Study on the reactive wetting process of TiZrNiCu on TA1/TC4 heterogeneous interface

-

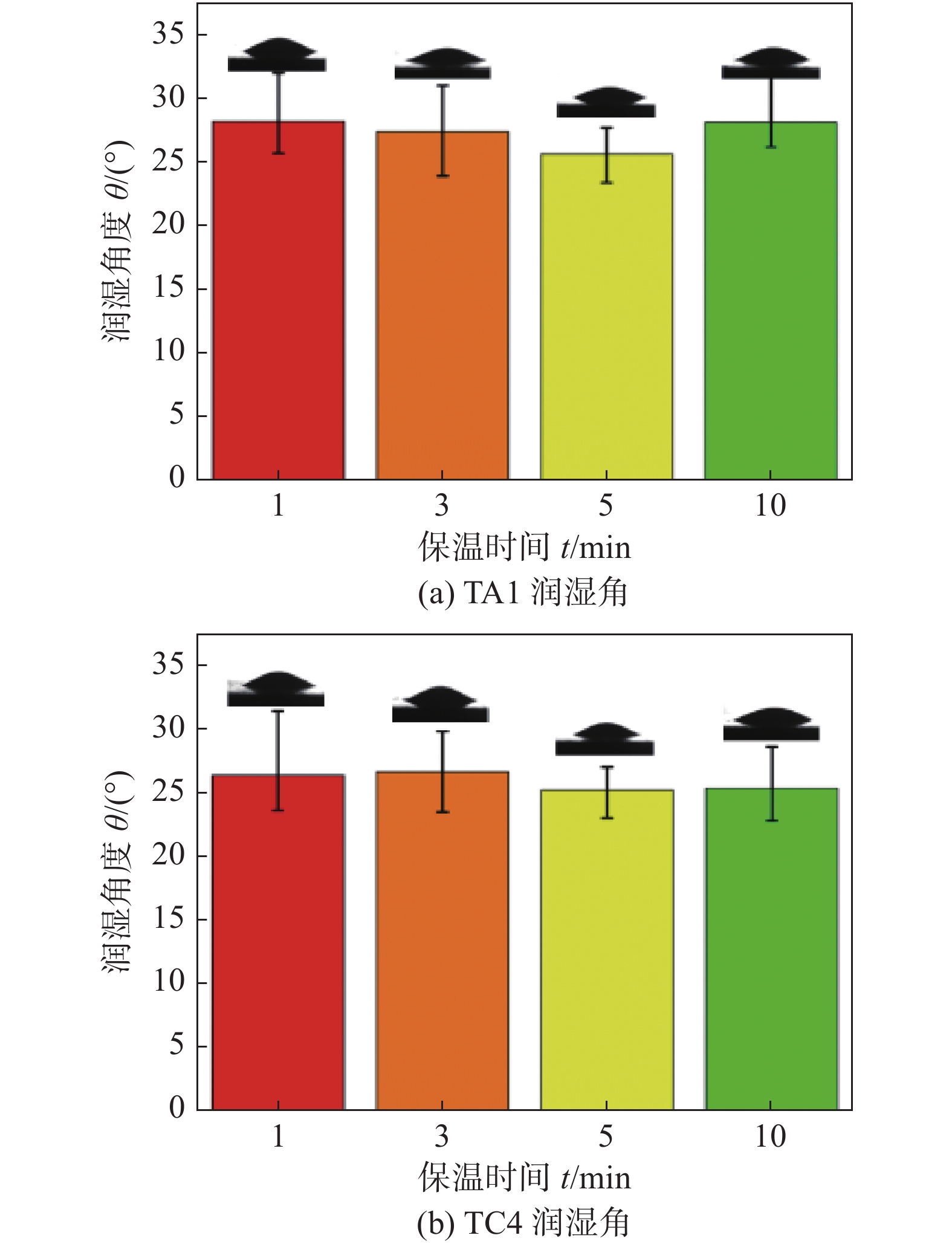

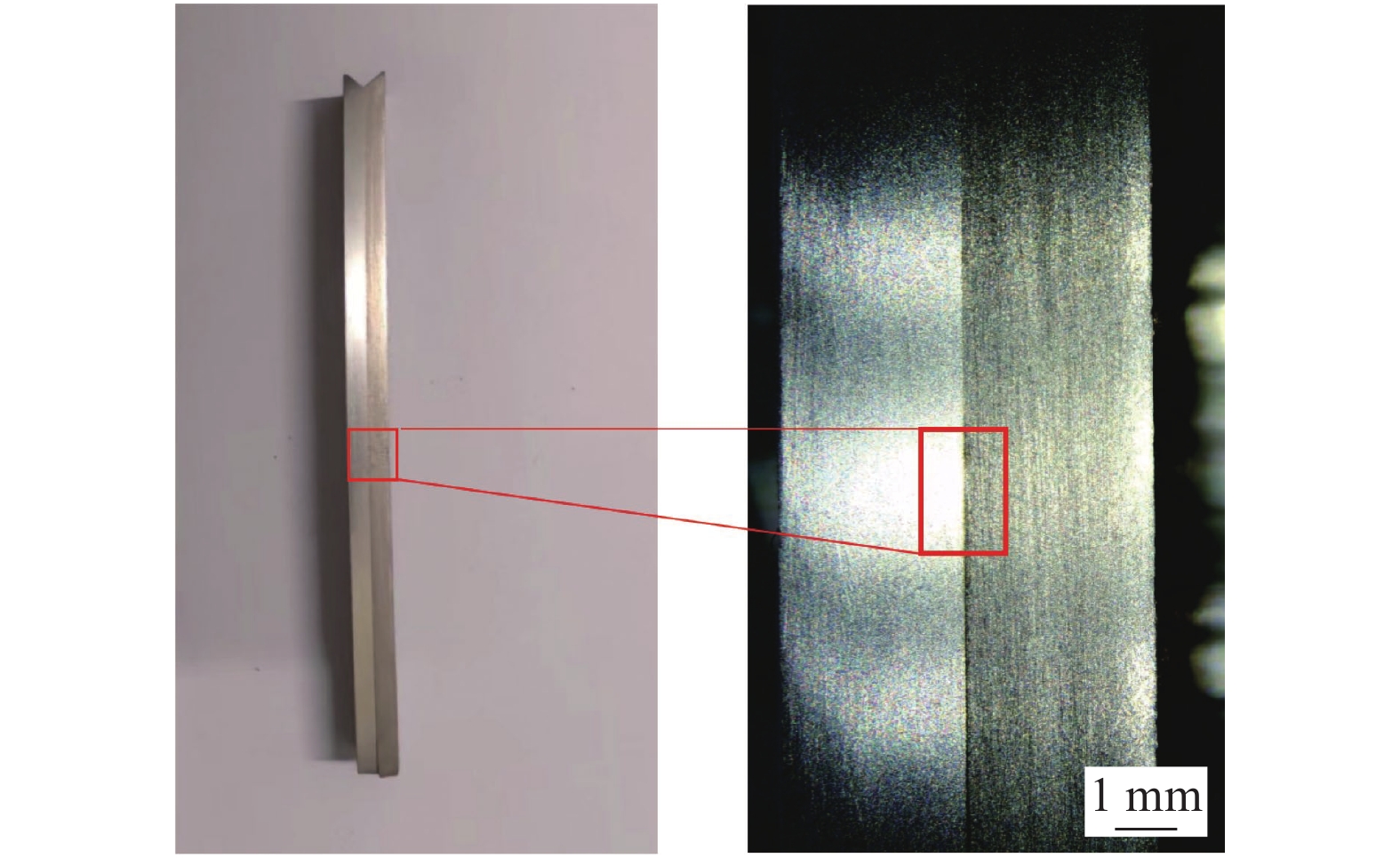

摘要: 试验采用Ti51ZrNiCu钎料,研究其在TA1/TC4异质界面的反应润湿过程,使用扫描电子显微镜(SEM)、能谱分析仪(EDS)及润湿角测量仪等分析方法研究了不同表面的润湿界面组织结构,并总结了试验参数对组织结构和润湿能力的影响规律. 而后进行了填缝试验,用于衡量Ti51ZrNiCu钎料在TA1/TC4异质界面的润湿铺展能力,总结了钎料填充经验公式. 结果表明,在试验参数为935 ℃/3 min的条件下,TiZrNiCu钎料对TA1和TC4母材填充能力可简化为经验公式:h = 4 000/a,其中钎缝间隙a的单位为μm,爬升高度h单位为mm.

-

关键词:

- TC4合金 /

- TA1合金 /

- TiZrNiCu钎料 /

- 润湿 /

- 填缝试验

Abstract: Ti51ZrNiCu filler alloy was used to study the reactive wetting process on TA1/TC4 heterogeneous interface. The interfacial microstructure of different surfaces was studied by scanning electron microscope(SEM), energy dispersive spectrometer(EDS) and wetting angle measuring instrument. And the influences of experiment parameters on interfacial microstructure and wettability were summarized. The filling experiment was finished to evaluate the wetting and spreading ability of TiZrNiCu on TA1/TC4 heterogeneous interface. The empirical equation of filling experiment was summarized. The empirical equation, h = 4000/a, was used to assess filling ability of TiZrNiCu on TA1/TC4 heterogeneous interface at 935 ℃ for 3 min. In this empirical equation, the unit of brazing gap a is μm, and the unit of climbing height h is mm.-

Keywords:

- TC4 alloy /

- TA1 alloy /

- TiZrNiCu filler alloy /

- wetting behaviour /

- filling experiment

-

-

表 1 TiZrNiCu钎料化学成分(质量分数, %)

Table 1 Chemical composition of TiZrNiCu filler alloy

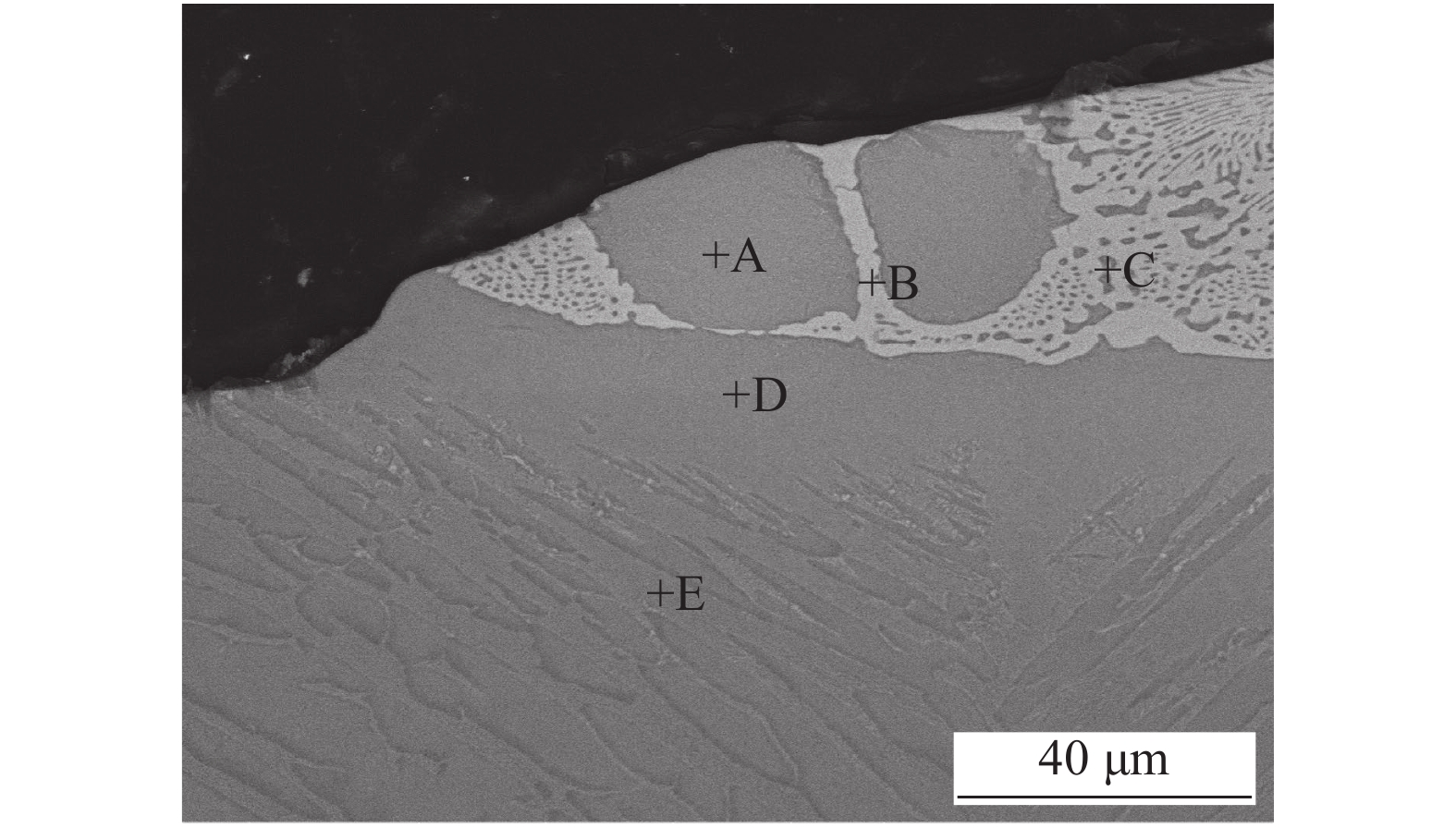

Ti Zr Ni Cu 余量 27±3 15±2 7±1.5 表 2 图2中A ~ E点能谱结果(原子分数,%)

Table 2 EDS results of A ~ E spots in Fig.2

位置 Ti Zr Ni Cu 可能的相 A 81.96 13.79 2.97 1.28 α-Ti B 44.09 20.40 24.14 11.37 (Ti,Zr)2(Ni,Cu) C 61.81 15.33 10.12 12.74 β-Ti D 80.72 9.19 6.85 3.24 α-Ti E 96.51 1.71 0.53 1.24 α-Ti 表 3 图3中A' ~ C'点能谱结果(原子分数,%)

Table 3 EDS results of A' ~ C' spots in Fig.3

位置 Ti Zr Ni Cu 可能的相 A' 82.50 11.99 2.40 3.11 α-Ti B' 41.93 20.85 26.69 10.53 (Ti,Zr)2(Ni,Cu) C' 62.61 13.59 12.19 11.61 β-Ti -

[1] 郭鲤, 何伟霞, 周鹏, 等. 我国钛及钛合金产品的研究现状及发展前景[J]. 热加工工艺, 2020, 49(22): 22 − 28. doi: 10.14158/j.cnki.1001-3814.20192060 Guo Li, He Weixia, Zhou Peng, et al. Research status and development prospect of titanium and titanium alloy products in China[J]. Hot Working Technology, 2020, 49(22): 22 − 28. doi: 10.14158/j.cnki.1001-3814.20192060

[2] 洪权, 郭萍, 周伟. 钛合金成形技术与应用[J]. 钛工业进展, 2022, 39(5): 27 − 32. doi: 10.13567/j.cnki.issn1009-9964.2022.05.010 Hong Quan, Guo Ping, Zhou Wei. Forming technique and application of titanium alloy[J]. Titanium Industry Progress, 2022, 39(5): 27 − 32. doi: 10.13567/j.cnki.issn1009-9964.2022.05.010

[3] Li Peng, Dong Honggang, Xia Yueqing, et al. Inhomogeneous interface structure and mechanical properties of rotary friction welded TC4 titanium alloy/316L stainless steel joints[J]. Journal of Manufacturing Processes, 2018, 33: 54 − 63. doi: 10.1016/j.jmapro.2018.05.001

[4] Lee M K, Park J J, Lee J G, et al. Phase-dependent corrosion of titanium-to-stainless steel joints brazed by Ag-Cu eutectic alloy filler and Ag interlayer[J]. Journal of Nuclear Materials, 2013, 439(1-3): 168 − 173. doi: 10.1016/j.jnucmat.2013.04.002

[5] 陈国庆, 张秉刚, 武振周, 等. TiAl /Ti60 电子束焊接接头组织及性能[J]. 焊接学报, 2009, 30(12): 41 − 44. doi: 10.3321/j.issn:0253-360X.2009.12.011 Chen Guoqing, Zhang Binggang, Wu Zhenzhou, et al. Microstructure and mechanical properties of electron beam welded dissimilar TiAl /Ti60 joint[J]. Transactions of the China Welding Institution, 2009, 30(12): 41 − 44. doi: 10.3321/j.issn:0253-360X.2009.12.011

[6] Liu Guanpeng, Li Yulong, Lei Min, et al. A novel method for fabricating micron-scale porous structure on the surface of commercially-pure Ti[J]. Materials Letters, 2021, 294: 129802. doi: 10.1016/j.matlet.2021.129802

[7] 毕宗岳, 杨军, 刘海璋, 等. TA1/X65复合板焊接工艺及焊缝组织和性能研究[J]. 金属学报, 2016, 52(8): 1017 − 1024. Bi Zongyue, Yang Jun, Liu Haizhang, et al. Investigation on the welding process and microstructure and mechanical property of butt joints of TA1/X65 clad plate[J]. Acta Metallurgica Sinica, 2016, 52(8): 1017 − 1024.

[8] 刘松. TiZrCuNi钎料真空钎焊纯钛TA1接头界面的显微组织和钎料元素扩散行为[J]. 机械工程材料, 2020, 44(1): 33 − 38. doi: 10.11973/jxgccl202001006 Liu Song. Microstructure and filler metal element diffusion behavior of TiZrCuNi filler metal vacuum brazing pure titanium TA1 joint interface[J]. Materials for Mechanical Engineering, 2020, 44(1): 33 − 38. doi: 10.11973/jxgccl202001006

[9] Liu Shilei, MiaoJiakai, Zhang Weiwei, et al. Interfacial microstructure and shear strength of TC4 alloy joints vacuum brazed with Ti–Zr–Ni–Cu filler metal[J]. Materials Science & Engineering A, 2020, 775: 1 − 10.

[10] Yang Zhenwen, Chen Yuhan, Niu Shiyu, et al. Phase transition, microstructural evolution and mechanical properties of Ti-6Al-4V and Ti-6.5Al-3.5Mo-1.5Zr-0.3Si joints brazed with Ti-Zr-Ni-Cu filler metal[J]. Archives of Civil and Mechanical Engineering, 2020, 20(3): 1 − 15.

[11] Ganjeh E, Sarkhosh H. Microstructural mechanical and fractographical study of titanium-CP and Ti–6Al–4V similar brazing with Ti-based filler[J]. Materials Science & Engineering A, 2013, 559: 119 − 129.

[12] Lin Qiaoli, Xie Kaibin, Ran Sui, et al. Kinetic analysis of wetting and spreading at high temperatures: A review[J]. Advances in Colloid and Interface Science, 2022, 305: 1 − 17.

[13] Jing Yongjuan , Yue Xishan, Gao Xingqiang, et al. The influence of Zr content on the performance of TiZrCuNi brazing filler[J]. Materials Science & Engineering: A, 2016, 678(15): 190 − 196.

[14] 冯吉才. 异种材料连接研究进展综述[J]. 航空学报, 2022, 43(2): 1 − 37. doi: 10.7527/j.issn.1000-6893.2022.2.hkxb202202001 Feng Jicai. Research progress on dissimilar materials joining[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(2): 1 − 37. doi: 10.7527/j.issn.1000-6893.2022.2.hkxb202202001

[15] Qiu Qiwen, Wang Ying, Yang Zhenwen. Microstructure and mechanical properties of TiAl alloy joints vacuum brazed with Ti–Zr–Ni–Cu brazing powder without and with Mo additive[J]. Materials & Design, 2016, 90: 650 − 659.

[16] Song Xiaoguo, Zhang Te, Feng Yangju, et al. Brazing of TiBw/TC4 composite and Ti60 alloy using TiZrNiCu amorphous filler alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(10): 2193 − 2201. doi: 10.1016/S1003-6326(17)60245-0

-

期刊类型引用(4)

1. 李春凯,王嘉昕,石玗,代悦. GTAW熔池激光条纹动态行为与熔透预测方法研究. 机械工程学报. 2024(06): 236-244 .  百度学术

百度学术

2. 苏立虎. 脉冲气体保护焊引弧和收弧控制技术研究. 上海电气技术. 2024(02): 40-43 .  百度学术

百度学术

3. 黄忠利,黄健康,张宏福,于晓全,刘光银,樊丁. 不同脉冲模式下熔滴过渡对铝合金增材微观组织及力学性能的影响. 材料导报. 2023(14): 114-118 .  百度学术

百度学术

4. 姚屏,许敏,林茜,黄韵怡,王晓军. 机器人双脉冲弧焊工艺模式对铝合金焊缝质量的影响. 广东技术师范大学学报. 2023(06): 1-7 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: