Microstructure and mechanical properties of Al-Mg-Cu alloy fabricated by heterogeneous twin-wire indirect arc additive manufacturing

-

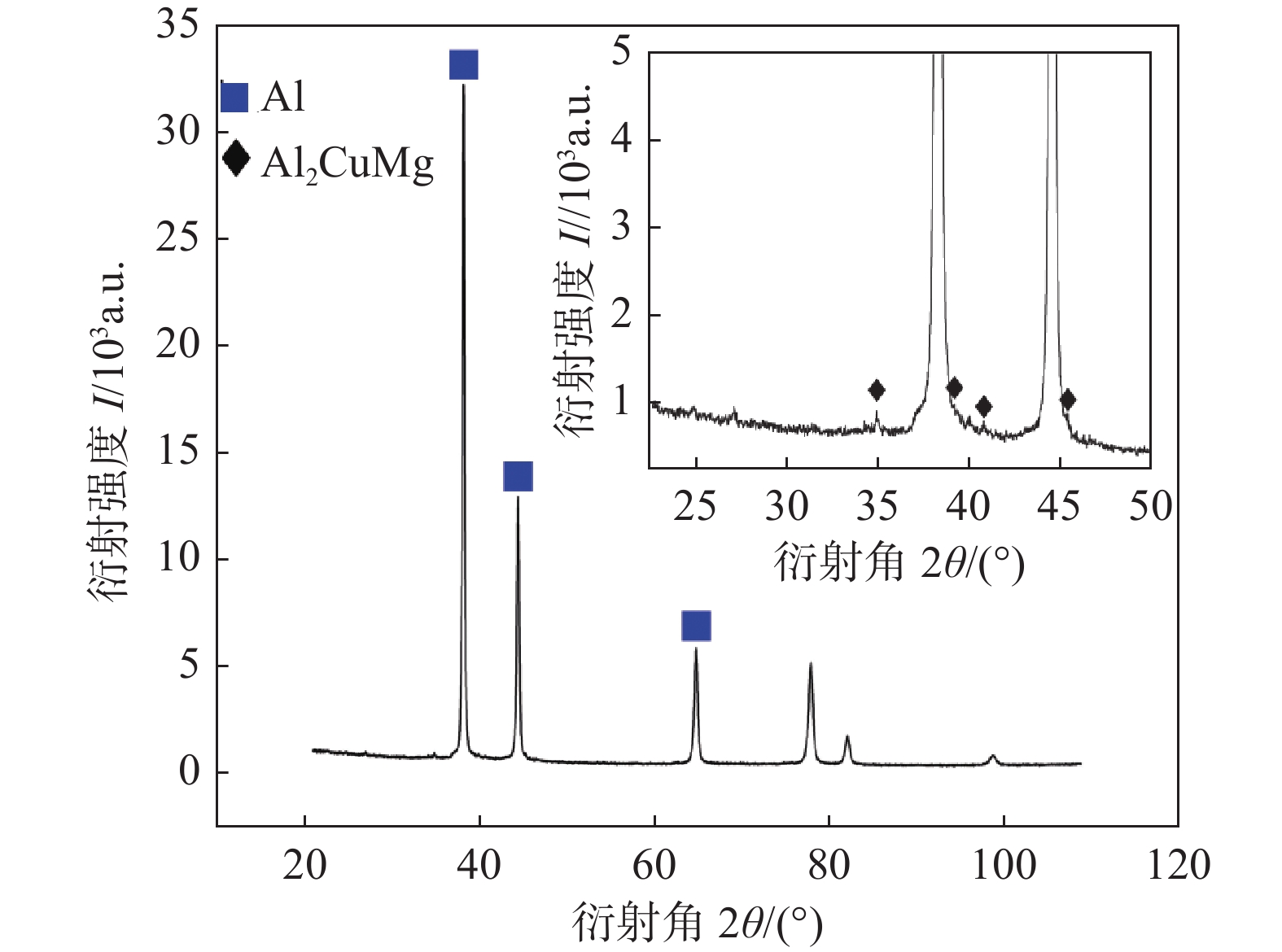

摘要: 提出了一种新型异质双丝间接电弧增材制造(TWIA-AM)方法,同步送进ER2319和ER5356两种焊丝,制备了Al-3.5Mg-1.7Cu合金试样,并对沉积的Al-3.5Mg-1.7Cu铝合金试样的组织和力学性能进行了研究. 结果表明,Al-3.5Mg-1.7Cu合金试样第二相主要由Al,Mg和Cu元素组成,为α-Al相和S相(Al2CuMg),晶粒形态在层间区域呈现粗大的柱状晶,层中心区域为等轴晶和细小的胞状晶组成;试样平均硬度为73.7 HV,存在周期性低硬度区. 试样平行增材方向(BD方向)、垂直于增材方向的平均抗拉强度和断后伸长率分别为225,235 MPa和9.0%,13.0%,力学性能表现为各向异性,观察断口形貌呈现典型的韧性断裂特征.

-

关键词:

- 双丝间接电弧 /

- 增材制造 /

- Al-Mg-Cu合金 /

- 微观组织 /

- 力学性能

Abstract: A new heterogeneous twin-wire indirect arc additive manufacturing (TWIA-AM) method was proposed. The ER2319 wire and ER5356 wire were fed synchronously and Al-3.5Mg-1.7Cu alloy components were prepared. The microstructure and mechanical properties of the deposited Al-3.5Mg-1.7Cu alloy components were investigated. The results showed that the second phase composition of Al-3.5Mg-1.7Cu alloy was mainly Al, Mg and Cu, and consisted of α-Al and S (Al2CuMg) phases. The grain morphology appeared as coarse columnar crystals at interlayer regions, and the center area of the layer is composed of equiaxed crystals and fine cellular crystals, and the layer center region was composed of equiaxed crystals and fine cellular crystals. The average micro-hardness of the sample is 73.7 HV with a periodic low hardness zone. The average tensile strength and elongation of the samples parallel to the building direction (BD direction) and perpendicular to the BD direction were 225, 235 MPa, 9.0% and 13.0%, respectively, exhibiting anisotropic mechanical properties. The fracture morphology exhibited the characteristics of typical plastic fracture. -

0. 序言

钛合金作为一种轻量化结构材料,具有密度低、比强度高、塑性及韧性好、抗疲劳和腐蚀性优越及生物相容性优异等特点,被广泛应用在航空航天、车辆工程、生物医学等领域[1-3]. 铜具有优良的导电、导热性,良好的冷、热加工性等特点,被广泛应用在电工电子、能源动力、化工核电等领域[4-6],因此,钛合金/铜的组合构件不仅能实现结构轻量化和功能多样化,还可以达到“物尽其用,优势互补”的目的. 目前,钛合金/铜异质金属连接主要应用在核能发电站的热交换器、发动机恒速装置、多元精密摩擦副类的组合构件及某些缸体与缸套柱塞转子之间的连接等. 根据钛合金/铜异质金属焊接性分析可知,钛/铜之间固溶度很低,易形成多种脆硬性金属间化合物,导致接头脆化,降低接头性能;钛/铜热物性参数相差较大,尤其是线膨胀系数和热导率,使焊后接头应力分布不均匀,增加接头变形和开裂的倾向;钛/铜界面易受N,H,O元素的影响,发生析氢吸氧反应,造成接头脆化和夹杂,需要在气体保护或真空条件下进行连接,因此,为实现钛合金/铜高质量连接,必须选择合适的焊接方法和工艺,降低接头的应力并减少脆硬相的生成,构筑新型微观界面,提高接头的强韧性.

用于钛合金/铜异质金属连接的焊接方法目前主要涉及到熔焊(弧焊[7-8]、激光焊[9-10]、电子束焊[11-12])、钎焊[13-14]、固相焊(摩擦焊[15-16]、爆炸焊[17]、扩散焊[18-20]),相较于其他焊接方法,真空扩散连接适用于大多数异种材料焊接,具有宏观塑性变形小、界面组织成分均匀、焊后试样不需要后续加工等优点,此外,真空环境下可以起到防止氧化和净化接头的作用. 然而,钛合金与铜直接扩散连接时,由于物理和化学性能差异较大,导致接头内部存在冶金不相容、应力难协调、性能不可靠等问题,界面容易出现焊接缺陷. Aydin等人[19]研究了TC4钛合金与电解铜的真空扩散连接,发现界面上出现空洞缺陷,接头抗剪强度只达到27 MPa. 此外,为了解决钛合金与铜扩散连接存在焊后接头开裂的问题,Wu等人[21]提出了一种焊后缓慢冷却热处理的方法对TC4钛合金与T2铜进行真空扩散连接,解决了接头自行开裂的难题,接头最大抗剪强度达到111 MPa. 然而,界面仍然存在多种TixCuy金属间化合物,严重影响接头力学性能,因此,为了完全隔绝钛合金与铜的扩散和反应,采用高熔点组元作为中间层来抑制有害相的生成,对于改善界面组织结构是一种有效的技术手段. 鉴于高熵合金(high-entropy alloy,HEA)在性能和结构上的显著特点,考虑到异质材料连接所面临的难题,将高熵合金作为中间层引入到焊接接头中,实现界面微观组织互锁和焊缝高熵化,可为异质材料连接和焊接提供一种新的方法和途径[22-24]. Li等人[22]采用AlCoCrCuNi2高熵合金作为中间层扩散连接TC4钛合金与316L不锈钢,HEA/316L界面上形成了固溶体扩散层,接头的抗剪强度达到214 MPa;刘玉林[25]采用扩散连接实现了铜与CoCrFeMnNi高熵合金的良好焊接,高熵合金与铜扩散时界面上的Kirkendall孔洞数量得到显著改善;Ding等人[26]使用CoCrFeMnNi单相高熵合金真空扩散连接钛和铜,FCC固溶体相生成在Ti/HEA/Cu界面上,高熵合金中元素的扩散速率为Mn > Cr > Fe > Co > Ni.

文中基于伪二元合金策略[27]和共晶高熵合金设计理念[28],设计并制备了VCrAl1.21Ni0.93Co1.85共晶高熵合金中间层用于真空扩散连接TC4钛合金和T2铜,通过高熵合金中的元素与两侧母材扩散反应,构筑一种新型的微观互锁和高熵化焊缝界面,提高接头的强韧性,并探索连接温度对接头组织演变、力学性能及扩散机制的影响规律.

1. 试验方法

1.1 母材与中间层

试验所用的TC4钛合金、T2母材及中间层的元素化学成分见表1,中间层主要由V,Cr,Al,Ni,Co五元合金元素组成,质量分数分别为17.01%,17.36%,10.91%,18.31%,36.41%,换算成摩尔比例的五元合金化学式为VCrAl1.21Ni0.93Co1.85. 试验采用真空电弧熔炼设备DHL-350制备合金铸锭,所用合金元素的纯度在99.9%以上,配料前需要去除原材料的表面氧化皮,并进行超声清洗,配料过程中使用精度为

0.0001 g的电子天平秤精准测量各元素的质量,将制备好的合金锭通过线切割机器切割成300 μm厚的薄片,再通过后续的打磨和抛光制成所需要的中间层,厚度约为160 μm,通过差热分析方法测得该中间层的熔点约1 314 ℃,TC4钛合金、T2母材及中间层的规格尺寸分别为5 mm × 5 mm × 5 mm,10 mm × 10 mm × 5 mm和5 mm × 5 mm × 0.16 mm.表 1 母材和中间层的化学成分(质量分数,%)Table 1. Chemical component of base materials and interlayer材料 Al V Co Cr Ni Si P S Ti Cu TC4 6.03 3.97 — — — — — — 余量 — T2 — — — — — ≤0.03 ≤0.02 ≤0.01 — 余量 中间层 10.91 17.01 36.41 17.36 18.31 — — — — — 1.2 扩散连接工艺

试验开始前,TC4钛合金和T2铜的被焊面需要使用不同型号(80号~2000号)的砂纸进行打磨,去除表面的氧化膜和杂质,并在丙酮中进行超声清洗10 min,以获得光滑平整的待焊表面,如图1所示. 焊接试样按照TC4/VCrAl1.21Ni0.93Co1.85/T2“三明治”的结构进行组装,放置于真空扩散焊炉ZTF2-10中,在真空度低于1 × 10−3 Pa条件下进行焊接见图1(a),试样的具体尺寸以及焊后用于力学性能测试和金相组织分析的试样见图1(b),包括3个抗剪测试试样和1个组织分析试样,通常扩散连接的理论连接温度介于0.6Tm ~ 0.8Tm(Tm是母材的熔点)[29]. 文中TC4钛合金与T2铜的熔点分别为1 667 ℃和1 084 ℃,因此,连接温度的范围为650 ~ 866 ℃,考虑到高熵合金中间层的迟滞扩散效应,连接温度范围应适当提高,以保证界面原子得到充分扩散和反应[30],因此,连接温度选择840 ~ 900 ℃,此外,考虑到T2铜高温屈服强度较低,为了保证焊接试样的有效连接和防止变形,需要严格控制焊接压力. 根据Hawkyard等人[31]的报道,纯铜在900 ℃时的屈服强度在10 MPa左右,因此,文中试验选择的焊接压力为8 MPa,以满足焊接要求和防止铜母材变形失效. 焊接工艺曲线见图1(c),设计了一个阶梯型的工艺曲线,在加热过程中分为2个阶段,第1阶段:温度从20 ℃升高到760 ℃,升温速率为10 ℃/min,在压力10 MPa下保温10 min,目的是促进界面紧密接触以达到微观孔洞闭合;第2阶段:继续升温至焊接温度,在焊接压力8 MPa下保温一段时间,当焊接完成时撤去压力,考虑到冷却过程中铜母材收缩严重,快速冷却容易导致接头界面开裂,因此设计了焊后随炉缓慢冷却热处理工艺,该工艺分为2个过程,通过控制冷却速率,均匀释放界面应力和缓慢收缩,降低接头开裂倾向和提高接头的连接质量,表2为试验所用的扩散连接工艺参数.

表 2 扩散连接工艺参数Table 2. Parameters of the diffusion bonding组 连接温度

T/℃保温时间

t/min连接压力

P/MPa中间层厚度

l/μm1 840 60 8 160 2 860 60 8 160 3 880 60 8 160 4 900 60 8 160 1.3 表征方法

使用TGA/DSC3 + 型热分析仪(differential thermal analyzer,DTA)对中间层固液相线温度进行测试,确定其熔点,相关技术指标包括测试温度25 ~ 1 600 ℃,试样质量0 ~ 1 000 mg;采用英斯特朗电子试验机Instron-5982对焊后接头进行抗剪试验,使用3D测量激光共聚焦显微镜OLS4000(laser confocal microscopy,LCM)观察中间层组织和接头界面宏观形貌;采用电子探针EPMA-JXA8530F分析接头的微观组织和元素分布;采用聚焦离子束(focusing ion beam,FIB)制备透射试样;使用扫描透射电子显微镜JEM-2100F(scanning transmission electron microscopy,STEM)分析界面产物的物相组成;采用X射线衍射仪XRD-D8 Advance对中间层和扩散连接头断口表面进行物相分析;XRD使用的是Cu靶材,其辐射、电压及电流分别为100 mSv/h,220 V和10 A;采用配备能谱仪(energy dispersive spectrometer,EDS)的扫描电子显微镜JSM-5600LV(scanning electron microscope, SEM)观察接头的断口形貌,并进行点成分测试和元素面扫描分析,SEM的加速电压、电子束束流及分辨率分别为12 kV,100 nA和0.8 nm.

2. 试验结果与分析

2.1 VCrAl1.21Ni0.93Co1.85 中间层设计与表征

根据元素的晶体结构、原子半径、电负性及二元相图等因素,选择V,Cr,Al,Ni,Co元素作为原材料制备多组元合金中间层,其中V,Cr,Al作为A类元素,定义为A1,A2和A3,Ni和Co作为B类元素,定义为B1和B2. 采用伪二元合金策略和共晶高熵合金设计理念,设计了一种新的共晶高熵合金VCrAl1.21Ni0.93Co1.85,作为TC4钛合金与T2铜扩散连接的中间层.为了判断该合金的种类,对原子半径差δ、混合焓$\varDelta H_{{\rm{m i x}}} $、价电子浓度VEC(V)和混合熵$\varDelta S_{{\rm{m i x}}} $进行计算. VCrAl1.21Ni0.93Co1.85多组元合金的δ,$\varDelta H_{{\rm{m i x}}} $,V和$\varDelta S_{{\rm{m i x}}} $可以通过式(1) ~ 式(4)获得.

$$ \delta =\sqrt{\sum _{i=1}^{n}{C}_{i}{\left(1-\frac{{r}_{i}}{r}\right)}^{2}} \text{,} r=\sum _{i=1}^{n}{C}_{i}{r}_{i} $$ (1) $$ \varDelta {H}_{{\rm{mix}}}=4\sum _{i=1,i\ne j}^{n}{\varDelta }_{{\rm{mix}}}^{{\rm{AB}}}{C}_{i}{C}_{j} $$ (2) $$ V=\sum _{i=1}^{n}{C}_{i}{\left(V\right)}_{i} $$ (3) $$ \varDelta {S}_{{\rm{mix}}}=-\mathrm{R}\sum _{i=1}^{n}\left({C}_{i}{\rm{ln}}{C}_{i}\right) $$ (4) 式中:n为元素的个数;i为元素的种类;Ci为元素的原子浓度;ri为元素的原子半径;r为平均原子半径;${\varDelta }_{{\rm{mix}}}^{{\rm{AB}}}$为A-B二元合金体系的混合焓;(V)i为不同种类的元素价电子浓度;R为气体常数(8.314 J·K−1·mol−1). Ni-Al,Ni-Cr和Ni-V二元合金体系的混合焓分别为−22,−7,−18 kJ/mol. 在VCrAl1.21Ni0.93Co1.85多组元合金中,V,Cr,Al,Ni,Co元素的摩尔浓度分别为0.167,0.167,0.202,0.155,0.309,因此,通过计算可以得到VCrAl1.21Ni0.93Co1.85合金的δ,$\varDelta {H}_{{\rm{mix}}} $,V和$\varDelta {S}_{{\rm{mix}}} $分别为0.07,−13.8 kJ/mol,6.75和1.57R. 根据合金中形成固溶体的条件0$ \leqslant $ δ $ \leqslant $8.4, −21$ \leqslant \varDelta {H}_{{\rm{mix}}}\leqslant $7 kJ/mol,1R$ \leqslant \varDelta {S}_{{\rm{mix}}}\leqslant $2.5R,当V<6.87时,形成的是BCC结构的固溶体. Yeh[32]指出当$\varDelta {S}_{{\rm{mix}}} $>1.5R时,合金可以定义为高熵合金. 根据A类元素与B类元素的二元相图,选择共晶点摩尔比作为原材料的配比,由此可以得到V,Cr,Al与Ni和Co的摩尔比分别为0.55∶0.45(MV∶MNi),0.52∶0.48(MCr∶MNi),0.93∶0.07(MAl∶MNi),0.42∶0.58(MV∶MCo),0.47∶0.53(MCr∶MCo),0.28∶0.72(MAl∶MCo). 通过计算合金中V,Cr,Al,Ni,Co元素的摩尔比为1∶1∶1.21∶0.93∶1.85,因此,根据上述的参数计算可以判断出VCrAl1.21Ni0.93Co1.85多组元合金属于一种共晶高熵合金.

图2为VCrAl1.21Ni0.93Co1.85共晶高熵合金的显微组织和XRD图谱,该合金主要由两相构成,即灰色BCC相和白色B2相,是一种双相固溶体组织,表3为在图2(a)中标记位置的EPMA(electronic probe micro-analyzer)定量点分析结果. 为了进一步分析中间层的元素分布情况,VCrAl1.21Ni0.93Co1.85中间层元素面扫描分析如图3所示,Al和Ni元素多富集在B2相上,而V和Cr元素多富集在BCC相上,Co元素则均匀分布于B2相和BCC相上. BCC和B2相所占的体积分数分别为58%和42%.

表 3 图2(a)中标记位置的EPMA定量点分析结果(原子分数,%)Table 3. EPMA quantitative analysis results of the marked locations in Fig. 2(a)位置 Al V Co Cr Ni 可能的相 A 19.1 15.8 35.5 15.8 13.8 B2 B 13.2 17.6 35.4 21.7 12.1 BCC 2.2 TC4/VCrAl1.21Ni0.93Co1.85/T2接头界面微观组织

不同连接温度下保温60 min获得TC4/VCrAl1.21Ni0.93Co1.85/T2扩散连接接头的微观组织形貌如图4所示,所有接头界面结合良好无缺陷产生,在TC4侧的连接界面附近发生了部分相变,由α-Ti向β-Ti进行转变,并且形成了部分魏氏组织. 图5为不同连接温度下接头界面放大微观组织形貌,研究发现两侧界面均形成一层明显的扩散层,并且随着连接温度的升高扩散层厚度逐渐增大,发现在TC4侧形成黑色和灰色两种相,当连接温度低于860 ℃时,这些黑色和灰色相以块状形式存在,当连接温度高于860 ℃时,这些黑色和灰色相逐渐转变成针状形态,说明有相变发生,形成针状的魏氏组织. 为了进一步推测扩散区相的成分,进行EPMA定量点成分分析,结果见表4,在TC4侧形成的黑色和灰色组织分别为Ti3Al和β-Ti相,Ti2( Co, Ni),Ti2(V, Cr, Al),Ti(V, Cr, Co)和(V, Cr)(Al, Ni, Co)相形成在TC4/VCrAl1.21Ni0.93Co1.85界面上,而VCrAl1.21Ni0.93Co1.85/T2界面扩散层上检测出(V, Cr)(Al, Ni, Co)和(V, Cr)(Cu, Ni, Co)3相,此外,TC4与VCrAl1.21Ni0.93Co1.85之间界面层上形成微观互锁结构的组织,起到接头强化作用,有效地提升接头的性能.根据界面上物相构成,可以推断出两侧界面均形成了高熵焊缝. 为了进一步判断高熵焊缝的形成,对其界面物相进行计算,根据EPMA获取的元素分布,可以计算出在TC4/VCrAl1.21Ni0.93Co1.85界面上Ti,V,Cr,Al,Ni,Co摩尔浓度分别为0.532,0.095,0.092,0.093,0.053,0.135,因此通过计算得到TC4/VCrAl1.21Ni0.93Co1.85界面上物相的$\varDelta {H}_{{\rm{mix}}} $,V和$\varDelta {S}_{{\rm{mix}}} $分别为0.07,−14.8 kJ/mol,5.18和1.52R. 而在VCrAl1.21Ni0.93Co1.85/T2界面上,V,Cr,Al,Ni,Co,Cu摩尔浓度分别为0.143,0.144,0.027,0.088,0.331,0.269,VCrAl1.21Ni0.93Co1.85/T2界面上物相的δ、$\varDelta {H}_{{\rm{mix}}} $、V和$\varDelta {S}_{{\rm{mix}}} $分别为0.03,−3.0 kJ/mol,8.48和1.59R,由此可以判断两侧界面上生成的扩散层均属于一种高熵焊缝,界面上生成的高熵焊缝和微观互锁结构能够极大地提高接头的强韧性.

![]() 图 5 不同连接温度下TC4/VCrAl1.21Ni0.93Co1.85和VCrAl1.21Ni0.93Co1.85/T2两侧的界面微观组织Figure 5. Interfacial microstructure on TC4/VCrAl1.21Ni0.93Co1.85 and VCrAl1.21Ni0.93Co1.85/T2 sides under various bonding temperature. (a) TC4 840 ℃; (b) T2 840 ℃; (c) TC4 860 ℃; (d) T2 860 ℃; (e) TC4 880 ℃; (f) T2 880 ℃; (g) TC4 900 ℃; (h) T2 900 ℃表 4 图5(e)和图5(f)中标记点处的元素分析结果(原子分数,%)Table 4. Elemental analysis results of the marked points in Fig. 5(e) and Fig. 5(f)

图 5 不同连接温度下TC4/VCrAl1.21Ni0.93Co1.85和VCrAl1.21Ni0.93Co1.85/T2两侧的界面微观组织Figure 5. Interfacial microstructure on TC4/VCrAl1.21Ni0.93Co1.85 and VCrAl1.21Ni0.93Co1.85/T2 sides under various bonding temperature. (a) TC4 840 ℃; (b) T2 840 ℃; (c) TC4 860 ℃; (d) T2 860 ℃; (e) TC4 880 ℃; (f) T2 880 ℃; (g) TC4 900 ℃; (h) T2 900 ℃表 4 图5(e)和图5(f)中标记点处的元素分析结果(原子分数,%)Table 4. Elemental analysis results of the marked points in Fig. 5(e) and Fig. 5(f)位置 Ti Cu Co Al V Cr Ni 可能的相 1 75.7 — 0.4 21.2 2.2 0.2 0.4 Ti3Al 2 70.0 — 4.8 10.8 8.0 4.7 1.7 β-Ti 3 58.8 — 19.0 6.8 3.4 3.1 8.9 Ti2(Co, Ni) 4 61.3 — 6.0 11.7 11.1 8.2 1.8 Ti2(V, Cr, Al) 5 39.4 — 15.5 9.5 14.1 16.4 5.1 Ti(V, Cr, Co) 6 7.5 — 25.7 16.4 19.1 23.3 8.0 (V, Cr)(Al, Ni, Co) 7 — 10.3 41.7 3.2 17.1 16.2 11.5 (V, Cr)(Cu, Ni, Co)2 8 — 43.5 24.4 2.1 11.5 12.5 6.0 (V, Cr)(Cu, Ni, Co)3 为了分析TC4/VCrAl1.21Ni0.93Co1.85侧界面元素分布情况,EPMA面扫描分析如图6所示. 可以看出TC4侧灰色的相主要含有Ti元素,也含有部分V和Al元素,而黑色的相主要分布Ti和Al元素,由此可以推断出黑色的相是Ti和Al形成的金属间化合物.界面上Ti和Co元素分布较多,同时也含有部分Al,V,Cr,Ni元素,由于高熵合金具有迟滞扩散效应,因此VCrAl1.21Ni0.93Co1.85中的Co,Cr,Ni元素扩散范围是有限的,界面上白色的相富集了大量的Co和Ni元素,由于Ti-Ni和Ti-Co之间的混合焓分别为−35 kJ/mol和−28 kJ/mol,相较于其他元素混合焓较负,具有较大的亲和力,易发生反应形成新相,界面上黑色的相主要分布着Ti和Al也含有少量的V和Cr. 图7为在880 ℃/60 min参数下VCrAl1.21Ni0.93Co1.85/T2侧的元素分布情况,界面上主要由Cu,Co,V,Cr,Ni元素组成,而Al元素没有进行扩散,出现这种现象的原因可能是Al原子半径为0.143 nm,相比其他几种元素要大得多,所以在扩散过程中,Al元素扩散受到阻碍,此外,Co,Cu,Ni,Cr属于相似元素,他们之间更容易扩散和结合,此外Cu与V,Cr,Ni,Co之间的混合焓均为正值,更容易形成固溶体,因此界面上没有Al元素进行扩散和反应.

2.3 接头界面物相TEM分析

图8为TC4/VCrAl1.21Ni0.93Co1.85界面上物相透射分析,在明场像标记位置的选区电子衍射(selected-area electron diffraction,SAED)对应的物相分别为Ti3Al,Ti2( Co, Ni),Ti2(V, Cr, Al),Ti(V, Cr, Co)和(V, Cr)(Al, Ni, Co),图8中给出了不同物相对应的米勒指数和晶带轴,Ti3Al,Ti2( Co, Ni),Ti2(V, Cr, Al),Ti(V, Cr, Co)和(V, Cr)(Al, Ni, Co)相对应的米勒指数分别为(001),(010),(011);(101),(011),(112);($0 \bar{2}1 $),(110),($1 \bar{1}1 $);($ 0\bar{1}\bar{1} $),(120),($ 11\bar{1} $)和($ 1\bar{1}1 $),(111),(202);此外,在BFI图中可以发现有大量的位错形成,这些位错线并不是直线而是呈现不同形状的曲线,说明该柏氏矢量与位错线既不平行也不垂直而是交成任意角度,形成一种混合型位错,这些位错发生缠绕阻碍晶界移动,起到位错强化的作用. 图9为VCrAl1.21Ni0.93Co1.85/T2侧界面扩散层物相透射分析,在BFI图中标记位置(1 ~ 3)对应的物相分别为(V, Cr)(Cu, Ni, Co)2,FCC和(V, Cr)(Cu, Co)3,(V, Cr)(Cu, Ni, Co)2,FCC和(V, Cr)(Cu, Co)3物相晶体结构的米勒指数分别为(101),(111),(212);(011),(100),(111);(111),(011),(122). 通过晶体学计算得到(V, Cr)(Cu, Ni, Co)2,FCC和(V, Cr)(Cu, Co)3晶带轴分别为[$10 \bar{1} $],[$0 \bar{1}1 $]和[$01 \bar{1} $],根据透射表征可以发现VCrAl1.21Ni0.93Co1.85/T2界面上形成了BCC和FCC双相固溶体结构,说明形成了一种类似高熵化焊缝的微观结构.

2.4 界面产物生长动力学分析

为了探索连接温度对扩散层反应产物的影响,研究了界面层的生长激活能,在扩散过程中,扩散层厚度与扩散时间满足下列关系

$$ {w}^{2}=kt $$ (5) 接头界面上生成物的生长速率k与焊接温度T满足Arrhenius公式,即

$$ k={k}_{0}\exp\left(\frac{-Q}{\mathrm{R}T}\right) $$ (6) 式中:w为扩散层厚度(μm);k为扩散系数(m2/s);t为扩散时间(s);k0为生长常数(m2/s);Q为扩散活化能(kJ/mol);T为温度(K). 当扩散时间是常量,连接温度为变量时,根据式(5)和式(6),可得到式(7),式(7)为$ {\rm{ln}}w $关于−1/T的一次函数,通过Origin软件数据拟合计算出不同扩散层的生长激活能.

$$ \ln w=-\frac{Q}{2\mathrm{R}T} + \frac{1}{2}\ln{k}_{0}t $$ (7) 图10为TC4/VCrAl1.21Ni0.93Co1.85和VCrAl1.21Ni0.93Co1.85/T2两侧界面层动力学分析,不同连接温度下扩散层对应的平均厚度见图10(a),图10(b)为扩散层I和II的生长激活能计算结果,扩散层I和II对应的生长激活能分别为229 kJ/mol和191 kJ/mol,扩散层I的生长激活能要大于扩散层II,说明在扩散过程中TC4与VCrAl1.21Ni0.93Co1.85之间的扩散层不容易先形成,而VCrAl1.21Ni0.93Co1.85与T2之间扩散过程只需要克服191 kJ/mol能量壁垒就能形成稳定的固溶体组织,此外,原子在固体中的扩散是通过空位或间隙原子等热缺陷产生得以实现的,因此扩散激活能实质上就是形成热缺陷所需要的能量. 通常,扩散激活能越大,元素扩散越困难.

![]() 图 10 TC4/VCrAl1.21Ni0.93Co1.85和VCrAl1.21Ni0.93Co1.85/T2两侧界面层动力学分析Figure 10. Kinetics of interfacial layers on TC4/VCrAl1.21Ni0.93Co1.85 and VCrAl1.21Ni0.93Co1.85/T2 sides. (a) thickness of diffusion layers for 60 min under different temperature; (b) growth activation energy of diffusion layers I and II

图 10 TC4/VCrAl1.21Ni0.93Co1.85和VCrAl1.21Ni0.93Co1.85/T2两侧界面层动力学分析Figure 10. Kinetics of interfacial layers on TC4/VCrAl1.21Ni0.93Co1.85 and VCrAl1.21Ni0.93Co1.85/T2 sides. (a) thickness of diffusion layers for 60 min under different temperature; (b) growth activation energy of diffusion layers I and II2.5 接头的抗剪强度

通过压剪试验测试了不同连接温度下接头的抗剪强度,如图11所示,随着焊接温度的升高,接头的抗剪强度先增大后减小,当焊接温度为880 ℃时,接头的抗剪强度达到最大为194 MPa,根据之前的研究表明[21],TC4/T2直接扩散接头的抗剪强度为111 MPa,文中TC4/VCrAl1.21Ni0.93Co1.85/T2扩散连接接头的抗剪强度相较于无中间层接头提高74.8%,这主要归因于界面微观互锁结构和高熵化焊缝改善了接头的微结构和强韧性. 图11(b)为抗剪试验的载荷−位移曲线,可以发现接头的抗剪强度最佳时,对应的载荷和位移最大,说明接头具有较高强度的同时也具有良好的压缩韧性和延展性,表现出良好的接头塑性变形能力. 因此,文中共晶高熵合金中间层对于改善钛合金/铜异质接头界面微观结构起到良好的促进作用.

2.6 接头的断裂机制分析

TC4/VCrAl1.21Ni0.93Co1.85/T2接头的断裂路径如图12所示. 在840 ℃时,接头沿着TC4/VCrAl1.21Ni0.93Co1.85界面断裂,界面上没有产生二次裂纹;当温度升高到860 ℃时,接头也主要沿着TC4/VCrAl1.21Ni0.93Co1.85界面断裂,但有二次裂纹产生,并且这些二次裂纹沿着中间层进行扩展,由于二次裂纹在断裂过程中需要吸收大量的断裂载荷,从而提高了接头的抗剪强度,当连接温度达到880 ℃时,接头主要沿着中间层断裂,需要吸收大量的能量,从而表现出较高的接头强度;而当连接温度达到900 ℃时,接头沿着VCrAl1.21Ni0.93Co1.85/T2界面断裂. 由于温度升高导致界面晶粒组织粗大,晶粒之间存在较大的晶粒取向差,在受到剪切载荷时裂纹沿着VCrAl1.21Ni0.93Co1.85/T2界面上的晶界断裂,表现出较低的接头强度.

在880 ℃/60 min下TC4/VCrAl1.21Ni0.93Co1.85/T2接头的断口形貌如图13所示,表5为在图13(b)和图13(d)中标记点的EDS分析结果. 断口表面平坦伴随少量的撕裂棱,整体呈现解理断裂特征,属于一种脆性断裂模式,在TC4侧,断口表面出现解理台阶,断口表面存在大面积光滑区域,这是由于塑性较好的FCC基体(位置3)相断裂形成,而在光滑区域中有少量的BCC基体相(位置5)剥落下来. 因为在FCC基体相中存在较多的滑移系,通过位错的滑移和攀移发生连续的塑性变形而导致塑性断裂,而BCC相的滑移系较少,只能通过特定的晶面发生脆性断裂[33]. 在T2侧,断口表面出现解理台阶扩展形成的河流花样(位置11),断口表面存在部分光滑区域,在光滑区域与河流花样交界处存在很明显的解理台阶(位置13),这是由于脆硬的B2相断裂所致. 此外,在BCC相前端的固溶体区具有较高的激活能,导致该区域在界面处宽度最窄,生长速度最慢,从而导致在剪切试验中BCC相固溶体易发生剥落. 根据表5可知,接头断裂主要是沿着BCC基体相和B2相交替断裂,在此过程中可能存在微观互锁结构和焊缝高熵化提升接头的抗剪强度.

表 5 图13(b)和图13(d)中标记点的元素分析结果(原子分数,%)Table 5. Elemental analysis results of the marked points in Fig. 13(b) and Fig. 13(d)位置 Ti Al V Cr Co Ni 可能的相 1 56.9 9.2 5.9 6.2 15.4 6.4 Ti3(Co, Ni) 2 48.4 17.7 5.3 5.3 18.0 5.5 Ti3AlCo 3 21.2 23.3 11.3 10.2 24.5 9.5 TiAl(V, Cr, Co, Ni) 4 58.0 9.4 5.8 5.4 14.9 6.5 Ti2(V, Cr, Co) 5 5.5 17.1 20.1 25.1 25.1 7.1 BCC 6 0.2 19.1 15.8 14.5 35.7 14.7 BCC 7 17.3 16.8 21.6 17.8 20.6 5.9 TiAl(V, Cr, Co)2 8 50.7 16.8 10.1 8.0 10.8 3.6 Ti3Al(V, Co) 9 0.6 24.2 15.4 12.3 32.9 14.6 B2 10 60.0 8.2 3.7 3.9 16.4 7.8 Ti2(Co, Ni) 11 0.1 12.4 18.8 21.8 34.7 12.2 BCC 12 19.2 20.6 12.7 10.1 27.2 10.2 TiAl(V, Cr)(Co, Ni) 13 0.3 22.5 15.5 14.7 33.6 13.4 B2 为了进一步分析断口表面的物相构成,对其表面进行XRD检测,不同参数下TC4/VCrAl1.21Ni0.93Co1.85/T2接头断口表面的XRD如图14所示. 在TC4和T2两侧断口表面上均检测到BCC和FCC相,说明接头主要沿着VCrAl1.21Ni0.93Co1.85/T2界面上形成的固溶体区断裂. 此外,在断口表面上被检测到β-Ti和Cu-FCC相,这是由于在进行XRD检测过程中是对断口整个表面进行检测,包含了部分TC4和T2的基体,因此,在断口表面存在β-Ti和Cu-FCC相.

3. 结论

(1)设计了一种双相固溶体(BCC和B2)VCrAl1.21Ni0.93Co1.85共晶高熵合金中间层用于真空扩散连接TC4钛合金和T2铜,Ti2( Co, Ni),Ti2(V, Cr, Al),Ti(V, Cr, Co)和(V, Cr)(Al, Ni, Co)相形成在TC4/VCrAl1.21Ni0.93Co1.85界面上,(V, Cr)(Al, Ni, Co)和(V, Cr)(Cu, Ni, Co)3相出现在VCrAl1.21Ni0.93Co1.85/T2界面上,通过对界面扩散层相关参数计算,两侧界面上均形成一种高熵化焊缝.

(2)通过动力学计算可知扩散层I和II对应的生长激活能分别为229 kJ/mol和191 kJ/mol,扩散层I的生长激活能要高于扩散层II,说明在扩散过程中VCrAl1.21Ni0.93Co1.85与T2之间的反应层最先形成,随着焊接温度的升高,接头的抗剪强度先增大后减小,当焊接温度为880 ℃时,接头的抗剪强度达到最大为194 MPa.

(3)当连接温度低于880 ℃时,接头主要是沿着TC4/VCrAl1.21Ni0.93Co1.85界面处断裂,断口表面平坦伴随少量的撕裂棱,整体呈现解理断裂特征,属于一种脆性断裂模式,在光滑区域中有少量的BCC基体相剥落下来,接头断裂主要是沿着BCC基体相和B2相交替断裂,通过XRD检测到在断口表面上存在β-Ti,BCC,FCC,Cu-FCC相.

-

图 5 Al-Mg-Cu合金的凝固途径[17]

Figure 5. Solidification pathways for Al-Mg-Cu alloys

表 1 基板和焊丝的化学成分(质量分数,%)

Table 1 Chemical compositions of substrate and welding wire

材料 Mg Cu Zn Mn Si Ti Fe Al 5083 4.0 0.10 0.25 0.40 0.40 0.15 0.20 余量 ER2319 0.20 6.30 0.05 0.30 0.10 0.15 0.10 余量 ER5356 4.50 0.05 0.05 0.13 0.15 0.13 0.20 余量 表 2 Al-Mg-Cu合金直壁墙增材制造工艺参数

Table 2 Process parameters of straight wall additive manufacturing of Al-Mg-Cu alloy

焊丝 极性 电流I /A 气体流速Q/ (L˙min−1) 焊丝伸出长度ls /mm 送丝速度vs / (m˙min−1) 焊丝端部与基板的距离la /mm ER2319 阳极 200 20 10 5.20 20 ER5356 阴极 200 20 10 14.30 20 表 3 TWIA-AMed Al-Cu-Mg合金的EDS结果(原子分数,%)

Table 3 EDS results of TWIA-AMed Al-Cu-Mg alloys

位置 Al Mg Cu A 96.37 3.37 0.26 B 74.28 13.77 11.95 C 85.70 8.57 5.73 -

[1] 张庆东. 美国铝业公司旗下航空航天产业发展路径分析[J]. 有色金属加工, 2022, 51(2): 1 − 5. Zhang Qingdong. Analysis on the development path of alcoa's aerospace industry[J]. Nonferrous Metals Processing, 2022, 51(2): 1 − 5.

[2] Qi Z W, Cong B Q, Qi B J, et al. Microstructure and mechanical properties of double-wire + arc additively manufactured Al-Cu-Mg alloys[J]. Journal of Materials Processing Technology, 2018, 255: 347 − 353. doi: 10.1016/j.jmatprotec.2017.12.019

[3] Huang T, Qi Z, Liu Z, et al. Enhanced damage tolerance through reconstructing residual stress and Cu-Mg co-clusters by pre-rolling in an Al-Cu-Mg alloy[J]. Materials Science & Engineering: A, 2017, 700: 241 − 249.

[4] 刘梦, 秦梦黎, 柏松, 等. 原子团簇尺寸对Al-Cu-Mg合金疲劳过程中滑移带形成及裂纹扩展行为的影响[J]. 有色金属科学与工程, 2023, 14(4): 501 − 510. Liu Meng, Qin Mengli, Bai Song, et al. Effect of solute cluster sizes on the formation of slip band in plastic deformation zone at fatigue crack tip and the fatigue crack propagation behavior of an Al-Cu-Mg alloy[J]. Nonferrous Metals Science and Engineering, 2023, 14(4): 501 − 510.

[5] Gao C J, Wolff S, Wang S R. Eco-friendly additive manufacturing of metals: Energy efficiency and life cycle analysis[J]. Journal of Manufacturing Systems, 2021, 60: 459 − 472. doi: 10.1016/j.jmsy.2021.06.011

[6] Wang Liwei, Chen Shujun, Xiao Jun, et al. Droplet-targeting laser hybrid indirect arc for additive manufacturing technology−A preliminary study[J]. China Welding, 2020, 29(1): 50 − 55.

[7] Wu D T, An Q, Matsuda K J, et al. Characteristics of bypass coupling twin-wire indirect arc welding with high-speed welding mode[J]. Journal of Materials Processing Technology, 2021, 291: 116995. doi: 10.1016/j.jmatprotec.2020.116995

[8] Zhang Z H, Wu D T, Zou Y. Effect of bypass coupling on droplet transfer in twin-wire indirect arc welding[J]. Journal of Materials Processing Technology, 2018, 262: 123 − 130. doi: 10.1016/j.jmatprotec.2018.06.032

[9] Wu D T, An Q, Zhao G L, et al. Corrosion resistance of stainless steel layer prepared by twin-wire indirect arc surfacing welding[J]. Vacuum, 2020, 177: 109348. doi: 10.1016/j.vacuum.2020.109348

[10] Shi C W, Zou Y, Zou Z D, et al. Twin-wire indirect arc welding by modeling and experiment[J]. Journal of Materials Processing Technology, 2014, 214: 2292 − 2299. doi: 10.1016/j.jmatprotec.2014.04.027

[11] Shi C W, Zou Y, Zou Z D, et al. Physical characteristics of twin-wire indirect arc plasma[J]. Vacuum, 2014, 107: 41 − 50. doi: 10.1016/j.vacuum.2014.04.003

[12] Wu K Y, Cao X W, Yin T, et al. Metal transfer process and properties of double-wire double pulsed gas metal arc welding[J]. Journal of Manufacturing Processes, 2019, 44: 367 − 375. doi: 10.1016/j.jmapro.2019.06.019

[13] 张天奕, 张兆栋, 王泽力, 等. 旁路耦合三丝间接电弧增材制造成形特性[J]. 焊接学报, 2022, 43(9): 25 − 30. Zhang Tianyi, Zhang Zhaodong, Wang Zeli, et al. Forming characteristics of bypass coupling triple-wire gas indirect arc additive manufacturing[J]. Transactions of the China Welding Institution, 2022, 43(9): 25 − 30.

[14] 王宣. 基于多丝共熔的高强铝合金电弧增材制造方法及工艺研究[D]. 北京: 北京工业大学, 2019. Wang Xuan. Research on the method and characteristics of wire and arc additive manufacturing of high strength aluminum alloys based on mutual melting technology of muti-wires[D]. Beijing: Beijing University of Technology, 2019.

[15] Rui F A, St A, Jl A, et al. Hot-wire arc additive manufacturing of aluminum alloy with reduced porosity and high deposition rate[J]. Materials & Design, 2020, 199: 109370.

[16] Ou W, Mukherjee T, Knapp G L, et al. Fusion zone geometries, cooling rates and solidification parameters during wire arc additive manufacturing[J]. International Journal of Heat and Mass Transfer, 2018, 127: 1084 − 1094. doi: 10.1016/j.ijheatmasstransfer.2018.08.111

[17] Pickin C G, Williams S W, Prangnell P, et al. Control of weld composition when arc welding high strength aluminum alloys using multiple filler wires[J]. Science and Technology of Welding and Joining, 2013, 15(6): 491 − 496.

[18] Jiang P F, Li X R, Zong X M, et al. Multi-wire arc additive manufacturing of Ti basic heterogeneous alloy: Effect of deposition current on the microstructure, mechanical property and corrosion-resistance[J]. Journal of Alloys and Compounds, 2022, 920: 166056. doi: 10.1016/j.jallcom.2022.166056

[19] Dixit M, Mishra R S, Sankaran K K. Structure–property correlations in Al 7050 and Al 7055 high-strength aluminum alloys[J]. Materials Science & Engineering A, 2007, 478(1-2): 163 − 172.

[20] Liu Y, Liang S, Jiang D. Influence of repetitious non-isothermal aging on microstructure and strength of Al-Zn-Mg-Cu alloy[J]. Journal of Alloys and Compounds, 2016, 689: 632 − 640. doi: 10.1016/j.jallcom.2016.08.017

[21] Xu X, Zheng J, Zhi L, et al. Precipitation in an Al-Zn-Mg-Cu Alloy during Isothermal Aging: Atomic-scale HAADF-STEM Investigation[J]. Materials Science & Engineering A, 2017, 691: 60 − 70.

[22] Ma T, Ge J, Chen Y, et al. Observation of in-situ tensile wire-arc additively manufactured 205A aluminum part: 3D pore characteristics and microstructural evolution[J]. Materials Letters, 2019, 237(15): 266 − 269.

-

期刊类型引用(5)

1. 刘自刚,张建峰,钱雪娇,叶佳城,孙仲侃. 大熔覆速率TIG焊研究现状与展望. 热加工工艺. 2024(01): 12-16 .  百度学术

百度学术

2. 王奕楷,庞世炫,王燮阳,黄增好,曹彪. 高频脉冲复合直流微TIG焊接电源及其电弧形态特征. 焊接. 2023(03): 54-59 .  百度学术

百度学术

3. 俞雄军,苏斌. 双钨极氩弧焊技术的发展及其在核承压设备耐腐蚀层堆焊中的应用. 东方电气评论. 2022(04): 64-68 .  百度学术

百度学术

4. 吴统立,杨嘉佳,王克鸿,郭顺,高琼. 高频复合双钨极氩弧焊电弧行为规律. 电焊机. 2019(05): 87-91 .  百度学术

百度学术

5. 吴统立,王克鸿,冯曰海. 高频复合双钨极氩弧焊电源研制. 电焊机. 2019(06): 83-88 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: