High temperature tensile fracture characteristics of FGH96/IN718 inertial friction welded joint

-

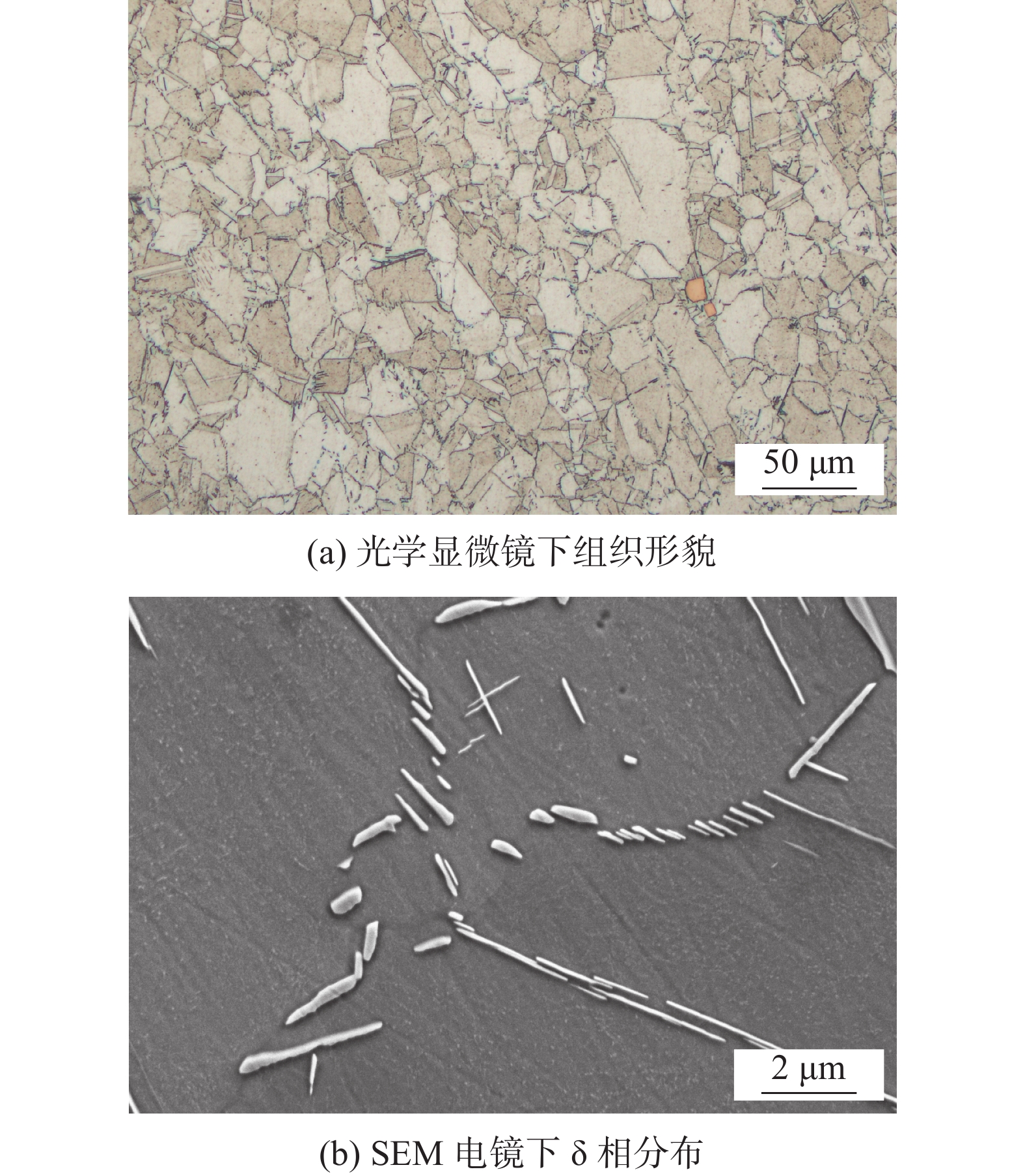

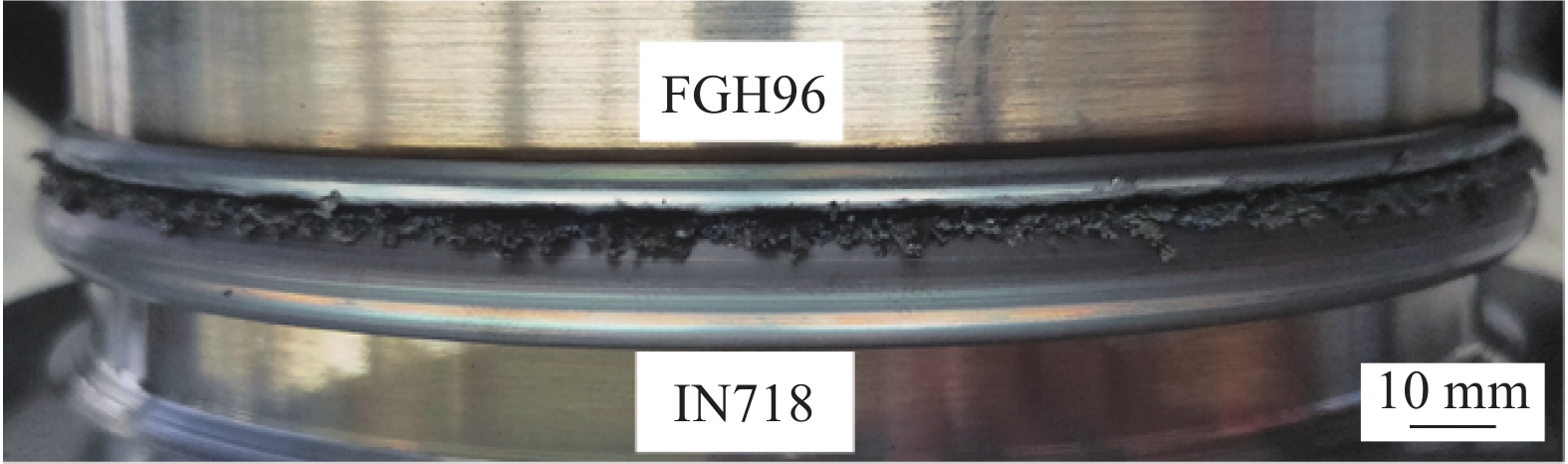

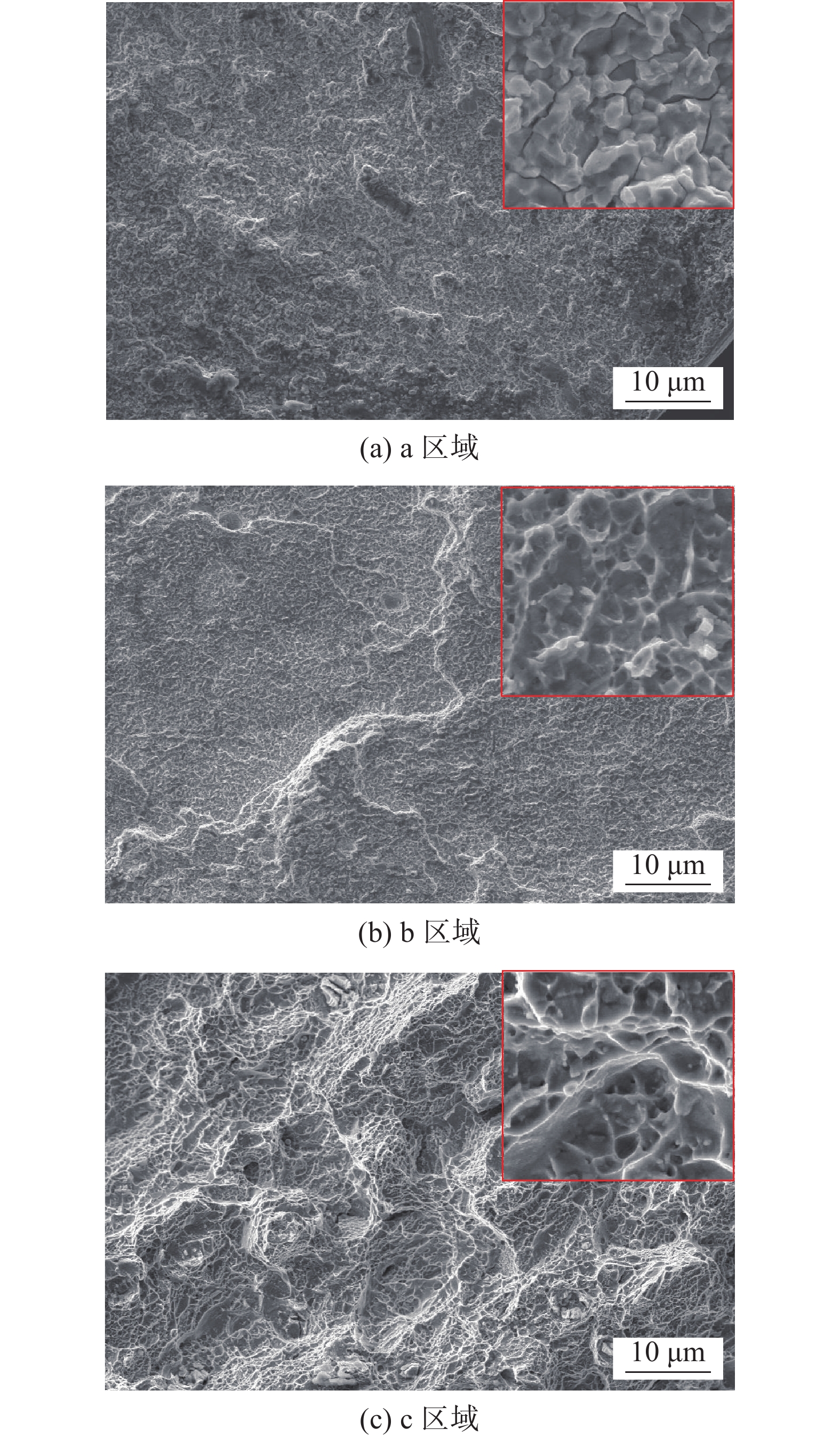

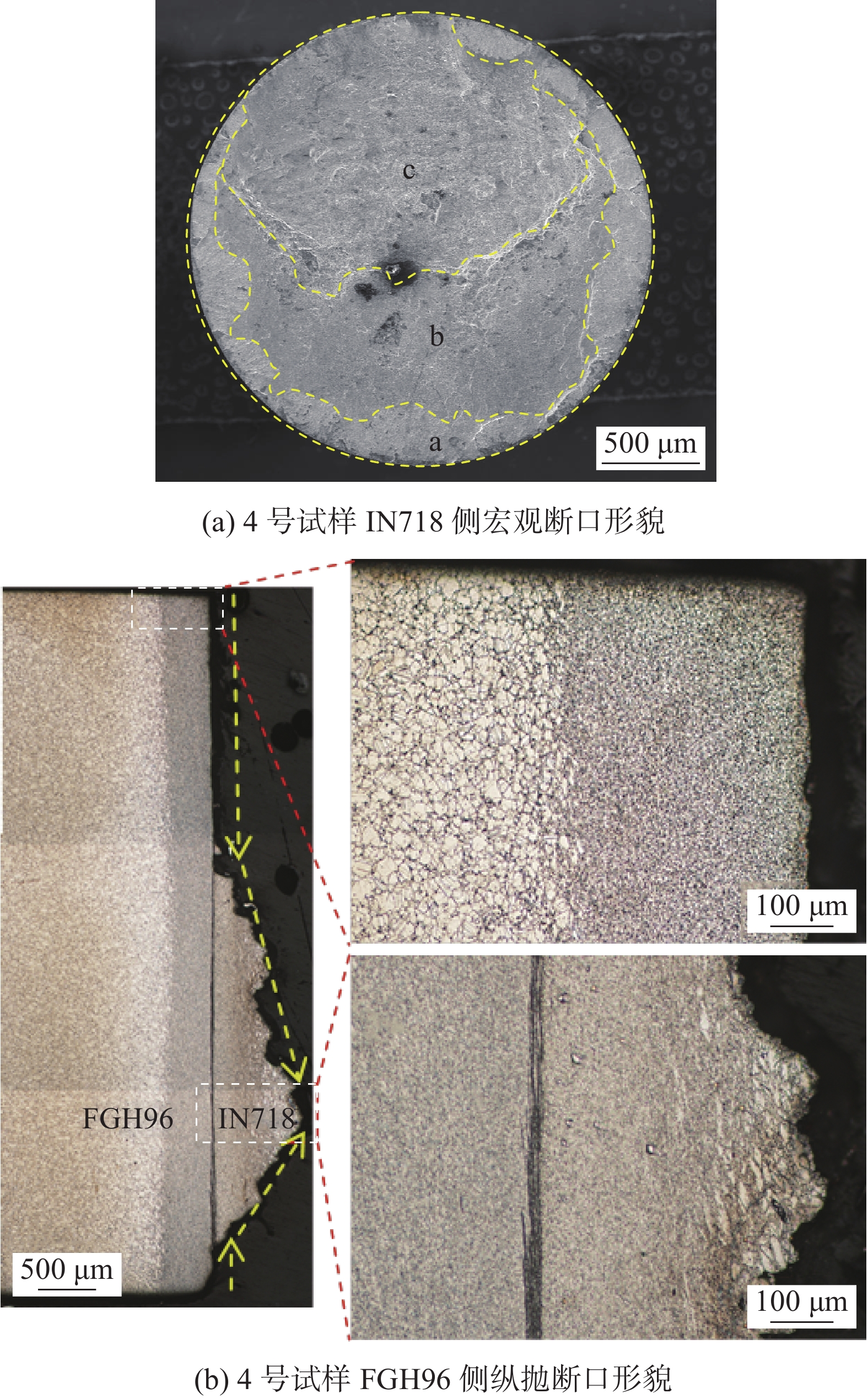

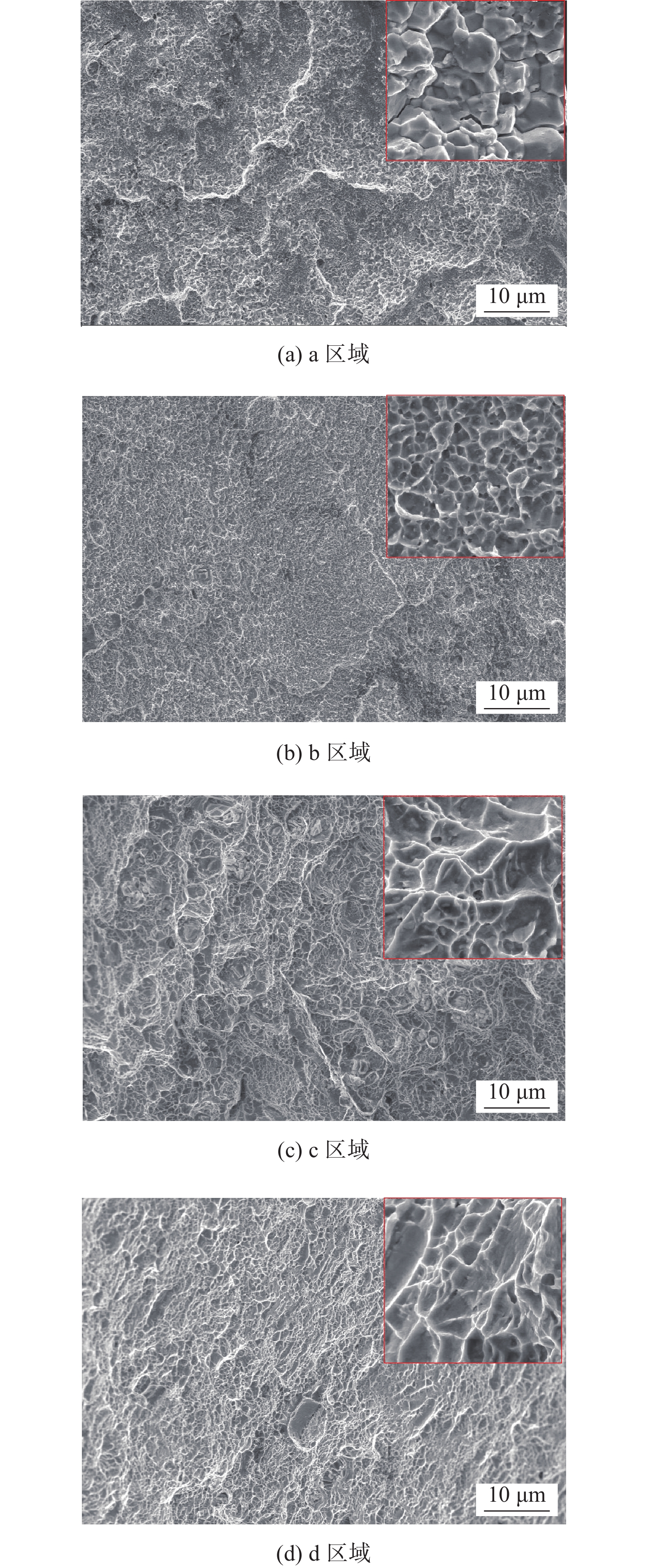

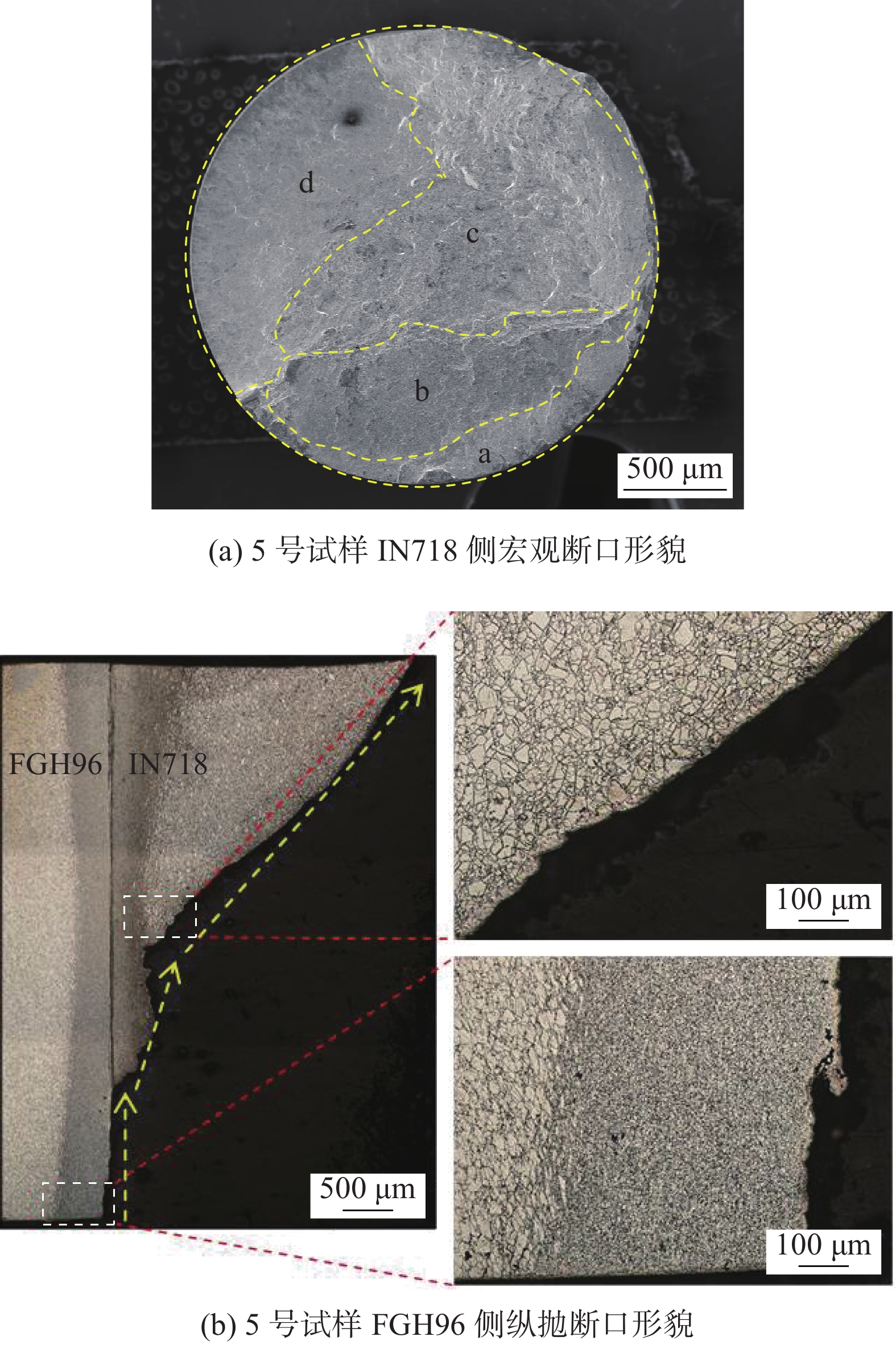

摘要: 为了实现航空用FGH96和IN718异质高温合金高可靠连接,为航空发动机关键部件安全评价及寿命预测提供基础数据及理论支持,采用扫描电子显微镜、金相显微镜研究了FGH96和IN718异质高温合金惯性摩擦焊接头显微组织形貌、高温拉伸试样断口形貌和断裂位置. 结果表明,焊接接头焊缝区FGH96和IN718均为等轴晶粒组织,晶粒尺寸约2 μm,焊缝区γ′和δ强化相基本全部溶解,热力影响区FGH96侧晶内γ′基本全部溶解,IN718侧δ强化相发生部分溶解,短棒状形貌消失,组织为粗细晶共存组织. 焊接接头650 ℃高温拉伸试样均断裂在焊缝区,但平均抗拉强度可达1 080.8 MPa,基本与IN718母材等强,高温拉伸试样起裂位置均处于试样边缘焊缝区,裂纹产生的原因主要是由于焊缝区γ′和δ强化相基本全部溶解,强化作用消失,性能降低. 裂纹产生后沿晶界由焊缝熔合线向试样内部扩展,当裂纹从试样边缘焊缝区四周同时向试样内部扩展时,在轴向拉力作用下形成“平台 + 凹坑”状断口特征,当裂纹从试样边缘焊缝区局部位置开始向试样内部扩展时,在轴向拉力作用下形成“平台 + 剪切”状断口特征.Abstract: In order to achieve highly reliable connection of FGH96 and IN718 dissimilar high-temperature alloys for aerospace applications, to provide basic data and theoretical support for the safety evaluation and life prediction of aero-engines key components. Scanning electron microscopy and metallurgical microscopy were used to study the FGH96 and IN718 dissimilar high-temperature alloy inertia friction welding joint microstructure morphology and high-temperature tensile specimens fracture morphology and fracture location. Test results show that the weld zone FGH96 and IN718 were equiaxed grain organization, the grain size is about 2 μm, the weld zone γ′ and δ strengthening phase were completely dissolved, the heat-force affected zone FGH96 side of the grain γ′also was completely dissolved, the IN718 side δ strengthening phase occured partially dissolved, the short rod-like shape was disappeared, coarse and fine crystal organization coexisted. The welded joint 650 ℃ high temperature tensile specimens were fractured with the weld zone, but the average tensile strength up to 1 080.8 MPa, basically with IN718 parent material equal strength, the high-temperature tensile specimens crack location were in the edge of the sample weld zone, the crack from the weld zone was mainly due to γ′ and δ strengthening phase basically all dissolved, the strengthening effect disappeared, the performance was reduced. The crack was generated along the grain boundary from the weld fusion line to the specimen internal expansion, the crack from the specimen edge weld area around the same time to the specimen internal expansion, under the action of axial tension to form a "platform + crater" fracture characteristics, when the crack from the specimen edge weld area local location to the specimen internal expansion, under the action of axial tension to form "platform + shear" fracture characteristics.

-

0. 序言

电弧增材制造(wire arc additive manufacturing, WAAM)是以电弧为热源,基于离散堆积原理通过自下至上材料逐层堆积的方式进行零件加工的新方法,具有成形效率高、设备成本低和材料利用率高的优点,在大尺寸零件成形和模具修复方面具有独特的优势[1-4]. 相关研究表明,以增材制造方式成形的构件力学性能要优于铸造方式加工出的构件[5]. 随着汽车、航空、航天等相关行业材料轻量化的提出,铸造铝合金的应用越来越广泛,其中Al-Si系合金凭借良好的耐磨性、良好的成形性和热裂倾向较低的优点被广泛应用于增材制造技术中[6-8]. 在成形方面,Köhler等人[9]对4047铝合金和5356铝合金的电弧增材制造成形工艺和力学性能进行研究,结果表明,4047铝合金薄壁构件比5356铝合金构件的表面光洁度更差,其几何结构更加不均匀. Evjemo等人[10]以4047铝合金焊丝为材料,研究了薄壁方盒的不熄弧增材路径,结果表明,能够提高增材效率,改善构件成形质量. 虽然电弧增材制造成形效率高,但是因其热量高导致增材件的精度低仍是增材制造技术面临的主要问题[11-12]. 为降低热量积累,相关学者对此进行过多项研究. Fu等人[13]研究了一种新的热丝电弧增材制造方法,结果表明,将导线连接到基板上产生的电阻热可以辅助焊丝熔化以降低电弧能量输入. Hackenhaar和Montevecchi等人[14-15]研究了向增材构件喷射气体的方法以加快其冷却,结果表明,向增材构件喷射气体可以有效降低层间温度,防止热量积累,但此种方法需外加空气射流装备,增加了试验成本. 陈克选等人[16]研究了基板底部有无水冷的温度场变化规律,结果表明,添加水冷条件后,基板的冷却速率显著降低,构件形貌的塌陷程度有较大的改善,但并未对其组织与性能进一步研究.

为降低增材制造过程中热量积累,优化4047铝合金构件的成形质量,通过在基板底部加装水冷铝板强制散热,选用ER4047铝合金焊丝进行电弧增材试验,制备了两种不同工艺的直壁增材构件,并与未加装水冷铝板制备的构件进行对比,研究水冷约束对增材构件微观组织和力学性能的影响,以期为改善电弧增材4047铝合金构件质量提供实践指导和理论依据.

1. 试验方法

选用直径为1.2 mm的ER4047铝合金焊丝和200 mm × 100 mm × 5 mm的6082铝合金基板作为试验材料.增材设备采用ABB IRB-1410型焊接机器人和MIG-500RP型焊机. 水冷铝板尺寸为240 mm × 120 mm × 15 mm. 采用TY-20型焊接冷却循环水箱,其最大流量为23 L/min. 采用的保护气体为纯度99.999%氩气;测温装置为CK-01A型红外温度传感器,数据在LabVIEW上读取和保存.

试验前,先去除基板表面氧化膜. 为防止试验时基板受热变形无法与水冷铝板接触,采用夹具对基板四周固定. 表1为设置的3种构件的工艺条件,电弧增材制造主要工艺参数见表2. 规定沿平行焊缝方向为横向,垂直于基板高度方向为纵向,横向和纵向各取3个拉伸试样测试抗拉强度,然后取平均值,在直壁构件纵向截面测试维氏硬度平均值. 图1为增材制造示意图,P点为基板温度监测点,沿覆层堆敷方向,距离堆覆层起点70 mm,距离覆层中线垂直距离为27.5 mm,成形后的直壁构件的取样位置如图2所示.

表 1 3种构件的工艺条件Table 1. Processing conditions of three components试验组号 工艺名称 水冷条件 层间冷却时间t/s 焊枪移动速度v/(mm·s−1) 焊接模式 增材路径 直壁构件长度l/mm A 水冷断续 有 200 5 双脉冲 往复式 140 B 无水冷断续 无 200 5 双脉冲 往复式 140 C 水冷连续 有 0 5 双脉冲 往复式 140 表 2 WAAM工艺参数Table 2. Processing parameters of WAAM焊接电流I/A 电弧电压

U/V双脉冲电流差值

I1/A峰值电流占空比η(%) 峰值电流频率

f/Hz电弧波形特性

参数S保护气体流量

Q/(L·min−1)焊枪喷嘴到基板

距离l0 /mm130 19.4 40 60 2 3 18 11 2. 试验结果与分析

2.1 增材构件宏观形貌与基板热循环曲线

图3为直壁增材构件宏观形貌. 从形貌上看, A组整体形貌较好,每层焊道之间纹理均匀分明,表面相对平整; B组增材构件侧壁略有沟壑起伏出现流淌现象,成形效果略差. 由于A组和B组层间有熄弧冷却,构件两端因逐层起弧和熄弧而出现塌陷. C组宏观形貌最优,成形最好,侧壁较为平整,因为增材过程中电弧未中断,电弧与焊丝的伸出长度在成形过程中相对稳定,构件两端没有塌陷现象产生,使得其形貌优于A,B组构件.

表3为3种构件成形后的尺寸和时间参数. 在增材过程中,增材构件若未能充分冷却,后续熔覆时热量会逐渐积累,使已增材部分保持较高的温度,下层熔覆时熔池的尺寸增加,熔覆焊道的熔宽增加. 由于焊接电流不变,总熔化焊丝体积不变,因此熔覆焊道的余高减小. 当增材相同层数时,A组工艺由于水冷铝板的散热作用,热积累现象降低,使得单层焊道的高度略高于B组. C组工艺无层间冷却,热量积累现象最为严重,增材至相同的高度时需要花费更多的层数. 制备相同高度的试样时,C组需要堆敷更多层数,但因为没有层间冷却, C组增材效率远优于A组和B组,效率约为原来的5倍.

表 3 增材构件的尺寸和制备时间Table 3. Size and preparation time of WAAM parts试验

组号构件高度

h/mm增材层数

n/层单层平均高度

h1/mm构件宽度

d/mm增材所需

时间t1/sA 47 27 1.74 9.8 6156 B 45 27 1.67 10.2 6156 C 45 44 1.02 13.7 1232 图4为3组试验基板温度监测点的热循环曲线. A组和B组试验基板每一层最高温度呈现先增大后减小的趋势,最低温度则呈现缓慢增长的趋势,C组试验基板每一层最高温度和最低温度均呈现先增大后减小的趋势. 对比A组和B组不同的冷却方式,A组在有水冷铝板的条件下,基板监测点在第11层最高温度为115 ℃. B组基板监测点温度的整体变化趋势与A组温度变化趋势大致相同,但由于无水冷,热量逐渐积累,监测点最高温度在第12层为134 ℃. C组由于无层间冷却,热量积累现象在3组试验中最为严重,在第18层峰值温度达到最高值190 ℃,随后各层的峰值温度呈现略微下降的趋势.

2.2 微观组织

沿直壁增材构件高度方向作切面,使用光学显微镜观测增材构件内部组织,图5、图6和图7分别为3种工艺下增材构件底层区(与基板相邻区域)、中间层区和顶层区微观组织. 由于基板散热较快,熔池冷却过冷度大,晶粒来不及生长,因此底层组织晶粒尺寸相对较小,多以等轴晶为主. 随着增材层数的增加,热量开始积累,熔池冷却速率减缓,构件的中间层区散热趋于多向化,晶粒以粗大的柱状晶和树枝晶为主,晶粒尺寸较底层有所增大. 由于构件顶层区未经历加热重熔,晶粒尺寸略小于中间层区晶粒尺寸,析出相多以鱼骨状为主.

对比3种增材构件从底层区至顶层区的微观组织,3种工艺条件下晶粒尺寸从底层区到中间层区都呈现增大的趋势,但顶层区未经历重熔,晶粒的尺寸要略小于中间层区晶粒尺寸,且3组试验中A组试样晶粒小于B组试样晶粒,C组试样晶粒最为粗大. 增材制造过程中,基板底部的水冷铝板通过基板带走部分热量,使每次增材时前一层已沉积部分的初始温度较小,减小了下一层沉积时的热积累,提高了冷却速度,使晶粒细化.

图8为3组增材试样X射线衍射仪(X-ray diffractometer, XRD)扫描结果. 4047铝合金焊丝的主要元素成分为Al和Si,因此在增材构件中发现较为典型的Al相和Si相. 3组试验中C组试样峰值强度略高,在半峰宽基本相同的情况下,由于C组构件在增材过程中长时间保持高温状态,后续层增材时相当于对前层增材组织进行热处理,使溶于Al基体中的Si析出,因而C组试验Al和Si的峰值强度要高于A组和B组.通过能谱仪(energy dispersive spectrometer,EDS)对B组试样不同区域组织进行点扫描测试,结果表明,增材构件主要由Al-Si共晶体和α-Al基体和少量的氧化物组成,如图9所示.

2.3 力学性能

图10为3种增材构件的力学性能试验结果. A组、B组、C组3组试样平均硬度值依次降低,增材构件的硬度与其晶粒大小有关,A组增材构件晶粒最小,因而其硬度相对较高,B组次之,C组试验由于增材时热积累最严重,晶粒最大,硬度最低. 对比抗拉强度,A组试样最高,C组试样最低,且3种构件的横向抗拉强度都高于纵向,在抗拉强度上略表现出各向异性. A组与B组相比,加装了水冷铝板,试样的抗拉强度提高;A组与C组相比,设置了层间冷却时间,试样的抗拉强度提高,造成这种现象的原因是构件晶粒得到细化,增材构件抗拉强度提高. 图10b为增材构件的断后伸长率,纵向试样取样于垂直堆敷层方向,相比于横向试样,纵向试样更易在层间结合处发生断裂,因此,纵向试样要低于横向试样的的断后伸长率. C组试样在增材过程中长时间处于高温状态,固溶的Si元素析出较多,固溶强化效果减弱,强度降低,塑性提高,其断后伸长率最高. 3种工艺制备的增材构件的力学性能均达到国家标准GB/T 1173—2013《铸造铝合金》[17]中ZL102铸造铝合金(与4047铝合金成分相近)的规定要求,具备相应的应用前景.

3. 结论

(1)在不同工艺条件下,电弧增材制造4047铝合金直壁构件. 水冷连续增材直壁构件宏观形貌最优且成形效率最高,虽然存在一定的热积累现象,但已无堆覆层塌陷问题;水冷断续工艺能够有效降低热积累,但增材直壁构件两端有塌陷产生.

(2) 3种增材构件底部微观组织以等轴晶为主,其余各部位以柱状晶和树枝晶为主,增材构件晶粒尺寸从底部至中间层部位逐渐增大. 3种工艺中,水冷断续工艺制备的构件晶粒尺寸最小,水冷连续工艺制备的构件晶粒尺寸最大.

(3) 3种工艺制备的直壁4047铝合金增材构件,其抗拉强度和断后伸长率均与ZL102铸造铝合金相当.

-

图 4 IN718/FGH96异质高温合金惯性摩擦焊接头显微组织

Figure 4. Microstructure of IN718/FGH96 heterogeneous superalloy inertial friction welding joint. (a) weld zone on FGH96 side; (b) thermal influence zone on FGH96 side; (c) heat affected zone on FGH96 side; (d) weld zone on IN718 side; (e) thermal affected zone on the IN718 side; (f) thermal affected zone on the IN718 side

表 1 FGH96合金化学成分(质量分数,%)

Table 1 Composition of FGH96 alloy

Cr Co W Mo Ta Nb Al Ti Zr Si Ce Ni 15.6 ~ 16.6 12.5 ~ 13.5 3.8 ~ 4.2 3.8 ~ 4.2 <0.2 0.6 ~ 1.0 2.0 ~ 2.4 3.5 ~ 3.9 0.025 ~ 0.05 <0.2 0.01 余量 表 2 IN718合金化学成分(质量分数,%)

Table 2 composition of IN718 alloy

C Ni Cr Mg Co Mo Al Ti Nb B Fe ≤0.08 50.0 ~ 55.0 17.0 ~ 21.0 0.01 ≤1.0 2.8 ~ 3.3 0.3 ~ 0.7 0.75 ~ 1.15 4.75 ~ 5.5 <0.001 余量 表 3 IN718/FGH96异质高温合金惯性摩擦焊接头高温拉伸性能

Table 3 High temperature tensile test data of IN718/FGH96 heterogeneous superalloy inertial friction welding joint

序号 试验温度T/℃ 抗拉强度Rm/MPa 屈服强度ReL/MPa 断后伸长率A(%) 断面收缩率Z(%) 1 650 1 099.0 948.5 11.5 4.5 2 650 1 102.5 952.0 11.5 4.5 3 650 1 001.0 927.5 5.0 8.5 4 650 1 102.5 952.0 16.5 6.5 5 650 1 099.0 990.5 10.0 10.5 -

[1] 张国庆, 张义文, 郑亮, 等. 航空发动机用粉末高温合金及制备技术研究进展[J]. 金属学报, 2019, 55(9): 1133 − 1144. Zhang Guoqing, Zhang Yiwen, Zheng Liang, et al. Research progress of powder superalloys for aero engines and their preparation technology[J]. Acta Metallica Sinica, 2019, 55(9): 1133 − 1144.

[2] 江河, 董建新, 张麦仓, 等. 800 ℃以上服役涡轮盘用难变形镍基高温合金研究进展[J]. 航空制造技术, 2019, 64(Z1): 62 − 73. Jiang He, Dong Jianxin, Zhang Maicang, et al. Research progress of refractory nickel-based superalloys for turbine disks in service above 800 ℃[J]. Aeronautical Manufacturing Technology, 2019, 64(Z1): 62 − 73.

[3] 夏春智, 李亚江, 王娟. 粉末高温合金焊接的研究进展[J]. 焊接, 2012(3): 14 − 17. Xia Chunzhi, Li Yajiang, Wang Juan. Research progress of powder superalloy welding[J]. Welding & Joining, 2012(3): 14 − 17.

[4] 刘新灵, 陶春虎. FGH96粉末高温合金损伤行为与寿命预测[J]. 失效分析与预防, 2011, 6(2): 124 − 129. Liu Xinling, Tao Chunhu. Damage behavior and life prediction of FGH96 powder superalloy[J]. Failure Analysis and Prevention, 2011, 6(2): 124 − 129.

[5] 胡连喜, 冯小云. 粉末冶金高温合金研究及发展现状[J]. 粉末冶金工业, 2018, 28(4): 1 − 7. Hu Lianxi, Feng Xiaoyun. Research and development status of powder metallurgy superalloys[J]. Powder Metallurgy Industry, 2018, 28(4): 1 − 7.

[6] 杨杰, 刘光旭, 王文莹, 等. 热挤压对FGH96镍基粉末高温合金微观组织的影响[J]. 中国冶金, 2021, 31(8): 40 − 48. Yang Jie, Liu Guangxu, Wang Wenying, et al. Effect of hot extrusion on microstructure of FGH96 nickel based powder superalloy[J]. China Metallurgy, 2021, 31(8): 40 − 48.

[7] 张春波, 周军, 张露, 等. IN718合金与FGH96合金惯性摩擦焊接头组织和力学性能[J]. 焊接学报, 2019, 40(6): 40 − 45. Zhang Chunbo, Zhou Jun, Zhang Lu, et al. Microstructure and mechanical properties of inertial friction welded joint of IN718 alloy and FGH96 alloy[J]. Transactions of the China Welding Institution, 2019, 40(6): 40 − 45.

[8] 周军, 张春波, 杜淼, 等. 摩擦焊在航空领域的应用[J]. 焊接, 2017(6): 1 − 5. Zhou Jun, Zhang Chunbo, Du Miao, et al. Application of friction welding in aviation[J]. Welding & Joining, 2017(6): 1 − 5.

[9] 张露, 韩秀峰, 王伦. 焊接工艺在商用航空发动机中的应用[J]. 焊接, 2016(8): 54 − 59. Zhang Lu, Han Xiufeng, Wang Lun. Application of welding technology in commercial aero engine[J]. Welding & Joining, 2016(8): 54 − 59.

[10] 王彬, 黄继华, 张田仓, 等. 转速对FGH96/IN718高温合金惯性摩擦焊接头组织与力学性能的影响[J]. 焊接, 2018(9): 57 − 60. Wang Bin, Huang Jihua, Zhang Tiancang, et al. Effect of rotational speed on microstructure and mechanical properties of FGH96/IN718 superalloy inertial friction welding Joint[J]. Welding & Joining, 2018(9): 57 − 60.

[11] 王彬, 黄继华, 张田仓, 等. 压力对FGH96/IN718高温合金惯性摩擦焊接头性能的影响[J]. 焊接学报, 2018, 39(4): 41 − 44,72. doi: 10.12073/j.hjxb.2018390092 Wang Bin, Huang Jihua, Zhang Tiancang, et al. Effect of pressure on performance of FGH96/IN718 superalloy inertial friction welding joint[J]. Transactions of the China Welding Institution, 2018, 39(4): 41 − 44,72. doi: 10.12073/j.hjxb.2018390092

[12] 何胜春, 张田仓, 郭德伦. 粉末高温合金FGH96惯性摩擦焊接头常温力学性能分析[J]. 航空材料学报, 2006(3): 122 − 125. doi: 10.3969/j.issn.1005-5053.2006.03.025 He Shengchun, Zhang Tiancang, Guo Delun. Mechanical poperties analysis of powder superalloy FGH96 inertial friction welding joint at room temperature[J]. Journal of Aeronautical Materials, 2006(3): 122 − 125. doi: 10.3969/j.issn.1005-5053.2006.03.025

[13] 何胜春, 廖云建, 张田仓, 等. 粉末高温合金FGH96惯性摩擦焊接头室温疲劳裂纹扩展速率测试与分析[J]. 航空制造技术, 2015, 480(11): 77 − 79. He Shengchun, Liao Yunjian, Zhang Tiancang, et al. Measurement and analysis of fatigue crack growth rate at room temperature in powder superalloy FGH96 inertial friction welding joint[J]. Aviation Manufacturing Technology, 2015, 480(11): 77 − 79.

[14] 王晓峰, 邹金文, 杨杰, 等. FGH96合金惯性摩擦焊焊区的微观组织表征[J]. 中国材料进展, 2019, 38(8): 806 − 812. Wang Xiaofeng, Zou Jinwen, Yang Jie, et al. Microstructure characterization of welding zone of FGH96 alloy by inertia friction welding[J]. Materials Progress in China, 2019, 38(8): 806 − 812.

-

期刊类型引用(1)

1. 马晓锋,夏攀,刘海生,史铁林,王中任. 全位置焊接熔池的深度学习检测方法. 机械工程学报. 2023(12): 272-283 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: