Process parameters optimization of 5083 aluminum alloy FSW joint based on principal component analysis and grey correlation analysis

-

摘要: 针对铝合金搅拌摩擦焊接工艺参数优化问题,对5083铝合金板材进行研究,开展其在不同搅拌摩擦焊工艺参数下的力学性能探索,运用主成分分析和灰色关联度分析法对试验结果进行探索,得出焊接接头最优工艺参数,并建立基于GRG的工艺参数二阶预测模型.结果表明,均值极差法得出最优工艺参数组合为转速1 400 r/min,焊接速度1 mm/s,下压量0.3 mm,接头抗拉强度最大达到225.5 MPa,达到了母材的95.4%,失效位移为10.6 mm. 在试验工艺参数范围内,影响接头抗拉强度的主要因素次序为下压量、焊接速度、转速;模型预测值与计算值无显著差异,回归模型与试验数据的吻合度好,说明预测模型可靠度高,此回归模型可作为其预测模型.Abstract: Aim at optimizing the friction stir welding (FSW) process parameters of aluminum alloy, 5083 aluminum alloy plate was selected as the research object in this study. The mechanical properties of 5083 aluminum alloy plate under different FSW process parameters were explored. Principal component analysis (PCA) and grey relational degree (GRG) analysis were employed to analyze the test results. The optimal process parameters were obtained, and a second-order prediction model of process parameters based on GRG was established. The results show that the optimal combination of process parameters is a rotation speed of 1400 r/min, welding speed of 1 mm/s and plunge depth of 0.3 mm. The maximum tensile strength of the joint reaches 225.5 MPa, 95.4% of the base metal, and the failure displacement is 10.6 mm. Among the tested process parameters, the main factors influencing the tensile strength of the joint are plunge depth of shoulder, welding speed and rotation speed in sequence. Besides, there is no significant difference between the predicted value of the model and the calculated value. The good agreement between the regression model and the experimental data indicates that the prediction model has high reliability. The regression model can be used as the prediction model.

-

Keywords:

- 5083 aluminum alloy /

- process parameters /

- grey relational degree /

- tensile strength

-

0. 序言

5083铝合金是一种属于Al-Mg系的变形铝,强度、耐腐蚀性和抗疲劳强度高,具有较好的焊接性能.作为使用范围较广的一种防锈铝,5083铝合金板材常被应用于舰艇与船舶制造、车辆、航空航天等多个领域.过去船舶制造过程中主要采用钢合金材料,为实现船舶结构轻量化,将5083铝合金应用于船身外侧的壁板结构中[1,2],目前船身外部板材连接工艺主要采用搅拌摩擦焊(friction stir welding,FSW). FSW是英国焊接研究所于1991年发明的一种新型的固相连接技术[3],该技术可解决铝合金等低熔点轻质金属在焊接时产生孔洞、裂纹和飞边问题. 为了提高该连接工艺在制造业应用的可靠性和稳定性,有必要对5083铝合金板材连接的相关工艺参数进行探索研究.

国内外学者对搅拌摩擦焊接工艺参数进行了一系列的研究. 张华等人[4]研究了2195铝锂合金,在不同搅拌摩擦焊参数下的焊接性,表明工艺参数对接头抗拉强度、断裂形式皆有影响. 范文学等人[5]采用响应曲面法探索工艺参数对7A52铝合金焊接接头抗拉强度的影响,通过单因素、交互作用影响分析,进行强度预测及验证.Abuajila等人[6]采用田口设计方法,设计了16组涉及转速、焊接速度和刀具倾斜角度的焊接试验. 运用田口正交阵列和信噪比分析,得到5.5 mm厚度的AA5083铝合金最佳焊接工艺参数,采用方差分析来确定各参数之间的影响. Anil等人[7]基于L9正交阵列,研究了AA3103和AA7075铝合金搅拌摩擦焊接输入参数的优化问题,优化选择的输入参数为刀具转速、焊接速度、刀具销轮廓,输出参数为硬度、抗拉、冲击强度. 运用极差、方差分析结果.周海波等人[8]采用降低焊接轴向力的超高转速搅拌摩擦焊接工艺,选择影响高硅铝合金焊接质量的3个主要工艺参数,基于转速、焊接速度和下压深度3个因素设计16组正交试验,依据对接头成形情况评分和抗拉强度值,采用信噪比和方差分析来获得最佳工艺参数. 高祎晗等人[9]采用无减薄搅拌摩擦焊工艺,确立优化的3个工艺参数为主轴转速、焊接速度和轴肩下压量,基于BBD响应面方法构建数学模型,分析断后伸长率和抗拉强度的拟合模型,通过等高线图探索工艺参数对接头拉伸性能的影响,对优化结果进行试验,验证了回归模型的准确性.

通过以上国内外研究,可知搅拌摩擦焊接加工的影响因素包括转速、焊接速度、下压量、刀具偏移量、搅拌针形貌等因素,在此次研究中考虑转速、焊接速度和下压深度这3个主要影响因素进行接头力学性能的探索,为后续对更多工艺参数的探索提供参考.

灰色关联分析是一种基于灰色关联度来分析各因素关联影响程度的多因素分析方法,适用于分析多个目标响应的问题,研究多个因素和变量之间的相互作用和影响[10]. 在关联度的计算方面,层次分析法客观性较弱,距离分析法客观性虽强,但计算相对复杂[11]. 搅拌摩擦焊在焊接成形过程中各因素与响应目标间的影响作用是复杂的,灰色关联分析方法可引入解决多目标优化问题,优化工艺参数致力于提高加工工件的力学性能和外观成形. 目前,此分析方法被用于注塑、切割加工、制备材料、激光熔覆等工程领域方面[12].

为扩大正交试验方法在FSW材料连接的应用范围,研究选用广泛用于制造业的5083铝合金板材为试验对象,采用正交试验方法进行9组试验,通过力学测试,计算各工艺参数下的接头平均抗拉强度及能量吸收值,计算响应目标对应的信噪比,进行主成分分析,利用灰色关联分析法、均值极差分析法得到各因素水平下的灰色关联度的影响程度,绘制变化趋势图进行分析. 选用响应曲面法构建灰色关联度的二阶回归预测模型,分析拟合度情况,以期优化焊接加工工艺参数组合.

1. 试验材料与方法

1.1 试验材料

试验材料选用5083铝合金板材,尺寸为112 mm × 112 mm × 3 mm,力学性能及化学成分见表1、表2.试件采用对接的形式在搅拌摩擦焊机进行焊接,设备型号为FSW-ST4022M. 焊接所用搅拌头工具轴肩直径为7 mm,针直径为3 mm,长度为2.5 mm.

表 1 5083铝合金力学性能Table 1. Mechanical properties of 5083 aluminum alloy抗拉强度Rm /MPa 断后伸长率A(%) ≥236 ≥12 表 2 5083铝合金化学成分(质量分数,%)Table 2. Chemical compositions of 5083 aluminum alloySi Cu Mg Zn Mn Ti Cr Fe 其他 Al <0.4 <0.1 4.0 ~ 4.9 <0.25 0.4 ~ 1.0 <0.15 0.05 ~ 0.25 <0.4 0.15 余量 1.2 试验方法

正交表具有均衡分散、综合可比的特点,保证所做试验的水平搭配均衡地分散在所有组合之中[13-14]. 焊接采用9组正交试验,通过L9(34)正交表进行试验对焊接工艺参数进行优化,考虑搅拌头转速、焊接速度、下压量3个主要因素为试验的研究因素,分别记作A(n),B(v)和C(H),影响工艺参数的因素水平见表3,具体试验加工的工艺参数见表4. 利用线切割机制取接头的拉伸试样,采用 MTS Landmark 100型试验机进行力学测试,试验的拉伸速度为5 mm/min,每组参数下测试3个拉伸试样,取平均值作为试验结果.

表 3 正交试验因素及水平Table 3. Orthogonal test factors and levels水平 转速A(n)/

(r·min−1)焊接速度B(v)/

(mm·s−1)下压量C(H)/

mm1 1 000 1 0.20 2 1 200 2 0.25 3 1 400 3 0.30 表 4 拉伸试验结果Table 4. Test result试验序号 转速A(n)/(r·min−1) 焊接速度B(v)/(mm·s−1) 下压量C(H)/mm 平均抗拉强度Rm/MPa 能量吸收平均值S/J 1 1 000 1 0.2 217.8 142.3 2 1 000 2 0.25 202.1 64.6 3 1 000 3 0.3 215.2 100.1 4 1 200 1 0.25 219 126.9 5 1 200 2 0.3 221.8 131.3 6 1 200 3 0.2 208.8 63.9 7 1 400 1 0.3 222.7 122.7 8 1 400 2 0.2 214.5 93.9 9 1 400 3 0.25 211.4 204.1 2. 试验结果及分析

2.1 正交试验结果

以搅拌摩擦焊为连接方式的材料发生碰撞时,焊接接头可通过自身形变吸收能量,能量吸收值的大小反映了接头缓冲吸震性能的优劣,该值越大则能承受更大的失效载荷和失效位移,将载荷—位移曲线积分后为所需的能量吸收值[15-16]. 根据表3的试验因素与各个水平参数,研究中将抗拉强度和能量吸收值作为响应目标,记录9组拉伸试样的测试结果于表4中.

2.2 信噪比分析

为进一步评估焊接接头的质量,选择信噪比(S/N)作为质量指标的评价标准,反应波动情况,保证其稳定性[17]. 信噪比根据具体情况可分为望目、望大以及望小三种特性[18],接头质量的评价指标为尽可能大的抗拉强度和能量吸收值,因此文中选取望大信噪比来衡量接头的力学性能. 信噪比计算公式为

$$ S/N = - 10\lg \left(\frac{1}{n}\sum\limits_{i = 1}^n {\frac{1}{{\alpha_ i^2}}} \right) $$ (1) 式中:

$\alpha_i$ 为第i次试验值;$ n $ 为试验的次数.2.3 灰色关联度系数

灰色关联法是基于灰色关联度来相对的衡量各因素间变化情况的关联程度,可以得出目标数据和影响因素之间的关联性[19-20]. 首先需要对原始数据进行无量纲化处理,应用以下方程,即

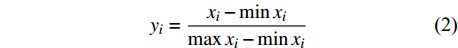

$$ y_i = \frac{{x_i - \min x_i}}{{\max x_i - \min x_i}} $$ (2) 式中:

$x_i$ 为第i次试验值;$y_i$ 为无量纲化值.灰色关联度系数为经过无量纲化处理后的试验值与理想值之间的关系,计算方式为

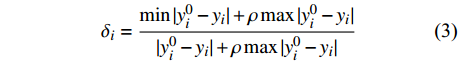

$$ \delta_i = \frac{{\min |y_i^0 - y_i| + \rho \max |y_i^0 - y_i|}}{{|y_i^0 - y_i| + \rho \max |y_i^0 - y_i|}} $$ (3) 式中,

$ y_i^0 $ 为参考数列,第i次无量纲化的理想最优数值;$ \rho $ 为分辨系数,$ \rho \in \left[ {0,1} \right] $ 文中取0.5,为削弱过大数值导致的失真影响.2.4 主成分分析(PCA)

主成分分析是利用降维的思想把多个指标转化为几个综合指标的多元统计方法,主成分分析可确定影响因子对响应目标的贡献率,进而得到响应目标所占权重值.文中用其计算抗拉强度和能量吸收值对灰色关联度的影响权重,计算分析过程如下.

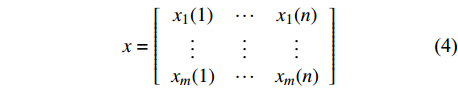

(1)建立响应目标原始序列矩阵,

$ x_i(j) $ 是对应灰色关联系数,i = 1,···,m,j = 1,···,n.$$ x = \left[ {\begin{array}{*{20}{c}} {x_1(1)}& \cdots &{x_1(n)} \\ \vdots & \vdots & \vdots \\ {x_m(1)}& \cdots &{x_m(n)} \end{array}} \right] $$ (4) 式中:m为试验的总次数,文中m = 9;n为响应数,文中n = 2.

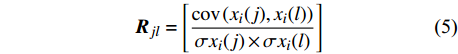

(2)建立相关系数矩阵R

$$ {{\boldsymbol{R}}}_{j l}=\left[\frac{\operatorname{cov}\left(x_i(j), x_i(l)\right)}{\sigma x_i(j) \times \sigma x_i(l)}\right]$$ (5) 式中:

${{\rm{cov}}} (x_i(j),x_i(l))$ 为$ x_i(j) $ 和$ x_i(l) $ 的协方差;$\sigma x_i(j)$ 为$x_i(j)$ 的标准差,j = 1,···, n;$ \sigma x_i(l) $ 为$ x_i(l) $ 的标准差,l = 1,···, n.(3)特征值与特征向量

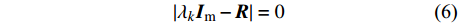

通过下式特征方程,求出特征值.

$$ \left| {\lambda_k{{\boldsymbol{I}}_{\rm{m}}} - {\boldsymbol{R}}} \right| = 0 $$ (6) 式中:k = 1,···,n;

${\boldsymbol{I}}_{\rm{m}}$ 为单位矩阵.(4)主成分和累计贡献率

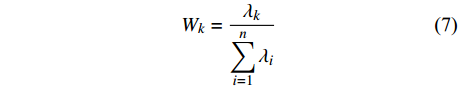

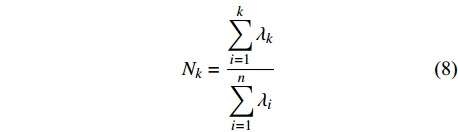

主成分贡献率和累计贡献率的计算分别运用以下方程,即

$$ W_k = \frac{{\lambda _k}}{{ \displaystyle\sum\limits_{i = 1}^n {\lambda_ i} }} $$ (7) $$ N_k = \frac{{ \displaystyle\sum\limits_{i = 1}^k {\lambda_ k} }}{{ \displaystyle\sum\limits_{i = 1}^n {\lambda _i} }} $$ (8) 通常当

$N_k$ ≥85%时,$\lambda_ 1$ ,$\lambda_ 2$ 分别为第一、第二主成分,类推即可.计算出的灰色关联度系数,运用式(5) ~ 式(8)可得到特征值,主成分和累计贡献率结果,见表5,表6.可知第一、第二主成分分别为抗拉强度Rm、能量吸收值S,其对应的贡献率分别为57.94%,42.06%.试验研究说明在搅拌摩擦焊接过程中,所连接材料的抗拉强度的贡献率占比大,应以提高接头抗拉强度为主要目标.

表 5 主成分计算结果Table 5. Calculation results of principal component成分 特征值 贡献率Wk(%) 第一主成分 1.159 57.94 第二主成分 0.841 42.06 累积贡献率(%) 100 表 6 灰色关联度分析结果Table 6. Results of grey correlation analysis试验 抗拉强度 能量吸收值 灰色关联度$ \alpha_{{\rm{G R G}}}$ 排序 信噪比 $y_i$ $\delta_ i$ 信噪比 $y_i$ $\delta_ i$ 1 46.76 0.773 0.687 43.06 0.689 0.616 0.657 5 2 46.11 0 0.333 36.21 0.009 0.335 0.333 9 3 46.66 0.655 0.591 40.01 0.387 0.449 0.531 6 4 46.81 0.833 0.749 42.07 0.591 0.55 0.665 4 5 46.92 0.964 0.932 42.37 0.62 0.568 0.778 2 6 46.39 0.333 0.428 36.11 0 0.333 0.388 8 7 46.95 1 1 41.78 0.562 0.533 0.803 1 8 46.63 0.619 0.567 39.45 0.331 0.427 0.508 7 9 46.50 0.464 0.482 46.20 1 1 0.699 3 2.5 灰色关联度(GRG)

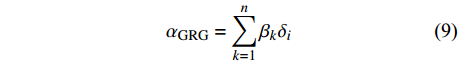

灰色关联度为其系数的加权和,公式如下,即

$$ \alpha_\mathrm{GRG}=\sum_{k=1}^n \beta_k \delta_i$$ (9) 式中:

$\displaystyle\sum_{k=1}^n \beta_k = 1$ ,$ \beta_ k $ 为第k个输出响应权重,由主成分分析法所得.由表5所得出式9中的

$ \beta_ 1 $ = 0.579 4,$ \beta _2 $ = 0.420 6,式(1) ~ 式(3)以及灰色关联度的计算结果见表6.由表6可知,第7组试验的响应值最高,灰色关联度越大,说明质量指标在各因素影响下越趋向于一致,所对应的参数水平最好. 分别对每个影响因素下的同一水平所对应的灰色关联度数值求取平均值,计算最大差值进行分析,极差表示各影响因素对所考察响应目标的影响程度. 通过对灰色关联度进行均值极差分析,可以得到目标响应最好的焊接工艺参数组合. 其中

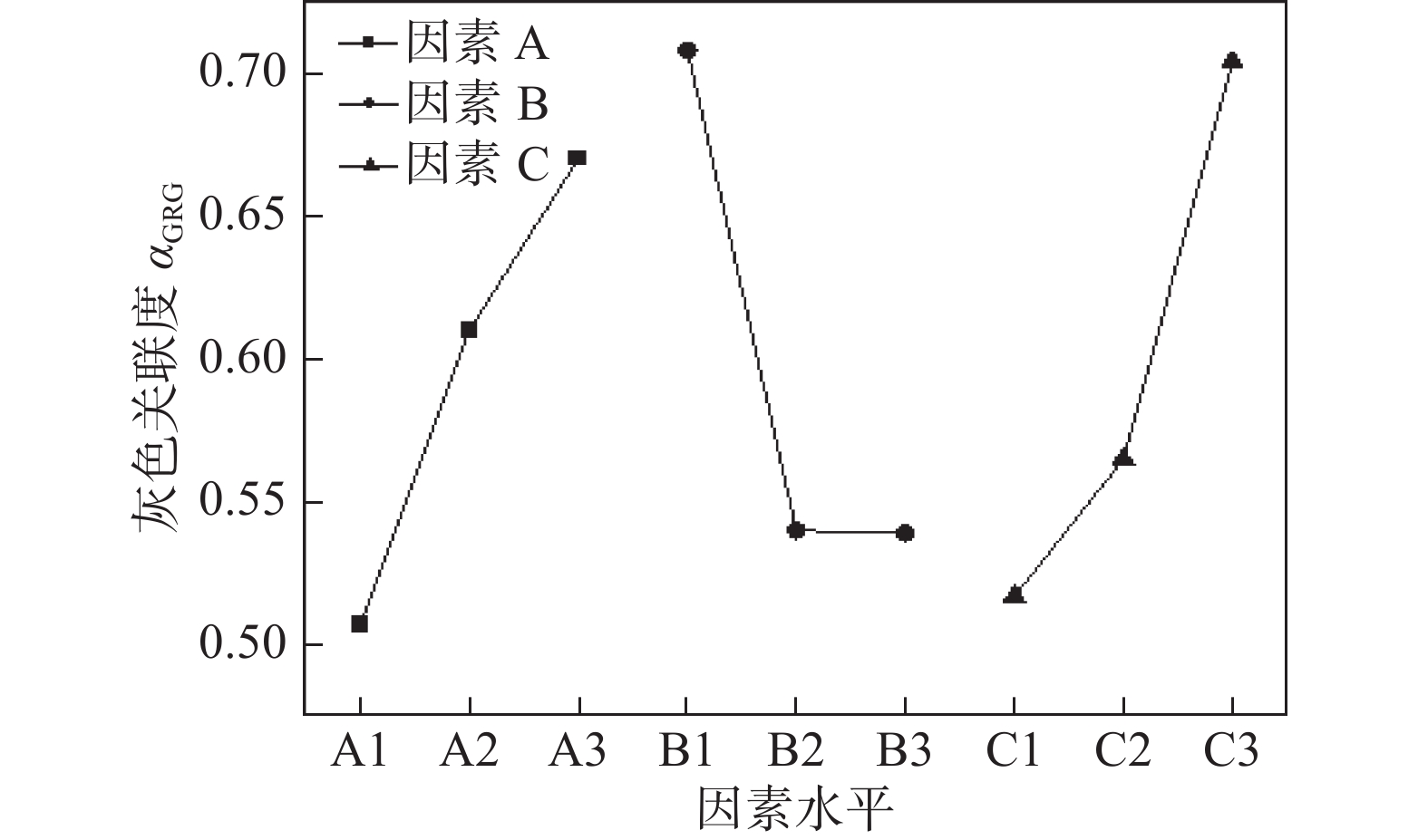

$ \gamma_ i $ 代表第i个水平下的灰色关联度均值,其分析结果见表7. 趋势图反映出质量指标的变化趋势,如图1所示.表 7 灰色关联度均值极差分析Table 7. Mean range analysis of grey correlation degree项目 转速

A(n)/(r·min−1)焊接速度

B(v)/(mm·s−1)下压量

C(H)/mm$ \gamma_ 1 $ 0.507 0.708 0.517 $ \gamma _2 $ 0.61 0.54 0.565 $ \gamma _3 $ 0.67 0.539 0.704 极差 0.163 0.169 0.187 通过对3个影响因素各水平极差的数据分析,表明下压量的极差值最大为0.187,转速的极差值最小为0.163,可得到影响抗拉强度质量的因素排序为H > v > n,说明下压量对接头抗拉强度质量影响显著,转速影响最小. 影响因素焊接速度和下压量的极差数值相差不大,说明影响程度约同等. 可知在焊接过程中,对下压量和焊接速度的合理控制是至关重要的,以期获得较好质量的焊接接头,根据优化质量指标的要求,对各因素进行选择,确定最优工艺条件.

从图1可知,获得最大抗拉强度的最优工艺参数组合为A3B1C3,即搅拌头转速为1 400 r/min,焊接速度为1 mm/s,下压量为0.3 mm,同时与表6中灰色关联度分析结果对照,其灰色关联度值最大,因此可认为该组合为最优工艺参数. 图1反应的是灰色关联度与各因素水平变化趋势的关系,由图1分析可得,转速在水平1到2时,灰色关联度增大明显,到水平3增大缓慢,表明在可取的范围值内,转速可以进一步提高,取值越大,灰色关联度逐渐增大,响应目标值变大;焊接速度从水平1到3,灰色关联度数值急速降低,说明在可取的范围值内越小,灰色关联度越大,在此焊接工况下,焊接速度值可进一步降低;下压量在水平1到3,灰色关联度数值先慢后快的增加,表明在范围值内,可通过进一步提升压入量来增大灰色关联度,改善接头质量的焊接情况. 可知在转速、焊接速度、下压量等工艺参数的合理范围值内,可以根据焊接实际情况适当增大或缩小影响因素水平的取值范围,提高焊接质量.

3. 力学性能分析

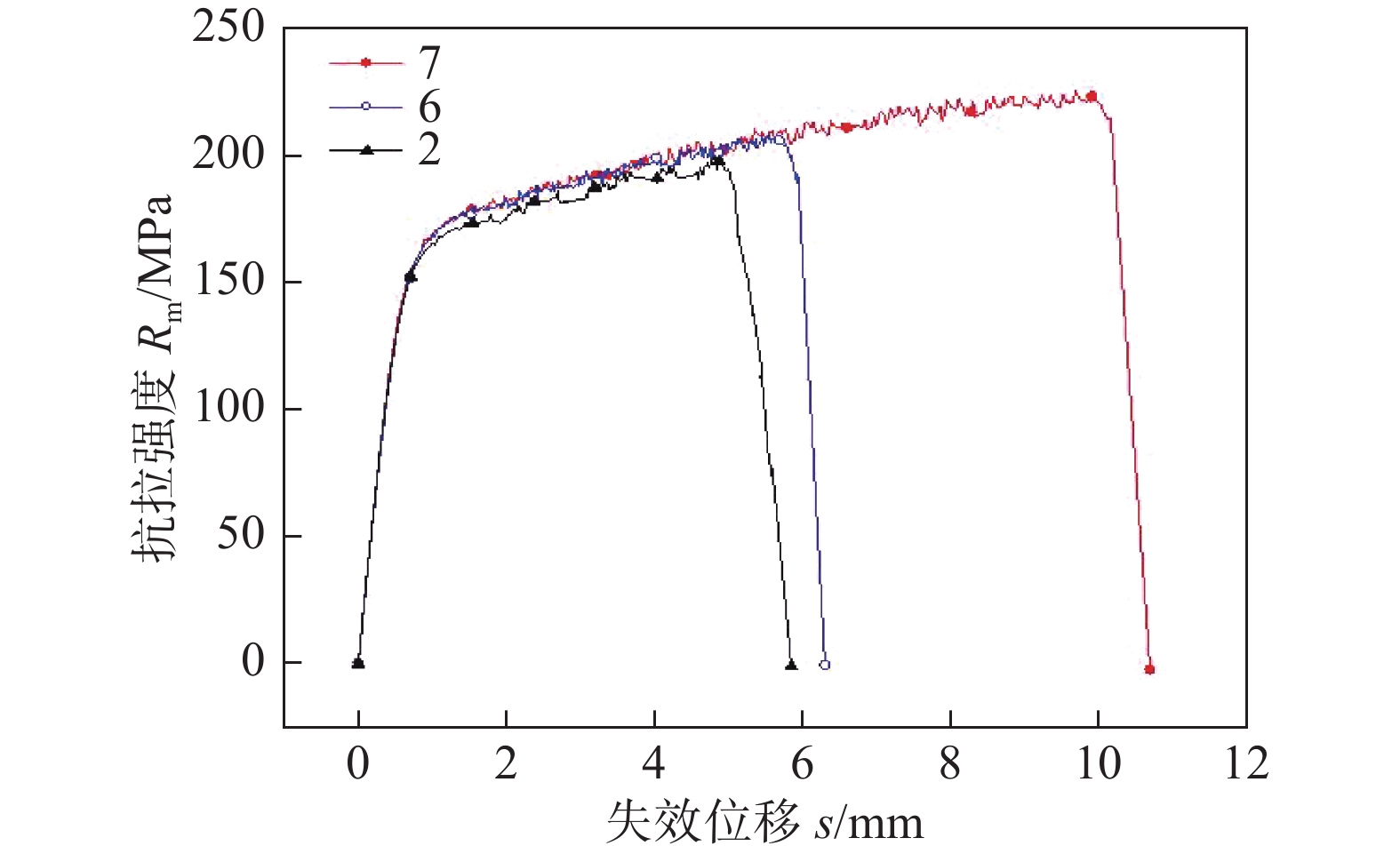

在9组正交试验中,第7组、第6组和第2组数据特征较明显. 选择以上3组典型数据绘制载荷位移曲线图,如图2所示. 可以看出3组焊接接头的载荷位移曲线在初始失效状态均呈现线性变化,为弹性变化阶段,此阶段3组接头变化一致,载荷位移曲线持续缓慢上升,在3个不同时段,载荷达到最大时接头失效,曲线急剧下降,证实焊接接头破坏. 当搅拌头转速为1 400 r/min,焊接速度为1 mm/s,下压量为0.3 mm时,接头抗拉强度为最大值225.5 MPa,失效位移为10.6 mm,强度达到了母材强度的95.4%. 当转速增大,焊接时机械搅拌作用变大,下压量在合理范围内偏大,未焊透的情况减小,材料受到的挤压力增加,随着产生的热输入增大,材料塑性流动增强,混合更充分[21-22],下压量在合理范围内偏大,未焊透的情况减小,所以抗拉强度提升达到最大值. 第6组试验的抗拉强度及失效位移介于两组之间.当转速为1 000 r/min,焊接速度为2 mm/s,下压量为0.25 mm时,接头抗拉强度最大达到200 MPa,失效位移为5.8 mm,强度达到了母材强度的84.6%. 转速和下压量变小,出现晶粒细化不完全或焊缝未焊透的现象,导致抗拉强度和失效位移减小,说明下压量对焊接接头质量的影响作用是可观的.

图3为9组不同工艺参数下焊接接头的拉伸性能,由图3可看出,各组平均抗拉强度变化较小,均高于200 MPa,平均失效位移的最大值比最小值增加了5.31 mm,说明所选工艺参数的正确性. 图4为不同工艺参数下制备的接头宏观断口形貌图,可看出接头断裂部位均为热影响区和焊核区,说明是焊接接头的薄弱区域,接头断裂处未出现明显的颈缩现象,断口处与拉伸方向呈现45°夹角.

4. GRG二阶预测模型分析

4.1 GRG响应模型构建

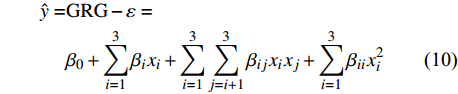

文中选用响应曲面法构建目标响应与工艺参数的二阶数学回归模型,进行搅拌摩擦焊接参数优化,焊接工艺参数与灰色关联度(GRG)的二阶回归方程可表示为

$$ \begin{split} \hat{y}=&\mathrm{GRG}-\varepsilon= \\ & \beta_0+\sum_{i=1}^3 \beta_i x_i+\sum_{i=1}^3 \sum_{j=i+1}^3 \beta_{i j} x_i x_j+\sum_{i=1}^3 \beta_{i i} x_i^2 \end{split} $$ (10) 式中:

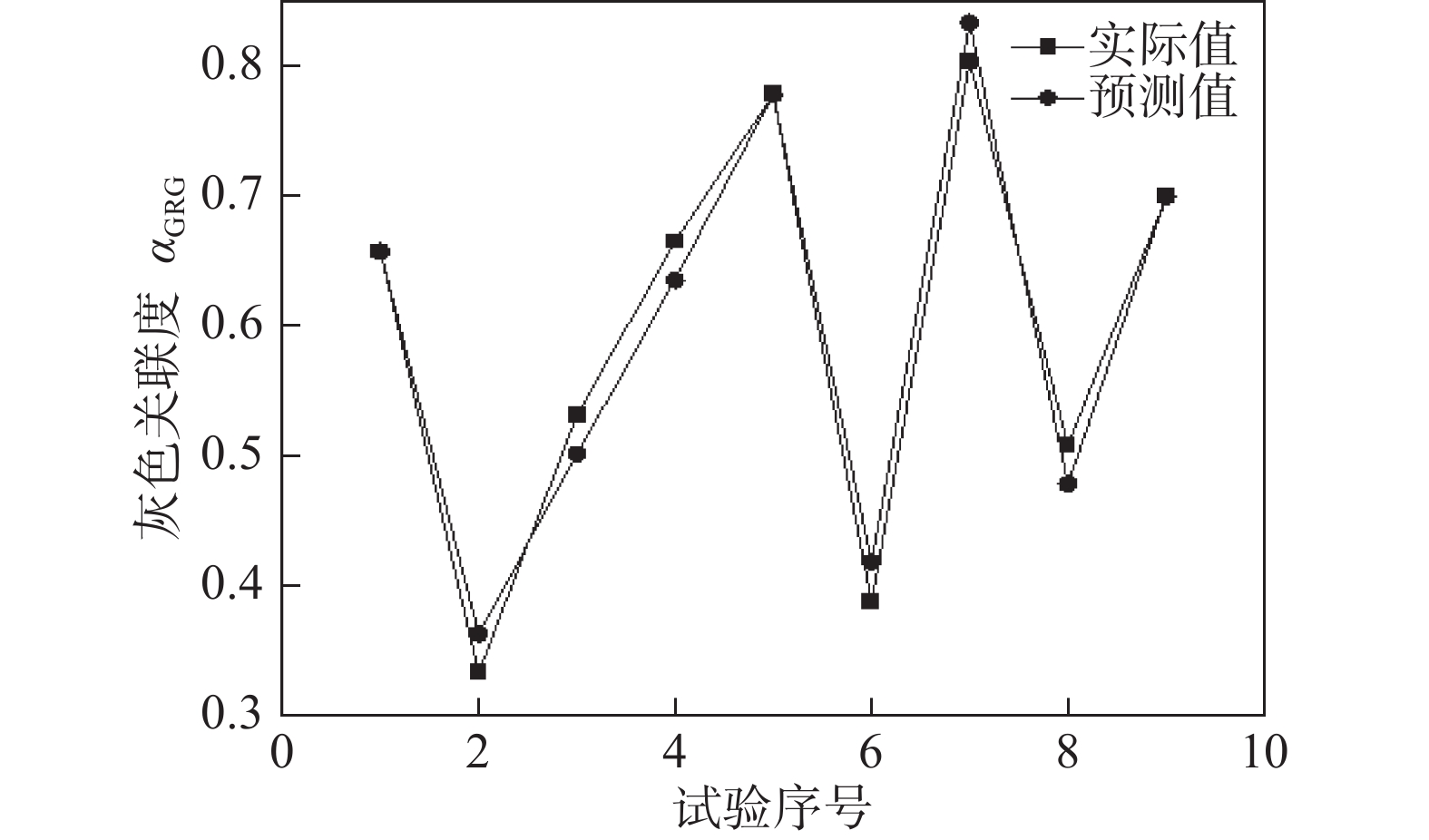

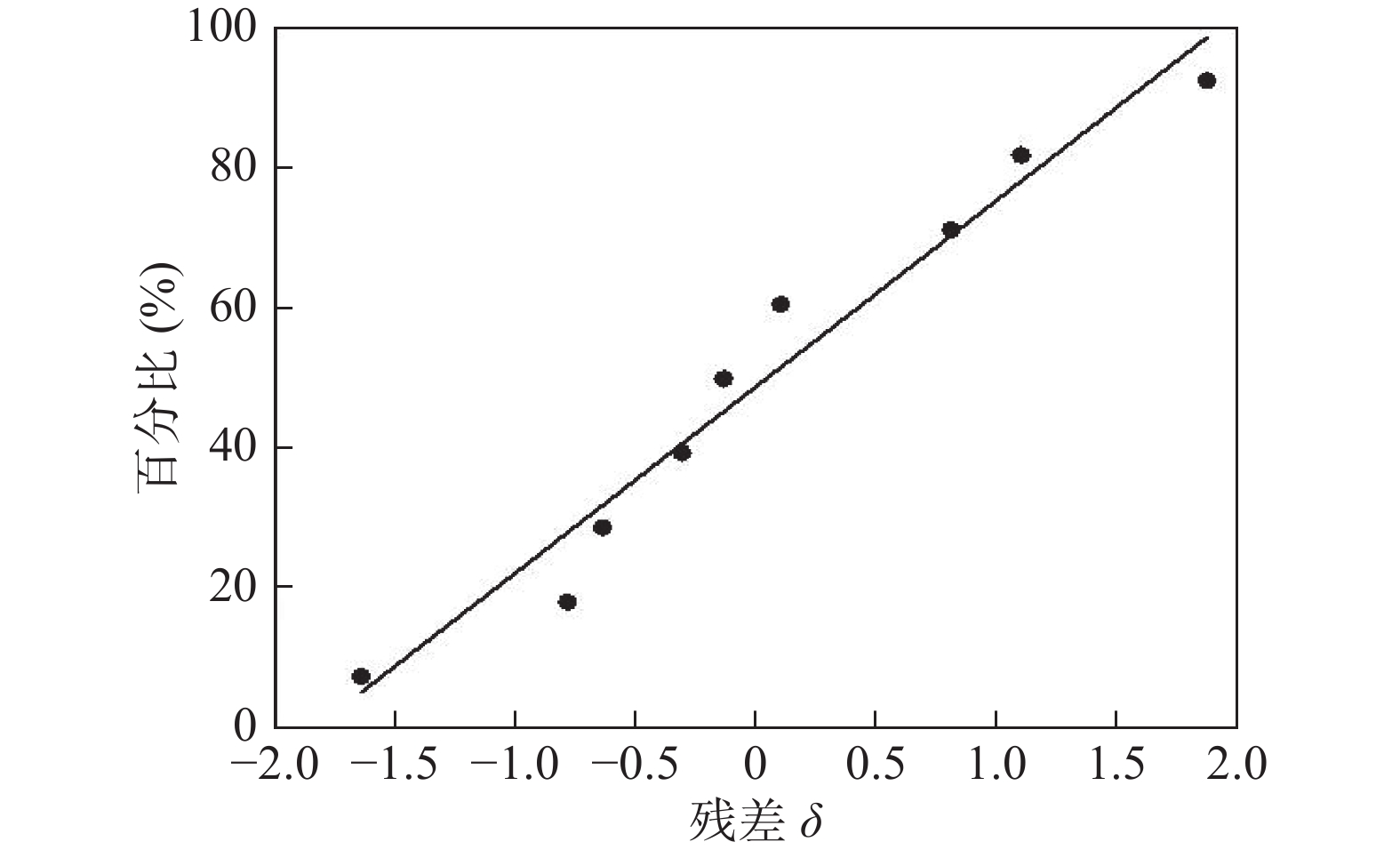

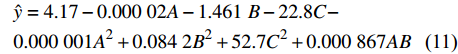

$ \hat y $ 为GRG预估值;x为工艺参数;$ \varepsilon $ 为试验误差;$ \beta $ 为回归系数.对试验数据回归分析处理,所建立的二阶预测模型见式(11),图5为GRG的试验预测值与计算值的分布图,可看出数值接近程度大,偏差值最大为0.03,两值之间无显著差异. R-Sq分析回归模型和试验数据的吻合度情况,GRG预测模型的方差分析结果见表8所示,其中R-Sq = 97.54%,R-Sq(adj) = 80.32%,两数值相差小,表明预测模型可靠度高. 图6为残差图,可看出残差值正常分布于零值附近,无异常点,说明模型的拟合度好. 表明在以此研究中的灰色关联度为分析对象,此回归模型可作为其预测模型.

表 8 预测模型的方差分析结果Table 8. Variance analysis results of the prediction model参数 自由度df 平方和ss 均方ms F值 显著性 回归平方和 7 0.214 066 0.030 581 5.66 是 残差平方和 1 0.193 575 0.064 525 总和 8 标准差SD = 0.0734847 R-Sq = 97.54% R-Sq(adj) = 80.32% $$ \begin{split} & \hat y = 4.17 - 0.000{\text{ }}02A - 1.461{\text{ }}B - 22.8C -\\& 0.000{\text{ }}001{A^2} + 0.084{\text{ }}2{B^2} + 52.7{C^2} + 0.000{\text{ }}867AB \end{split} $$ (11) 4.2 预测模型结果

研究中以灰色关联度的值为优化对象,结合MINITAB软件的响应优化器部分进行分析,在95%的置信区间,拟合出响应的GRG最大值为1.017,对应工艺参数组为A(n) = 1 000 r/min,B(v) = 1 mm/s和C(H) = 0.3 mm. 表明在转速为1 000 r/min的工况下所产生的热量已经能够让焊缝区的金属达到塑性状态,已满足焊接条件,当转速再增大时,所产生的热量也不再增加,温度持稳定状态[23]. 对该焊接工艺参数下的接头进行力学试验,得到抗拉强度值为225.9 MPa,失效位移为9.04 mm,强度值有些许提高,由极差结果可知,研究中转速为影响较小的因素.说明此回归模型可作为其预测模型,模型的准确性好,可靠度高.

5. 结论

(1) 以5083铝合金薄板材料为研究对象,开展9组正交试验研究,以抗拉强度和能量吸收值为响应目标,在所研究的3个影响因素中,影响抗拉强度的主要因素次序为下压量、焊接速度和转速,说明对下压量的合理控制是提高焊接质量的关键部分.

(2) 基于正交试验,结合主成分分析、灰色关联分析法,得出第一、第二主成分对应的贡献率分别为57.94%和42.06%.均值极差分析得到最优工艺参数为:转速1 400 r/min,焊接速度1 mm/s,下压量0.3 mm.此时接头抗拉强度最大达到225.5 MPa,强度达到母材强度的95.4%,失效位移为10.6 mm,表明焊接质量较好. 焊接工艺参数符合优化要求,为焊接加工工艺方面提供参考依据.

(3) 建立基于GRG的二阶预测模型,得出预测值与真实值无显著差异,回归模型与试验数据的吻合度好,说明预测模型可靠度高,模型的拟合度好. 说明此回归模型可作为其预测模型.

-

表 1 5083铝合金力学性能

Table 1 Mechanical properties of 5083 aluminum alloy

抗拉强度Rm /MPa 断后伸长率A(%) ≥236 ≥12 表 2 5083铝合金化学成分(质量分数,%)

Table 2 Chemical compositions of 5083 aluminum alloy

Si Cu Mg Zn Mn Ti Cr Fe 其他 Al <0.4 <0.1 4.0 ~ 4.9 <0.25 0.4 ~ 1.0 <0.15 0.05 ~ 0.25 <0.4 0.15 余量 表 3 正交试验因素及水平

Table 3 Orthogonal test factors and levels

水平 转速A(n)/

(r·min−1)焊接速度B(v)/

(mm·s−1)下压量C(H)/

mm1 1 000 1 0.20 2 1 200 2 0.25 3 1 400 3 0.30 表 4 拉伸试验结果

Table 4 Test result

试验序号 转速A(n)/(r·min−1) 焊接速度B(v)/(mm·s−1) 下压量C(H)/mm 平均抗拉强度Rm/MPa 能量吸收平均值S/J 1 1 000 1 0.2 217.8 142.3 2 1 000 2 0.25 202.1 64.6 3 1 000 3 0.3 215.2 100.1 4 1 200 1 0.25 219 126.9 5 1 200 2 0.3 221.8 131.3 6 1 200 3 0.2 208.8 63.9 7 1 400 1 0.3 222.7 122.7 8 1 400 2 0.2 214.5 93.9 9 1 400 3 0.25 211.4 204.1 表 5 主成分计算结果

Table 5 Calculation results of principal component

成分 特征值 贡献率Wk(%) 第一主成分 1.159 57.94 第二主成分 0.841 42.06 累积贡献率(%) 100 表 6 灰色关联度分析结果

Table 6 Results of grey correlation analysis

试验 抗拉强度 能量吸收值 灰色关联度 $ \alpha_{{\rm{G R G}}}$ 排序 信噪比 $y_i$ $\delta_ i$ 信噪比 $y_i$ $\delta_ i$ 1 46.76 0.773 0.687 43.06 0.689 0.616 0.657 5 2 46.11 0 0.333 36.21 0.009 0.335 0.333 9 3 46.66 0.655 0.591 40.01 0.387 0.449 0.531 6 4 46.81 0.833 0.749 42.07 0.591 0.55 0.665 4 5 46.92 0.964 0.932 42.37 0.62 0.568 0.778 2 6 46.39 0.333 0.428 36.11 0 0.333 0.388 8 7 46.95 1 1 41.78 0.562 0.533 0.803 1 8 46.63 0.619 0.567 39.45 0.331 0.427 0.508 7 9 46.50 0.464 0.482 46.20 1 1 0.699 3 表 7 灰色关联度均值极差分析

Table 7 Mean range analysis of grey correlation degree

项目 转速

A(n)/(r·min−1)焊接速度

B(v)/(mm·s−1)下压量

C(H)/mm$ \gamma_ 1 $ 0.507 0.708 0.517 $ \gamma _2 $ 0.61 0.54 0.565 $ \gamma _3 $ 0.67 0.539 0.704 极差 0.163 0.169 0.187 表 8 预测模型的方差分析结果

Table 8 Variance analysis results of the prediction model

参数 自由度df 平方和ss 均方ms F值 显著性 回归平方和 7 0.214 066 0.030 581 5.66 是 残差平方和 1 0.193 575 0.064 525 总和 8 标准差SD = 0.0734847 R-Sq = 97.54% R-Sq(adj) = 80.32% -

[1] 方远方, 张华. 厚板5083铝合金搅拌摩擦焊接头沿厚度方向组织与力学性能[J]. 机械工程学报, 2022, 58(4): 94 − 101. Fang Yuanfang, Zhang Hua. Microstructure and mechanical properties of friction stir welded joint of thick plate 5083 aluminum alloy along thickness direction[J]. Journal of Mechanical Engineering, 2022, 58(4): 94 − 101.

[2] Rao D, Huber K, Heerens J, et al. Asymmetric mechanical properties and tensile behaviour prediction of aluminium alloy 5083 friction stir welding joints[J]. Materials Science & Engineering A, 2013, 565: 44 − 50.

[3] Mishra R S, Ma Z Y. Friction stir welding and processing[J]. Materials Science and Engineering:Reports, 2005, 50(1-2): 1 − 78. doi: 10.1016/j.mser.2005.07.001

[4] 张华, 秦海龙, 吴会强. 工艺参数对2195铝锂合金搅拌摩擦焊接头力学性能的影响[J]. 焊接学报, 2016, 37(4): 19 − 23. Zhang Hua, Qin Hailong, Wu Huiqiang. Effect of process parameters on mechanical properties of friction stir welded joints of 2195 Al-Li alloy[J]. Transactions of the China Welding Institution, 2016, 37(4): 19 − 23.

[5] 范文学, 陈芙蓉. 基于响应面法7A52高强铝合金FSW接头抗拉强度预测及优化[J]. 焊接学报, 2021, 42(9): 55 − 60. doi: 10.12073/j.hjxb.20210322001 Fan Wenxue, Chen Furong. Prediction and optimization of tensile strength of FSW joint of 7A52 high strength aluminum alloy based on response surface method[J]. Transactions of the China Welding Institution, 2021, 42(9): 55 − 60. doi: 10.12073/j.hjxb.20210322001

[6] Abuajila R, Vidosav M, Aleksandar S, et al. Optimization of AA5083 friction stir welding parameters using Taguchi method[J]. Technical Gazette, 2018, 25(3): 861 − 866.

[7] Anil R, Kumar P J, Anil M R, et al. Optimization of friction stir welding parameters during joining of AA3103 and AA7075 aluminium alloys using Taguchi method[J]. Materials Today:proceedings, 2021, 46(17): 7733 − 7739.

[8] 周海波, 浦娟, 龙伟民, 等. 基于田口法的高硅铝合金超高转速搅拌摩擦焊接工艺优化[J]. 焊接, 2022(2): 32 − 38. Zhou Haibo, Pu Juan, Long Weimin, et al. Optimization of friction stir welding process for high-silicon aluminum alloy with ultra-high rotating speed based on Taguchi method[J]. Welding& Joining, 2022(2): 32 − 38.

[9] 高祎晗, 国旭明, 莫春立. 铝合金无减薄搅拌摩擦焊工艺优化及特征分析[J]. 焊接学报, 2019, 40(4): 141 − 147. doi: 10.12073/j.hjxb.2019400115 Gao Yihan, Guo Xuming, Mo Chunli. Process optimization and characteristics analysis of aluminum alloy friction stir welding without thinning[J]. Transactions of the China Welding Institution, 2019, 40(4): 141 − 147. doi: 10.12073/j.hjxb.2019400115

[10] 赵丹丹, 焦锋. 基于灰色关联分析的35CrMoV钢活塞杆激光熔覆工艺参数优化[J]. 兵工学报, 2018, 39(10): 2073 − 2080. doi: 10.3969/j.issn.1000-1093.2018.10.022 Zhao Dandan, Jiao Feng. Optimization of laser melting process parameters of 35CrMoV steel piston rod based on grey correlation analysis[J]. Acta Armamentarii, 2018, 39(10): 2073 − 2080. doi: 10.3969/j.issn.1000-1093.2018.10.022

[11] 王敬敏, 郭继伟, 连向军. 两种改进的灰色关联分析法的比较研究[J]. 华北电力大学学报, 2005, 32(6): 72 − 76. Wang Jingmin, Guo Jiwei, Lian Xiangjun. Comparative study of two improved grey correlation analysis methods[J]. Journal of North Electric Power University, 2005, 32(6): 72 − 76.

[12] 杨来侠, 桂玉莲, 李素丽, 等. 信噪比与灰色关联分析选区激光烧结成型工艺的研究[J]. 塑料工业, 2020, 48(1): 78 − 81. doi: 10.3969/j.issn.1005-5770.2020.01.017 Yang Laixia, Gui Yulian, Li Suli, et al. Signal noise ratio and gray correlation analysis of selective laser sintering molding process[J]. Plastic Industry, 2020, 48(1): 78 − 81. doi: 10.3969/j.issn.1005-5770.2020.01.017

[13] Pitchipoo P, Muthiah A, Jeyakumar K, et al. Friction stir welding parameter optimization using novel multi objective dragonfly algorithm[J]. International Journal of Lightweight Materials and Manufacture, 2021, 4(4): 460 − 467. doi: 10.1016/j.ijlmm.2021.06.006

[14] Shunmugasundaram M, Kumar P A, Sankar P L, et al. Optimization of process parameters of friction stir welded dissimilar AA6063 and AA5052 aluminum alloys by Taguchi technique[J]. Materials Today:Proceedings, 2020, 27(2): 871 − 876.

[15] 张先炼, 何晓聪, 程强, 等. 1420铝锂合金自冲铆异质组合接头静力学性能研究[J]. 材料导报, 2015, 29(24): 76 − 79. Zhang Xianlian, He Xiaocong, Cheng Qiang, et al. Study of the static mechanical properties of 1420 aluminum-lithium alloy self-piercing riveted heterogeneous composite joints[J]. Materials Reports, 2015, 29(24): 76 − 79.

[16] Lei L, He X C, Xing B Y, et al. Effect of foam copper interlayer on the mechanical properties and fretting wear of sandwich clinched joints[J]. Journal of Materials Processing Tech, 2019, 274: 116285. doi: 10.1016/j.jmatprotec.2019.116285

[17] Anbarasi J, Yaknesh S, Sampathkumar K, et al. Performance characteristics optimization in dissimilar friction stir welding using Grey relational analysis[J]. Materials Today:Proceedings, 2022, 55(2): 294 − 298.

[18] Mostafa A, Parviz A. Optimization of microstructural and mechanical properties of friction stir welded A356 pipes using Taguchi method[J]. Materials Research Express, 2019, 6(6): 066545. doi: 10.1088/2053-1591/ab0d72

[19] 王排岗, 王晓强, 刘志飞, 等. 基于灰色关联分析方法的超声滚挤压工艺参数优化[J]. 塑性工程学报, 2022, 29(3): 36 − 43. doi: 10.3969/j.issn.1007-2012.2022.03.005 Wang Paigang, Wang Xiaoqiang, Liu Zhifei, et al. Optimization of ultrasonic rolling extrusion process parameters based on grey correlation analysis method[J]. Chinese Journal of Plastic Engineering, 2022, 29(3): 36 − 43. doi: 10.3969/j.issn.1007-2012.2022.03.005

[20] 梁存光, 李新梅. 基于灰色关联分析与回归分析WC-12Co涂层工艺参数的多目标优化[J]. 材料导报, 2018, 32(10): 1752 − 1756. doi: 10.11896/j.issn.1005-023X.2018.10.034 Liang Cunguang, Li Xinmei. Multi-objective optimization of WC-12Co coating process parameters based on grey correlation analysis and regression analysis[J]. Materials Reports, 2018, 32(10): 1752 − 1756. doi: 10.11896/j.issn.1005-023X.2018.10.034

[21] 苏孺, 王朋朋, 张亮. 主轴转速对2A12铝合金搅拌摩擦焊接头组织和性能的影响[J]. 沈阳大学学报, 2019, 31(6): 443 − 447. Su Ru, Wang Pengpeng, Zhang Liang. Effect of spindle speed on microstructure and properties of friction stir welding joint of 2A12 aluminum alloy[J]. Journal of Shenyang University, 2019, 31(6): 443 − 447.

[22] 朱海, 于明玉, 郭春成, 等. 6061-T6铝合金无针搅拌摩擦焊全焊缝力学性能研究[J]. 塑性工程学报, 2021, 28(12): 97 − 102. doi: 10.3969/j.issn.1007-2012.2021.12.012 Zhu Hai, Yu Mingyu, Guo Chuncheng, et al. Research on mechanical properties of 6061-T6 aluminum alloy friction stir welding without pin[J]. Chinese Journal of Plastic Engineering, 2021, 28(12): 97 − 102. doi: 10.3969/j.issn.1007-2012.2021.12.012

[23] 郭柱, 朱浩, 崔少朋, 等. 7075铝合金搅拌摩擦焊接头温度场及残余应力场的有限元模拟[J]. 焊接学报, 2015, 36(2): 92 − 96. Guo Zhu, Zhu Hao, Cui Shaopeng, et al. Finite element simulation of temperature field and residual stress field of 7075 aluminum alloy friction stir welding joint[J]. Transactions of the China Welding Institution, 2015, 36(2): 92 − 96.

-

期刊类型引用(6)

1. 刘金浩,李家辰,张亮亮,吴宝生,李鹏,董红刚. Al-Mg合金搅拌摩擦焊接头的组织演变及腐蚀性能. 机械制造文摘(焊接分册). 2025(02): 13-22+36 .  百度学术

百度学术

2. 金聪聪,黄立兵,黄文彬,王大力,马月婷,李鹏,董红刚. 新型铝合金MIG焊接头微观组织与力学性能. 焊接学报. 2024(07): 74-82 .  本站查看

本站查看

3. 薛新莲,臧华平,王洪建,李顺方. 铝合金板激光切割实验工艺研究. 激光杂志. 2024(09): 183-187 .  百度学术

百度学术

4. 陈晓,闫成旗,代俊辉. 基于IRSM的7075铝合金焊接接头抗拉强度可靠性优化设计. 焊接. 2024(10): 32-41 .  百度学术

百度学术

5. 刘金浩,李家辰,张亮亮,吴宝生,李鹏,董红刚. Al-Mg合金搅拌摩擦焊接头的组织演变及腐蚀性能. 焊接学报. 2024(10): 8-18 .  本站查看

本站查看

6. 邓伟,罗坤,雷基林,宋仲模,徐远志,张勇. 基于灰色关联性分析的铝合金缸体铸造工艺参数优化. 特种铸造及有色合金. 2024(11): 1511-1517 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: