Analysis of the theory and temperature field of additive manufacturing with powder core wire based on Cu-Al-Fe alloy

-

摘要: 目前有关粉芯丝材增材制造的研究较少,其理论尚不成熟. 将Cu-Al-Fe合金作为研究对象,系统论述了粉芯丝材电弧增材制造的相关理论 (沉积成形理论、梯度传热理论和晶粒细化理论),并使用Simufact-Welding平台搭建了单道多层数值模型,通过对多组别温度场的分析,获得了试验条件下的最佳工艺窗口,即输入电流140 A和扫描速度0.4 m/min,最后开展了优化工艺窗口下的粉芯丝材沉积成形试验. 结果表明,在此工艺窗口下可获得形状较好的薄壁墙,该研究为开展粉芯丝材电弧增材制造提供必要的理论基础与试验依据.Abstract: There are few studies on additive manufacturing with powder core wire, and its theory is still immature. Taking Cu-Al-Fe alloy as the research object, this paper systematically discusses the relevant theories of additive manufacturing with powder core wire (deposition forming theory, gradient heat transfer theory and grain refinement theory). The Simulact-Welding platform was used to build a single-channel and multi-layer numerical model. Through the analysis of the multi-group temperature field, the optimal process window under the test conditions is obtained, the input current of 140 A and scanning speed of 0.4 m/min. Finally, the deposition forming test of powder core wire under the optimized process window is carried out. The results indicate that taking the optimized process can obtain a thin wall with a good shape. And this study can provide the necessary theoretical and experimental basis for arc additive manufacturing with powder core wire.

-

0. 序言

近年来,通过增材制造技术制备Cu-Al系形状记忆合金引起了人们极大的兴趣[1-3]. 以形状记忆合金与增材制造技术相结合是研究Cu-Al系记忆合金材料4D构件的新方向,也是当今解决Cu-Al系记忆合金这种智能材料构件复杂成形问题的有效手段. Lu等人[4] 阐述了金属直接成形和结构体的“设计-材料-制造”一体化是增材制造重要的发展趋势.

以粉末材料为代表的激光选区熔化技术,除所制备合金致密度尚不够理想之外,还存在着粉末利用率低、元素易烧损等问题[5]. 以丝材为代表的电弧增材制造技术,合金实心丝材制备成形往往受合金塑形等因素的影响,故实心丝材的选用主要集中于塑性材料,而焊接材料中的药芯焊丝因含造渣剂不适合用于增材制造金属直接成形[6];粉芯丝材,以往主要作为表面工程与再制造工程中热喷涂和堆焊,其具有成分调节容易、调节范围广、可获得特殊合金成分等独特的优越性[7]. 王宏宇等人[8] 提出了以高沸点外皮包裹低沸点粉芯制备增材制造记忆合金用材的新思路,所制备的记忆合金增材制造粉芯丝材,不仅具有粉芯丝材便于调整合金成分等优点,还可以抑制记忆合金中易烧损元素的烧损,从而为在保证记忆合金成分准确及便于调控的情况下获得良好记忆性能的形状记忆合金提供了一种新型增材制造用原材料.

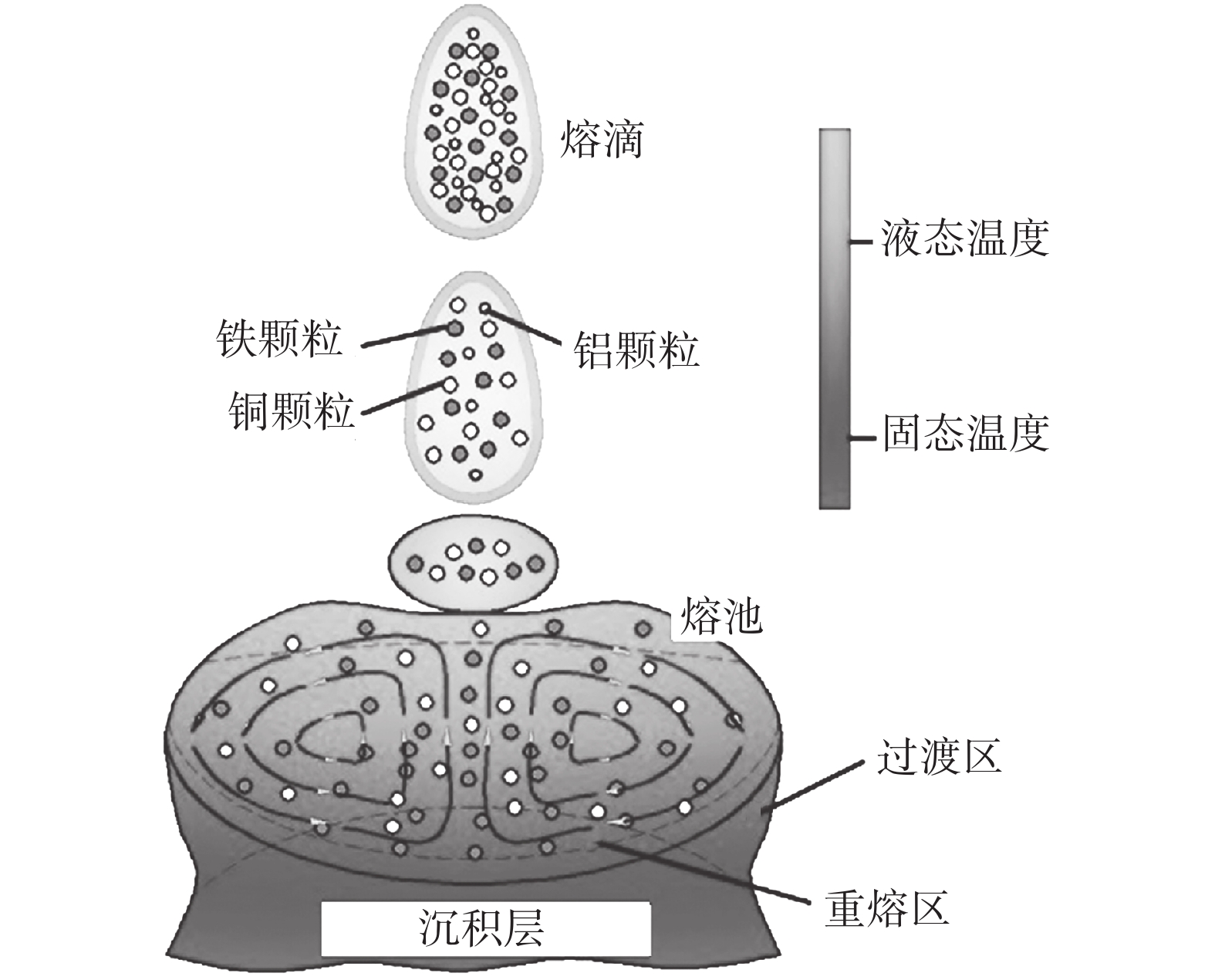

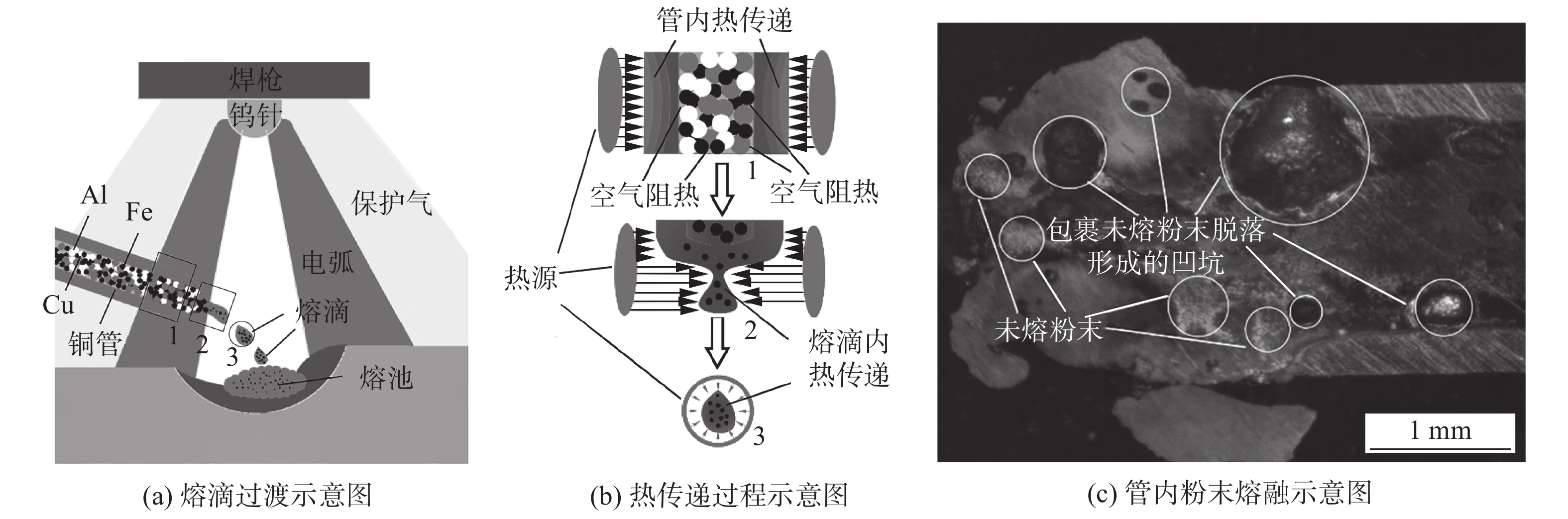

与传统的丝材 + 电弧增材制造不同的是,粉芯丝材增材制造成形过程是在弧柱区以梯度传热形式先熔化外皮形成熔滴空腔再逐渐侵吞、熔化内部粉末,在弧柱区球化增大后受重力影响落入熔池,随后熔滴内外层彻底熔融并于熔池内湿润铺展沉积成形. 然而, 涉及粉芯丝材电弧增材制造形状记忆合金研究工作较少,相关理论研究尚未成熟. 故基于课题组前期的研究[9-10],系统论述了粉芯丝材电弧增材制造的相关理论,并以Cu-Al-Fe合金为对象,对粉芯丝材电弧增材制造温度场进行了研究.

1. 粉芯丝材熔融沉积成形理论

1.1 粉芯丝材的构成与制作

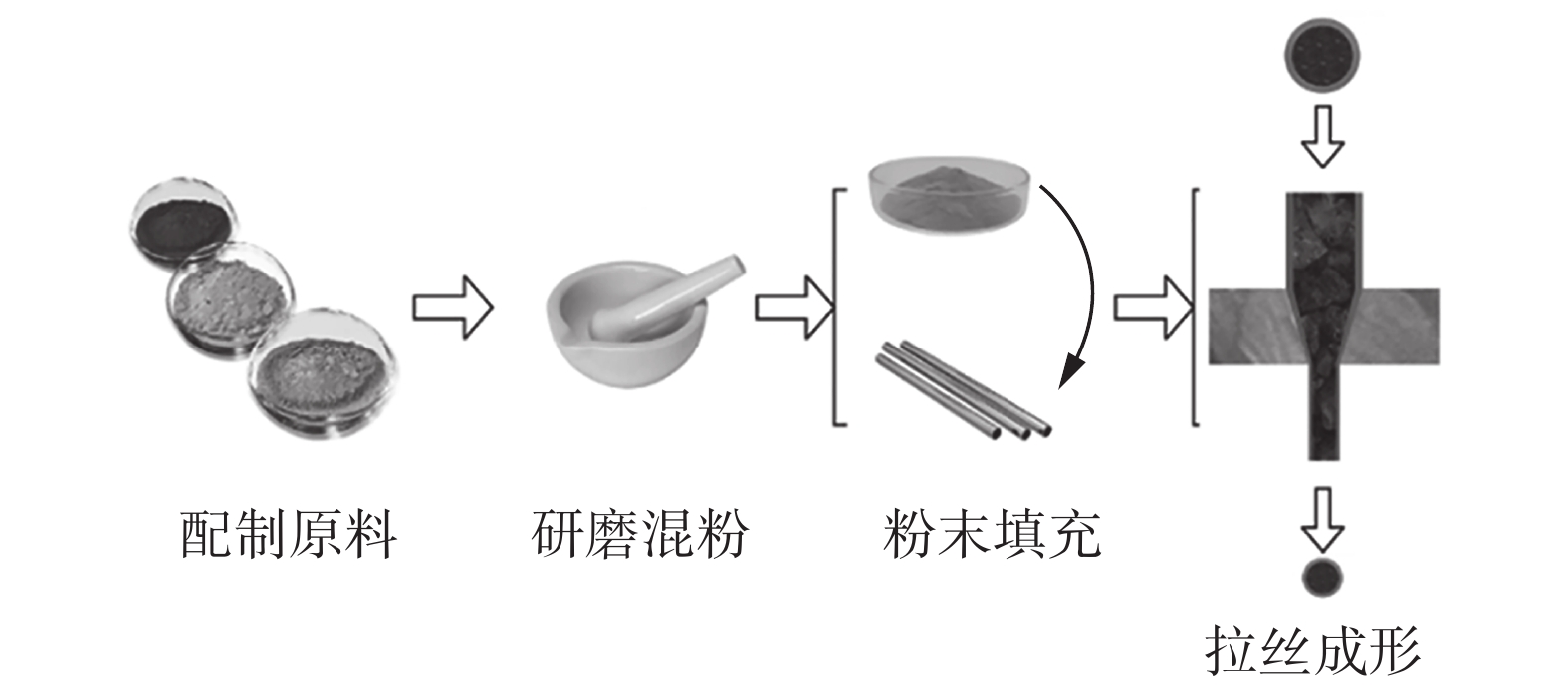

粉芯丝材作为一种典型的“皮包粉”结构,同时结合了实心丝材与药芯焊丝的优势,在便捷调控成分的同时,又降低了成形时成分的氧化烧损比率. 所涉及的新型粉芯丝材[11] 利用的是以高沸点、低熔点、导热性较佳的紫铜管作为外皮包裹混合粉末,外皮内粉末中一般存在易烧损元素 (被保护对象)、改性元素 (第三/第四组元、孕育剂) 和配重补充元素 (外皮元素粉末). 其制备工艺流程如图1所示,主要包含配制原料、研磨混粉、粉末填充、拉丝成形等步骤. 按照“等成分、等体积”[12] 设计原则配制后经充分研磨制成混合粉,研磨时间必须严格控制,在达到预合金化前提下尽量减少空气污染;称量混合粉在振动灌装装置辅助下将其填入铜管,最后,采用轧尖拉拔装置拉制成丝.

1.2 粉芯丝材熔融沉积成形机制

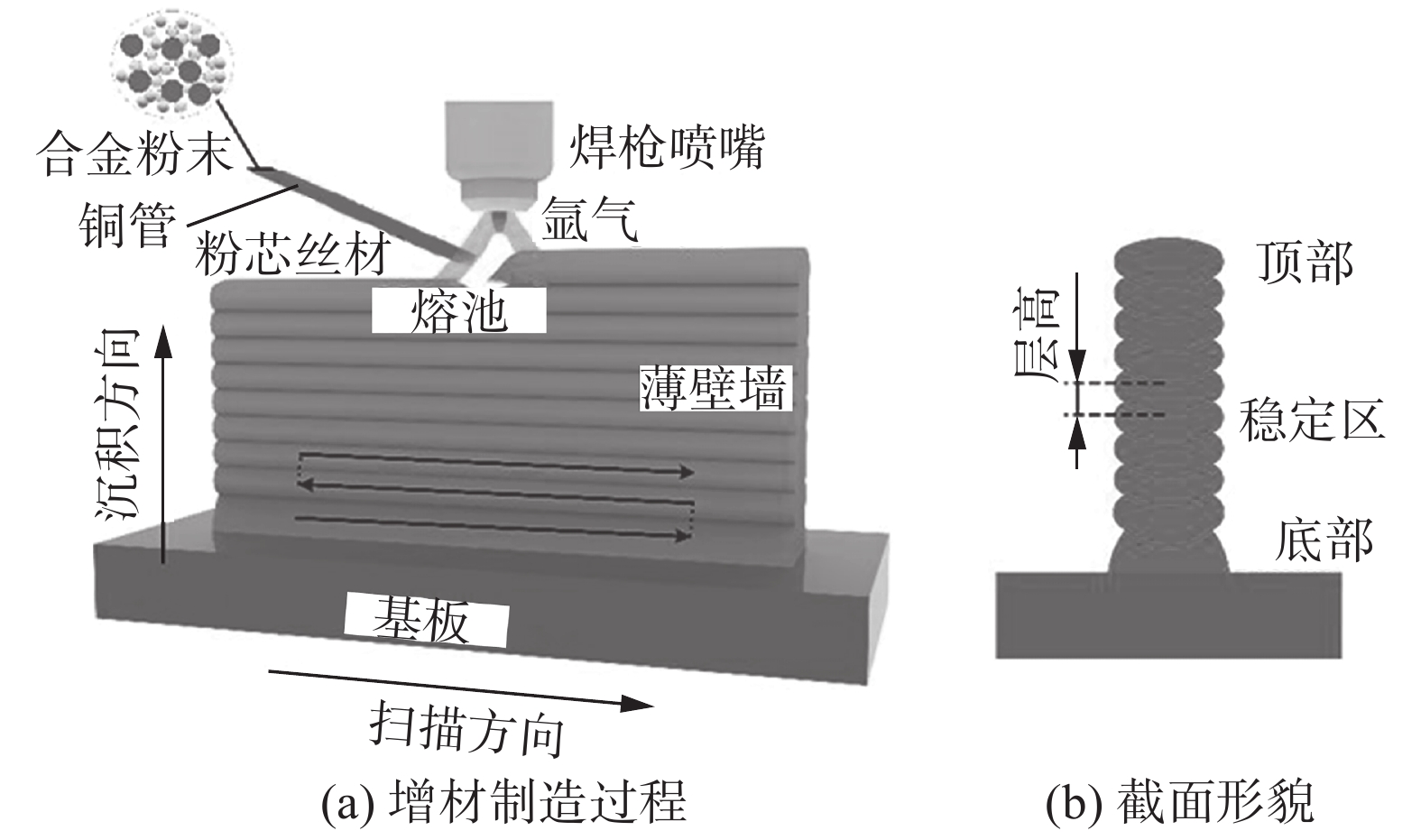

粉芯丝材 + 电弧增材制造,与其它增材制造方式一样能通过逐层沉积材料,以离散−堆积形式直接从专用3D CAD模型中成形3D制件. 现较为流行的实芯丝材 + 电弧增材制造成形方式是通过单丝/多丝 (混合元素金属或纯金属) 形式在电弧作用下形成以熔滴−熔池过渡形式的沉积成形,采用多成分单丝时可直接形成混合熔滴耦入熔池中,但是成分难以调控,且弱元素 (蒸汽压低的元素) 直接在弧柱区暴露容易造成蒸发,而采用多成分多丝时形成多熔滴−熔池耦合模型,易造成熔池内成分不均. 如图2和图3所示,粉芯丝材 + 电弧增材制造过程中粉芯丝材表皮熔化后在表面张力作用下一边球化增大,一边侵吞内部粉末,随后受重力影响源源不断汇聚于熔池中,过程中伴随着旧沉积层的重熔与熔池凝固带来新沉积层的形成. 比较特别的是,粉芯丝材熔滴内含有粉末,因而所需能量相对实心丝材较少,熔池热累积减少,在弧柱区形成的熔滴空腔减少了元素在弧柱区的暴露时间,降低元素受蒸汽压影响而挥发,相比药芯焊丝,熔池中少了助溶剂等成分有利于控制堆层间夹杂物的形成,从而降低缺陷 (裂纹、孔隙、氧化夹渣等) 对于特殊成分的敏感性[13]. 而等比例填入的粉末在熔化过程中逐渐与外皮融为一体,在重力、表面张力、电磁力、等离子流力和斑点压力等作用力综合影响下在熔池中被充分搅拌,液态金属流动、铺展,至最终凝固形成成分较为均匀的合金.

粉芯丝材 + 增材制造在熔池成分均匀化、元素止损、成分调控等方面具有显著优势. 作为一种新型的制造方式,粉芯丝材增材制造方法为沉积成形制造提供了一种新思路,尤其是关于内部粉末在微观组织与性能调控方面具有积极作用. 粉芯丝材的独特性对于增材制造而言,与液态金属流动性以及气孔缺陷呈现高相关性. 根据文献[13]可知,气孔的形成会破坏合金的力学性能与记忆性能,液态金属流动性控制更是在制件的成形精度与质量方面得到充分体现,而这些均与增材制造时的熔池温度有较高的联系. 与焊接不同的是,电弧增材制造是焊缝层逐层堆积的过程,沉积层的组织与性能和热循环过程息息相关,而热循环过程则受焊接电流、扫描速度与丝材直径等直接影响. 这些参数在成形过程中直接关系到粉芯丝材熔融沉积过程中各层间热累积差异,进而对熔融区、热影响区等代表性区域的元素分布以及含量、微观组织演变等造成较大影响. 尤其是在起弧与熄弧阶段,此时熔池流动紊乱,温度变化影响明显,对获得较好的沉积特性十分不利. 因而,面向粉芯丝材 + 增材制造的相关研究必须基于所涉及合金取得最佳工艺窗口基础上展开.

1.3 粉芯丝材增材制造梯度传热机制

聚焦于粉芯丝材内部,其中的粉芯即使经过拉拔拥有较高紧实度,但究其实质而言仍类似于“多孔材料”,内部形成“金属−空气−金属−空气”[14]的导热形式,空气导热效果差,孔中残存的空气对热量传递势必形成热阻,如图4所示.

粉芯丝材熔融沉积过程中,热量首先作用在作为外皮的铜管上,然后经铜管传至管内粉芯,尽管粉末化一定程度上会降低材料熔点,但是由于空气的隔热作用使得能量传递呈现梯度性,熔化粉芯内部粉末的速度逐层降低. 而作为外皮的铜管热传导速度则很快,在弧柱区先熔化外皮形成熔滴空腔再逐渐侵吞、熔化内部粉末,在孤柱区球化增大后受重力影响落入熔池,随后熔滴内外层彻底熔融,并于熔池内润湿铺展沉积成形.

增材制造过程中元素的烧损,主要包括飞溅、氧化和蒸发3种形式. 考虑到增材制造过程多在保护气氛下进行,如电弧熔融沉积多在高纯氩气保护下进行的,故增材制造中的元素烧损主要以飞溅、蒸发为主. 以Cu-Al-Fe合金为例,增材制造所采用的粉芯丝材,以较高沸点铜作为外皮,以净含量为99.99%的铜、铝、铁粉混合研磨后的混合粉作为粉芯 (表1),可以较好地保护易烧损元素,从而较好地保证记忆合金成分的准确性.

表 1 Cu-Al-Fe合金中元素的熔点、沸点和粒径Table 1. Melting point, boiling point and particle size of elements in Cu-Al-Fe alloy元素 熔点Tm /℃ 沸点Tb /℃ 粒径d/目 Cu 1 085 2 562 325 Al 660.3 2 470 200 Fe 1 538 2 862 300 粉芯丝材在增材制造成形过程中对于成分保护来源于两个方面:一方面,受梯度传热效应影响,内部粉末熔化较慢,在熔滴的包裹作用下,紧实度高、混合均匀的内部粉末不会产生空腔剧烈爆炸反应而大面积溅射,相比其它用材飞溅更少,大大提高了粉末利用率. 同时,受外皮熔覆层保护作用,尽管铝粉蒸气压小易蒸发,但暴露面积大幅度缩减,从而对抑制铝粉的氧化烧损具有积极作用; 另一方面,相比纯铝粉,熔点较高的第3组元铁粉、配重补充元素铜粉与低熔点铝粉混合形成的预合金粉末整体熔点更高,可以有效地抑制副反应,从而提高其耐高温能力.

1.4 粉芯丝材晶粒细化机制

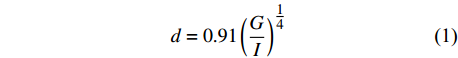

新型粉芯丝材特色是高沸点铜皮包裹低沸点混合粉末,同时在粉末中引入高熔点第3组元. 以Cu-Al-Fe合金为例,如图4所示,在熔化区,熔滴球化增大受重力影响落入熔池,熔池凝固过程中,部分未熔高熔点粉末作为初生相异质形核核心极大地提高了相变形核率.相变反应刚结束时,其晶粒尺寸为

$${{{{{d}}}}}=0.91\left(\dfrac{G}{I}\right)^{\tfrac{1}{4}} $$ (1) 式中:d为粒径;I为形核速率;G为核长大速率.

由式 (1) 推知,形核率与晶粒尺寸呈反比,形核密度越高,晶粒尺寸越小. 同时,液固相变过程中析出含铁κ相,在析出相的钉扎作用下,一方面,当钉扎作用力大于晶粒长大驱动力时,晶粒长大过程受析出相影响发生尺寸细化;另一方面,晶界迁移受到限制从而抑制了晶粒间相互吞噬行为造成的晶粒粗化. 综上,再次堆积时析出相可有效抑制已沉积层受弧柱区热影响而使底层晶粒异常长大[15] 产生混晶,促使合金形成均匀组织.

2. 粉芯丝材增材制造的温度场分析

电弧熔丝增材制造成形过程中的温度场变化会直接影响到制件形貌和性能的变化,基于粉芯丝材单道多层沉积成形热累积效应研究对于制备形性均一且优良的Cu-Al-Fe大型复杂件极具意义. 通过单一变量变化设计仿真数据,采用SIMUFACT公司开发的Simufact-Welding平台对电弧增材制造Cu-Al-Fe合金的温度场进行数值仿真. 以各层探测点温度为对象,探究热累积影响下不同层间温度变化的规律,以金属粉末熔沸点为数据参考并结合课题组前期研究成果,进而获得电弧增材制造Cu-Al-Fe记忆合金的最优工艺参数,并通过试验结果进行验证.

2.1 粉芯丝材参数的确定

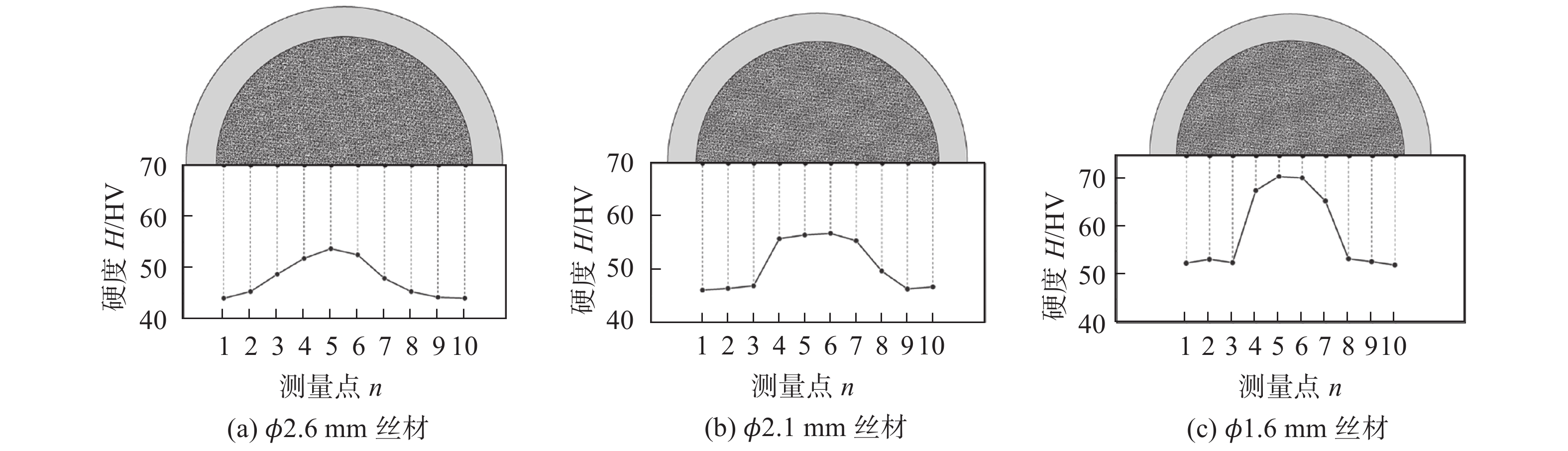

基于“等成分、等体积”圆管配材方法,以粉芯丝材振实密度和拉拔后粉芯体显微硬度为优化目标,经过进一步深化制备了以下3种符合试验要求的3种粉芯丝材. 粉芯丝材的直径分别为1.6,2.1,2.6 mm,填充率为28%,如图5所示.对比3种丝材发现,其显微硬度由中间向两边递减,外圈较为稳定. 其中,ϕ1.6 mm丝材靠近管内侧的粉末硬度水平区间较大,丝材中心部分硬度逐渐上升,其径向形状误差相对另外两者最大,这是在拉拔过程中残余应力不断累积所造成;ϕ2.1 mm丝材中心粉末硬度趋于平稳,且粉芯外侧与内侧硬度落差小;ϕ2.6 mm丝材从外到内部粉末硬度一直呈递增趋势,近乎没有水平区间.

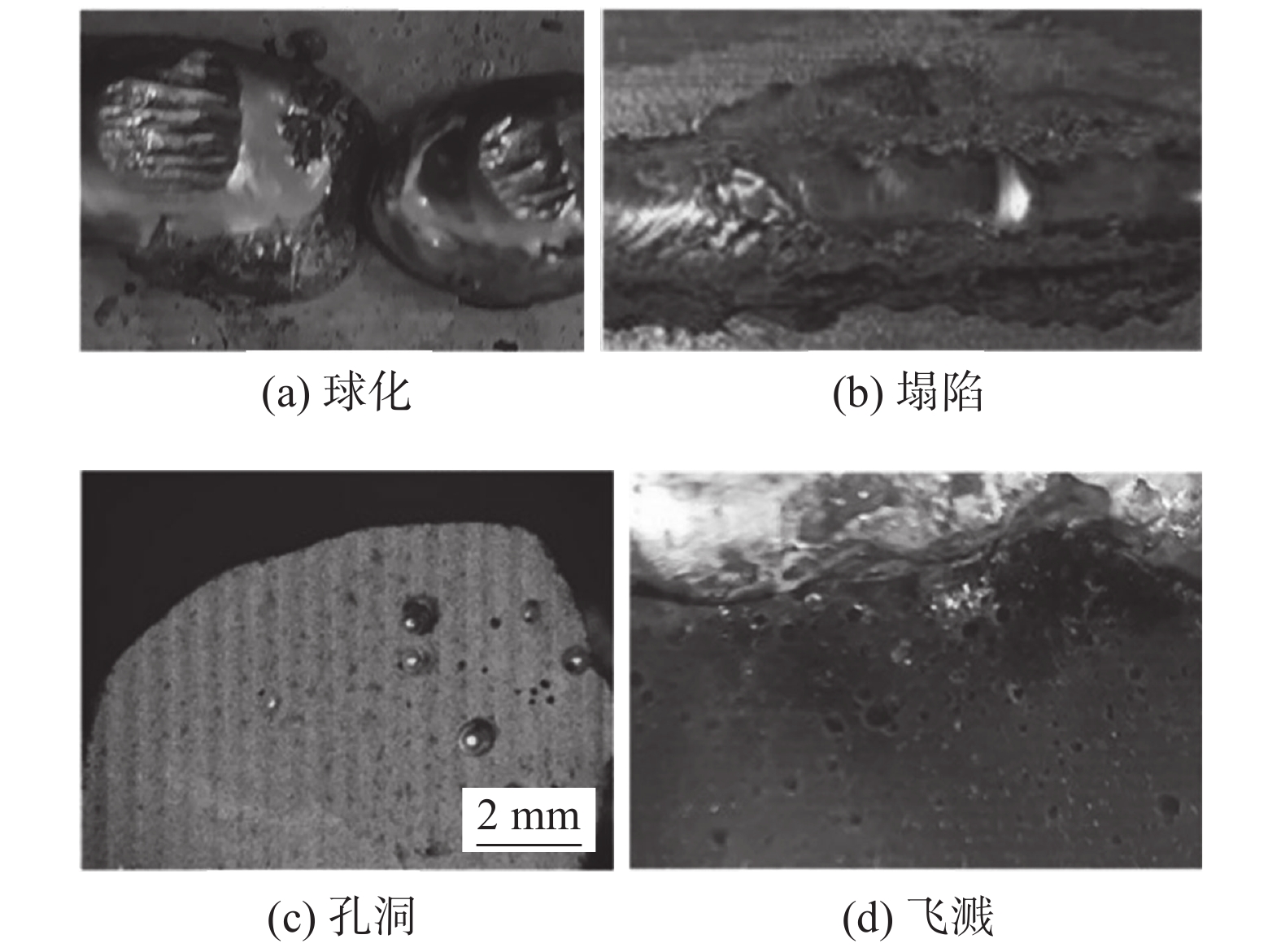

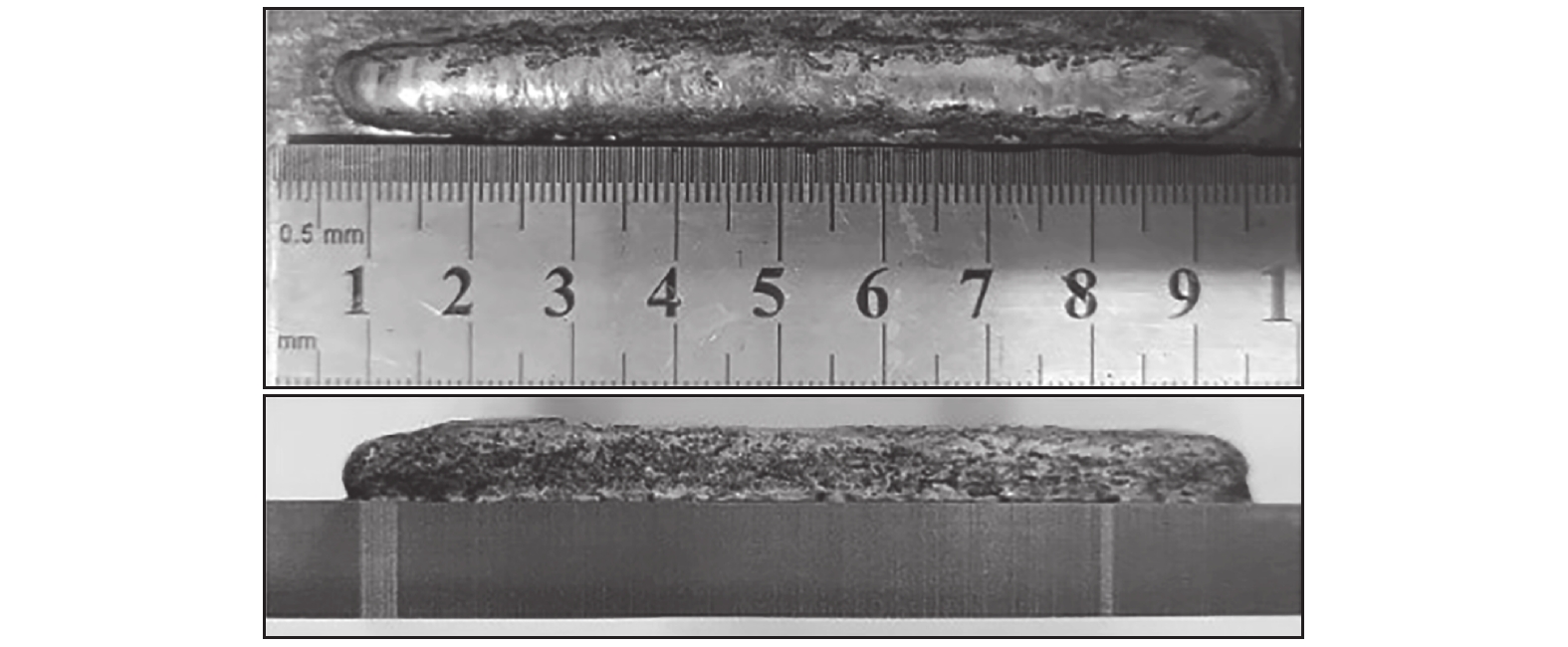

为了最终确定试验所需丝材直径,对上述3种丝材进行了成形试验.采用ϕ1.6 mm 丝材成形时,由于直径过细,熔滴成形受到阻碍,在堆积时出现不连续球化等不良现象. 采用ϕ2.6 mm丝材成形时,由于拉拔道次与拉拔终径的影响,存在粉末喷溅,且制件表面氧化发黑较明显,局部存在气孔,同时,在堆积过程中粉末喷溅造成高层容易坍塌(图6). 然而,采用ϕ2.1 mm丝材成形时,在堆层与基板上均未发现明显粉末喷溅和内部气孔.综上所述,试验最终采用ϕ2.1 mm粉芯丝材进行Cu-Al-Fe合金电弧增材制造试验.

2.2 数值仿真模型的搭建

考虑到粉芯丝材增材制造实际成形过程的复杂性,同时兼顾确保仿真模型的可靠性. 数值模型作如下设计:①基板和堆层分别采用各自对应材料;②忽略材料各相异性;③忽略熔池形状与熔池流动,仅考虑在自身辐射放热、对流换热以及热传导过程中的温度变化;④材料内部是连续的,忽略粉芯丝材空气介质阻热作用;⑤材料均匀,仅考虑粉芯丝材熔融过程,因而将其内芯与外皮视作均匀性材料. 具体的数值仿真模型及参数设置、边界条件、控制方程等详见陈特[12]的研究.

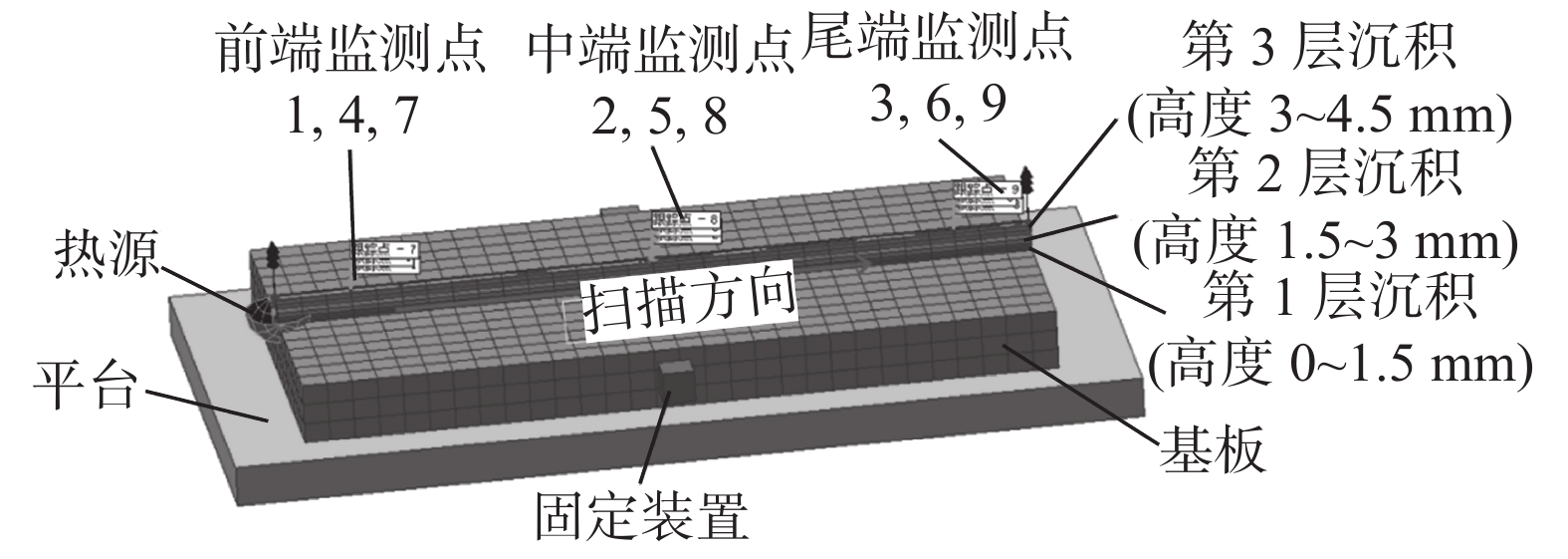

利用NX软件构建几何模型,采用参数与实物比例为1∶1,即基板尺寸分别为100 mm × 100 mm × 10 mm,沉积层尺寸拟构建尺寸为100 mm × 10 mm,堆积厚度为1.5 mm,共计3层,宽度随层渐窄. 采用Hypermesh进行网格划分,为保持温度的准确分布,基板网格与堆层网格保持连续,且在焊缝区进行局部加密. 利用Simufact-Welding平台对3层的前端 (沉积时距离起始点10 mm的位置)、中端 (沉积时每层的中间位置) 与末端 (沉积时距离结束点10 mm的位置) 分别设立监测点,检测起弧、中间区域与熄弧阶段的温度变化,以电流与扫描速度为变量进行温度采集.所构建的粉芯丝材增材制造有限元模型如图7所示.

2.3 输入电流对温度场的影响

采用电弧增材制造成形件时,考虑到交直流逆变焊接系统中电压维持稳定,因而输入电流的变化是对于温度场影响最大的因素.输入电流大小将直接影响热源的输出形状与覆盖范围,进而影响熔池流动与成形,并最终对电弧增材制造金属的成形、性能和微观组织造成影响.因此,通过输入电流对温度场的影响进行模拟,可以有效选择电弧增材制造的输入电流I. 在固定扫描速度条件下,探究输入电流120,140 A和160 A对温度场的影响.

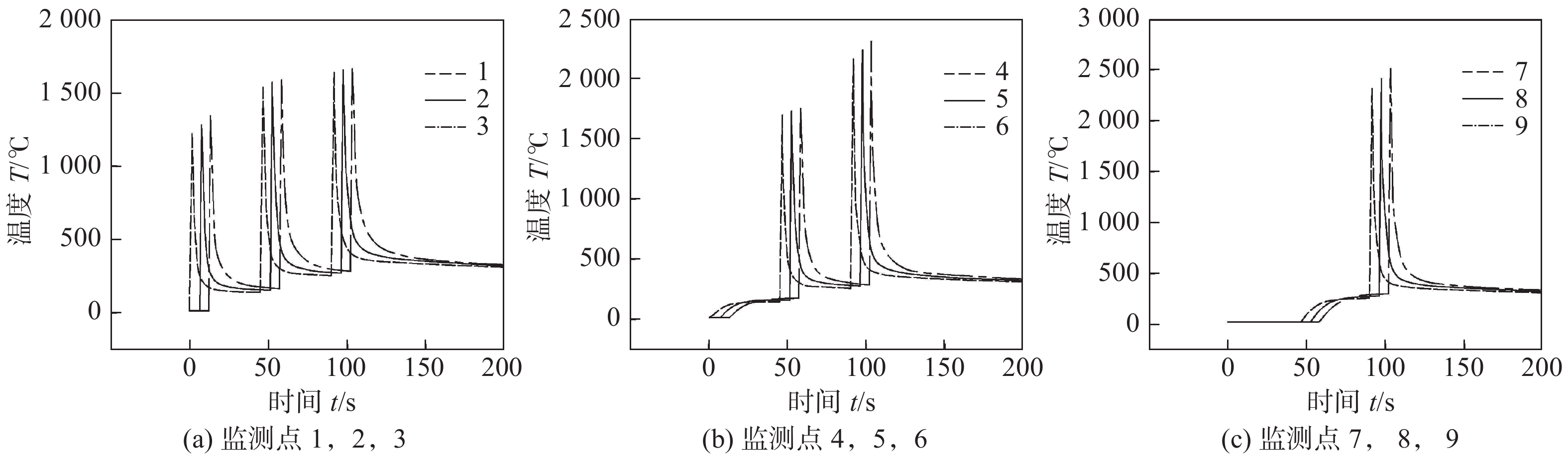

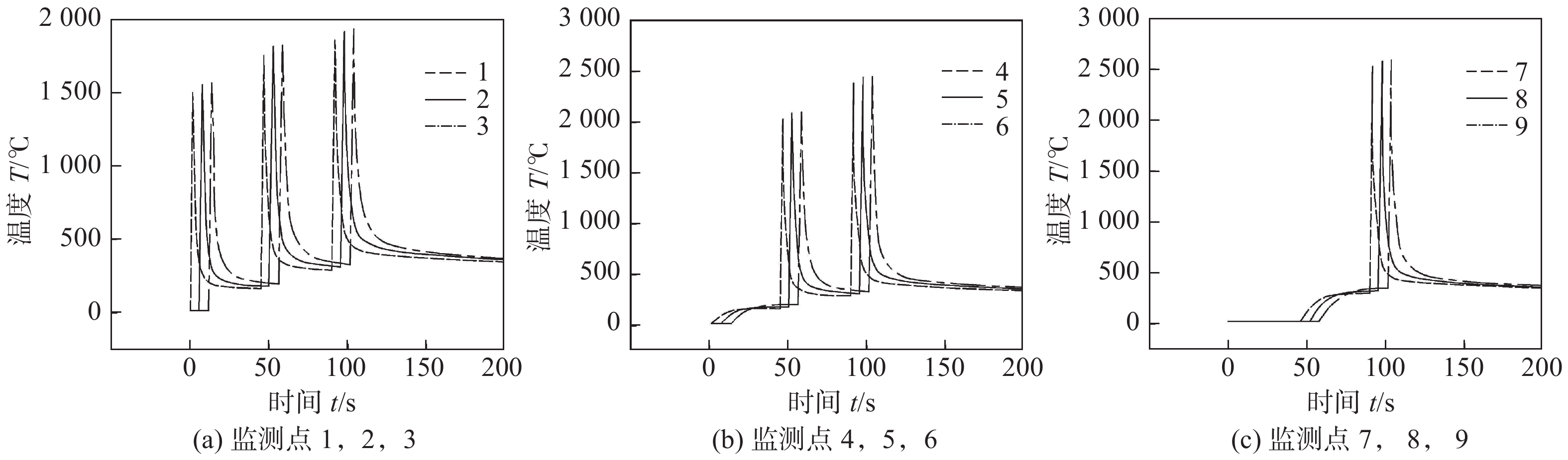

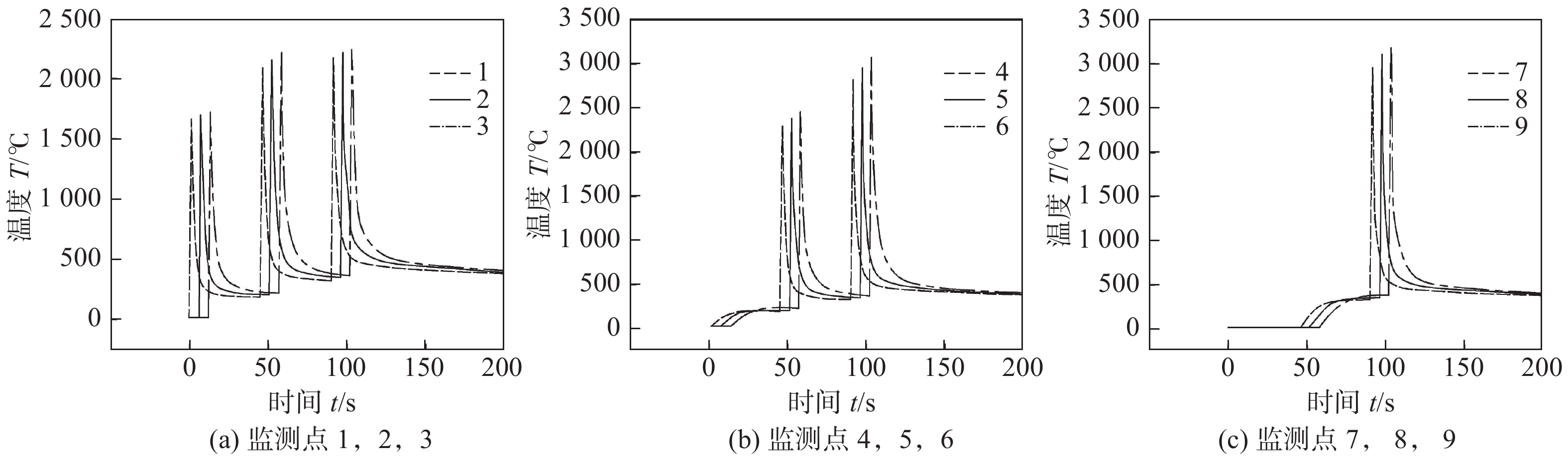

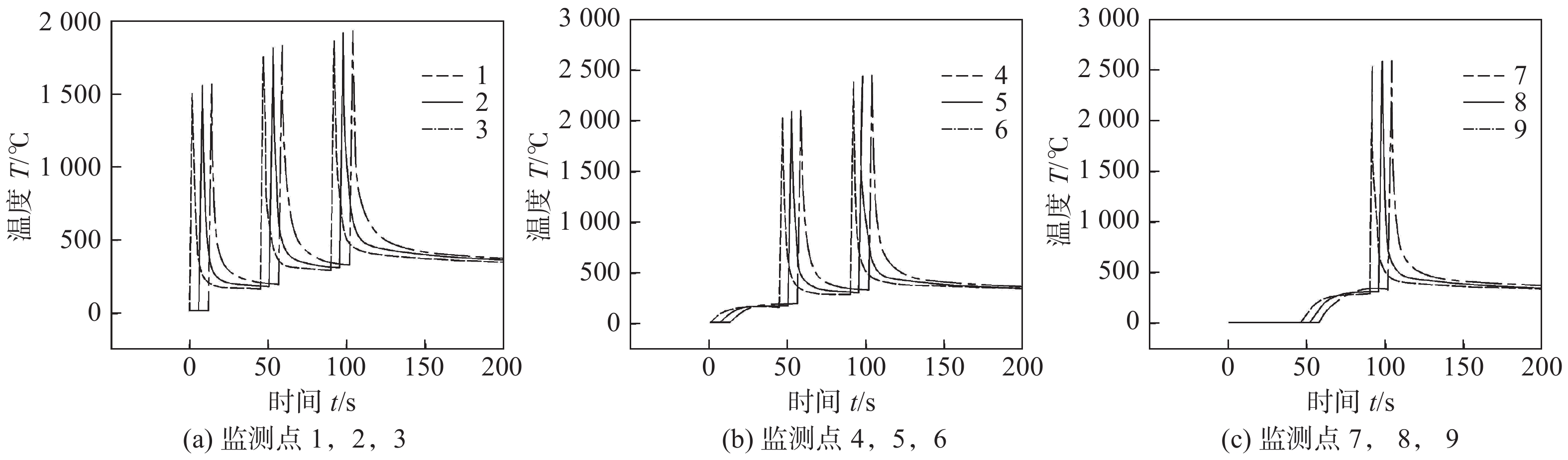

图8、图9和图10分别为输入电流120,140 A和160 A对温度场的影响. 受输入电流的影响,同一监测点在经历重熔时温度均呈现上升趋势,这一规律在同一层监测点和同一水平位置不同层检测点均得到体现. 同时,受重熔影响,第1层与第2层出现多峰结构,在第1层中其热过程为3次,故而3个监测点中观测到了3个高温峰;第2层的监测点4,5,6受到两次热源影响,故而有两个高温峰;而第3层的监测点7,8,9仅循环一次,故而只形成一个高温峰.

考虑到电弧增材制造成形时,中间层受热影响最大,而第1层与第2层最能代表新沉积层下温度变化,故分析时以下面两层温度变化作为主要因素考虑. 从图8的结果可知,采用输入电流120 A进行单道多层沉积时在第1层所产生的峰值温度位于1 200 ~ 1 700 ℃之间,而铁的熔点为1 538 ℃,在此输入电流下铁粉将无法充分熔融. 由图9可知,在输入电流140 A时,沉积第1层产生的峰值温度在1 500 ~ 1 900 ℃之间,沉积第2层时产生的峰值温度在2 200 ~ 2 300 ℃之间,在此温度下能够充分熔融所设计Cu-Al-Fe合金的所有元素,需要注意的是,第3层峰值温度为2 591 ℃,这可能导致Al (沸点2470 °C) 元素的少量烧损. 由图10可知,采用输入电流160 A时,沉积第2层所产生的峰值温度在2 500 ~ 3 100 ℃之间,而第3层峰值温度甚至全部超过3 000 ℃,在此温度范围内,将会造成Cu,Fe (Cu沸点:2 562 ℃;Fe沸点:2 862 ℃) 等高沸点元素蒸发,破坏粉芯丝材结构使其失去保护作用. 综上,使用粉芯丝材进行增材制造成形Cu-Al-Fe合金时,采用输入电流140 A较为合适.

2.4 扫描速度对温度场的影响

扫描速度作为电弧增材制造的重要参数之一,主要影响沉积层的凝固成形与层间冷却过程,扫描速度过慢会导致沉积层组织的热累积现象较为严重,将使沉积层组织因热量无法散发而影响电弧增材制造的成形质量和制件性能. 在上述所选输入电流140 A的条件下,将探究0.2,0.4 m/min和0.6 m/min的扫描速度对电弧增材制造温度场的影响规律.

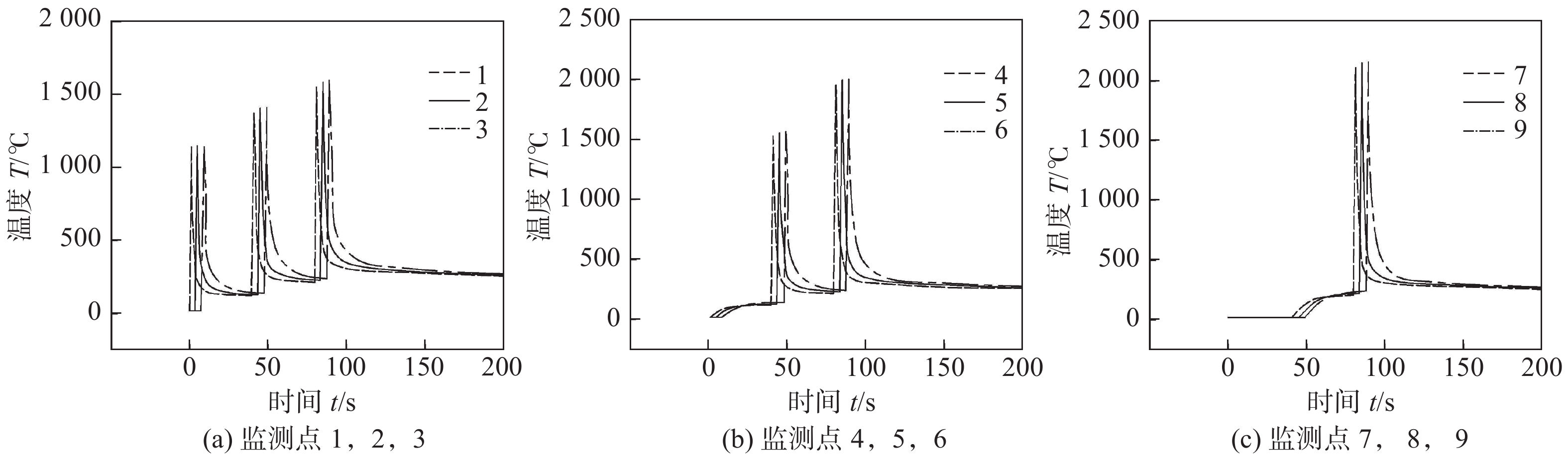

图11、图12和图13为不同扫描速度下温度场情况. 由图11 ~ 图13可知,沉积层各点温度受热累积效应仍保持一定上升.采用扫描速度0.2 m/min时,第1层沉积层与基板导热达到平衡的时间提前到达,在沉积第3层时该层温度开始下降,而第2层在热影响下经历重熔温度仍保持上升趋势. 而采用扫描速度为0.4,0.6 m/min时,第1层温度在堆积过程中一直保持上升趋势.

由图11可知,在扫描速度0.2 m/min下,虽然能够充分熔融所有元素,但是第3层产生的峰值温度超3 000 ℃,高温下铝易氧化、蒸发元素损失严重. 由图12可知,在0.4 m/min扫描速度下,沉积时第1层与第2层温度适宜,Cu-Al-Fe合金的所有元素都能够充分熔融,且其相较于扫描速度0.2 m/min,在扫描速度0.4 m/min下沉积过程所产生的温度使得Al元素的蒸发相对较少. 由图13可知,在扫描速度0.6 m/min下,由于扫描速度过快,沉积第1层产生的峰值温度过低,温度范围为1 100 ~ 1 600 ℃之间,而铁的熔点超过1 500 ℃,在此电流下将无法充分熔融. 综上,选用扫描速度0.4 m/min作为粉芯丝材电弧增材制造的扫描速度较为合适.

2.5 优化工艺窗口下的沉积成形试验

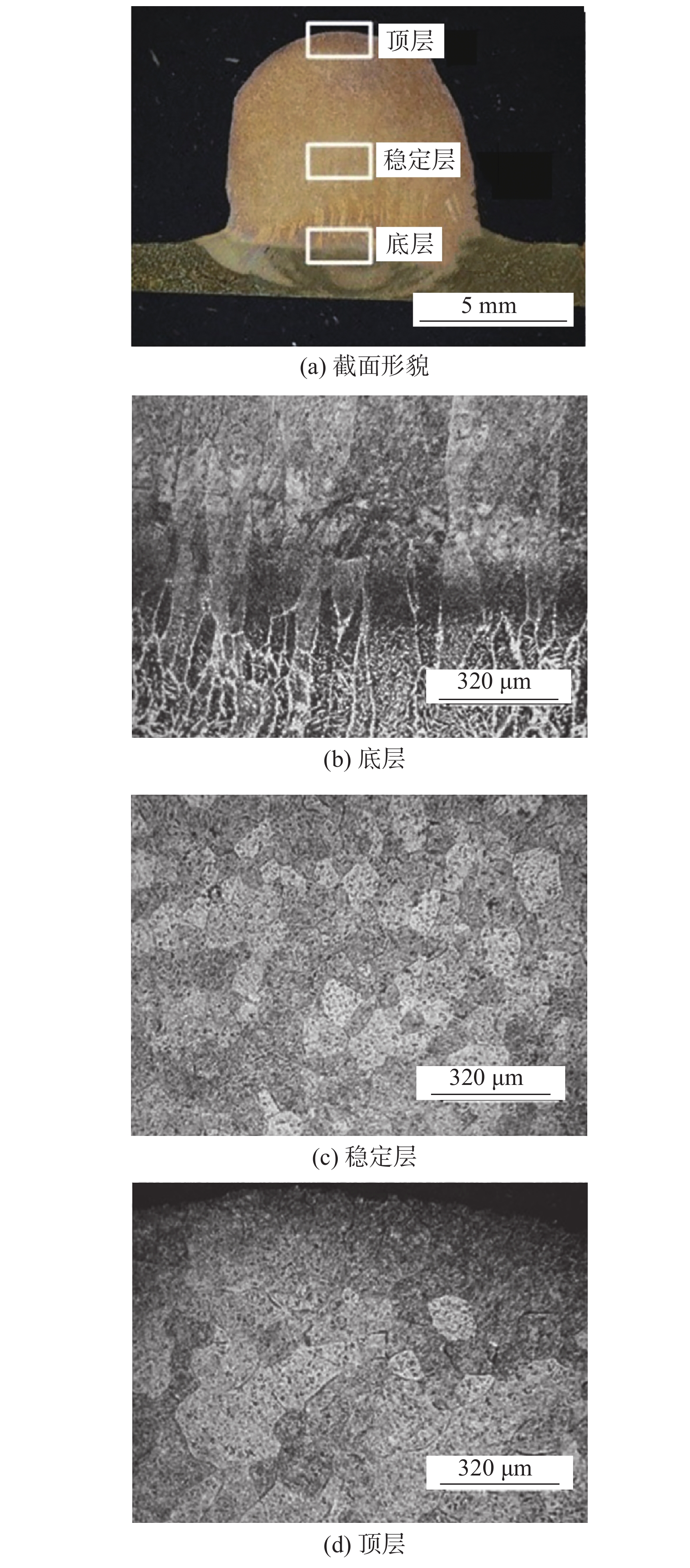

基于上述探索试验与温度场数值模拟结果,确定最终选取输入电流为140 A、扫描速度为0.4 m/min、丝材直径为2.1 mm工艺参数进行试验. 图14与图15分别反映了最优工艺下宏观形貌(完整沉积层 + 截面形貌)与上、中、下3层的微观组织. 截面组织清晰地反映了增材制造特征,即由底部的柱状区域过渡到稳定区的等轴状,再至顶层细晶区.

采用交流电弧增材制造时,合金凝固组织的形核−长大主要受到脉冲电流、磁场力复合作用. 一方面在电磁场作用下各成分原子相互碰撞、迁移,熔池成分得以较均匀,组织生长过程中偏析现象得以弱化甚至被抑制;另一方面,强大的电磁力促使形成强制对流,枝晶树被振碎,因而导致在沉积态中难以发现枝晶组织[16]. 形成的初生相一般为均匀的等轴晶或者柱状晶组织,又因为冷却速率的不同,表层组织在结构上与稳定区无异. 但是受到对流换热影响,冷却速率较内部快,晶粒尺寸有所减小,形成一层均匀的小晶粒等轴晶,而底部组织同时受到热传导与成分差异性影响,所以一般为从基体过渡到薄壁墙底部的均匀柱状晶.

3. 结论

(1) 粉芯丝材沉积过程是在弧柱区以梯度传热形式先熔化外皮形成熔滴空腔再逐渐侵吞、熔化内部粉末,球化增大后受重力影响落入熔池,随后熔滴内外层彻底熔融并于熔池内铺展沉积成形.

(2) 粉芯丝材的熔化机制不仅使其具有抑制元素烧损的作用,还在一定程度上未熔粉末充当异质形核核心还能起到细化晶粒的效果.

(3) 通过探索试验和温度场的模拟仿真,得到了Cu-Al-Fe粉芯丝材增材制造的最佳工艺参数,即粉芯丝材直径为2.1 mm、输入电流为140 A、扫描速度为0.4 m/min.

-

表 1 Cu-Al-Fe合金中元素的熔点、沸点和粒径

Table 1 Melting point, boiling point and particle size of elements in Cu-Al-Fe alloy

元素 熔点Tm /℃ 沸点Tb /℃ 粒径d/目 Cu 1 085 2 562 325 Al 660.3 2 470 200 Fe 1 538 2 862 300 -

[1] Chen L, He Y, Yang Y, et al. The research status and development trend of additive manufacturing technology[J]. The International Journal of Advanced Manufacturing Technology, 2017, 89: 3651 − 3660. doi: 10.1007/s00170-016-9335-4

[2] 张金田, 王杏华, 王涛. 单道多层电弧增材制造成形控制理论分析[J]. 焊接学报, 2019, 40(12): 63 − 67. Zhang Jintian, Wang Xinghua, Wang Tao. Research on forming control for single-pass multi-layer of WAAM[J]. Transactions of the China Welding Institution, 2019, 40(12): 63 − 67.

[3] Wang H, Huang J, Xu D, et al. Comparison of microstructure and shape memory properties between two Cu-Al-Mn alloys produced by additive manufacturing technology[J]. Materialia, 2022, 26: 101594. doi: 10.1016/j.mtla.2022.101594

[4] Lu Bingheng, Li Dichen, Tian Xiaoyong. Development trends in additive manufacturing and 3D printing[J]. Engineering, 2015, 1(1): 175 − 183.

[5] 牛锐锋, 林冰华, 王亚妮, 等. 铝合金脉冲激光焊Mg元素烧损行为及接头硬度分布[J]. 焊接学报, 2010, 31(3): 81 − 84. Niu Ruifeng, Lin Binghua, Wang Yani, et al. Evaporation loss of Mg element in pulsed laser welding of 5A05 aluminum alloy and distribution of micro-hardness of welding joint[J]. Transactions of the China Welding Institution, 2010, 31(3): 81 − 84.

[6] Jafari D, Vaneker T H J, Gibson I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts[J]. Materials & Design, 2021, 202: 109471.

[7] 贺定勇, 蒋建敏, 周正, 等. 粉芯丝材在表面与再制造技术中的应用[J]. 电焊机, 2012, 42(5): 12 − 14. doi: 10.3969/j.issn.1001-2303.2012.05.003 He Dingyong, Jiang Jianmin, Zhou Zheng, et al. Application of cored wires for surface engineering and remanufacturing technology[J]. Electric Welding Machine, 2012, 42(5): 12 − 14. doi: 10.3969/j.issn.1001-2303.2012.05.003

[8] 王宏宇, 张祥, 吴勃, 等. 硼化硅增强的激光增材制造用CuZnAl微纳粉芯丝材及其制备方法: 中国, CN110508799B [P]. 2021-05-25. Wang Hongyu, Zhang Xiang, Wu Bo, et al. CuZnAl micro-nano powder core wire and its preparation method for laser additive manufacturing reinforced by silicon borate: China, CN110508799B[P]. 2021-05-25.

[9] 朱建, 王宏宇, 史东辉, 等. 增材制造记忆合金的元素烧损行为及其补损分析[J]. 焊接学报, 2022, 43(9): 50 − 55. doi: 10.12073/j.hjxb.20220105001 Zhu Jian, Wang Hongyu, Shi Donghui, et al. Element loss behavior and compensation of additive manufacturing memory alloy[J]. Transactions of the China Welding Institution, 2022, 43(9): 50 − 55. doi: 10.12073/j.hjxb.20220105001

[10] 赵磊. 基于微纳粉芯丝材的Fe-Mn-Si-Cr-Ni记忆合金增材制造工艺、组织和性能研究[D]. 镇江: 江苏大学, 2021. Zhao Lei. Research on additive manufacturing process, microstructure and properties of Fe-Mn-Si-Cr-Ni memory alloy with micro-nano powder core wire[D]. Zhenjiang: Jiangsu University, 2021.

[11] 王宏宇, 许增, 袁晓明, 等. 激光增材制造用功能低损型形状记忆合金微纳粉芯丝材: 中国, CN201810487378.7[P]. 2018-11-06. Wang Hongyu, Xu Zeng, Yuan Xiaoming, et al. Low-loss shape memory alloy micro-nano powder core wire for laser additive manufacturing : China, CN201810487378.7[P]. 2018-11-06.

[12] 陈特. 铜基记忆合金粉芯丝材制备与其电弧增材制造特性研究[D]. 镇江: 江苏大学, 2020. Chen Te. Research on preparation of Cu-based memory alloy powder core wire and its arc additive manufacturing characteristics[D]. Zhenjiang: Jiangsu University, 2020.

[13] Wu B, Pan Z, Ding D, et al. A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement[J]. Journal of Manufacturing Processes, 2018, 35: 127 − 139. doi: 10.1016/j.jmapro.2018.08.001

[14] 余和五, 张燕清. LaNi5 粉末导热性能的研究[J]. 南京师大学报(自然科学版), 1992(1): 36 − 39. Yu Hewu, Zhang Yanqing. Study of thermal conductivity in the LaNi5 powder[J]. Journal of Nanjing Normal University (Natural Science), 1992(1): 36 − 39.

[15] Yamanaka K, Saito W, Mori M, et al. Abnormal grain growth in commercially pure titanium during additive manufacturing with electron beam melting[J]. Materialia, 2019, 6: 100281. doi: 10.1016/j.mtla.2019.100281

[16] 李宁, 张蓉, 张利民, 等. 低压交流电脉冲下 Al-7% Si 合金晶粒细化机理研究[J]. 金属学报, 2017, 53: 192 − 200. doi: 10.11900/0412.1961.2016.00247 Li Ning, Zhang Rong, Zhang Limin, et al. Study on grain refinement mechanism of hypoeutectic Al-7%Si alloy under low voltage alternating current pulse[J]. Acta Metallurgica Sinica, 2017, 53: 192 − 200. doi: 10.11900/0412.1961.2016.00247

-

期刊类型引用(2)

1. 温钟淳,关峰,李明,毕婧涵,谢洪志,王正. 激光选区熔化成形TC4锥形管的仿真模拟研究. 金属加工(热加工). 2025(02): 28-33 .  百度学术

百度学术

2. 朱长顺,毛计洲,王宏宇,黄金雷,朱建. 粉芯丝材激光增材制造Fe-xMn-6Si-9Cr-5Ni合金记忆性能. 焊接学报. 2023(07): 102-108+135 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: