Microstructure and toughness of heat-affected zone in girth welding of X80 steel pipe with different Nb content

-

摘要:

为研究Nb含量对焊接热影响区微观组织和性能的影响,采用熔化极气体保护焊(gas metal arc welding,GMAW)和手工焊条电弧焊(shielded metal arc welding,SMAW)对0.055%Nb和0.075%Nb含量的X80钢管进行环焊. 采用夏比冲击试验和金相分析方法,研究热影响区的微观组织差异和夏比冲击韧性. 并借助扫描电镜和超高温激光共聚焦显微镜分析不同Nb含量X80管体的微观组织对热影响区性能的影响. 结果表明,在0 ℃和−20 ℃时,0.075%Nb和0.055%Nb的X80钢管GMAW环焊接头热影响区均具有较高的冲击韧性,其平均冲击吸收能量均高于150 J. 其中0.055%Nb略高于0.075%Nb的GMAW环焊接头热影响区夏比冲击吸收能量;焊接热输入较低时,0.055%Nb低于0.075%Nb的X80环焊接头粗晶区的韧脆转变温度,具有更好的低温韧性. 焊接热输入较高时,0.075%Nb的X80环焊接头粗晶区具有更高的上平台冲击吸收能量,且上平台温度和韧脆转变温度也更低,其低温韧性也更优异;还发现了X80环焊接头热影响区的冲击韧性不仅与热输入量和热影响区马氏体−奥氏体组织(M-A)的形状、大小、分布有关,而且还受管体中Nb含量、原始的强度与韧性、微观组织状态的遗传影响.

Abstract:In order to study the effect of Nb content on the microstructure and properties of heat affected zone (HAZ), the 0.055%Nb and 0.075%Nb content X80 steel pipes were girth welded by Gas metal arc welding (GMAW) and shielded metal arc welding (SMAW). Charpy impact test and metallographic analysis were used to study the impact toughness and microstructure differences in the HAZ. The effects of the microstructure of X80 pipe body with different Nb content on the properties of the heat-affected zone were analyzed by scanning electron microscope and confocal laser microscope with high temperature. The results show that at 0 ℃ and −20 ℃, 0.075%Nb and 0.055%Nb X80 steel pipes have high impact toughness in the HAZ of GMAW girth welded joints, and their average impact absorbed energy are higher than 150J. However, the Charpy impact absorbed energy in the HAZ of GMAW girth welded joint of X80 steel pipe with 0.055% Nb is higher than that of X80 steel pipe with 0.075%Nb. When GMAW is used, the ductile-brittle transition temperature (DBTT) of X80 girth welded joint with 0.055%Nb is lower than that of X80 with 0.075%Nb because of the low welding heat input. When SMAW is used, due to higher heat input, the coarse grain heat affected zone (CGHAZ) of X80 girth welding joint with 0.075%Nb has higher impact absorbed energy on the upper-shelf and lower temperature of upper-shelf zone and DBTT, and its low temperature toughness is better. It is also discussed that the impact toughness of the HAZ of X80 girth welded joint is not only related to the heat input and the shape, size and distribution of M-A, but also genetically influenced by the content of Nb in the pipe body and the original strength, toughness and microstructure state.

-

Keywords:

- X80 steel pipe containing niobium /

- girth welded joint /

- HAZ /

- impact toughness /

- M-A

-

0. 序言

铌微合金化高强度钢应用历史已达70多年[1]. 特别是在20世纪80年代早期,人们加入铌来设计新一代高强度低合金钢[2],充分利用铌的固溶和析出行为,结合热机械轧制工艺,达到细化晶粒、控制相变和析出强化的效果,从而获得高强度、高韧性的钢材,如X80管线钢. 在随后的焊接过程中,根据焊接工艺的不同,含铌管线钢热影响区(heat-affected zone, HAZ)经历了一系列的奥氏体形成和分解循环,尤其是在临界再热影响区(inter-critically reheated HAZ,ICHAZ)奥氏体的部分形成和分解导致了微观组织的复杂性. 因此,X80管线钢热影响区的微观组织演化受基体中Nb含量的强烈影响[3].

焊接热影响区的微观组织和韧性是影响高钢级的油气管道完整性的重要因素. 虽然X80高强度管线钢具有良好的抗延性断裂能力,但焊接过程中形成的热影响区,尤其是粗晶区(coarse-grained heat -affected zone, CGHAZ),其微观组织分布不均匀,且具有高的局部化特征,使得该区域力学性能变差,容易形成诱发裂纹的局部脆性区,是整个焊接结构的薄弱地带. 参考文献[4]研究认为,对于含Nb量为0.1%的X80管线钢,虽然热影响区原始奥氏体晶粒的平均尺寸不会随热输入增加而过于粗大,但当热输入高于40 kJ/cm时,会使得原始奥氏体晶粒内粒状贝氏体的晶体取向选择过于单一,大角晶界(大于15°)密度会明显降低,有效晶粒尺寸较大,马氏体−奥氏体组元(M-A)也由于热输入量过大而明显粗化,从而导致热影响区粗晶区韧性明显降低.Teixeira等人[5]研究了高强钢热影响区的组织梯度对焊接接头不稳定断裂行为的影响,认为粗晶区微观组织基本由粗贝氏体组成,并在大的原始奥氏体晶粒的晶界处有少量马氏体和先共析铁素体. 随着预制疲劳裂纹前缘侵入CGHAZ,其韧性明显下降. 文献[6]通过试验和3D有限元模拟,研究了焊接热模拟X80管线钢在不同温度下的断裂韧度,认为随着温度降低断裂韧性减小,并使钢材由韧性性断裂向脆性断裂转变,不同温度下测得的裂纹尖端张开位移值均具有一定的分散性,且分散程度随温度升高而增大. 袁军军等人[7]认为冲击试样的取样位置、缺口尖端组织状态和缺陷等因素对X70管线钢药芯焊丝多层多道焊接头冲击性能的稳定性有一定影响,且试样缺口处柱状晶所占比例和粗大晶粒是导致冲击韧性出现波动和低值的主要原因. 管线钢热影响区微观组织及其性能还受焊接热输入量、其它合金元素和碳当量的影响.Mohammadijoo等人[8]研究发现,X70管线钢热影响区软化程度随着Mo,Mn,Ti,N和碳当量的增加逐渐减小,但合金的添加对HAZ韧性产生了不利影响,尤其是对填充焊和盖面焊热影响区的影响. 文献[9]采用热模拟试样研究了铌微合金钢焊接热影响粗晶区的微观组织组成,主要相为含有大量M-A的粒状贝氏体,并利用原子探针断层扫描技术,研究了铌在原始奥氏体晶界(prior austenite grain boundary,PAGB)、铁素体/M-A界面和铁素体晶界的分布,结果表明,Nb在铁素体/M-A界面处富集最明显,Nb偏析降低了PAGB的吉布斯能. 原始奥氏体晶界处Nb的强偏析可以有效地防止高温时奥氏体晶粒的生长,而铁素体/M-A界面处Nb偏析可以抑制冷却时贝氏体、铁素体的生长,进一步解释了焊接后含Nb微合金钢中贝氏体组织较细的原因,Nb原子与空位的结合能预测结果也表明焊接热循环对Nb的偏析是非平衡机制所致.

采用熔化极气体保护焊与手工焊条电弧焊的实焊方法,进行夏比冲击试验,且利用高温激光共聚焦显微镜观察微观组织结构,研究不同Nb含量X80钢管在低热输入和较高热输入下环焊缝HAZ的微观组织与性能,为高强度管线钢的成分优化设计与焊接工艺选择提供了试验依据.

1. 试验方法

1.1 试验材料

试验材料选用了含铌量为0.055%和0.075%的X80直缝埋弧焊钢管,钢管直径为1 219 mm,壁厚为22 mm. 两种铌含量钢管分别标记为N055和N075,具体化学成分和焊接冷裂纹敏感系数(CEPcm)见表1. N055和N075管体纵向的拉伸屈服强度分别为567 MPa和565 MPa,抗拉强度分别为645 MPa和689 MPa,断后伸长率分别为21%和25%,N055和N075管体纵向平均冲击吸收能量在0 ℃时分别为401 J和375 J,在−20 ℃时分别为391 J和340 J.

表 1 试验钢管的化学成分(质量分数,%)Table 1. Chemical compositions of steel pipes编号 C Mn Si P S Cr Mo Ni Nb V Ti Cu B Al N Fe CEPcm N055 0.049 1.74 0.15 0.010 0.0025 0.25 0.093 0.16 0.058 0.0043 0.011 0.022 0.0003 0.027 0.0031 余量 0.165 N075 0.051 1.72 0.16 0.013 0.0026 0.26 0.088 0.16 0.082 0.0045 0.012 0.026 0.0003 0.025 0.0033 余量 0.167 1.2 环焊缝焊接与试验方法

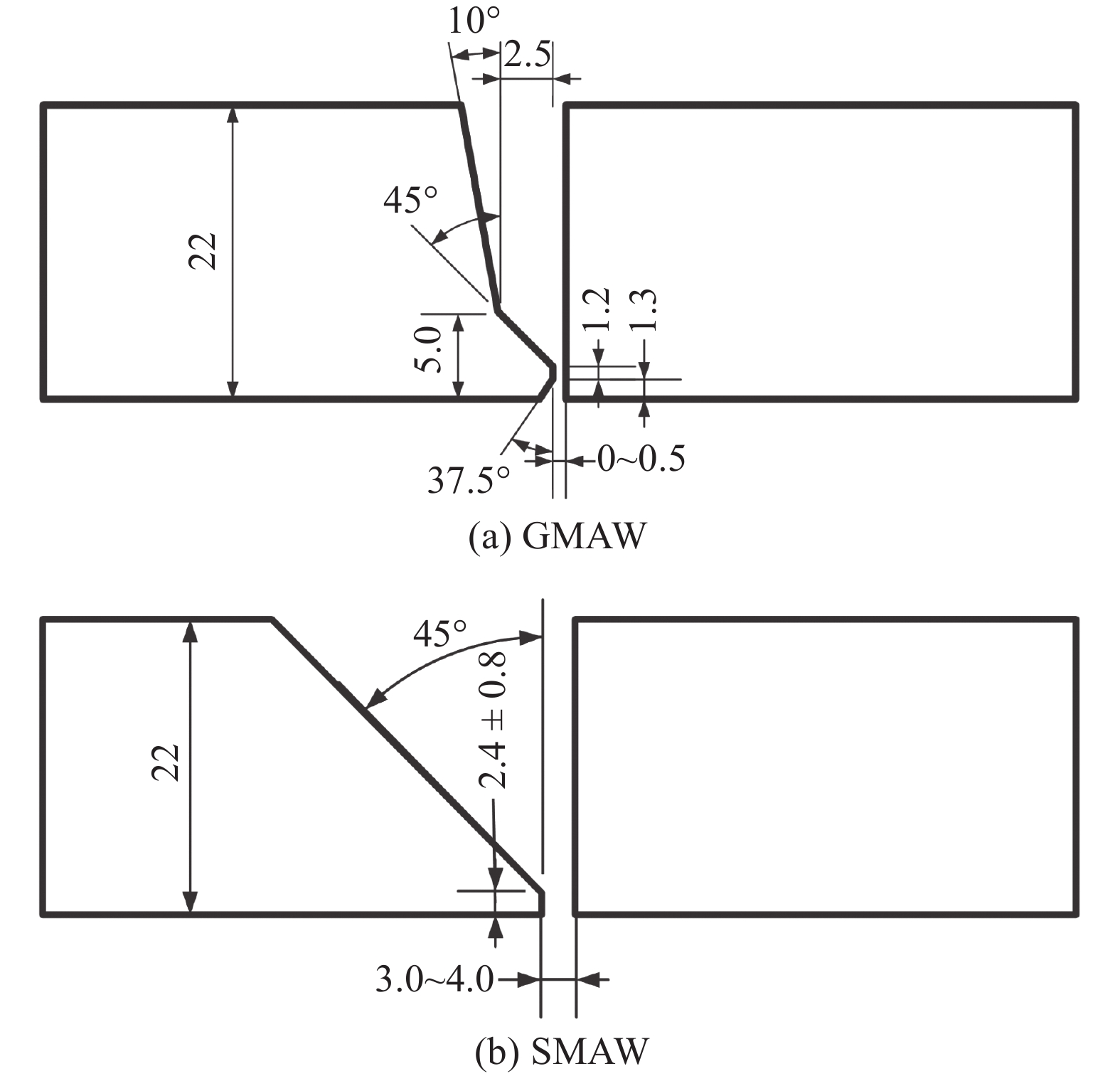

由于实际的环焊接头熔合区的形状极不规则,对熔合线处的夏比冲击离散性影响较大. 因此,为了更准确的研究在熔化极气体保护自动焊(Auto-GMAW)和SMAW两种典型热输入下,不同Nb含量X80环焊接头热影响区的韧性,参照API RECOMMENDED PRACTICE 2Z《海上结构用钢板预生产评定推荐作法》标准,采用如图1所示的单侧V形坡口. GMAW环焊采用直径为1.0 mm的ER80S-G(BOHLER SG 8-P)的实心焊丝;SMAW采用直径为3.2 mm的E9018-G 焊条进行根焊,填充和盖面焊采用直径为4.0 mm的E11018-G焊条. GMAW和SMAW的焊接工艺参数分别如表2和表3所示.

焊接完成后,从环焊接头3点钟位置截取试块制备成金相试样,经2%硝酸酒精溶液浸蚀后,在OLS 4100激光共聚焦显微镜下观察直边侧坡口热影响区的微观组织. 并从立焊位置(环焊缝2点钟至5点钟)截取试块,在壁厚中心制备V形缺口夏比冲击试样,以保证试样位于填充焊道热影响区. 冲击试样尺寸为55 mm × 10 mm × 10 mm,V形缺口轴向位于直边侧HAZ不同位置处.FL0.5,FL1.0和FL2.0(FL为缺口位置位于50%WM + 50%HAZ,)分别代表缺口轴线距FL处0.5 mm,1.0 mm,2.0 mm.图2为缺口位于FL0.5的示意图. 并利用PSW750型冲击试验机,依据GB/T 229-2020《金属材料夏比摆锤冲击试验方法》进行夏比冲击试验. 由于Boltzmann函数具有S形曲线形状,与金属材料冲击吸收能量−温度关系曲线的形状非常吻合,满足下平台区、转变温度区和上平台区3阶段分布特征,物理意义明确、相关性高,是较为认可的数学模型[10-12]. 因此,采用Bolztmann函数模型对系列冲击试验测试数据进行拟合,获得热影响区的韧脆转变温度(ductile-brittle transition temperature,DBTT).

表 2 单侧双V形坡口GMAW焊接工艺参数Table 2. Welding process parameters of single side double V-groove GMAW girth welding焊接层 焊接电流

I/A电弧电压

U/V送丝速度

vf/(m·min−1)焊接速度

vw/(mm·min−1)保护气体 平均热输入

$ \overline Q $/(kJ·mm−1)混合比例(Ar : CO2) 流量Q/(L·min−1) 根焊 150 ~ 200 22 ~ 26 8.13 ~ 9.65 460 ~ 660 4∶1 20 ~ 25 0.48 热焊 180 ~ 240 24 ~ 27 11.43 ~ 12.92 560 ~ 760 4∶1 30 ~ 35 0.52 填充焊 160 ~ 220 24 ~ 26 8.13 ~ 10.92 330 ~ 460 4∶1 25 ~ 35 0.75 盖面焊 150 ~ 200 22 ~ 26 7.62 ~ 9.14 330 ~ 460 4∶1 20 ~ 30 0.65 表 3 单侧V形坡口SMAW焊接工艺参数Table 3. Welding process parameters of single side V-groove GMAW girth welding焊接

层数焊接电流I/A 电弧电压U/V 焊接速度vw/(mm·min−1) 平均热输入$ \overline Q $/(kJ·mm−1) 根焊 130 ~ 150 24 ~ 27 90 ~ 100 2.10 热焊 130 ~ 150 24 ~ 27 100 ~ 120 1.91 填充焊 170 ~ 210 24 ~ 27 90 ~ 120 2.84 盖面焊 170 ~ 200 24 ~ 27 90 ~ 120 2.70 为了进一步研究管体母材的性能和原始微观组织状态对环焊接头热影响区微观组织和韧性的影响,采用显微硬度试验测试了GMAW环焊接头的硬度云图分布,并借助扫描电镜观察了N055和N075管体的微观组织. 同时,采用高温激光共聚焦显微镜观察在相同的条件下N055和N075分别加热至1 350 ℃保温1 s,冷却至150 ℃后,二次加热至780 ℃保温1 s,再冷却至200 ℃,以此模拟X80管道环焊接头粗晶区进行二次热循环的微观组织转变过程,进一步对比不同Nb含量对X80环焊热影响区组织转变的影响.

2. 试验结果与分析

2.1 不同热输入量的热影响区冲击韧性

图3为N055和N075钢管GMAW环焊接头热影响区不同位置的夏比冲击吸收能量与管体纵向夏比冲击吸收能量的对比. 从图3中可以看出,N075和N055热影响区均具有较高的冲击韧性,其平均值高于150 J. N055与N075环焊接头热影响区相比,采用较低热输入的环焊工艺时,N055焊接接头热影响区FL,FL0. 5,FL1.0和FL2.0在0 ℃和−20 ℃时夏比冲击吸收能量均略高于N075.

图4为不同Nb含量X80单边V形坡口GMAW和SMAW环焊接头粗晶区的韧脆转变曲线. 图4(a)表明,低热输入焊接时,N055和N075在粗晶区FL0.5处韧脆转变的上平台温度分别达到−80 ℃和−60 ℃,且二者的上平台吸收能量相当,均约为300 J. 经Bolztmann函数拟合计算,N055的韧脆转变温度约为−104 ℃,N075的韧脆转变温度为−85 ℃. 因此,采用低热输入的GMAW环焊时,N055和N075均具有优良的低温韧性.

图4(b)为 N055和N075采用较高热输入的SMAW环焊接头FL0.5处的韧脆转变曲线. 由图4可知,在较高热输入下,N055和N075在粗晶区FL0.5处韧脆转变的上平台温度分别达到−30 ℃和−50 ℃,且N075的上平台能约为275 J,而N055的上平台能约为230 J. 同时,从图4可以看出,N055和 N075较高热输入的SMAW环焊接头粗晶区的韧脆转变温度分别为−56 ℃和−77 ℃. 因此,较大热输入环焊时,与N055相比,N075具有更高上平台冲击吸收能量和更低的上平台温度,其低温韧性更优异.

2.2 微观组织

焊接接头粗晶区的微观组织分布不均匀,且在临界二次加热粗晶区(intercritically reheated coarse grained HAZ,ICCGHAZ)存在链状分布的 M-A 组元,因其具有高的局部化特征被认为是韧性变差的主要原因[13-14]. 图5和图6分别为不同铌含量X80在较低热输入的GMAW和较高热输入的SMAW焊接下粗晶区的微观组织. 结果表明,在较低热输入和较高热输入下,N055和N075粗晶区的组织均以粒状贝氏体(BL)为主. 在较低热输入GMAW环焊时,N055和N075临界二次加热粗晶区的原始奥氏体晶界上分布有M-A链状组织,但是N075的IC CGHAZ内晶粒相对较小且更为均匀,M-A组织占比更高. 当采用热输入较高的SMAW环焊时,粗晶区晶界分布的M-A链状组织逐渐细化或消失,但N075粗晶区比N055粗晶态的晶粒尺寸更均匀细小,促进了M-A弥散分布,因此,N075SMAN粗晶区的韧性好于N055.

2.3 讨论与分析

焊接热影响区粗晶区的韧性恶化或波动影响因素极其复杂. 通常认为,主要受热影响区中粗大的M-A组元、取样位置、缺口尖端组织状态、缺陷、试验温度、合金元素含量和碳当量的影响[4-8]. 同时,管体母材的强度、韧性和原始组织状态对热影响区韧性也有明显的遗传性影响.

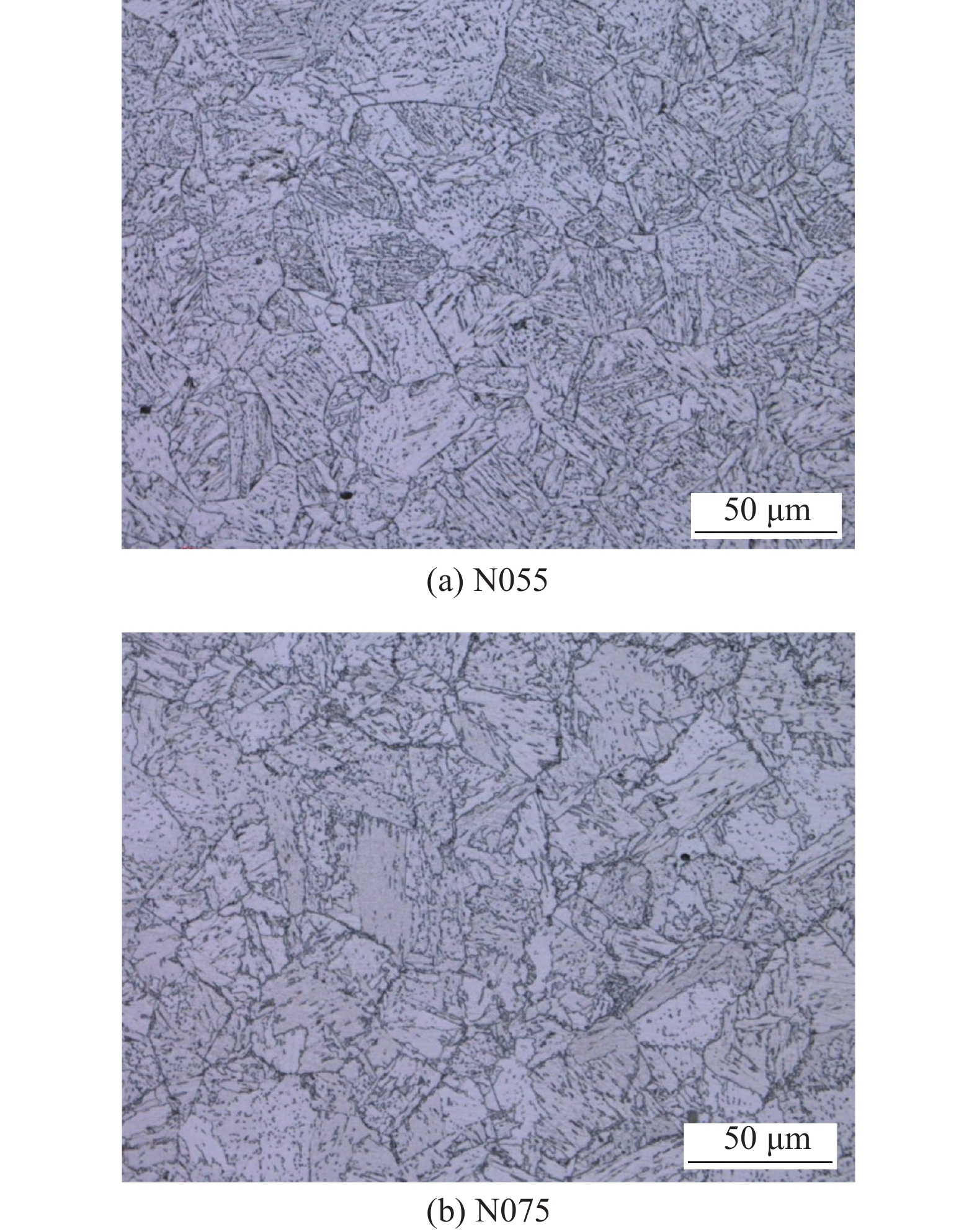

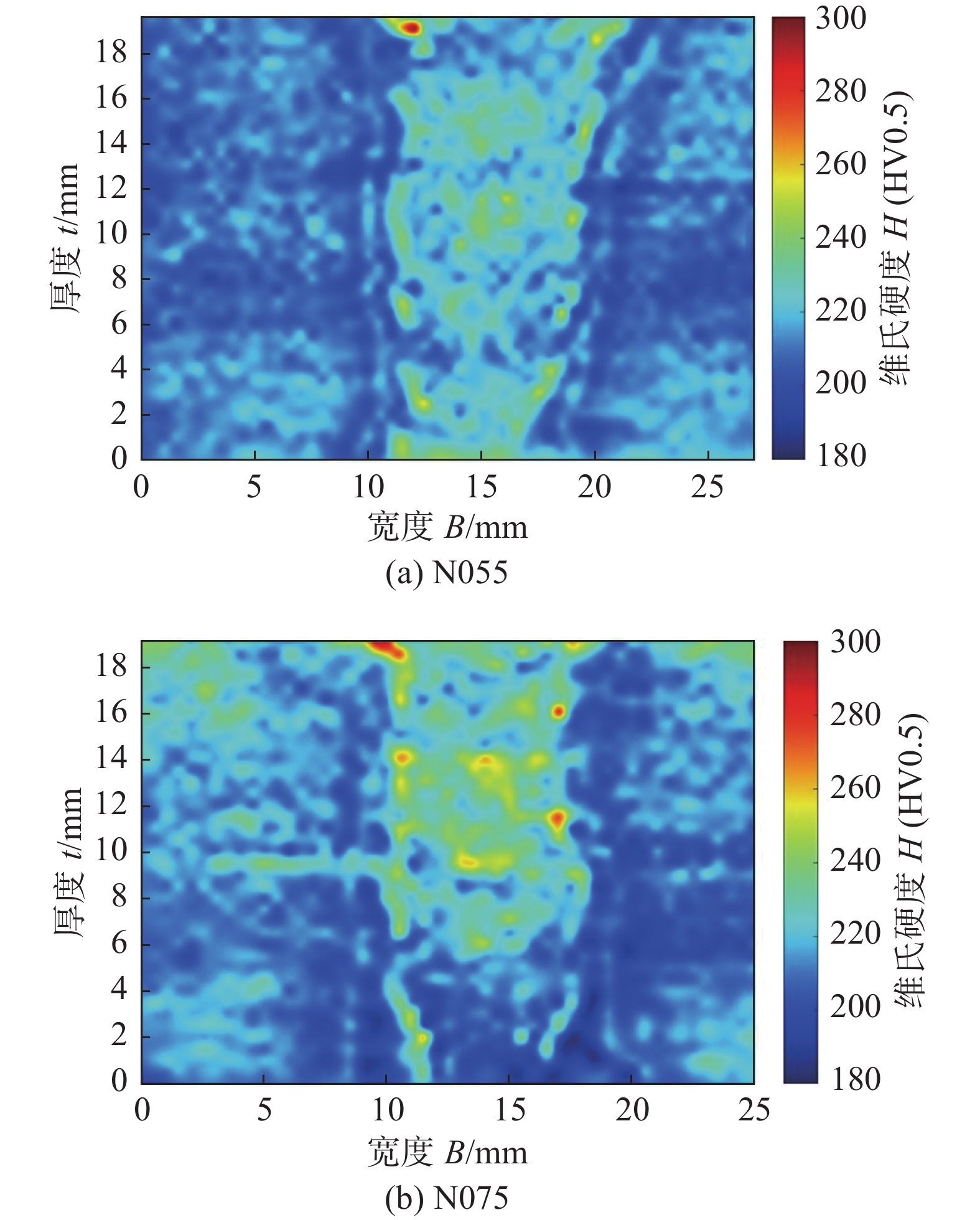

图7为GMAW环焊接头的硬度云图. 从图7中可以看出,N075接头两侧管体硬度高于N055,壁厚中心附近N075热影响区的平均硬度约为205 HV0.5,N055热影响区的平均硬度约为198 HV0.5. 因此,N075热影响区的硬度略高于N055,即表明N075热影响的强度也高于N055. 同时,上文中图3的对比结果表明,N055管体的纵向冲击韧性高于N075. 图8为扫描电镜下N055和N075管体壁厚中心的微观组织. 从图8可以看出来,与N055相比,N075管体具有更多的粒状贝氏体组织,且在晶粒内分布有较多的板条亚结构. 因此,N075管体纵向强度高于N055,而平均冲击韧性低于N055. 管体原始的微观组织和性能导致0.055%Nb含量高于0.075%Nb含量的X80钢管GMAW环焊接头热影响区不同位置的冲击韧性.

CGHAZ的韧性受贝氏体相变后其晶体学结构影响,而ICCGHAZ则主要受沿原奥氏体晶界形成的链状M-A影响. 在试样受冲击过程中,裂纹在二次热循环产物M-A处形成核. 当遇到岛型M-A组分时,裂纹发生偏转,而当遇到M-A型纤细组分时,则呈直线传播. 裂纹偏转越小,传播路径消耗的能量越小,从而降低韧性[15]. 通过优化母材合金成分(比如加入Nb),细化CGHAZ的奥氏体晶粒尺寸,获得最佳晶体学结构匹配的组织,有利于改善焊接热影响区的韧性[16].

图9为激光共聚焦观察到N055和N075二次热循环后的微观组织. 从图9可以看出,N075在二次热循环后热影响区的晶粒尺寸明显小于N055. GMAW环焊时,由于热输入较低,热影响区很窄,而N075在ICCGHAZ形成的M-A较粗,但其晶粒相对较细. 因此,M-A所占比例较高,在管体原始冲击韧性遗传影响下,N075热影响区的韧性低于N055. 当较高热输入的SMAW环焊时,N075热影响区的奥氏体晶粒尺寸细化,M-A也随之细化,M-A分布趋于不连续或消失,ICCGHAZ表现出更好的韧性. 因此,较高热输入的SMAW环焊时,与N055相比,N075粗晶区具有更高的韧脆转变上平台能和更低的韧脆转变温度.

3. 结论

(1) 在0 ℃和 −20 ℃时,0.075%Nb和0.055%Nb的X80钢管GMAW环焊接头热影响区均具有较高的冲击韧性,其平均冲击吸收能量高于150 J. 但是,0.055%Nb略高于0.075%Nb的X80钢管GMAW环焊接头热影响区的夏比冲击吸收能量.

(2) 当采用低热输入焊接时,0.055%Nb低于0.075%Nb的X80环焊接头粗晶区的韧脆转变温度,具有更好的低温韧性;当采用较高热输入焊接时,0.075%Nb的X80环焊热影响区的上平台冲击吸收能量更高,且具有更低的上平台温度和韧脆转变温度,其的低温韧性更优异.

(3) X80环焊接头热影响区的冲击韧性不仅与焊接热输入量和热影响中M-A形状、大小、分布有关,而且还受管体的化学成分、原始的强韧性和微观组织状态的遗传影响.

-

表 1 试验钢管的化学成分(质量分数,%)

Table 1 Chemical compositions of steel pipes

编号 C Mn Si P S Cr Mo Ni Nb V Ti Cu B Al N Fe CEPcm N055 0.049 1.74 0.15 0.010 0.0025 0.25 0.093 0.16 0.058 0.0043 0.011 0.022 0.0003 0.027 0.0031 余量 0.165 N075 0.051 1.72 0.16 0.013 0.0026 0.26 0.088 0.16 0.082 0.0045 0.012 0.026 0.0003 0.025 0.0033 余量 0.167 表 2 单侧双V形坡口GMAW焊接工艺参数

Table 2 Welding process parameters of single side double V-groove GMAW girth welding

焊接层 焊接电流

I/A电弧电压

U/V送丝速度

vf/(m·min−1)焊接速度

vw/(mm·min−1)保护气体 平均热输入

$ \overline Q $/(kJ·mm−1)混合比例(Ar : CO2) 流量Q/(L·min−1) 根焊 150 ~ 200 22 ~ 26 8.13 ~ 9.65 460 ~ 660 4∶1 20 ~ 25 0.48 热焊 180 ~ 240 24 ~ 27 11.43 ~ 12.92 560 ~ 760 4∶1 30 ~ 35 0.52 填充焊 160 ~ 220 24 ~ 26 8.13 ~ 10.92 330 ~ 460 4∶1 25 ~ 35 0.75 盖面焊 150 ~ 200 22 ~ 26 7.62 ~ 9.14 330 ~ 460 4∶1 20 ~ 30 0.65 表 3 单侧V形坡口SMAW焊接工艺参数

Table 3 Welding process parameters of single side V-groove GMAW girth welding

焊接

层数焊接电流I/A 电弧电压U/V 焊接速度vw/(mm·min−1) 平均热输入$ \overline Q $/(kJ·mm−1) 根焊 130 ~ 150 24 ~ 27 90 ~ 100 2.10 热焊 130 ~ 150 24 ~ 27 100 ~ 120 1.91 填充焊 170 ~ 210 24 ~ 27 90 ~ 120 2.84 盖面焊 170 ~ 200 24 ~ 27 90 ~ 120 2.70 -

[1] Morrison W B. Microalloy steels - the beginning[J]. Materials Science and Technology, 2009, 25(9): 1066 − 1073. doi: 10.1179/174328409X453299

[2] Deardo A, Hua M, Cho K, et al. On strength of microalloyed steels: an interpretive Review[J]. Materials Science and Technology, 2009, 25(9): 1074 − 1082. doi: 10.1179/174328409X455233

[3] Fateh F, Matthias M. Effect of Nb on austenite formation and decomposition in an X80 linepipe steel[J]. Journal of Iron and Steel Research International, 2011, 18: 658 − 663.

[4] 缪成亮, 尚成嘉, 王学敏, 等. 高Nb X80管线钢焊接热影响区显微组织与韧性[J]. 金属学报, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803 Miao Chengliang, Shang Chengjia, Wang Xuemin, et al. Microstructure and toughness of HAZ in X80 pipeline steel with high Nb content[J]. Acta Metallurgica Sinica, 2010, 46(5): 541 − 546. doi: 10.3724/SP.J.1037.2009.00803

[5] Teixeira P, Loureiro A, Rodrigues D, et al. Effect of the HAZ microstructural gradient on the unstable fracture behaviour of welds in a high strength steel[J]. Materials Science Forum, 2006, 514-516(5): 539 − 543.

[6] 徐杰, 卓小敏, 李朋朋. 温度对X80管线钢韧/脆转变区断裂韧性的影响[J]. 工程力学, 2016, 33(S): 56 − 61. Xu Jie, Zhuo Xiaomin, Li Pengpeng. Effect of temperature on the fracture toughness of X80 pipeline steel in ductile-to-brittle transition region[J]. Engineering Mechanics, 2016, 33(S): 56 − 61.

[7] 袁军军, 禅志善, 曹睿, 等. 多层多道平焊接头冲击性能不稳定的原因分析[J]. 焊接学报, 2017, 38(5): 100 − 103. Yuan Junjun, Chan Zhishan, Cao Rui, et al. Analysis of impact toughness variation for flat position multi-pass weld joint[J]. Transactions of the China Welding Institution, 2017, 38(5): 100 − 103.

[8] Mohammadijoo M, Collins L, Rashid M F, et al. Influence of steel chemistry and field girth welding procedure on performance of API X70 line pipe steels[C]//International Pipeline Conference. ASME, Virtual, Online, 2020.

[9] Wang H, Wang J, Tong Z, et al. Characterization of Nb interface segregation during welding thermal cycle in microalloyed steel by atom probe tomography[J]. Metallurgical and Materials Transactions A, 2018(12): 6224 − 6230.

[10] 赵建平, 张秀敏, 沈士明. 材料韧脆转变温度数据处理方法探讨[J]. 石油化工设备, 2004, 33(4): 29 − 32. Zhao Jianping, Zhang Xiumin, Shen Shiming. On the method of data processing for ductile-brittle transition temperature[J]. Petro-chemical Equipment, 2004, 33(4): 29 − 32.

[11] 周昌玉, 夏翔鸣. CrMo钢材料韧脆转变温度曲线的回归分析[J]. 压力容器, 2003, 20(6): 13 − 18. Zhou Changyu, Xia Xiangming. Regression analysis of ductile- brittle transition temperature curve for CrMo steel[J]. Pressure Vessel Technology, 2003, 20(6): 13 − 18.

[12] 周腾飞, 关凯书. 不同缺口形式小冲杆试样测试3Cr1MoV钢韧脆转变温度的对比[J]. 机械工程材料, 2018, 42(12): 21 − 26. Zhou Tengfei, Guan Kaishu. Comparison of ductile-brittle transition temperature testing of 3CrlMoV steel with small punch specimens of different notch forms[J]. Materials for Mechanical Engineering, 2018, 42(12): 21 − 26.

[13] 李学达, 尚诚嘉, 韩昌柴, 等. X100 管线钢焊接热影响区中链状M-A组元对冲击韧性和断裂机制的影响[J]. 金属学报, 2016, 52(9): 1025 − 1035. Li Xueda, Shang Chengjia, Han Changchai, et al. Influence of necklace-type M-A constituent on impact toughness and fracture mechanism in the heat affected zone of X100 pipeline steel[J]. Acta Metallurgica Sinica, 2016, 52(9): 1025 − 1035.

[14] 李学达, 李春雨, 曹宁, 等. 高强管线钢焊接临界再热粗晶区中逆转奥氏体的逆相变晶体学[J]. 金属学报, 2021, 57(8): 967 − 976. Li Xueda, Li Chunyu, Cao Ning, et al. Crystallography of reverted austenite in the intercritically reheated coarse-grained heat-affected zone of high strength pipeline steel[J]. Acta Metallurgica Sinica, 2021, 57(8): 967 − 976.

[15] Qi Xiaonan, Huan Pengcheng, Wang Xiaonan, et al. Effect of root welding heat input on microstructure evolution and fracture mechanism in intercritically reheat-coarse grained heat-affected zone of X80 pipeline steel[J]. Materials Today Communications, 2022, 31: 1 − 9.

[16] 王学林, 李学达, 尚成嘉. 高强度管线钢焊接热影响区显微组织精细表征[J]. 焊管, 2019, 42(7): 27 − 37. Wang Xuelin, Li Xueda, Shang Chengjia. Fine characterization of high strength pipeline steel welding HAZ microstructure[J]. Weld Pipe and Tube, 2019, 42(7): 27 − 37.

下载:

下载: