Process and performance of pure copper parts formed by blue laser directed energy depostion

-

摘要: 金属高反材料对短波长激光拥有较高的吸收率,文中使用大功率蓝光激光器作为能量源在不锈钢基板上进行纯铜的沉积,将激光功率、扫描速度和送粉速率从5个水平形成不同的工艺参数组合进行全因子试验. 先从宏观尺寸分析了工艺参数对沉积层的影响,后从相对密度、组织结构和力学性能3个方面对多道多层工艺进行探究. 结果表明,单位送粉激光能量(laser energy per unit powder feed,LEPF)在2.592 ~ 6.048 kJ/g范围内可进行稳定的连续沉积,而当LEPF值大于6.050 kJ/g时,因用于沉积的激光能量过多而导致气孔出现. 使用LEPF值为4.53 kJ/g打印出了表面质量较好的纯铜薄壁圆筒零件. 通过正交扫描得到最高相对密度为99.10%的纯铜块状样件,并观察到了两种孔隙:近球形的气体包封孔隙(I型)以及未熔合和未熔化的粉末孔隙(II型). 最后进行拉伸测试,从结果发现,远离基板成形位置抗拉强度为196.55 MPa,靠近基板成形位置的断后伸长率为26.72%.Abstract: High reflective metal materials have high absorptivity to short wavelength laser. In this paper, high-power blue laser is used as energy source to deposit pure copper on stainless steel substrate. The laser power, scanning speed and powder feeding rate are combined to form different process parameters on five levels for full factor test. Firstly, the influence of process parameters on the deposition layer was analyzed from the macro dimension, and then the multi-channel and multi-layer process was explored from the three aspects, including relative density, microstructure and mechanical properties. The results showed that continuous deposition can be performed when the laser energy per unit powder feed (LEPF) is in the range of 2.592 ~ 6.048 kJ/g. When the LEPF value is more than 6.050 kJ/g, the pores appear due to the excessive laser energy used. The pure copper thin-walled cylindrical part with good surface quality was printed with LEPF value of 4.53 kJ/g. Pure copper bulk samples with the highest relative density of 99.10% were obtained through orthogonal scanning, and two kinds of pores were observed: near spherical gas encapsulated pores (type I) and unfused powder pores (type II). Finally, tensile tests were carried out, and the results showed that, The tensile strength far from the base plate is 196.55 MPa, and the elongation after fracture near the base plate is 26.72%.

-

0. 序言

纯铜因其具有优异的导热、导电性能,在电子电路、电感线圈、热交换器、汽车发动机、航空航天燃烧室零部件等对零部件的导热、导电性能有较高要求的工业领域应用广泛[1]. 但是现有大多数纯铜增材制造的研究集中在粉末床上,少有定向能量沉积方面的研究.文中采用激光定向能量沉积(laser directed energy deposition,LDED)技术进行纯铜打印,该技术是通过激光辐照熔融粉末材料在零件上形成涂层,与等离子转移弧焊和热喷涂等传统的涂层方法相比,激光定向能量沉积可以实现较小的热效应,与基体有良好的冶金结合[2].

相对密度与各项性能有着重要联系,但纯铜直接激光加工存在一定难度,Santo等人[3] 采用激光粉末床熔融(laser powder bed fusion,LPBF)技术,连续光纤激光器在150 W下打印的纯铜相对密度仅71.0%; Ikeshoji等人[4]采用高功率光纤激光器将打印件密度提升到96.6%;最终,Colopi等人[5]采用1 kW单模光纤激光器打印纯铜粉,优化工艺参数和打印策略后,相对密度达到99.1%.

铜的光反射率因波长和温度而异. 在室温条件下,波长为1 064 nm的红外激光器,其光反射率高达90%,而在450 nm的波长范围内,光吸收率约为红外波长的6倍[6].

随着蓝光激光器的发展,在增材制造领域上的应用逐渐增多,Nuburu公司的Finuf等人[7]采用275 W连续蓝光波激光在500 μm厚的铜箔板上进行焊道测试,结果表明,波长的高吸收使得传导模式和小孔焊接模式都能产生高度稳定的焊缝熔池. Asano等人[8]采用蓝光和红外二极管激光器在304不锈钢上激光沉积纯铜,将红外光激光金属沉积与蓝光激光金属沉积进行比较,结果表明,由于铜对蓝光二极管激光器的吸收率较高,较小的激光功率即可获得铜涂层. Britten等人[9]展示了在钢和铜衬底上高功率蓝光激光熔覆纯铜粉末的性能,演示了将铜基板预热至250 ℃,并结合使用1 kW蓝光和1.5 kW 近红外激光,最终形成相对密度大于95%的块状铜样件,红-蓝复合激光或将成为解决纯铜增材制造难点的重要途径.

铜在短于红外波段的波长范围内表现出较小的反射率,且蓝光范围内的激光更能有效地加热飞粉,通过大功率蓝光激光器进行加工,有望成为解决传统红外激光器加工困难、成形质量差的有效手段.上述研究证明通过高功率红外激光选区熔化可获得高致密度样件,以及采用蓝光激光器可进行纯铜无飞溅焊接. 然而目前缺乏纯铜同轴送粉蓝光激光定向能量沉积完整的单道单层、单道多层和多道多层研究.文中采用蓝光激光器在不锈钢基板上沉积纯铜,分析单道单层的尺寸特征、单道多层薄壁件成形质量和多道多层的组织结构和力学性能,探索1 000 W蓝光激光功率、2.0 mm光斑直径下,LDED直接成形纯铜的可行性.

1. 试验方法

基材选用200 mm × 100 mm × 10 mm 和100 mm × 100 mm × 10 mm两种尺寸的316L不锈钢钢板,定向能量沉积使用粉末为北京康普锡威有限公司研发的铜粉. 采用化学法对使用的纯铜粉末进行分析,其纯度为99.96%,成分分析结果见表1.

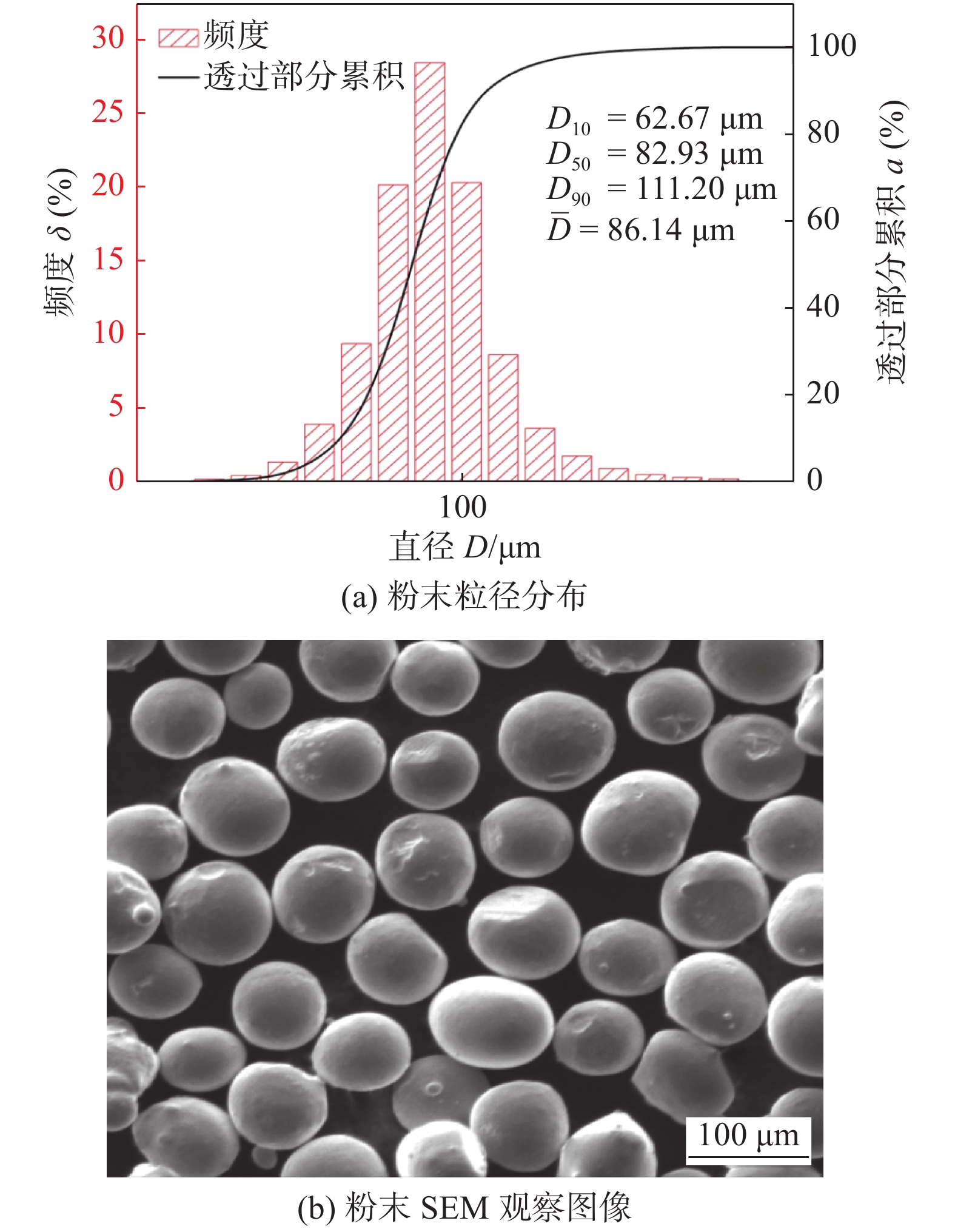

表 1 纯铜粉末的化学成分(质量分数,%)Table 1. Chemical composition of pure copper powderAg Fe Ni Pb Zn Sn Cu 0.0012 0.01 0.02 < 0.01 < 0.01 < 0.01 余量 图1显示了粉末的粒径分布和扫描电子显微镜SEM观察图像,采用气体雾化法生产的纯铜粉末,粒径分布为45 ~ 106 µm,平均粒度为86.14 µm,SEM形貌显示大多数铜颗粒球形度高,畸形粉末少.

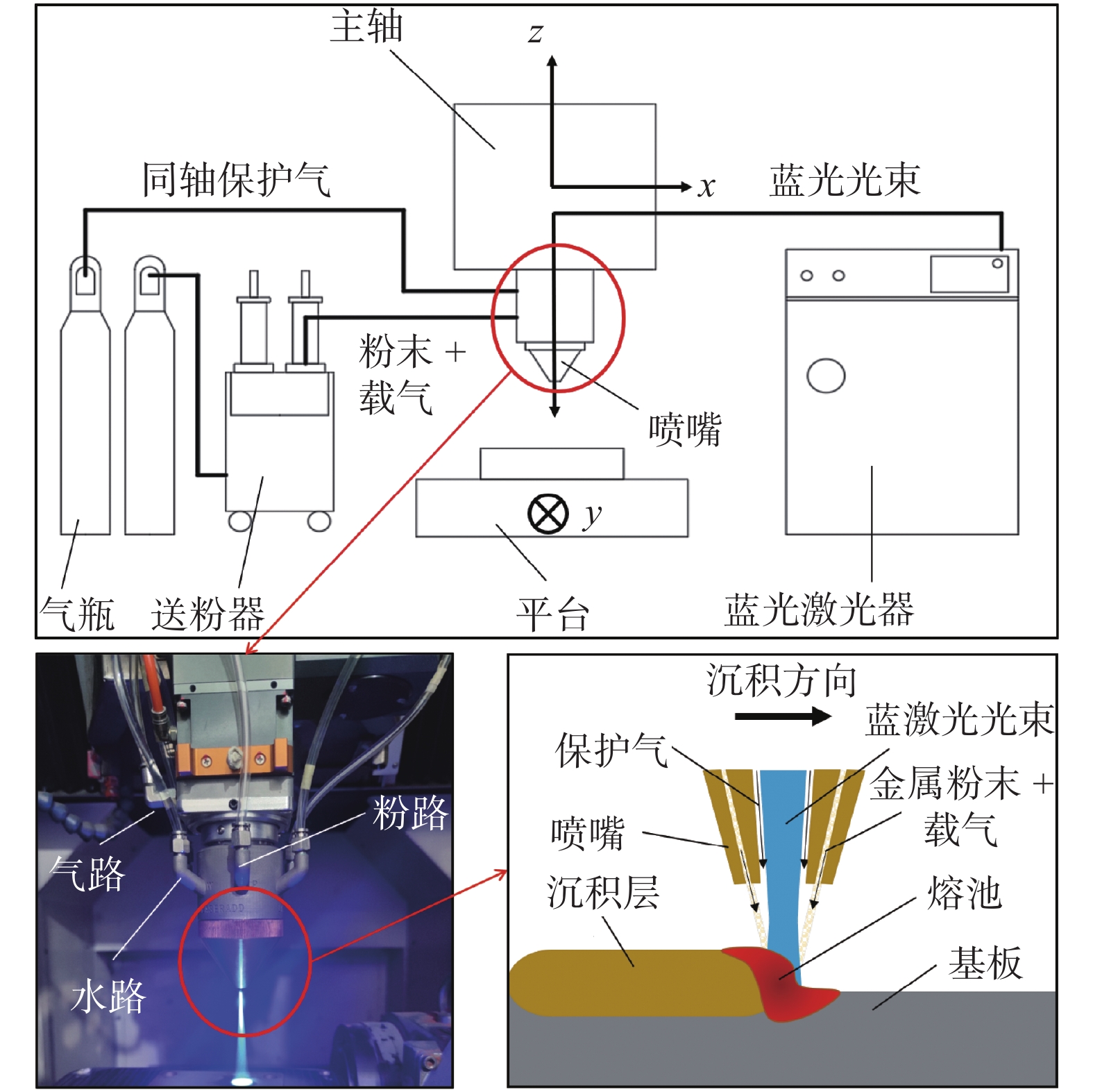

在激光定向能量沉积技术中,激光束通过喷嘴照射到基板上,并在基板表面上形成一个局部加热区域,称为熔池,金属粉末由惰性气体氩气携带送入其中进行沉积,同时还提供同轴保护气体,防止加工过程产生的烟尘进入喷嘴,使激光光学透镜免受污染,以确保加工过程的稳定性. 蓝光激光定向能量沉积试验系统由5个单元组成:激光系统、送粉系统、送气系统、冷却系统和运动控制系统, 如图2所示. 激光器为蓝光激光器(UM1000-455),波长455 nm,峰值功率1 000 W;金属粉末使用氩气作为载体,经双桶送粉器(LAMPF-TD)输送到环形同轴喷嘴,再同保护气一起注入熔池;采用冷水机(东露阳)对激光器及激光头进行冷却,保证设备的正常使用;x-y-z工作台可以沿3个线性轴移动,以实现三维沉积,运动由计算机数控控制器集成和控制. 沉积头底部到基体的工作距离为13.0 mm,光斑直径2.0 mm.

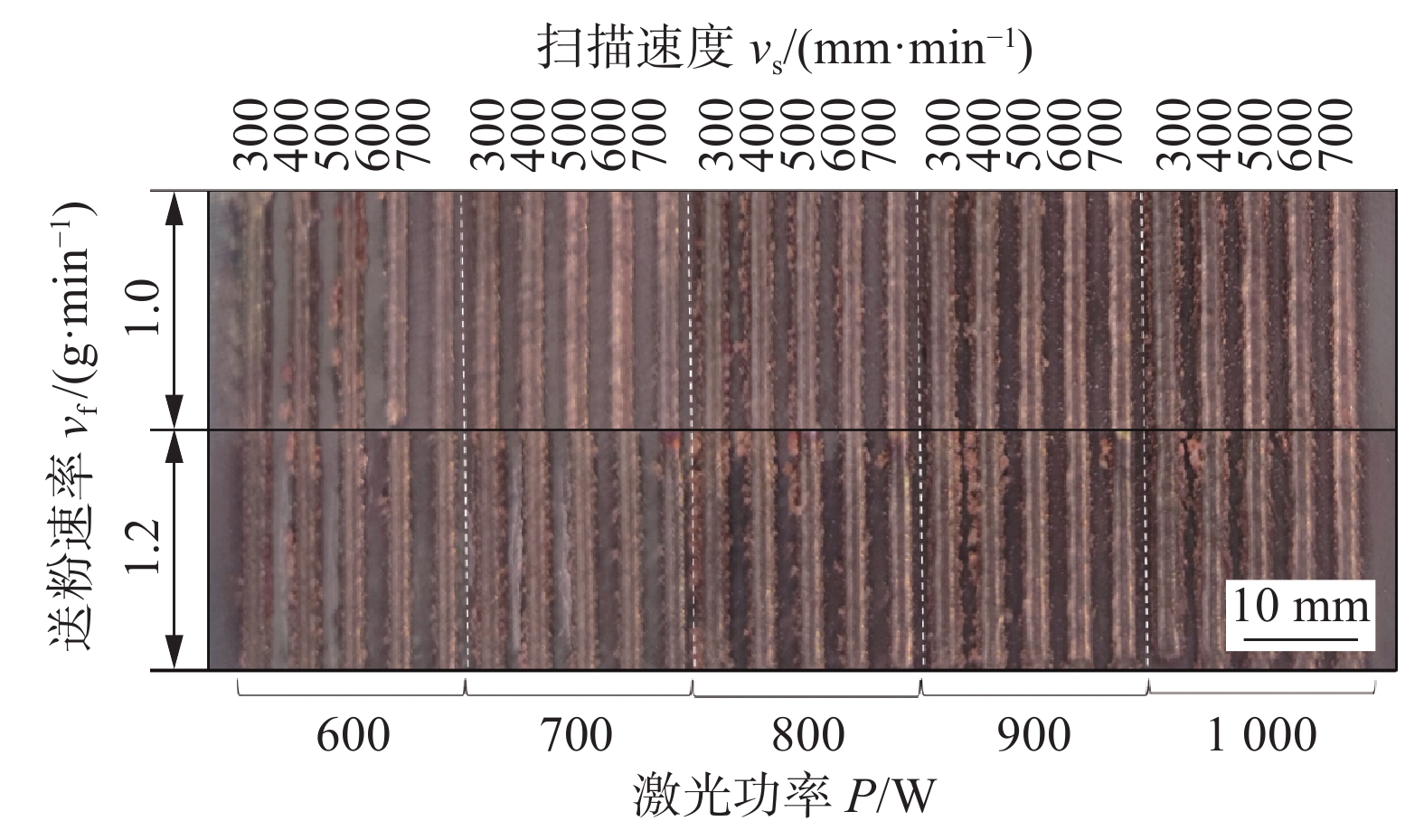

第一步,实施全因子试验设计,以探究激光功率P,扫描速度vs,送粉速率vf对沉积层成形的影响,其它因素如载气流量、保护气流量和喷嘴高度保持不变. 有研究表明,由于大块钢基板的导热性较低,且铜和钢之间存在混合,因此第一层在450 nm波长处仅需要600 W的功率[9]. 同时,引入在红外波段下的工艺参数,铜熔化和与基体润湿所需的最小LEPF值为4.5 kJ/g,对应于600 W的激光功率和8 g/min的送粉速率. LEPF值(27 kJ/g)的上限受到裂纹和气孔生成的限制[10],对应于1 800 W的激光功率和4 g/min的送粉速率. 考虑到纯铜对蓝光的吸收率高于红外光,因此在上述范围基础上扩大了送粉速率的范围,最终选择5个水平上通过改变激光功率、扫描速度和送粉速率进行全因子试验. 用于铜单道单层定向能量沉积试验的工艺参数如表2所示. 图3显示了成形质量较好的纯铜定向能量沉积单道试样. 对所有单道试样进行线切割,然后对其截面打磨、抛光、腐蚀,腐蚀液由5 g FeCl3 + 50 mL HCl + 100 mL H2O配制而成,腐蚀20 ~ 30 s,最后采用超景深三维显微镜(Keyence VHX-5000)测量其沉积层宽度、沉积层高度和基材熔深.

表 2 激光定向能量沉积试验工艺参数Table 2. Technological parameters of laser directional energy deposition test激光功率

P/W扫描速度

vs /(mm·min−1)送粉速度

vf /(g·min−1)600 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 700 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 800 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 900 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 1 000 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 第二步,根据第一步所得规律选择合适的工艺参数,进行单道多层探究,并打印出尺寸为ϕ80 mm × 100 mm的多层薄壁的圆筒零件.

第三步,进行纯铜激光定向能量沉积的多道多层工艺探究,主要工艺参数如表3所示. 采用正交扫描的方式打印并切割出10 mm × 10 mm × 5 mm的块状试样,并对其组织和致密度进行分析. 选取成形方块的侧面进行打磨、抛光、腐蚀,然后用光学显微镜OM观察其显微组织.同时,采用两道搭接沿z轴成形方向循环往复扫描,并通过线切割得到拉伸样件,对其进行打磨抛光后,使用万能试验机进行力学性能测试.

表 3 LDED成形主要工艺参数Table 3. Main process parameters of LDED forming激光功率

P/W扫描速度

vs /(mm·min−1)送粉速度

vf /(g·min−1)光斑直径

D/mm搭接率

ε ( % )900 200 2.98 2.0 50 950 550 9.92 2.0 40 2. 试验结果与讨论

2.1 工艺参数对沉积层成形的影响

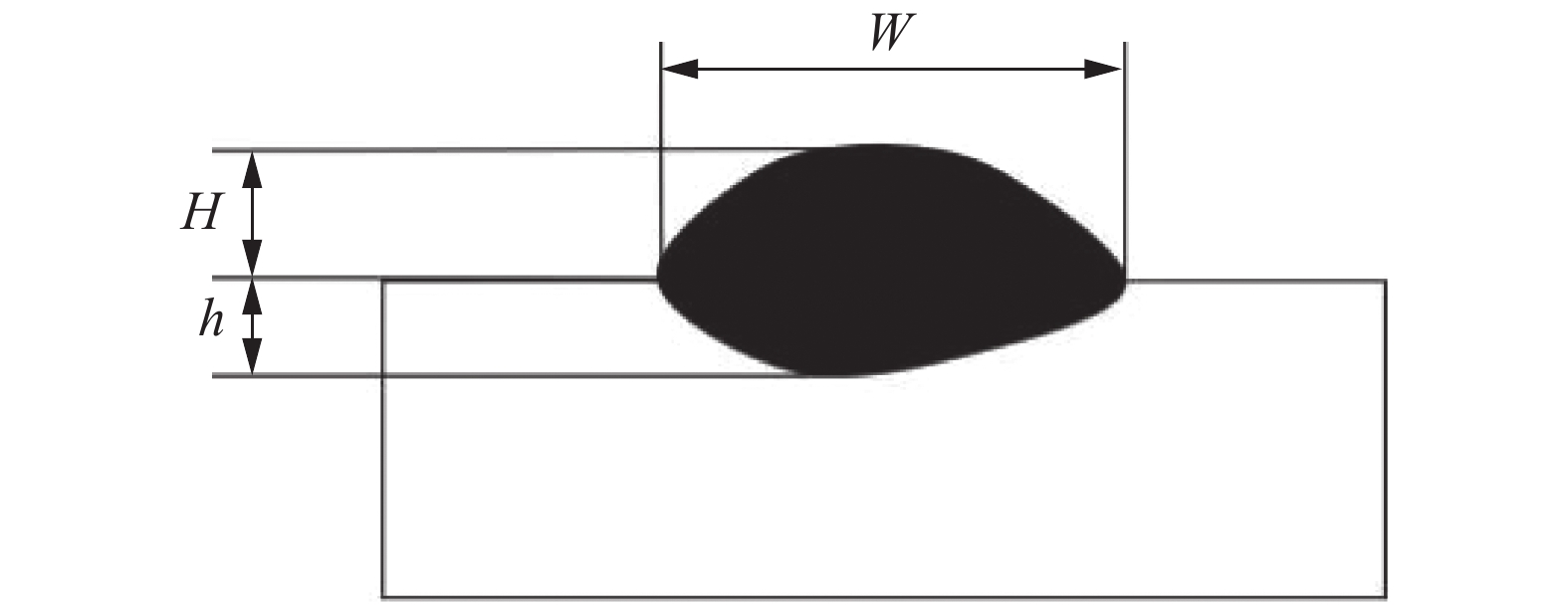

工艺参数的变化会影响沉积层成形的宏观尺寸,如沉积层的宽度、沉积层的高度、搭接表面平整度和尺寸差异等[11],从而影响了所打印零件的宏观尺寸和尺寸精度. 激光定向能量沉积层的宏观尺寸可以用沉积层的形状特征来表示,具体是指沉积层的宽度W、沉积层的高度H、沉积层的厚度即基材熔深h与沉积层的高度之和,图4所示为形状特征示意图.

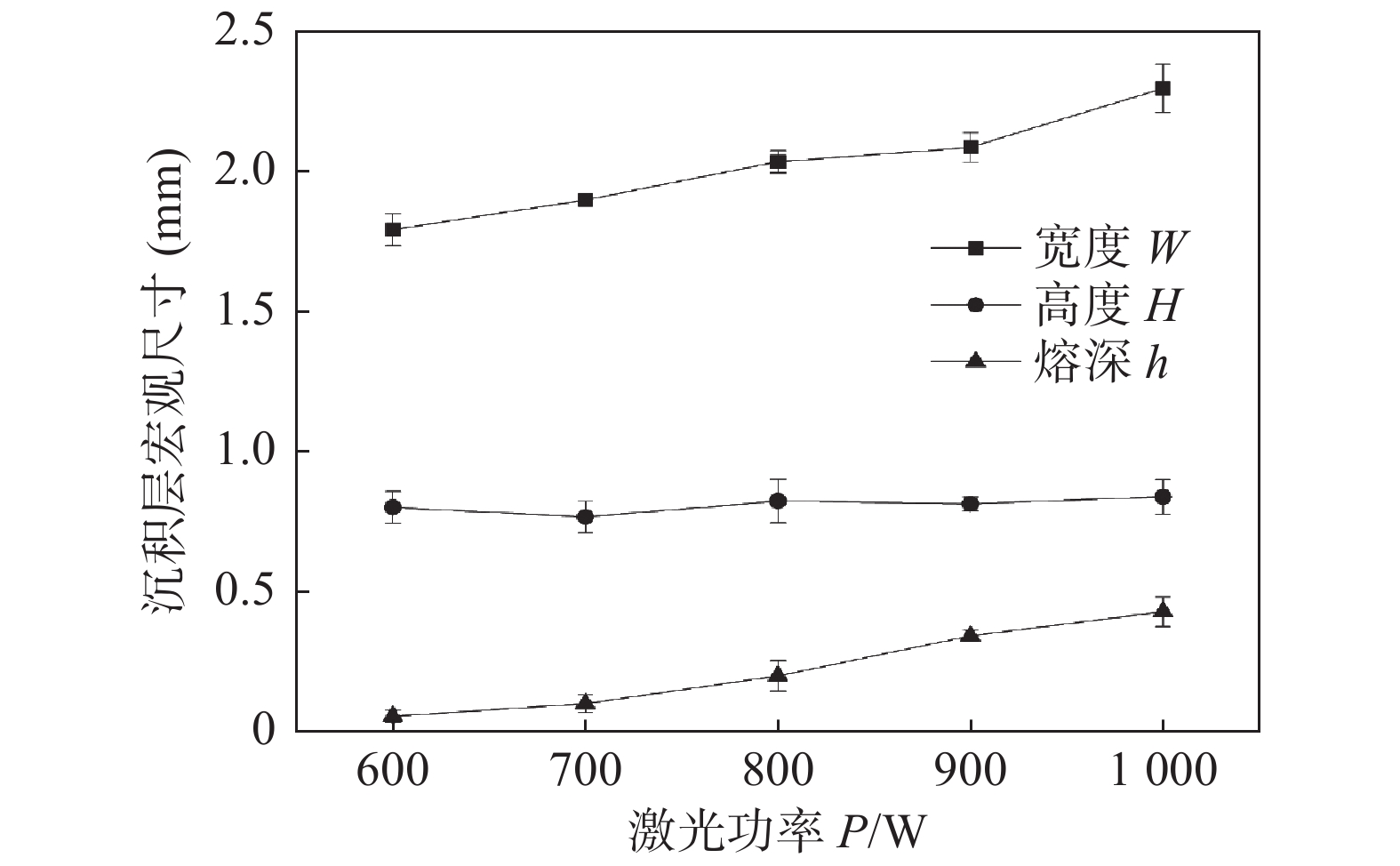

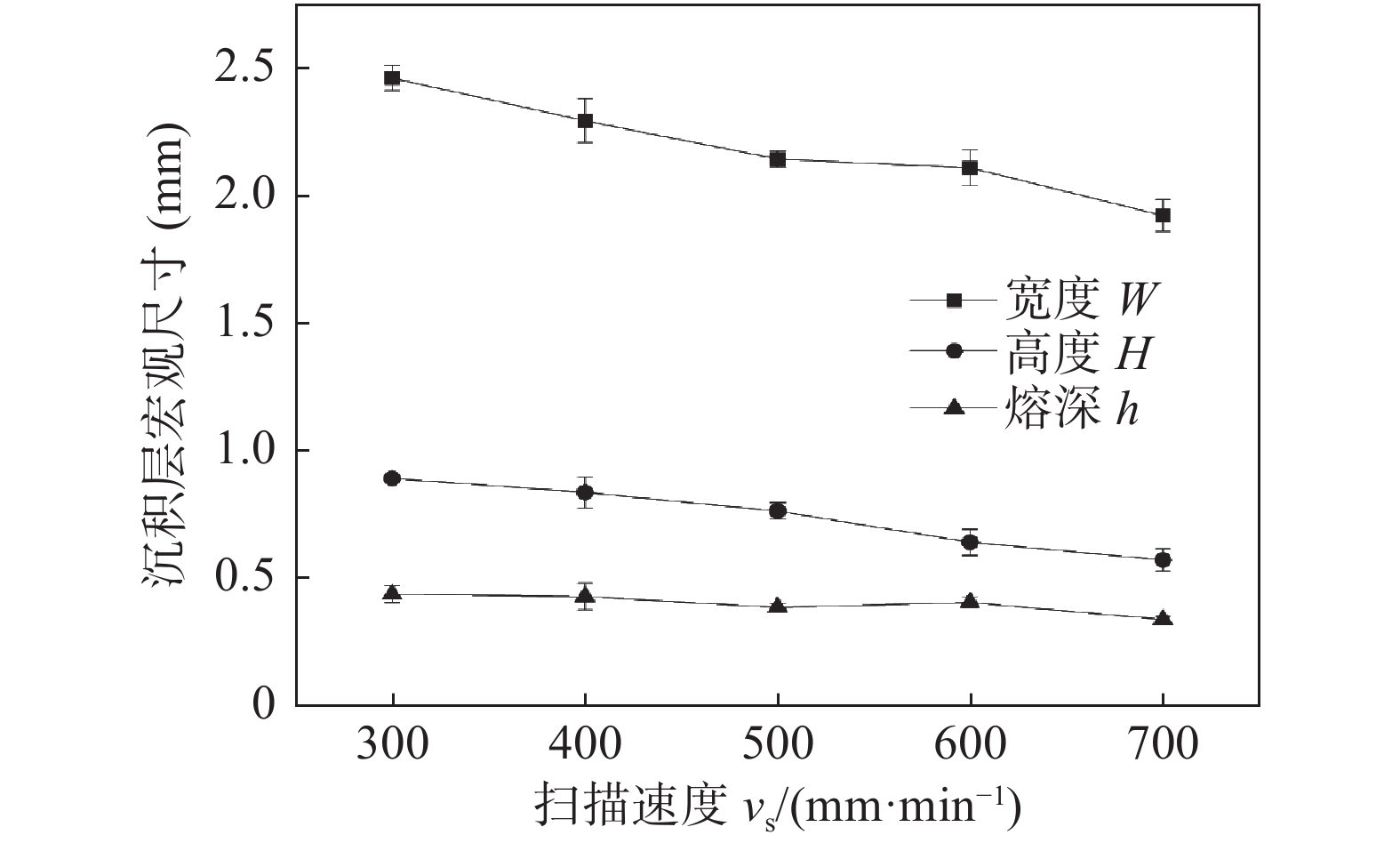

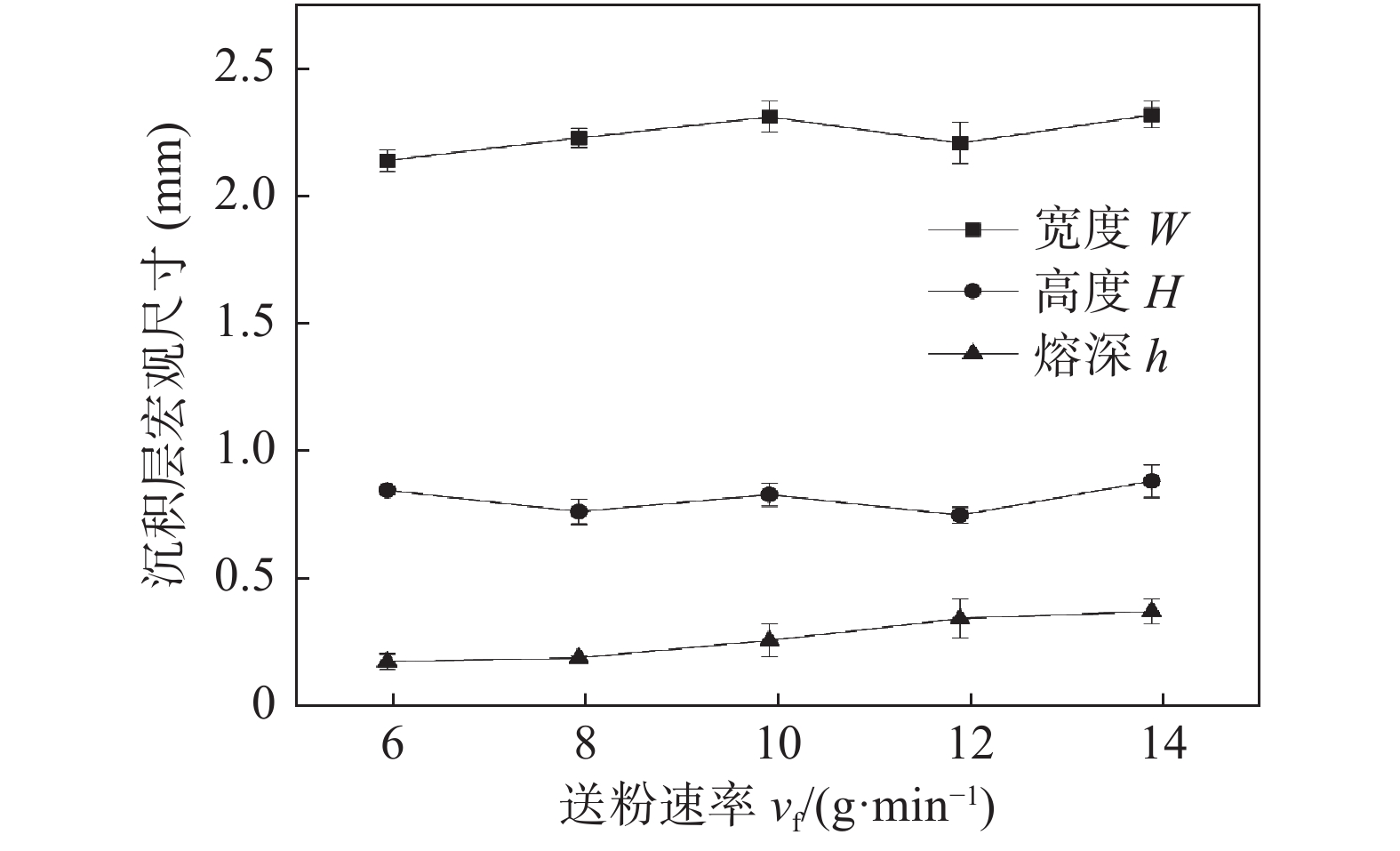

激光功率 P是激光定向能量沉积的能量来源,是功率密度的主要因子,也是影响沉积层成形尺寸的重要因素. 由图5可知,在其它参数不变,扫描速度为400 mm/min和送粉速率为13.89 g/min时,激光功率对沉积层的高度影响不大,随着功率的增加,熔道宽度、基材熔深均增加. 试验是在不锈钢基板上沉积纯铜,由于纯铜良好的导热性和散热性,使得熔道高度增加更为困难,相反不锈钢基板散热性相较而言更差,更容易热集中,因此使得激光功率对熔道宽度的影响大于对熔道高度的影响,同时随着激光功率的增加,单位面积上得到的能量也相应增加,使熔池变大变深.

扫描速度是改变激光能量密度的重要因素之一. 由图6可知,在其它参数不变,激光功率为1 000 W、送粉速率为13.89 g/min时,随着扫描速度的增加沉积层宽度和沉积层高度都降低. 这是因为随着扫描速度的增加,金属粉末与激光在熔池中的作用时间降低,导致单位时间单位面积上的能量输入降低.同时扫描速度的增加也使得单位空间内送入熔池的粉末量减少,也导致沉积层变窄. 当扫描速度超过一定使得能量密度低于金属粉末熔点的数值之后,就无法得到完整且连续的熔覆层,因此选择合理的扫描速度既可以得到成形质量较高的沉积层,也可以为后续单层多道、多层多道的成形提供保障.

送粉速率是影响单位时间内被送入熔池的金属粉末量的重要参数.由图7可知,保持其参它数不变,激光功率为900 W、扫描速度为300 mm/min时,随着送粉速率的增加沉积层高度变化不大,沉积层宽度及熔池深度均有增加. 在316L不锈钢上沉积铜时,熔池中心区域的温度高于边缘区域,这种温差导致表面张力梯度朝向熔池边缘[12].此外粉末颗粒为熔池增加了质量和动量.这些添加剂会影响熔池中的流体温度分布和流动模式.由于颗粒撞击力的不同,粉末速度会影响熔池的流型和穿透力. 较大的颗粒具有更大的冲击力,导致熔池流速增加[13]. 因此增加粉末量也难以提高沉积层高度,反而增加了沉积层的宽度和深度,促进了铜和不锈钢的连接.

2.2 蓝光LDED成形纯铜薄壁零件

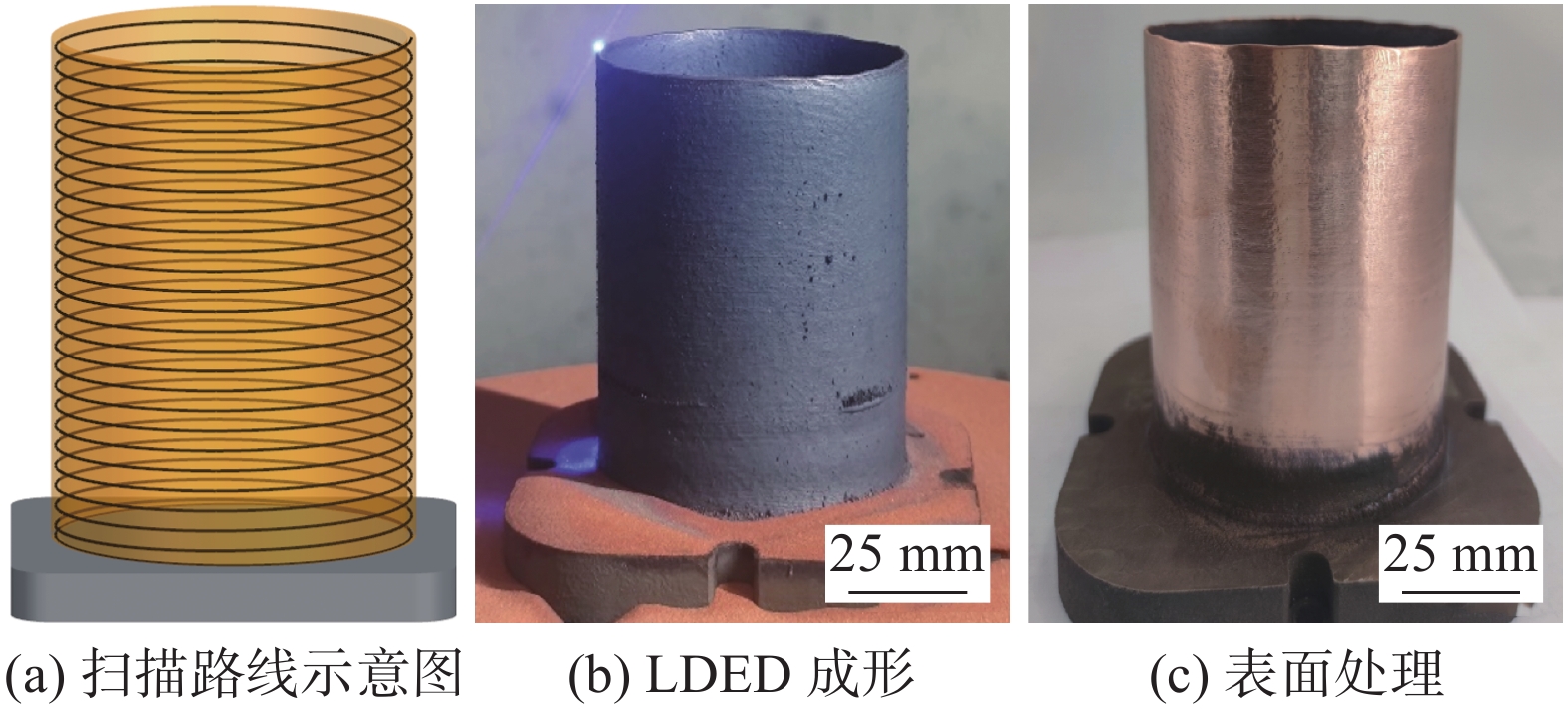

送粉速率、激光功率和扫描速度3个工艺参数对于外观成形的影响较为显著,是单道多层试验中首要考虑优化的工艺参数,同时为保证沉积的稳定性和能量的利用率,选用激光功率750 W,扫描速度300 mm/min,送粉速度9.92 g/min的工艺参数进行连贯螺旋线扫描打印,如图8a所示,第一圈z轴不变,从第二圈开始,每旋转一周z轴方向抬高0.4 mm,最后打印出ϕ80 mm × 100 mm的薄壁圆筒零件. LDED成形后其上表面平整光滑无凸点,内外侧边可见明显但分布均匀的层纹,如图8b所示. 简单抛光后,其表面光洁无孔隙,如图8c所示.

2.3 蓝光LDED成形组织和性能分析

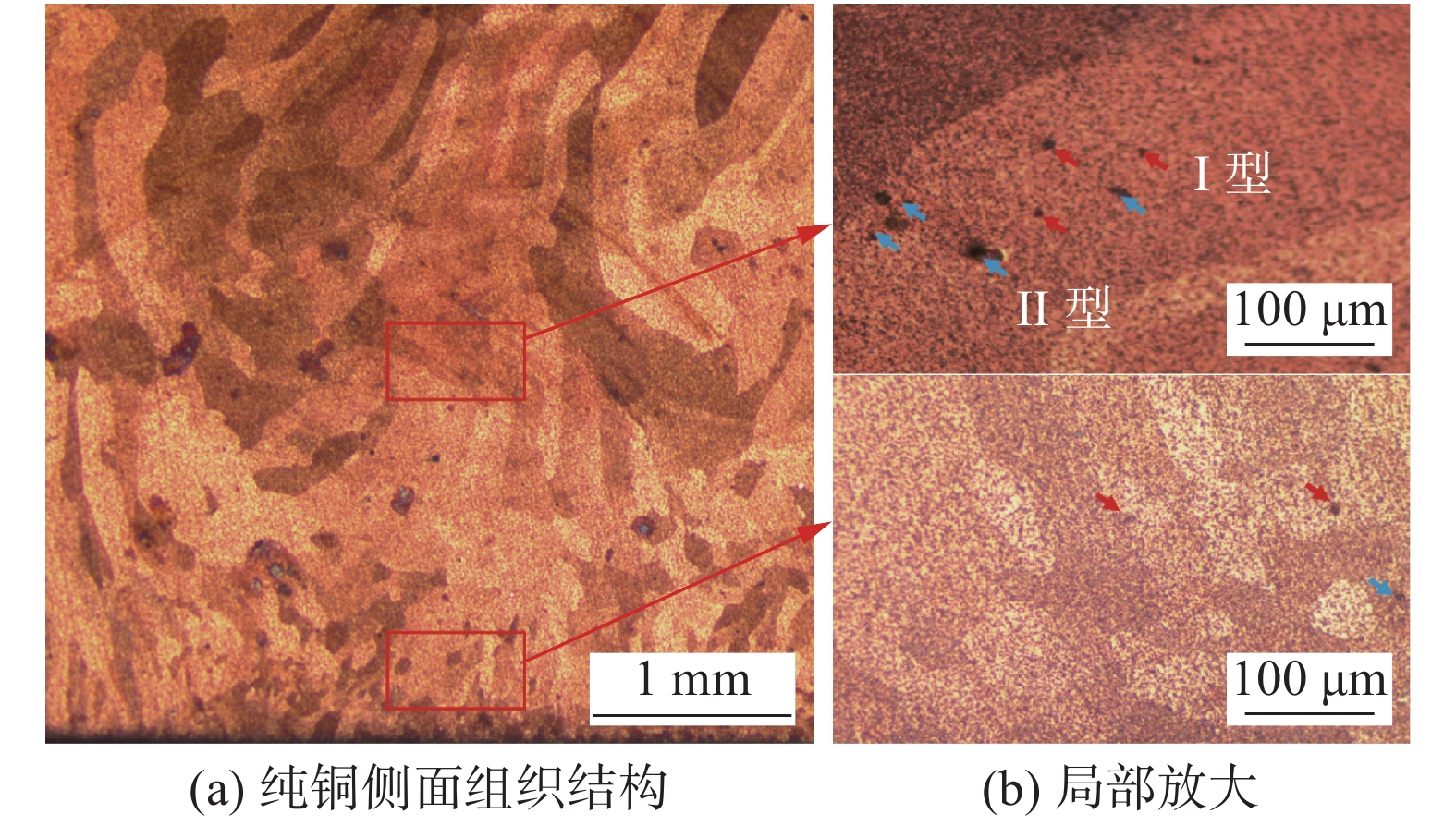

通过进一步正交扫描打印方块样件发现,随着打印层数的增加,纯铜沉积所需的能量需要进一步增加,因此扩大了工艺参数范围,当激光功率为900 W,扫描速度为200 mm/min,送粉速率为2.98 g/min,填充间距为1.0 mm,层厚为0.6 mm时,得到了的最高相对密度为99.10%块状样件. 图9显示了工艺变量下,用蓝光激光定向能量沉积制造的块状铜样品的显微组织结构.

从OM图发现,晶粒的形态取决于成形位置和扫描方向,沿着成形方向(z)的不同,晶粒形态也有所不同. 靠近基板(结合区),熔池边界冷却速度快,因此晶粒比较细且取向比较杂乱. 随着沉积高度的上升,到中间区域晶粒结构逐渐粗大(稳定区),最后随着温度梯度的变化,晶粒沿着扫描方向外延生长,如图9a所示. 此外,随着沉积高度的增长,因纯铜良好的导热性致使孔隙逐渐增多,从以近球形为特征的因熔池内的气体包裹而形成的气体包封孔隙(I型),到缺乏熔合以及包含未熔化粉末的不规则孔隙(II型)[14]. 据观察,I型和II型孔隙分别出现在结合区和稳定区,但II型在稳定区出现频率更高,如图9b.

激光加工零件的微观组织决定了零件的性能,而金属增材制造成形组织形貌主要取决于冷却速度和温度梯度[15].温度梯度G、凝固速率R和过冷度ΔT是控制凝固模式、微观结构细化以及晶粒结构发展的关键因素[16]. 对于用LDED加工的特定材料,G, R和ΔT值是由工艺参数组合隐式决定,即使工艺参数保持不变,晶粒结构在微观和宏观尺度上也不一定一致.例如结合区内部观察到的晶粒形态的不均匀性归因于动态G/R[17]. 从稳定区可以看出,晶粒生长方向的倾斜由最大热流方向决定,这意味着它与最高温度梯度一致. 在结合区,更深的熔池有利于促进铜沉积层和衬底之间形成良好连接.

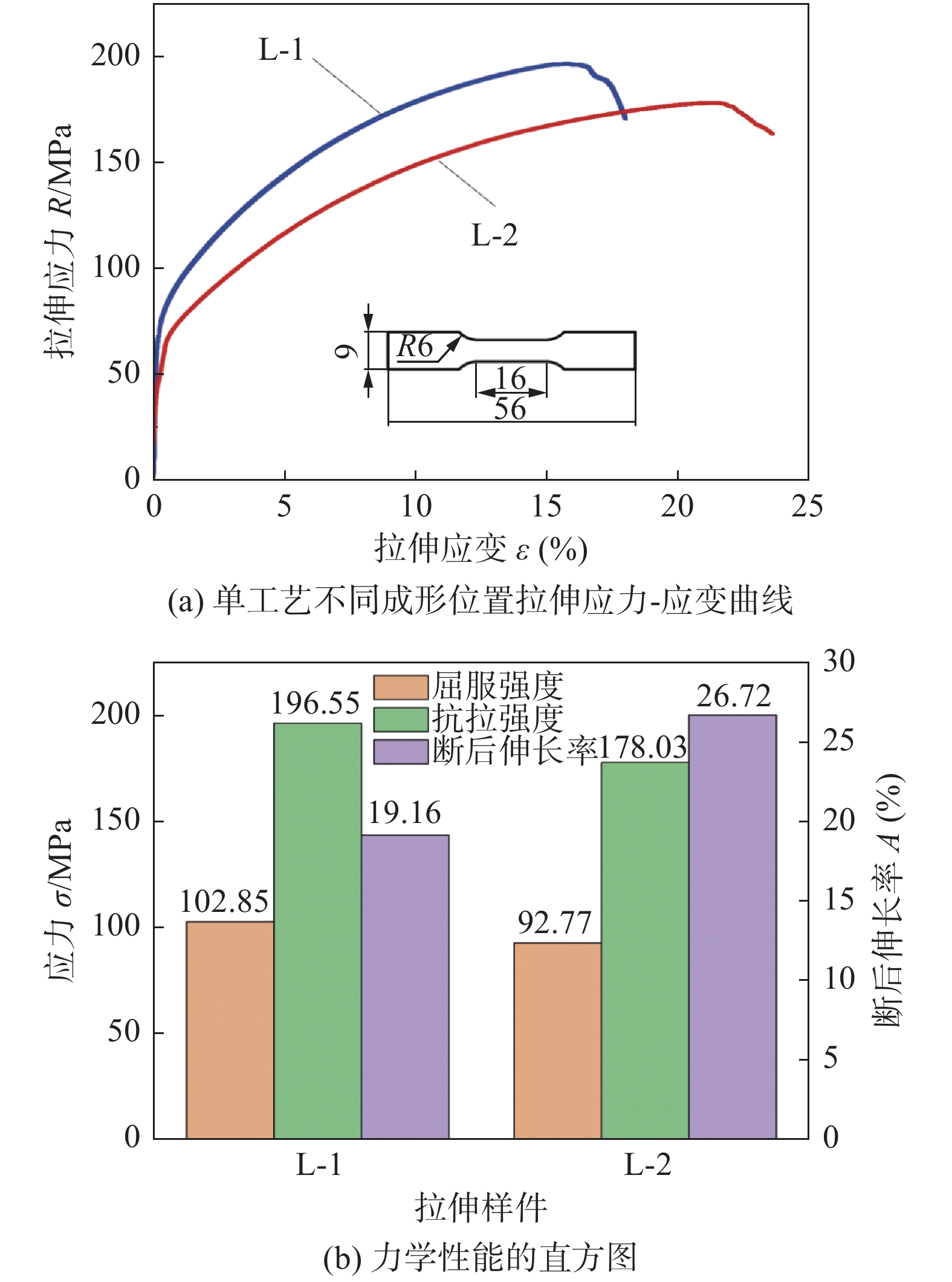

优化工艺参数后,采用两道搭接,沿z轴方向循环往复打印,打印出具有一定厚度的块件,再通过电火花线切割机进行拉伸件的切割. 最后对比远离基板一侧的拉伸样件L-1、靠基板更近的L-2的力学性能.

远离基板一侧的L-1极限拉应力为196.55 MPa,与传统工艺铸造的纯铜样件最小极限拉应力200 MPa[18]相比差距不大. 同一工艺参数下打印的同一样件,针对不同的成形位置分别制取的L-1和L-2力学拉伸试样,试验结果如图10所示. L-1试样的横向抗拉强度、屈服强度均强于L-2试样的,分别高出了10.40%和10.87%,但L-2的断后伸长率相比L-1高出了7.56%.

2.4 讨论

试验提供了关于在不锈钢基板上采用蓝光激光定向能量沉积纯铜工艺参数对其沉积尺寸的影响,结果证实,激光功率、扫描速度和送粉速度对沉积层的尺寸起着关键作用. 这里引入激光功率和送粉速率的比值,该参数被称为每单位送粉激光能量(LEPF). 从所有结果观察到,LEPF值在2.592 ~ 6.048 kJ/g范围内会进行连续稳定沉积,而LEPF值大于6.050 kJ/g时,由于可用于沉积的激光能量过多会导致气孔的出现.

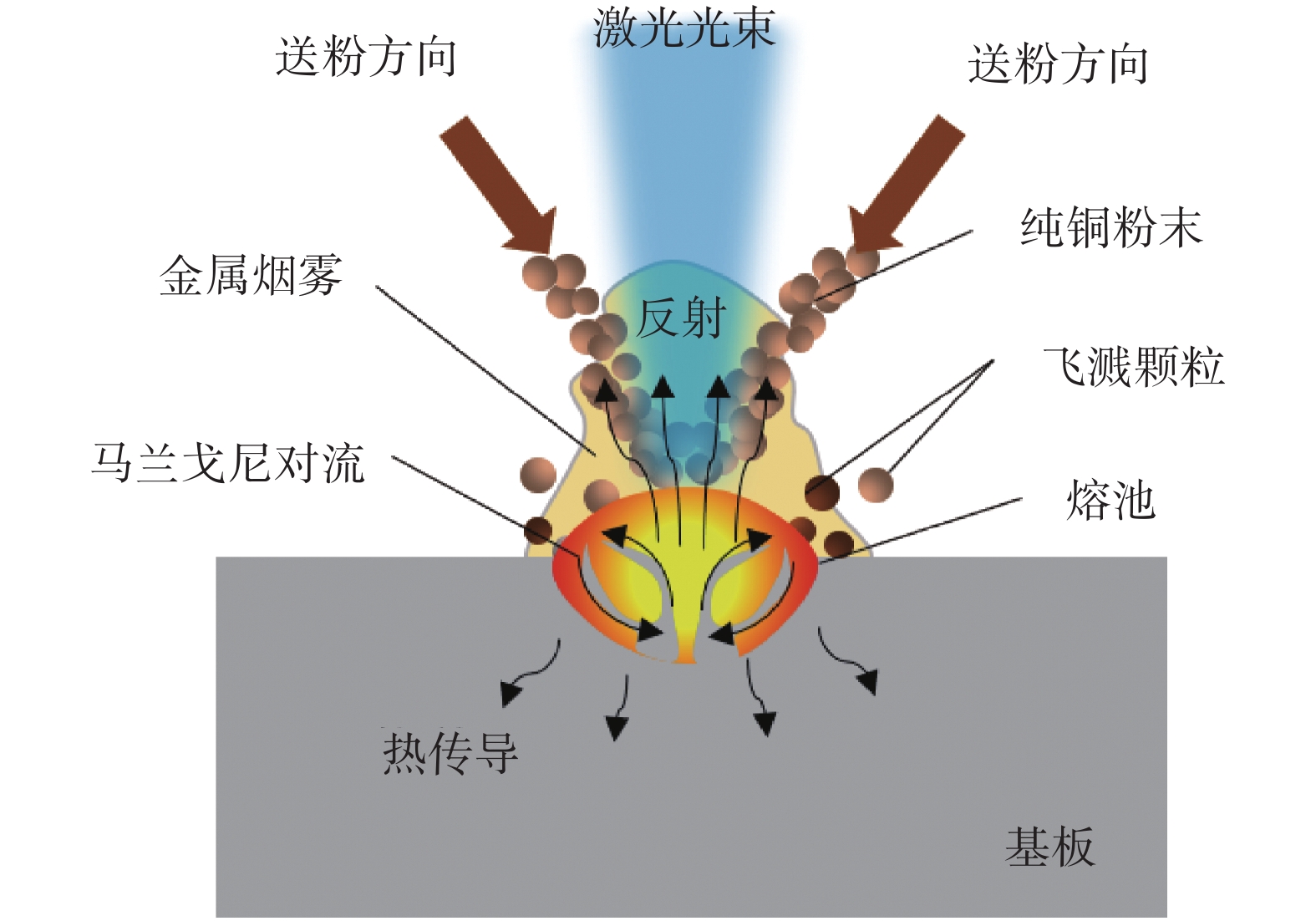

热效应驱动的马兰戈尼对流与表面张力和温度梯度成正比[19]. LDED熔池反应机理如图11所示. 在316L不锈钢上沉积铜时,熔池中心区域的温度高于边缘区域.这种温差导致表面张力梯度朝向熔池边缘[12]. 此外,纯铜极高的导热系数增大了温度梯度G,从而强化了熔池中马兰戈尼对流的动力学. 同时,液态金属由于重力向下流动到熔池底部,因此在熔池中实现了循环液体流动,这有利于铜和不锈钢在界面上的显著扩散.

在多道多层研究中,通过对试样组织分析,在其侧面发现了两种稳定的孔隙,对其致密度和力学性能有着决定性影响. 为了获得均匀和无缺陷的沉积,应考虑合理的激光功率、扫描速度和送粉速率工艺组合. 随着沉积层数的增加,纯铜沉积所需的能量也需要进一步增加,直至最大激光功率1 000 W,因此更高功率的短波长激光器或红-蓝光复合激光定向能量沉积将成为纯铜增材制造的主要解决方案.

3. 结论

(1) 激光功率、扫描速度和送粉速度对沉积层的尺寸起着关键作用,LEPF值在2.592 ~ 6.048 kJ/g范围内会进行连续稳定沉积,而LEPF值大于6.050 kJ/g时,由于可用于沉积的激光能量过多会导致气孔的出现.

(2) 采用LEPF值为4.53 kJ/g的工艺参数,螺旋连贯扫描打印出层间均匀、表面平整的ϕ80 mm × 100 mm的圆筒薄壁件. 当激光功率为900 W,扫描速度为200 mm/min,填充间距为1.0 mm,层厚为0.6 mm时,获得的最高相对密度为99.10%的块状样件.

(3) 靠近基板(结合区),冷却速度快,熔池晶粒结构晶粒比较细,且取向比较杂乱. 随着沉积高度的上升,到中间区域晶粒结构逐渐粗大(稳定区),到最后随着温度梯度的变化,致使晶粒沿着扫描方向外延生长. 在两个区域均检测到两种类型的孔隙:近球形的气体包封孔隙(I型)以及未熔合和未熔化的粉末孔隙(II型),在稳定区观察到II型更多. 相同工艺参数下,远离基板位置试样的抗拉强度、屈服强度比靠近基板位置的试样分别高出了10.40%和10.87%,但靠近基板位置试样的断后伸长率高7.56%.

-

表 1 纯铜粉末的化学成分(质量分数,%)

Table 1 Chemical composition of pure copper powder

Ag Fe Ni Pb Zn Sn Cu 0.0012 0.01 0.02 < 0.01 < 0.01 < 0.01 余量 表 2 激光定向能量沉积试验工艺参数

Table 2 Technological parameters of laser directional energy deposition test

激光功率

P/W扫描速度

vs /(mm·min−1)送粉速度

vf /(g·min−1)600 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 700 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 800 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 900 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 1 000 300,400,500,600,700 5.95,7.94,9.92,11.90,13.89 表 3 LDED成形主要工艺参数

Table 3 Main process parameters of LDED forming

激光功率

P/W扫描速度

vs /(mm·min−1)送粉速度

vf /(g·min−1)光斑直径

D/mm搭接率

ε ( % )900 200 2.98 2.0 50 950 550 9.92 2.0 40 -

[1] Gu D D, Meiners W, Wissenbach K, et al. Laser additive manufacturing of metallic components: materials, processes and mechanisms[J]. International Materials Reviews, 2012, 57(3): 133 − 164. doi: 10.1179/1743280411Y.0000000014

[2] Vilar R. Laser cladding[J]. Journal of Laser Applications, 1999, 11(2): 64 − 79. doi: 10.2351/1.521888

[3] Santo L, Quadrini F, Bellisario D, et al. Local density measurement of additive manufactured copper parts by instrumented indentation[C]// AIP Conference Proceedings. AIP Publishing LLC, 2018: 100014.

[4] Ikeshoji T T, Nakamura K, Yonehara M, et al. Selective laser melting of pure copper[J]. Jom, 2018, 70(3): 396 − 400. doi: 10.1007/s11837-017-2695-x

[5] Colopi M, Demir A G, Caprio L, et al. Limits and solutions in processing pure Cu via selective laser melting using a high-power single-mode fiber laser[J]. The International Journal of Advanced Manufacturing Technology, 2019, 104(5): 2473 − 2486.

[6] Spisz E W. Solar absorptances and spectral reflectances of 12 metals for temperatures ranging from 300 to 500 K [M]. Washington D.C: National Aeronautics and Space Administration, 1969.

[7] Finuf M J, Gray B, Fritz R, et al. Laser welding copper with hight power cw blue laser[C]//International Congress on Applications of Lasers & Electro-Optics. Laser Institute of America, 2017: P101.

[8] Asano K, Tsukamoto M, Sechi Y, et al. Laser metal deposition of pure copper on stainless steel with blue and IR diode lasers[J]. Optics Laser Technology, 2018, 107: 291 − 296. doi: 10.1016/j.optlastec.2018.06.012

[9] Britten S W, Ocylok S. Blues skies for copper cladding with 450nm[C]//Laser 3D Manufacturing VI. SPIE, 2019: 41-48.

[10] Yadav S, Paul C P, Jinoop A N, et al. Laser directed energy deposition based additive manufacturing of copper: process development and material characterizations[J]. Journal of Manufacturing Processes, 2020, 58: 984 − 997. doi: 10.1016/j.jmapro.2020.09.008

[11] 黄凤晓. 激光熔覆和熔覆成形镍基合金的组织与性能研究[D]. 长春: 吉林大学, 2011. Huang Fengxiao. Study on microstructure and properties of nickel base alloy formed by laser cladding and cladding [D]. Changchun: Jilin University, 2011.

[12] Zhang Z, Zhou H, Ren L, et al. Surface morphology of laser tracks used for forming the non-smooth biomimetic unit of 3Cr2W8V steel under different processing parameters[J]. Applied Surface Science, 2008, 254(8): 2548 − 2555. doi: 10.1016/j.apsusc.2007.09.102

[13] Li L, Huang Y. Interaction of laser beam, powder stream and molten pool in laser deposition processing with coaxial nozzle[C]//Journal of Physics: Conference Series. IOP Publishing, 2018: 012078.

[14] Abdelhafiz M, Al-Rubaie K S, Emadi A, et al. Process-structure-property relationships of copper parts manufactured by laser powder bed fusion[J]. Materials, 2021, 14(11): 2945.

[15] Park J, Kim J, Ji I, et al. Numerical and experimental investigations of laser metal deposition (LMD) using STS 316L[J]. Applied Sciences, 2020, 10(14): 4874. doi: 10.3390/app10144874

[16] Kurz W, Giovanola B, Trivedi R. Theory of microstructural development during rapid solidification[J]. Acta Metallurgica, 1986, 34(5): 823 − 830. doi: 10.1016/0001-6160(86)90056-8

[17] Kou S. Welding metallurgy[J]. New Jersey, USA, 2003, 431(446): 223 − 225.

[18] Bai Y, Williams C B. An exploration of binder jetting of copper[J]. Rapid Prototyping Journal, 2015, 21: 177 − 185.

[19] Tan C, Zhou K, Ma W, et al. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture[J]. Materials & Design, 2018, 155: 77 − 85.

-

期刊类型引用(5)

1. 郑富凯,韩光达,张思雨,郭鑫辉,冯靖凯. 铜合金在增材制造领域的研究进展. 铜业工程. 2025(02): 110-129 .  百度学术

百度学术

2. 伍亚东,朱仁江,晏日,彭雪芳,王涛,蒋丽丹,佟存柱,宋晏蓉,张鹏. 高转换效率腔内倍频外腔面发射蓝光激光器. 物理学报. 2024(01): 180-186 .  百度学术

百度学术

3. 罗震,苏杰,王小华,肖斌斌,孙立国,杨越,毕元波,张熠轩. 激光-电弧复合焊接铝合金的研究进展分析. 华南理工大学学报(自然科学版). 2024(03): 57-74 .  百度学术

百度学术

4. 张宁波,温斯涵,张景琪,康黎,李启军,石刚,郦江涛,郑文海,黄凤春. 铜合金增材制造技术在航天领域应用进展. 军民两用技术与产品. 2024(01): 17-25 .  百度学术

百度学术

5. 王迪,卫洋,田印仟,温娅玲,周恒,李阳,杨永强. 应用于增材制造的纯铜/铜合金材料研究前沿进展. 工业技术创新. 2023(03): 9-23 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: