Diffusion bonding of 316L stainless steel

-

摘要: 印刷电路板式换热器具有多层薄壁、微通道的结构,如何实现其高质量连接的问题亟待解决. 316L不锈钢因其优异的力学性能、焊接性能与耐腐蚀性能,常用于印刷电路板式换热器的制造. 文中采用真空扩散连接的方法实现了316L奥氏体不锈钢的连接,并探究了最优工艺参数,建立了工艺参数—界面组织—力学性能之间的关系. 结果表明,随焊接温度升高和保温时间的延长,接头焊合率、变形率上升,晶粒尺寸增长,硬度下降,抗拉伸剪切强度先升高后降低. 1 000 ℃–60 min–10 MPa为最优参数,此时接头抗剪强度最高,为626 MPa. 该参数下的断裂方式为塑性断裂,断口呈典型的韧窝花样.Abstract: The printed circuit heat exchanger (PCHE) has a multilayer, thin-walled, micro-channel structure. Solving the problem of achieving its high-quality connection is urgently needed. 316L stainless steel is commonly used to manufacture PCHE due to its excellent mechanical properties, weldability, and corrosion resistance. In this study, vacuum diffusion bonding was used to connect 316L stainless steel. The optimal process parameters of the diffusion bonding process were explored, and the relationship between the process parameters, interface structure, and mechanical properties was established. With increasing bonding temperature and holding time, the bonding rate, grain size, and deformation rate of the joints continue to increase, while the hardness continues to decrease. The tensile shear strength initially increases and then decreases. A temperature of 1000 ℃, time of 60 min, and pressure of 10 MPa are the optimal parameters, giving a maximum joint strength of 626 MPa. The fracture morphology of the bonded joint was a dimple pattern with features of ductile fracture.

-

0. 序言

316L不锈钢具有优良的力学性能、焊接性能及耐腐蚀性能,广泛应用于石油化工、海洋环境装置等领域[1]. 印刷电路板式换热器是海上天然气液化装置用紧凑高效换热器的首选,由多层经过化学蚀刻得到带有流体通道的薄板连接后形成的换热器芯体和封头组成,制造难点为将多层大面积薄板精密连接为整体结构[2]. 目前,不锈钢薄板的主要连接方法有熔焊、搅拌摩擦焊等[3-10]. 其中,熔焊难以实现大面积薄板的多层连接;搅拌摩擦焊会挤压薄板上的流动通道,难以实现精密连接. 扩散连接具有接头质量好、变形小、精度高等优点,可以连接大面积复杂板件,提高结构完整性,更适于印刷电路板式换热器的制造[11-12].

David[13]研究了用于制造扩散连接紧凑型热交换器材料的特性. 316L不锈钢能够满足其室温和高温强度要求,在扩散连接方法制造紧凑型热交换器领域具有广泛的应用前景. 杨晓雅[14]研究了316LN奥氏体不锈钢的奥氏体晶粒长大规律. 结果表明,当温度低于等于1 000 ℃时,晶粒长大速度很慢,温度高于1 100 ℃时,晶粒急剧长大,初始晶粒中的细小晶粒几乎已经被吞并完全,奥氏体晶粒明显锐化. 王敏等人[15]研究了温度对316L不锈钢力学性能的影响,随温度升高,316L不锈钢的屈服极限和弹性模量均明显下降,在600 ℃下,屈服极限和弹性模量分别降至室温时的73%和39%;在1 000 ℃下,屈服极限和弹性模量分别降至室温时的25%和14%. 因此,需确定316L不锈钢扩散连接的工艺参数,使其在晶粒不过分长大,且能保证一定的强度和塑性的条件下完成良好连接.

文中对316L不锈钢进行扩散连接,并研究其最优工艺参数,分析工艺参数对接头显微组织和力学性能的影响规律,为印刷电路板式换热器的实际应用提供一定理论基础.

1. 试验方法

试验采用的不锈钢母材为316L不锈钢,牌号为022Cr17Ni12Mo2,熔点为1 375 ℃. 扩散焊试验在真空高温扩散焊炉中进行,试验开始时的真空度为1.5 × 10−3 Pa,试验过程中真空度一直保持在5.0 × 10−3 Pa以下. 采用电火花线切割机床将316L不锈钢板加工成尺寸为40 mm × 40 mm × 2 mm的试样,将试样表面依次用100号到7000号砂纸水磨,之后置入丙酮溶液进行超声清洗、烘干.图1a为装配示意图,采用搭接形式,搭接长度为 2.0 mm.加热曲线如图1b所示,加热速率为10 ℃/min,在升温至400,800 ℃时分别保温10 min, 加热完成后以 5 ℃/min的降温速度降至400 ℃ 后随炉冷却. 焊接温度区间为900 ~ 1 100 ℃,保温时间区间为30 ~ 120 min,焊接压力为10 MPa.

通过电子万能试验机(型号MTS-E45.105)进行室温下的拉伸剪切试验评估接头的强度,加载速率为0.06 mm/s,每个试验参数下至少取3个试样进行测试. 利用热场发射扫描电镜(JSM-7800F)观察接头微观组织和断口形貌,利用电制冷能谱探头(EDS)分析界面的元素扩散情况,通过电子背散射衍射(EBSD)研究晶粒取向差异. 在维氏硬度仪(MH-6L)上测试接头的显微硬度,测试载荷和时间分别是0.1 N和15 s.

2. 结果与讨论

2.1 工艺参数对接头界面组织的影响

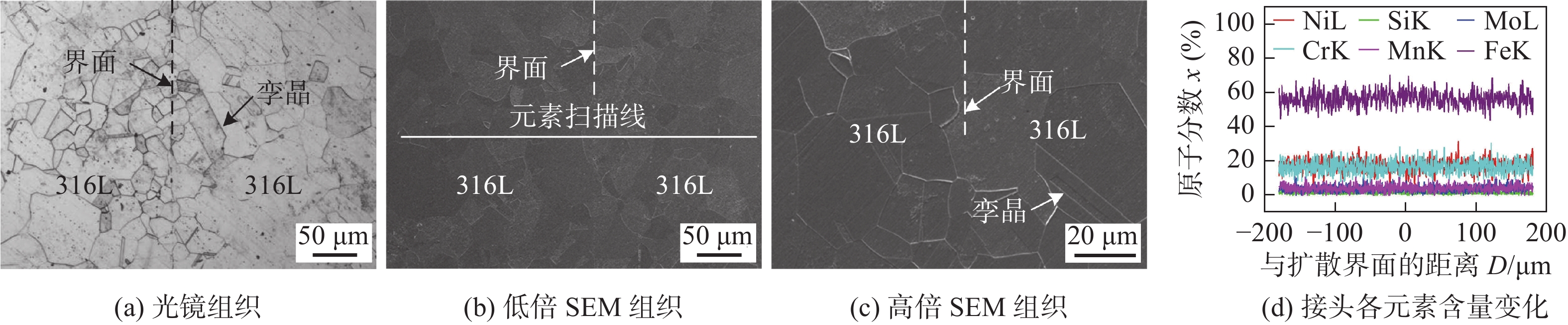

图2为在温度1 000 ℃,保温时间60 min,焊接压力10 MPa条件下,316L不锈钢真空扩散焊接头的典型组织和元素线扫描结果. 从图2中可以观察到,接头中没有明显的孔洞、裂纹等缺陷,表明在该工艺参数下可以达成较好的冶金连接. 在316L不锈钢扩散焊试样的晶粒内部可观察到孪晶组织. 根据线扫描结果可得,对应316L不锈钢试样的扩散界面处与母材位置的元素成分相比没有变化,接头中不存在元素偏聚,没有第二相析出.

图3为316L不锈钢在1 000 ℃–60 min– 10 MPa扩散焊工艺参数下接头的EBSD分析结果,由此可知接头界面处无特征晶粒取向,界面组织为等轴晶,部分晶粒内部可观察到孪晶. 不锈钢母材经过热处理后晶粒长大,晶界趋向平直,且层错能较低,易形成孪晶. 根据EBSD统计晶界角度可知,在316L不锈钢扩散连接界面扫描区域内,基本均为>15º的大角度晶界,小角度晶界出现频率仅为7.7%. 在60º取向差附近存在一个较明显的峰,这是组织中存在∑3(60º/<111>)孪晶界造成的. 根据反极图可以看出极密度强度(MUD)最大为2.830,一般认为当MUD>10之后择优取向比较明显,因此界面组织晶粒取向分布均匀,未出现明显织构.

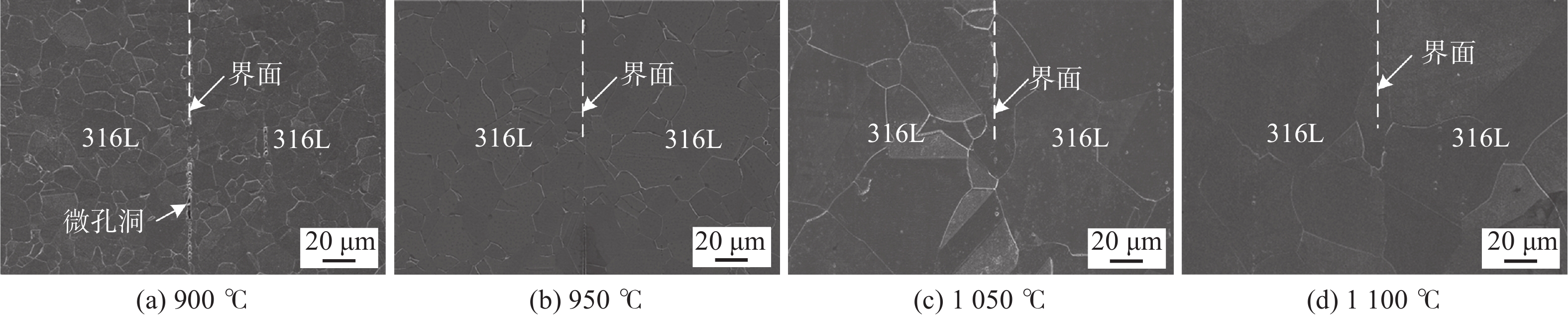

为进一步探究工艺参数对接头组织的影响,进行了不同工艺参数的扩散焊连接实验. 图4为在固定保温时间60 min和焊接压力10 MPa条件下,焊接温度分别为900,950,1 050,1 100 ℃的试样接头显微组织. 图4中不同尺寸的晶粒显示原奥氏体晶粒的长大是大晶粒逐渐吞并小晶粒的过程. 此外,随着加热温度的升高,奥氏体晶界逐渐平直,晶粒平均尺寸增大.

在固定焊接温度为1 000 ℃,焊接压力为 10 MPa条件下,探究了时间参数对316L不锈钢扩散连接界面组织的影响. 图5是保温时间分别为30,60,90,120 min的试样接头显微组织. 可以看出,晶粒在保温过程中不断合并长大,仍然遵循随着保温时间延长晶粒通过晶界迁移发生长大,晶粒尺寸增长的规律. 但对比之下,加热温度对晶粒大小的影响明显大于保温时间.

为了确定不同参数下的晶粒尺寸和焊合率,根据国家标准GB/T 6394—2017《金属平均晶粒度测定方法》计算试样的晶粒尺寸. 经测定,未经热处理母材的晶粒尺寸为12.30 μm,随焊接温度的升高与保温时间的延长,扩散界面处的未焊合区域逐渐减少,孔洞数量逐渐减少,焊合率升高,晶粒尺寸增大,与界面组织结果一致. 焊接温度为1 000 ℃,保温时间为60 min时,焊合率约为93.86%,为扩散连接的最佳参数,见表1、表2.

表 1 各温度参数下接头晶粒尺寸与焊合率统计Table 1. Statistical table of joint grain size and bonding rate at various temperature焊接温度T/℃ 晶粒尺寸d/μm 焊合率ε(%) 900 23.04 55.99 950 38.74 86.21 1 000 70.81 93.86 1 050 125.43 94.81 1 100 197.51 99.22 表 2 各时间参数下接头晶粒尺寸与焊合率统计Table 2. Statistical table of joint grain size and bonding rate at various time保温时间t/min 晶粒尺寸d/μm 焊合率ε(%) 30 57.31 74.15 60 70.81 93.86 90 75.10 94.15 120 132.59 98.61 2.2 工艺参数对接头力学性能的影响

图6a为固定保温时间60 min,接头变形率与拉伸剪切强度随温度的变化规律. 随着温度的升高,接头的变形率逐渐增大. 由于在更高温度下316L不锈钢的塑性升高,施加压力后试样更易变形. 随着温度的升高,试样的强度先升高后降低,在温度为1 000 ℃时强度最高为626 MPa. 未经热处理的316L母材拉伸强度为637 MPa. 焊接温度较低时,接头的焊合率较低,界面上存在尚未闭合的孔洞,接头的强度小于母材的强度,在接头位置断裂. 焊接温度较高时接头的焊合率较高,扩散连接过程更加完全,接头强度达到母材强度,导致试样在更为薄弱的母材位置断裂. 在1 000,1 050,1 100 ℃参数试样的对比中,晶粒尺寸异常增长的影响较大,晶粒的长大致使位错塞积群中的位错数量增多,应力集中增加,晶粒粗化致使裂纹源增多,裂纹扩展晶界阻力降低,强度降低.

保温时间对接头力学性能的影响与扩散温度的规律一致,如图6b所示. 随着保温时间的延长,316L不锈钢在高温条件下受压时间延长,塑性变形量更大,接头的变形率逐渐增大. 整体来看随着保温时间的延长,原子扩散更加充分,有利于成分和组织的均匀分布,但扩散连接的温度处于金属再结晶温度以上,过长的保温时间并不能够提高接头质量,反而会使接头区域晶粒变大,强度降低. 在时间为60 min时强度最高,为626 MPa.

固定保温时间为60 min,焊接温度分别为900 ,1 000 ,1 100 ℃下接头各区域显微硬度的变化情况如图7a所示. 界面附近与母材区域的维氏硬度值并没有明显变化,整体保持在15 HV以内的波动,这是由于在316L不锈钢扩散连接过程中并无元素的偏聚,没有第二相的产生. 经过测定未经过热处理的316L母材硬度为200 HV,与其相比各个温度参数的硬度均降低. 扩散连接的温度在316L不锈钢的固溶温度区间内,此时会发生碳化物和合金元素的充分溶解,获得更为均匀的单相奥氏体组织. 316L不锈钢随温度升高,弹性模量E明显下降,室温下塑性升高,硬度值降低,因此接头的硬度值会随着焊接温度的升高而降低.

图7b为选取了焊接温度为1 000 ℃,保温时间为30,60,120 min下接头各区域显微硬度的变化情况. 保温时间延长,接头组织成分均匀化的时间延长,奥氏体化更加充分,致使其在室温下的塑性越好,硬度值越低,这与不同焊接温度下接头硬度的变化规律基本一致.

2.3 接头断口位置及断口微观形貌分析

通过观察典型断口形貌,对接头的断裂机理进行了分析. 图8显示了在不同扩散温度下的316L不锈钢扩散连接接头的断口形貌(60 min,10 MPa). 从图8中可以明显区分出两种典型的断裂类型,分别为接头界面(图8a)和母材(图8b)处断裂.

在焊接温度分别为900 ,950 ℃时,拉伸剪切断口位置在接头,而其余3个接头的断口位置在母材. 在焊接温度较低时,韧性断裂的特征较不明显,部分位置存在小而浅的韧窝,接头中存在未连接的孔洞. 因此,裂纹首先在孔洞区域萌生、扩展,而后沿着接头处的界面断裂,接头的强度较低. 当焊接温度增加到1 000 ℃时,断裂发生在母材上,断口形貌主要为等轴韧窝,接头形成良好的扩散连接. 与950 ℃断口相比,韧窝尺寸逐渐增大,韧窝深度逐渐加深. 根据断口理论,韧窝的大小和深浅决定于材料断裂时微孔数量和材料本身的相对塑性,韧窝越小越浅,材料塑性越差,反之塑性良好,可知材料的塑性随着焊接温度升高而提高,接头的强度也随之升高. 此外,晶粒尺寸的增长使316L不锈钢母材的强度略有下降. 因此,焊接温度较低时会导致孔洞未闭合、扩散反应不充分,而焊接温度较高导致晶粒尺寸增长,强度降低.

3. 结论

(1) 焊接温度与保温时间会显著影响316L不锈钢扩散连接接头的焊合率和晶粒尺寸. 在900 ~ 1 100 ℃温度范围内,随着焊接温度的升高接头中孔洞逐渐减少,焊合率自55.99%升高至99.22%,晶粒尺寸从23.04 μm长大到197.51 μm. 在30 ~ 120 min时间范围内,随着保温时间的延长,元素扩散更充分,焊合率自74.15%升高至98.61%,晶粒尺寸从57.31 μm增至132.59 μm.

(2) 焊接温度与保温时间均会对316L不锈钢扩散连接接头的变形率、拉伸剪切强度、硬度等性能产生显著影响. 温度较低时扩散反应不完全,温度较高时会导致晶粒粗化从而影响力学性能. 在900 ~ 1 100 ℃温度范围内,随着温度的升高,变形率从0.26%升高到10.32%,抗拉伸剪切强度自 339 MPa先升至626 MPa再降至570 MPa,硬度从183 HV降到159 HV. 在30 ~ 120 min时间范围内,随着保温时间的延长,变形率从0.67%升高到7.67%,抗拉伸剪切强度自601 MPa先升至626 MPa再降至490 MPa,硬度从178 HV降到163 HV. 最优工艺参数为1 000 ℃保温60 min,此时接头抗拉伸剪切强度最高,为626 MPa.

(3) 在900 ℃下保温60 min时试样与在950 ℃下保温60 min、950 ℃–60 min时试样断裂位置为接头界面外,其它参数下断裂位置在母材处,断裂方式为韧性断裂,断口呈现出典型韧窝花样.

-

表 1 各温度参数下接头晶粒尺寸与焊合率统计

Table 1 Statistical table of joint grain size and bonding rate at various temperature

焊接温度T/℃ 晶粒尺寸d/μm 焊合率ε(%) 900 23.04 55.99 950 38.74 86.21 1 000 70.81 93.86 1 050 125.43 94.81 1 100 197.51 99.22 表 2 各时间参数下接头晶粒尺寸与焊合率统计

Table 2 Statistical table of joint grain size and bonding rate at various time

保温时间t/min 晶粒尺寸d/μm 焊合率ε(%) 30 57.31 74.15 60 70.81 93.86 90 75.10 94.15 120 132.59 98.61 -

[1] 胡建伟, 张 骁, 蒋佳良, 等. 316L不锈钢电热管弯曲断裂的研究[J]. 全面腐蚀控制, 2019, 33(5): 64 − 67. Hu Jianwei, Zhang Xiao, Jiang Jialiang, et al. Bending fracture of 316L stainless steel electric heating tube[J]. Total Corrosion Control, 2019, 33(5): 64 − 67.

[2] Mueggenburg H H, Hidahl J W, Kessler E L, et al. Platelet actively cooled thermal management devices, AIAA 92-3127[R]. Nashville: American Institute of Aeronautics and Astronautics, 1992.

[3] Xu Tao, Wang Zishun, Shi Yonghua. Investigation of C276 alloy and 316L SS TIG welded joints with ERNiCrMo-4 and ER304 welding wires[J]. China Welding, 2021, 30(4): 9 − 16.

[4] Torkamany M J, Sabbaghzadeh J, Hamedi M J. Effect of laser welding mode on the microstructure and mechanical performance of dissimilar laser spot welds between low carbon and austenitic stainless steels[J]. Materials & Design, 2012, 34: 666 − 672.

[5] 程小华, 李小宇. 核电用不锈钢双钨极氩弧焊接头组织与性能[J]. 焊接学报, 2022, 43(7): 108 − 112. doi: 10.12073/j.hjxb.20220617001 Cheng Xiaohua, Li Xiaoyu. Structure and properties of the double tungsten argon arc hybrid welding joint of stainless steel used in nuclear power plant[J]. Transactions of the China Welding Institution, 2022, 43(7): 108 − 112. doi: 10.12073/j.hjxb.20220617001

[6] 王晓光, 刘奋成, 方 平, 等. CMT电弧增材制造316L不锈钢成形精度与组织性能分析[J]. 焊接学报, 2019, 40(5): 100 − 106. doi: 10.12073/j.hjxb.2019400135 Wang Xiaoguang, Liu Fencheng, Fang Ping, et al. CMT arc additive manufacturing 316L stainless steel forming accuracy and tissue properties analysis[J]. Transactions of the China Welding Institution, 2019, 40(5): 100 − 106. doi: 10.12073/j.hjxb.2019400135

[7] 杨明轩, 齐铂金, 从保强, 等. 不锈钢超高频直流脉冲GTAW焊缝成形行为[J]. 焊接学报, 2012, 33(11): 31 − 34. Yang Mingxuan, Qi Bojin, Cong Baoqiang, et al. Stainless steel UHF DC pulse GTAW weld seam forming behavior[J]. Transactions of the China Welding Institution, 2012, 33(11): 31 − 34.

[8] Meysam H, Saman M. Microstructure and mechanical properties of friction stir processed AISI 316 stainless steel: Evaluation of the effect of cooling media and multi-step processing on microstructure and mechanical properties of friction stir processed AISI 316 stainless steel[J]. Metallography, Microstructure, and Analysis, 2022, 11: 72 − 87. doi: 10.1007/s13632-021-00815-w

[9] Hamed J A, Altino L. Effect of inverse differential friction stir welding on properties of AA7075 and AISI304 welds[J]. Chinese Journal of Nonferrous Metals (English Edition), 2019, 29(5): 964 − 975.

[10] Lu Y, Xu X, Zhang B, et al. Microstructural analysis and mechanical behavior of TC4 Titanium alloy and 304 stainless steel by friction stir lap welding[J]. Weld World, 2021, 65: 1915 − 1930. doi: 10.1007/s40194-021-01133-z

[11] He P, Feng J C, Zhang B G, et al. Microstructure and strength of diffusion-bonded joints of TiAl base alloy to steel[J]. Materials Characterization, 2002, 48(5): 401 − 406. doi: 10.1016/S1044-5803(02)00319-4

[12] He P, Zhang J H, Feng J C, et al. Diffusion bonding of TiAl to Ti and TC4 alloy[J]. Acta Metallurgica Sinica (English Letters), 2000, 13(1): 162 − 167.

[13] David S. Diffusion bonding in compact heat exchangers[J]. Transactions of the American Nuclear Society, 2009, 100: 265 − 267.

[14] 杨晓雅. 核电用316LN奥氏体不锈钢热变形组织演变与断裂行为[D]. 北京: 北京科技大学, 2016. Yang Xiaoya. Heat deformation tissue evolution and fracture behavior of 316LN austenitic stainless steel for nuclear power[D]. Beijing: University of Science and Technology Beijing, 2016.

[15] 王敏, Michel G, Jullien J F. 316L奥氏体不锈钢焊接热影响区性能[J]. 上海交通大学学报, 2001, 35(3): 424 − 426. Wang Min, Michel G, Jullien J F. Thermal simulation on the welding heat affected zone of 316L Steel[J]. Journal of Shanghai Jiao Tong University, 2001, 35(3): 424 − 426.

-

期刊类型引用(2)

1. 蒋健安. 扩散焊参数对316L不锈钢微通道结构板片的焊接影响研究. 科技资讯. 2024(05): 95-97 .  百度学术

百度学术

2. Qimeng Liu,Jingyu Chang,Yuanzhi Wang,Dong Xia,Jianfei Zhang,Xinlong Guan,Yuwei Zhou,Bing Yang. Influence of Multiple Repair Welding on Microstructure and Properties of 06Cr19Ni10 Stainless Steel. Chinese Journal of Mechanical Engineering. 2024(05): 500-517 .  必应学术

必应学术

其他类型引用(4)

下载:

下载: