Defecting monitored of friction stir welding based on acoustic emission multi-feature fusion

-

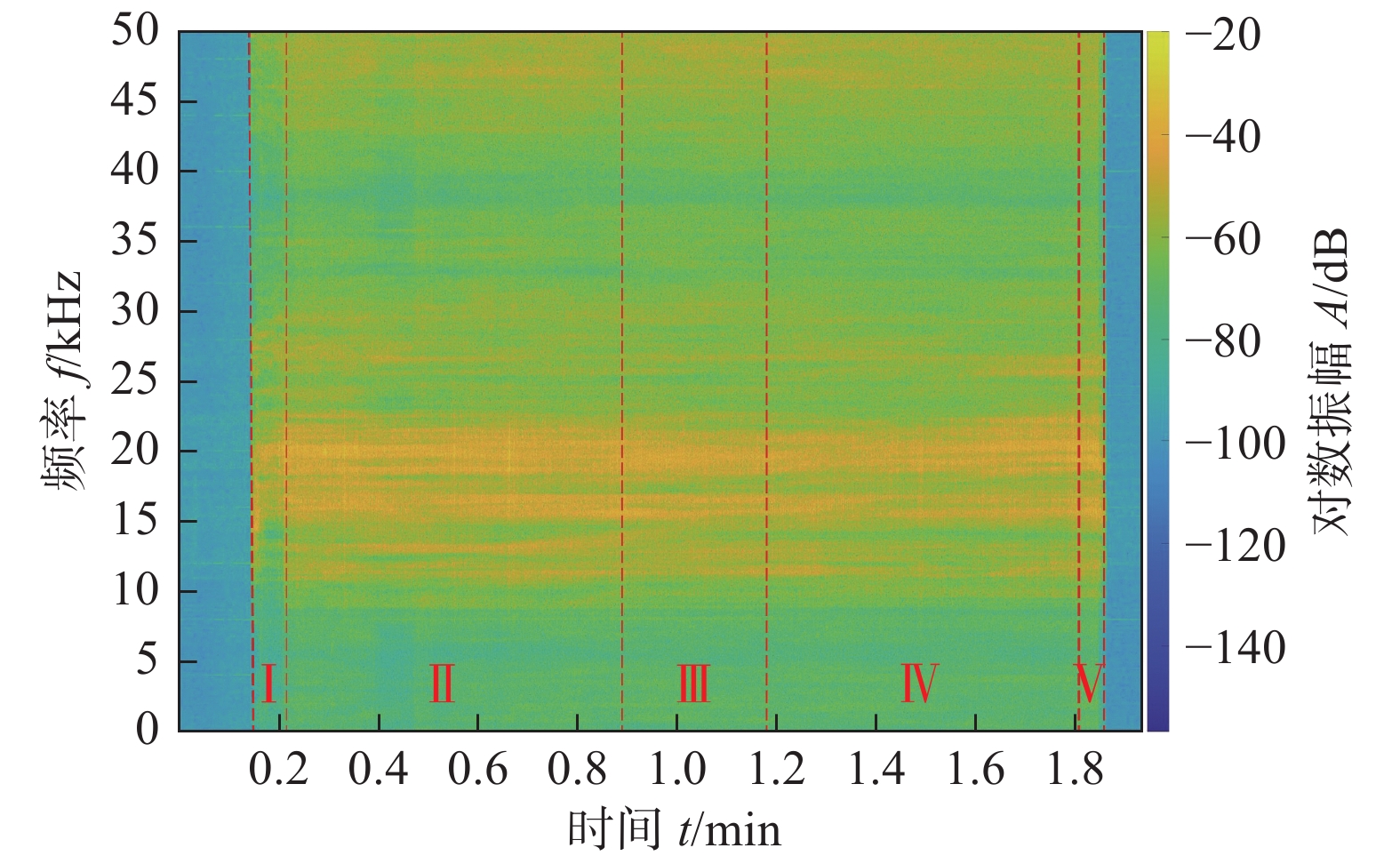

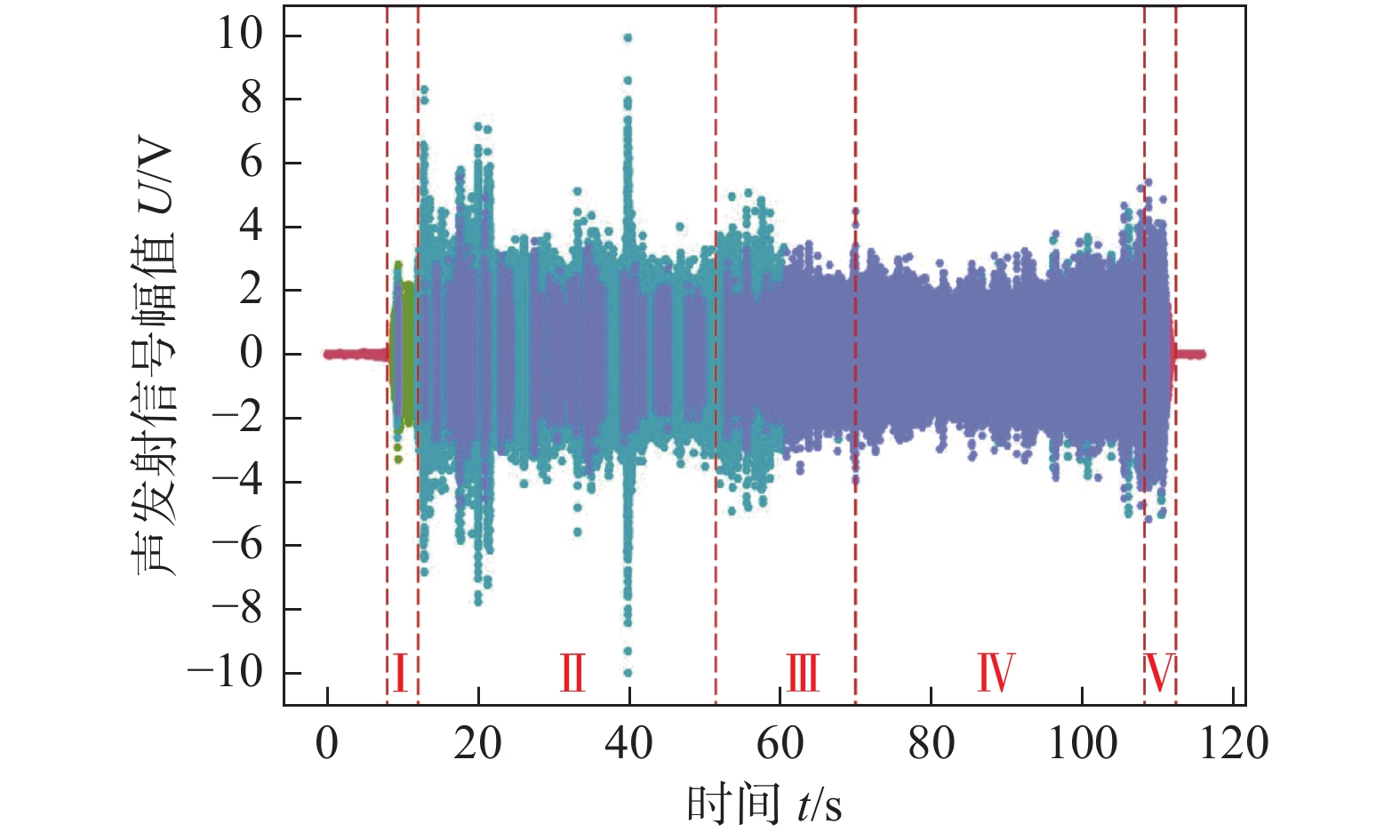

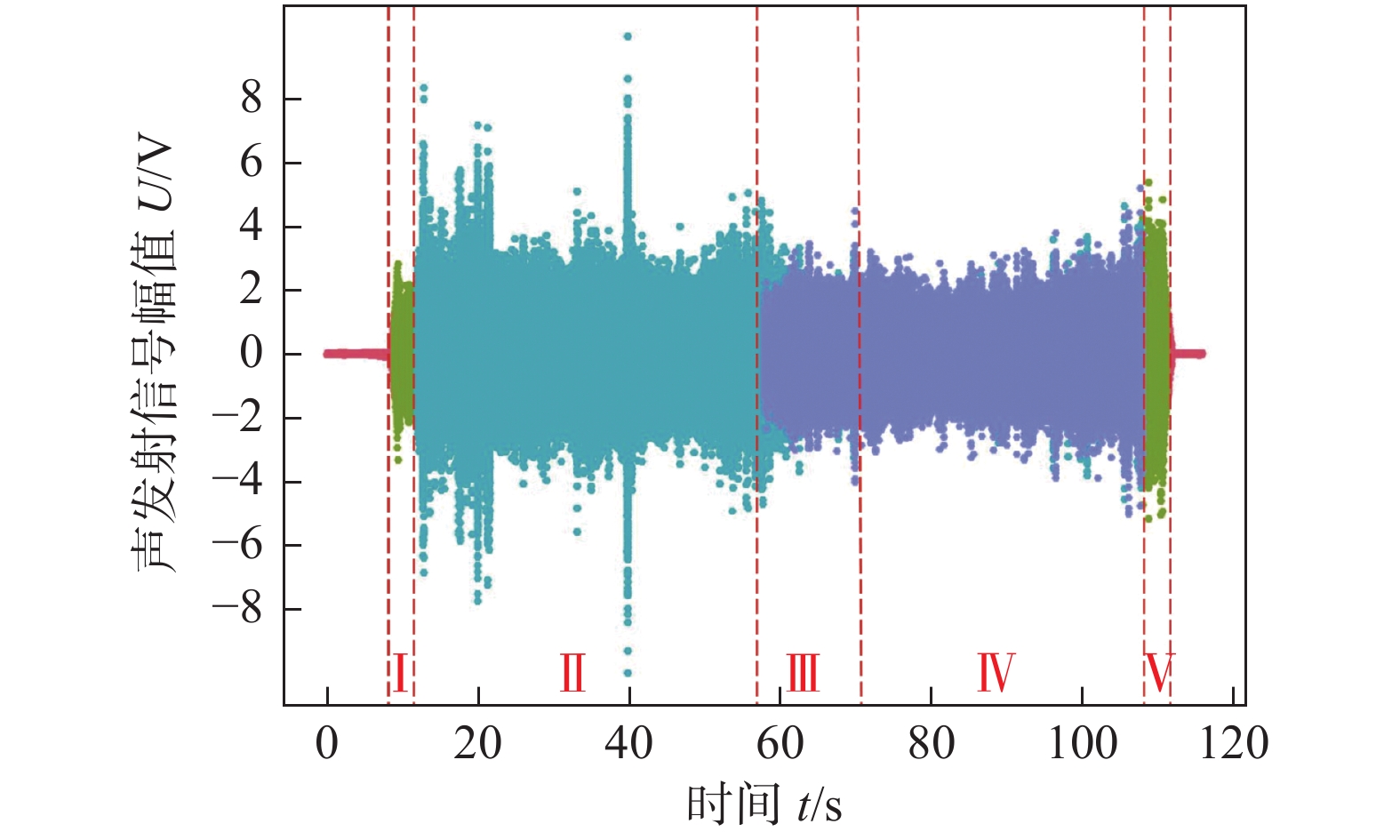

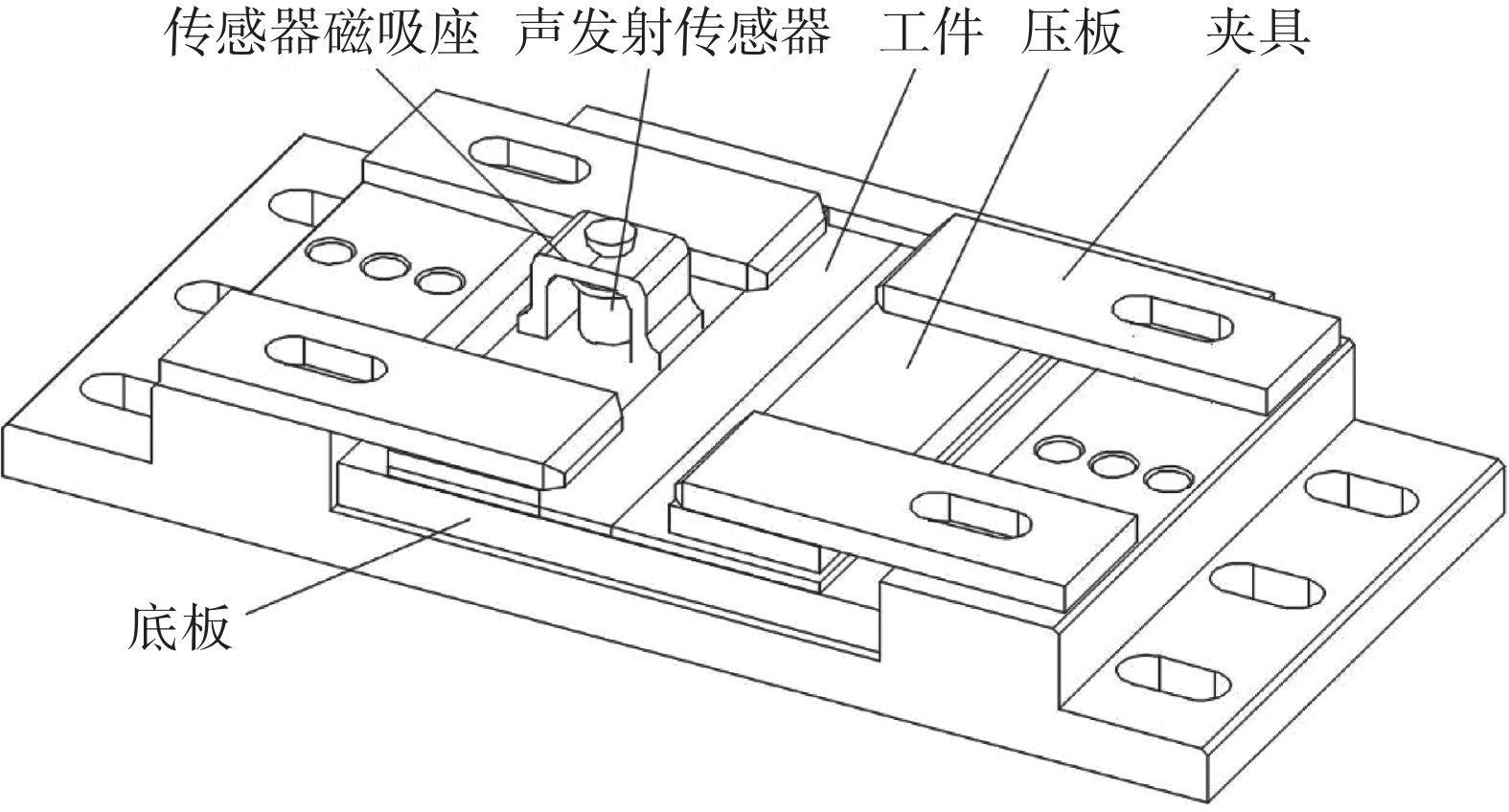

摘要: 搅拌摩擦焊(friction stir welding, FSW)是一个多物理场耦合过程,焊接过程中声发射信号与焊接缺陷具有关联性. 基于声发射检测与多特征融合研究FSW缺陷监测方法,实时检测固态介质中的声发射信号,利用短时傅里叶变换、小波变换、梅尔频谱对声发射信号进行分析,确定焊接缺陷与声发射信号之间的相关性,最后通过concat融合方法构建多特征向量. 结果表明,FSW在预制缺陷处具有不同的声发射信号特征. 短时傅里叶、小波变换的主要频段集中在20 kHz,出现缺陷时功率分别达到−40,0.8 dB以上,梅尔频谱的主要频段集中在3.5 kHz出现缺陷时功率达到−40 dB以上. 应用多层神经网络分别建立基于单特征、多特征向量的焊接缺陷识别模型,多特征向量的焊接缺陷识别模型在数据集中的平均识别率达到97%,比基于单一特征缺陷识别模型提高18%. 研究的多特征缺陷识别模型能更准确地对焊接状态进行识别与监测.Abstract: Friction stir welding (FSW) is a multi-physical field coupling process. The acoustic emission signal in the welding process is directly related to the welding defects. Based on acoustic emission detection and multi-feature fusion, the defecting monitored of FSW method is studied. Experiments of prefabricated defect FSW are carried out. The acoustic emission signal in the solid medium is detected in real time, and analyzed by short-time fourier transform, wavelet transform and Mel spectrum which explore the correlation between welding defects and acoustic emission signal. Finally, multi-feature vectors are constructed by the concat fusion method. It is indicated that FSW has different acoustic emission signal characteristics at the prefabricated defects. Short-time fourier and wavelet time-frequency analysis shows that the frequency of acoustic emission signal is concentrated in 20 kHz and the power at prefabricated defects is more than −40 and 0.8 dB respectively. Mel time-frequency analysis shows that the frequency of acoustic emission signal is mainly concentrated in 3.5 kHz and the power is more than −40 dB at prefabricated defects. The multi-layer neural network is applied to establish the welding defect recognition model based on single feature and multi-feature vector respectively. The average recognition accuracy of the multi-feature welding defect recognition model is 97% in the dataset, which is 18% higher than the single-feature defect recognition model. The multi-feature welding defect recognition model can more accurately recognize and monitor the welding state.

-

-

表 1 FSW焊接工艺参数

Table 1 FSW process parameters

针头下压量

h/mm焊接速度

v/(mm·min−1)搅拌头转速

n/(r·min−1)2.3 60 1 600 表 2 单特征与多特征识别模型准确率(%)

Table 2 Accuracy of single feature and multi feature recognition models

识别模型 试验数据1 试验数据2 试验数据3 短时傅里叶变换 75.60 67.35 76.65 梅尔频谱 80.61 76.34 70.12 小波变换 69.91 77.89 74.02 多特征识别模型 97.06 96.45 97.37 表 3 单特征与多特征识别模型准确率(%)

Table 3 Accuracy of single feature and multi feature recognition model

识别模型 试验数据4 试验数据5 短时傅里叶变换 47.61 55.24 梅尔频谱 34.43 48.37 小波变换 65.12 63.75 多特征识别模型 87.39 85.81 -

[1] Thomas W M, Nicholas E D, Needham J C, et al. Friction stir butt welding: International patent application No. PCT/GB92/02203 [P]. 1991–12–08.

[2] 秦丰, 周军, 侯振国, 等. 6082铝合金双面搅拌摩擦焊接头组织与性能[J]. 焊接学报, 2021, 42(2): 75 − 80. doi: 10.12073/j.hjxb.20201231001 Qin Feng, Zhou Jun, Hou Zhenguo, et al. Microstructure and properties of double-sided friction stir welded joints of 6082 aluminum alloy[J]. Transactions of the China Welding Institution, 2021, 42(2): 75 − 80. doi: 10.12073/j.hjxb.20201231001

[3] 张聃, 夏佩云, 崔凡, 等. 6061-T6铝合金微搅拌摩擦焊工艺[J]. 焊接学报, 2019, 40(3): 102 − 106. doi: 10.12073/j.hjxb.2019400080 Zhang Dan, Xia Peiyun, Cui Fan, et al. Micro friction stir welding process of 6061-T6 aluminum alloy[J]. Transactions of the China Welding Institution, 2019, 40(3): 102 − 106. doi: 10.12073/j.hjxb.2019400080

[4] 刘伟, 熊江涛, 赵华夏, 等. 铝合金薄板搅拌摩擦焊搭接界面缺陷与接头性能[J]. 焊接学报, 2018, 39(10): 11 − 15. Liu Wei, Xiong Jiangtao, Zhao Huaxia, et al. Interfacial defects, and joint properties of friction stir welding of aluminum alloy sheets[J]. Transactions of the China Welding Institution, 2018, 39(10): 11 − 15.

[5] Dmitriev A, Polyakov V, Kolubaev E A. Diagnostics of aluminum alloys with friction stir welded joints based on multivariate analysis of acoustic emission signals[J]. Journal of Physics: Conference Series, 2020, 1615: 012003. doi: 10.1088/1742-6596/1615/1/012003

[6] Gaja H, Liou F. Defect classification of laser metal deposition using logistic regression and artificial neural networks for pattern recognition[J]. International Journal Advanced Manufacturing Technology, 2018, 94: 315 − 326. doi: 10.1007/s00170-017-0878-9

[7] Nasir V, Kooshkbaghi M, Cool J. et al. Cutting tool temperature monitoring in circular sawing: measurement and multi-sensor feature fusion-based prediction[J]. International Journal Advanced Manufacturing Technology, 2021, 112: 2413 − 2424. doi: 10.1007/s00170-020-06473-6

[8] He Zhaopeng, Shi Tielin. Multi-sensor fusion technology and machine learning methods for milling tool wear prediction[J]. Advances in Intelligent Automation and Soft Computing, 2021, 80: 602 − 610.

[9] 徐彦伟, 刘明明, 刘洋, 等. 基于信息融合的机器人薄壁轴承故障智能诊断[J]. 光学精密工程, 2019, 27(7): 1577 − 1592. doi: 10.3788/OPE.20192707.1577 Xu Yanwei, Liu Mingming, Liu Yang, et al. Intelligent fault diagnosis of thin wall bearing based on information fusion[J]. Optics Precision Engineering, 2019, 27(7): 1577 − 1592. doi: 10.3788/OPE.20192707.1577

[10] 高向东, 李国华, 萧振林, 等. 焊接缺陷的磁光成像小波多尺度识别及分类[J]. 光学精密工程, 2016, 24(4): 930 − 936. doi: 10.3788/OPE.20162404.0930 Gao Xiangdong, Li Guohua, Xiao Zhenlin, et al. Detection and classification of welded defects by magneto-optical imaging based on multi-scale wavelet[J]. Optics and Precision Engineering, 2016, 24(4): 930 − 936. doi: 10.3788/OPE.20162404.0930

[11] 叶赵伟, 左敦稳, 左立生. 基于多传感器技术的搅拌摩擦焊在线监测系统开发[J]. 机床与液压, 2019, 47(1): 61 − 65. doi: 10.3969/j.issn.1001-3881.2019.01.015 Ye Zhaowei, Zuo Dunwen, Zuo Lisheng. Development of on-line detection system for friction stir welding based on multi-sensor technology[J]. Machine Tool and Hydraulics, 2019, 47(1): 61 − 65. doi: 10.3969/j.issn.1001-3881.2019.01.015

[12] 胡怀辉. 基于超声TOFD的搅拌摩擦焊近表面缺陷识别与检测信号特征研究[D]. 南昌: 南昌航空大学, 2014. Hu Huaihui. Study of signal characteristic and near surface defect recognition of friction stir welding based on ultrasonic TOFD technology[D]. Nanchang: Nanchang Hangkong University, 2014.

[13] Rajaprakash B M, Suresha C N, Upadhya S. Application of acoustic emission as an effective tool to monitor FSW of AA2024-T3 aluminum alloy: Friction stir welding and processing VIII[J]. Springer, Cham, 2021, 80: 241 − 249.

[14] 徐蒋明, 柯黎明. 搅拌摩擦焊焊缝缺陷超声检测信号特征分析与神经网络模式识别[J]. 核动力工程, 2020, 41(1): 163 − 166. Xu Jiangming, Ke Liming. Characteristic extraction based on wavelet packet and pattern recognition for ultrasonic inspection signals from defects in FSW joints using artificial neural network[J]. Nuclear Power Engineering, 2020, 41(1): 163 − 166.

-

期刊类型引用(12)

1. 牛宗冉,莫文剑,袁志钟,易翠,王致远. 铜磷锡镍粉末钎料的钎焊性能和显微组织. 粉末冶金工业. 2025(01): 31-37 .  百度学术

百度学术

2. 钟素娟,秦建,王蒙,崔大田,龙伟民. CuSn预合金粉芯复合银钎料的润湿铺展机理. 焊接学报. 2023(02): 16-21+129-130 .  本站查看

本站查看

3. 郭亚东,陈明亮. 黄铜Type-C接口绿激光焊接工艺研究. 热加工工艺. 2022(09): 148-150 .  百度学术

百度学术

4. 张冠星,钟素娟,董媛媛,刘晓芳,常云峰,薛行雁. 焊后钎剂残渣腐蚀行为分析. 焊接. 2022(11): 47-53 .  百度学术

百度学术

5. 王蒙,张冠星,钟素娟,沈元勋,龙伟民,董宏伟,刘晓芳. 低熔合金粉末对药芯银钎料钎焊过程的影响. 稀有金属材料与工程. 2021(08): 2859-2866 .  百度学术

百度学术

6. 刘捷,黄建林,任刚,黄映杰. 黄铜-钢异种金属激光熔覆技术研究及应用. 江西科学. 2021(06): 1077-1079 .  百度学术

百度学术

7. 刘晓芳,张冠星,常云峰,王蒙,钟素娟. 干燥过滤器焊后泄露原因. 焊接. 2021(10): 34-37+62-63 .  百度学术

百度学术

8. 李华晨,周广涛,陈梅峰,刘雪松,崔贺鹏,杨浩. 分步气体介质下低功率激光焊接薄板紫铜成形及组织和性能. 焊接学报. 2020(10): 65-72+101 .  本站查看

本站查看

9. 王毅. 黄铜与铝合金纳秒激光焊接的工艺研究. 材料保护. 2020(12): 91-94+105 .  百度学术

百度学术

10. 张敏霞,潘光勇,鲍熠朗. 空调四通阀焊缝泄漏原因分析. 理化检验(物理分册). 2019(12): 859-863 .  百度学术

百度学术

11. 于奇,潘建军,于新泉,纠永涛,鲍丽. 微量硅元素对铜磷锡粉状钎料性能的影响. 焊接. 2019(10): 17-20+66 .  百度学术

百度学术

12. 刘文东,李红. 黄铜与不锈钢异种金属激光焊接工艺研究. 应用激光. 2019(06): 966-969 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: