Fatigue crack growth analysis of weathering steel joints based on analytical algorithm and J-integral method

-

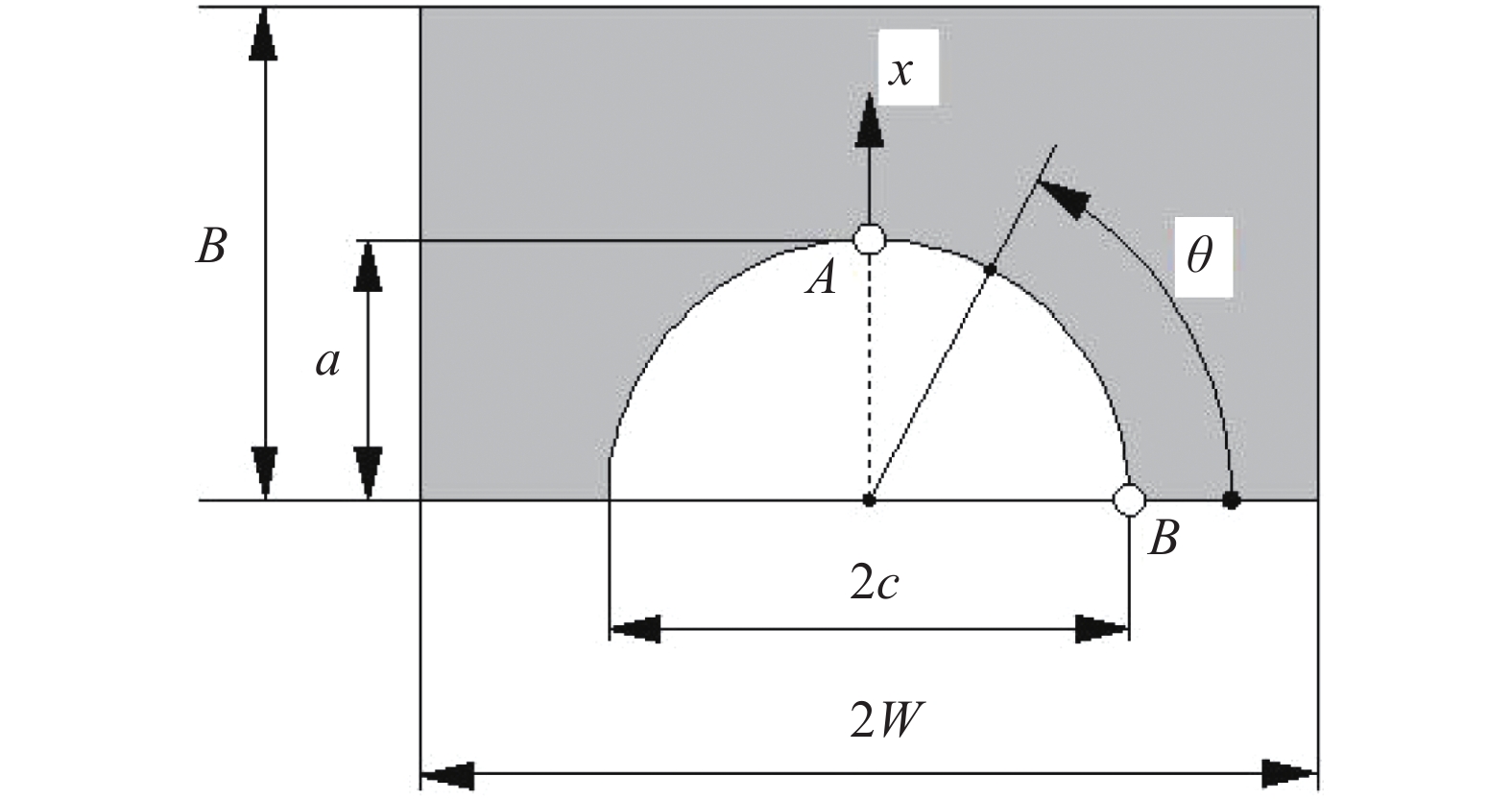

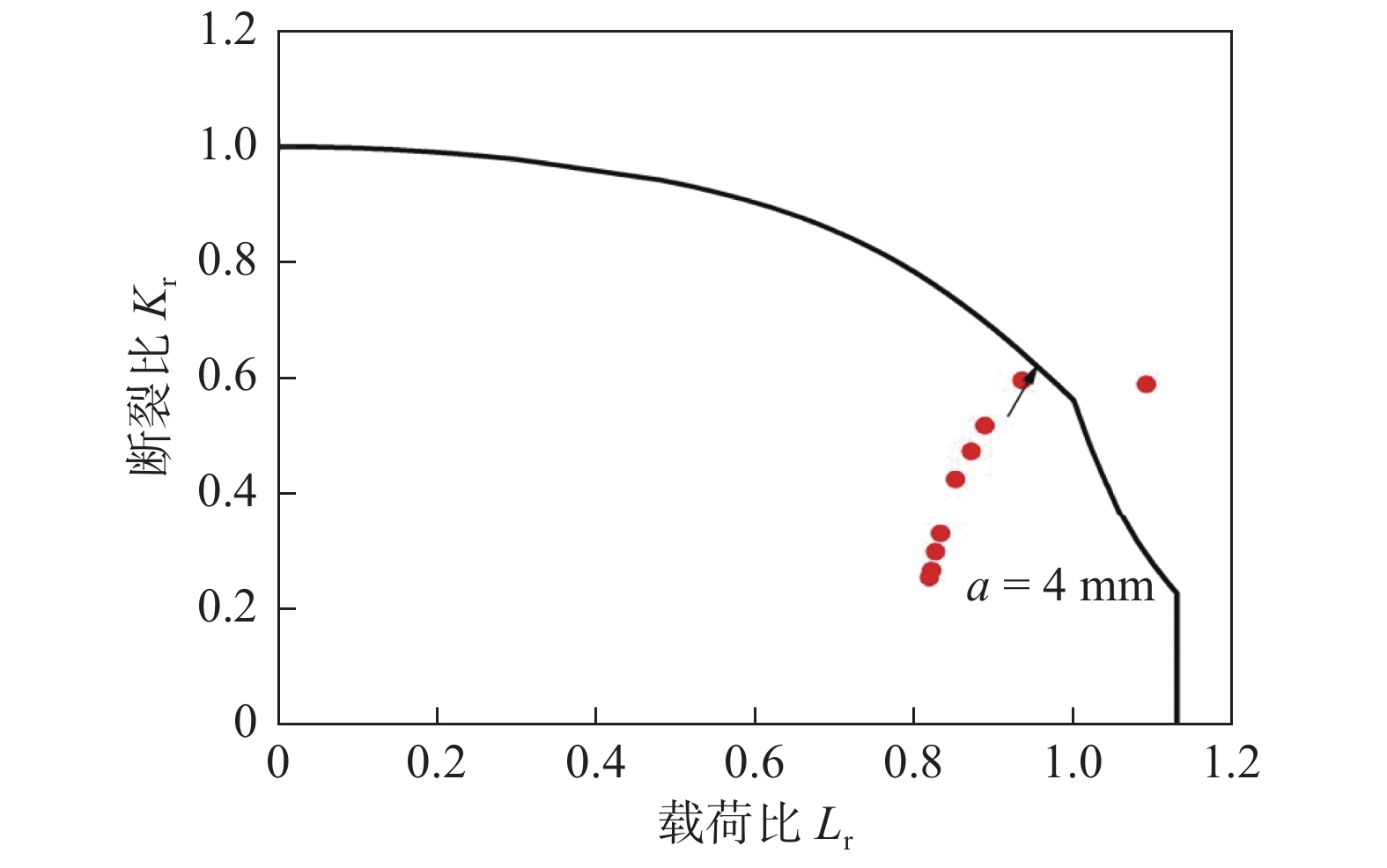

摘要: 为准确描述焊接接头疲劳裂纹在扩展中的动态过程,借助多阵元超声相控阵设备对12 mm厚耐候钢对接接头的表面裂纹扩展动态进行实时监测,得到半椭圆形裂纹深度、长度与寿命的演化关系.借助Abaqus建立有限元分析模型,将裂纹几何变化历程输入,计算裂纹尖端7个方向的能量释放率,获得裂纹尖端应力强度因子幅值.将裂纹尖端(θ = 90º)的K值与BS7910标准中推荐解析公式对比分析,其结果吻合性好.在此基础上,分别采用简化公式与两阶段扩展模型计算试样的疲劳寿命. 结果表明,两阶段裂纹扩展模型能准确地预测对接接头裂纹的疲劳寿命,且与试验结果高度吻合.Abstract: The surface crack propagation dynamics of 12 mm thick weathering steel butt joints were monitored by using multi-element ultrasonic phased array to accurately describe the dynamic process of fatigue crack propagation in welded joints, and the geometric evolution between semi-elliptical crack depth, length relating with fatigue life was obtained. By using Abaqus, the finite element analysis model was established, with the geometric dimension of the crack as the input, the energy release rate G in seven directions of the crack tip was calculated, and then the range of stress intensity factor of the crack tip was calculated. The K value of the crack tip (θ = 90°) is compared with the analytical formula recommended in the BS7910, and the results were in good agreement with each other. Furthermore, the fatigue life of the specimen was calculated by using the simplified formula and the two-stage propagation formula, respectively. The results show that the two-stage crack growth model could accurately predict the fatigue life of butt joints and was in good agreement with the experimental results.

-

-

表 1 SMA490BW与CHW-55CNH的合金成分(质量分数,%)

Table 1 Chemical compositions of SMA490BW and CHW-55CNH

材料 C Mn Si P S Cr Cu Ni SMA490BW 0.18 1.4 0.55 0.035 0.035 0.30~0.35 0.20~0.35 - CHW-55CNH 0.08 1.4 0.45 0.012 0.008 0.65 0.25 0.35 表 2 TIG焊接工艺参数

Table 2 TIG welding process parameters

焊接电压U/V 焊接电流I/A 焊接速度v/(mm·s−1) 22.6 227 2.87 表 3 C2-1试件的疲劳试验参数

Table 3 Fatigue test loading parameters of C2-1

板厚

t/mm加载宽度

b/mm名义应力

Rn /MPa应力比

R最小加载力

Fmin /kN最大加载力

Fmax /kN实际寿命

N/周次12 80 230 0.1 30.67 306.67 312154 表 4 试件C2-1裂纹尺寸数据表

Table 4 Data of crack size of specimen C2-1

循环次数

N/万次裂纹深度

a/mm裂纹长度

2c/mm循环次数

N/万次裂纹深度

a/mm裂纹长度

2c/mm0 0 0 28 12.5 30.3 5 0.9 3.1 29 12.5 33.6 10 1.2 3.3 29.5 12.5 37.2 13 1.5 4.2 30 12.5 40.2 16 1.8 5.2 30.5 12.5 42.3 18 2 10.2 30.7 12.5 45.1 20 2.6 12.1 30.9 12.5 47.6 22 2.8 15.6 31 12.5 51.6 24 3.8 19.1 31.05 12.5 56.3 25 7.1 20.5 31.1 12.5 61.3 26 9.2 23.5 31.11 12.5 62.1 27 10.5 27.1 31.12 12.5 65.3 表 5 裂纹尖端扩展位移δ及Ki(Δσ = 104 MPa,节点38357)

Table 5 Displacement δ and stress intensity factor Ki of crack tip

扩展位移

δ/mm应力强度因子

(Ki /MPa·mm0.5)扩展位移

δ/mm应力强度因子

(Ki /MPa·mm0.5)扩展位移

δ/mm应力强度因子

(Ki /MPa·mm0.5)0.01 160 1.40 204 6.89 369 0.05 161 2.04 225 7.71 392 0.14 164 2.85 251 8.46 414 0.30 169 3.85 282 9.30 445 0.55 177 5.01 316 10.10 504 0.91 188 6.02 345 表 6 基于BS7910的Ki值

Table 6 Stress intensity factor Ki of BS7910

节点号 应力范围Δσ = 287.5 MPa 应力范围Δσ = 104 MPa 裂纹深度a/mm 应力强度因子Ki /(MPa·mm0.5) 裂纹深度a/mm 应力强度因子Ki /(MPa·mm0.5) 38357 0.9 414.60 0.9 149.98 1.2 437.85 1.2 158.39 1.5 494.56 1.5 178.90 1.8 550.83 1.8 199.26 2.0 706.97 2.0 255.74 2.6 798.47 2.6 288.84 2.8 876.50 2.8 317.06 3.8 1032.25 3.8 373.41 7.1 1236.15 7.1 447.16 9.2 1376.04 9.2 497.77 10.5 1538.23 10.5 556.44 表 7 SMA490BW焊接接头的裂纹扩展速率常数(R > 0.5)

Table 7 Crack growth rate constant of SMA490BW welded joint (R > 0.5)

阶段B 转折点 简化曲线 系数A 系数m ΔK/(N·mm−1.5) 系数A 系数m 1.29 × 10−12 2.88 144 5.21 × 10−13 3 表 8 基于BS7910的裂纹寿命分析

Table 8 Crack life analysis based on BS7910

公式 初始裂纹

深度ai1/mm临界裂纹

深度af1/mm临界前循环

次数N1/周次临界裂纹

深度af/mm裂纹最终

深度aF/mm临界后循环

次数N2/周次裂纹扩展总

寿命N3/周次试验寿命

N4/周次简化公式 0.001 4 1206190 4 12 8190 1214380 312154 两阶段公式 0.001 4 345830 4 12 3539 349370 312154 -

[1] British Standards Institution. Guide to methods for assessing the acceptability of flaws in metallic structures, BS 7910[S]. London British Standards Institution, 2016.

[2] American Society of Mechanical Engineers. Fitness-for-service, API 579-1/ASME FFS-1[S]. New York American Society of Mechanical Engineers, 2007.

[3] Revision 4 British Energy. Assessment of the integrity of structures containing defects, R6[S]. Gloucester Revision 4 British Energy, 2013.

[4] 王东辉, 李杰, 郑会, 等. 小径管对接焊缝缺陷验收准则分析[J]. 设备管理与维修, 2022(1): 28 − 31. Wang Donghui, Li Jie, Zheng Hui, et al. Analysis of acceptance of small diameter pipe butt welds[J]. Plant Maintenance Engineering, 2022(1): 28 − 31.

[5] 阮宏宝, 黄小平. LNG船纵骨端部表面裂纹疲劳扩展寿命计算[J]. 船舶与海洋工程, 2020, 36(2): 25 − 31. Ruan Hongbao, Huang Xiaoping. Fatigue life calculation of surface cracks at the longitudinal stiffener end joints of an LNG vessel[J]. Naval Architecture and Ocean Engineering, 2020, 36(2): 25 − 31.

[6] Zhang Y H, Matthew D. Fatigue crack growth assessment using BS 7910: 2013 - Background and recommended developments[J]. International Journal of Pressure Vessels and Piping, 2018(168): 79 − 86.

[7] 童乐为, 任珍珍, 景爽, 等. 高强度结构钢系列的疲劳裂纹扩展速率试验研究[J]. 工程力学, 2020, 37(12): 191 − 201. Tong Lewei, Ren Zhenzhen, Jing Shuang, et al. Experimental study on fatigue crack growth rate of high strength structural steel series[J]. Engineering Mechanics, 2020, 37(12): 191 − 201.

[8] 吕刘帅, 张小春, 苏博, 等. 镍基合金压力容器环形焊缝残余应力数值模拟与失效应力分析[J]. 核技术, 2019, 42(7): 70 − 78. Lü Liushuai, Zhang Xiaochun, Su Bo, et al. Numerical simulation of residual stress in girth weld and failure stress analysis of reactor vessel[J]. Nuclear Techniques, 2019, 42(7): 70 − 78.

[9] 邓彩艳, 张玉凤, 霍立兴, 等. 基于BS 7910海底外输管线ECA评估[J]. 焊接学报, 2006, 27(1): 17 − 20. Deng Caiyan, Zhang Yufeng, Huo Lixing, et al. Engineering critical assessment used for welded pipe based on BS 7910[J]. Transactions of the China Welding Institute, 2006, 27(1): 17 − 20.

[10] 邓彩艳. 焊接压力管道"先漏后断"评定理论及应用研究[D]. 天津: 天津大学, 2006. Deng Caiyan. Study on the theory and application of leak-beofre-break assessment procedure for the welded pressure pipeline[D]. Tinajin: Tianjin University, 2006.

[11] 刘明亮, 张玉凤, 霍立兴, 等. 海底管道安全性评定方法的分析[J]. 焊接学报, 2006, 27(8): 75 − 78. Liu Mingliang, Zhang Yufeng, Huo Lixing, et al. Methods of safe assessment for offshore pipeline[J]. Transactions of the China Welding Institution, 2006, 27(8): 75 − 78.

[12] 刘俊, 霍立兴, 张玉凤. SINTAP标准和BS 7910标准中FAD图评定方法横坐标求解方法的比较及分析[J]. 焊接学报, 2006, 27(1): 97 − 100. Liu Jun, Huo Lixing, Zhang Yufeng. Comparison and analysis of the abscissa of the FAD in SINTAP and BS 7910[J]. Transactions of the China Welding Institute, 2006, 27(1): 97 − 100.

[13] 丁浩, 鲍雨梅, 张锐之, 等. T2紫铜-45钢异种材料电子束焊的焊接接头强度与缺陷评定[J]. 焊接学报, 2018, 39(5): 43 − 46. doi: 10.12073/j.hjxb.2018390119 Ding Hao, Bao Yumei, Zhang Ruizhi, et al. Study on welding strength and defect assessment of the T2 copper-45 steel dissimilar material[J]. Transactions of the China Welding Institute, 2018, 39(5): 43 − 46. doi: 10.12073/j.hjxb.2018390119

[14] Xu S, Tyson W, Duan D M. ECA of embedded flaws in pipeline girth welds-a review[J]. International Journal of Pressure Vessels and Piping, 2019(172): 79 − 89.

[15] 李继红, 张建勋. 含损伤焊接接头裂纹体J积分的有限元数值研究[J]. 西安交通大学学报, 2003(9): 937 − 940. doi: 10.3321/j.issn:0253-987X.2003.09.015 Li Jihong, Zhang Jianxun. Numerical investigations to J-integral in cracked weldment containing damage based on finite element method[J]. Journal of Xi’an Jiaotong University, 2003(9): 937 − 940. doi: 10.3321/j.issn:0253-987X.2003.09.015

[16] 戴悦, 杨杰, 陈浩峰. 核电安全端结构中材料拘束的作用范围[J]. 金属学报, 2021, 57(12): 1645 − 1652. doi: 10.11900/0412.1961.2020.00445 Dai Yue, Yang Jie, Chen Haofeng. Effect range of material constraint in nuclear safe end structure[J]. Acta Metallurgica Sinica, 2021, 57(12): 1645 − 1652. doi: 10.11900/0412.1961.2020.00445

-

期刊类型引用(1)

1. 王祉冰,王剑,张硕. 基于FAD图法的铁路货车车体断裂评估. 轨道交通装备与技术. 2024(05): 21-25 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: