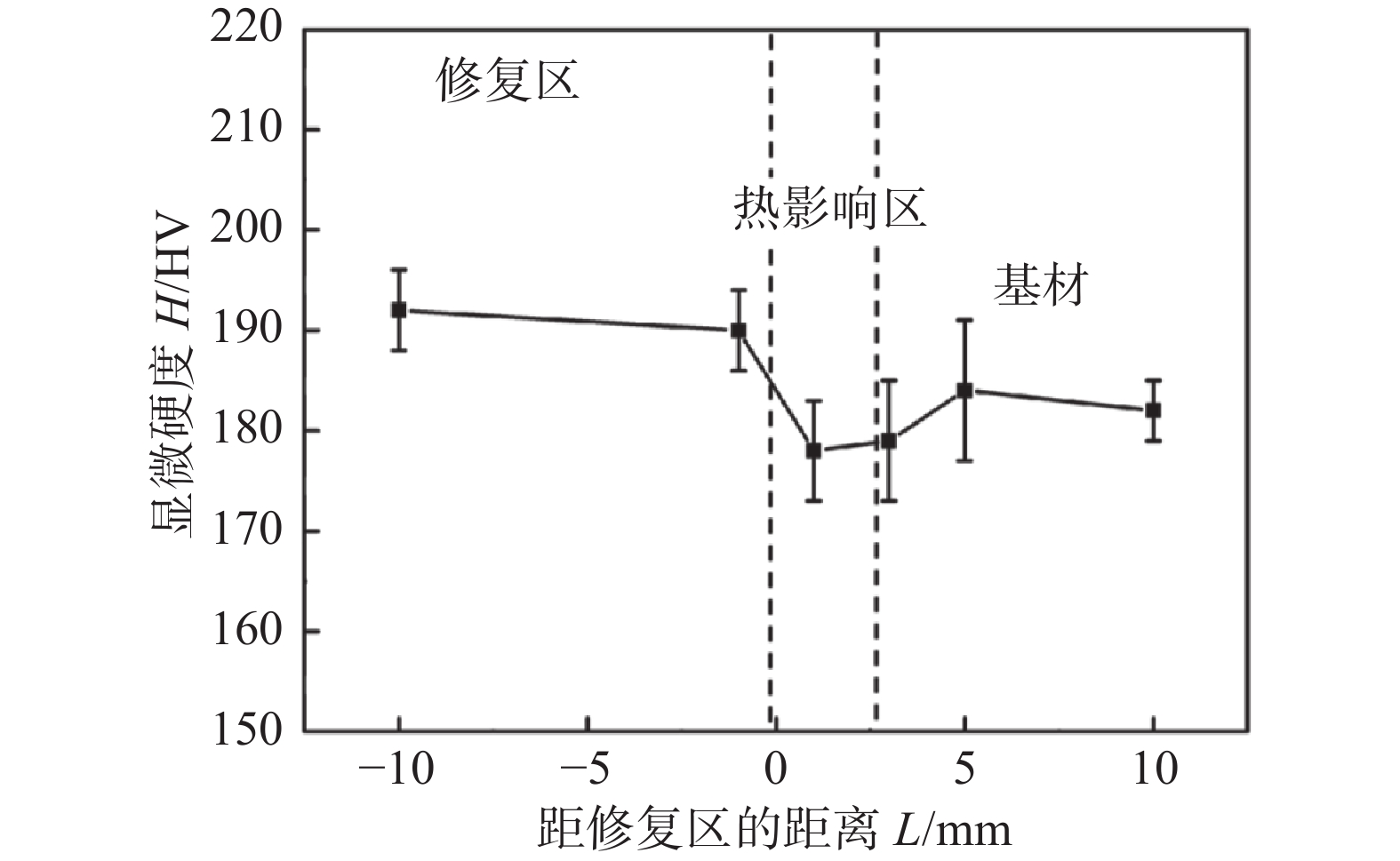

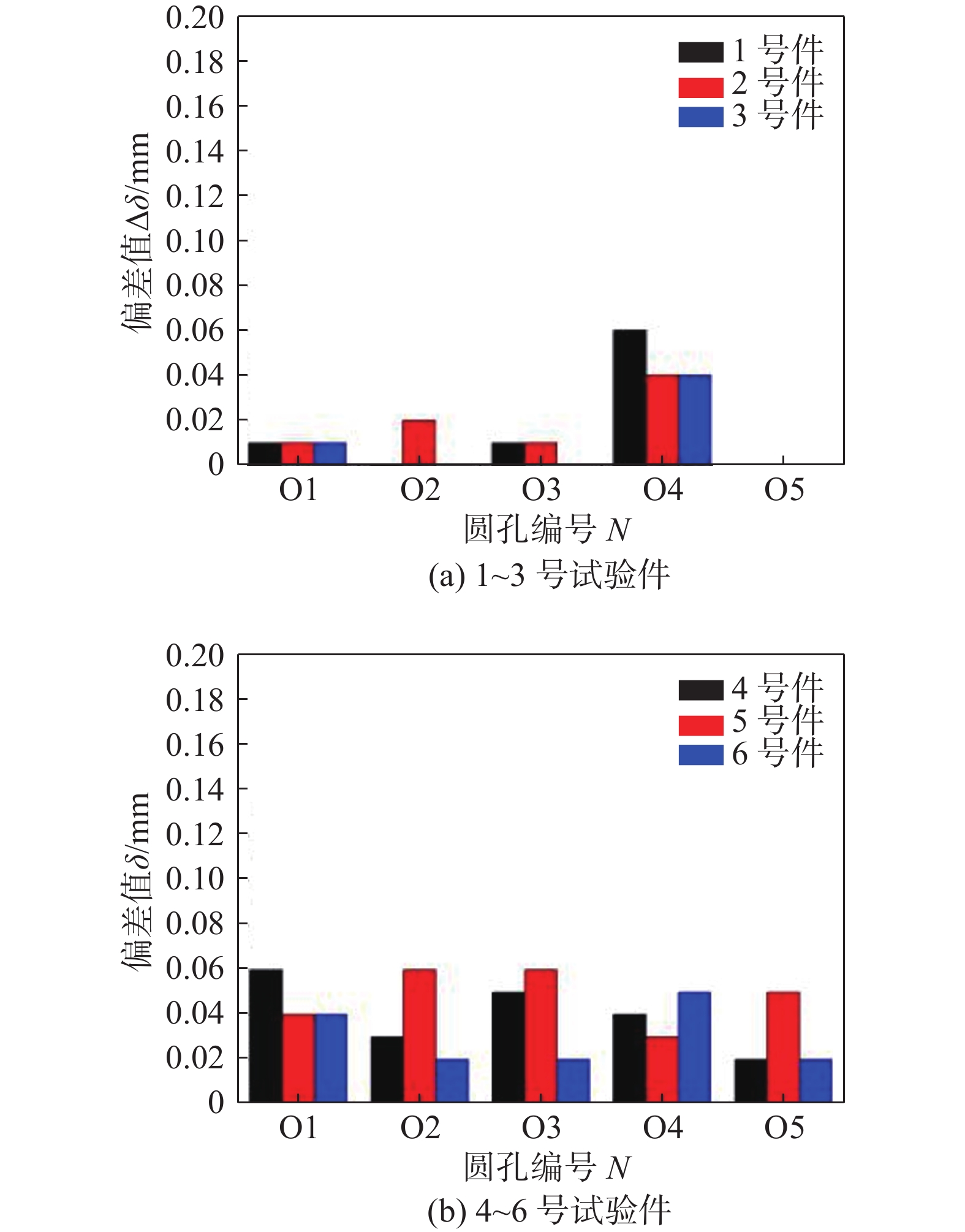

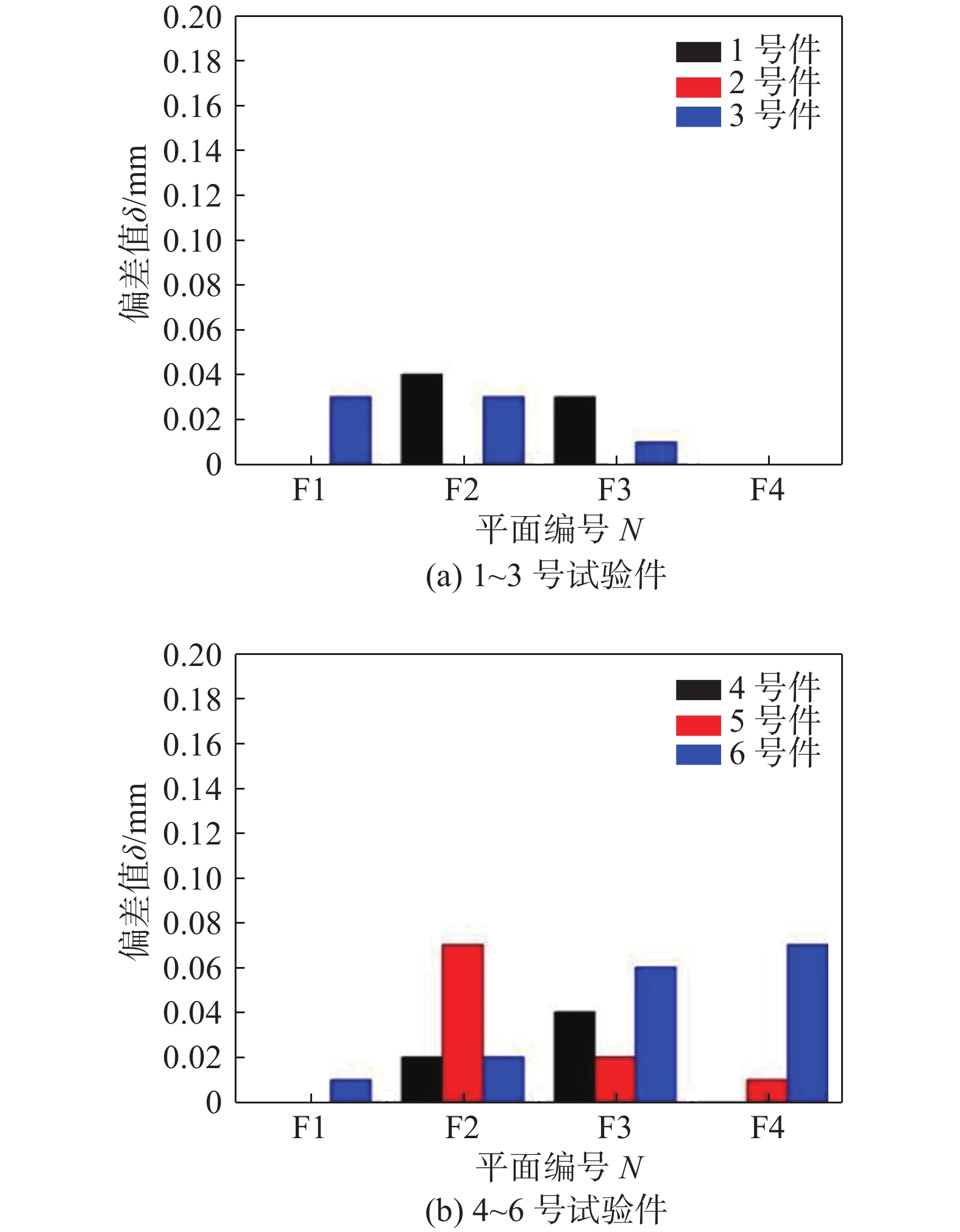

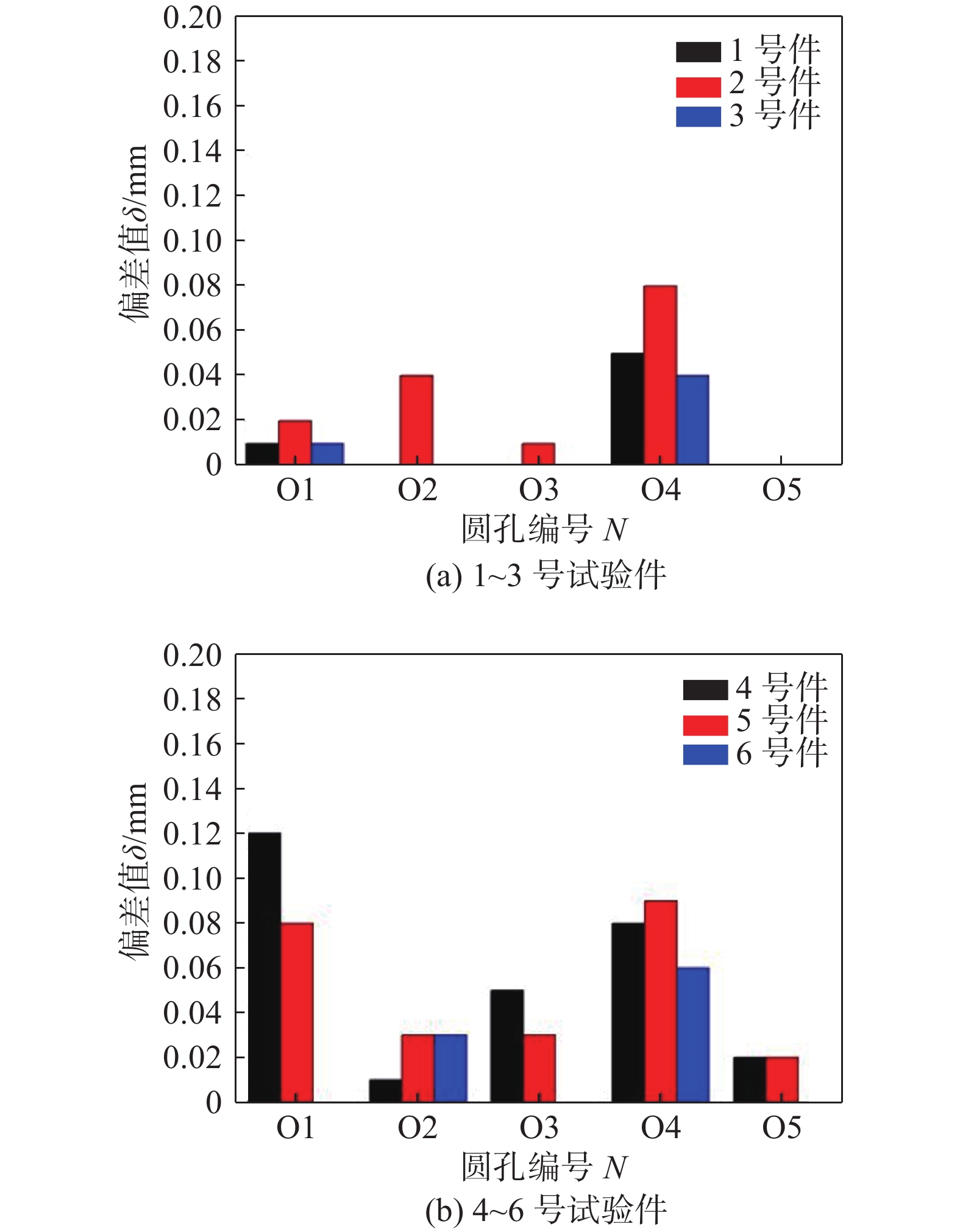

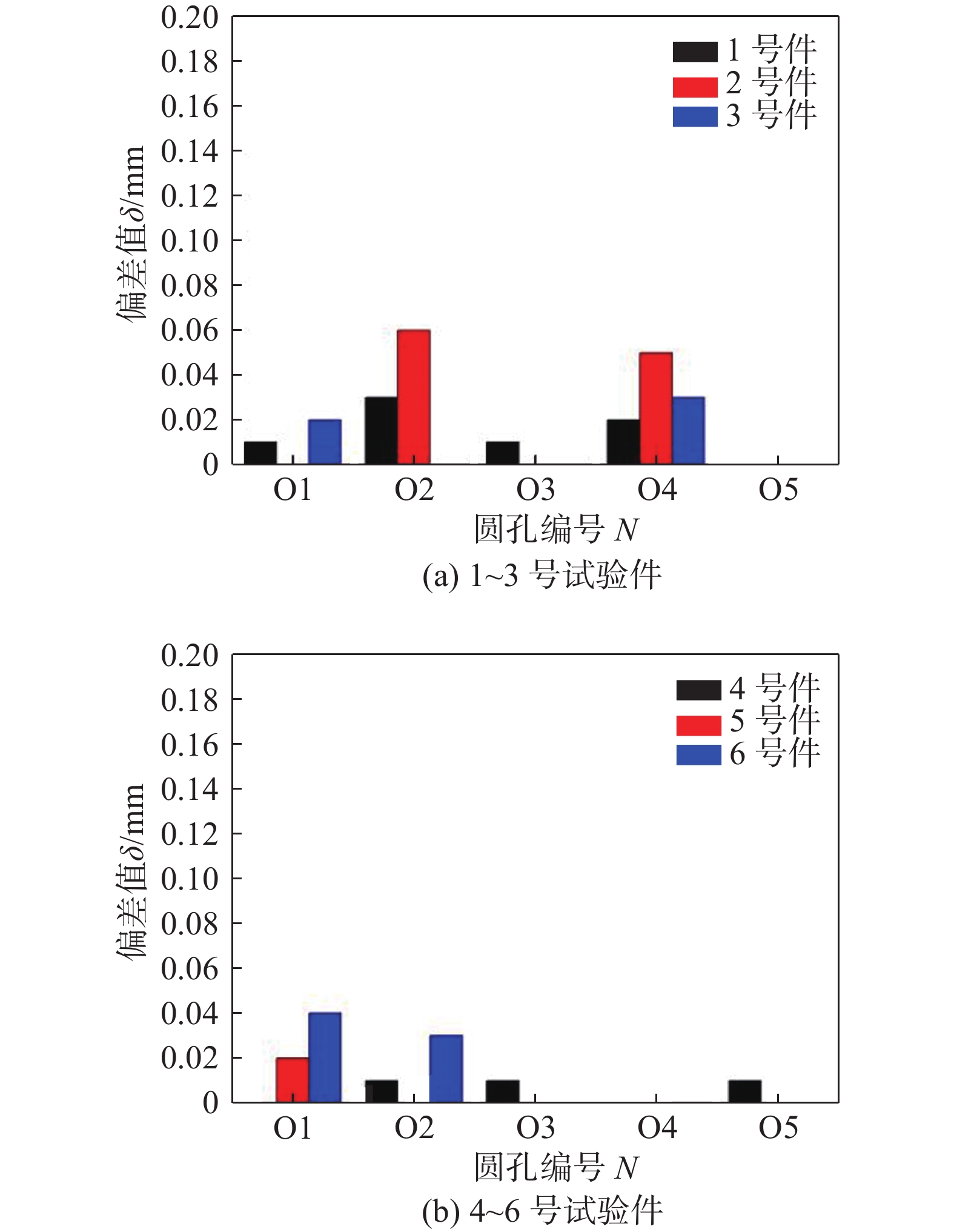

采用激光沉积修复技术对铸造铝合金ZL114A基材进行修复,分析了修复区域组织和性能,并评估了沉积修复过程对尺寸变形的影响. 结果表明,修复区界面冶金结合良好,界面区基材存在部分共晶Si重熔的现象;修复区组织以树枝晶和等轴晶为主,修复区底部为外延生长的树枝晶,修复区中部和顶部为等轴晶区. 修复区细密、均匀的枝晶组织提高了修复区硬度,但在热影响区附近硬度值出现了下降趋势. 经过T6态热处理可以提升修复区和基材的整体性能,50%修复比例条件下抗拉强度可以达到330 MPa. 激光沉积修复变形量较小,可以保证低变形条件下机加零件或者返修零件的修复.

Abstract:Laser deposition repair technology was used to repair the cast aluminum alloy ZL114A. The microstructure and properties of the repaired area were analyzed, and the impact of the deposition repair process on dimensional deformation was evaluated. The results show that the interface in the repaired area has good metallurgical bonding, and partial remelting of eutectic Si in the substrate interface area was observed. The microstructure in the repaired area mainly consists of dendritic and equiaxed grains. Wherein, epitaxial growth dendrites are located at the bottom of the repaired area, while equiaxed grains were exist in the middle and top of the repaired area. The fine and uniform dendritic microstructure in the repaired area enhances the hardness of the repaired area, but there is a decreasing trend in hardness near the heat-affected zone. The overall performance of the repaired area and the substrate can be improved through T6 heat treatment, with tensile strength reaching up to 330 MPa under a 50% repair ratio. The deformation of the laser deposition repair is minimal, ensuring that machined parts or repaired parts can be restored under low deformation conditions.

-

0. 序言

激光熔覆是复杂金属零件快速制造及修复的关键技术之一,常广泛应用于航空航天、船舶、汽车及电子等高端制造领域[1],其激光熔覆制件成形精度和性能备受关注. 激光熔覆工艺参数较多,并决定多道多层制件的成形精度及力学性能. 对不同熔覆系统和材料,最优工艺参数需重新确认,因而熔覆工艺优化至今仍是研究热点[2].

在确定表面光洁度、层厚度及最终制件的尺寸精度方面,熔覆层几何形貌有着重要作用,所以,为了确定熔覆最佳的工艺参数,现有研究主要以熔覆层几何形貌为目标,进而开展工艺优化工作. 目前熔覆工艺优化方法主要采用数值模拟方法,解析法及经验统计分析等. 数值模拟可通过复杂的传热、相变仿真,实现熔覆几何形貌预测,有利于提高工艺优化的效率. 例如,Gao等人[3-4]通过三维瞬态数值模型分析不同工艺参数对单道熔覆层高度、宽度及熔池深度的影响,计算并验证了瞬态温度场和熔覆层几何形貌. 解析法方面,Huang等人[5]提出了熔覆过程的综合分析模型,将高斯能量分布、粉末流及结构相互耦合,实现熔覆层几何形貌的快速预测及优化. Ertay等人[6]开发了耦合沉积热历史和几何形貌的解析模型,运用质量及能量平衡方程描述了局部激光−材料的相互作用,并实现了热历史和几何形貌的预测,可进一步应用于工艺优化研究.

文献报道的数值模型及解析模型均能够描述激光熔覆过程,但考虑激光束、粉末及基体之间存在许多复杂物理耦合作用,实现熔覆模拟及计算具有一定难度. 相较而言,经验统计模型可避免定量分析复杂物理过程,更适于工业应用推广. 经验统计模型主要通过试验设计方法、回归分析、方差分析等,实现熔覆层几何形貌预测及工艺参数优化. 不少研究利用回归分析探索了单道熔覆层几何形貌与耦合工艺参数的关系,结果表明回归模型的预测值与试验测量值吻合良好,可进一步用于熔覆工艺优化[7-9]. Wen[10]和Sun[11]等人利用响应曲面法,研究了激光功率、送粉率及扫描速度对熔覆层几何形貌的影响,并通过经验统计模型优化得到了最佳的工艺参数. Alam等人[12]采用中心复合设计和响应曲面法,研究不同工艺参数对AISI420单道熔覆层几何形貌的影响,并进一步评估工艺参数对熔覆制件硬度的影响,为选择合适工艺参数提供指导.

工艺参数会对微观组织结构产生影响,而微观组织结构直接决定熔覆制件的力学性能. 因此工艺优化的目标不应仅考虑熔覆层宏观几何形貌,还应考虑微观组织结构. Zhang等人[13]通过比较连续激光技术和脉冲激光技术,发现脉冲激光的熔覆层具有更快的冷却速率,平均晶粒尺寸更加细小,显微硬度由210 HV提高至1 160 HV. Li等人[14-15]制备了具有纳米级尺寸晶粒的激光熔覆层,不仅提高了显微硬度,还一定程度上提升熔覆层的耐磨性. Montero等人[16]研究不同激光功率对熔覆层微观组织结构影响,发现较低功率能产生更随机、细小晶粒,可指导获取力学性能更佳的熔覆制件. Zhang等人[17]发现工艺参数影响熔覆过程中的能量输入及冷却速率,直接决定熔覆层的微观组织结构和性能. Zhang等人[18]优化了钛合金增材制造工艺,生成了超细晶粒,有效提升了熔覆制件的屈服强度和抗拉强度.

综上所述,熔覆工艺优化多以宏观几何形貌为目标,而熔覆制件的成形质量由几何形貌和微观组织结构共同决定. 为此,文中以316L不锈钢为例,利用完全析因设计建立熔覆层宏观几何形貌、微观晶粒平均截距与主要工艺参数之间的经验统计模型,有利于分析各工艺参数及耦合作用对几何形貌和晶粒平均截距的影响规律. 在此基础上,以宏观、微观性能为优化目标,确定最佳工艺参数及合适工艺参数窗口,并进一步评估其拉伸性能及显微硬度,验证所提出的宏微性能统计优化方法的可靠性.

1. 试验方法

1.1 试验设计

根据设备工艺条件和前期试验基础,熔覆的主要工艺参数有激光功率P、扫描速度v、送粉量Q、粉末离焦量D. 多次重复试验虽能准确估计试验误差,但是增加试验次数和成本. 因此,文中采用全析因试验设计方法,设计了四中心四因子二水平试验. 该试验设计方法可减少试验重复次数,并准确估计试验误差及随机误差. 此外,全析因设计可充分考虑工艺参数耦合作用. 由于工艺参数的量纲并不一致,为方便对比,所以将因子水平编码处理,转化为无量纲,即高低水平分别取1和−1、中心点取0,具体因子水平见表1.

表 1 工艺参数及其因子水平Table 1. Process parameters and factor levels水平 激光功率P/W 扫描速度v/(mm·min−1) 送粉量Q/(g·min−1) 粉末离焦量D/mm 1 1 400 700 15.5 1.5 0 1 200 600 14 1.0 −1 1 000 500 12.5 0.5 编码后各因子对应的回归系数可直接用于比较,回归系数绝对值越大则表明对响应影响越显著. 自然变量(即实际的工艺参数大小)和编码处理后规范变量之间转换为

$$ {X^*} = (X - M)/d $$ (1) 式中:X*为规范变量;X为自然变量;中心点M为高水平与低水平之和的一半,半间距d为高水平同低水平差值的一半.

1.2 试验分析

熔覆层宏观几何形貌有:宽高比

$\lambda $ 、接触角θ和稀释率κ (熔覆深度dp与熔覆总高度h + dp之和的比值),如图1所示. 微观组织结构的表征为晶粒平均截距l,如图2所示. 晶粒平均截距l的测量方式采用直线截点法[19]. 在熔覆层内部的3个区域内,绘制测量线与晶粒(含柱状晶)边界相交,记录测量截点数(不少于50个)为np,测量线总长为L,可得到晶粒平均截距l为$$ l = L/np $$ (2) 通过统计分析,获得工艺参数和多尺度特征响应的映射关系,建立经验统计模型,即多元回归模型.

$$ {Y_i} = {\beta _0} + \sum\limits_{j = 1}^k {{\beta _j}{x_j} + } \sum\limits_{i < j}^{} {\sum\limits_{j = 2}^k {{\beta _{ij}}{x_i}{x_j}} } + \varepsilon $$ (3) 式中:

$ {Y_i} $ 响应预测值;$ {\beta _0} $ 为常数;$ {\beta _j} $ 为第j个线性回归系数;$ {\beta _{ij}} $ 为第i个交互作用回归系数;${x_i} $ 和$ {x_j} $ 为工艺参数变量;k为因子数量;$ \varepsilon $ 为相关误差.1.3 优化方法

回归模型可用于工艺参数优化. 优化过程中,将多尺度特征响应转化为无量纲的合意性函数

$ {d_i} $ ,根据特定响应的要求可转化为最小值及目标值[10]. 其中最小值为$$ {d_i} = \left\{ \begin{gathered} \begin{array}{*{20}{c}} {}&{} \end{array}0\;\;\;\;\;\;\;\;\;\;, \\ \\ {\left( {\frac{{{H_i} - {Y_i}}}{{{H_i} - L_i}}} \right)^{w{t_i}}}, \\ \\ \begin{array}{*{20}{c}} {}&{} \end{array}1\;\;\;\;\;\;\;\;\;\;,\;\; \\ \end{gathered} \right.\left. \begin{gathered} \;\;\;\;\;\;\;\;{Y_i} \leqslant {L_i} \\ \\ \\ \;\;\;\;{L_i} < {Y_i} < {H_i} \\ \\ \;\;\;\;\;\;\;\;{Y_i} \geqslant {H_i} \\ \end{gathered} \right. $$ (4) 当优化目标为具体一个值时,其表达式为

$$ {d_i} = \left\{ \begin{gathered} {\left( {\frac{{{Y_i} - {L_i}}}{{{T_i} - {L_i}}}} \right)^{w{t_i}}}\;\;\;, \\ \\ {\left( {\frac{{{Y_i} - {H_i}}}{{{T_i} - {H_i}}}} \right)^{w{t_i}}}\;\;\;,\;\; \\ \end{gathered} \right.\left. \begin{gathered} \\ \;\;\;\;\;{L_i} < {Y_i} < {T_i} \\ \\ \\ \\ \;\;\;\;\;{T_i} < {Y_i} < {H_i} \\ \end{gathered} \right. $$ (5) 式中:

$ {d_i} $ 为单个响应的合意性;$Y_i $ 为响应值;$H_i $ ,$L_i $ 为限定的上、下限;$ {T_i} $ 为优化的目标值;$ w{t_i} $ 为响应权重系数. 对于宏微特征响应的优化,将宏微特征响应的合意性$ {d_i} $ 组合成复合合意性函数,即$$ D_h=\left(d_1^{r_1} \times d_2^{r_2} \times \cdots d_n^{r_n}\right)^{1 / \Sigma r_i}=\left(\prod_{i=1}^n d_i^{r_i}\right)^{1 / \Sigma r_i}$$ (6) 式中:n为响应的数量;

$ {r_i} $ 为响应的重要程度;可通过复合合意性的大小选择最优的工艺参数.2. 试验设置

2.1 设备及材料

激光熔覆加工系统为五轴联动增减材复合加工中心,可实现多轴联动增减材复合制造,其结构如图3所示. 数控主轴上集成了光外同轴送粉熔覆头,配置了2 000 W光纤激光器,送粉器为双筒转盘进料送粉器,进料偏差为2%. 同时,采用高纯度氩气作为载气和保护气.

金属粉末为316L奥氏体不锈钢,粉末目数为100目 ~ 200目,为保证粉末流动性,试验前先干燥粉末. 基板采用45号钢,其规格为270 mm × 150 mm × 10 mm,试验前基板先用砂纸打磨除去锈渍,再用酒精擦除油污后烘干.

2.2 试验表征

熔覆单道长度为65 mm,相邻间距为5 mm. 每道次熔覆结束后,均需冷却到室温,避免温度对熔覆成形的影响. 试验后,采用线切割设备沿垂直于扫描方向截取熔覆层横截面试样,对试样分别进行镶嵌、研磨、抛光和腐蚀处理. 试样共腐蚀2次,先采用4%硝酸酒精溶液蚀刻基体,再采用腐蚀液 (酒精∶硝酸∶盐酸体积比为1∶1∶1)蚀刻熔覆层.

宏观几何形貌和微观组织结构分别通过基恩士VHX-5000超景深三维光学显微镜、日本电子JSM-IT500A扫描电镜进行观察和测量. 显微硬度测量采用维氏显微硬度计,在熔覆层高度上,每间隔0.06 mm测量一次,施加载荷为2.94 N,加载持续时间为15 s. 拉伸试样的取样位置为熔覆层(厚度约30 mm),取样方向为沿着熔覆扫描方向. 拉伸力学性能测试采用万能试验机,加载速度为2 mm/min,拉伸试样平行于扫描方向,如图4所示.

3. 结果和讨论

3.1 方差分析

将全析因试验随机排序,按试验运行序分别记录响应值,见表2. 各试验单道熔覆层的横截面如图5所示.

表 2 因子水平及响应结果Table 2. Factor levels and response results运行序 工艺参数 响应值 激光功率P /W 扫描速度V /(mm·min−1) 送粉量Q /(g·min−1) 粉离焦量D /mm 宽高比λ 接触角θ /(°) 稀释率κ 晶粒平均截距l/μm 1 1 000 500 15.5 0.5 2.443 101.598 0.059 7.438 2 1 200 600 14.0 1.0 3.680 122.952 0.193 4.918 3 1 000 500 12.5 1.5 3.703 123.256 0.141 4.000 4 1 400 500 12.5 1.5 4.187 128.930 0.353 5.806 5 1 400 500 15.5 1.5 3.651 122.569 0.250 6.923 6 1 400 700 12.5 0.5 4.912 134.687 0.349 5.085 7 1 400 700 12.5 1.5 5.569 141.889 0.353 4.615 8 1 400 500 15.5 0.5 3.205 115.872 0.275 7.500 9 1 200 600 14.0 1.0 3.912 125.947 0.200 5.769 10 1 000 700 15.5 1.5 3.495 120.840 0.037 4.983 11 1 400 700 15.5 0.5 4.085 127.829 0.220 4.451 12 1 000 500 15.5 1.5 2.950 111.723 0.063 6.383 13 1 200 600 14.0 1.0 3.575 123.448 0.212 5.085 14 1 000 700 12.5 1.5 4.555 132.588 0.091 4.110 15 1 000 700 12.5 0.5 4.149 128.524 0.094 5.263 16 1 200 600 14.0 1.0 3.912 125.947 0.200 5.769 17 1 000 700 15.5 0.5 3.073 114.183 0.039 5.357 18 1 400 500 12.5 0.5 3.573 121.529 0.316 5.488 19 1 000 500 12.5 0.5 2.579 104.422 0.095 5.769 20 1 400 700 15.5 1.5 4.124 128.552 0.264 5.625 方差分析中效应的p值小于0.05表明该工艺参数因子对响应有显著的影响. R2值大小、及预测值Pred R2和调整值Adj R2是否接近(一般差值小于0.2),表明预测值和试验值之间的相关性. 宽高比λ、接触角θ、稀释率κ和晶粒平均截距l的方差分析结果见表3. 采用式(3)的二阶交互模型进行拟合. 以晶粒平均截距为例,拟合效应的p值为0(<0.05),说明拟合模型是有效的,除激光功率P外,其余因子均为显著的,其中还存在显著的交互项PD,VQ. 表3中激光功率P对晶粒平均截距l影响并不显著,但由于其交互项PD是显著的,所以构成交互项的P也予以保留. R2值为0.856,调整值Adj R2为0.636,预测值Pred R2为0.789,差值小于0.2,均说明目前模型拟合良好.

表 3 方差分析结果Table 3. Results of ANOVA宽高比 λ p 值 接触角 θ p 值 稀释率 κ p 值 晶粒平均截距 l p 值 模型 0 模型 0 模型 0 模型 0 P 0 P 0 P 0 P 0.242 V 0 V 0 Q 0 V 0 Q 0 Q 0 — — Q 0 D 0 D 0 — — D 0.048 VQ 0 VD 0.048 — — PD 0.019 VD 0.045 — — — — VQ 0.006 QD 0.020 — — — — — — R2 = 0.980 Adj. R2 = 0.969 R2 = 0.938 Adj. R2 = 0.916 R2 = 0.968 Adj. R2 = 0.965 R2 = 0.856 Adj. R2 = 0.789 — Pred. R2 = 0.943 — Pred. R2 = 0.856 — Pred. R2 = 0.955 — Pred. R2 = 0.636 3.2 工艺参数对多尺度特征的影响

根据方差分析结果,可得到对应的回归系数. 上节已对因子进行编码处理,绝对值越大则说明其影响更显著. 由式(1)和式(3)可得各响应的表达式为

$$ \begin{split} \lambda = & 3.766 + 0.397{P^*} + 0.479{V^*} - 0.388{Q^*} + 0.263{D^*} -\\& 0.163{V^*}{Q^*} - 0.073{V^*}{D^*} - 0.087{Q^*}{D^*} \end{split} $$ (7) $$\begin{split} \theta =& 122.437 + 5.295{P^*} + 6.200{V^*} - 4.541{Q^*} + \\&3.856{D^*} - 1.526{V^*}{D^*} \end{split} $$ (8) $$ \kappa = 0.190 + 0.110{P^*} - 0.036{Q^*} $$ (9) $$\begin{split} l =& 5.517 + 0.137{P^*} - 0.614{V^*} + 0.533{Q^*} - 0.244{D^*} +\\& 0.3{P^*}{D^*} - 0.365{V^*}{Q^*} \end{split} $$ (10) 根据式(7) ~ 式(10),规范化的回归系数见表4. 此外,图6 ~ 图9为各工艺参数对多尺度特征响应的影响.

表 4 规范化的各响应回归系数Table 4. Normalized regression coefficients for responses回归系数对应变量 激光功率P* 扫描速度V* 送粉量Q* 粉离焦量D* 扫描速度送粉量V*Q* 扫描速度粉离焦量V*D* 送粉量粉离焦量Q*D* 激光功率粉离焦量P*D* 宽高比 λ 0.397 0.479 −0.388 0.263 −0.163 −0.073 −0.087 — 接触角 θ 5.295 6.200 −4.541 3.856 — −1.526 — — 稀释率 κ 0.110 — −0.036 — — — — — 晶粒平均截距 l 0.137 −0.614 0.533 −0.244 −0.365 — — 0.300 3.2.1 宽高比

结合表4和图6可以看出,激光功率P、扫描速度V、送粉量Q及粉末离焦量D对宽高比λ有显著的影响,其中最大正效应是扫描速度V. 随着扫描速度V增加,宽高比λ相应增加,即在单位时间内,较高的扫描速度V导致粉末熔化量减少,引起熔覆层变“薄”. 最大负效应的是送粉量Q,宽高比λ随其增加而减小,因为在一定范围内,随着送粉量Q增加,激光能量熔化相对更多的粉末,引起熔覆层变“厚”. 最大的交互效应是VQ,产生显著负效应.

3.2.2 接触角

根据表4和图7所示,接触角θ受到激光功率P、扫描速度V、送粉量Q及粉末离焦量D的显著影响. 其中最大正效应为扫描速度V,随着扫描速度V的增加,接触角θ先快速增加,然后增加速度逐渐减缓. 最大负效应为送粉量Q,接触角θ随其增加而减小. 交互效应VD也会对接触角θ产生显著负效应.

3.2.3 稀释率

根据表4和图8所示,稀释率κ受到工艺参数激光功率P及送粉量Q的显著影响. 其中最大正效应为激光功率P,随着激光功率P的增加,更多的能量到达基板,稀释率κ相应地增加. 最大负效应为送粉量Q,随着送粉量Q的增加,加强了粉末对激光的“屏蔽效应”,减弱到达基板上的能量,稀释率κ先平缓减小,然后减小速度逐渐加快. 交互效应对稀释率κ均不产生显著影响.

3.2.4 晶粒平均截距

根据表4和图9所示,晶粒平均截距l主要受到扫描速度V、送粉量Q及粉末离焦量D的显著的影响,而激光功率P对晶粒平均截距l的影响较小. 其中最大正效应为送粉量Q,随着送粉量Q的增加,在一定范围内,降低了整体的能量输入,引起更长的冷却时间,导致晶粒粗化,即晶粒平均截距l增加. 最大负效应为扫描速度V,较高的扫描速度V会引起热源快速移动,加快冷却速率,易产生较细晶粒,即晶粒平均截距l减小. 交互效应VQ和PD也会对晶粒平均截距l产生显著影响,其中VQ有明显负效应作用,而PD则有明显的正效应作用.

3.3 优化及验证

3.3.1 多尺度特征优化

式(6)为多尺度特征响应的复合合意性函数,以宏观、微观尺度的特征为目标,用于工艺参数优化. 根据多尺度特征的要求,其中宽高比λ及接触角θ是与熔覆形貌密切相关的形状系数,反映熔覆层和基体的润湿性,为得到良好的润湿性,宽高比λ需大于3,接触角θ一般不小于100°[20]. 在满足冶金结合的基础上,稀释率κ取值为0.35 ~ 0.4[11]. 晶粒平均截距l以最小值为优化目标. 宏观几何形貌和微观晶粒平均截距均其重要性一致,所以将各响应重要程度

$ {r_i} $ 、权重系数$ w{t_i} $ 都设为相同值[10]. 表5给出了优化结果,其中,当P = 1 400.00 W,V = 503.13 mm/min,Q = 12.50 g/min,D = 0.50 mm时,具有最大复合合意性.表 5 优化结果和试验Table 5. Optimization results and validation experiment激光功率P/W 扫描速度v /(mm·min−1) 送粉量Q/(g·min−1) 粉离焦量D/mm 宽高比λ 接触角θ/(°) 稀释率κ(%) 晶粒平均截距l/μm 合意性 结果 预测值 1 400.00 503.13 12.50 0.50 3.50 121.26 0.34 5.31 0.79 优化 1 350.00 550.00 12.50 0.50 3.74 123.55 0.31 5.23 0.53 — 1 350.00 516.92 12.50 0.50 3.49 121.00 0.31 5.31 0.56 — 1 400.00 500.00 12.50 0.50 4.00 124.70 0.31 5.57 — — 误差δ(%) — — — — 12.50 2.76 9.68 4.67 — — 通过复合合意性确定的最优工艺参数为空间离散点. 然而实际良好熔覆质量常为连续工艺参数区间. 因此,通过叠加多尺度特征响应值的等高线,还可获得多尺度特征协同优化的连续工艺参数窗口. 根据式(7) ~ 式(10),以扫描速度V和送粉量Q为变量,激光功率P和粉末离焦量D为常量,以3.5<λ<4,120°<θ<130°,0.35<κ<0.4及最小化l为目标边界,构建了响应面. 通过叠加多个响应面并在V与Q构建的平面上投影,确定了响应等高线,如图10所示,阴影区域为满足多尺度特征要求的连续工艺参数窗口,图中A点表示上述优化中具有最大复合合意性的优化结果.

3.3.2 试验验证

采用具有最大复合合意性的工艺参数进行验证. 预测误差见表5,其中宽高比

$\lambda$ 误差为12.5%、接触角θ误差为2.76%、稀释率κ误差为9.68%、平均截距l的误差为4.67%,说明该模型具有较高的预测精度. 最优化工艺参数的微观组织结构如图11所示,熔覆层与基体形成了良好的冶金结合,整个熔覆层没有气孔和裂纹. 图11b显示了熔覆层底部的微观组织结构,主要分布为等轴晶,熔合线交界面上分布部分柱状晶,其形成主要是由温度梯度和冷却速率共同决定的[21]. 图11c和图11d分别为熔覆层的中部和右侧的微观组织结构,由于远离热源,具有较高的冷却速率,形成了细小的等轴晶.试验组19的微观组织结构如图12所示,在该工艺参数下,较低的激光功率降低了输入的能量密度,在单位时间和单位距离内没充足的能量熔化粉末,所以形成过小的熔池,导致基体和熔覆层的冶金结合不良. 熔覆层和基体之间存在未熔合的区域,熔化的金属液体流向熔池外侧,在流动过程中逐渐凝固,然后形成一个不与基体结合的区域,如图12a所示. 在熔覆层搭接时,未熔合区域易形成重叠空隙,对成形质量极为不利. 激光能量密度过小,不利于熔覆层内部气体的逸出,容易产生较小的孔隙,如图12b ~ 12d所示,影响熔覆制件性能.

在微观组织结构上,优化组和试验组19的晶粒平均截距分别为5.570 μm和5.769 μm,说明优化组具有更加细小的晶粒. 在熔覆层高度方向上,分别测量优化组及试验组19的显微硬度,结果如图13所示. 从图中可看出,2组试验的显微硬度具有基本一致的分布趋势,优化组的整体显微硬度也略高于试验组19.

在拉伸性能方面,采用最优工艺参数:P = 1 400.0 W,V = 500.0 mm/min,Q = 12.5 g/min,D = 0.5 mm,得到熔覆制件,其中扫描间距为1.2 mm、单层抬升高度为0.7 mm. 通过万能试验机测试得到拉伸曲线,如图14所示. 从图中可看出试样具有较高的屈服强度和抗拉强度,分别达到了439 MPa和751 MPa,抗拉强度超过316L锻造的商业标准525 ~ 624 MPa[22]. 同时还具有一定的塑形,其断后伸长率为26%. 试样截面如图15所示,可看出相邻熔覆层内部主要分布着细小等轴晶,未发现明显孔隙、未熔合及裂纹等瑕疵.

4. 结 论

(1) 采用全析因设计和回归分析所构建的经验统计模型,可实现宏微观特征较准确的预测,其中宽高比λ、接触角θ、稀释率κ及晶粒平均截距l的误差分别为12.5%,2.76%,9.68%及4.67%.

(2) 以熔覆层宏微观特征为优化目标,获取最佳工艺参数为P = 1 400 W,V = 500 mm/min,Q = 12.5 g/min及D = 0.5 mm. 此外,通过叠加多个响应的等高线,获得宏微观特征协同优化的合适工艺窗口,同样适用于指导熔覆成形.

(3) 使用最佳工艺参数进行验证,熔覆层具有良好的几何形貌,未发现明显的气孔、裂纹等缺陷. 熔覆层内部以细小等轴晶分布为主,具有更高的显微硬度. 最后,熔覆制件具有良好拉伸性能:屈服强度为439 MPa,抗拉强度为751 MPa,断后伸长率为26%.

-

表 1 ZL114A铝合金的室温拉伸力学性能

Table 1 Tensile properties of ZL114A aluminium alloy at room temperature

拉伸试样状态 屈服强度ReL/MPa 抗拉强度Rm/MPa 断后伸长率A(%) 基材热处理态 293.4 325.4 3.0 修复件沉积态 90.5 142.5 10.1 修复件热处理态 297.5 330.7 2.6 -

[1] 朱浩, 吕丹, 朱亮. 6061铝合金断裂机理的原位拉伸研究[J]. 机械工程学报, 2009, 45(2): 94 − 99. doi: 10.3901/JME.2009.02.094 Zhu Hao, Lü Dan, Zhu Liang. Investigation of fracture mechanism of 6061 aluminum alloy by means of in-situ observation[J]. Journal of Mechanical Engineering, 2009, 45(2): 94 − 99. doi: 10.3901/JME.2009.02.094

[2] 孙和祥. 金属型铝合金铸件缺陷分析[J]. 金属加工(热加工), 2005(12): 69 − 69. Sun Hexiang. Defect analysis of metallic aluminum alloy castings[J]. Metal Working, 2005(12): 69 − 69.

[3] 章敏. 送粉式和送丝式的钛合金激光增材制造特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2013. Zhang Min, Research on laser additive manufacturing characteristics of titanium alloy with powder and wire[D]. Harbin: Harbin Institute of Technology, 2013.

[4] 单长龙. 铸件表面缺陷等离子喷焊与堆焊修复研究[D]. 长春: 吉林大学, 2013. Shan Changlong. Study on plasma spray welding and overlaying in repairing the surface defects of cast iron parts[D]. Changchun, Jilin University, 2013.

[5] 李金华, 张德强, 姚芳萍, 等. 基于激光熔覆技术的铝合金模具修复研究[J]. 工艺与检测, 2014, 12: 162 − 164. Li Jinhua, Zhang Deqiang, Yao Fangping, et al. Research of repairing Al alloy mold on laser cladding technology[J]. Technology and Test, 2014, 12: 162 − 164.

[6] 刘云雷, 赵剑锋, 潘浒, 等. 基于激光熔覆的镍基高温合金激光的数值模拟[J]. 应用激光, 2013, 33(2): 125 − 130. doi: 10.3788/AL20133302.0125 Liu Yunlei, Zhao Jianfeng, Pan Hu, et al. Numerical simulation on laser repairing of nicked-based superalloy based on laser cladding[J]. Applied Laser, 2013, 33(2): 125 − 130. doi: 10.3788/AL20133302.0125

[7] Zhuang W, Liu Q, Djugum R, et al. Deep surface rolling for fatigue life enhancement of laser clad aircraft aluminium alloy[J]. Applied Surface Science, 2014(320): 558 − 562.

[8] 高菁菁. 211Z铝合金焊接及焊后热处理工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2013. Gao Qingqing. Study on Welding and post welding heat treatment of 211Z aluminium alloy[D]. Harbin: Harbin Institute of Technology, 2013.

[9] Totten G E, Mackenzie D S. Handbook of aluminum: Vol. 1: Physical Metallurgy and Processes[M]. Florida: CRC Press, 2003.

[10] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690 − 2698. Wang Huaming. Materials, fundamental issues of laser additive manufacturing for high-performance large metallic component[J]. Acta Aeronautica et Astronautica Science, 2014, 35(10): 2690 − 2698.

[11] 林鑫, 黄卫东. 高性能金属构件的激光增材制造[J]. 中国科学: 信息科学, 2015, 45(9): 1111 − 1126. Lin Xin, Huang Weidong. Laser additive manufacturing of high-performance metal components[J]. Science China Press, 2015, 45(9): 1111 − 1126.

[12] Liu Q, Brandt M, Janardhana M, et al. Potential application and certification of laser cladding technology for repair of ageing aircraft components[C]// 30th International Congress on Applications of Laser and Electro Optics, AIP Publishing, 2011: 257 − 266.

[13] Li X P, O Donnell K M, Sercombe T B. Selective laser melting of Al-12Si alloy: Enhanced densification via powder drying[J]. Additive Manufacturing, 2016, 10: 10 − 14. doi: 10.1016/j.addma.2016.01.003

[14] Bartkowiak K, Ullrich S, Frick T, et al. New developments of laser processing aluminium alloys via additive manufacturing technique[J]. Physics Procedia, 2011, 12(1): 393 − 401.

[15] Louvis E, Fox P, Sutcliffe C J. Selective laser melting of aluminium components[J]. Journal of Materials Processing Technology, 2011, 211(2): 275 − 284. doi: 10.1016/j.jmatprotec.2010.09.019

[16] Kimura T, Nakamoto T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting[J]. Materials & Design, 2016, 89: 1294 − 1301.

[17] 陶汪, 王宪, 陈奥, 等. 铝合金激光熔化沉积应力场及力学性能分析[J]. 焊接学报, 2020, 41(4): 62 − 66. doi: 10.12073/j.hjxb.20191013002 Tao Wang, Wang Xian, Chen Ao, et al. Stress field and mechanical properties of laser metal deposited aluminum alloys[J]. Transactions of the China Welding Institution, 2020, 41(4): 62 − 66. doi: 10.12073/j.hjxb.20191013002

[18] 钦兰云, 庞爽, 杨光, 等. 激光沉积修复ZL114A铝合金组织和力学性能分析[J]. 中国激光, 2016, 43(12): 1 − 7. Qin Lanyun, Pang Shuang, Yang Guang, et al. Microstructure and mechanical property analysis of ZL114A aluminum alloy repaired by laser deposition[J]. Chinese Journal of Lasers, 2016, 43(12): 1 − 7.

[19] 钦兰云, 庞爽, 杨光, 等. 激光沉积修复ZL114A铝合金的显微组织及显微硬度研究[J]. 红外与激光工程, 2017, 46(5): 1 − 6. Qin Lanyun, Pang Shuang, Yang Guang, et al. Microstructure and micro-hardness of laser deposition repair ZL114A aluminum alloy[J]. Infrared and Laser Engineering, 2017, 46(5): 1 − 6.

[20] 钦兰云, 庞爽, 杨光, 等. 激光沉积修复ZL114A铝合金的组织及力学性能[J]. 稀有金属材料与工程, 2016, 46(6): 1596 − 1061. Qin Lanyun, Pang Shuang, Yang Guang, et al. Microstructure and mechanical properties of laser deposition repaired cast ZL114A aluminium alloy[J]. Rare Metal Materials and Engineering, 2016, 46(6): 1596 − 1061.

[21] 郭永利, 梁工英, 李路. 铝合金的激光熔覆修复[J]. 中国激光, 2008, 35(2): 303 − 306. doi: 10.3321/j.issn:0258-7025.2008.02.030 Guo Yongli, Liang Gongying, Li Lu. Laser cladding reparation of aluminum alloy[J]. Chinese Journal of Lasers, 2008, 35(2): 303 − 306. doi: 10.3321/j.issn:0258-7025.2008.02.030

-

期刊类型引用(1)

1. 孙淼,马帅,张慧铭,张瑞. Ti_3SiC_2基复合材料高温氧化性能研究进展. 化工新型材料. 2022(S1): 161-167 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: