Characterization and analysis of key characteristics of powder stream in laser coaxial powder feeding additive manufacturing

-

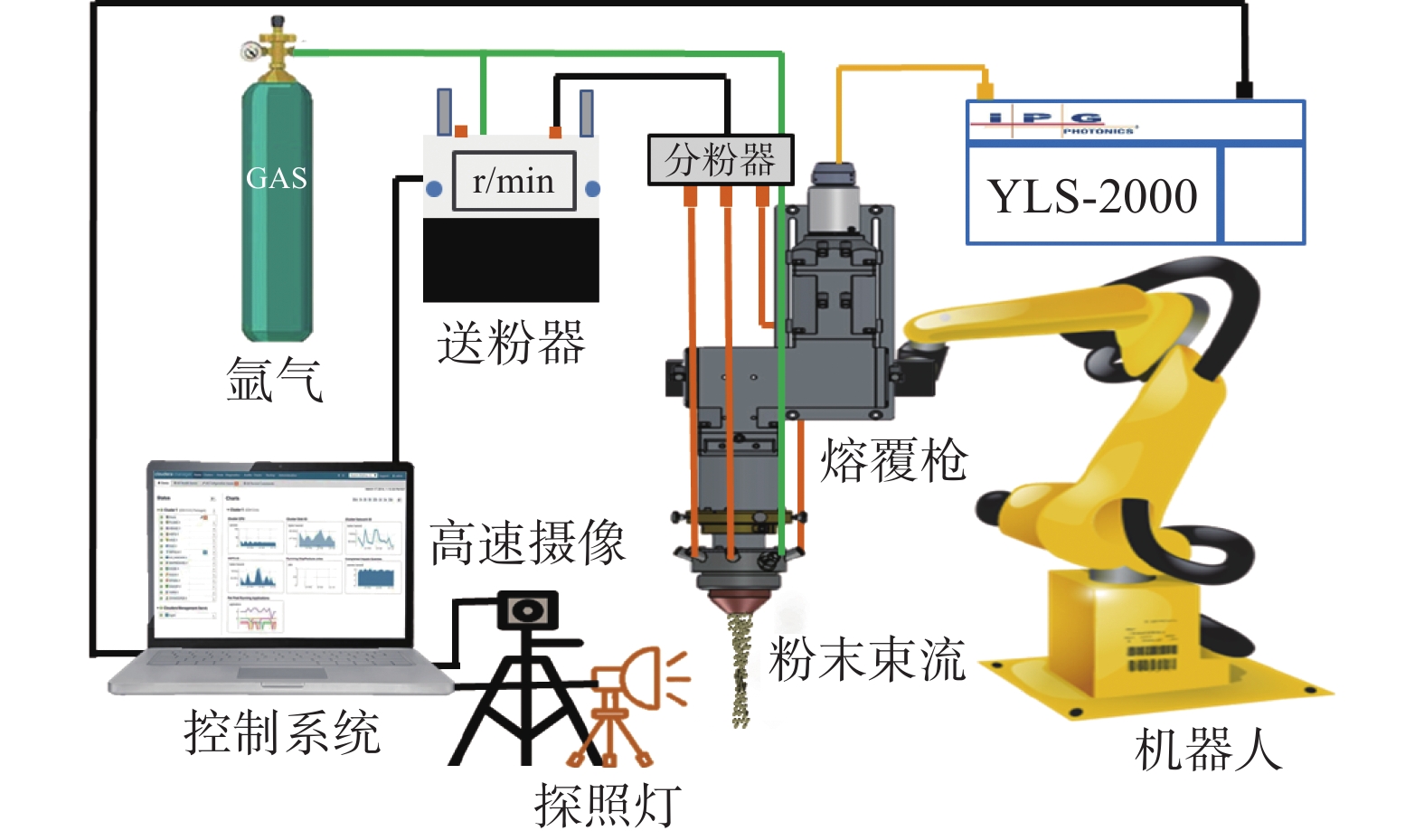

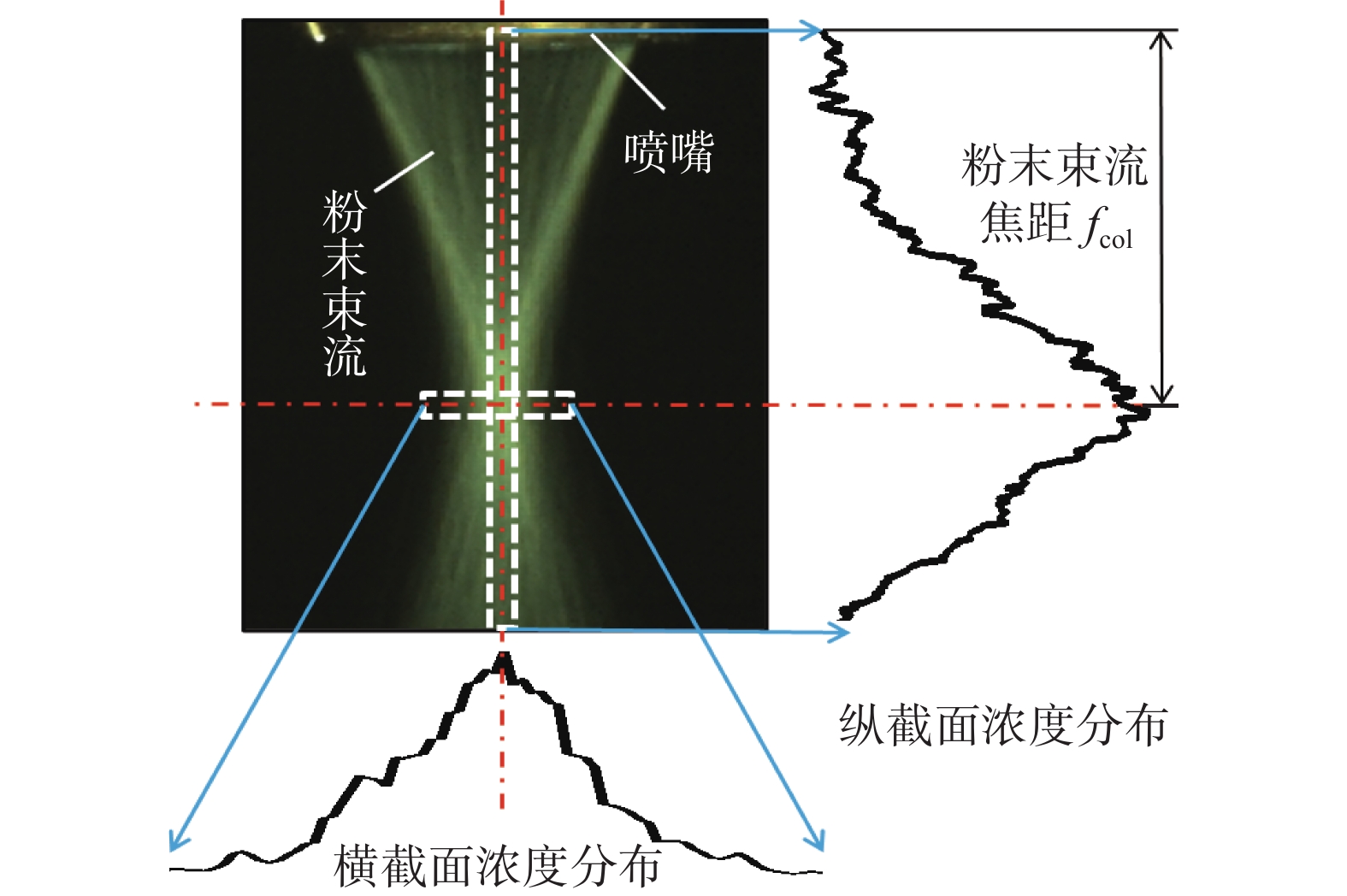

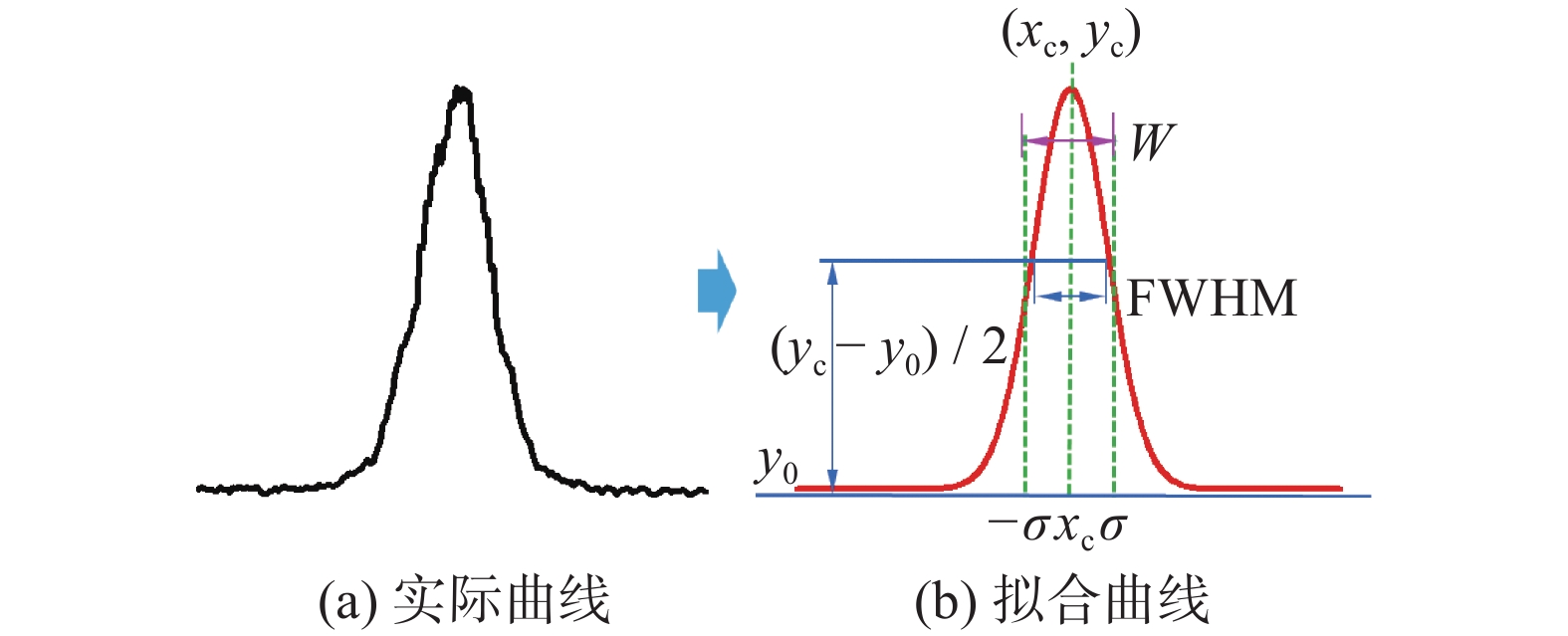

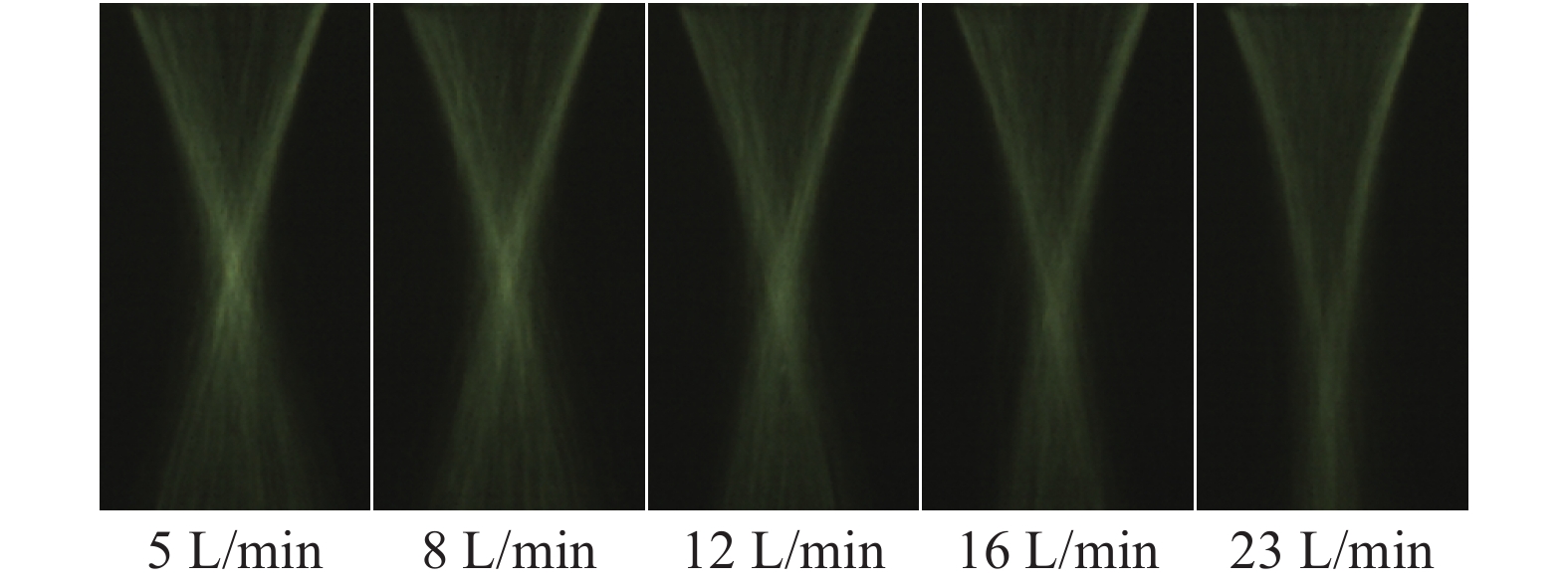

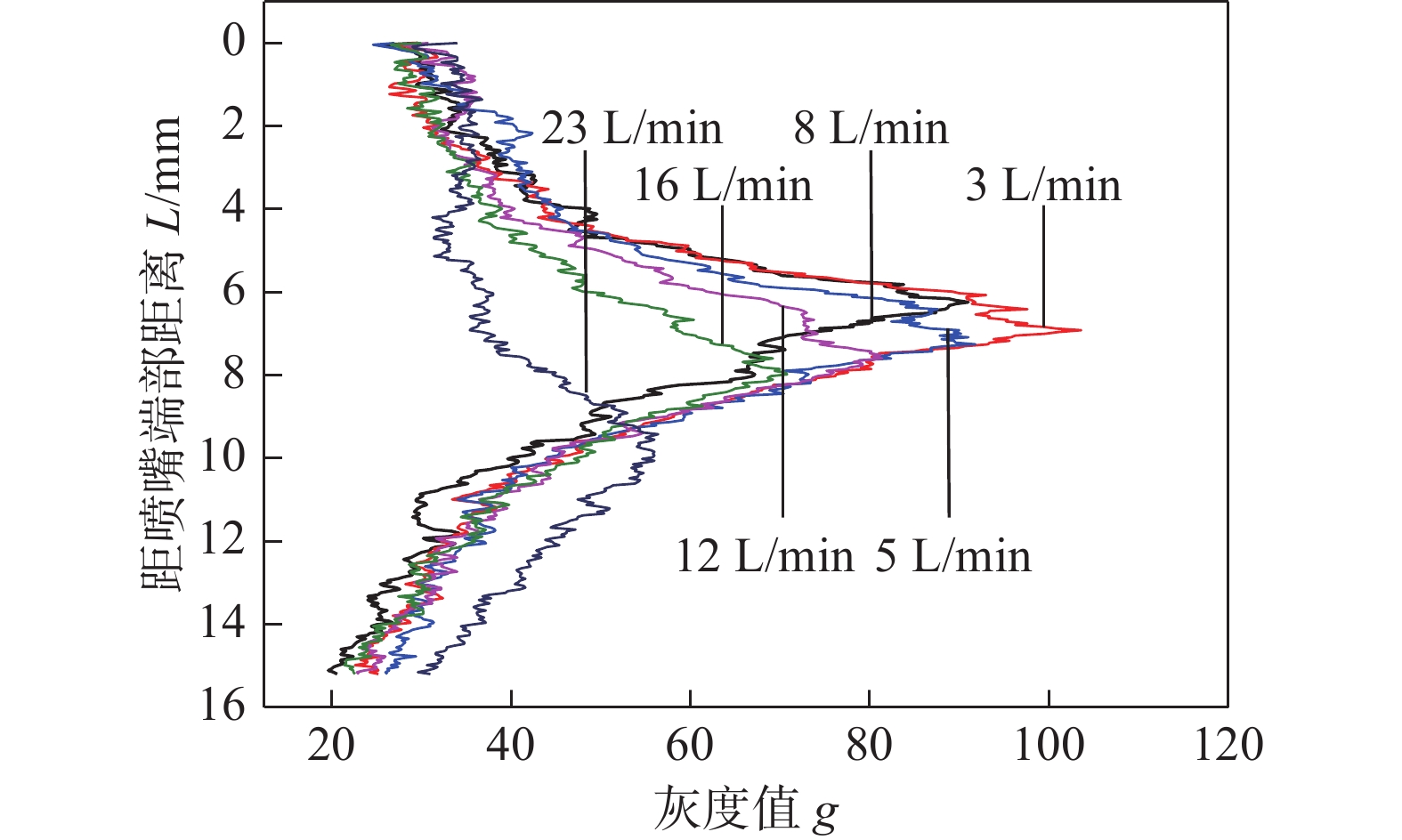

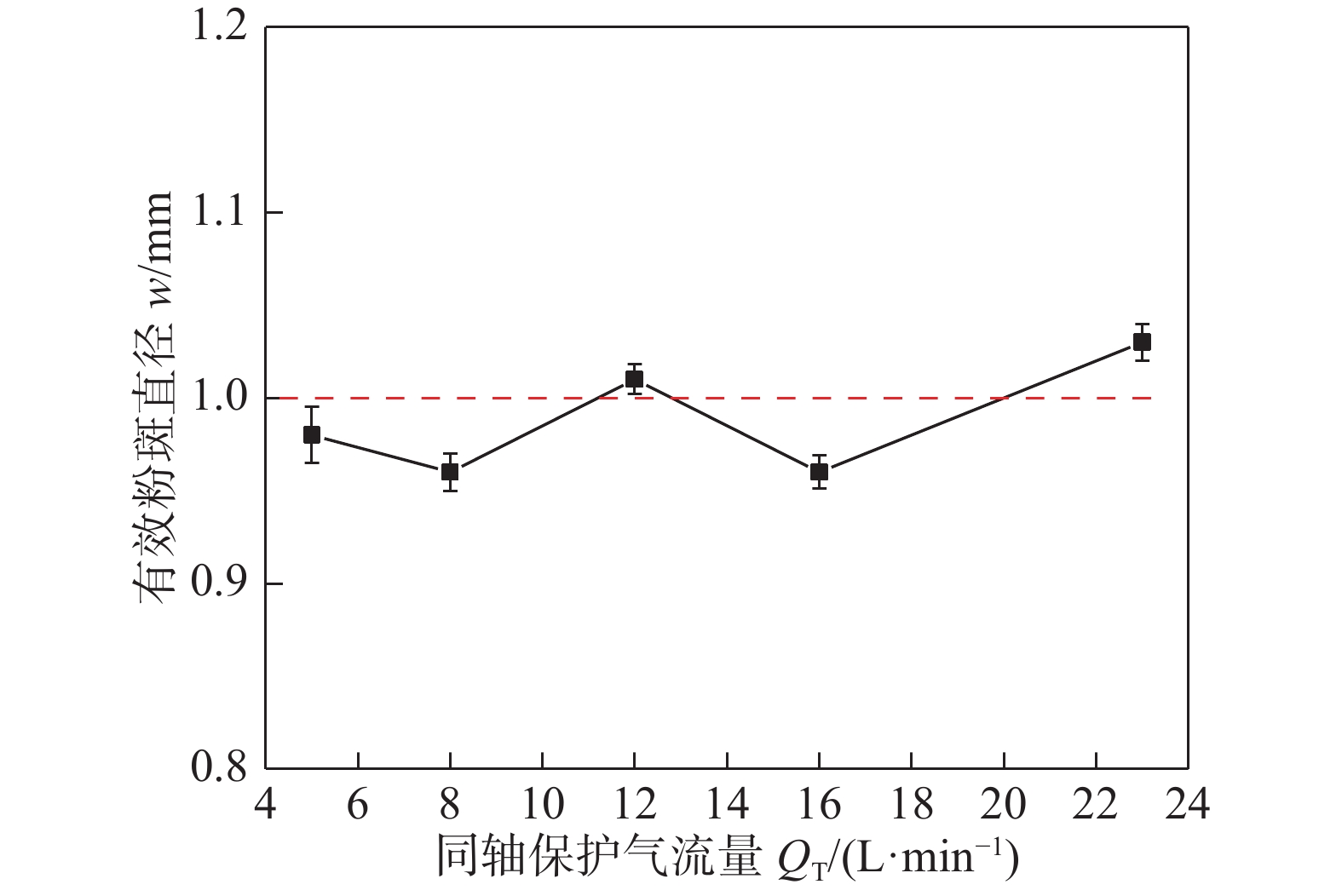

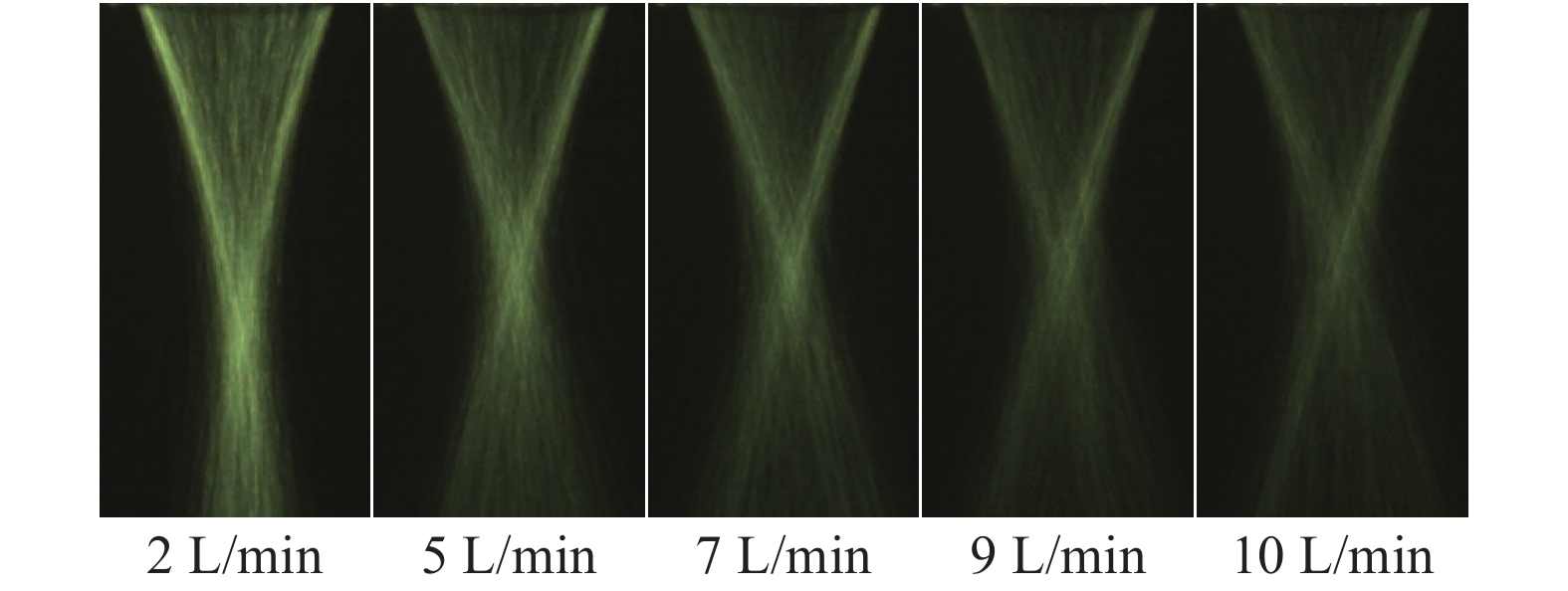

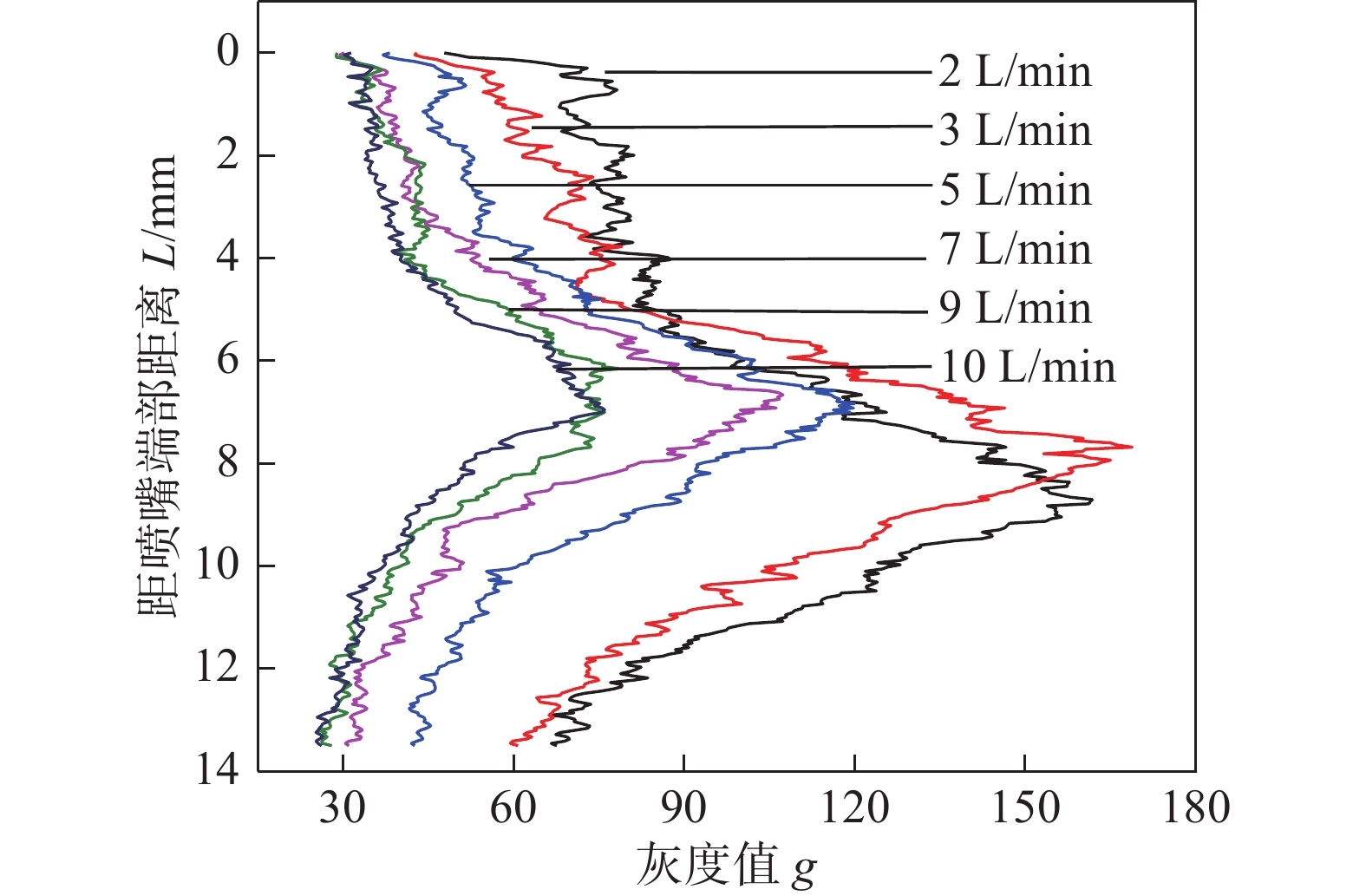

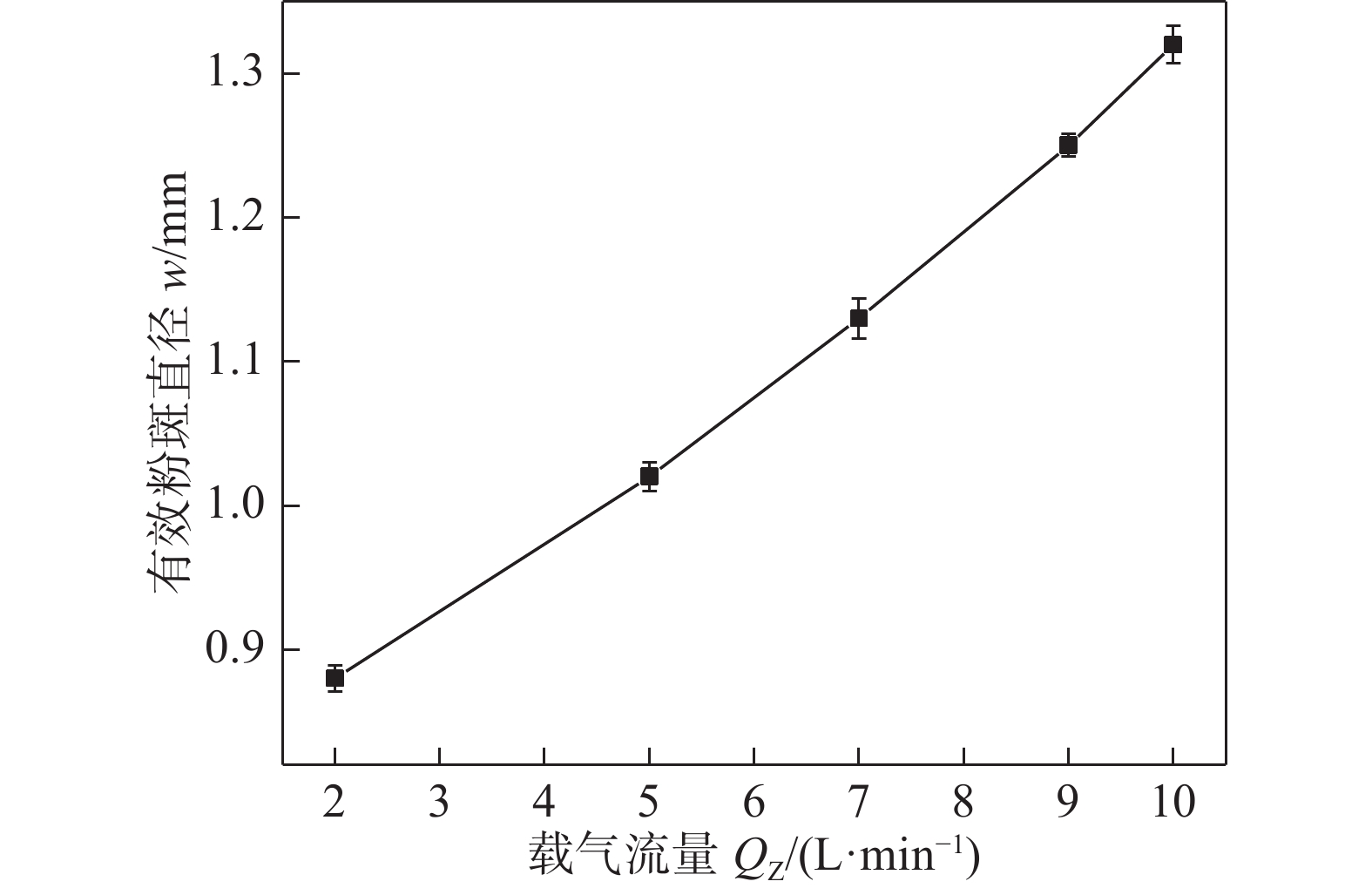

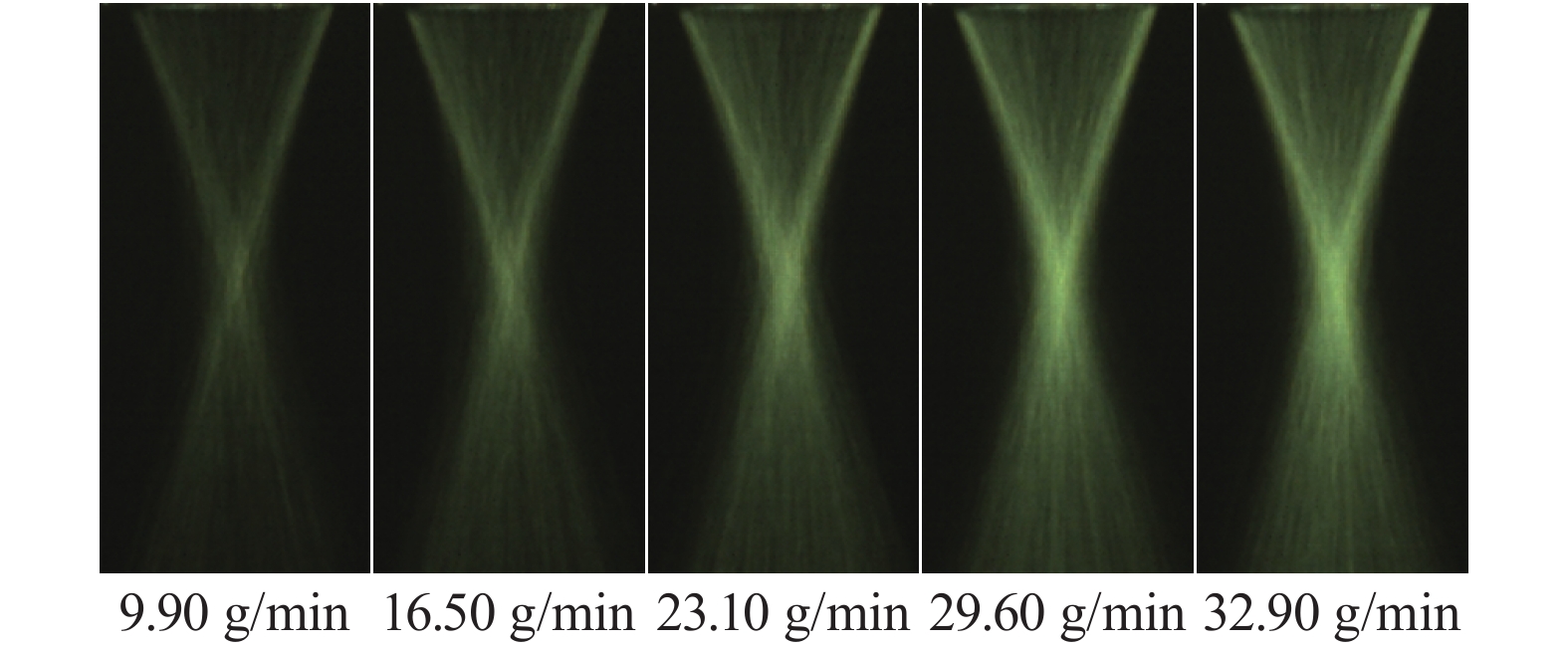

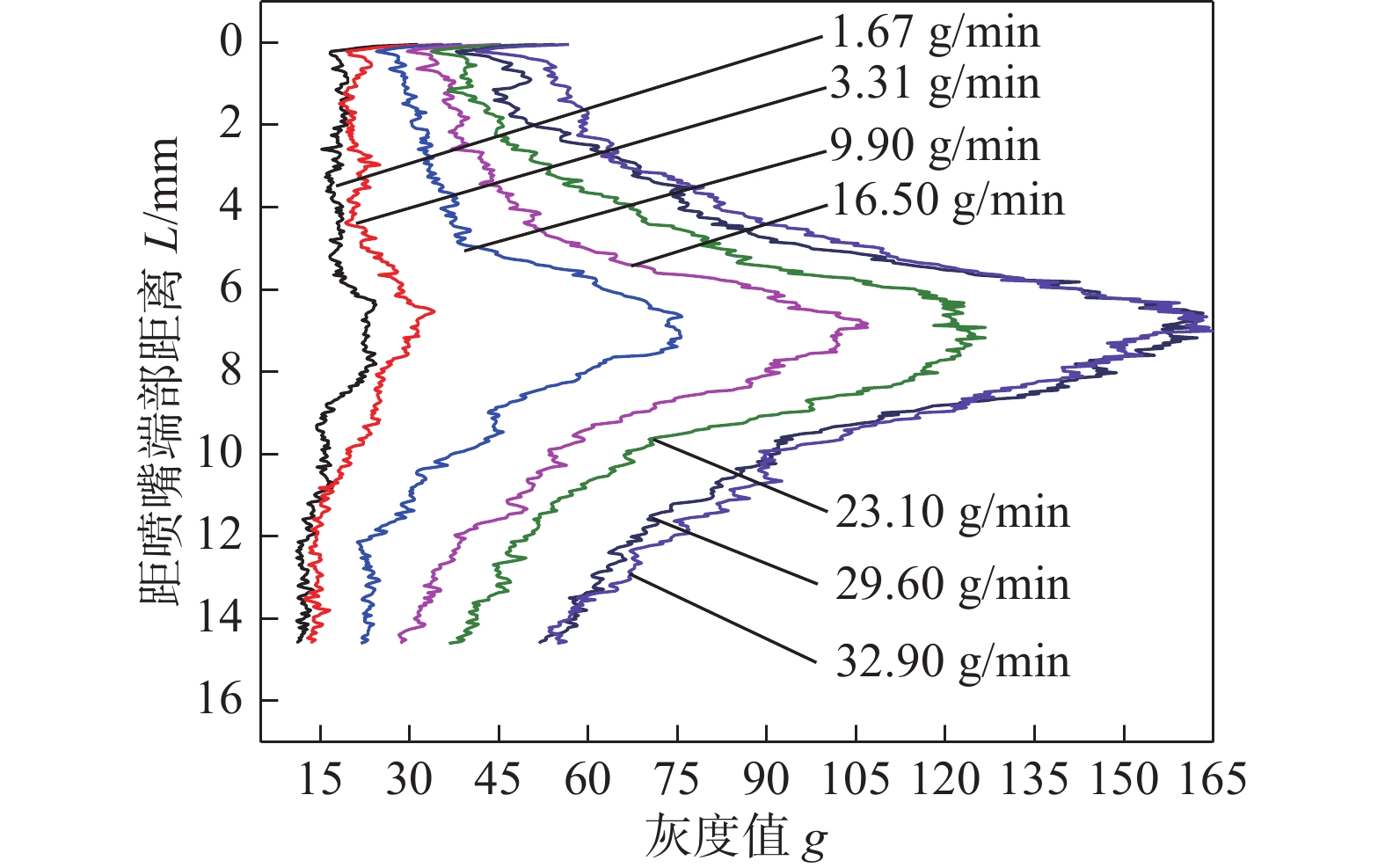

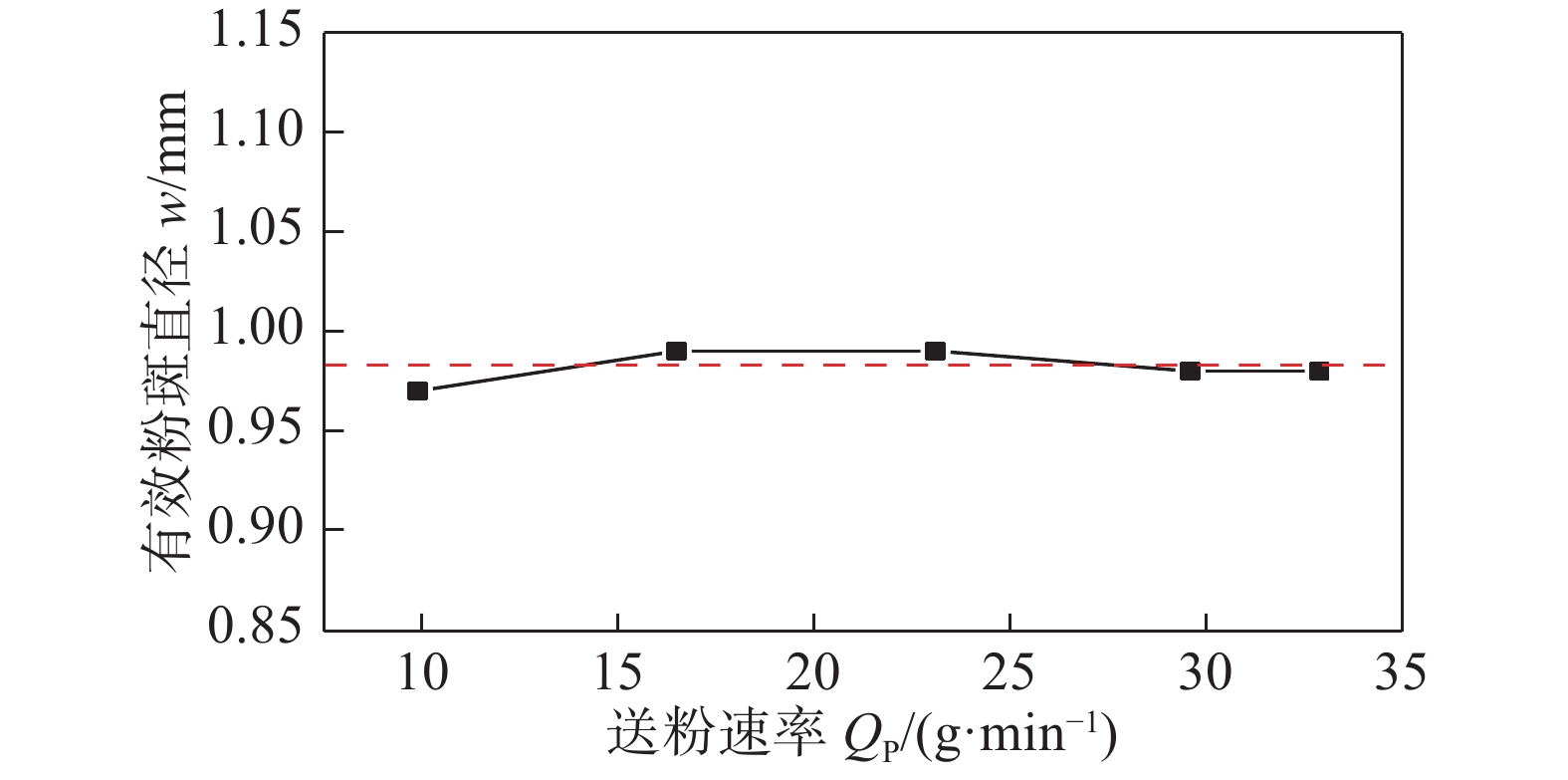

摘要: 粉末束流焦距和焦点位置处的粉末颗粒的空间分布是粉末束流的两个关键特征,对激光同轴送粉增材制造工艺特性影响较大. 利用高速摄像拍摄粉末束流的宏观形貌,以图像灰度处理技术为基础,建立了粉末束流焦距和焦点位置处粉末颗粒空间浓度分布表征方法,提出利用有效粉斑直径定量分析粉末束流的汇聚性,系统研究了载气流量、同轴保护气流量、送粉速率等主要工艺参数对粉末束流关键特征的影响规律. 结果表明,工艺参数的改变几乎不影响粉末束流焦点位置处粉末颗粒呈高斯分布这一规律;载气流量增加,粉末束流焦距变小,有效粉斑直径变大,粉末束流汇聚性变差;同轴保护气流量增加,粉末束流焦距变长,有效粉斑直径基本不变;送粉速率提高,粉末束流的焦距和有效粉斑直径变化均不大.Abstract: The focal length of the powder stream and the spatial distribution of the powder particles at the focal position are two key characteristics of the powder beam, which have a greater impact on the characteristics of the laser coaxial powder feeding additive manufacturing process. Using high-speed photography to capture the macro morphology of the powder beam, based on the image gray-scale processing technology, a method for characterizing the spatial concentration distribution of powder particles at the focal positions of the powder stream was established, and the effective powder spot diameter was used to quantitatively analyze the powder beam. The main process parameters such as carrier gas flow rates, coaxial shielding gas flow rates, and powder feeding rates have been systematically studied on the key characteristics of the powder beam. The research results show that the change of process parameters hardly affects the law that the spatial distribution of powder particles at the focal position of the powder stream is Gaussian. As the carrier gas flow increases, the focal length of the powder beam will be shorten, the effective powder spot diameter will become larger, and the flow convergence becomes worse. With increasing the coaxial shielding gas flow, the focal length of the powder stream becomes longer, and the effective powder spot diameter is almost unchanged. With the increase of powder feeding rates, the focal length of the powder stream and the effective powder spot diameter change little.

-

0. 序言

高强低合金钢(high strength low alloy steel,HSLA)是一种C含量和合金元素含量比较低,而强度较高的工程结构用钢,低合金高强钢因综合力学性能优异和经济效益显著而被广泛应用. 目前,屈服强度为690 MPa级HSLA钢已广泛用于桥梁建筑、工程结构、海洋平台、大型船舶、工程机械等领域[1-5]. HSLA钢C含量一般低于0.06%处于易焊接区域,具有良好的焊接性能,690 MPa级HSLA钢处于难焊与易焊区交接边界区域,有一定预热和层间温度控制要求[6-7],690 MPa级HSLA钢焊接25.4 mm以下钢板时,预热温度可以降低到16 ℃,当板厚超过25.4 mm后,预热温度在52 ~ 93 ℃之间[8],不预热或较低预热温度能够极大降低焊接要求,提高焊接效率并显著降低焊接成本. 目前,690 MPa级HSLA钢尚未完全解决等强匹配不预热焊接问题,HSLA钢焊接相关研究滞后其开发研究,相关焊材匮乏限制了HSLA钢的推广使用,迫切需要改进和开发相应的焊接填充金属材料及配套焊接工艺. 改善焊缝金属塑性及强韧性能够降低冷裂纹出现概率,利于降低预热温度,实现等强不预热焊接. 在焊缝金属强韧性调控中,成分调控是提高其强韧性的主要措施之一,Evans等人[9]研究Mn,Si匹配,Kang和Zhang等人[10-11]研究Mn,Ni配比,Bhole等人[12]研究Ni-Mo配比,王学林等人[13]研究Mn,Ni,Mo配比等. 另一方面,焊接工艺能够显著改变焊缝金属中组织赋存形态、相对比例、分布状态、本征力学特性等,焊接工艺调控对HSLA钢焊缝金属强韧性及抗裂性能调控具有显著影响. 目前,相关690 MPa级HSLA钢等强不预热焊接工艺参数研究报道较少,相关强韧性机制仍有待进一步研究,探讨焊条电弧焊(shielded metal arc welding, SMAW)焊接热输入对焊缝金属组织与力学性能的影响及机制,为相关研究及应用提供一定依据和参考.

1. 试验方法

采用500 mm × 150 mm × 27 mm的690 MPa级HSLA钢试板及自研配套直径为4.0 mm的焊条,在不预热、无后热条件下进行SMAW对接接头焊接,焊后试板缓慢冷却至室温,最后进行加工、力学性能检测及微观结构观察. 焊条经400 ℃ × 1 h烘烤充分去除水分,道间温度控制在100 ~ 120 ℃,平均值108 ~ 114 ℃,对接接头焊接电流为164 ~ 173 A,电弧电压为22 ~ 32 V,焊接速度平均值15 ~ 21 cm/min,焊接热输入平均值13 ~ 19 kJ/cm,焊接工艺参数见表1. 熔敷金属焊接工艺参数参考对接接头焊接工艺,焊后在焊缝中心上部检测熔敷金属化学成分见表2.

表 1 对接接头焊接工艺参数Table 1. Welding parameters of butt joints类型 道间温度 T/℃ 焊接电流

I/A电弧电压

U/V焊接速度v/(cm·min−1) 焊接热输入E/(kJ·cm−1) 实测值 平均值 实测值 平均值 对接接头No.1 104 ~ 120 114 165 ~ 171 22 ~ 32 21 11 ~ 16 13 对接接头No.2 102 ~ 117 108 164 ~ 167 24 ~ 28 16 14 ~ 18 16 对接接头No.3 100 ~ 119 112 169 ~ 173 23 ~ 32 15 16 ~ 21 19 熔敷金属 101 ~ 118 111 166 ~ 168 24 ~ 28 15 12 ~ 21 17 表 2 熔敷金属的化学成分(质量分数,%)Table 2. Chemical compositions of deposited metalC Si Mn + Ni + Cr Mo Ti等 P S 0.034 0.20 4.99 0.40 微量 0.007 9 0.004 8 垂直对接接头焊缝试板边部切除20 ~ 30 mm,按GB/T 2651—2023《金属材料焊缝破坏性试验 横向拉伸试验》、GB/T 2653—2008《焊接接头弯曲试验法》、GB/T 229—2020《金属材料 夏比摆锤冲击试验方法》、GB/T 2652—2022《金属材料焊缝破坏性试验 熔化焊接头焊缝金属纵向拉伸试验》(含GB/T 228.1—2021《金属材料拉伸试验 第1 部分:室温试验方法》),在焊缝中依次切取板拉伸(37 mm宽 × 27 mm厚 × 300 mm长,平行段宽度25 mm)、正/反弯(30 mm宽 × 27 mm厚 × 300 mm长,D = 5ts)、V型缺口冲击(10 mm × 10 mm × 55 mm)、焊缝拉伸(直径5 mm)和金相试样,进行焊缝金属力学性能检测,冲击均值通过3个试样检测获得. 焊缝拉伸、焊缝中心冲击试样取样位置,对接接头硬度(HV5)检测位置及冲击断口侧面观察位置如图1所示. 对接接头金相试样截面经机械研磨、抛光、侵蚀和干燥后,采用GX53金相显微镜(optical microscope, OM)观察焊缝金属微观组织和M-A组元,采用Quanta 650场发射扫描电镜(scanning electron microscope, SEM)观察焊缝金属微观组织、焊缝冲击断口正面和剖面断裂形貌. 微观组织通过4%硝酸酒精侵蚀4 ~ 8 s,M-A组元通过Lepera试剂侵蚀40 ~ 180 s,冲击试样中心切开,镶嵌保护冲击断口边部,经机械研磨、抛光、4%硝酸酒精侵蚀4 ~ 8 s和干燥后,采用Quanta 650观察冲击断口边部裂纹和微观组织,按GB/T2654—2008《焊接接头硬度试验方法》采用EV500-2A型维氏硬度仪,在载荷5 N的条件下,检测对接接头后焊面下2 mm和中心硬度分布.

2. 试验结果与分析

焊接工艺调控对于HSLA钢焊缝金属强韧性及抗裂性能调控具有显著影响,主要针对焊接热输入对690 MPa级钢焊缝金属组织与力学性能的影响进行研究,并对其强韧性机理进行分析.

2.1 焊缝金属组织与性能

采用自研直径4.0 mm焊条,在不同热输入条件下,对690 MPa级HSLA钢进行不预热焊接,对接接头完好,焊缝中未出现气孔、夹渣、裂纹等缺陷,熔合区无裂纹等缺陷,对接接头截面形貌如图2所示,可见,自研直径4.0 mm焊条可对690 MPa级HSLA钢进行不预热焊接.

图3为不同热输入条件下对接接头、焊缝金属的力学性能,13 ~ 19 kJ/cm热输入条件下,对接接头拉伸断裂位置均为母材,120°正、反弯(D = 5ts)对接接头完好无裂纹;热输入由13 kJ/cm提高至19 kJ/cm,对接接头抗拉强度由841 MPa降低至819 MPa,呈现降低趋势;焊缝金属−50 ℃冲击吸收能量呈现先升高后降低趋势,在16 kJ/cm时达到最大值,热输入13,16,19 kJ/cm对应−50 ℃冲击吸收能量均值分别为61,80,56 J,最小值分别为59,71,49 J. 由此可见,690 MPa级HSLA钢采用自研直径4.0 mm焊条,焊接热输入为16 kJ/cm强韧性匹配最优,对接接头抗拉强度828 MPa,焊缝中心−50 ℃冲击吸收能量为71 ~ 90 J,均值为80 J. 图4为后焊面下2 mm(表面)、焊缝中心分布和焊缝金属的平均硬度,热输入由13 kJ/cm提高至19 kJ/cm,对接接头、焊缝中心硬度呈现降低趋势,热输入超过16 kJ/cm以后,焊缝金属硬度降低幅度减小. 对接接头不同位置观察,焊缝金属表面、板厚中心硬度呈下降趋势,表面下降幅度高于板厚中心. 焊缝金属表面硬度平均值由287 HV5降低至269 HV5,板厚中心硬度平均值由295 HV5降低至273 HV5,此外,热输入由13 kJ/cm提高至19 kJ/cm,对接接头热影响区硬度也呈现降低趋势.

图5为不同热输入条件下对接接头焊缝金属微观组织和M-A组元形貌,其中偏亮白色的为M-A组元,图6为对接接头焊缝金属微观形貌SEM. 焊缝金属组织主要为贝氏体(lath bainite, LB和bainite, B)、针状铁素体(acicular ferrite, AF)、侧板条铁素体(ferrite side plates, FSP)、晶界铁素体(grain boundary ferrite, GBF)、M-A组元等. 热输入对焊缝金属中M-A组元影响十分显著,13 kJ/cm较低热输入条件下,焊缝金属中M-A组元较少,主要分布于针状铁素体之间见图5(d);热输入提高至16 kJ/cm,焊缝金属中M-A组元数量显著提高,主要分布于针状铁素体之间,呈显著弥散分布,晶界上存在一定非连续的M-A组元见图5(e);热输入提高至19 kJ/cm,焊缝金属中M-A组元数量减少,呈现显著粗化现象,呈现弥散分布于针状铁素体之间见图5(f).

13 kJ/cm焊接热输入条件下,焊后冷速较高,形成了显著的板条贝氏体、一定针状铁素体及粗大侧板条铁素体组织见图6(a)和图6(d). 在较高冷速条件下,针状铁素体孕育不足形成时间较短,形成了较低含量针状铁素体组织,难以充分分割细化组织结构,然而,有利于形成板条贝氏体组织及侧板条铁素体组织,并且,由于过冷奥氏体中C,Mn等元素扩散受到抑制,M-A组元难以形成见图5(d). 板条贝氏体及长针状针状铁素体形成温度较低,其中,贝氏体铁素体宽度较低及位错密度较高,通常其强度较高[14-15]. 当热输入温度提高至16 kJ/cm,在较缓慢冷速条件下,板条贝氏体结构逐渐消失,其强度降低,塑性得到改善. 针状铁素体具有了充足的形核时间,在其充分形成后分割细化了原始奥氏体晶粒,随后贝氏体组织将在其分割细化组织之间形成,最终形成贝氏体、针状铁素体组织呈现交织分布见图6(b)和图6(e). 因此,在中温转变过程中,促进针状铁素体形成将十分利于分割细化晶粒,最终形成细小焊缝金属组织结构[16-17],同时可以发现,在晶界上侧板条铁素体逐渐消失,逐渐被晶界铁素体取代,对焊缝金属强韧性影响已显著降低,针状铁素体在形成过程中同时向周围排C,温度提高亦改善了C,Mn等元素扩散动力学条件,导致在针状铁素体之间形成了弥散分布的M-A组元,晶界上存在非连续分布的M-A组元见图5(e)[18-20]. 热输入进一步提高至19 kJ/cm,在更加缓慢冷却条件下,针状铁素体边界逐渐钝化,一部分针状铁素体呈现显著长大现象,M-A组元在充分成分扩散后呈现显著长大现象,并在晶界附近形成了较粗大的晶界铁素体组织见图6(c)和图6(f).

随着热输入由13 kJ/cm提高至19 kJ/cm,针状铁素体呈现出形成不足、充分细小形成、细小结构长大的变化规律;贝氏体结构呈现板条结构、板条结构弱化的变化过程,其强度伴随着降低;M-A组元呈现从少到多,从细小弥散到粗大生长的变化过程;侧板条铁素体及晶界铁素体呈现此消彼长现象. 这些现象的形成主要与热输入提高冷速降低,导致成分扩散条件和组织形成条件改善等因素相关. 在此过程中,高含量、高塑性针状铁素体形成、弥散细小M-A组元形成具有最佳热输入或冷速条件,控制该条件对于调控焊缝金属强韧性性能及失效机制十分关键. 以下结合强韧性性能及失效分析对以上组织形态调控结果进行阐释.

2.2 焊缝金属冲击断口分析

图7为不同热输入条件下对接接头焊缝金属冲击断口中心SEM,观察位置为冲击裂纹稳定扩展区,对冲击断口分析引入断裂单元描述,断裂单元与有效晶粒(亚晶)及断裂行为具有对应关系[21],13 ~ 19 kJ/cm热输入条件下,焊缝金属冲击断口断裂单元见图7(d) ~ 图7(f)中区域1 ~ 区域3.

在焊接热输入13 kJ/cm条件下,冲击断裂面中存在环型条带状韧窝,其内部呈现准解理断裂,断面中存在二次裂纹见图7(a). 断裂单元内部存在较平坦的断裂面,其内部仅存在少量细小撕裂棱,表明组织脆性较高、塑性及韧性较低见图7(d)中区域1. 焊缝金属组织主要为板条贝氏体、长针状针状铁素体及侧板条铁素体,其均为脆性较高组织,该组织不利于冲击韧性提高. 条带状韧窝边部所勾勒的边界与晶体、亚晶具有一定的对应关系. 在无显著晶界脆性元素、脆性相(如链状M-A组元等)存在条件下,裂纹穿越晶界或亚晶界时将受到阻碍作用. 冲击断裂阻碍作用较高区域应是晶界或亚晶界,其存在导致出现了环型条带状韧窝,形成了较粗大的晶体或亚晶结构,主要是由于针状铁素体较少,分割细化作用较弱所致. 在16 kJ/cm热输入条件下,冲击断裂面中呈现较细小环形韧窝结构,断裂单元内部存在较多细小撕裂棱,表明组织塑性及韧性较高见图7(b)和图7(e). 贝氏体板条结构逐渐弱化,强度降低,针状铁素体充分形成,针状铁素体组织产生分割细化作用,获得较细小的亚晶结构,在冲击断裂过程中形成了环形韧窝结构见图7(b). 在断裂单元内部较多细小撕裂棱,表明组织塑性良好见图7(e)中区域2. 由此可见,组织塑性提高及细化两方面作用,共同提高了焊缝金属韧性. 在19 kJ/cm热输入条件下,冲击断裂面中呈现较显著的准解理断裂特征,条带状或环形韧窝结构消失,取而代之是长条形撕裂棱见图7(c). 同时,断裂单元内部细小撕裂棱结构增加,表明组织塑性进一步提高见图7(f)中区域3. 针状铁素体之间形成较粗大的M-A组元促进了微裂纹扩展,亚晶界阻碍裂纹扩展能力降低,故出现长条形撕裂棱而非环形韧窝结构. 由此可知,粗大的M-A组元对韧性产生的负面作用超过了组织塑性改善对韧性的正面作用,导致了19 kJ/cm冲击韧性低于16 kJ/cm.

热输入由13 kJ/cm提高至19 kJ/cm对焊缝金属组织结构及其强韧性产生了显著影响,热输入13 kJ/cm韧性较低主要与焊缝金属中所形成的脆性相相关,热输入19 kJ/cm韧性较低主要与焊缝金属中粗大的M-A组元形成相关. 热输入16 kJ/cm充分形成了塑性良好针状铁素体组织,并且针状铁素体与贝氏体呈交织分布,提高了焊缝金属韧性. 细小弥散分布的M-A组元并未对其韧性产生显著负面作用. 热输入由13 kJ/cm提高至19 kJ/cm,韧窝结构由条带状转变为环形直至消失,其中,条带状环形韧窝结构主要与晶界、亚晶界良好的塑性相关,环形韧窝结构主要与针状铁素体形成后分割细化所得细小亚晶相关,韧窝结构消失主要与针状铁素体之间形成粗大M-A组元弱化亚晶界相关,随着热输入由13 kJ/cm提高至19 kJ/cm,焊缝金属组织塑性持续改善,在断裂单元内部易出现细小撕裂棱.

2.3 焊缝金属强韧化机理

为进一步证实以上分析,将焊缝金属冲击断口从中心切开,对断口中心侧面进行精细组织和断裂结构观察,如图8所示,为便于观察拓片断口侧面,绘制断口轮廓线,断口中心侧面断口轮廓线见图8(a) ~ 图8(c). 冲击值大小与断裂路径直接相关,断裂路径长表示冲击断裂扩展过程中受到较高阻碍,提高了冲击吸收能量. 16 kJ/cm热输入焊缝金属冲击裂纹扩展阶段路径比13 kJ/cm和19 kJ/cm长,这与其−50 ℃冲击吸收能量最高相对应. 图8(d) ~ 图8(f)为焊缝中心断口中心组织与断口对应关系,可以看出,13 kJ/cm和19 kJ/cm热输入条件下,断口中同时存在韧窝及解理断面,16 kJ/cm断口中则主要为韧窝结构,然而,13 kJ/cm和19 kJ/cm热输入解理面的出现缘由各不相同,以下进一步放大观测倍数探究二者失效机制差异.

图9为不同热输入条件下焊缝金属冲击断口微孔及微裂纹SEM,图9(i)和图9(l)分别为16 kJ/cm、19 kJ/cm热输入断口背散射电子形貌像,其余为二次电子形貌相. 用I、II、III、IV、V、VI分别表示针状铁素体中、贝氏体中、针状铁素体与贝氏体界面、M-A组元与针状铁素体界面、晶界上、夹杂物附近微孔.

![]() 图 9 焊缝金属冲击断口中微孔及微裂纹SEM像Figure 9. SEM of micro-voids and micro-cracks in impact fracture of weld metals. (a) 13 kJ/cm; (b) circle region in figure 9a; (c) another observation region of 13 kJ/cm; (d) circle region in figure 9(c); (e) secondary crack of 13 kJ/cm; (f) 16 kJ/cm; (g) elliptic region in figure 9(f); (h) circle region in figure 9(f); (i) backscattered electron image corresponding to figure 9(h); (j) 19 kJ/cm; (k) elliptic region in figure 9(j); (l) backscattered electron image corresponding to figure 9(k)

图 9 焊缝金属冲击断口中微孔及微裂纹SEM像Figure 9. SEM of micro-voids and micro-cracks in impact fracture of weld metals. (a) 13 kJ/cm; (b) circle region in figure 9a; (c) another observation region of 13 kJ/cm; (d) circle region in figure 9(c); (e) secondary crack of 13 kJ/cm; (f) 16 kJ/cm; (g) elliptic region in figure 9(f); (h) circle region in figure 9(f); (i) backscattered electron image corresponding to figure 9(h); (j) 19 kJ/cm; (k) elliptic region in figure 9(j); (l) backscattered electron image corresponding to figure 9(k)在焊接热输入13 kJ/cm条件下,冲击断口主裂纹边界平直,主裂纹贯穿板条贝氏体、侧板条铁素体,呈现脆性断裂特征见图9(b)中区域1,其中,形态呈长针状针状铁素体组织为高塑性相,在断裂过程中其中能够出现微孔,可以看到主裂纹边部主要存在针状铁素体(I型)、针状铁素体/贝氏体界面(III型)孔洞见图9(b). 主裂纹扩展经过针状铁素体时其产生撕裂,出现韧窝结构见图9(d),一般情况下,长针状铁素体由于形成温度较低其塑性较差,然而该焊缝金属中长针状铁素体保持了较高的塑性和韧性,这主要与焊缝金属中超低碳含量密不可分. 另一方面,冲击过程中主裂纹在晶界旁侧经过,并在晶界上萌生了微孔,表明晶界具有良好塑韧性见图9(d),由此可知,13 kJ/cm断口中条带状韧窝对应晶界或亚晶界,其中断裂单元中撕裂棱主要为针状铁素体撕裂,较平滑解理面对应板条贝氏体及侧板条铁素体脆性断裂. 图9(e)可以直观看出,板条贝氏体脆性较高,二次裂纹易于在该组织中形成,由此可见,冷速较高抑制了针状铁素形成,而促进了板条贝氏体及侧板条铁素体形成,导致断口裂纹扩展区中存在混合断裂(韧性 + 脆性断裂),脆性断裂部分主要是由于低塑性板条贝氏体、侧板条铁素体形成所致,韧性部分与针状铁素体相关.

热输入提高至16 kJ/cm,板条贝氏体结构弱化强度降低,针状铁素体充分形成并分割细化晶粒,冲击断口主裂纹边界曲折,针状铁素体呈撕裂,贝氏呈现一定形变,表明其具有一定塑性见图9(g)中区域2. 主裂纹边界附近孔洞较密集,呈现一定弥散分布特征,微孔洞存在针状铁素体(I)、贝氏体与针状铁素体界面(III型)、M-A组元与针状铁素体界面(IV型)、晶界(V型)、夹杂物孔洞(VI型)见图9(g)和图9(h). 针状铁素体中孔洞(I型)尺寸显著较大,表明其塑性较高,针状铁素体抑制了裂纹萌生,在主裂纹附近未观察到显著的二次裂纹,针状铁素体具有良好的塑性,在裂纹扩展过程中产生黏性撕裂,能够抑制主裂纹扩展. 另一方面,主裂纹虽然较平直穿过贝氏体组织,然而在针状铁素体与贝氏体交界面产生了显著的偏折见图9(g)中区域2. 由此可见,针状铁素体分割细化所形成的交织的针状铁素体、贝氏体组织,在裂纹扩展中能够抑制裂纹扩展. 此外,焊缝金属冲击断口中存在细小弥散分布M-A组元,此类型M-A组元能够促进微孔弥散形核,利于冲击吸收能量提高,并且,主裂纹扩展过程中并未沿着或穿过M-A组元扩展,M-A组元对冲击裂纹扩展无显著影响见图9(h)和图9(i),分别为二次电子相和背散射电子相,背散射电子相中白亮的相为M-A组元. 可见,焊缝金属冲击韧性较高与塑性良好针状铁素体,以及针状铁素体和贝氏体交织分布相关,细小M-A组元并未对其韧性产生负面作用密切相关.

焊接热输入提高至19 kJ/cm,贝氏体组织强度持续降低,针状铁素体塑性持续改善,呈更加显著撕裂现象,贝氏体发生了显著的形变,表明二者塑性优良见图9(k). 虽然这两种组织塑性持续改善,但是,显著粗化的M-A组元促进了微孔弥散形核和裂纹扩展. 可以看到,主裂纹边部附近孔洞较密集,微孔主要出现在针状铁素体(I型)、贝氏体与铁素体界面(III型)、M-A组元与针状铁素体界面(IV型),其中,IV型微孔居多、尺寸较小,并且,冲击断口主裂纹边界较平直,主裂纹扩展从M-A组元边界穿过,M-A组元为主裂纹扩展提供了通道,促进了主裂纹扩展见图9(k)和图9(l). 由此可见,虽然热输入提高持续改善了贝氏体、针状铁素体的塑性,然而,粗大M-A组元促进了微孔萌生及主裂纹扩展,降低了焊缝金属冲击韧性. 综上可知,断口侧面形貌观察结果与上述组织、性能分析结果吻合.

3. 结论

(1) 采用自研直径4.0 mm焊条对690 MPa级HSLA钢进行不预热焊接,获得强韧性良好对接接头,焊接热输入由13 kJ/cm提高至19 kJ/cm对焊缝金属组织结构及其强韧性产生了显著影响. 对接接头抗拉强度由841 MPa降低至819 MPa呈现降低趋势,焊缝表面、心部硬度均呈现降低趋势,焊缝金属−50 ℃冲击吸收能量呈现先升高后降低现象,焊接热输入为16 kJ/cm强韧性匹配最优,对接接头抗拉强度828 MPa,焊缝中心−50 ℃冲击吸收能量为71 ~ 90 J,均值为80 J.

(2) 在焊缝金属超低碳成分体系条件下,13 ~ 19 kJ/cm热输入焊缝金属中针状铁素体、晶界塑性均良好,贝氏体塑性、M-A组元尺寸则对热输入较敏感. 热输入13 kJ/cm条件下,组织中形成的板条贝氏体、侧板条铁素体等脆性组织降低了其冲击韧性;热输入19 kJ/cm条件下,粗大的M-A组元为裂纹扩展提供了通道降低了其冲击韧性. 热输入16 kJ/cm充分形成了塑性良好针状铁素体组织,针状铁素体与贝氏体交织分布,提高了焊缝金属韧性,细小弥散分布的M-A组元并未对其韧性产生显著的负面作用.

(3) 热输入由13 kJ/cm提高至19 kJ/cm,冲击扩展过程中出现的韧窝结构由条带状转变为环形直至消失,依次与晶界或亚晶界良好的塑性、针状铁素体分割细化致亚晶尺寸降低、针状铁素体之间形成粗大M-A组元弱化亚晶界相关.

-

表 1 同轴保护气流量对应的回归方程系数

Table 1 Regression equation coefficients corresponding to shielding gas flow rates

同轴保护气流量

QT/(L·min−1)有效粉斑直径

w/mm系数

A系数

H决定系数

R25 0.98 89.3 75.3 0.98 8 0.96 86.6 67.4 0.98 12 1.01 74.3 62.04 0.99 16 0.96 61.2 51.7 0.99 23 1.03 51.3 39.0 0.98 表 2 载气流量对应的回归方程系数

Table 2 Regression equation coefficients corresponding to carrier gas flow rates

载气流量

QZ/(L·min−1)有效粉斑直径

w/mm系数

A系数

H决定系数

R22 0.88 149.5 134.4 0.99 5 1.02 128.55 97.3 0.99 7 1.13 106.55 82.04 0.98 9 1.24 95.15 60.3 0.99 10 1.32 83.85 50.2 0.98 表 3 送粉速率对回归方程关键系数的影响规律

Table 3 Regression equation coefficients corresponding to powder feeding rates

送粉速率

QP/(g·min−1)有效粉斑直径

w/mm系数

A系数

H决定系数

R29.90 0.97 71 58.4 0.98 16.50 0.99 103.5 83.6 0.99 23.10 0.99 141.1 113.8 0.99 29.60 0.98 173.5 145.7 0.99 32.90 0.98 182.1 148.1 0.99 -

[1] 王帅, 付立铭, 袁勇, 等. NiFe基合金激光增材制造热裂纹形成机理及调控[J]. 焊接学报, 2022, 43(5): 8 − 13. doi: 10.12073/j.hjxb.20220101001 Wang Shuai, Fu Liming, Yuan Yong, et al. Mechanism and elimination of hot cracks in laser additive manufacturing of NiFe based superalloy[J]. Transactions of the China Welding Institution, 2022, 43(5): 8 − 13. doi: 10.12073/j.hjxb.20220101001

[2] 种润, 郭绍庆, 张文扬, 等. GH4169合金激光增材制造过程热-力发展数值模拟[J]. 焊接, 2021(3): 13 − 21. Chong Run, Guo Shaoqing, Zhang Wenyang, et al. Numerical simulation of thermal-mechanical development of GH4169 alloy in laser additive manufacturing process[J]. Welding & Joining, 2021(3): 13 − 21.

[3] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690 − 2698. Wang Huaming. Materials' fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2690 − 2698.

[4] Lin X, Huang W D. Laser additive manufacturing of high-performance metal compo- nents[J]. Scientia Sinica, 2015, 45(9): 1111.

[5] Liu J, Li L. Effects of powder concentration distribution on fabrication of thin-wall parts in coaxial laser cladding[J]. Optics & Laser Technology, 2005, 37(4): 287 − 292.

[6] Liu Z, Zhang H C, Peng S, et al. Analytical modeling and experimental validation of powder stream distribution during direct energy deposition[J]. Additive Manufacturing, 2019, 30: 100848. doi: 10.1016/j.addma.2019.100848

[7] Singh A, Kapil S, Das M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition[J]. Additive Manufacturing, 2020, 35: 101388. doi: 10.1016/j.addma.2020.101388

[8] Lin P Y, Shen F C, Wu K T, et al. Process optimization for directed energy deposition of SS316L components[J]. The International Journal of Advanced Manufacturing Technology, 2020, 111(5-6): 1 − 14.

[9] Huang W, Zhang Y, Dai W, et al. Mechanical properties of 304 austenite stainless steel manufactured by laser metal deposition[J]. Materials Science and Engineering A, 2019, 758(5): 60 − 70.

[10] Jhang S S, Lo Y L, Le T N. Systematic modeling approach for analyzing the powder flow and powder energy absorptivity in direct energy deposition system[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(1-4): 1765 − 1776. doi: 10.1007/s00170-019-04441-3

[11] 杨义成, 王威, 王旭友, 等. 工艺参数对同轴送出粉末流动状态的影响[J]. 焊接学报, 2017, 38(5): 13 − 17. doi: 10.12073/j.hjxb.20170503 Yang Yicheng, Wang Wei, Wang Xuyou, et al. The effect of process parameter on powder flow statues in coaxial powder feeding[J]. Transactions of the China Welding Institution, 2017, 38(5): 13 − 17. doi: 10.12073/j.hjxb.20170503

[12] 刘吴, 虞钢, 何秀丽, 等. 粉末性质对同轴送粉激光熔覆中粉末流场的影响规律[J]. 中国激光, 2013, 40(5): 102 − 110. Liu Wu, Yu Gang, He Xiuli, et al. Effect of powder proper-ties on the convergence of powder stream in coaxial laser cladding[J]. Chinese Journal of Lasers, 2013, 40(5): 102 − 110.

[13] 靳晓曙, 杨洗陈, 冯立伟, 等. 激光制造中载气式同轴送粉粉末流场的数值模拟[J]. 机械工程学报, 2007, 43(5): 161 − 166. doi: 10.3321/j.issn:0577-6686.2007.05.028 Jin Xiaoshu, Yang Xichen, Feng Liwei, et al. Numerical simulation of coaxial powder flow with carrying gas in laser manufacturing[J]. Journal of Mechanical Engineering, 2007, 43(5): 161 − 166. doi: 10.3321/j.issn:0577-6686.2007.05.028

[14] Pant P, Chatterjee D, Samanta S K, et al. Experimental and numerical analysis of the powder flow in a multi-channel coaxial nozzle of a direct metal deposition system[J]. Journal of Manufacturing Science and Engineering, 2021, 143(7): 071003. doi: 10.1115/1.4049640

-

期刊类型引用(0)

其他类型引用(3)

下载:

下载: