A rough-fuzzy control method for the penetration state of variable gap MAG welding

-

摘要:

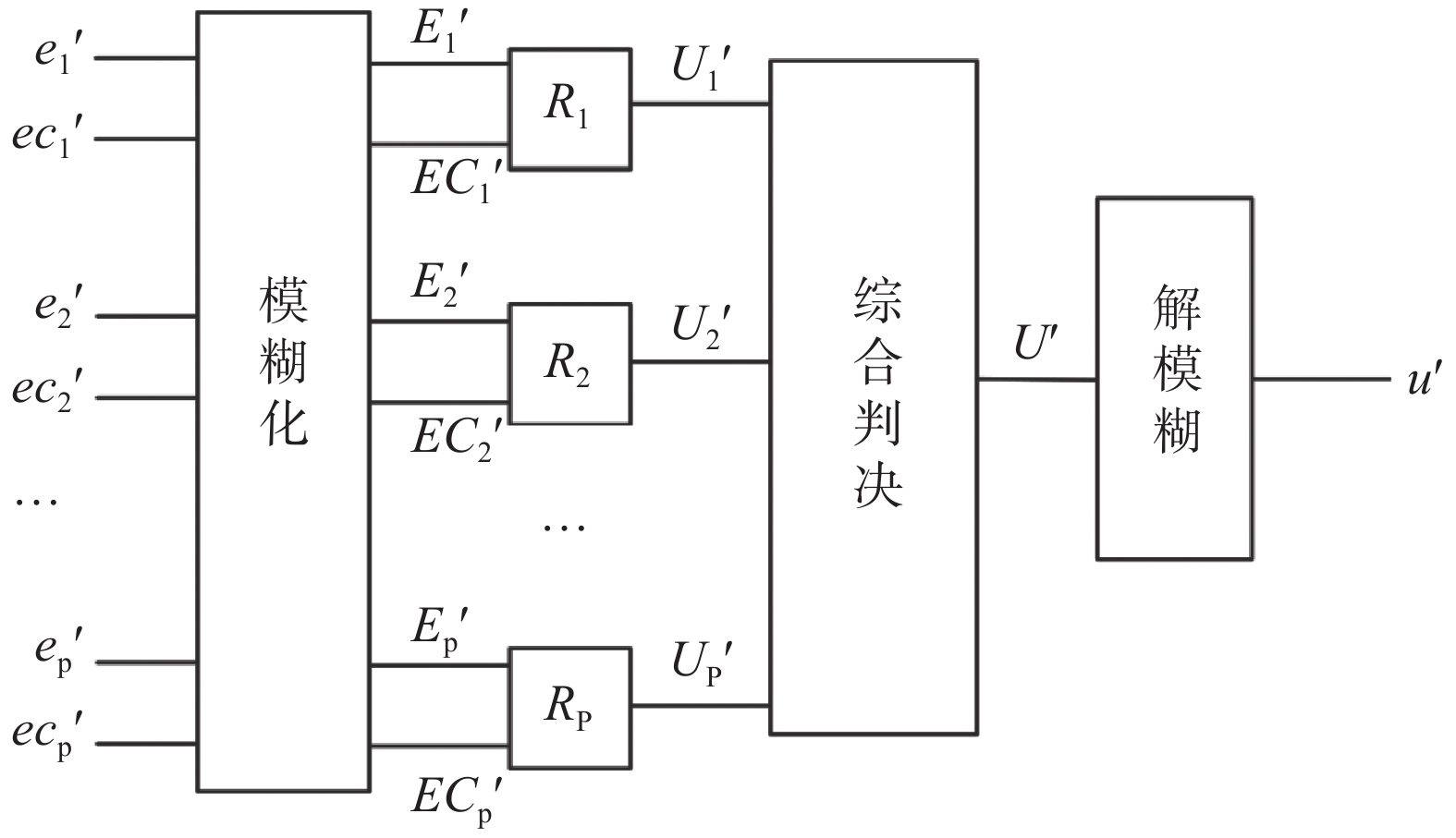

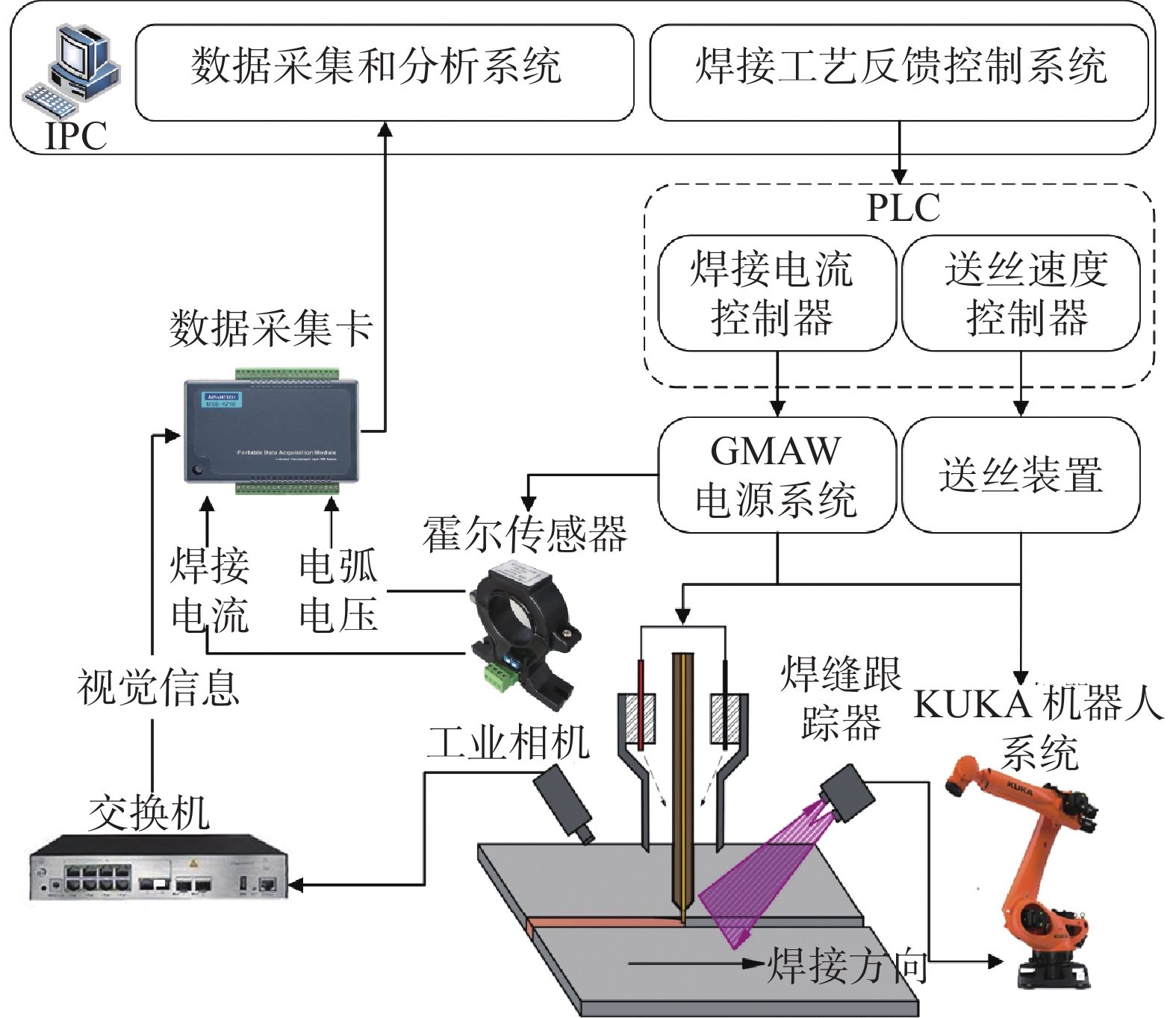

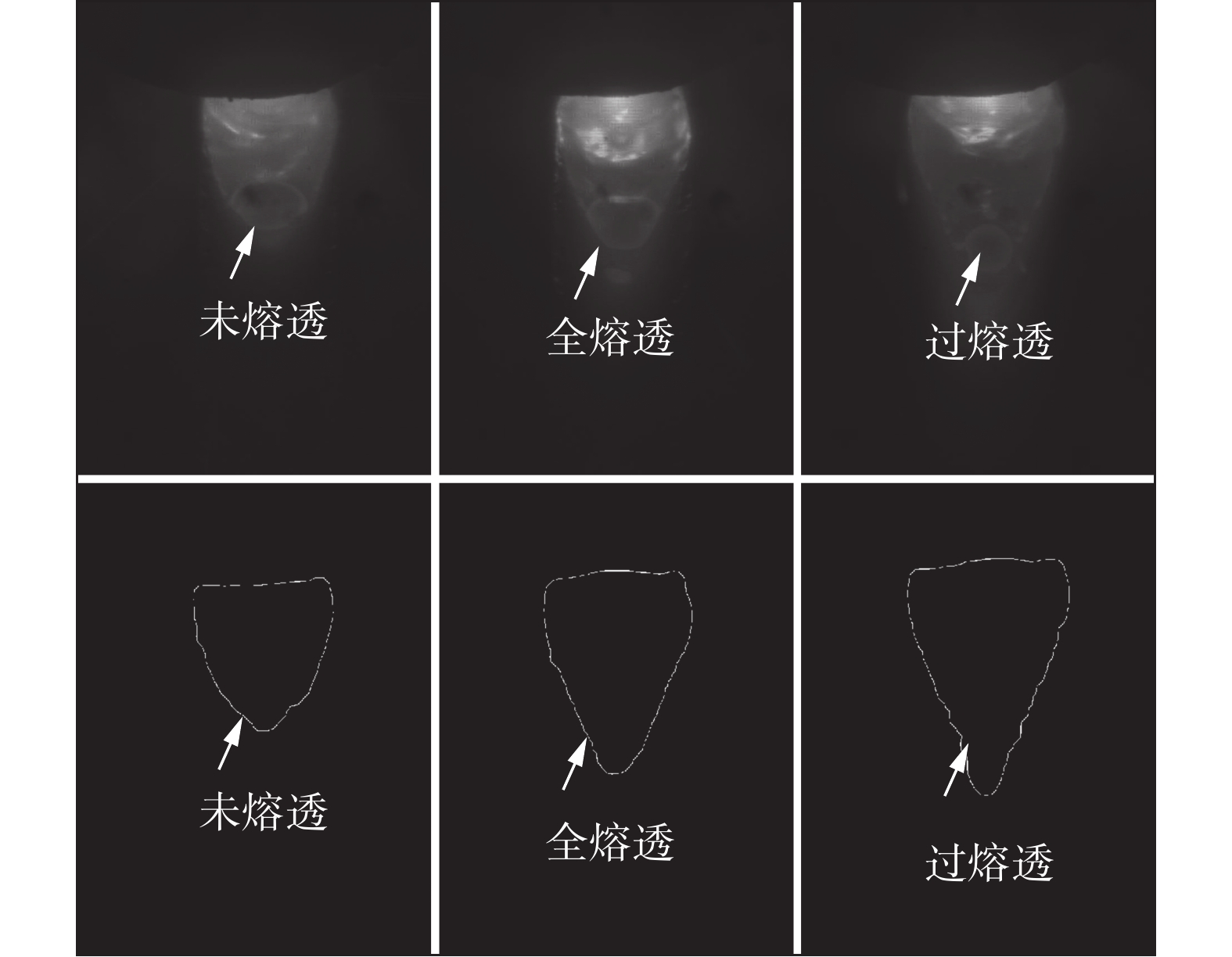

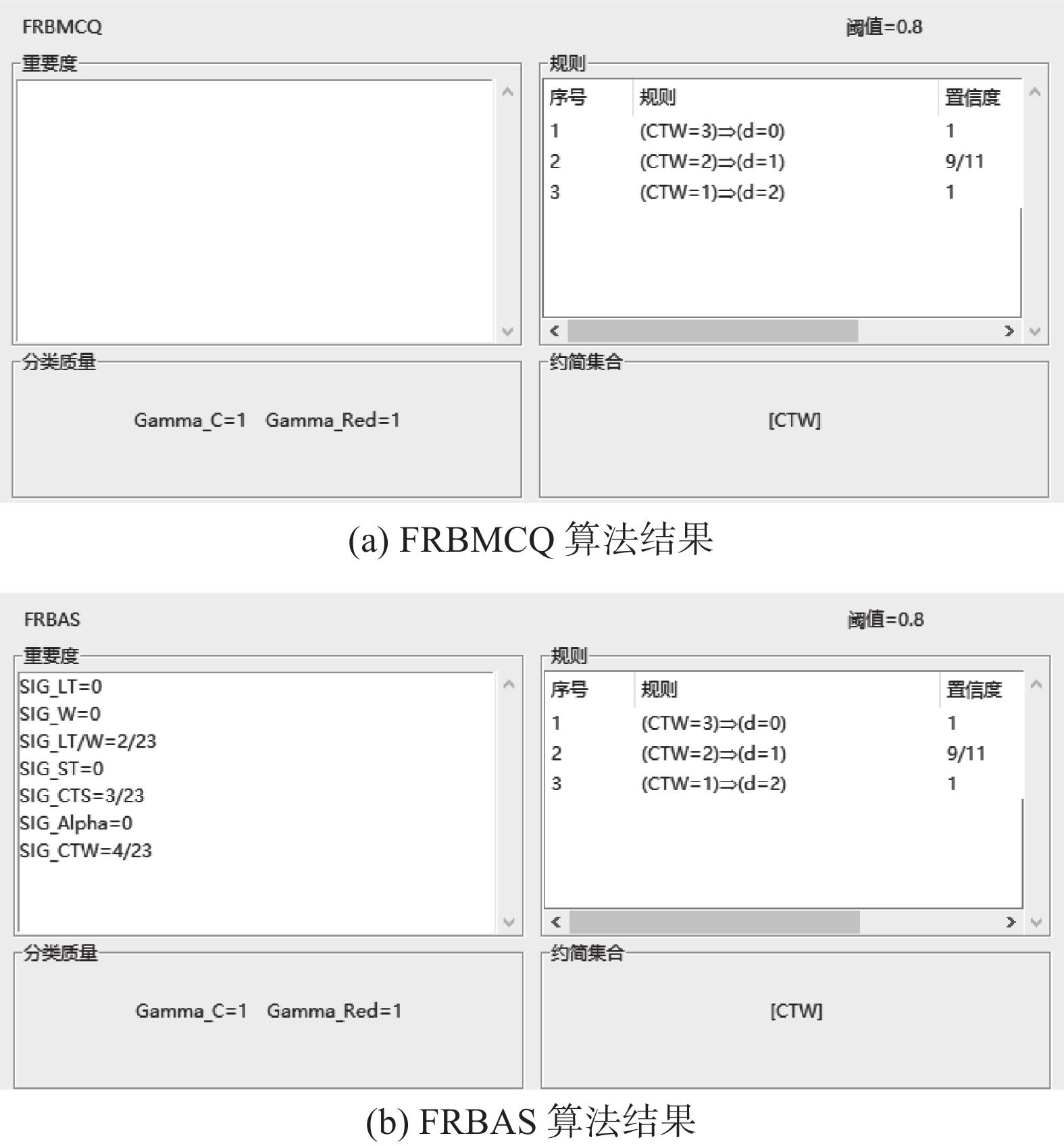

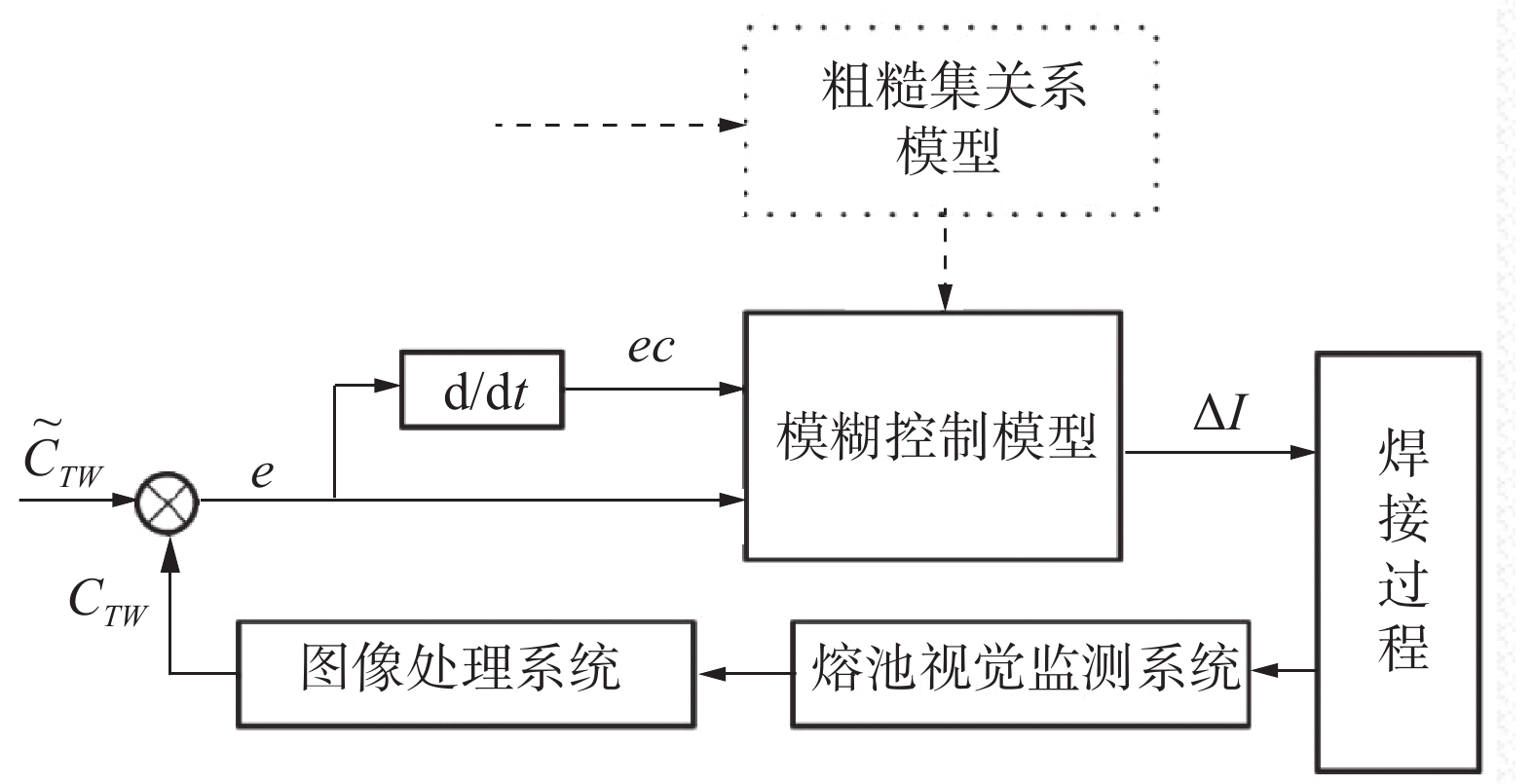

正面熔池与熔透状态之间存在一定的对应关系. 然而与熔透状态潜在相关的熔池特征众多,如何去除冗余特征,建立一个反映熔池特征与熔透状态对应关系的简洁的知识模型,对实现焊接熔透在线控制具有重要意义. 提出一种焊接熔透状态的粗糙-模糊控制方法,并在变间隙MAG焊接实验中进行验证. 给出2种基于变精度粗糙集的属性约简算法,以求解表征熔透状态的熔池最小特征集. 通过变间隙-电流焊接试验建立熔透状态决策信息系统,引入2个用以描述熔池尾部尖削程度的形状参数,基于粗糙集知识约简和规则提取算法获取熔透状态分类规则. 构建熔池尾宽系数的模糊控制模型,利用最小化模糊熵来构造误差论域上的隶属函数. 通过2组变间隙焊接实验对该控制模型进行验证,结果表明,闭环控制下焊缝背面熔宽均匀一致,符合焊接规范要求.

Abstract:There is a certain correspondence between the frontal molten pool and the penetration state. However, due to the numerous potential weld pool features related to the penetration state, how to remove redundant features and establish a concise knowledge model that reflects the corresponding relationship between weld pool features and penetration state is of great significance for achieving online control of welding penetration. A rough-fuzzy control method for welding penetration state is proposed and verified in variable gap MAG welding experiments. To solve the minimal feature set of the melt pool that characterizes the penetration state, we provide two attribute reduction algorithms based on variable precision rough sets. A decision information system for penetration state is established through variable gap-current welding experiments, and two shape parameters are introduced to describe the degree of sharpness at the tail of the molten pool. The classification rules of penetration status are obtained using rough set knowledge reduction and rule extraction algorithms. We establish a fuzzy control model for the width coefficient of the molten pool tail, and use the minimization of fuzzy entropy to construct membership functions of the error domain. The proposed control model is validated through two sets of variable gap welding experiments, and the results show that under closed-loop control, the weld back width is uniform and consistent, which can meet the requirements of welding specifications.

-

Keywords:

- penetration status /

- features of molten pool /

- rough set /

- fuzzy control /

- groove gap /

- MAG welding

-

0. 序言

近年来,复合焊工艺在航空航天、船舶制造、工程机械等领域成为研究与应用的热点[1-4]. 其中,等离子弧−MIG复合焊接是将两电弧共熔池作用于工件,兼具等离子弧能量集中、熔深大[5-6]和MIG电弧效率高、速度快的优点[7],但焊接过程中等离子弧直流正接,MIG电弧直流反接,电弧在电磁力作用下发生排斥,影响焊接过程稳定性和质量.国内外大多采用外加磁场辅助的方式促使电弧有效耦合,但该方法焊接工艺参数较多,结构复杂[8-10].

为解决这一问题,提出了一种新型的等离子弧−MIG焊丝振荡式复合焊接工艺,即在复合焊接中使MIG焊丝发生位移振荡,可有效促进双弧耦合,增强对熔池的搅拌作用加快气体的排出,使焊缝组织更加均匀.系统介绍了该方法的振荡频率、振荡振幅对电弧形态、熔滴过渡行为的影响以寻求一种优化的等离子弧−MIG复合焊接方法,实现稳定高效焊接.

1. 试验方法

试验所用等离子弧−MIG焊丝振荡式复合焊接试验系统如图1所示,系统主要由自主设计的复合焊炬、LHM8-300A型直流脉冲等离子弧焊电源、德国乐驰S8 MIG焊机、安川DX100型焊接机器人组成. 复合焊炬是由自主设计的等离子弧焊枪、MIG焊枪旁轴式构成.

为探究MIG焊丝位移规律性的振荡焊接效果,设计了焊丝振荡系统. 通过可调式偏心转子带动曲柄连杆间接调节MIG焊炬的振荡振幅,设计振荡振幅调节范围为0 ~ 6 mm;利用直流电机的无级变速调节MIG焊丝的水平振荡频率. 电机电源采用KXN-3030D型电源,驱动电机采用DC-12V 775型号直流电机,转速0 ~ 2 500 r/min可调,对应理论振荡频率范围为0 ~ 41 Hz. 冷却循环装置用来避免喷嘴温度过高,利用机器人控制振荡式复合焊枪姿态完成焊接过程.振荡式复合焊接平台可实现MIG焊炬振荡振幅和频率的调节,如图2所示.

平板堆焊试验母材为200 mm × 50 mm × 6 mm的Q235钢板,对接试验所用试板尺寸为200 mm × 80 mm × 6 mm,采用尺寸规格为ϕ1.2 mmER50-6焊丝,母材和焊丝成分如表1所示. 等离子弧喷嘴在前,离子气流量2 L/min,轴线垂直于工件表面,喷嘴距离工件高度为4 mm. 经过对比试验确定等离子弧−MIG堆焊工艺参数如表2中试验组别1 ~ 3所示,对接工艺参数如表2中试验组别4 ~ 7所示. 电机转速0,1 000,1 500,2 000 r/min分别对应振荡频率0,16,25,33 Hz.

表 1 Q235钢和ER50-6焊丝的化学成分(质量分数,%)Table 1. Chemical compositions of Q235 steel and ER50-6 welding wire材料 C Mn Si P S Ni Fe Q235 ≤0.18 0.35 ~ 0.80 ≤0.30 ≤0.040 — — 余量 ER50-6 0.06 ~ 0.15 1.40 ~ 1.85 0.80 ~ 1.15 0.025 0.025 0.15 余量 表 2 焊接工艺参数Table 2. Welding process parameters组别 等离子弧电流IP /A MIG电流IM /A 焊接速度v/(mm·s−1) 电机转速n/(r·min−1) 振荡振幅A/mm 1 40 120 4 0 0 2 40 120 4 1 000,1 500,2 000,2500 3 3 40 120 4 1 000 1,2,3,4,5,6 4 100 100 4 0 3 5 100 100 4 1 000,1 500,2 000 3 6 100 100 4 1 000 4 7 100 100 4 1 500 3 根据标准GB/T 2651—2008《焊接接头拉伸试验方法》采用WAW-600型微机控制电液伺服万能试验机进行力学性能试验,设定拉伸速度为3 mm/min. 采用线切割切取拉伸试样,去除焊缝表面余高,每组参数选定3个试样进行拉伸试验,取3个拉伸试样检测结果的平均值作为最终测试结果. 根据标准GB/T 2653—2008《焊接接头弯曲试验方法》采用的弯曲压头直径为20 mm的弯曲半圆弧压头和三点式弯曲方法进行弯曲试验.从每组焊接试样中切取制作3个弯曲试样.

2. 试验结果与分析

2.1 振荡频率对电弧形态和熔滴过渡行为的影响

图3为在无振荡条件下,当电机转速为1 000 r/min(振荡频率16 Hz)、振荡振幅为3 mm时,等离子弧−MIG复合焊接所得焊缝成形情况. 从图3可知,焊缝宏观成形均未有明显缺陷.

固定MIG焊炬振荡振幅为3 mm,采集电机转速0,1 000,1 500,2 000,2 500 r/min下,对应振荡频率理论值为0,16,25,33,41 Hz的复合焊接电弧形态如图4所示. 当电机转速为0 r/min即无振荡时,等离子弧在前,MIG电弧在后,两电弧耦合效果较差,如图4a所示. 这是由于等离子弧采用直流正接,而MIG电弧采用直流反接,由于电磁力影响两电弧势必会产生排斥现象,不利于共熔池焊接过程. 随着MIG电弧进行水平位移振荡后,两电弧耦合程度发生了变化. 伴随着电机转速(振荡频率)的增加,等离子弧与MIG电弧排斥效果减弱,耦合趋势增大,尤其是电机转速为2 000 r/min(振荡频率为33 Hz)时,焊接过程更稳定;MIG焊丝熔滴过渡过程中产生的爆破效果比无振荡时更加明显,并且指向等离子弧方向;随着MIG焊丝振荡运动,其电弧形状不断变化,有时呈爆破状,有时呈钟形,因此MIG电弧的熔滴过渡形式可能为短路过渡和射流过渡并存.焊接过程中,等离子弧受到电磁压缩能量集中[11]且由于惯性作用会偏向MIG电弧一侧,有利于电弧发生耦合. 随着振荡频率的增大,MIG电弧与等离子弧形态之间相互影响变小,耦合区域变大,MIG焊丝振荡也会增强对熔池的搅拌作用. 当电机转速2 500 r/min(振荡频率为41 Hz)时,发现等离子弧出现不稳定的波动,如图4e所示. 这是由于电机转速(振荡频率)增大,使整个复合焊接装置尤其是等离子弧焊炬产生晃动,影响了焊接效果.

![]() 图 4 不同转速(振荡频率)下复合焊接电弧形态Figure 4. Arc morphology of hybrid welding at different rotational speed (oscillation frequency). (a) rotational speed 0 r/min (0 Hz); (b) rotational speed 1 000 r/min (16 Hz); (c) rotational speed 1 500 r/min (25 Hz); (d) rotational speed 2 000 r/min (33 Hz); (e) rotational speed 2 500 r/min (41 Hz)

图 4 不同转速(振荡频率)下复合焊接电弧形态Figure 4. Arc morphology of hybrid welding at different rotational speed (oscillation frequency). (a) rotational speed 0 r/min (0 Hz); (b) rotational speed 1 000 r/min (16 Hz); (c) rotational speed 1 500 r/min (25 Hz); (d) rotational speed 2 000 r/min (33 Hz); (e) rotational speed 2 500 r/min (41 Hz)图5为不同转速下复合焊接熔滴过渡及电信号采集. 从图5可以看出,焊接过程中MIG焊丝振荡频率不同,但熔滴过渡方式均表现为短路过渡形式. 从图5a看出,MIG电源形式为直流脉冲且每3个脉冲完成一次短路过渡;而当电机转速为1 500 r/min(振荡频率25 Hz)时,图5c中4 ~ 9完成当前一次熔滴过渡用时减少为约0.007 5 s,同时在两次熔滴过渡之间,存在多次电弧点燃且熔滴短路过程总是表现出高电压低电流特点.

2.2 振荡振幅对电弧形态和熔滴过渡行为的影响

在表2中第3组工艺参数下,保持电机转速为1 000 r/min(振荡频率16 Hz),调节MIG焊炬振荡振幅分别为1,2,3,4,5和6 mm情况下观察复合焊接电弧形态和熔滴过渡行为,如图6所示. 当振荡振幅为1 mm时,MIG电弧形状较为规则,相对于较大的振荡振幅,电弧形态较为稳定,如图6a所示. 在较大振荡振幅复合焊接中,作往复运动的MIG电弧对熔池具有更强的搅拌能力,显然更能促进气体的排出;而振荡振幅达到6 mm时,等离子电弧与MIG电弧耦合作用减弱,这主要是由于过大的振动使整个装置不稳定造成的.

通过对不同转速和振荡振幅下振荡焊接熔滴过渡和电信号分析发现,MIG熔滴过渡频率受振荡影响显著. 由熔滴过渡图像可以看出,在无振荡复合焊接下熔滴过渡呈现多脉一滴的短路过渡行为;而在振荡加入后,熔滴过渡行为发生了变化如图7所示.

相比于无振荡时的多脉一滴,加入振荡后存在一个脉冲周期内出现两次短路过渡的情况.每次短路过渡,焊丝尖部均为小熔滴过渡[12],与熔池短暂接触后快速分离,爆破力很小,因此振荡式复合焊接减小了焊接飞溅,整个过渡过程更为平稳,焊接热输入更稳定.

2.3 焊缝的力学性能

图8为不同转速(振荡频率)下对接焊缝成形.每组焊缝均未出现明显焊接缺陷,实现了单面焊双面成形.但是在背部也存在热输入不稳定问题.

表3为拉伸试验和弯曲试验的测试结果.振荡加入后,焊接接头的抗拉强度均大于无振荡时接头的抗拉强度,并且随着转速(振荡频率)的提高呈现先增大再减小的趋势,抗拉强度最大值为278 MPa. 这是由于一定频率的焊丝振荡起到了搅拌熔池的作用,有利于熔池中气孔的消除.弯曲试验结果表明,在无振荡情况下,弯曲90º时出现了裂纹;振荡加入后转速为1000,2 000 r/min时均未发现裂纹.从表3可知,随振荡频率的提高,抗弯强度呈先增大后减小趋势,最大为272 MPa;焊丝水平位移振荡后,两电弧排斥减弱,提高了焊接接头的力学性能;但振荡过大会使焊接过程的稳定性受影响,造成了抗拉强度和抗弯强度先增大后减小的现象.

表 3 拉伸和弯曲试验的测试结果Table 3. Results of tensile and bending tests电机转速n/( r·min−1) 抗拉强度Rm /MPa 抗弯强度Rτ /MPa 实测值 平均值 实测值 平均值 0 167,178,155 167 200,175,179 185 1 000 220,240,285 248 280,235,300 272 1 500 325,275,235 278 260,220,265 248 2 000 260,225,174 220 305,200,205 237 3. 结论

(1) 基于等离子弧和MIG弧焊工艺设计了一种新型焊丝振荡式复合焊接系统,实现了MIG焊炬振荡频率为0,16,25,33,41 Hz及振荡振幅0 ~ 6 mm可调的稳定复合焊接过程.

(2) 研究了振荡式复合焊接焊丝振荡频率和振荡振幅对电弧形态及熔滴过渡行为的影响. 结果表明,振荡系统有效促进了等离子弧和MIG电弧的耦合,尤其是振荡频率为33 Hz时,两电弧之间的排斥减弱,共熔池耦合作用明显;随着MIG焊丝振荡频率和振荡振幅的增大,MIG电弧对熔池的搅拌能力增强,可以有效促进熔池中的气体排出;振动中的MIG焊炬能实现小熔滴短路过渡,减少飞溅,增加熔滴过渡频率.其中当电机转速为1 500 r/min(振荡频率25 Hz)时,完成当前一次熔滴过渡用时减少为约0.007 5 s,使焊接过程更稳定.

(3)从拉伸和弯曲试验结果发现,振荡式复合焊接相比于不振荡情况下接头的抗拉强度和抗弯强度均有较大提高;随振荡频率的增大,接头的抗拉强度和抗弯强度呈现先增大后减小的趋势.

-

表 1 焊接熔透状态决策信息表

Table 1 Decision information table for welding penetration states

焊接样本集U 熔池形状

参数c1熔池形状

参数c2… 熔池形状

参数cn熔透状态

dx1 v11 v12 … v1n vd1 x2 v21 v22 … v2n vd2 … … … … … … xm vm1 vm2 … vmn vdm 表 2 变间隙-电流焊接下的焊缝背面熔宽

Table 2 Weld back width under variable gap-current welding conditions (mm)

坡口间隙

G /mm焊接电流I /A 155 165 185 205 215 0.4 0 0 0 0 3.44 0.7 0 0 0 3.39 4.72 1.2 2.09 2.42 3.09 4.31 5.15 1.7 2.59 3.40 4.03 5.03 5.37 2.0 3.67 3.87 4.90 — — 表 3 变间隙电流焊接熔透状态决策信息表

Table 3 Decision information table for penetration status of variable gap-current welding

样本号 熔池尾部长度

$ {L_{\rm{T}}} $/μm熔池最大宽度

$ W $/μm熔池尾部长宽比

${L_{\rm{T}}}$/W熔池尾部面积

$ {S_T} $/μm2熔池尾面积系数

${C_{{\rm{TS}}} }$熔池后拖角

$ \alpha $(°)熔池尾宽系数

${C_{{\rm{TW}}} }$熔池背面宽度

$ {W_B} $/mmx1 203.5 227.4 0.895 34 264.2 0.740 58.39 0.818 0 x2 227.1 246.4 0.922 40220.0 0.718 56.96 0.795 0 x3 287.2 279.0 1.029 55 542.4 0.693 51.84 0.766 0 … … … … … … … … … x10 356.5 286.8 1.243 61 489.8 0.601 43.82 0.611 4.724 x11 198.2 195.4 1.015 25 912.6 0.669 52.58 0.722 2.092 x12 229.0 222.6 1.029 33977.0 0.667 51.84 0.708 2.420 … … … … … … … … … x21 222.7 184.4 1.207 26597.0 0.647 45.06 0.678 3.672 x22 250.0 210.8 1.186 33 429.4 0.634 45.74 0.662 3.872 x23 323.8 222.4 1.458 35 481.6 0.618 37.94 0.621 4.904 表 4 离散化后的熔透状态决策信息表

Table 4 Decision information table of penetration state after discretization

样本号 熔池尾部长度

LT熔池最大宽度

W熔池尾部长宽比

LT/W熔池尾部面积

ST熔池尾面积系数

CTS熔池后拖角

α熔池尾宽系数

CTW熔池背面宽度

WBx1 1 2 1 1 3 3 3 0 x2 1 2 1 1 3 3 3 0 x3 2 3 1 3 3 3 3 0 … … … … … … … … … x10 3 3 2 3 1 2 1 2 x11 1 1 1 1 2 3 2 1 x12 1 2 1 1 2 3 2 1 … … … … … … … … … x21 1 1 2 1 2 2 2 1 x22 1 1 2 1 2 2 2 1 x23 2 2 2 1 1 1 1 2 表 5 熔池尾部宽度系数控制规则

Table 5 Control rules for width coefficient of molten pool tail

误差变化率ec 误差e NB ZE PB NB NB NB ZE ZE NB ZE PB PB ZE PB PB 表 6 误差类型及其聚类中心

Table 6 Types of error and their clustering centers

类型 $ e $ $ \bar e $ NB −0.074, −0.055, −0.051, −0.05, −0.041, −0.04 −0.047 ZE −0.007, −0.004, 0, 0.001, 0.002, 0.017, 0.025,

0.04, 0.043, 0.047, 0.0610.023 PB 0.092, 0.105, 0.121, 0.133, 0.134, 0.157 0.127 -

[1] 殷树言. 气体保护焊工艺基础[M]. 北京: 机械工业出版社, 2007. Yin Shuyan. Basic technology of gas shielded welding[M]. Beijing: China Machine Press, 2007.

[2] 吴林, 陈善本. 弧焊机器人智能化技术[M]. 北京: 国防工业出版社, 2000. Wu Lin, Chen Shanben. Intelligent technology of arc welding robot[M]. Beijing: National Defense Industry Press, 2000.

[3] Feng Yanzhu, Gao Xiongdong, Zhang Yanxi, et al. Simulation and experiment for dynamics of laser welding keyhole and molten pool at different penetration status[J]. International Journal of Advanced Manufacturing Technology, 2021, 112: 2301 − 2312.

[4] Ye Guangwen, Guo Xiangdong, Liu Qianwen, et al. Prediction of weld back width based on top vision sensing during laser-MIG hybrid welding[J]. Journal of Manufacturing Processes, 2022, 84: 1376 − 1388.

[5] 杨嘉佳, 王克鸿, 吴统立, 等. 基于熔池视觉特征的铝合金双丝焊熔透识别[J]. 焊接学报, 2017, 38(3): 49 − 52. Yang Jiajia, Wang Kehong, Wu Tongli, et al. Welding penetration recognition in aluminum alloy tandom arc welding based on visual characters of weld pool[J]. Transactions of the China Welding Institution, 2017, 38(3): 49 − 52.

[6] 林俊, 高向东. 电弧焊熔池表征与熔透状态映射研究[J]. 焊接, 2016(10): 34 − 37. doi: 10.3969/j.issn.1001-1382.2016.10.008 Lin Jun, Gao Xiangdong. Mapping relationship between weld pool surface feature and weld penetration during arc welding[J]. Welding & Joining, 2016(10): 34 − 37. doi: 10.3969/j.issn.1001-1382.2016.10.008

[7] 高向东, 林俊, 萧振林, 等. 电弧焊熔透ICA-BP神经网络识别模型[J]. 焊接学报, 2016, 37(5): 33 − 36. Gao Xiangdong, Lin Jun, Xiao Zhenlin, et al. Recognition model of arc welding penetration using ICA-BP neural network[J]. Transactions of the China Welding Institution, 2016, 37(5): 33 − 36.

[8] 刘文焕, 王克争, 何方殿. 人工神经网络控制在焊接中的研究应用[J]. 电焊机, 1997(5): 15 − 18. Liu Wenhuan, Wang Kezheng, He Fangdian. Development and application of artificial neural network in welding[J]. Electric Welding Machine, 1997(5): 15 − 18.

[9] 陈善本, 娄亚军, 赵冬斌, 等. 脉冲GTAW熔池动态过程模糊神经网络建模与控制[J]. 自动化学报, 2002, 28(1): 74 − 82. doi: 10.16383/j.aas.2002.01.010 Chen Shanben, Lou Yajun, Zhao Dongbin, et al. Fuzzy-neural network modeling and control of pool dynamic process in pulsed GTAW[J]. Acta Automatica Sinica, 2002, 28(1): 74 − 82. doi: 10.16383/j.aas.2002.01.010

[10] 张勇, 陈善本, 邱涛, 等. 焊接柔性加工单元中熔池的实时控制[J]. 焊接学报, 2002, 23(4): 1 − 5. doi: 10.3321/j.issn:0253-360X.2002.04.001 Zhang Yong, Chen Shanben, Qiu Tao, et al. Study on real-time control of welding pool in welding flexible manufacturing cell[J]. Transactions of the China Welding Institution, 2002, 23(4): 1 − 5. doi: 10.3321/j.issn:0253-360X.2002.04.001

[11] 徐中路, 李静, 陈丹, 等. 基于受限波尔兹曼机的GMAW管道打底焊的熔透预测方法[J]. 计算机应用与软件, 2013, 30(10): 239 − 242. doi: 10.3969/j.issn.1000-386x.2013.10.066 Xu Zhonglu, Li Jing, Chen Dan, et al. A weld penetration prediction method based on RBM for GMAW pipe-line backing welding[J]. Computer Applications andSoftware, 2013, 30(10): 239 − 242. doi: 10.3969/j.issn.1000-386x.2013.10.066

[12] 刘亮, 杨长祺, 倪加明, 等. 2219铝合金变极性TIG焊熔透状态识别方法[J]. 上海交通大学学报, 2016, 50(Suppl.1): 71 − 74. doi: 10.16183/j.cnki.jsjtu.2016.S.018 Liu Liang, Yang Changqi, Ni Jiaming, et al. Recognition method research for variable polarity TIG welding penetration state of 2219 aluminum alloy[J]. Journal of Shanghai Jiao Tong University, 2016, 50(Suppl.1): 71 − 74. doi: 10.16183/j.cnki.jsjtu.2016.S.018

[13] Feng Y, Chen Z, Wang D, et al. Deep welding: A deep learning enhanced approach to GTAW using multisource sensing images[J]. IEEE Transactions on Industrial Informatics, 2020, 16(1): 465 − 474. doi: 10.1109/TII.2019.2937563

[14] Jiao W, Wang Q, Cheng Y, et al. End-to-end prediction of welding penetration: A deep learning and transfer learning based method[J]. Journal of Manufacturing processes, 2021, 63: 191 − 197. doi: 10.1016/j.jmapro.2020.01.044

[15] Cai W, Jiang P, Shu L S, et al. Real-time monitoring of laser keyhole welding penetration state based on deep belief network[J]. Journal of Manufacturing processes, 2021, 72: 203 − 214. doi: 10.1016/j.jmapro.2021.10.027

[16] Niu Yue, Gao Peng P, Gao Xiangdong. Recognition of DC01 mild steel laser welding penetration status based on photoelectric signal and neural network[J]. Metals. 2023, 13, 871: 1 − 17.

[17] Xiong J, Zou S. Active vision sensing and feedback control of back penetration for thin sheet aluminum alloy in pulsed MIG suspension welding[J]. Journal of Process Control, 2019, 77: 89 − 96. doi: 10.1016/j.jprocont.2019.03.013

[18] 王万东, 王志江, 胡绳荪, 等. 基于模型的GMAW-P焊接熔深自适应预测控制[J]. 机械工程学报, 2019, 55(19): 138 − 145. doi: 10.3901/JME.2019.19.138 Wang Wandong, Wang Zhijiang, Hu Shengsun, et al. Adaptive predictive control of weld penetration depth based on Hammerstein model in pulsed gas metal arc welding[J]. Journal of Mechanical Engineering, 2019, 55(19): 138 − 145. doi: 10.3901/JME.2019.19.138

[19] 吴頓. 基于多源信息融合的铝合金VPPAW成形预测和智能控制研究[D]. 上海: 上海交通大学, 2018. Wu Dun. Research on predicting and intelligent control for weld formation during VPPAW process using multi-information fusion[D]. Shanghai: Shanghai Jiao Tong University, 2018.

[20] Pawlak Z. Rough sets: Theoretical aspects of reasoning about data. Dordrecht: Kluwer Academic Publishing, 1991.

[21] 王国胤, 姚一豫, 于洪. 粗糙集理论与应用研究综述[J]. 计算机学报, 2009, 32(7): 1229 − 1246. doi: 10.3724/SP.J.1016.2009.01229 Wang Guoyin, Yao Yiyu, Yu Hong. A survey on rough set theory and its application[J]. Chinese Journal of Computers, 2009, 32(7): 1229 − 1246. doi: 10.3724/SP.J.1016.2009.01229

[22] Wang B, Chen S B, Wang J J. Rough set based knowledge modeling for the aluminum alloy pulsed GTAW process[J]. The International Journal of Advanced Manufacturing Technology, 2005, 25(9): 902 − 908.

[23] 黎文航, 陈善本, 王加友, 等. 基于变精度粗糙集的脉冲GTAW过程建模方法[J]. 焊接学报, 2008, 29(7): 57 − 59. doi: 10.3321/j.issn:0253-360X.2008.07.015 Li Wenhang, Chen Shanben, Wang Jiayou, et al. Modeling method for pulsed GTAW welding process based on variable precision rough set[J]. Transactions of the China Welding Institution, 2008, 29(7): 57 − 59. doi: 10.3321/j.issn:0253-360X.2008.07.015

[24] Feng Zhiqiang, Liu Cungen, Huang Hu. Knowledge modeling based on interval valued fuzzy rough sets and similarity-based inference: prediction of welding distortion[J]. Journal of Zhejiang University-Science C, 2014, 15(8): 636 − 650. doi: 10.1631/jzus.C1300370

[25] Ziarko W. Variable precision rough set model[J]. Journal of Computer and System Sciences, 1993, 46(1): 39 − 59. doi: 10.1016/0022-0000(93)90048-2

[26] An A, Shan N, Chan C, et al. Discovering rules for water demand prediction: An enhanced rough-set approach[J]. Engineering Application and Artificial Intelligence, 1996, 9(6): 645 − 653. doi: 10.1016/S0952-1976(96)00059-0

[27] 王国胤, 于洪, 杨大春. 基于条件信息熵的决策表约简[J]. 计算机学报, 2002, 25(7): 759 − 766. doi: 10.3321/j.issn:0254-4164.2002.07.013 Wang Guoyin, Yu Hong, Yang Dachu. Decision table reduction based on conditional information entropy[J]. Chinese Journal of Computers, 2002, 25(7): 759 − 766. doi: 10.3321/j.issn:0254-4164.2002.07.013

[28] 于锟, 刘知贵, 黄正良. 粗糙集理论应用中的离散化方法综述[J]. 西南科技大学学报, 2005, 20(4): 32 − 36. doi: 10.3969/j.issn.1671-8755.2005.04.008 Yu Kun, Liu Zhigui, Huang Zhengliang. Overview of the discretization methods in the application of rough set theory[J]. Journal of Southwest University of Science and Technology, 2005, 20(4): 32 − 36. doi: 10.3969/j.issn.1671-8755.2005.04.008

[29] 丁洁琼. MAG焊单面焊双面成形熔池视觉特征与控制模型研究[D]. 南京: 南京理工大学, 2010. Ding Jieqiong. Research on characteristic of MAG weld pool visual image and control model in one-side welding with back formation weld [D]. Nanjing: Nanjing University of Science & Technology, 2010.

[30] Wang K H, Tang X C, Liu Y. Methods of visional detecting MAG weld pool information[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(3): 369 − 374.

[31] 杨伦标, 高英仪. 模糊数学原理及应用[M]. 广州: 华南理工大学出版社, 2005. Yang Lunbiao, Gao Yingyi. Principle and application of fuzzy mathematics[M]. Guangzhou: South China University of Technology Press, 2005.

[32] 章卫国, 模糊控制理论与应用[M]. 西安: 西北工业大学出版社, 2000. Zhang Weiguo. Fuzzy control theory and application[M]. Xi’an: Northwestern Polytechnical University Press, 2000.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: