Effect of vibration amplitude on ultrasonic welding of Cu/Al

-

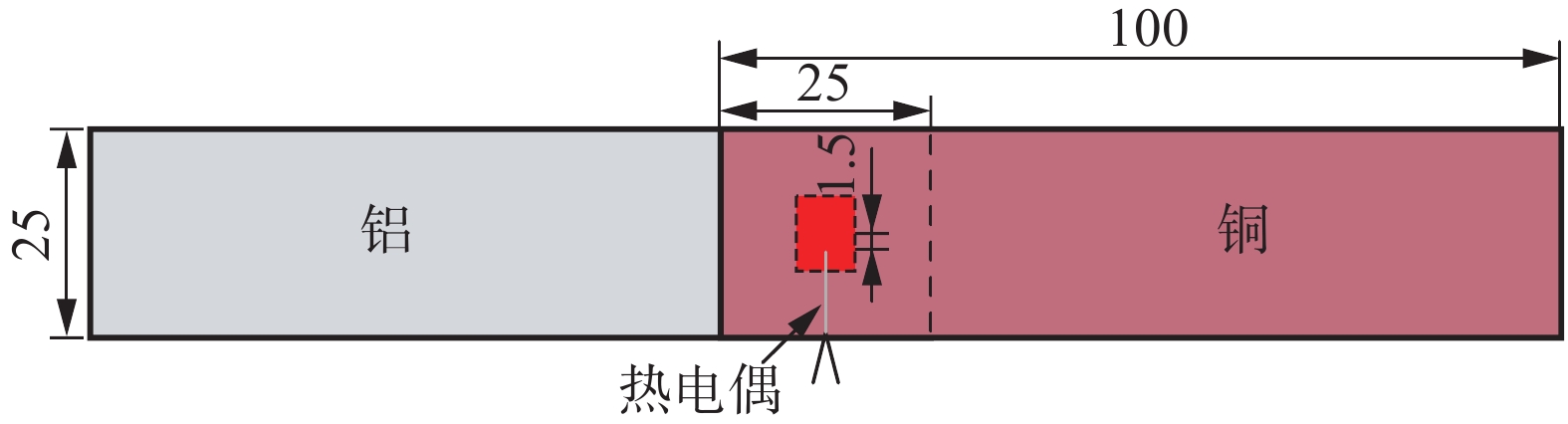

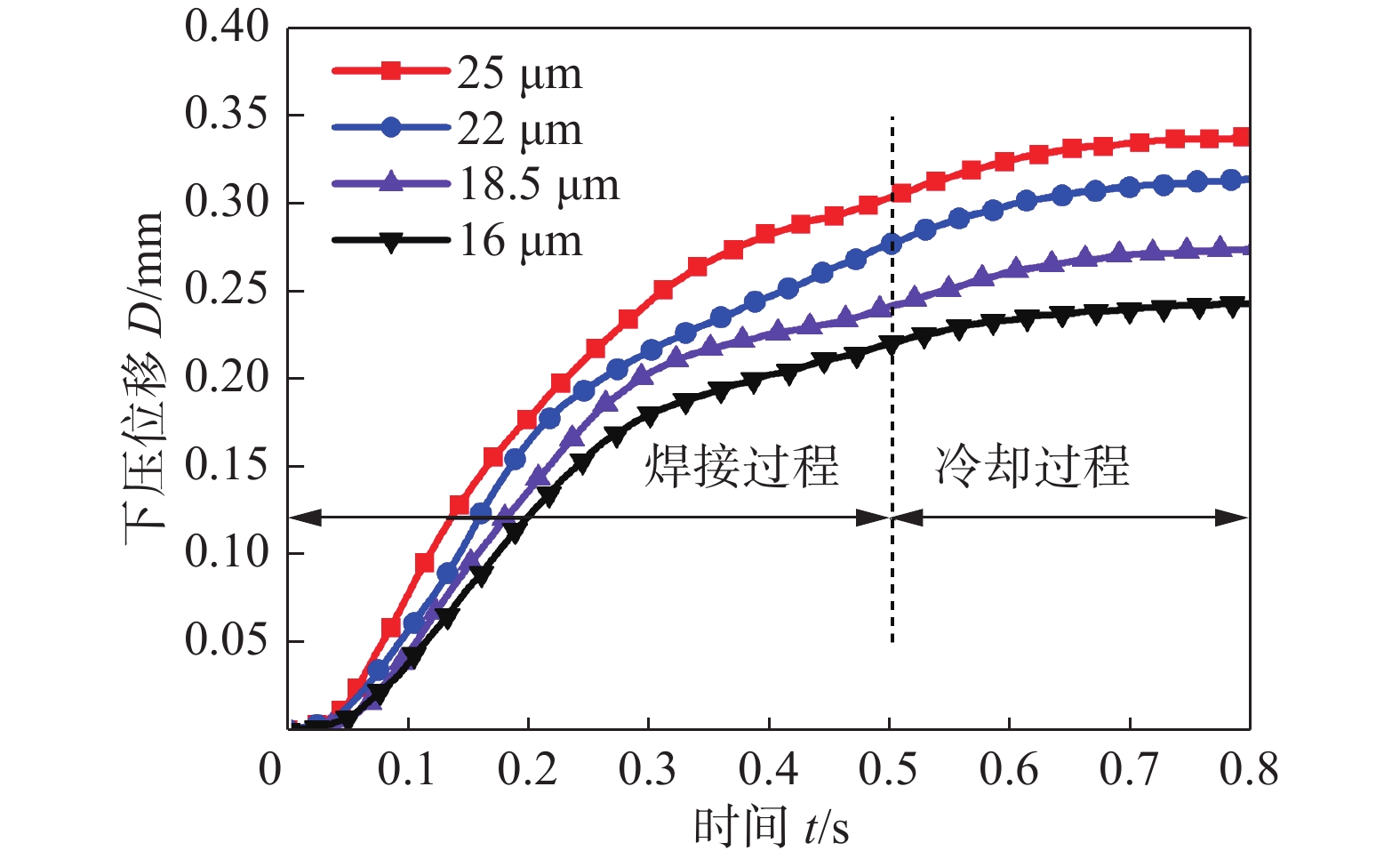

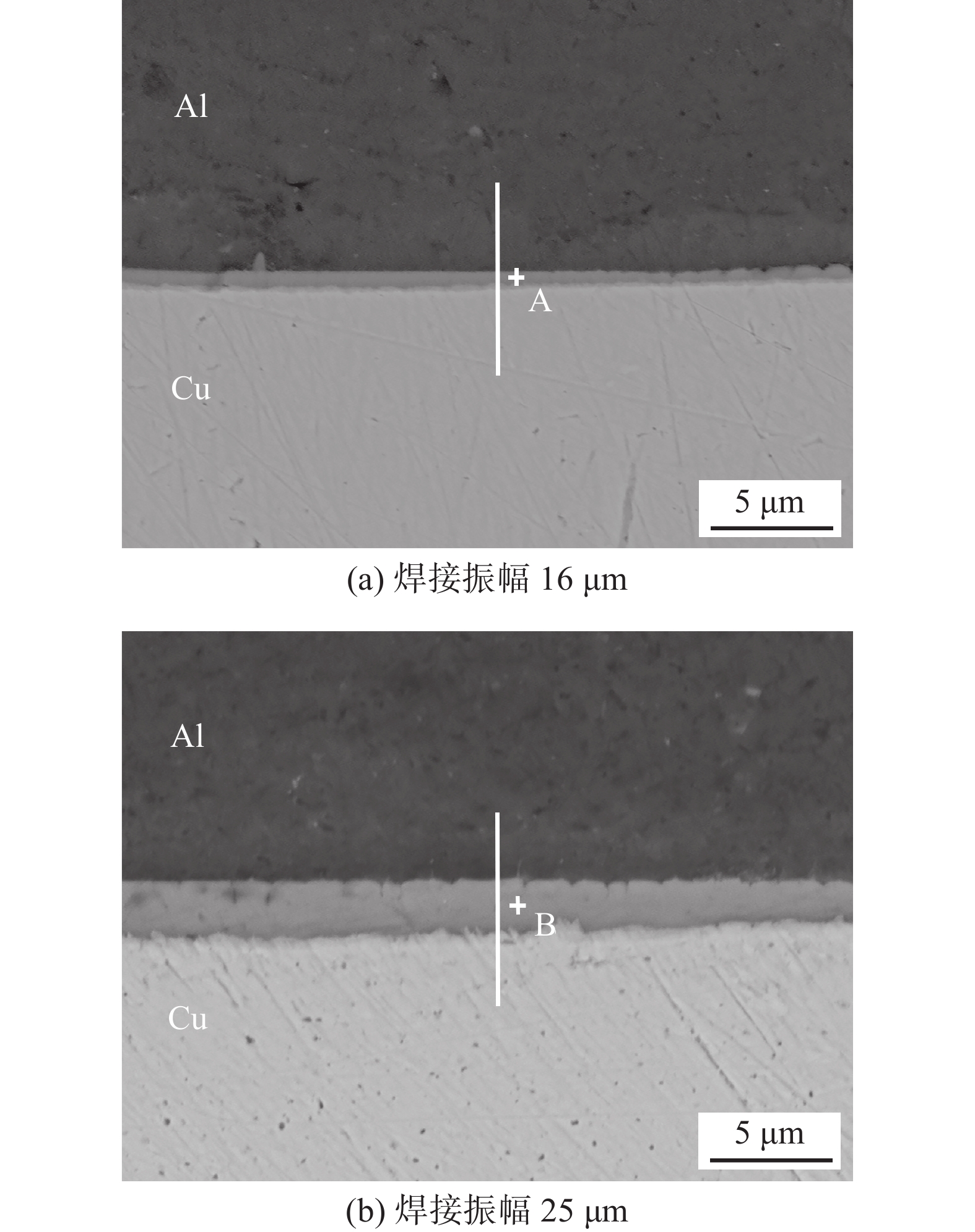

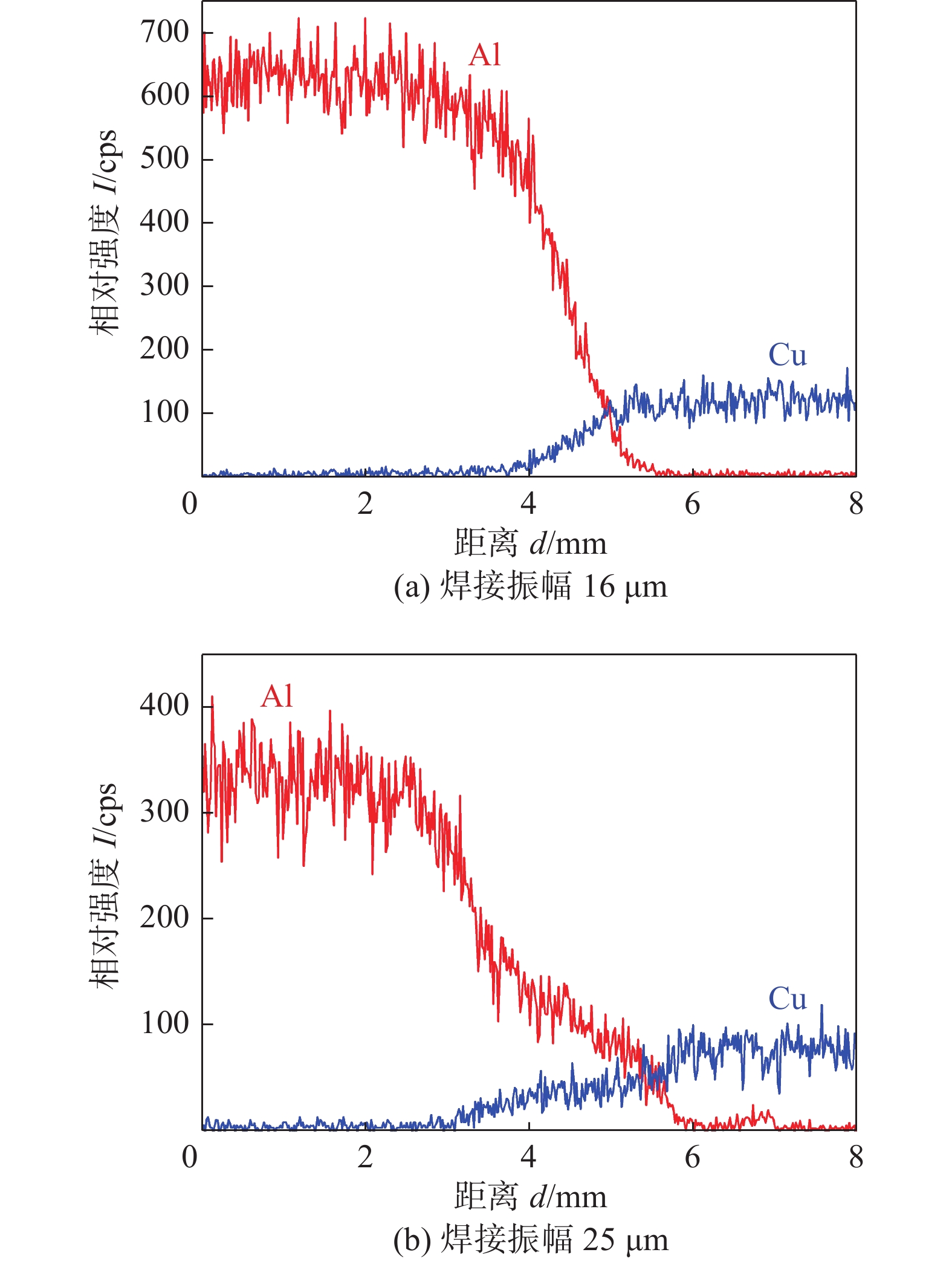

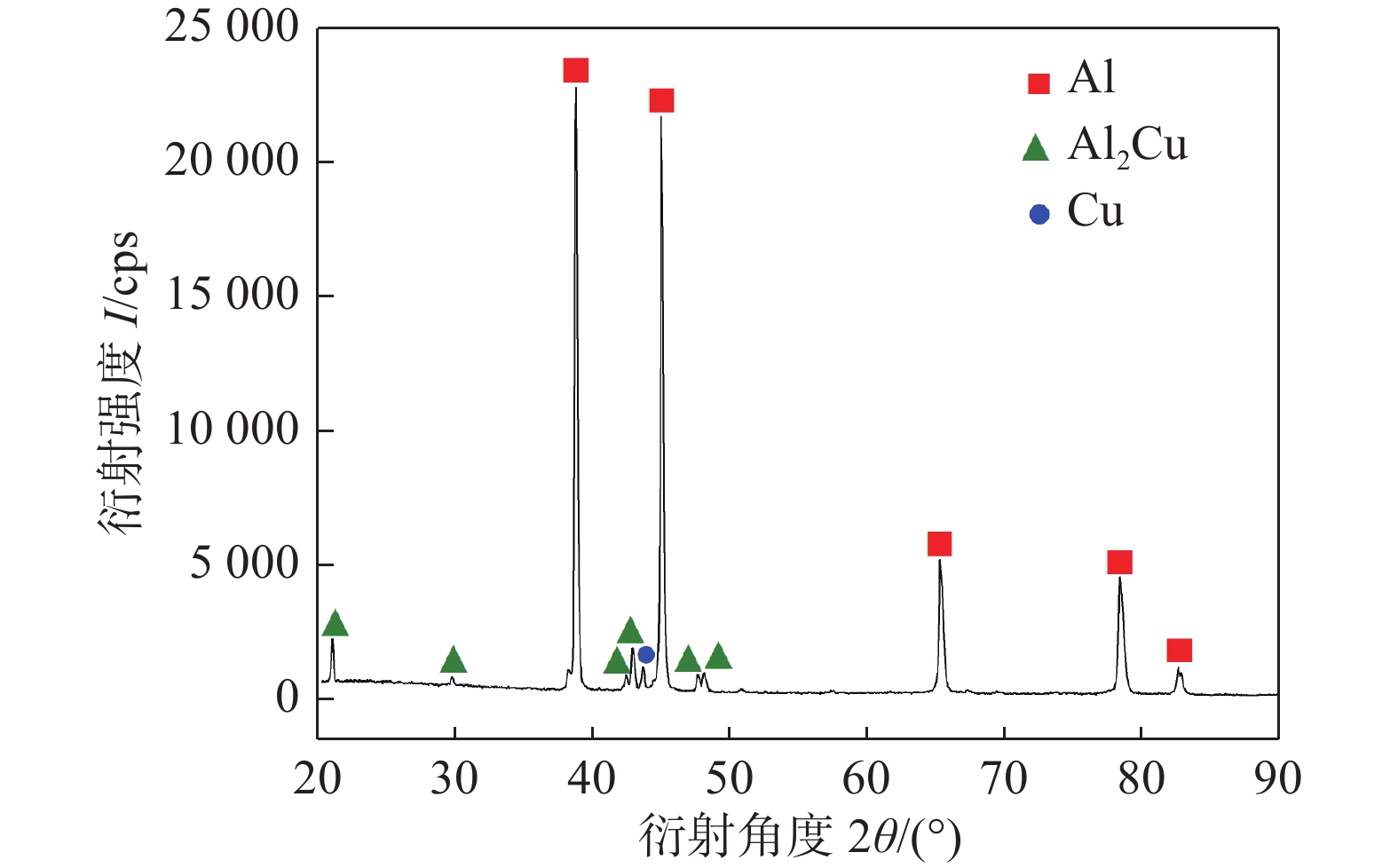

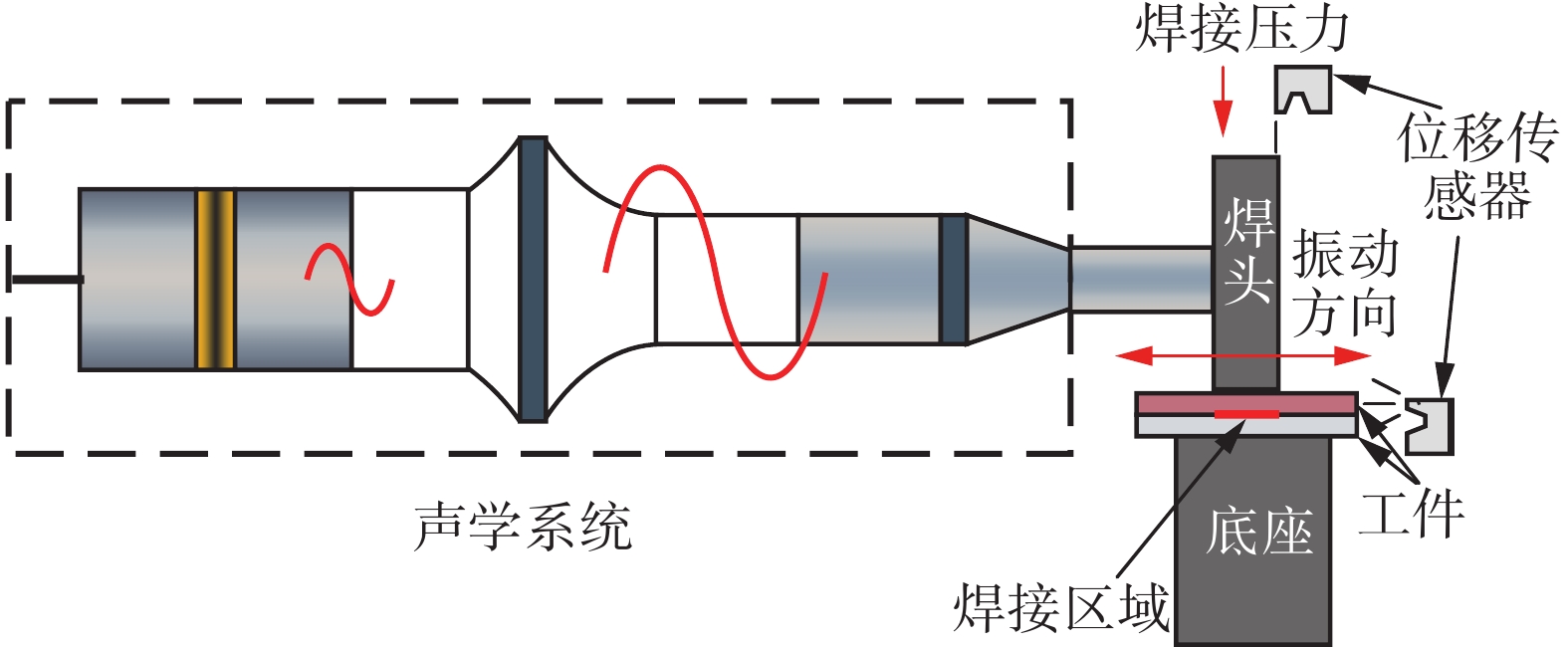

摘要: 焊接振幅是超声波焊接的主要参数,但目前关于焊接振幅对超声波焊接影响机制的认识较少. 研究了焊接振幅对铜/铝超声波焊接过程,包括工件的振幅分配、界面温度、中间相分布、材料塑性变形以及接头性能的影响. 结果表明,在焊接压力1 575 N、焊接时间0.5 s时,随着焊接振幅增大,上工件振幅呈现近似线性增长;下工件振幅在焊接过程中均呈现逐渐近似线性增加的趋势. 在整个焊接过程中,焊接振幅越大,下工件的振幅越高. 在焊接振幅为25 μm时,获得了最大拉剪力为3150 N的铜/铝接头. 高的焊接振幅提升了焊头与上工件以及工件之间的相对运动速度,加速了焊接界面的温度升高及材料的塑性变形,增强了界面原子的扩散,最终促进了较高质量的铜/铝超声波焊接接头的形成.Abstract: Vibration amplitude is an important parameter of ultrasonic welding, but insights into the influence mechanism of vibration amplitude on ultrasonic welding are few. The effects of vibration amplitude on the process of Cu/Al ultrasonic welding were investigated in this study, including vibration amplitude distribution of specimens, interfacial temperature, intermediate phase distribution, materials plastic deformation, and properties of joint. The results show that under the welding pressure of 1575 N and welding time of 0.5 s, with the increase of welding amplitude, the vibration amplitudes of the upper specimen exhibit a linear growth, and the amplitudes of the lower specimen tend to show a near-linear growth. During the welding process, the higher the vibration amplitude, the higher the vibration amplitude of the lower specimen is. When the vibration amplitude is set at 25 μm, a Cu/Al joint is obtained with a maximum tensile-shear force of 3150 N. High vibration amplitude has increased the relative motion speed among the sonotrode, the upper specimen and the specimen, which has sped up the temperature rise in the welding interface and the plastic deformation of the material, thus accelerated the interfacial atoms diffusion and promoted the formation of high quality Cu/Al ultrasonic welding joints.

-

Keywords:

- ultrasonic welding /

- amplitude /

- plastic deformation /

- microstructure /

- mechanical property

-

-

图 4 材料物理属性[15]

Figure 4. Material properties. (a) thermophysical properties; (b) mechanical properties

-

[1] Hu G F, Huang P F, Bai Z H, et al. Comprehensively analysis the failure evolution and safety evaluation of automotive lithium ion battery[J]. eTransportation, 2021, 10(11): 100140.

[2] Liu J, Cao B, Yang J W. Texture and intermetallic compounds of the Cu/Al dissimilar joints by high power ultrasonic welding[J]. Journal of Manufacturing Processes, 2022, 76(4): 34 − 45.

[3] 于江, 潘俊林, 苗惺林, 等. 铝/铜异种金属电阻热辅助超声波缝焊工艺特性[J]. 焊接学报, 2022, 43(7): 76 − 81. doi: 10.12073/j.hjxb.20220124001 Yu Jiang, Pan Junlin, Miao Xinglin, et al. Process characteristics of the resistance heat-assisted ultrasonic seam welding of aluminum alloy and copper dissimilar metals[J]. Transactions of the China Welding Institution, 2022, 43(7): 76 − 81. doi: 10.12073/j.hjxb.20220124001

[4] Leon M D, Shin H S. Review of the advancements in aluminum and copper ultrasonic welding in electric vehicles and superconductor applications[J]. Journal of Materials Processing Technology, 2022, 307(6): 117691.

[5] Yan S H, Shi Y. Influence of laser power on microstructure and mechanical property of laser-welded Al/Cu dissimilar lap joints[J]. Journal of Manufacturing Processes, 2019, 45(9): 312 − 321.

[6] Das A, Masters I, Williams D. Process robustness and strength analysis of multi-layered dissimilar joints using ultrasonic metal welding[J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1-4): 881 − 900. doi: 10.1007/s00170-018-2936-3

[7] Elkjaer A, Sorhaug J A, Ringen G, et al. Electrical and thermal stability of Al-Cu welds: Performance benchmarking of the hybrid metal extrusion and bonding process[J]. Journal of Manufacturing Processes, 2022, 79(7): 626 − 638.

[8] Feng M N, Yan X, Zhao C F, et al. Microstructure and mechanical performance of ultrasonic spot welded open-cell Cu foam/Al joint[J]. Journal of Manufacturing Processes, 2018, 33(6): 86 − 95.

[9] 柳健, 杨景卫, 曹彪, 等. 铜/铜超声波焊接的相对运动及断面微观演变[J]. 焊接学报, 2018, 39(9): 41 − 44. Liu Jian, Yang Jingwei, Cao Biao, et al. Relative motion and its relation to microstructure evolution during high-power ultrasonic welding of copper sheets[J]. Transactions of the China Welding Institution, 2018, 39(9): 41 − 44.

[10] 李东, 赵杨洋, 张延松. 焊接能量对铝/铜超声波焊接接头显微组织的影响[J]. 焊接学报, 2014, 35(2): 47 − 50. Li Dong, Zhao Yangyang, Zhang Yansong. Effect of welding energy on microstructures of the Al /Cu joints obtained by ultrasonic welding[J]. Transactions of the China Welding Institution, 2014, 35(2): 47 − 50.

[11] 谷晓燕, 刘东锋, 刘婧, 等. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600 − 1607. Gu Xiaoyan, Liu Dongfeng, Liu Jing, et al. Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(5): 1600 − 1607.

[12] Cheng X M, Yang K, Wang J, et al. Ultrasonic system and ultrasonic metal welding performance: A status review[J]. Journal of Manufacturing Processes, 2022, 84(12): 1196 − 1216.

[13] Kong C Y, Soar R C, Dickens P M. Characterisation of aluminium alloy 6061 for the ultrasonic consolidation process[J]. Materials Science & Engineering: A, 2003, 363(1-2): 99 − 106. doi: 10.1016/S0921-5093(03)00590-2

[14] Shin H S, De Leon M. Parametric study in similar ultrasonic spot welding of A5052-H32 alloy sheets[J]. Journal of Materials Processing Technology, 2015, 224(10): 222 − 232.

[15] Li H, Cao B, Liu J, et al. Modeling of high-power ultrasonic welding of Cu/Al joint[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(1-4): 833 − 844. doi: 10.1007/s00170-018-2002-1

[16] 李欢. 基于数值模拟的超声焊及电阻热辅助超声焊过程研究[D]. 广州: 华南理工大学, 2018. Li Huan. Study of the ultrasonic welding and resistance heat assisted welding process based on simulation analysis[D]. Guangzhou: South China University of Technology, 2018.

[17] Wang Y X, Ao S S, Zhang W, et al. Numerical simulation of ultrasonic spot welding of superelastic NiTi alloys: Temperature distribution and deformation behavior[J]. Journal of Manufacturing Science and Engineering, 2022, 144(8): 081003. doi: 10.1115/1.4053523

[18] 李欢, 周亢, 曹彪, 等. 铝合金大功率超声波焊接界面及接头性能研究[J]. 机械工程学报, 2021, 57(6): 87 − 95. doi: 10.3901/JME.2021.06.087 Li Huan, Zhou Kang, Cao Biao, et al. Analysis of welding interface and joint properties of high power ultrasonic welding of aluminum alloy[J]. Journal of Mechanical Engineering, 2021, 57(6): 87 − 95. doi: 10.3901/JME.2021.06.087

[19] Ni Z L, Yang J J, Gao Z T, et al. Joint formation in ultrasonic spot welding of aluminum to copper and the effect of particle interlayer[J]. Journal of Manufacturing Processes, 2020, 50(2): 57 − 67.

[20] Levine L. The ultrasonic wedge bonding mechanism: Two theories converge[C]//SPIE-The International Society for Optical Engineering. Proceedings of SPIE. Austin, United States, 1995: 242 − 246.

[21] Satpathy M P, Sahoo S K. Microstructural and mechanical performance of ultrasonic spot welded Al-Cu joints for various surface conditions[J]. Journal of Manufacturing Processes, 2016, 22(4): 108 − 114.

[22] Ma Q C, Song C, Zhou J L, et al. Dynamic weld evolution during ultrasonic welding of Cu-Al joints[J]. Materials Science & Engineering: A, 2021, 823(8): 141724.

-

期刊类型引用(2)

1. 张超,周猛兵,崔雷,陶欣,王军,王伟,刘永长. 9Cr-1.5W-0.15Ta耐热钢搅拌摩擦焊焊缝组织和冲击性能分析. 焊接学报. 2024(04): 36-42+131 .  本站查看

本站查看

2. 王猛,张立平,赵琳瑜,吴军,熊然,蒙永胜,李军红. 增材制造和锻造TC11钛合金激光焊接头组织与力学性能. 焊接学报. 2023(10): 102-110+138-139 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: