Arc heat input distribution of fillet welding of dissimilar steel with applied transverse magnetic field

-

摘要: 提出对电弧施加横向磁场的方法,通过偏转电弧改变焊缝两侧电弧热分配,从而提升焊缝成形质量. 为了掌握外加横向磁场对电弧热输入分配的影响机制,开展了GTAW电弧热输入分配规律研究;建立了外加横向磁场下的异种钢角焊缝GTAW电弧-熔池耦合瞬态三维模型,对电弧温度场、电磁场、流场开展了耦合计算;对比分析了偏转焊枪与外加横向磁场偏转电弧两种电弧热量分配方式;在上述工作的基础上,研究了外加横向磁场偏转电弧方式磁感应强度对熔透形态和电弧热分配的影响规律. 结果表明,偏转焊枪方式在角焊中适应性较差,而外加横向磁场偏转电弧可获得更好的焊接质量. 相关研究可为此类异种钢角焊的焊接工艺参数优化提供技术支持.Abstract: In this paper, a method of applying transverse magnetic field to the arc is proposed to change the arc heat distribution on both sides of the weld by deflecting the arc, so as to improve the weld forming quality. In order to understand the influence mechanism of applied transverse magnetic field on arc heat input distribution, the rule of GTAW arc heat input distribution was studied. A three-dimensional model of GTAW arc pool coupling in dissimilar steel fillet weld under applied transverse magnetic field was established, and the coupling calculation of arc temperature field, electromagnetic field and flow field was carried out. Two kinds of arc heat distribution methods of deflecting the torch and external transverse magnetic field deflected arc were compared and analyzed. On the basis of the above work, the effect of magnetic induction intensity on the penetration form and the heat distribution of arc under the applied transverse magnetic field deflected arc was studied. The results show that the adaptability of deflection welding gun is poor in fillet welding, while the deflection arc with applied transverse magnetic field can obtain better welding quality. The relevant research can provide technical support for the optimization of welding process parameters of this kind of dissimilar steel fillet welding.

-

0. 序言

随着科技的发展,机械装备向大型化、轻量化方向发展,对构件性能提出更高要求[1],单一金属材料已不能满足工程的使用要求. Q235低碳钢具有较好的力学性能,且价格低廉;304L作为一种超低碳奥氏体不锈钢,具有优异的抗腐蚀性能,大量应用于防腐、防锈设备,但其价格偏高. Q235/304L异种钢焊接结构件兼顾不同材料的优异性能与良好的经济效益,在石油化工[2]、航空航天、电站锅炉等行业的装备和构件中有广泛应用前景[3-5].

Q235与304L异种钢焊接时,焊缝两侧材料热导率、比热容等热物理性能的差异[6],以及焊缝两侧材料导磁性能的差异造成的磁偏吹现象,导致焊接过程中焊缝两侧材料电弧热输入分配发生变化[7],可能在焊缝处产生较大的集中应力[8],甚至产生裂纹等焊接缺陷[9-10]. 由于304L不锈钢热导率小于Q235低碳钢,且304L不锈钢比热容低于Q235低碳钢,为获得良好的焊缝熔透质量,Q235一侧应被给予更多的电弧热输入,这也意味着必须对电弧热输入实施干预. 基于上述情况,提出一种对电弧施加横向磁场,通过偏转电弧进而调节焊缝两侧热输入的方法,达到提升焊接质量的目的. Rong等人[11]的研究表明,在316L/EH36焊接中应用外加磁场,能有效细化焊缝组织并降低焊接变形;Li等人[12]研究了外加磁场对AA6061 /HSLA350焊接接头的影响,结果表明外加磁场的引入显著减少了焊缝界面的金属间化合物层. 目前,对于外加磁场的异种钢焊接大多局限于接头组织和性能研究[13],除此以外,由外加磁场引起的焊接热输入分配变化同样会对焊接质量产生影响,因此研究外加磁场对异种钢焊接热输入分配的影响具有重要意义.

以Q235低碳钢和304L不锈钢为研究对象,采用钨极惰性气体保护焊 (gas tungsten arc welding,GTAW) 对异种钢角焊的电弧热输入分配规律开展研究,建立了外加横向磁场下的异种钢角焊电弧−熔池耦合三维模型,对电弧和熔池的瞬态温度场以及外加横向磁场对电弧和熔池的影响规律进行模拟,并与试验进行对比验证,探究了异种钢角焊的熔池形成规律以及电弧热输入分配对熔池形态的影响,研究结果可为异种钢角焊两侧母材热量调控提供技术支持.

1. 试验方法

试验材料为Q235和304L,尺寸为170 mm × 50 mm × 4 mm,保护气体为高纯度氩气,焊接电流为直流120 A,不填丝,试验装置如图1所示. 试验时,在线圈中通以恒定电流,使其产生一定大小的横向磁场,并测量钨针正下方2 mm处的磁感应强度,在不同磁场条件下进行Q235/304L角焊试验.

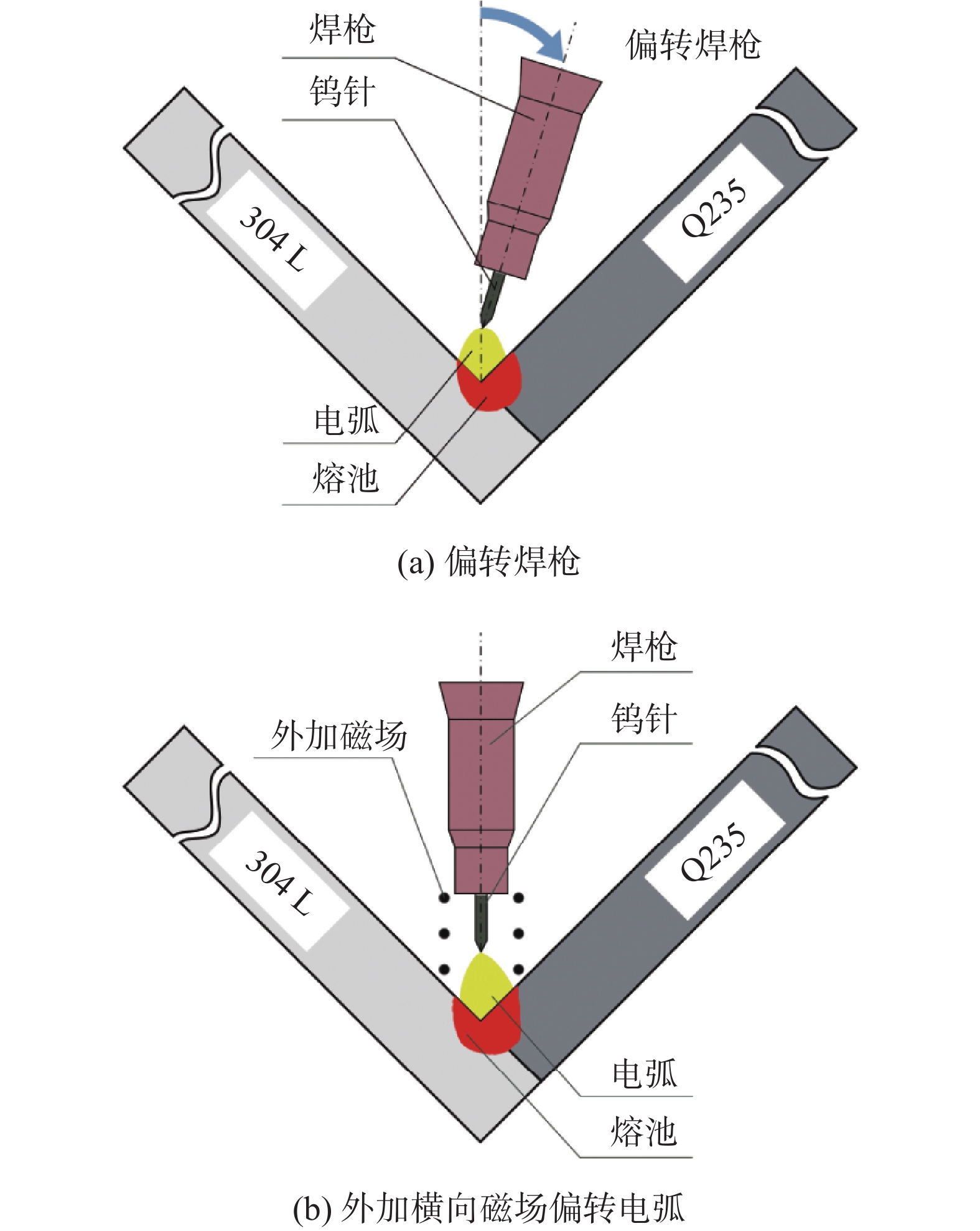

试验中采用偏转焊枪与外加磁场偏转电弧两种方法调节电弧热输入,如图2所示.

2. 数学模型

2.1 基本假设

为了降低模型的复杂度,减少模型的计算时间,计算时对电弧做出如下假设.

(1) 氩气、等离子体均处于标准大气压下,且不可压缩.

(2) 电弧为光学薄膜介质,并且处于局部热力学平衡(LTE)下.

(3) 忽略电弧粘性效应导致的热损失和重力影响.

(4) 氩气和电弧等离子体的流动状态为层流.

(5) 外加横向磁场对保护气的电导率没有影响.

(6) 外加横向磁场只与电弧之间有力的关系.

(7) 忽略焊接缺陷的影响.

2.2 控制方程

基于以上基本假设和流体动力学以及传热学,得出下列控制方程.

质量守恒方程

$$ \frac{{\partial \rho }}{{\partial t}} + \nabla \cdot \rho v = 0 $$ (1) 式中:ρ为密度;t为时间;v为速度矢量.

动量守恒方程

$$ \frac{{\partial v}}{{\partial t}} + v \cdot \nabla v = - \nabla P + \nabla \cdot \tau + j \cdot B + \rho g $$ (2) 式中:P为动量;τ为黏性应力张量;j为电流密度,B为磁感应强度,j·B为电磁力项;ρg为重力项.

能量守恒方程

$$ \rho {C_{\rm{p}}}\left( {\frac{{\partial T}}{{\partial t}} + v \cdot \nabla T} \right) = \nabla \cdot \left( {k\nabla T} \right) + S $$ (3) 式中:T为温度;CP为定压比热;k为导热系数.

源项S的表达式为

$$ S = j \cdot E + \frac{{5{k_{\rm{B}}}}}{{2e}}j \cdot \nabla T - 4{\text{π}} {\varepsilon _{\rm{N}}} $$ (4) 式中:E为电场强度;kB为玻尔兹曼常数,值为5.670 373 × 10−8 W/(m2·K4);e为电子电量. 式(4)中三项分别表示电弧焦耳热、电子传输焓以及电弧辐射热损失.

电流连续性方程

$$ \nabla \cdot \left( {\sigma \nabla V + \sigma \frac{{\partial A}}{{\partial t}}} \right) = 0 $$ (5) 式中:σ为电导率;V为电势;A为磁矢势. 推导出电场及电流密度方程为

$$ E = - \nabla V - \frac{{\partial A}}{{\partial t}} $$ (6) $$ j = - \sigma \nabla V - \sigma \frac{{\partial A}}{{\partial t}} $$ (7) 磁矢量方程

$$ \sigma \frac{{\partial A}}{{\partial t}} + \nabla \left( {\frac{1}{{{\mu _0}}}\nabla \cdot A} \right) + \sigma \nabla V = 0 $$ (8) 式中:μ0为真空磁导率.

磁感应强度为

$$ B = \nabla\cdot A $$ (9) 2.3 模型及边界条件

三维异种钢角焊缝GTAW电弧-熔池耦合瞬态模型如图3所示.

在图3a中,区域1为氩气入口域,氩气流量为15 L/min,相对应的气体流速为ug;区域2和区域3分别为304L和Q235材料域,尺寸为50 mm × 20 mm × 4 mm;区域4为氩气出口域;区域5为钨针域,施加焊接电流(I0 = 120 A),钨针尖端角度为60°,电弧弧长为3 mm;表面1和表面2为工件上表面,即模型阳极;表面3为钨针外表面,即模型阴极,边界条件如表1所示.

表 1 模型边界条件Table 1. Model boundary condition区域 速度v/(m·s−1) 温度T/K 磁矢势A/Tm 电势ϕ/V 区域1 ug 1 000 ∂A/∂n=0 ∂ϕ/∂n=0 区域2 — T0 ∂A/∂n=0 0 区域3 — T0 ∂A/∂n=0 0 区域4 — 1 000 ∂A/∂n=0 ∂ϕ/∂n=0 区域5 — 3 000 ∂A/∂n=0 n·j=−I(t)/πRc2 表面1 — 式(11) — — 表面2 — 式(11) — — 表面3 — 式(10) — — 在钨针-电弧、电弧-熔池界面处,电弧温度、电流密度、电弧压力梯度较大,不满足LTE状态. 在这两处界面分别添加边界条件.

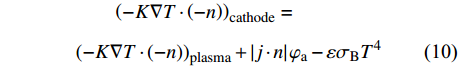

电弧-钨针边界层

$$ \begin{split} &\qquad {\left( { - K\nabla T \cdot \left( { - n} \right)} \right)_{{\rm{cathode}}}} =\\& {\left( { - K\nabla T \cdot \left( { - n} \right)} \right)_{{\rm{plasma}}}} + \left| {j \cdot n} \right|{\varphi _{\rm{a}}} - \varepsilon {\sigma _{\rm{B}}}{T^4} \end{split}$$ (10) 电弧-熔池边界层

$$\begin{split} &\qquad {\left( { - K\nabla T \cdot \left( { - n} \right)} \right)_{{\rm{anode}}}} = \\&{\left( { - K\nabla T \cdot \left( { - n} \right)} \right)_{{\rm{plasma}}}} + \left| {j \cdot n} \right|{\varphi _{\rm{a}}} - \varepsilon {\sigma _{\rm{B}}}{T^4} \end{split} $$ (11) 式中:jivi为钨针发射电子造成的能量损失;jeφc为电弧正离子撞击钨针释放的能量;|j·n|φa为电子冷凝热项;εσBT 4为辐射散热;ji和je分别为离子电流密度和电子电流密度.计算时在区域4内施加稳恒磁场以模拟外加磁场对焊接电弧的影响.式(10)和式(11)中ε为焊接工件的表面辐射系数,文中Q235不锈钢侧表面辐射系数取0.4,304L不锈钢侧取0.9,σB为Stefan-Boltzman常数,Q235与304L的热物性参数如图4所示.

3. 结果与讨论

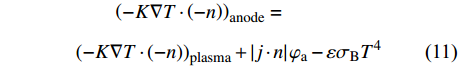

3.1 电弧热输入调节方法对比

图5为未对电弧热输入进行调节时的电弧温度场. 由于Q235的磁导率大于304L,电弧周围的磁力线分布不均匀,Q235一侧的磁力线更加密集,焊接时电弧受电磁力而向Q235侧偏转,电弧最高温度位于钨针下方1.3 mm处,电弧整体呈心形.

图6显示了0 ~ 3.0 s的温度场计算结果,焊接时熔池大部分位于Q235侧,导致焊接质量差,焊接接头强度不足,表征熔池尺寸的参数如图7所示.

图8为角焊缝熔池尺寸随时间的变化曲线. 焊接时,Q235率先熔化并迅速形成焊脚,1.5 s后焊脚尺寸增长缓慢,最大焊脚尺寸为5.1 mm. 在熔池形成过程中,熔池和熔宽迅速形成到一定尺寸后基本保持不变,并随着电弧加热而加深,最终形成的熔池中,两侧母材的熔深差异较大,熔池明显偏向Q235一侧.

图9为熔池熔合线对比.图9c中左侧熔合线吻合良好,右侧仿真熔池略深而熔宽一致,原因在于模型氩气出口域(区域4)中设置的固定氩气流速(ug)会增大电弧偏向一侧的熔深.

采用两种方式调节GTAW电弧热量. 偏转焊枪与外加横向磁场偏转电弧. 为使异种钢角焊缝焊接电弧向左侧304L不锈钢侧偏转5°,采取以下措施. ①偏转焊枪的方式需要将焊枪向右侧偏转18°;②外加横向磁场偏转电弧的方式所需磁感应强度为25 mT.

图10为两种电弧热量分配方式电弧温度场对比. 如图10a所示,偏转焊枪时,由于角焊缝的狭小空间,钨针偏转侵占了电弧空间,挤压偏向侧电弧,使电弧分散并降低了能量密度; 而外加横向磁场通过洛伦兹力偏转电弧,并不会挤压电弧,如图10b所示.

图11为电弧-熔池耦合模型计算的两种电弧热量分配方式的熔池温度场与实际熔合线. 图11a中,钨针对电弧空间的侵占使电弧热量分散,左侧熔深较浅,右侧熔池较宽. 而类似的情况在图11b中并未发生,这是由于采用外加磁场偏转电弧时,钨针本身不发生偏转,不会挤压电弧而导致热量分散. 对比结果表明,采用外加横向磁场偏转电弧的热量分配方式,不会侵占电弧空间而对电弧造成挤压,电弧热量更集中,焊接成形质量得到提升.

3.2 外加横向磁场下的电弧-熔池形态

通过调节磁感应强度改变电弧偏转角,可以改变两侧母材的热量分配比例,达到焊接质量与熔池形态的改善. 图12为不同磁感应强度下的电弧偏转角度. 图13为不同磁感应强度下的电弧-熔池温度场及熔池熔合线. 图14为不同磁感应强度下的异种钢角焊缝焊接试验获得的熔池轮廓. 熔池尺寸随磁感应强度的变化如图15所示.

无外加磁场时,电弧的磁偏吹使大部分电弧热量作用于Q235一侧,导致304L的熔池较小. 角焊缝熔池大部分位于Q235一侧,Q235侧熔深为3.2 mm,304L侧熔深仅为0.9 mm,磁场的引入改善了这一现象;随着外加磁场的加强,电弧热量向304L偏转,304L获得的电弧热量增加,熔深增大;在外加磁感应强度为15 mT时,两侧熔深与熔宽基本保持一致.

3.3 电弧热输入分布

图16为不同磁感应强度下两侧母材电弧热流密度分布. 由于异种钢焊接时的磁偏吹现象,电弧偏向Q235侧,电弧热流也大部分位于Q235侧. 随着磁感应强度的增大,向Q235侧的偏转角度逐渐减小,Q235侧电弧热流密度逐渐降低,304L侧电弧热流密度逐渐增高. 在磁感应强度B=15 mT时,取得了较好的焊缝质量,此时Q235侧热流密度最大值为1.14 × 107 W/m2,304L侧热流密度最大值为0.95 × 107 W/m2;在磁感应强度B = 20 mT时,电弧偏转角度为0°,此时焊缝两侧热流密度基本相等,最大值为1 × 107 W/m2. 随着磁感应强度继续增大,电弧向304L侧偏转角度加大,导致304L侧热流密度持续升高.

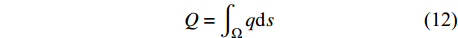

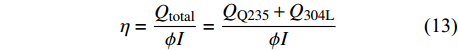

$$ Q = \int_\Omega {q{\rm{d}}s} $$ (12) $$ \eta = \frac{{{Q_{{\rm{total}}}}}}{{\phi I}} = \frac{{{Q_{{\rm{Q}}235}} + {Q_{304{\rm{L}}}}}}{{\phi I}} $$ (13) 式中:B为磁感应强度;I为焊接电流;ϕ为电势;Qtotal为总热输入;Q235为Q235侧热输入;Q304L为304L侧热输入;η为焊接热效率.

利用式(12)分别对两侧热流密度进行积分得到两侧母材热流总量,并由式(13)计算相应的焊接热效率η,计算结果如表2所示.

表 2 不同磁感应强度下电弧热流总量与电弧热效率Table 2. Total arc heat flow and arc thermal efficiency under different magnetic induction intensity磁感应强度

B/mT焊接电流

I/A电势

ϕ/V理论热输出

ϕI/W总热输入

Qtotal/WQ235侧热输入

Q235/WQ304L侧热输入

Q304L/W焊接热效率

η(%)0 120 9.2 1104 750.72 457.4 293.32 68.0 5 120 9.3 1116 762.3 441.6 320.68 68.3 10 120 9.6 1152 794.9 454 340.9 69.0 15 120 9.9 1188 825.66 440.8 384.86 69.5 20 120 10.2 1224 869.04 436 433.04 71.0 25 120 9.9 1188 831.6 389.6 442.05 70 30 120 9.5 1140 790.02 330.7 459.32 69.3 35 120 9.4 1128 772.68 304.3 468.38 68.5 外加磁场磁感应强度为15 mT时,两侧母材的热流密度均取得较大值,两侧熔宽与熔深基本保持一致,取得了较好的焊缝质量,可判断为电弧热输入分配合理,此时电弧热流总量为825.66 W,Q235侧所占热流总量为440.8 W,304L侧热流总量为384.86 W; 在外加磁场磁感应强度为20 mT时,电弧热流总量最大,此时两侧母材的电弧热量分布基本相等. 焊接热效率随电弧偏转角度减小而变大,在外加磁场磁感应强度为20 mT时,电弧偏转角度为0°,此时焊接热效率最大(为71%).

图17为不同磁感应强度下焊缝两侧热流总量及所占比例. 无外加磁场时,受磁偏吹的影响,Q235侧电弧热流占总热量的61%,而304L不锈钢侧仅占39%;随着外加磁场磁感应强度的逐渐增强,Q235低碳钢侧电弧热流总量不断降低,所占总热量的比例也不断降低,304L侧不锈钢所占比例逐渐升高. 在磁感应强度为15 mT时,取得较好的焊接质量,此时Q235侧电弧热流总量占53.4%,304L侧电弧热流总量占46.6%;在磁感应强度为20 mT时,两侧所占比例相等.

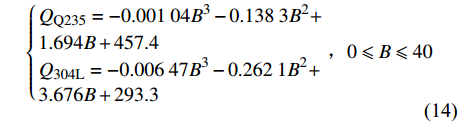

对图17中的不同磁感应强度下热流总量进行数值拟合,建立热流总量与外加磁感应强度的回归方程,如式(14)所示.

$$ \left\{ \begin{gathered} {Q_{{\rm{Q}}235}} = - 0.001\;04{B^3} - 0.138\;3{B^2} + \\ 1.694B + 457.4 \\ {Q_{304{\rm{L}}}} = - 0.006\;47{B^3} - 0.262\;1{B^2} + \\ 3.676B + 293.3 \\ \end{gathered} \right.,{0 \leqslant B \leqslant 40} $$ (14) 4. 结论

(1) 建立了异种钢角焊缝GTAW电弧-熔池耦合模型,揭示了磁偏吹以及两种电弧热输入调节方式对异种钢焊接熔池成形的影响.

(2) 偏转焊枪与外加横向磁场偏转电弧两种电弧热输入分配结果表明,偏转焊枪会导致能量密度降低,不适合角焊缝等焊缝空间狭小的焊缝;而外加横向磁场偏转电弧可更好地实现在狭小空间的电弧热输入分配.

(3) 在外加横向磁场磁感应强度为15 mT时获得了较好的角焊缝质量,此时Q235侧电弧热流总量占53.4%,304L侧电弧热流总量占46.6%.

-

表 1 模型边界条件

Table 1 Model boundary condition

区域 速度v/(m·s−1) 温度T/K 磁矢势A/Tm 电势ϕ/V 区域1 ug 1 000 ∂A/∂n=0 ∂ϕ/∂n=0 区域2 — T0 ∂A/∂n=0 0 区域3 — T0 ∂A/∂n=0 0 区域4 — 1 000 ∂A/∂n=0 ∂ϕ/∂n=0 区域5 — 3 000 ∂A/∂n=0 n·j=−I(t)/πRc2 表面1 — 式(11) — — 表面2 — 式(11) — — 表面3 — 式(10) — — 表 2 不同磁感应强度下电弧热流总量与电弧热效率

Table 2 Total arc heat flow and arc thermal efficiency under different magnetic induction intensity

磁感应强度

B/mT焊接电流

I/A电势

ϕ/V理论热输出

ϕI/W总热输入

Qtotal/WQ235侧热输入

Q235/WQ304L侧热输入

Q304L/W焊接热效率

η(%)0 120 9.2 1104 750.72 457.4 293.32 68.0 5 120 9.3 1116 762.3 441.6 320.68 68.3 10 120 9.6 1152 794.9 454 340.9 69.0 15 120 9.9 1188 825.66 440.8 384.86 69.5 20 120 10.2 1224 869.04 436 433.04 71.0 25 120 9.9 1188 831.6 389.6 442.05 70 30 120 9.5 1140 790.02 330.7 459.32 69.3 35 120 9.4 1128 772.68 304.3 468.38 68.5 -

[1] Yin Yan, Kang Ping, Zhang Ruihua, et al. Effect of heat treatment on microstructure and properties of VG10 and 3Cr13 dissimilar welded joints[J]. China Welding, 2021, 30(1): 21 − 29.

[2] Dak G, Pandey C. A critical review on dissimilar welds joint between martensitic and austenitic steel for power plant application[J]. Journal of Manufacturing Processes, 2020, 58: 377 − 406. doi: 10.1016/j.jmapro.2020.08.019

[3] Maurya A K, Pandey C, Chhibber R. Dissimilar welding of duplex stainless steel with Ni alloys: A review[J]. International Journal of Pressure Vessels and Piping, 2021, 192: 104439. doi: 10.1016/j.ijpvp.2021.104439

[4] Echezona N, Akinlabi S A, Jen T C, et al. TIG welding of dissimilar steel: A review[C]// Advances in Material Science and Engineering: Selected Articles from ICMMPE , 2020: 1-9.

[5] 郑韶先, 曾道平, 孟倩, 等. 填充ER309焊丝的异种钢接头二型边界形成机理[J]. 焊接学报, 2021, 42(4): 56 − 61. doi: 10.12073/j.hjxb.20200902001 Zheng Shaoxian, Zeng Daoping, Meng Qian, et al. Formation mechanism analysis of the type-II boundary of dissimilar steel joint with the filler metal of ER309[J]. Transactions of the China Welding Institution, 2021, 42(4): 56 − 61. doi: 10.12073/j.hjxb.20200902001

[6] 王海燕, 牛春菊, 崔国涛, 等. 焊接工艺对TP304/SS400异种钢焊接接头组织和性能的影响[J]. 焊接学报, 2019, 40(5): 131 − 136. doi: 10.12073/j.hjxb.2019400140 Wang Haiyan, Niu Chunju, Cui Guotao, et al. Effect of welding process on microstructure and properties of welded joint of TP304/SS400 dissimilar steel[J]. Transactions of the China Welding Institution, 2019, 40(5): 131 − 136. doi: 10.12073/j.hjxb.2019400140

[7] 郭舒, 王海涛, 韩恩厚. 核电站接管安全端异种金属焊接接头残余应力预测的研究现状[J]. 机械工程材料, 2021, 45(10): 1 − 12. doi: 10.11973/jxgccl202110001 Guo Shu, Wang Haitao, Han Enhou. Research status of residual stress prediction of dissimilar metal welded Joint at safetye end of nozzles in nuclear power plants[J]. Materials for Mechanical Engineering, 2021, 45(10): 1 − 12. doi: 10.11973/jxgccl202110001

[8] 杨庆旭, 王学, 马君鹏, 等. 超超临界锅炉水冷壁T23/12Cr1MoV异种钢焊接接头焊后热处理裂纹分析[J]. 金属热处理, 2021, 46(7): 218 − 222. Yang Qingxu, Wang Xue, Ma Junpeng, et al. Post-weld heat treatment crack analysis of water wall T23/12Cr1MoV dissimilar steel welded joint of ultra-supercritical boiler[J]. Heat Treatment of Metals, 2021, 46(7): 218 − 222.

[9] Rakesh C, Asha I, Kanak K. Stress analysis of dissimilar metal weld between carbon steel and stainless steel formed by transition grading technique[J]. Materials Today: Proceedings, 2015, 2(4-5): 1657 − 1664.

[10] 蔡建鹏, 叶延洪, 张彦杰, 等. 坡口形式对Q345/SUS304异种钢对接接头残余应力和变形的影响[J]. 机械工程学报, 2015, 51(10): 55 − 61. doi: 10.3901/JME.2015.10.055 Cai Jianpeng, Ye Yanhong, Zhang Yanjie, et al. Effect of groove form on residual stress and deformation of butt joint of Q345/SUS304 dissimilar steel[J]. Journal of Mechanical Engineering, 2015, 51(10): 55 − 61. doi: 10.3901/JME.2015.10.055

[11] Rong Y M, Xu J J, Lei T, et al. Magnetism aided mitigation of deformation and residual stress in dissimilar joint 316L with EH36[J]. Journal of Materials Processing Technology, 2018, 259: 23 − 32. doi: 10.1016/j.jmatprotec.2018.04.022

[12] Li R, Yuan X J, Zhang H B, et al. Effect of axial magnetic field on TIG welding-brazing of AA6061 aluminum alloy to HSLA350 steel[J]. Journal of Materials Research and Technology-Jmr & T, 2021, 12: 882 − 893.

[13] Yan F, Wang X W, Chai F, et al. Improvement of microstructure and performance for steel/Al welds produced by magnetic field assisted laser welding[J]. Optics and Laser Technology, 2019, 113: 164 − 170.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: