Microstructure and dynamic fracture behaviors of 17-4PH stainless steel fabricated by selective laser melting

-

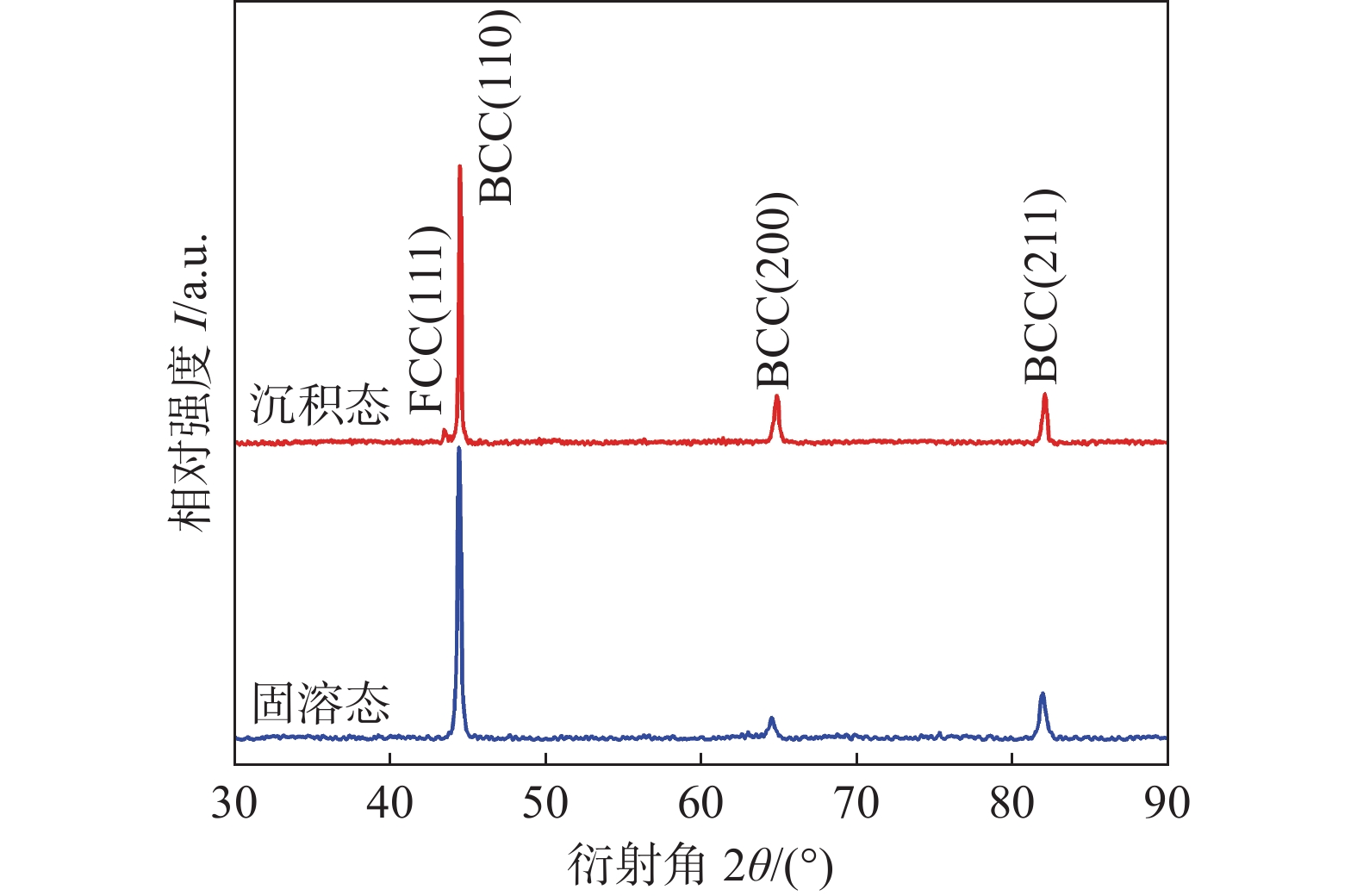

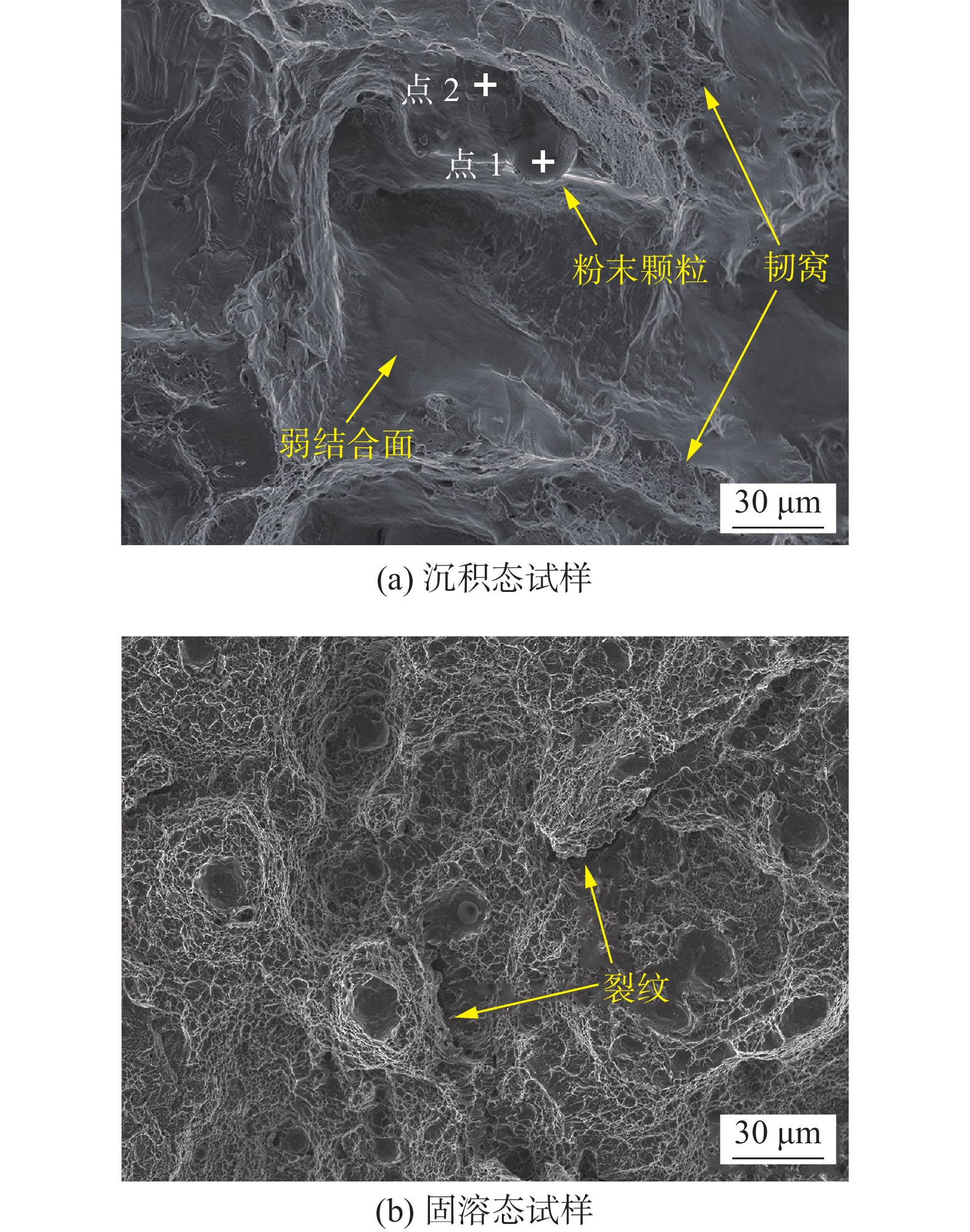

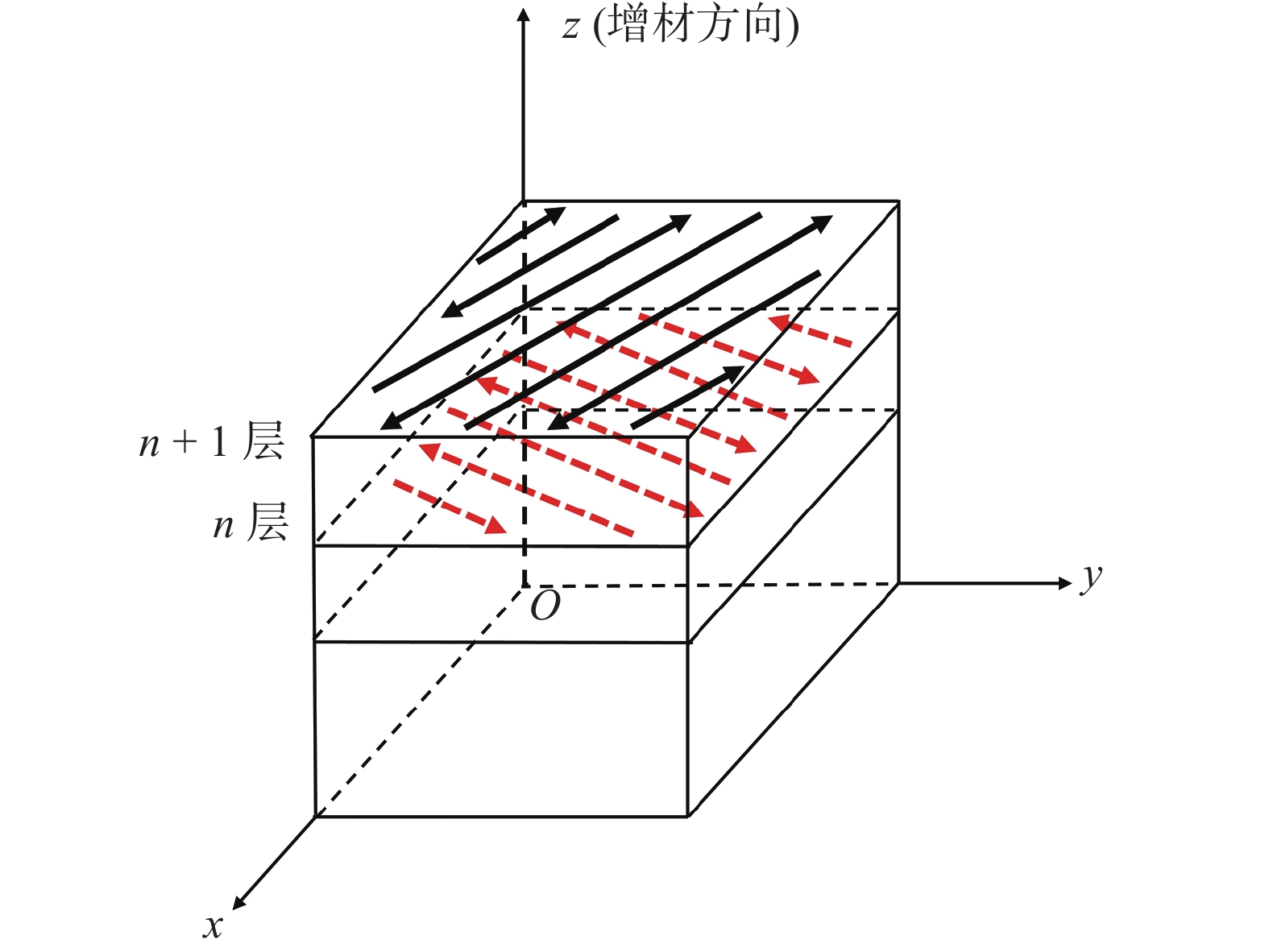

摘要: 通过激光选区熔化(selective laser melting, SLM)技术制备了17-4PH不锈钢,采用电子背散射衍射(electron backscattered diffraction, EBSD)和透射电子显微镜(transmission electron microscope, TEM)等方法对沉积态和固溶态试样微观组织结构进行了分析. 通过示波冲击试验确定了裂纹萌生扩展的特征阶段和动态裂纹扩展阻力曲线(J−R曲线),研究了微观组织与动态断裂性能之间的关系. 结果表明,沉积态试样主要由<100>择优且沿增材方向拉长的δ铁素体柱状晶、取向随机的细小马氏体,以及少量奥氏体组成,不同截面具有显著的组织各向异性;大尺寸δ铁素体柱状晶与细小晶粒的结合面作为薄弱环节,使其脆性增加,J−R曲线的撕裂模量较低,以准解理方式断裂. 固溶热处理明显弱化组织各向异性,微观组织由尺寸细小、均匀的马氏体组成,其冲击吸收能量提升1倍,动态断裂韧性优良,属于韧性断裂. 大尺寸δ铁素体柱状晶与周围细小马氏体晶粒界面结合较弱是沉积态17-4PH不锈钢动态断裂性能较差的主要原因.Abstract: 17-4PH stainless steel was fabricated by selective laser melting (SLM). The microstructure of the as-built and solution heat treated 17-4PH was analyzed by electron backscattered diffraction (EBSD) and transmission electron microscope (TEM). The relationship between microstructure and dynamic fracture behavior was investigated by performing instrumented impact test. Absorbed impact energies related to crack initiation, stable and unstable propagation were calculated and the dynamic J−R curves were estimated.The results demonstrate that as-built 17-4PH stainless steel mainly consists of coarse columnar δ ferrite grains growing along the building direction with <100> texture and fine martensitic grains with random orientation. A small amount of austinite can also be found in the as-built sample. As-built 17-4PH stainless steel displays low resistance to crack initiation and propagation, resulting in marginally rising J−R curve and quasi-cleavage fracture. After solution heat treatment, the retained ferrite transforms into martensite and microstructural anisotropy can be eliminated. The impact toughness is 1 times higher than that in as-built conditions and the dynamic J−R curve rises steeply, indicating superior dynamic mechanical properties. Fracture surfaces revealed that the inferior dynamic fracture toughness of as-built 17-4PH stainless steel can be attributed to the weak boundaries between the coarse δ ferrite grains and surrounding fine martensite grains.

-

Keywords:

- selective laser melting /

- stainless steel /

- microstructure /

- mechanical properties

-

-

表 1 17-4PH不锈钢粉末的化学成分(质量分数,%)

Table 1 Chemical compositions of 17-4PH stainless steel powder

C Cr Ni Cu Nb Si Mn N Fe 0.011 15.92 4.66 4.2 0.30 0.62 0.33 0.01 余量 表 2 示波冲击试验裂纹扩展不同阶段冲击吸收能量

Table 2 Absorbed impact energies associated with different stages of instrumented Charpy impact tests J

试样类型 裂纹萌生功Win 稳定扩展功Wstable 失稳扩展功Wunstable 总冲击吸收能量Wtotal 沉积态 4.81 ± 0.32 4.29 ± 0.45 4.74 ± 0.28 17.20 ± 1.01 固溶态 6.84 ± 0.46 15.59 ± 1.21 4.48 ± 0.36 34.86 ± 0.98 -

[1] Guennouni N, Barroux A, Grosjean C, et al. Comparative study of the microstructure between a laser beam melted 17-4PH stainless steel and its conventional counterpart[J]. Materials Science & Engineering: A, 2021, 823: 141718.

[2] 巴培培, 董志宏, 张炜, 等. 选区激光熔化成形12CrNi2合金钢的显微组织和力学性能[J]. 焊接学报, 2021, 42(8): 8 − 17. doi: 10.12073/j.hjxb.20210323003 Ba Peipei, Dong Zhihong, Zhang Wei, et al. Microstructure and mechanical properties of 12CrNi2 alloy steel manufactured by selective laser melting[J]. Transactions of the China Welding Institution, 2021, 42(8): 8 − 17. doi: 10.12073/j.hjxb.20210323003

[3] 周博康, 魏正英, 李俊峰, 等. 90W-7Ni-3Fe激光选区熔化热行为及试验分析[J]. 焊接学报, 2020, 41(11): 76 − 82. doi: 10.12073/j.hjxb.20200518002 Zhou Bokang, Wei Zhengying, Li Junfeng, et al. 90W-7Ni-3Fe selective laser melting heat behavior analysis and experimental research[J]. Transactions of the China Welding Institution, 2020, 41(11): 76 − 82. doi: 10.12073/j.hjxb.20200518002

[4] 尹燕, 刘鹏宇, 路超, 等. 选区激光熔化成形316L不锈钢微观组织及拉伸性能分析[J]. 焊接学报, 2018, 39(8): 77 − 81. doi: 10.12073/j.hjxb.2018390205 Yin Yan, Liu Pengyu, Lu Chao, et al. Microstructure and tensile properties of selective laser melting forming 316L stainless steel[J]. Transactions of the China Welding Institution, 2018, 39(8): 77 − 81. doi: 10.12073/j.hjxb.2018390205

[5] Rafi H K, Pal D, Patil N, et al. Microstructure and mechanical behavior of 17-4 precipitation hardenable steel processed by selective laser melting[J]. Journal of Materials Engineering and Performance, 2014, 23(12): 4421 − 4428. doi: 10.1007/s11665-014-1226-y

[6] Ponnusamy P, Sharma B, Masood S H, et al. A study of tensile behavior of SLM processed 17-4PH stainless steel[J]. Materials Today: Proceedings, 2021, 45: 4531 − 4534. doi: 10.1016/j.matpr.2020.12.1104

[7] Alnajjar M, Christien F, Wolski K, et al. Evidence of austenite by-passing in a stainless steel obtained from laser melting additive manufacturing[J]. Additive Manufacturing, 2019, 25: 187 − 195. doi: 10.1016/j.addma.2018.11.004

[8] Sabooni S, Chabok A, Feng S C, et al. Laser powder bed fusion of 17-4 PH stainless steel: a comparative study on the effect of heat treatment on the microstructure evolution and mechanical properties[J]. Additive Manufacturing, 2021, 46: 102176. doi: 10.1016/j.addma.2021.102176

[9] Lobodyuk V A, Meshkov Yu Ya, Pereloma E V. On tetragonality of the martensite crystal lattice in steels[J]. Metallurgical and Materials Transactions A, 2019, 50(1): 97 − 103. doi: 10.1007/s11661-018-4999-z

[10] Ryde L. Application of EBSD to analysis of microstructures in commercial steels[J]. Materials Science and Technology, 2006, 22(11): 1297 − 1306. doi: 10.1179/174328406X130948

[11] Baek M-S, Kim K-S, Park T-W, et al. Quantitative phase analysis of martensite-bainite steel using EBSD and its microstructure, tensile and high-cycle fatigue behaviors[J]. Materials Science & Engineering: A, 2020, 785: 139375. doi: 10.1016/j.msea.2020.139375

[12] Chang Y, Lin M, Hangen U, et al. Revealing the relation between microstructural heterogeneities and local mechanical properties of complex-phase steel by correlative electron microscopy and nanoindentation characterization[J]. Materials & Design, 2021, 203: 109620.

[13] Murr L E, Martinez E, Hernandez J, et al. Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting[J]. Journal of Materials Research and Technology, 2012, 1(3): 167 − 177. doi: 10.1016/S2238-7854(12)70029-7

[14] Hooper P A. Melt Pool Temperature and cooling rates in laser powder bed fusion[J]. Additive Manufacturing, 2018, 22: 548 − 559. doi: 10.1016/j.addma.2018.05.032

[15] Alexopoulos N D, Stylianos A. Impact mechanical behaviour of Al-7Si-Mg (A357) cast aluminum alloy. The effect of artificial aging[J]. Materials Science & Engineering: A, 2011, 528(19-20): 6303 − 6312.

[16] Alexopoulos N D, Stylianos A, Campbell J. Dynamic fracture toughness of Al-7Si-Mg (A357) aluminum alloy[J]. Mechanics of Materials, 2013, 58(2): 55 − 68. doi: 10.1016/j.mechmat.2012.11.005

[17] 马力深, 钟约先, 马庆贤, 等. δ铁素体对12%Cr超超临界转子钢冲击性能的影响[J]. 清华大学学报(自然科学版), 2008, 48(11): 1887 − 1890. doi: 10.3321/j.issn:1000-0054.2008.11.004 Ma Lishen, Zhong Yuexian, Ma Qingxian, et al. Effect of δ-ferrite on impact properties of 12%Cr rotor steel for ultra-supercritical steam conditions[J]. Journal of Tsinghua University (Science and Technology), 2008, 48(11): 1887 − 1890. doi: 10.3321/j.issn:1000-0054.2008.11.004

[18] Toshiro K, Isamu Y, Mitsuo N. Evaluation of dynamic fracture toughness parameters by instrumented charpy impact test[J]. Engineering Fracture Mechanics, 1986, 24(5): 773 − 782. doi: 10.1016/0013-7944(86)90249-3

[19] Lin Y, Yu Q, Pan J, et al. On the impact toughness of gradient-structured metals[J]. Acta Materialia, 2020, 193: 125 − 137. doi: 10.1016/j.actamat.2020.04.027

[20] Tronskar J P, Mannan M A, Lai M O. Measurement of fracture initiation toughness and crack resistance in instrumented charpy impact testing[J]. Engineering Fracture Mechanics, 2002, 69(3): 321 − 338. doi: 10.1016/S0013-7944(01)00077-7

-

期刊类型引用(2)

1. 张超,周猛兵,崔雷,陶欣,王军,王伟,刘永长. 9Cr-1.5W-0.15Ta耐热钢搅拌摩擦焊焊缝组织和冲击性能分析. 焊接学报. 2024(04): 36-42+131 .  本站查看

本站查看

2. 王猛,张立平,赵琳瑜,吴军,熊然,蒙永胜,李军红. 增材制造和锻造TC11钛合金激光焊接头组织与力学性能. 焊接学报. 2023(10): 102-110+138-139 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: