Effect of welding process on the microstructure and mechanical properties of Fe-Cr-Ni-Mo deposited metals

-

摘要: 分别采用钨极氩弧焊(TIG焊)和熔化极活性气体保护焊(MAG焊)方法制备了785 MPa级Fe-Cr-Ni-Mo系熔敷金属.利用扫描电子显微镜、透射电子显微镜和电子背散射衍射仪对熔敷金属的组织类型和晶体学特征进行了详细的表征分析,结果表明,采用不同焊接方法制备得到的熔敷金属组织均为贝氏体,但钨极氩弧焊熔敷金属(DM-TIG)中出现大量聚合贝氏体;由于焊接过程中使用的保护气体不同,熔化极活性气体保护焊熔敷金属(DM-MAG)中存在大量夹杂物. 经过电子背散射衍射分析结果表明,相比于DM-TIG,DM-MAG中由于存在大量自催化形核现象,晶体学取向非常复杂.力学性能测试结果表明,DM-MAG中大尺寸夹杂物在冲击过程中作为裂纹源,从而导致DM-MAG的韧性明显低于DM-TIG,实际工程应用中对于低温韧性要求较高的结构部件应合理选择焊接方法.Abstract: In this research, 785 MPa grade Fe-Cr-Ni-Mo deposited metals were prepared by tungsten inert gas (TIG) welding and metal active gas arc (MAG) welding processes, respectively. Scanning electron microscopy, transmission electron microscopy and electron backscatter diffraction were adopted to characterize the microstructure and crystallographic characteristics of the deposited metals. The results showed that the microstructure prepared by different welding processes composed of lath bainite. However, a large amount of coalesced bainite appeared in the microstructure of the TIG deposited metal (DM-TIG). In addition, there were a large number of inclusions in the MAG deposited metal (DM-MAG) due to the active shielding gas. After electron backscatter diffraction analysis, results indicated that the crystallographic orientation of DM-MAG was complex compared to DM-TIG due to the large number of autocatalytic nucleation. The results of the mechanical properties of different deposited metals indicted that the toughness of DM-TIG was significantly better than that of DM-MAG. This was due to the large-sized inclusions in DM-MAG, which became the source of cracks during the fracture process. In practical engineering application, welding method should be selected reasonably for components with high requirement of low temperature toughness.

-

Keywords:

- coalesced bainite /

- autocatalytic nucleation /

- inclusion /

- mechanical properties

-

0. 序言

近年来,随着陆地和近海区域油气资源的逐渐匮乏,油气资源的开采逐渐向深海和极地区域扩展.海洋中油气资源的勘探与开发高度依赖海洋平台,所以海洋平台的发展对于油气资源的开发具有至关重要的作用[1]. 目前,国内海洋平台的发展与国际仍然存在客观的差距,主要是海洋平台相关材料以及加工技术的差距.海洋平台的作业环境非常恶劣,要求其材料具有较高的强韧性匹配、焊接性、耐腐蚀性和抗疲劳性能[2-3]. 为了装置的安全服役,特别对材料的低温韧性提出了更高的要求. 为了轻量化需求,目前海洋平台用钢已经达到了785 MPa级别. 通过控轧控冷技术,板材可以达到非常优异的强韧性匹配,但是海洋平台作为大型的钢结构,焊接是建造过程中必不可少的加工手段. 但是,高强海工钢配套焊接材料的研制明显滞后于板材,熔敷金属作为一种典型的铸态组织,其强度的提高往往伴随着韧性的恶化,难以实现高强韧性匹配[4]. 当前高强海工钢焊接时往往采用低强匹配,严重限制了新型高强度板材的应用. 如何有效改善熔敷金属的综合力学性能是急需解决的问题. 熔敷金属的力学性能主要取决于焊接材料和焊接方法. 屈服强度达到785 MPa及以上的焊接材料往往采用Fe-Cr-Ni-Mo体系,Mao和Keehan等人[5-6]均研制了该体系焊接材料,熔敷金属强度可以达到785 MPa级别,但是韧性往往较差. 常用的焊接方法是TIG焊和MAG焊. TIG焊能够实现高品质焊接得到性能优良的焊缝且焊接过程稳定,但是焊接效率差且成本高;而MAG焊可以实现高效率焊接且成本低,但焊接过程不稳定,焊缝质量较差,由于MAG焊采用活性气体保护,熔敷金属中会生成大量的夹杂物. Barrick等人[2]系统研究了TIG焊和MAG焊对10Ni钢熔敷金属组织和力学性能的影响,研究发现,由于焊接过程保护气体和热输入不同,通过TIG焊制备得到的熔敷金属中几乎没有夹杂物存在且马氏体组织中有效晶粒尺寸小,从而使通过TIG焊制备得到的熔敷金属韧性明显高于通过MAG焊制备得到的熔敷金属. 为了评价焊接材料的焊接工艺性,保证焊接材料的工程化应用,急需开展焊接方法对熔敷金属组织演变和力学性能的影响研究.

以自行研制的785 MPa级Fe-Cr-Ni-Mo系焊接材料为填充材料,分别采用TIG焊和MAG焊进行熔敷金属的制备,研究不同焊接方法对熔敷金属组织演变和力学性能的影响.

1. 试验方法

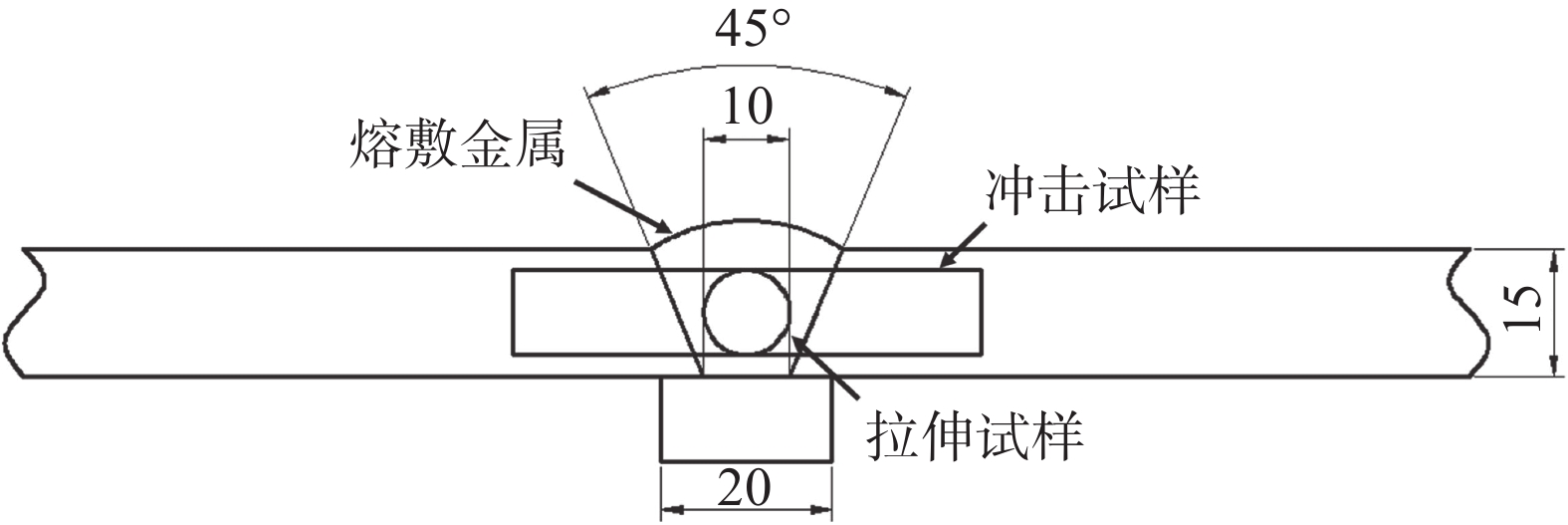

首先使用自动TIG和MAG焊机分别进行熔敷金属制备,母材为A517GrQ海工钢板,采用V形坡口,接头示意图如图1所示,焊接工艺参数如表1所示,填充材料为自行研制直径为1.2 mm的实心焊丝,母材、焊丝以及熔敷金属化学成分如表2所示.

表 1 焊接工艺参数Table 1. Welding parameters焊接方法 保护气体 气体流量Q/(L·min−1) 焊接电流I/A 电弧电压U/V 热输入E/(kJ·mm−1) 层间温度T/℃ TIG焊 100% Ar 15 180 14 0.15 60 ~ 70 MAG焊 95% Ar + 5% CO2 20 240 29 1.39 80 ~ 110 表 2 母材、焊丝及熔敷金属的化学成分(质量分数,%)Table 2. Chemical compositions of base metal, welding wires and deposited metals材料 C Si Mn Cr + Ni + Mo V Fe A517GrQ 0.15 0.21 1.04 3.34 <0.01 余量 焊丝 0.036 0.38 1.08 6.41 <0.1 余量 DM-TIG 0.025 0.38 1.05 6.02 <0.1 余量 DM-MAG 0.061 0.32 0.93 6.74 <0.1 余量 根据标准GB/T 8110—2008《气体保护电弧焊用碳钢、低合金钢焊丝》制备拉伸和冲击试样,对熔敷金属的力学性能进行测试,取样位置如图1所示. 分别在Z150型电子拉伸试验机(拉伸速率:屈服前0.5 mm/min,屈服后3.5 mm/min)和SANS-ZBC2452-C型冲击试验机进行室温拉伸试验和低温(−60 ℃)冲击试验.

为研究焊接方法对熔敷金属组织的影响,对熔敷金属横截面柱状晶区组织进行表征,试样经研磨、抛光及用体积分数为4%的硝酸酒精溶液浸蚀后,采用FEI Inspect F50型扫描电子显微镜和FEI Talos F200X型透射电子显微镜观察熔敷金属的组织形貌. 采用装配有电子背散射衍射(electron backscatter diffraction, EBSD)探头的FEI Explorer 4 Analyzer型扫描电子显微镜对熔敷金属的晶体学特征进行表征,用于EBSD测试的样品采用离子刻蚀方法去除表面应力层. 采用FEI Explorer 4 Analyzer型扫描电子显微镜对不同熔敷金属中的夹杂物进行表征.

2. 试验结果与讨论

2.1 焊接方法对熔敷金属组织演变的影响

图2和图3为采用不同焊接方法得到的熔敷金属微观组织. 通过不同方法得到的熔敷金属均为贝氏体组织,但是贝氏体类型具有明显区别,DM-TIG中存在大量聚合贝氏体,而DM-MAG中未发现聚合贝氏体存在.聚合贝氏体是一种常见于高强钢熔敷金属中的粗大组织[7],在贝氏体转变过程中由贝氏体铁素体板条发生聚合而形成,熔敷金属中粗大的柱状晶为贝氏体铁素体板条的聚合提供了空间. 采用TIG焊时,因热输入小,熔敷金属冷却速度快,导致贝氏体转变驱动力比较大,促进贝氏体铁素体板条聚合;采用MAG焊时,因热输入较大,熔敷金属冷却速度慢,贝氏体转变驱动力较小;此外,DM-MAG中存在大量的自催化形核也抑制了聚合贝氏体的生成[8].

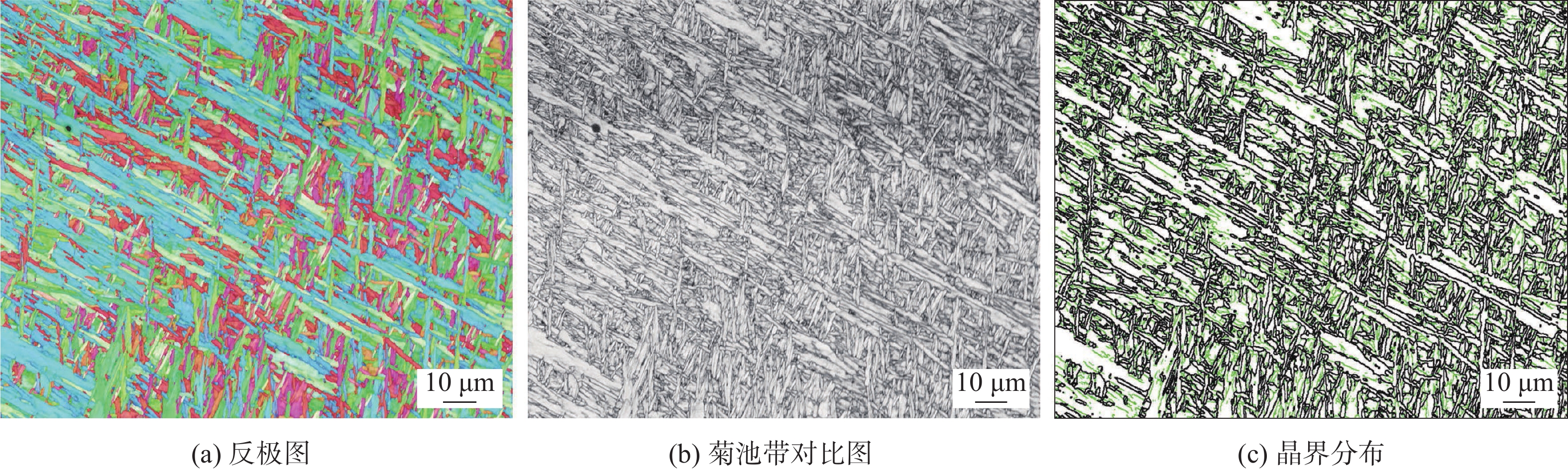

为进一步分析熔敷金属的组织差异,采用EBSD对不同熔敷金属的晶体学特征进行表征,图4和图5分别为DM-TIG和DM-MAG晶体学特征. 从图4a和图5a可知,DM-TIG的晶体学取向相对一致,而DM-MAG的晶体学取向则非常复杂. 通过图4b和图5b菊池带对比图分析发现,DM-TIG中存在大量由于贝氏体铁素体板条聚合产生的块状聚合贝氏体,而DM-MAG中并没有明显的聚合贝氏体存在. 文中定义取向差大于15°为大角度晶界,取向差高于2°低于15°为小角度晶界. 在图4c和图5c中黑色线条表示大角度晶界,绿色线条表示小角度晶界,由于在DM-TIG中贝氏体铁素体板条取向比较一致,所以大角度晶界比较少,而DM-MAG中存在大量的大角度晶界.目前广泛认为大角度晶界对裂纹的扩展具有有效的阻碍作用[9-10]. 从晶体学角度进行分析,DM-MAG理论上具有更加优异的韧性.

2.2 焊接方法对熔敷金属中夹杂物的影响

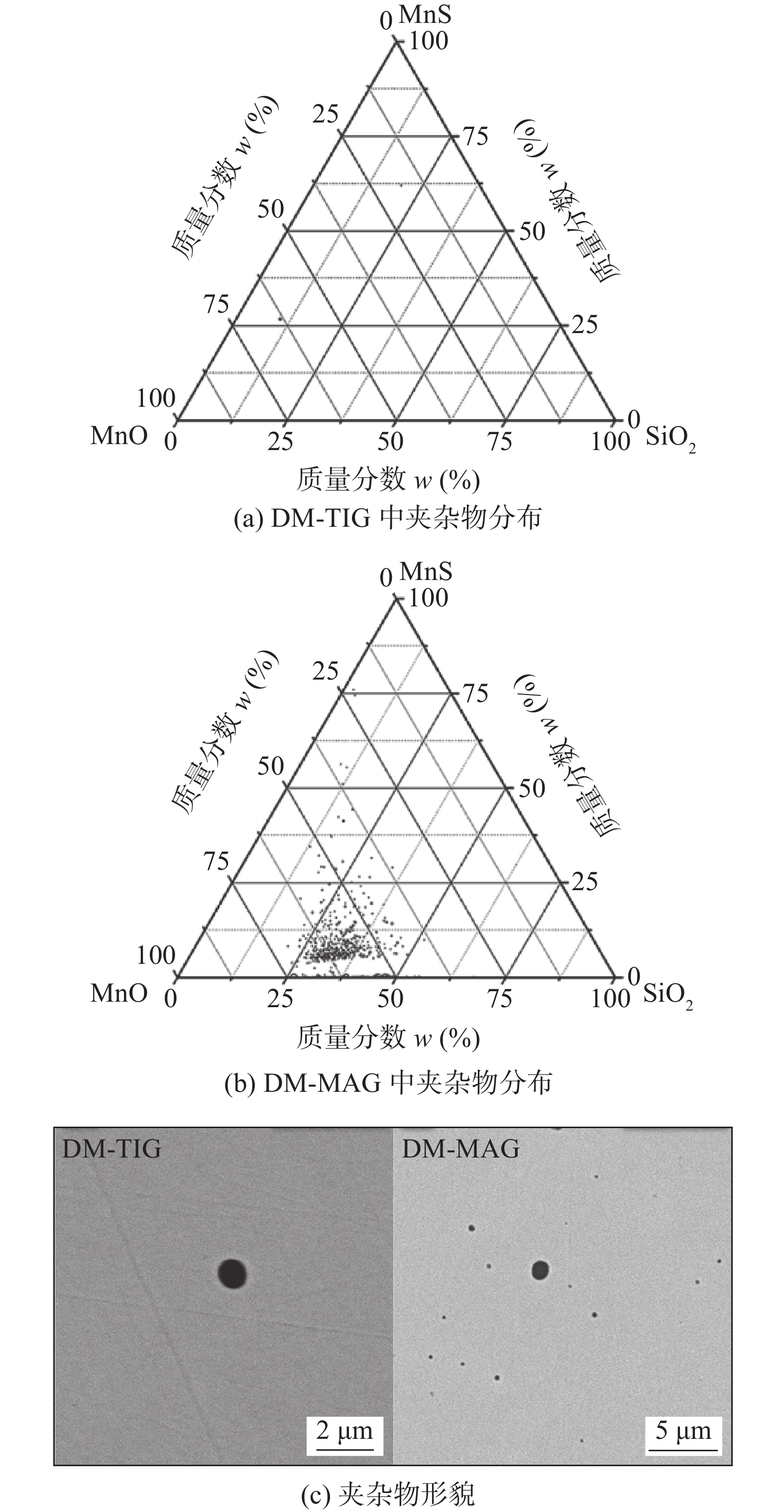

由于不同焊接方法采用的保护气体不同,导致熔敷金属中的夹杂物存在差异. 图6为熔敷金属中夹杂物分析. 从图6可知,DM-TIG中夹杂物非常少,且呈圆球状,而DM-MAG中夹杂物非常多,也呈圆球状,主要为Si和Mn的复合氧化物.

不同焊接方法得到的夹杂物差别非常明显. 如表3可知,相同面积下DM-TIG中夹杂物数量只有9个,而DM-MAG中夹杂物数量为1 393个,DM-MAG中的夹杂物密度远高于DM-TIG,夹杂物平均尺寸均超过1 μm,且DM-MAG中最大夹杂物尺寸达到了6.67 μm,远大于DM-TIG中最大夹杂物尺寸(2.58 μm). 这主要是由于采用MAG焊时,焊接过程中保护气体中存在5%的CO2分解产生的氧离子与熔敷金属中的Si和Mn结合,生成大量氧化物.

表 3 夹杂物分析Table 3. Analysis of inclusion熔敷金属 扫描面积S/mm2 夹杂物数量n/个 平均直径d/μm 最大直径dmax /μm 面积分数wf (%) DM-TIG 26.68 9 1.36 2.58 0.003 DM-MAG 25.76 1 393 1.25 6.67 0.6 2.3 焊接方法对熔敷金属力学性能的影响

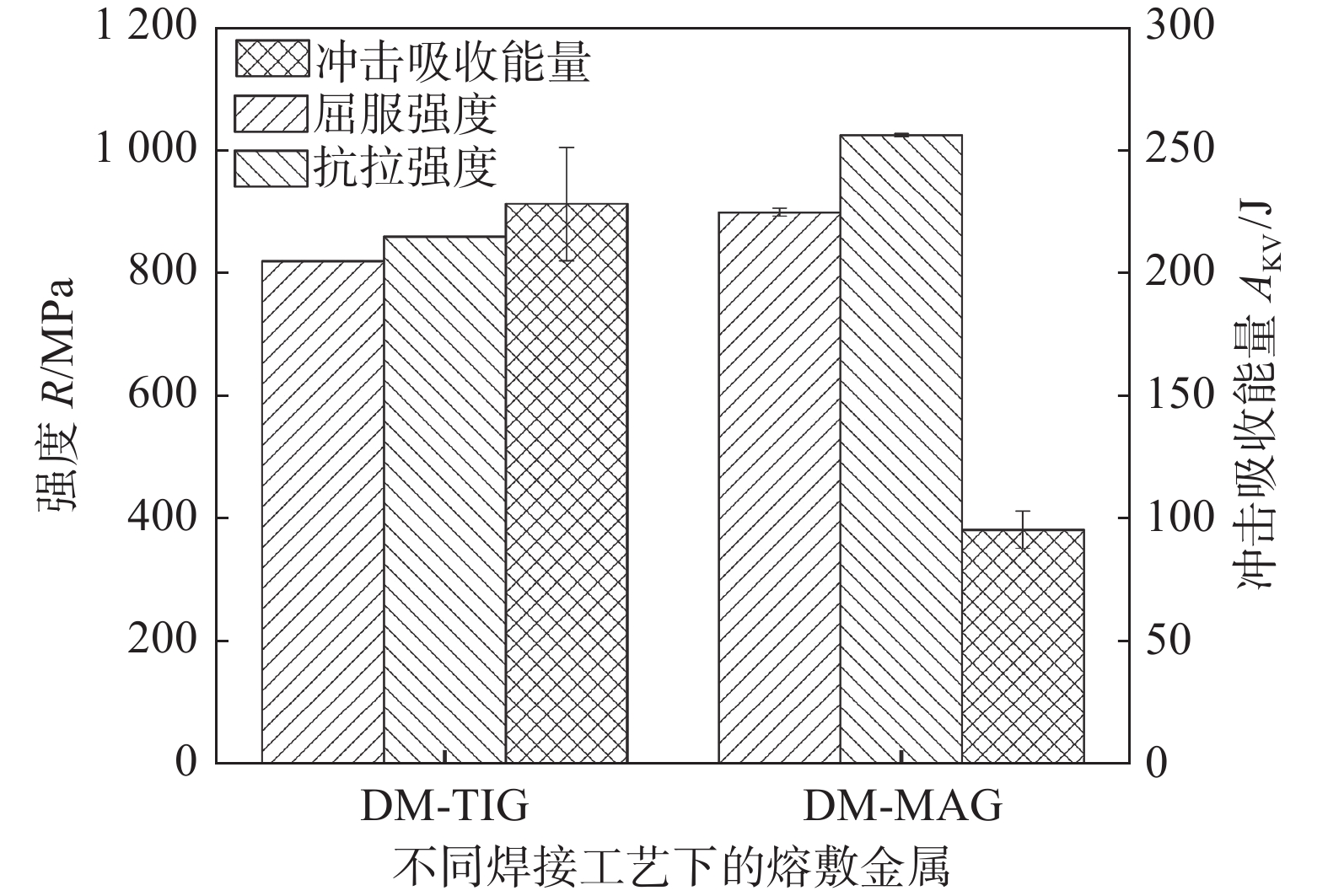

图7为不同焊接方法熔敷金属的力学性能. 由于不同焊接过程元素烧损存在差异,导致DM-TIG中碳含量低于DM-MAG,固溶强化作用比较弱,因此DM-TIG的强度低于DM-MAG,但DM-TIG的韧性明显优于DM-MAG. 不同焊接方法熔敷金属屈服强度均超过785 MPa,且−60 ℃条件下的冲击吸收能量均超过80 J,说明该熔敷金属性能优异,可以满足海洋工程结构件对强度和韧性的要求.

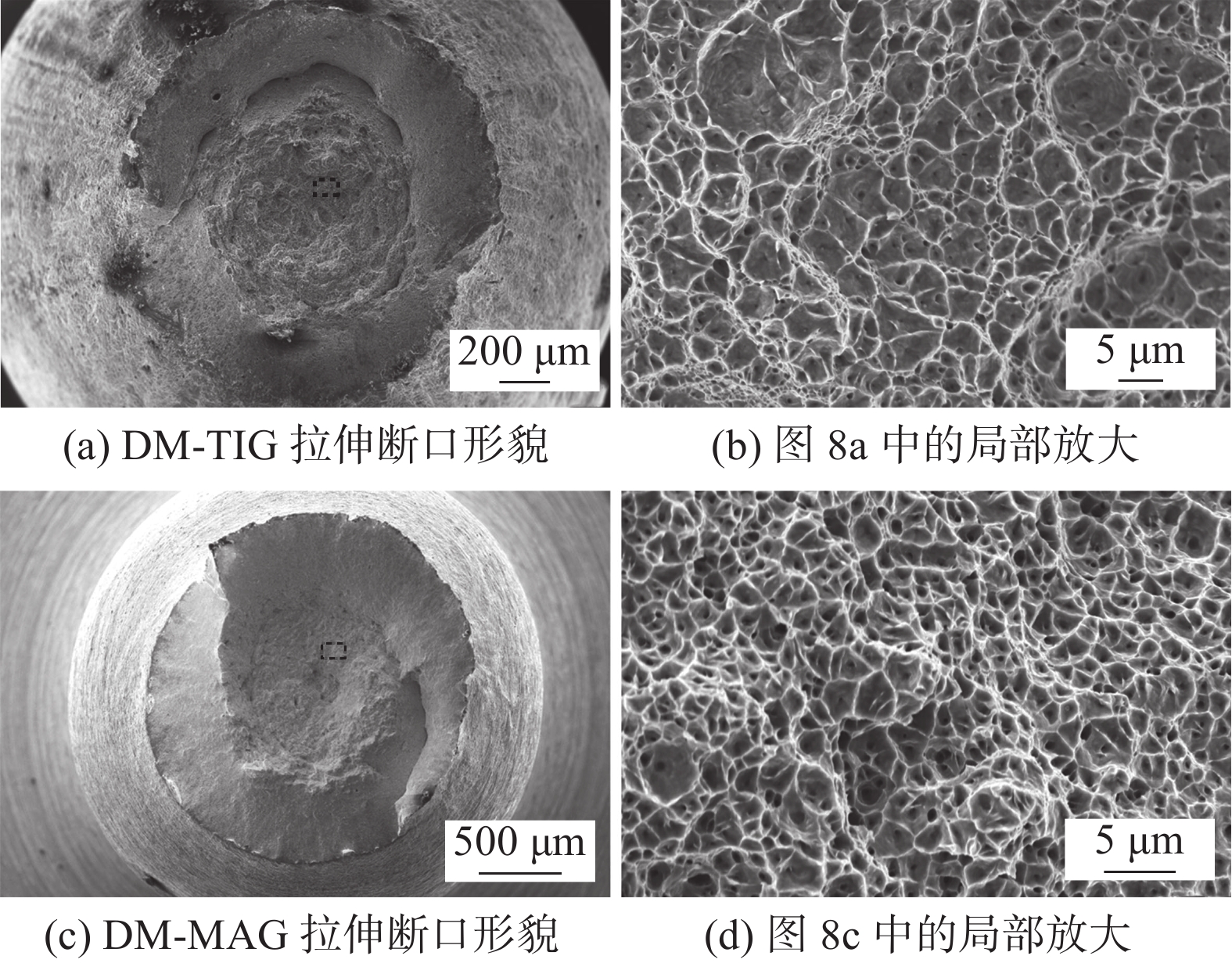

图8和图9分别为不同熔敷金属室温拉伸断口和−60 ℃条件下的冲击断口形貌. 从图8a和图8c可知,不同熔敷金属室温拉伸断口均为典型的杯锥状断口,且拉伸断口的变形程度均比较大,说明其塑性均很好. 从图8b和图8d可知,断口均由韧窝组成,断裂模式均为微孔聚集性断裂. 从图9a和图9c可知,DM-TIG比DM-MAG的冲击断口变形程度大. 从图9b和图9d可知,DM-TIG断口均由韧窝组成,而DM-MAG断口表面的夹杂物附近存在明显的解理断裂特征.

不同焊接方法熔敷金属组织均由板条贝氏体组成,且在DM-TIG中出现大量聚合贝氏体,聚合贝氏体会降低裂纹扩展功,从而降低韧性. 此外,EBSD分析表明,DM-MAG中大角度晶界的比例明显高于DM-TIG,大角度晶界比例增加会显著提高组织对裂纹扩展的阻力,进而提高其韧性. 力学性能测试结果表明,DM-TIG的韧性明显优于DM-MAG,与以上组织分析结果相矛盾,这是由于DM-MAG中存在大量夹杂物且尺寸较大,拉伸过程中变形速率比较缓慢,因此强度并没有明显受到夹杂物的影响;但在冲击过程中变形速率非常快,在夹杂物处形成应力集中,促进裂纹的产成,进而以韧窝或解理形式开裂,导致韧性明显降低. 以上分析表明,熔敷金属中夹杂物对冲击性能的影响远大于熔敷金属中聚合贝氏体以及大角度晶界比例的影响,因此实际工程应用中对于低温韧性要求较高的部件应合理选择焊接方法.

3. 结论

(1) 不同焊接方法制备的熔敷金属组织均为板条贝氏体,但DM-TIG中生成大量聚合贝氏体,而DM-MAG由于冷却速度慢,贝氏体转变温度高,驱动力降低从而抑制了聚合贝氏体的生成.

(2) EBSD晶体学分析表明,相比于DM-TIG,由于DM-MAG中存在大量的自催化形核,其晶体学取向非常复杂,导致DM-MAG中大角度晶界比例明显高于DM-TIG. DM-TIG中夹杂物非常少,可以忽略,而DM-MAG中夹杂物非常多,呈圆球状,主要为大尺寸的Si和Mn复合氧化物.

(3) 只有在相同组织类型和纯净度的条件下,才能使用大角度晶界比例评价材料韧性,焊接工艺对接头韧性影响明显,实际工程应用中对于低温韧性要求较高的部件应合理选择焊接方法.

-

表 1 焊接工艺参数

Table 1 Welding parameters

焊接方法 保护气体 气体流量Q/(L·min−1) 焊接电流I/A 电弧电压U/V 热输入E/(kJ·mm−1) 层间温度T/℃ TIG焊 100% Ar 15 180 14 0.15 60 ~ 70 MAG焊 95% Ar + 5% CO2 20 240 29 1.39 80 ~ 110 表 2 母材、焊丝及熔敷金属的化学成分(质量分数,%)

Table 2 Chemical compositions of base metal, welding wires and deposited metals

材料 C Si Mn Cr + Ni + Mo V Fe A517GrQ 0.15 0.21 1.04 3.34 <0.01 余量 焊丝 0.036 0.38 1.08 6.41 <0.1 余量 DM-TIG 0.025 0.38 1.05 6.02 <0.1 余量 DM-MAG 0.061 0.32 0.93 6.74 <0.1 余量 表 3 夹杂物分析

Table 3 Analysis of inclusion

熔敷金属 扫描面积S/mm2 夹杂物数量n/个 平均直径d/μm 最大直径dmax /μm 面积分数wf (%) DM-TIG 26.68 9 1.36 2.58 0.003 DM-MAG 25.76 1 393 1.25 6.67 0.6 -

[1] 魏世同, 孙健, 刘景武, 等. V含量及回火工艺对高强钢TIG焊熔敷金属组织性能的影响[J]. 焊接学报, 2020, 41(11): 1 − 6. doi: 10.12073/j.hjxb.20200116001 Wei Shitong, Sun Jian, Liu Jingwu, et al. Effect of V content and tempering treatment on microstructure and mechanical properties of the high strength steel TIG weld metal[J]. Transactions of the China Welding Institution, 2020, 41(11): 1 − 6. doi: 10.12073/j.hjxb.20200116001

[2] Barrick E J, DuPont J N. Microstructural characterization and toughness evaluation of 10 wt% Ni steel weld metal gas tungsten arc and gas metal arc weld fusion zones[J]. Materials Science & Engineering: A, 2020, 796: 140043.

[3] 李少峰, 马成勇, 宋志刚, 等. 800 MPa级高强钢焊接接头组织及力学性能[J]. 焊接学报, 2020, 41(5): 91 − 96. Li Shaofeng, Ma Chengyong, Song Zhigang, et al. Study on the welding joint microstructure and mechanical properties of 800 MPa grade high stress steel[J]. Transactions of the China Welding Institution, 2020, 41(5): 91 − 96.

[4] 巴凌志, 王东坡, 张智, 等. 热输入对海工用钢不同合金系焊缝金属韧性的影响[J]. 焊接学报, 2020, 41(6): 42 − 47. Ba Lingzhi, Wang Dongpo, Zhang Zhi, et al. Effect of welding heat input on toughness of different alloys weld metal in ocean engineering steel[J]. Transactions of the China Welding Institution, 2020, 41(6): 42 − 47.

[5] Mao G J, Cao R, Cayron C, et al. Microstructural evolution and mechanical property development with nickel addition in low-carbon weld butt joints[J]. Journal of Materials Processing Technology, 2018, 262: 638 − 649. doi: 10.1016/j.jmatprotec.2018.07.009

[6] Keehan E, Karlsson L, Andren H O, et al. Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: Part 1-effect of nickel content[J]. Science and Technology of Welding and Joining, 2006, 11(1): 9 − 18. doi: 10.1179/174329306X77830

[7] Pak J, Suh D W, Bhadeshia H, Promoting the coalescence of bainite platelets[J]. Scripta Materialia, 2012, 66(11): 951-953.

[8] Liu J, Sun J, Wei S, et al. Influence of chromium content on the bainite transformation nucleation mechanism and the properties of 800 MPa grade low carbon bainite weld deposited metal[J]. Materials Science & Engineering: A, 2022, 840: 142893.

[9] Nakanishi D, Kawabata T, Aihara S. Brittle crack propagation resistance inside grain and at high angle grain boundary in 3% Si-Fe alloy[J]. Acta Materialia, 2018, 144: 768 − 776.

[10] Fan S, Hao H, Meng L, et al. Effect of deep cryogenic treatment parameters on martensite multi-level microstructures and properties in a lath martensite/ferrite dual-phase steel[J]. Materials Science & Engineering: A, 2021, 810: 141022.

下载:

下载: