Microstructure and mechanical properties of CuCrZr/316LN laser welding joints

-

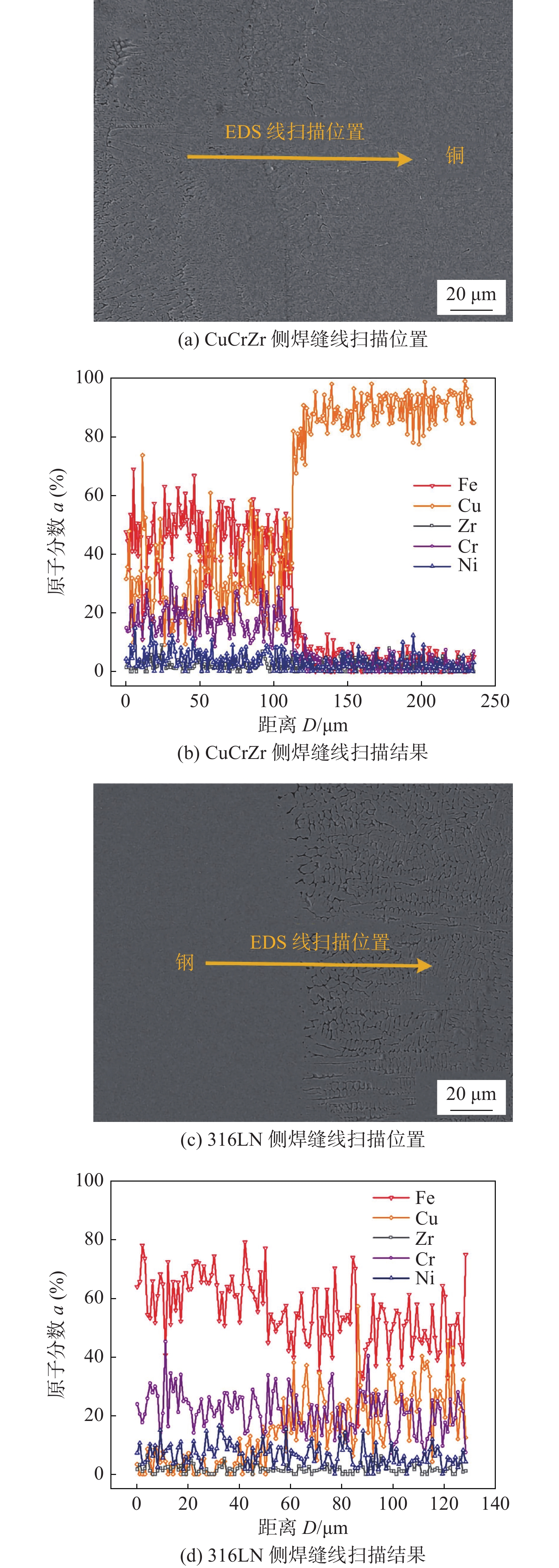

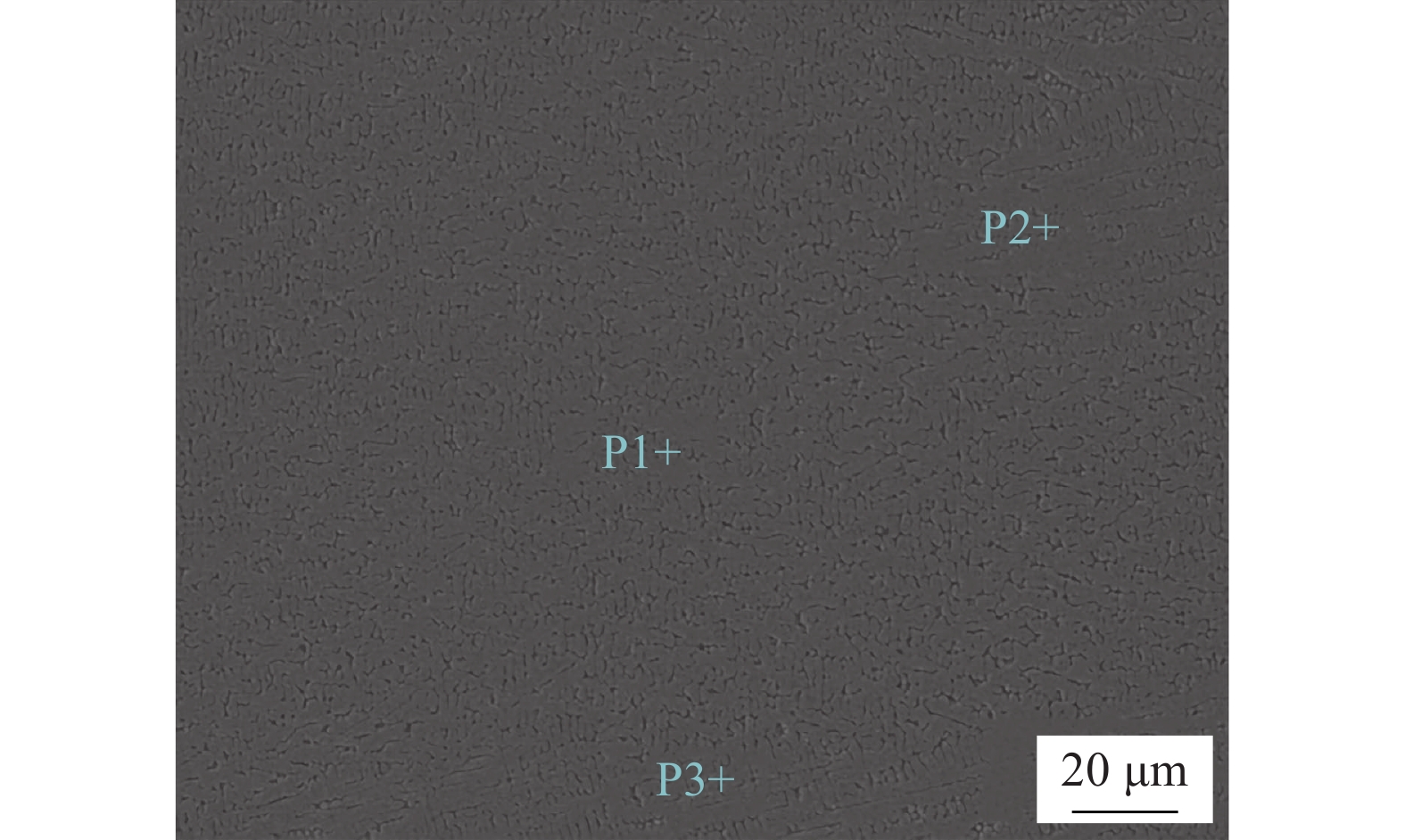

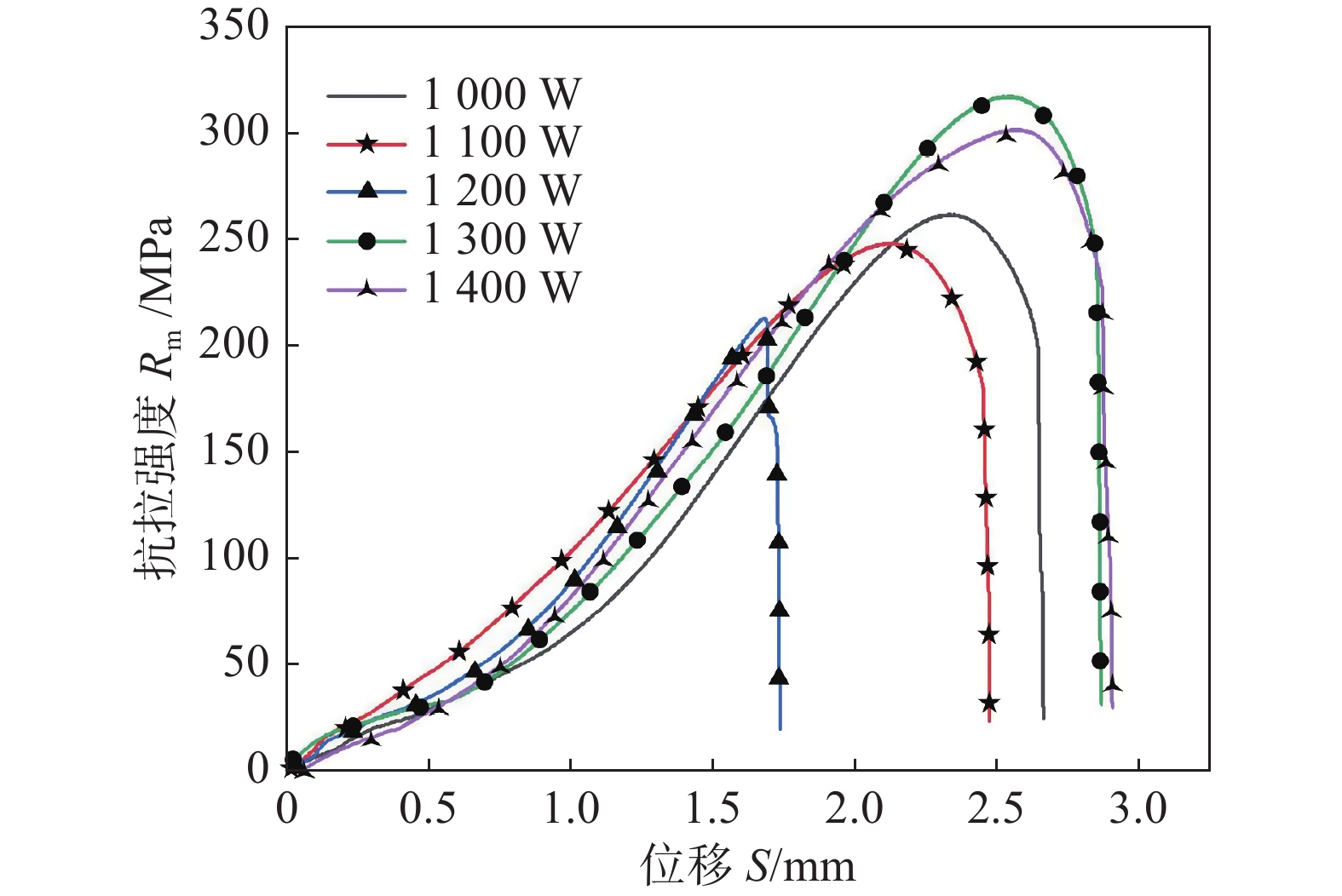

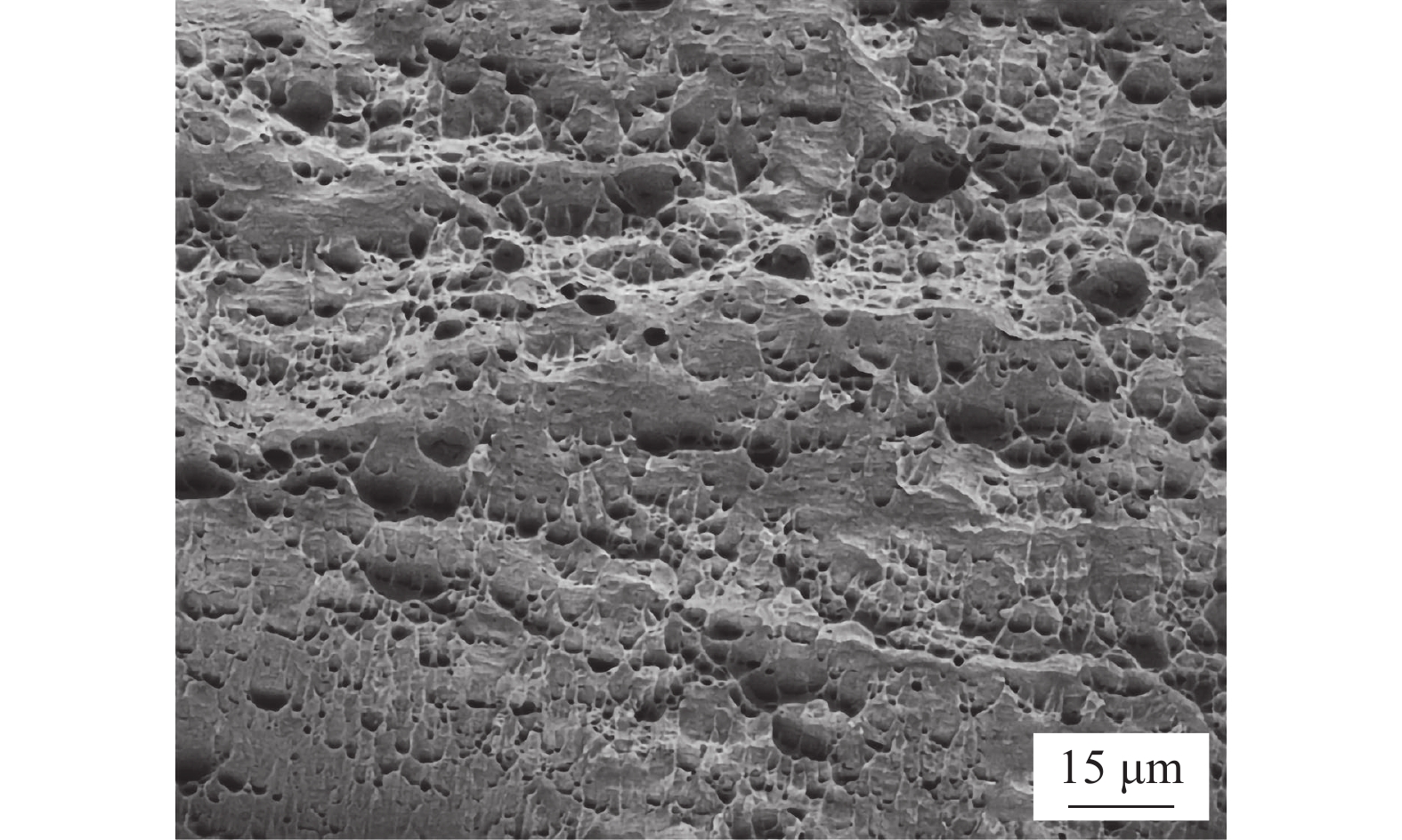

摘要: 对CuCrZr与316LN异种材料合金管进行激光焊试验,观察分析试样的接头形貌、微观组织、化学成分以及力学性能分析. 结果表明,在激光功率1 100 ~ 1 400 W、离焦量 + 20 mm、焊接速度14.5 mm/s和氩气流量15 L/min时焊缝成形良好,可实现CuCrZr/316LN合金管的全位置焊接,焊缝内部缺陷较少,但随着激光功率的增加,焊缝下塌现象明显;CuCrZr/316LN焊缝与母材连接界面元素过渡明显,由于Fe,Cu互溶,在焊缝内部主要以形状不同的富Fe的Fe/Cu固溶体存在;CuCrZr/316LN合金管激光焊接接头抗拉强度较高,主要断裂位置为晶粒粗大的铜侧热影响区位置,断裂形式以韧性断裂为主.Abstract: In this paper, the laser butt welding experiment of CuCrZr and 316LN dissimilar material alloy tube was carried out, and the joint morphology, microstructure, chemical composition and mechanical properties of each sample were observed and analyzed. The experimental results show that the weld is in good shape under the laser power of 1100 − 1400 W, the defocus amount of + 20 mm, the welding speed of 14.5 mm/s and shielded by Ar gas of 15 L/min, which can realize all-position welding of CuCrZr/316LN tube with less internal defects. However, the phenomenon of weld collapse is obvious with the increase of welding power. The transition of the interface elements between the CuCrZr/316LN weld and the base metal is obvious, and there is mainly Fe-rich Fe/Cu solid solution in the weld due to the mutual solubility of Fe and Cu. The tensile strength of the laser welded joint of CuCrZr/316LN tube is higher, the main fracture location is the heat affected zone of copper with coarse grain, the fracture form is mainly ductile fracture.

-

Keywords:

- CuCrZr /

- 316LN stainless steel /

- laser welding /

- interface microstructure /

- mechanical properties

-

-

表 1 316LN不锈钢的化学成分(质量分数,%)

Table 1 Chemical compositions of 316LN stainless steel

C Si Mn P S Ni Cr Mo N C + N Fe ≤0.03 ≤0.75 ≤2.00 ≤0.03 ≤0.02 10.00 ~ 14.00 16.00 ~ 18.50 0.12 ~ 0.17 0.12 ~ 0.17 ≤0.15 余量 表 2 CuCrZr的化学成分(质量分数,%)

Table 2 Chemical compositions of CuCrZr

Al Mg Zr Cr Fe Si P 杂质 Cu 0.10 ~ 0.25 0.10 ~ 0.25 0.65 0.65 0.05 0.05 0.01 0.2 余量 表 3 焊接工艺参数

Table 3 Welding process parameters

离焦量△f /mm 转速n/(mm·min−1) 氩气流量Q/(L·min−1) 激光偏移量δ/mm 焊接速度v/(mm·min−1) + 20 300 15 0 870 表 4 焊缝成分分析结果(原子分数,%)

Table 4 Analysis results of weld compositions

位置 Fe Cr Cu Ni Zr P1 50.25 22.37 20.67 6.06 0.65 P2 52.51 20.65 20.26 5.30 1.28 P3 54.13 21.26 18.14 4.86 1.61 -

[1] Jiao Y, Xu G. DA optimization experiences in the HEPS lattice design[J]. Journal of Physics: Conference Series, 2018, 1067(3): 1367 − 1370.

[2] 姜晓明, 王九庆, 秦庆, 等. 中国高能同步辐射光源及其验证装置工程[J]. 中国科学, 2014, 44(10): 1075 − 1094. Jiang Xiaoming, Wang Jiuqing, Qin Qing, et al. Chinese high energy photon source and the test facility[J]. Science China, 2014, 44(10): 1075 − 1094.

[3] Pravin K N, Siva S N, Sreedhar G. High cycle fatigue behaviour of Inconel 625 weld overlay on AISI 316L plate[J]. Surface & Coatings Technology, 2021, 415: 127 − 138.

[4] Vemanaboina H, Kotthinti N K, Chittemsetty V. Multipass dissimilar joints for SS316L to Inconel 625 using gas tungsten arc welding[J]. Materials Today: Proceedings, 2021, 46: 567 − 571. doi: 10.1016/j.matpr.2020.11.287

[5] Duan M, Han L, Sun W, et al. Development and performance test of CuCrZr/316L explosive welding plate for EAST lower divertor heat sink[J]. Fusion Engineering and Design, 2020, 160: 1 − 6.

[6] Zhao S X, Wang M J, Kou S Z, et al. Microstructures and mechanical properties of electron beam welded CuCrZr/Inconel/316L tube-to-tube junctions for WEST project[J]. Fusion Engineering and Design, 2020, 151: 111384.

[7] Wang M J, Zhao S X, Wang W J et al. Preliminary results of CuCrZr/316L tube-to-tube junctions fabricated with rotary friction welding[J]. Fusion Engineering and Design, 2019, 148: 1 − 7.

[8] Chai M Y, Zhang J, Zhang Z X, et al. Acoustic emission studies for characterization of fatigue crack growth in 316LN stainless steel and welds[J]. Applied Acoustics, 2017, 126: 101 − 113. doi: 10.1016/j.apacoust.2017.05.014

[9] 马锐, 吴继红, 施未来, 等. 316L(N)/CuCrZr中空结构件爆炸焊接工艺[J]. 解放军理工大学学报(自然科学版), 2016, 17(2): 180 − 186. Ma Rui, Wu Jihong, Shi Weilai, et al. Explosive welding process for manufacturing 316L(N)/CuCrZr hollow structural member[J]. Journal of PLA University of Science and Technology (Natural Science Edition), 2016, 17(2): 180 − 186.

[10] Chai M Y, Duan Q, Zhang Z X. Acoustic emission response of 316LN welded joint during intergranular corrosion[J]. Materials Science Forum, 2014, 809: 401 − 405.

[11] Lalvani H, Mandal P. Cold forming of Al-5251 and Al-6082 tailored welded blanks manufactured by laser and electron beam welding[J]. Journal of Manufacturing Processes, 2021, 68: 1615 − 1636. doi: 10.1016/j.jmapro.2021.06.070

[12] Li N, Wang T, Jiang S, et al. Microstructure evolution and strengthening mechanism of electron beam welded TiBw/Ti6Al4V composite joint[J]. Materials Characterization, 2021, 178: 1 − 10.

[13] 刘莹莹, 李洁洁, 张乐. 电子束焊接工艺参数对Ti2AlNb/TC18接头组织与性能的影响[J]. 中国有色金属学报, 2021, 31(3): 699 − 706. doi: 10.11817/j.ysxb.1004.0609.2021-35973 Liu Yingying, Li Jiejie, Zhang Le. Effects of electron beam welding processing parameters on microstructure and properties of Ti2AlNb/TC18 joint[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 699 − 706. doi: 10.11817/j.ysxb.1004.0609.2021-35973

[14] Fan X, Shen X, Zhang Y, et al. Microstructure and mechanical properties of similar and dissimilar joints of RAFM and 316L by electron beam welding[J]. Fusion Engineering and Design, 2021, 162: 1 − 8.

[15] Niu H, Jiang H C, Zhao M J, et al. Effect of interlayer addition on microstructure and mechanical properties of NiTi/stainless steel joint by electron beam welding[J]. Journal of Materials Science & Technology, 2021, 61: 16 − 24.

[16] 邓彩艳, 尹庭辉, 龚宝明. TC11钛合金电子束焊接接头超高周疲劳性能[J]. 焊接学报, 2018, 39(4): 23 − 26. doi: 10.12073/j.hjxb.2018390088 Deng Caiyan, Yin Tinghui, Gong Baoming. Properties of very-high-cycle fatigue of TC11 titanium alloy EBW welded joints[J]. Transactions of the China Welding Institution, 2018, 39(4): 23 − 26. doi: 10.12073/j.hjxb.2018390088

[17] Wang Liwei, Chen Shujun, Xiao Jun, et al. Droplet-targeting laser hybrid indirect arc for additive manufacturing technology-A preliminary study[J]. China Welding, 2020, 29(1): 50 − 55.

[18] Tian Deyong, Yan Tingyan, Gao Qiyu, et al. Thermal cycle and its influence on the microstructure of laser welded butt joint of 8 mm thick Ti-6Al-4V alloy[J]. China Welding, 2019, 28(3): 61 − 66.

[19] 唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙: 中南大学出版社, 2009. Tang Renzheng, Tian Rongzhang. Binary alloy phase diagrams and crystal structure of intermediate phase[M]. Changsha: Zhongnan University Press, 2009.

-

期刊类型引用(2)

1. 张超,周猛兵,崔雷,陶欣,王军,王伟,刘永长. 9Cr-1.5W-0.15Ta耐热钢搅拌摩擦焊焊缝组织和冲击性能分析. 焊接学报. 2024(04): 36-42+131 .  本站查看

本站查看

2. 王猛,张立平,赵琳瑜,吴军,熊然,蒙永胜,李军红. 增材制造和锻造TC11钛合金激光焊接头组织与力学性能. 焊接学报. 2023(10): 102-110+138-139 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: