Multi-objective optimization of laser cladding parameters based on PCA and RSM-DE algorithm

-

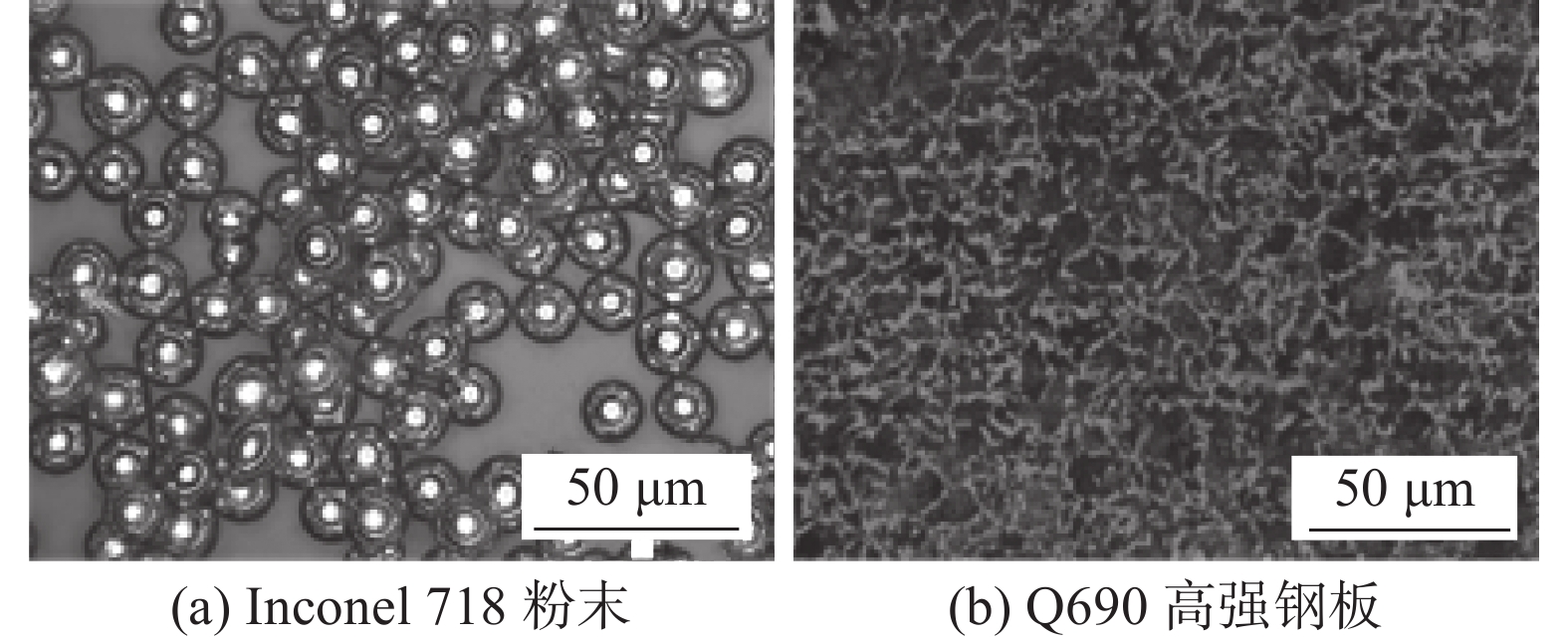

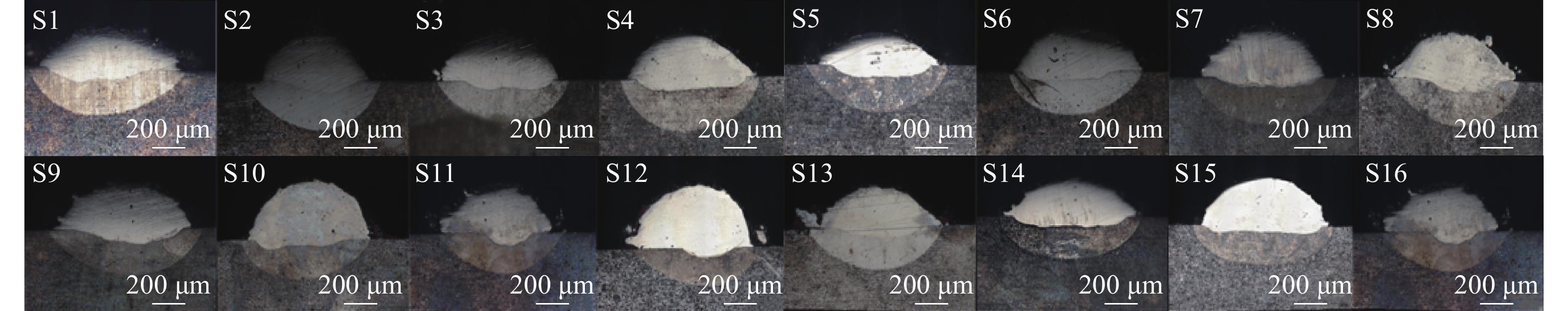

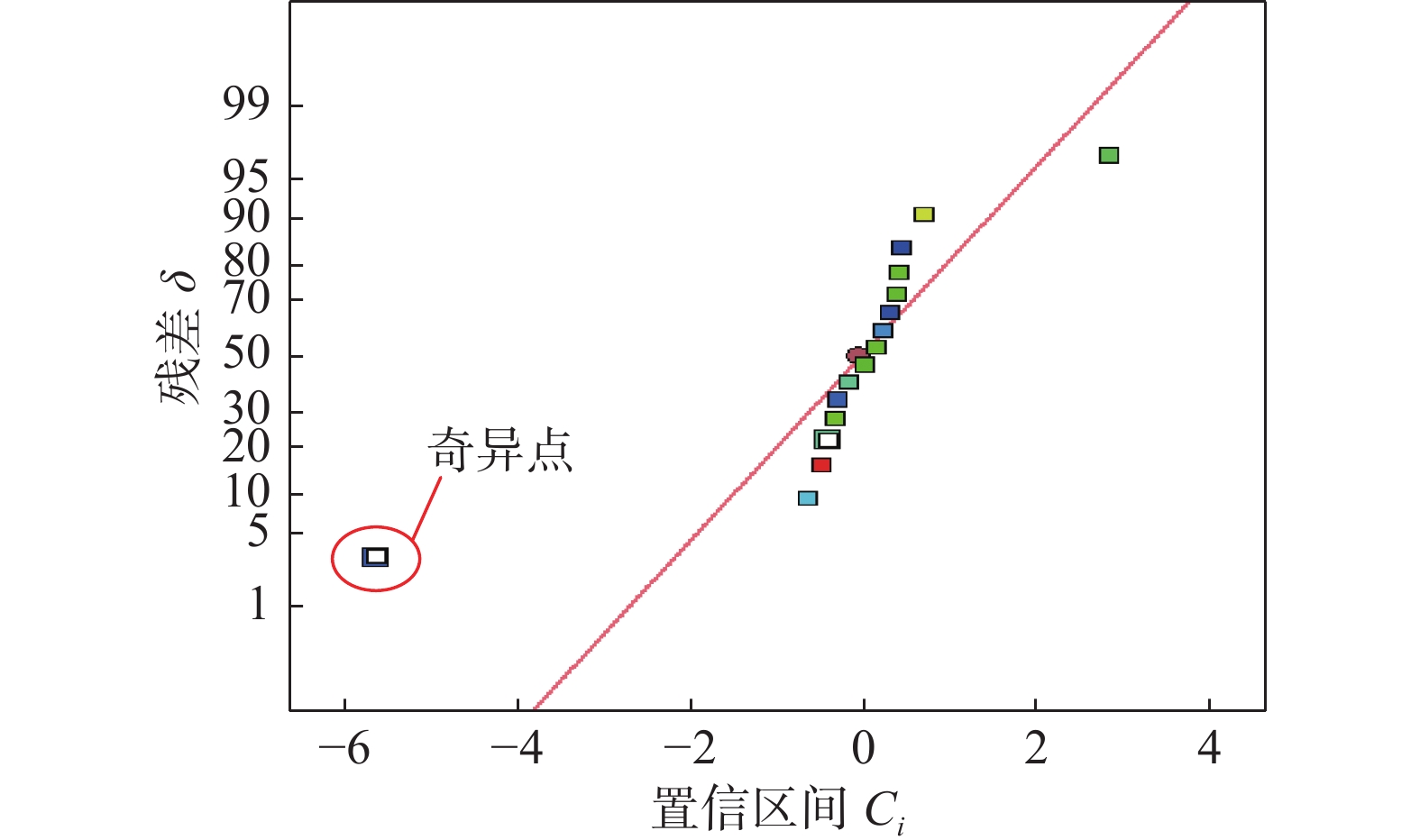

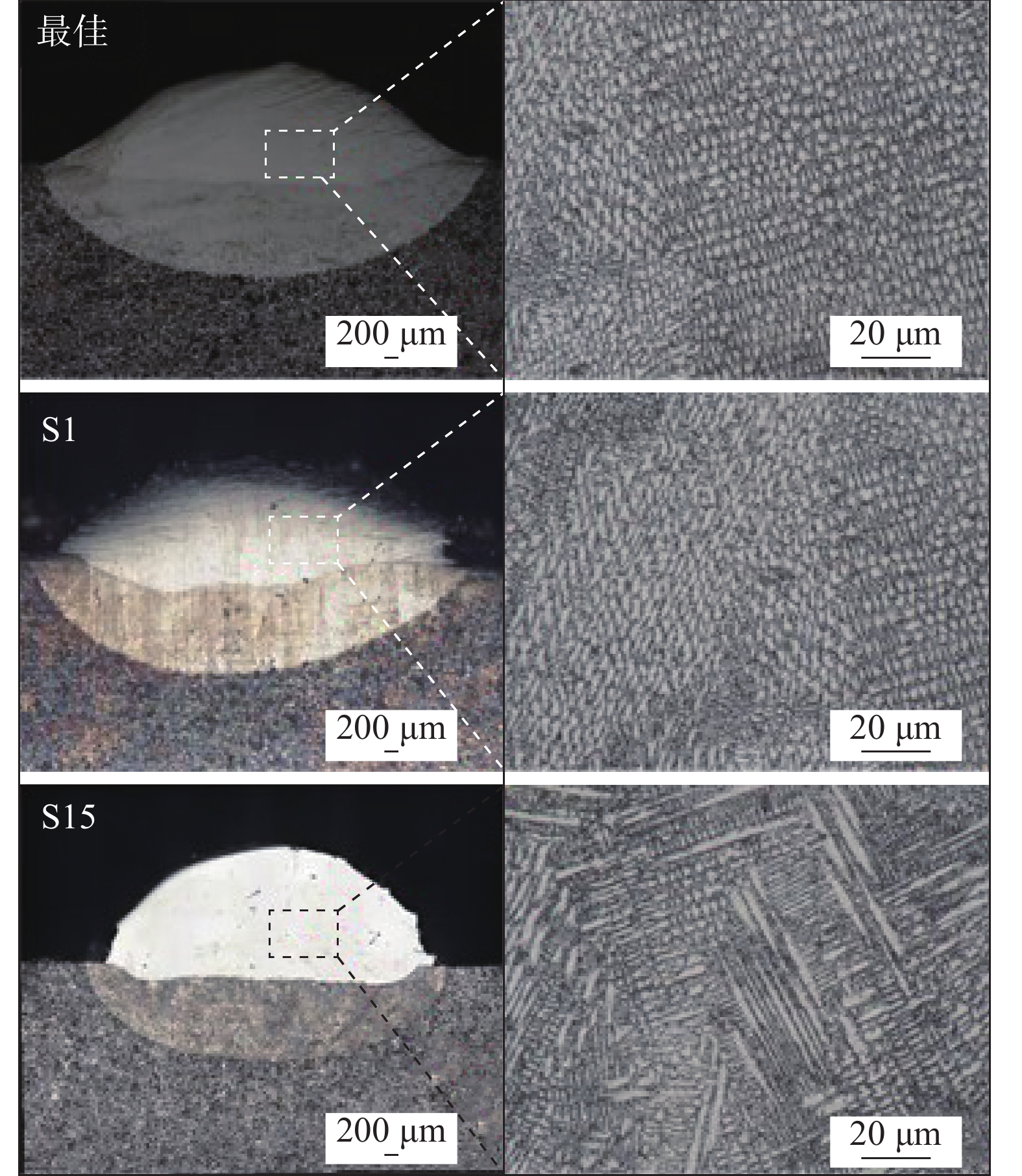

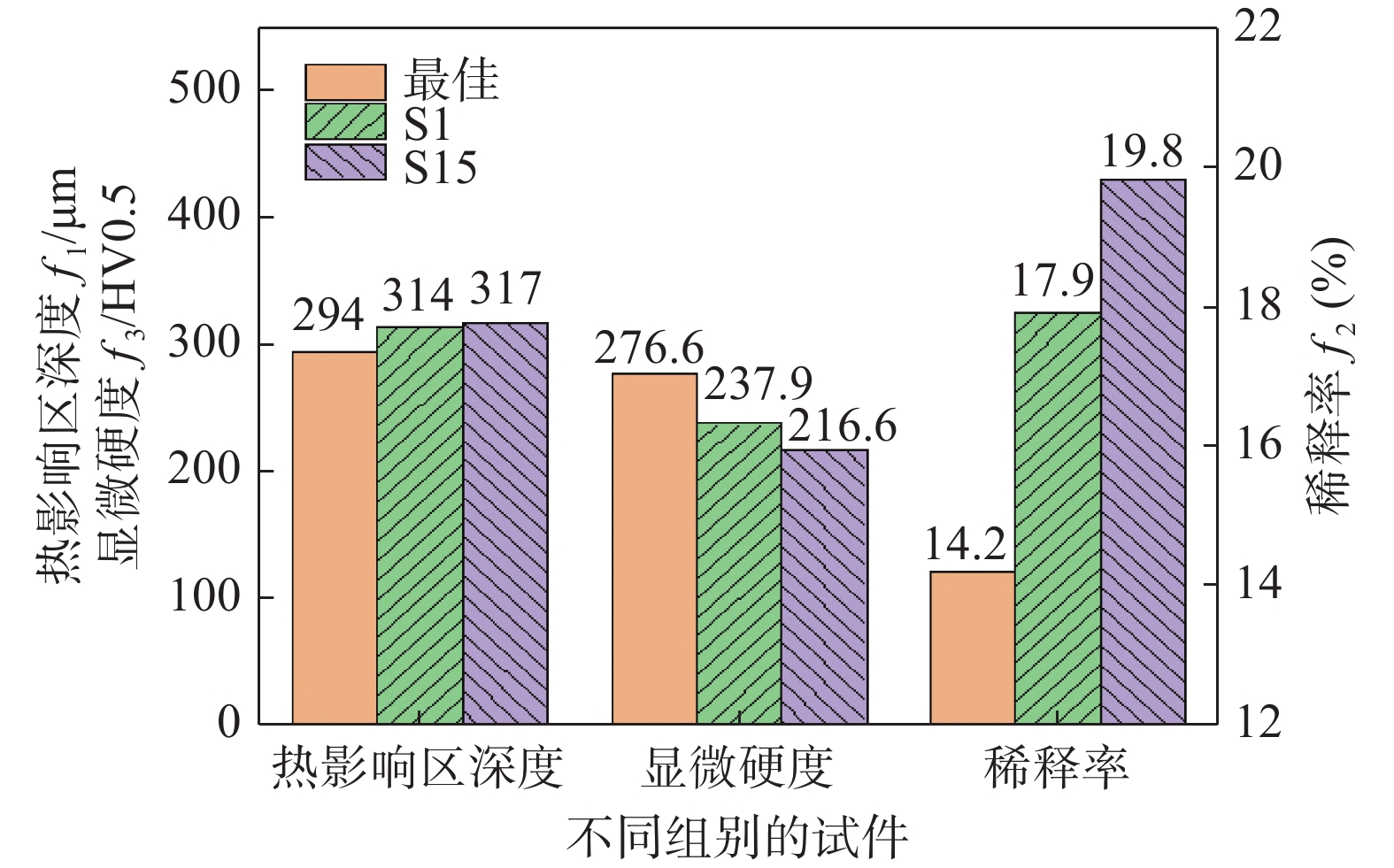

摘要: 为获得激光熔覆Inconel 718粉末在Q690高强钢板上的最优熔覆工艺参数,设计响应曲面法中的BBD(Box-Benhnken Design)试验设计模型. 构建输入变量(激光功率、扫描速度、送粉速率)与响应值(稀释率、热影响区深度、显微硬度)之间的数学模型,通过主成分分析法建立熔覆层综合评价指标,利用差分进化算法进行寻优,确定最优工艺参数. 采用最优工艺参数进行试验验证,对其最优工艺参数下试件的宏观形貌与组织形态进行观察与分析,并与优选出的试件进行响应值比较. 结果表明,最优工艺参数为激光功率1 800 W、扫描速度28 mm/s、送粉速率1.9 r/min,该参数下获得的热影响区深度为294 μm,稀释率为14.2%,显微硬度为276.6 HV0.5. 最优工艺参数下的试件热影响区深度减小了6.8%,稀释率降低了24.7%,显微硬度增大了21.7%,且最优试件中的组织形态为较小的树枝晶与少量的胞状晶.Abstract: The Box-Benhnken Design (BBD) experimental design model, as one of the response surface methods, was designed to obtain the optimal parameters for laser cladding of Inconel 718 powder on Q690 high-strength steel plate. A mathematical model between input variables (laser power, scanning speed, powder delivery rate) and response values (dilution rate, heat affected zone depth, microhardness) was established. Principal component analysis method was used to establish the comprehensive evaluation index of cladding layer, and differential evolution algorithm was used to optimize and determine the optimal process parameters. The optimal process parameters were used for test verification, and the macro-morphology and microstructure of the specimen under the optimal process parameters were observed and analyzed, and the response values were compared with the optimized specimen. The results showed that the optimal processing parameters were laser power of 1 800 W, scanning speed of 28 mm/s, and powder feeding rate of 1.9 r/min, under which the heat affected zone depth was 294 μm, the dilution rate was 14.2%, and the microhardness was 276.6 HV0.5. The optimum specimens showed a 6.8% reduction in the depth of the heat affected zone, a 24.7% reduction in dilution, and a 21.7% increase in microhardness, and the optimum specimens showed small dendritic crystals with a small amount of cellular crystals.

-

0. 序言

为满足轻量化及高可靠性的设计需求,具有高比强度的7xxx系(Al-Zn-Mg-Cu)高强铝合金被广泛应用于飞机蒙皮、桁条等零部件的制造[1-2]. 上述构件通常采用电阻点焊及铆接等传统工艺方法. 然而,电阻点焊在焊接铝合金时易产生裂纹和气孔等缺陷. 铆接会增加结构自重,也易产生间隙腐蚀. 回填式搅拌摩擦点焊(refill friction stir spot welding, RFSSW)是一种新型的固相点焊技术,该方法可通过搅拌头的旋转以及各部件的上下往复运动使焊点金属塑化,并同时进行金属的挤出和回填,最终实现冶金结合[3- 4]. 该方法可有效避免电阻点焊所引起的焊接缺陷. 同时,由于不需要填充材料,利于实现结构的轻量化. 此外,与传统直插式搅拌摩擦点焊相比,RFSSW可对匙孔进行回填,增加焊点面积,提高接头承载能力[5-6]. 基于此,RFSSW有望成为飞机制造新一代主导连接技术之一.

然而,由于Al-Zn-Mg-Cu体系共晶点较低,在RFSSW过程中会发生组分液化,并形成共晶组织,甚至产生液化裂纹,这将严重降低接头的力学性能[7]. 然而,常规RFSSW方法采用恒定的搅拌头转速,在搅拌套扎入阶段为了使材料快速塑化搅拌头转速相对较高,导致后续回填阶段热输入过高,难以有效抑制组分液化的发生.

针对上述问题,研究中发明了可变转速回填式搅拌摩擦点焊(variable rotation speed-refill friction stir spot welding, V-RFSSW)新方法. 该方法通过在在扎入阶段采用较高转速使材料快速塑化以保障焊点成形,后续回填阶段通过降低转速控制焊接热输入,以达到抑制组分液化,增加焊点材料强度,提升接头承载能力的目的. 文中针对7B04-T74铝合金开展V-RFSSW有限元数值仿真及焊接工艺试验,通过对焊接温度场及接头组织性能的研究,揭示V-RFSSW新方法对焊接热输入及接头组织性能的调控机制.

1. 有限元模型的建立

1.1 几何模型及网格划分

将工件设为两块75 mm × 75 mm × 1.9 mm板材搭接组成,搭接面积为75 mm × 30 mm (图1). 为了避免接触不稳定等问题,搭接界面被忽略. 采用尺寸疏密过渡的四面体网格对模型进行划分. 在搅拌头下方的焊接区域工件网格边长为0.5 mm,焊接区以外网格边长由1 mm向3 mm过渡. 搅拌针、搅拌套、压紧环以及垫板的网格边长设置为0.8 mm.

1.2 材料本构及摩擦产热模型

7B04铝合金本构模型可以用Arrhenius方程进行描述,真实应力σ、温度T以及应变速率ε之间的关系可表述为

$$ \varepsilon = A{(\sin \alpha \sigma )^n}\exp \left(\frac{{ - Q}}{{RT}}\right) $$ (1) 式中:A为结构因子,为1.15×1017;α为应力水平参数,为0.00882;n为应力指数,为6.3346;Q为热变形激活能,为228 620 J/mol;R为气体常数,为8.314 J/(mol∙K)[8]. 此外,不同温度热导率、换热系数等参数取值参照文献[8]. 采用剪切摩擦模型描述焊具与被焊板材之间的摩擦行为,摩擦力f可表示为

$$ f = m\tau $$ (2) 式中:m为剪切摩擦因子;τ为材料剪切屈服应力.根据文献[8],当温度低于475 ℃时,m = 0.32保持恒定;当温度高于475 ℃时,7B04铝合金沉淀相开始局部熔化,m呈线性下降;当材料温度升至532 ℃时,材料整体开始熔化,此时m降至0.

采用此模型对搅拌头扎入阶段转速ω1 = 1500 r/min、搅拌头回填阶段转速ω2 = 1000 r/min的V-RFSSW进行三维热-流耦合数值仿真,并与试验测温结果进行对比. 图2为距焊点中心6 mm且距离上表面1 mm处焊接热循环模拟与实际测量的热循环曲线对比. 结果表明,二者吻合良好,表明所建立的模型具有较好的预测精度.

2. 试验方法

试验采用2 mm厚7B04-T74铝合金作为母材,其化学成分及力学性能如表1所示. 试验采用航天工程装备(苏州)有限公司生产的FSSW-04C型回填式搅拌摩擦点焊设备. 搅拌头由搅拌针、搅拌套、压紧环三者间隙装配组成, 其中搅拌针、搅拌套、压紧环外径分别为5.2,9.0和18.0 mm. 采用RFSSW与V-RFSSW对比的方式进行试验研究. 首先,固定两种焊接方法的搅拌套扎入深度(2.5 mm)及焊接时间(5 s)相同. 其中,RFSSW搅拌头转速ω1 = ω2 = 1500 r/min. 相应的V-RFSSW搅拌头扎入阶段转速ω1 = 1500 r/min,而搅拌头回填阶段转速降低至ω2 = 1000 r/min. 为了更充分的对比V-RFSSW的效果,采用与V-RFSSW的平均转速相同的RFSSW试验进行对比,即ω = 1/2(ω1 + ω2). 此时选取的RFSSW工艺参数为ω1 = ω2 = 1250 r/min. 具体工艺参数如表2所示.

表 1 7B04-T74铝合金的化学成分和力学性能Table 1. Chemical compositions and mechanical properties of 7B04-T74 aluminum alloy化学成分(质量分数,%) 力学性能 Zn Mg Cu Mn Fe Cr Si Ni Ti Al 抗拉强度Rm/MPa 屈服强度ReL/MPa 断后伸长率A(%) 5.86 2.51 1.62 0.34 0.18 0.15 0.07 0.05 0.03 余量 550 492 10.0 表 2 工艺参数Table 2. Welding parameters序号 方法 扎入阶段转速

ω1 /(r·min−1)回填阶段转速

ω2 /(r·min−1)下扎深度

p /mm焊接时间

tw /s峰值温度

Tmax /℃高温停留时间

th /s1 RFSSW 1250 1250 2.5 5 475 0 2 RFSSW 1500 1500 2.5 5 522 1.6 3 V-RFSSW 1500 1000 2.5 5 493 0.4 3. 结果与讨论

3.1 温度场及热循环

图3为ω1 = 1500 r/min,ω2 = 1000 r/min时V-RFSSW接头不同时刻的温度场分布特征. 温度场围绕搅拌头轴线呈圆形对称分布. 在下扎阶段初期,被搅拌头加热的塑性金属向上流入搅拌套的空腔内,导致高温区域集中在此处,此时搅拌套内塑形金属温度趋于一致. 随着焊接的进行,空腔内材料温度逐渐升高,且由于底部散热条件较差,高温区域集中在空腔底部,在纵向上呈现明显的温度梯度. 随着焊接进入回填阶段,由于转速降低,空腔内温度有所下降.

![]() 图 3 不同时刻V-RFSSW接头上表面及横截面的温度分布Figure 3. Temperature distributions of the top surface and cross-section of the joints at different time for V-RFSSW. (a) t = 1 s (the top surface); (b) t = 2.5 s (the top surface); (c) t = 4 s (the top surface); (d) t=1 s (cross-section); (e) t = 2.5 s (cross-section); (f) t = 4 s (cross-section)

图 3 不同时刻V-RFSSW接头上表面及横截面的温度分布Figure 3. Temperature distributions of the top surface and cross-section of the joints at different time for V-RFSSW. (a) t = 1 s (the top surface); (b) t = 2.5 s (the top surface); (c) t = 4 s (the top surface); (d) t=1 s (cross-section); (e) t = 2.5 s (cross-section); (f) t = 4 s (cross-section)为了揭示V-RFSSW方法焊接热循环特征及降低焊接热输入的效果,采用焊接结束时焊点中轴线上距离上表面1 mm的特征点,其热循环来代表RFSSW及V-RFSSW搅拌区热循环,结果如图4所示. 对于RFSSW,当ω1 = ω2 = 1500 r/min时,搅拌区焊接热循环曲线呈现为先升高后下降的趋势,峰值温度出现在下扎阶段t = 3 s时,达到522 ℃. 对于7B04铝合金,当温度超过475 ℃时材料开始发生组分液化[9],因此,研究中把温度超过此温度的时间定义为高温停留时间(th),此时th = 1.6 s. 对于V-RFSSW,在扎入阶段搅拌区升温速率几乎相同. 由于回填阶段转速ω2由1500 r/min降为1000 r/min,导致热循环曲线发生陡降,峰值温度在焊接扎入阶段结束时刻,即t = 2.5 s时出现,峰值温度493 ℃,相应的高温停留时间th = 1.6 s. 可见,V-RFSSW通过降低回填阶段的搅拌头转速可明显抑制焊接热输入,降低搅拌区峰值温度及高温停留时间. 虽然对于以上两种方法在扎入阶段完全相同,但是由于回填阶段转速不同,必然对搅拌区材料流动造成了影响. 而研究中针对两种方法选取的搅拌区热循环特征点是焊点成形以后的相同位置点,由于之前经历的材料流动行为的差异导致了扎入阶段热循环曲线有所差异.

将V-RFSSW与平均转速相同的RFSSW相对比,此时RFSSW工艺参数为ω1 = ω2 = 1250 r/min. 结果表明,此参数下焊接扎入阶段升温速率明显下降,搅拌区峰值温度Tmax = 475 ℃,高温停留时间th = 0. 可见,V-RFSSW对比于平均转速相同的RFSSW,并未降低焊接热输入.

3.2 焊点成形及接头微观组织特征

图5为不同焊接方法下焊点横截面宏观形貌. 对于RFSSW,当ω1 = ω2 = 1500 r/min时,可以获得良好的焊点成形(图5a). 将搅拌套直接作用区定义为搅拌区,此区域为焊点的主要承载区域. 紧邻搅拌区材料受到搅拌区内剧烈流动塑性材料的剪切作用,也发生了一定程度的塑性变形,可定义为热力影响区. 与热力影响区相邻,只受到焊接热作用的区域定义为热影响区. 对于V-RFSSW,降低回填阶段转速ω2至1000 r/min,仍可获得较好的焊点成形(图5b). 然而,与V-RFSSW平均转速相同RFSSW,即ω1 = ω2 = 1250 rpm时,在焊点上表面出现明显的环沟槽缺陷(图5c),这将显著降低焊点上板的承载厚度,导致承载能力的下降. 这是由于当扎入阶段转速较低时,焊接产热不足以使被焊材料发生充分的塑化,无法全部进入搅拌套的空腔内,在回填阶段塑性材料不足以填满整个焊点,导致缺陷的生成. V-RFSSW方法既可以通过较高的扎入阶段转速保证焊点成形,又可以通过降低回填阶段转速抑制焊接热输入,降低峰值温度及高温停留时间.

图6为RFSSW和V-RFSSW搅拌区微观组织形貌. 如图6a和图6b所示,两种焊接方法下搅拌区内均呈现细小的等轴晶,这是由于铝合金在高温及大塑性变形下发生了动态再结晶[10]. 在RFSSW搅拌区内发现了大量的黑色条带状组织,如图6a箭头所示. 通过扫描电子显微镜(scanning electron microscope,SEM)对该组织进行放大观察(图6c),可以判断其为聚集在晶界附近的共晶组织. 经能谱仪(energy dispersive spectrometer,EDS)分析,发现相对母材晶界共晶组织内Zn,Cu等合金元素发生了富集,如图6d所示. 这说明RFSSW过程中7B04铝合金沉淀相在晶界处发生了组分液化并形成局部液相,在随后的冷却过程中液相来不及向基体内扩散,并在晶界处发生了liquid→α-Al + S(Al2CuMg) + η(MgZn2)等三元共晶反应[11]. 而V-RFSSW搅拌区内并未发现明显的黑色条带组织,说明采用该方法成功抑制了组分液化的发生. 值得注意的是,虽然V-RFSSW搅拌区峰值温度超过了组分液化的起始温度(475 ℃),但由于高温停留时间较短,不足以生成足够的液相来形成共晶组织.

![]() 图 6 RFSSW和V-RFSSW接头搅拌区微观组织Figure 6. Microstructures in stir zones of RFSSW and V-RFSSW joints. (a) ω1 = ω2 = 1500 r/min; (b) ω1 = 1500 r/min, ω2 = 1000 r/min; (c) SEM magnification of black strip microstructure in Fig. 6a; (d) EDS results of eutectic phase

图 6 RFSSW和V-RFSSW接头搅拌区微观组织Figure 6. Microstructures in stir zones of RFSSW and V-RFSSW joints. (a) ω1 = ω2 = 1500 r/min; (b) ω1 = 1500 r/min, ω2 = 1000 r/min; (c) SEM magnification of black strip microstructure in Fig. 6a; (d) EDS results of eutectic phase3.3 接头的力学性能

对不同焊接方法接头横截面显微硬度分布进行了测试,结果如图7所示. 不同焊接方法下,接头的显微硬度分布曲线均呈“W”形. 对于RFSSW,当ω1=ω2=1500 r/min时,搅拌区范围较大,但平均硬度较低. V-RFSSW通过降低回填阶段搅拌头转速可抑制焊接热输入,此时搅拌区范围有所收窄,平均显微硬度有所增加. 对于平均转速相同的RFSSW,由数值仿真结果可知,此时焊接热输入最低,相应的搅拌区范围最窄,平均硬度值最高.

不同接头拉剪失效载荷及断裂接头横截面如图8所示. 不同方法所获得的接头均以“纽扣”形式发生断裂,裂纹的萌生和扩展均发生在搅拌区,这说明搅拌区为接头承载的主要区域. 当ω1 = ω2 = 1500 r/min时,RFSSW接头平均拉剪失效载荷为8162 N. 而V-RFSSW接头(ω1 = 1500 r/min,ω2 = 1000 r/min)拉剪失效载荷显著提高,达到8835 N. 这主要由于V-RFSSW通过降低了焊接热输入,提高了搅拌区材料强度的同时,抑制了该区域的组分液化,避免了脆硬的共晶组织生成,对裂纹的萌生及扩展起到了较好的抑制作用. 虽然在ω1 = ω2 = 1250 r/min下RFSSW接头搅拌区的显微硬度较高,同时也无共晶组织生成,但焊点表面出现了环沟槽缺陷,导致接头的力学性能较低.

4. 结论

(1) 针对2 mm厚的7B04-T74铝合金,采用可变转速回填式搅拌摩擦点焊进行数值模拟分析及试验研究发现,V-RFSSW温度场围绕搅拌头轴线呈圆形对称分布. 焊点高温区域集中在搅拌套空腔内部. 与扎入阶段转速相同的常规RFSSW相比,V-RFSSW新方法通过降低回填阶段搅拌头转速可显著降低焊接峰值温度及高温停留时间.

(2) V-RFSSW新方法既可在扎入阶段使材料充分塑化以保证焊点成形,又可以通过降低焊接热输入抑制组分液化的发生,避免共晶相的生成.

(3) V-RFSSW与常规RFSSW接头显微硬度均呈“W”形分布,且扎入阶段转速相同的情况下V-RFSSW接头搅拌区的平均硬度值较高. 在拉剪载荷下均以“纽扣”形式发生断裂,其中V-RFSSW接头拉剪失效载荷为8835 N,高于RFSSW接头的8162 N.

-

表 1 Inconel 718粉末与Q690高强钢板的化学成分(质量分数,%)

Table 1 Chemical compositions of Inconel 718 powder and Q690 high-strength steel plate

材料 Ni Cr Si C S P Fe Inconel 718 50 17 0.35 0.08 0.01 0.01 余量 Q690 1.50 1.20 0.60 0.18 0.30 0.25 余量 表 2 BBD试验设计变量与其响应值

Table 2 BBD experimental design input variables and their response values

试验序号 输入变量 响应值 综合目标Q 激光功率A/W 扫描速度B/(mm·s−1) 送粉速率C/(r·min−1) 热影响区深度f1/μm 稀释率f2(%) 显微硬度f3/HV0.5 S1 1 800 30 2.0 314 17.9 237.9 125.199 S2 1 800 16 2.0 377 26.1 184.5 113.146 S3 1 800 23 2.5 374 26.0 231.5 113.261 S4 1 800 23 1.5 429 17.6 221.8 114.128 S5 2 250 16 2.5 377 22.2 210.5 106.155 S6 2 250 30 1.5 360 17.6 192.7 97.1126 S7 2 250 30 2.5 344 20.3 204.6 98.3154 S8 2 250 16 1.5 363 26.5 243.5 99.781 S9 2 250 23 2.0 364 14.9 246.7 111.008 S10 2 250 23 1.5 331 25.0 202.4 101.418 S11 2 250 16 2.0 299 15.0 250.3 112.623 S12 2 250 23 2.5 325 19.2 239.6 103.217 S13 2 700 30 2.0 426 26.0 249.2 108.544 S14 2 700 16 2.0 360 18.7 222.6 99.2062 S15 2 700 23 2.5 317 19.8 216.6 117.613 S16 2 700 23 1.5 393 26.1 224.6 106.232 表 3 矩阵R的参数

Table 3 Parameters of matrix R

成分 特征值λ 方差百分比δ(%) 累计贡献率br(%) 1 1.581 52.699 52.699 2 0.849 28.288 80.987 3 0.57 19.013 100 表 4 综合目标Q的残差分析

Table 4 Residual analysis of composite objective Q

F值 P值 失拟项Lf 相关平方系数R2 9.81 0.0058 9.89 0.9364 -

[1] 李聪波, 冯亚, 杜彦斌, 等. 基于改进模糊神经网络的废旧零部件再制造工艺方案决策方法[J]. 计算机集成制造系统, 2016, 22(3): 728 − 737. doi: 10.13196/j.cims.2016.03.016 Li Congbo, Feng Ya, Du Yanbin, et al. Decision-making method for used components remanufacturing process plan based on modified FNN[J]. Computer Integrated Manufacturing Systems, 2016, 22(3): 728 − 737. doi: 10.13196/j.cims.2016.03.016

[2] 徐国建, 李春光, 郭云强, 等. 激光熔覆Stellite-6 + VC混合粉末的熔覆层组织[J]. 焊接学报, 2017, 38(6): 73 − 78. Xu Guojian, Li Chunguang, Guo Yunqiang, et al. Organization of clad layer using mixed powder of Stellite-6 and VC[J]. Transactions of the China Welding Inesitution, 2017, 38(6): 73 − 78.

[3] Lee C, Park H, Yoo J, et al. Residual stress and crack initiation in laser clad composite layer with Co-based alloy and WC + NiCr[J]. Applied Surface Science, 2016, 345: 286 − 294.

[4] 鄢然, 李浩, 李军超, 等. 基于响应面法的聚苯乙烯粉末选择性激光烧结成型工艺参数优化[J]. 中国激光, 2019, 46(3): 5 − 13. Yan Ran, Li Hao, Liu Junchao, et al. Process parameters optimization of polystyrene powder selective laser sintering based on response surface methodology[J]. Chinese Journal of Lasers, 2019, 46(3): 5 − 13.

[5] Zhang Chengyan, Wang, Lixin, Zu, Xiaoli, et al. Multi-objective optimization of experimental and analytical residual stresses in pre-stressed cutting of thin-walled ring using glowworm swarm optimization algorithm[J]. The International Journal of Advanced Manufacturing Technology, 2020, 107: 376 − 382.

[6] Janicki D. Laser cladding of Inconel 625-based composite coatings reinforced by porous chromium carbide particles[J]. Optics & Laser Technology, 2017, 94: 6 − 14.

[7] 鲁耀钟, 雷卫宁, 任维彬, 等. 激光熔覆 Inconel 718 合金裂纹分析及裂纹控制研究[J]. 表面技术, 2020, 49(9): 233 − 243. Lu Yaozhong, Lei Weining, Ren Weibin, et al. Crack analysis and control of laser cladding Inconel 718 alloy[J]. Surface Technology, 2020, 49(9): 233 − 243.

[8] Chen W J, Chen H, Li C C, et al. Microstructure and fatigue crack growth of EA4T steel in laser cladding remanufacturing[J]. Engineering Failure Analysis, 2017, 79: 120 − 129. doi: 10.1016/j.engfailanal.2017.03.005

[9] 李响, 来佑彬, 杨波, 等. 等离子熔覆 Fe-Cr-C 合金涂层工艺优化及性能研究[J]. 表面技术, 2020, 49(6): 177 − 184. Li Xiang, Lai Youbin, Yang Bo, et al. Process optimization and properties of Fe-Cr-C alloy coating prepared by plasma cladding[J]. Surface Technology, 2020, 49(6): 177 − 184.

[10] 舒林森, 林冉. 基于均匀设计的铁基合金粉末激光熔覆工艺参数优化[J]. 材料热处理学报, 2021, 42(4): 167 − 174. doi: 10.13289/j.issn.1009-6264.2020-0425 Shu Linsen, Lin Ran. Optimization of laser cladding process parameters of iron-based alloy powder based on uniform design[J]. Transactions of Materials and Heat Treatment, 2021, 42(4): 167 − 174. doi: 10.13289/j.issn.1009-6264.2020-0425

[11] Lu C, Shi J. Relative density and surface roughness prediction for Inconel 718 by selective laser melting: central composite design and multi-objective optimization[J]. The International Journal of Advanced Manufacturing Technology, 2022, 39(4): 41 − 49.

[12] Mohd Danish, Munish Kumar Gupta, Saeed Rubaiee, et al. Influence of graphene reinforced sunflower oil on thermo-physical, tribological and machining characteristics of Inconel 718[J]. Journal of Materials Research and Technology, 2021, 15(36): 362 − 368.

[13] Chen T, Wu W, Li W, et al. Laser cladding of nanoparticle TiC ceramic powder: Effects of process parameters on the quality characteristics of the coatings and its prediction model[J]. Optics & Laser Technology, 2019, 116: 345 − 355.

[14] 赵凯, 梁旭东, 王炜, 等. 基于NSGA-Ⅱ算法的同轴送粉激光熔覆工艺多目标优化[J]. 中国激光, 2020, 47(1): 96 − 105. Zhao Kai, Liang Xudong, Wang Wei, et al. Multi-objective optimization of coaxial powder feeding laser cladding based on NSGA-II[J]. Chinese Journal of Lasers, 2020, 47(1): 96 − 105.

[15] 赵尧, 虞钢, 何秀丽, 等. 基于主成分分析法与逼近理想解法的38MnVS6 激光熔覆工艺研究[J]. 兵工学报, 2019, 40(12): 1000 − 1093. Zhao Yao, Yu Gang, He Xiuli, et al. Research on laser cladding processing for 38MnVS6 by PCA-TOPSIS method[J]. Acta Armamentarii, 2019, 40(12): 1000 − 1093.

[16] Liu Jiaqi, Yu Huijun, Chen Chuanzhong, et al. Research progress of laser cladding self-fluxing alloy coatings on titanium alloys[J]. China Welding, 2018, 27(2): 45 − 51.

-

期刊类型引用(2)

1. 赵衍华,张粟泓,王非凡,郝云飞,宋建岭,孙世烜,王国庆. 搅拌摩擦焊接与加工技术进展. 航天制造技术. 2025(01): 1-25 .  百度学术

百度学术

2. 刘柏韬,顾彬,余海东. 关于铝合金薄板高速搅拌摩擦焊接搅拌头的新型设计. 机械设计与研究. 2023(05): 152-157 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: