Process optimization on friction stir lap welding of 6061-T6 aluminum alloy/Q235 steel with ultrasonic vibration

-

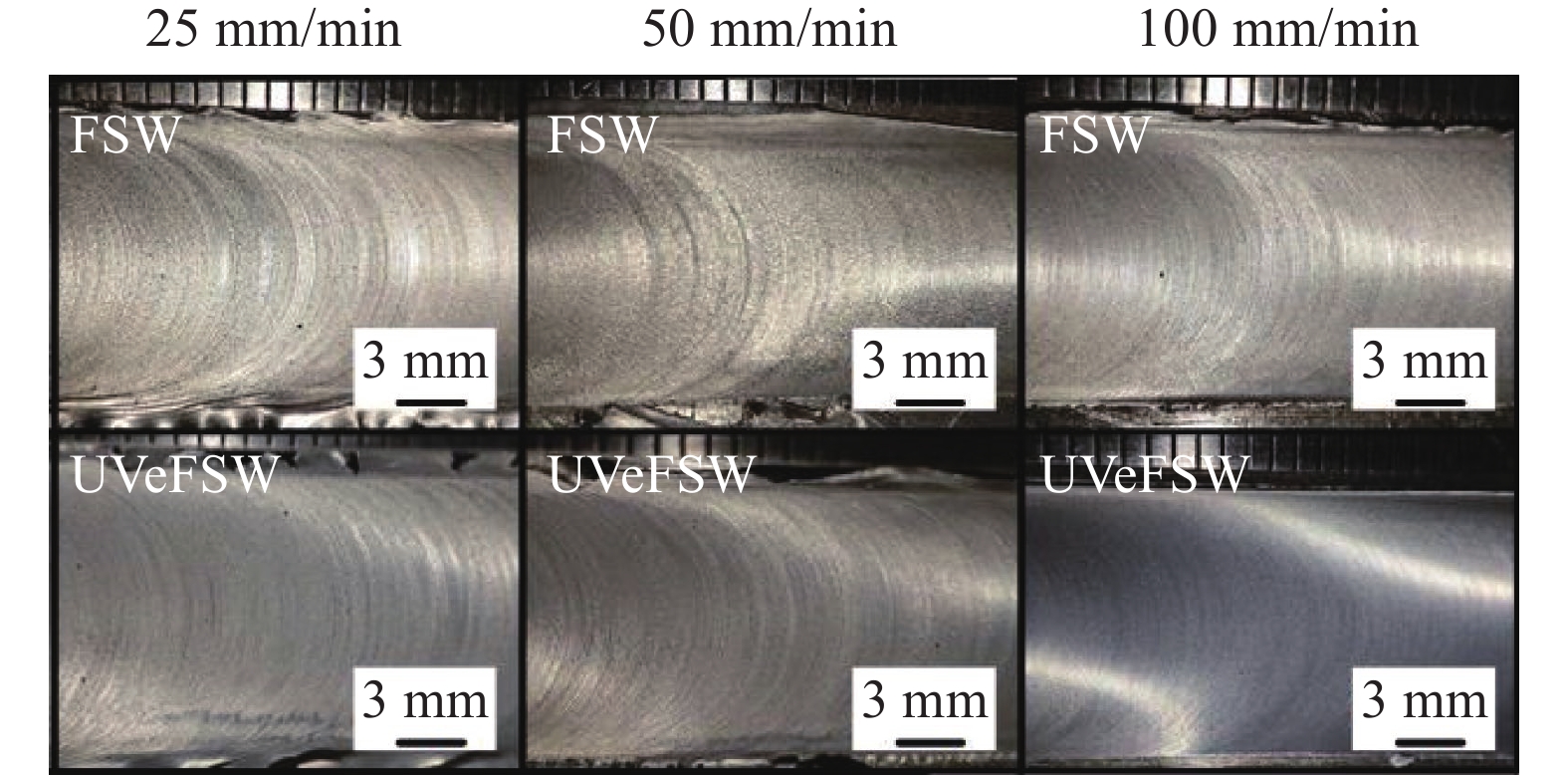

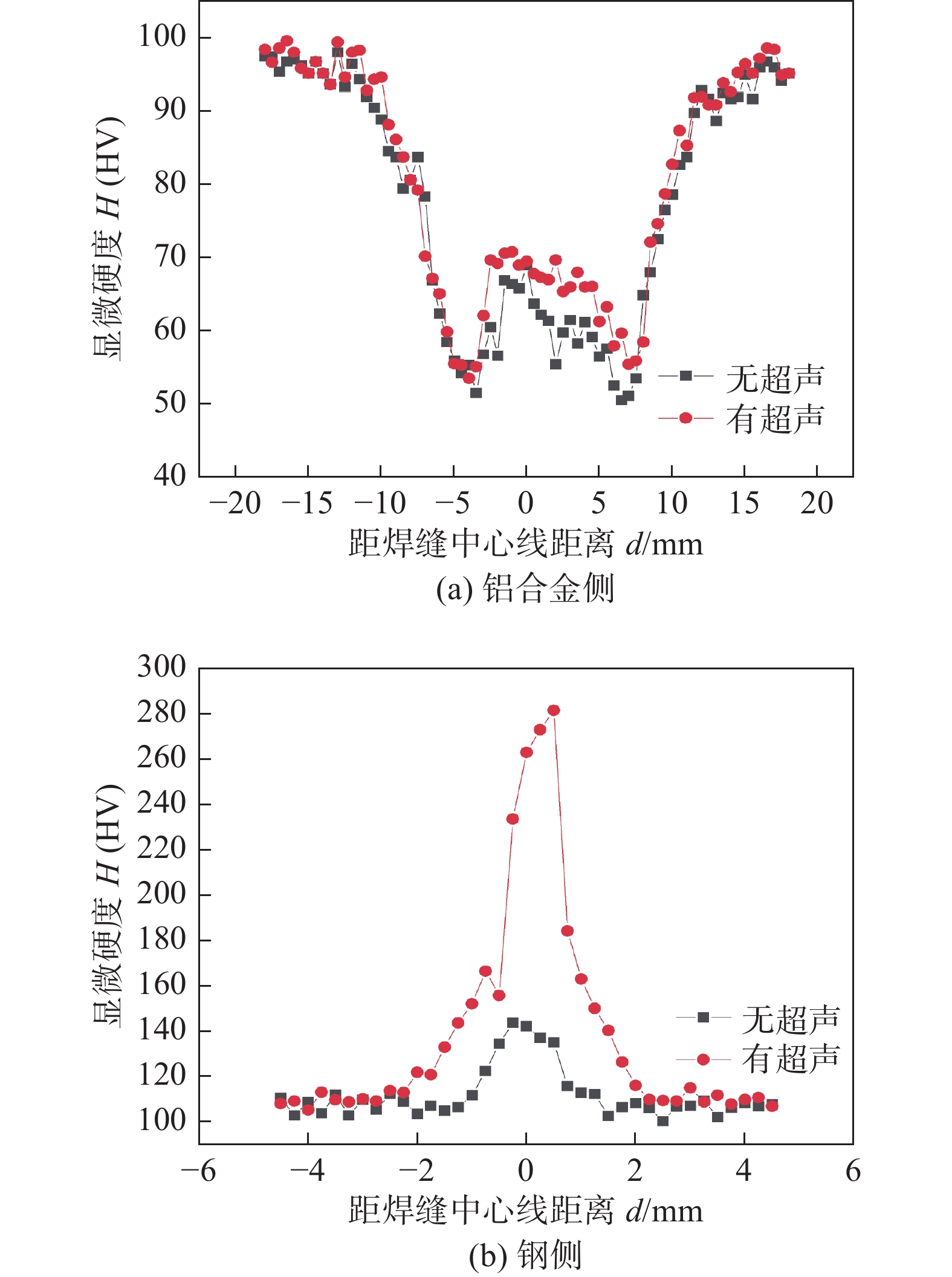

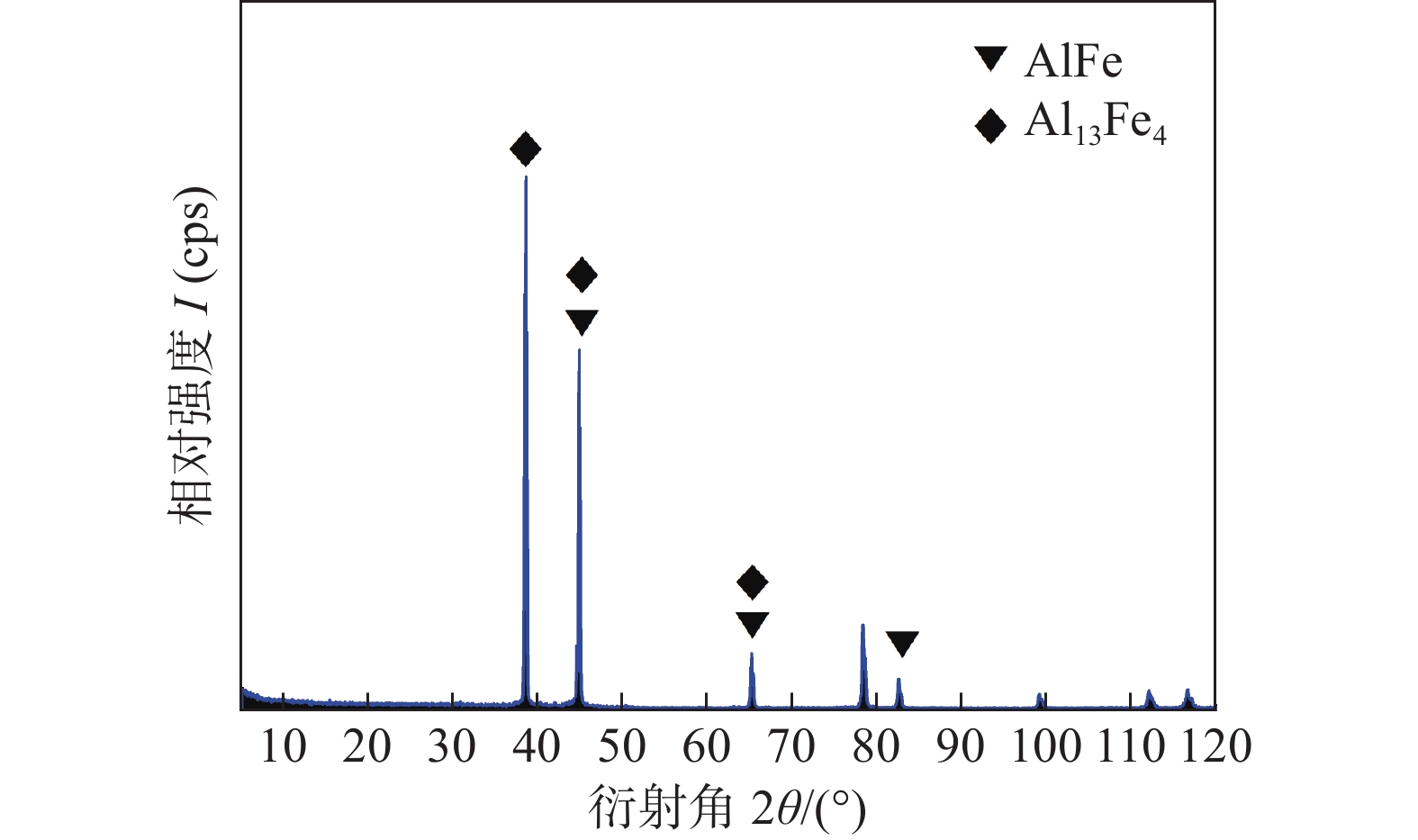

摘要: 采用超声振动强化搅拌摩擦焊接工艺实现了6061-T6铝合金和Q235钢异种金属的有效连接,考察了超声能量对焊缝成形、接头组织、力学性能以及焊接载荷的影响.结果表明,施加超声能量可以显著改善焊缝表面成形,增加铝/钢界面区和焊核区的宽度.超声振动细化了焊核区和热力影响区的晶粒组织,改变了搭接接头的断裂机制和断裂位置,提高了接头的力学性能.对焊接过程中焊接载荷的变化进行分析,发现施加超声能量后搅拌头扭矩、焊接轴向力和主轴输出功率均有所下降.Abstract: The effective connection between 6061-T6 aluminum alloy and Q235 steel was realized by ultrasonic vibration enhanced friction stir welding (UVeFSW) process. The effects of ultrasonic energy on weld formation, joint microstructure, mechanical properties and welding load were investigated. The results show that the application of ultrasonic energy can significantly improve the weld surface forming and expand the width of aluminum / steel interface zone and weld nugget zone. Ultrasonic energy refines the grain structure of weld nugget zone and thermal mechanically affected zone, changes the fracture mechanism and cracking location of lap joint, improves the mechanical properties of joint. The variation of welding loading during welding was analyzed. It is found that the tool torque, the welding axial force and the spindle power decrease after applying ultrasonic energy.

-

-

表 1 6061-T6主要化学成分(质量分数,%)

Table 1 Main chemical compositions of 6061-T6

Cu Mg Si Fe Ti Mn Zn Cr Al 0.15 ~ 0.4 0.8 ~ 1.2 0.4 ~ 0.8 0.7 0.15 0.15 0.25 0.04 ~ 0.35 余量 表 2 Q235主要化学成分(质量分数,%)

Table 2 Main chemical compositions of Q235

C Mn Si P S Fe 0.13 0.37 0.22 0.018 0.012 余量 -

[1] 李岩, 胡志力, , 于海洋, 等. 铝与钢异种材料连接技术及其研究进展[J]. 材料导报, 2020, 34(7): 13167 − 13174. Li Yan, Hu Zhili, Yu Haiyang, et al. Research progress and technology of dissimilar joining between aluminum and steel[J]. Materials Reports, 2020, 34(7): 13167 − 13174.

[2] Mehta K P. A review on friction-based joining of dissimilar aluminum-steel joints[J]. Journal of Materials Research, 2019, 34(1): 78 − 96. doi: 10.1557/jmr.2018.332

[3] Mishra R S, Ma Z Y. Friction stir welding and processing[J]. Materials Science & Engineering R, 2005, 50(1): 1 − 78.

[4] 王希靖, 申志康, 张忠科. 铝和镀锌钢板的搅拌摩擦焊搭接分析[J]. 焊接学报, 2011, 32(12): 97 − 100. Wang Xijing, Shen Zhikang, Zhang Zhongke. Analysis of lap joint between aluminum and galvanized steel plate by friction stir welding[J]. Transactions of the China Welding Institution, 2011, 32(12): 97 − 100.

[5] Safeen M W, Spena P R, Buffa G, et al. Effect of position and force tool control in friction stir welding of dissimilar aluminum-steel lap joints for automotive applications[J]. Advances in Manufacturing, 2020, 8(1): 59 − 71. doi: 10.1007/s40436-019-00290-1

[6] Wan L, Huang Y X. Microstructure and mechanical properties of Al/steel friction stir lap weld[J]. Metals-Open Access Metallurgy Journal, 2017, 7(12): 1 − 14.

[7] Batisto B F, Bergmann L A, Gargarella P, et al. Characterization of dissimilar friction stir welded lap joints of AA5083 and GL D36 steel[J]. Journal of Materials Research and Technology, 2020, 9(6): 15132 − 15142. doi: 10.1016/j.jmrt.2020.10.078

[8] 马潇天, 闫德俊, 孟祥晨, 等. 铝/钢搅拌摩擦焊金属间化合物调控研究进展[J]. 焊接学报, 2020, 41(7): 1 − 11. doi: 10.12073/j.hjxb.20200617001 Ma Xiaotian, Yan Dejun, Meng Xiangchen, et al. Research progress of intermetallic compound control in friction stir welding of aluminum/steel[J]. Transactions of the China Welding Institution, 2020, 41(7): 1 − 11. doi: 10.12073/j.hjxb.20200617001

[9] Thomä M, Wagner G, Straß B, et al. Ultrasound enhanced friction stir welding of aluminum and steel: Process and properties of EN AW 6061/DC04-Joints[J]. Journal of Materials Science & Technology, 2018, 34: 163 − 172.

[10] Hong K R, Wang Y, Zhou J J, et al. Investigation on ultrasonic assisted friction stir welding of aluminum/steel dissimilar alloys[J]. High Temperature Materials and Processes, 2021, 40(1): 45 − 52. doi: 10.1515/htmp-2021-0011

[11] Liu X, Wu C, Padhy G K. Characterization of plastic deformation and material flow in ultrasonic vibration enhanced friction stir welding[J]. Scripta Materialia, 2015, 102: 95 − 98. doi: 10.1016/j.scriptamat.2015.02.022

[12] Liu X C, Wu C S, Padhy G K. Improved weld macrosection, microstructure and mechanical properties of 2024Al-T4 butt joints in ultrasonic vibration enhanced friction stir welding[J]. Science and Technology of Welding and Joining, 2015, 20(4): 345 − 352. doi: 10.1179/1362171815Y.0000000021

[13] Lü X Q, Wu C S, Padhy G K. Diminishing intermetallic compound layer in ultrasonic vibration enhanced friction stir welding of aluminum alloy to magnesium alloy[J]. Materials Letters, 2017, 203: 81 − 84. doi: 10.1016/j.matlet.2017.05.090

[14] 赵俊杰, 宿浩, 石磊, 等. 超声功率对UVeFSW铝-镁合金异质接头组织与性能的影响[J]. 机械工程学报, 2020, 56(6): 24 − 32. doi: 10.3901/JME.2020.06.024 Zhao Junjie, Su Hao, Shi Lei, et al. Effect of exterted ultrasonic power on microstructure and properties of dissimilar Al/Mg alloys UVeFSW joints[J]. Journal of Mechanical Engineering, 2020, 56(6): 24 − 32. doi: 10.3901/JME.2020.06.024

[15] 王国庆, 赵衍华. 铝合金的搅拌摩擦焊接[M]. 北京: 中国宇航出版社, 2010. Wang Guoqing, Zhao Yanhua. Friction stir welding process of aluminum alloy[M]. Beijing: China Aerospace Press, 2010.

[16] Padhy G K, Wu C S, Gao S. Subgrain formation in ultrasonic enhanced friction stir welding of aluminium alloy[J]. Materials Letters, 2016, 183(15): 34 − 39.

[17] Padhy G K, Wu C S, Gao S. Precursor ultrasonic effect on grain structure development of AA6061-T6 friction stir weld[J]. Materials & Design, 2016, 116: 207 − 218.

[18] Hu Y Y, Liu H J, Fujii H, et al. Vacancy-induced θ′ precipitation during ultrasonic-affected friction stir welding of Al–Cu alloy[J]. Journal of Materials Science, 2020, 55(54): 14626 − 14641.

-

期刊类型引用(1)

1. 王晨,雷正龙,宋文清,杨烁,李旭东. CoCrW与T800焊丝对DZ125高温合金表面激光熔覆耐磨层组织及性能的影响. 中国激光. 2025(04): 101-109 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: