Analysis of weld forming in magnetically controlled Plasma-FCAW underwater hybrid welding process

-

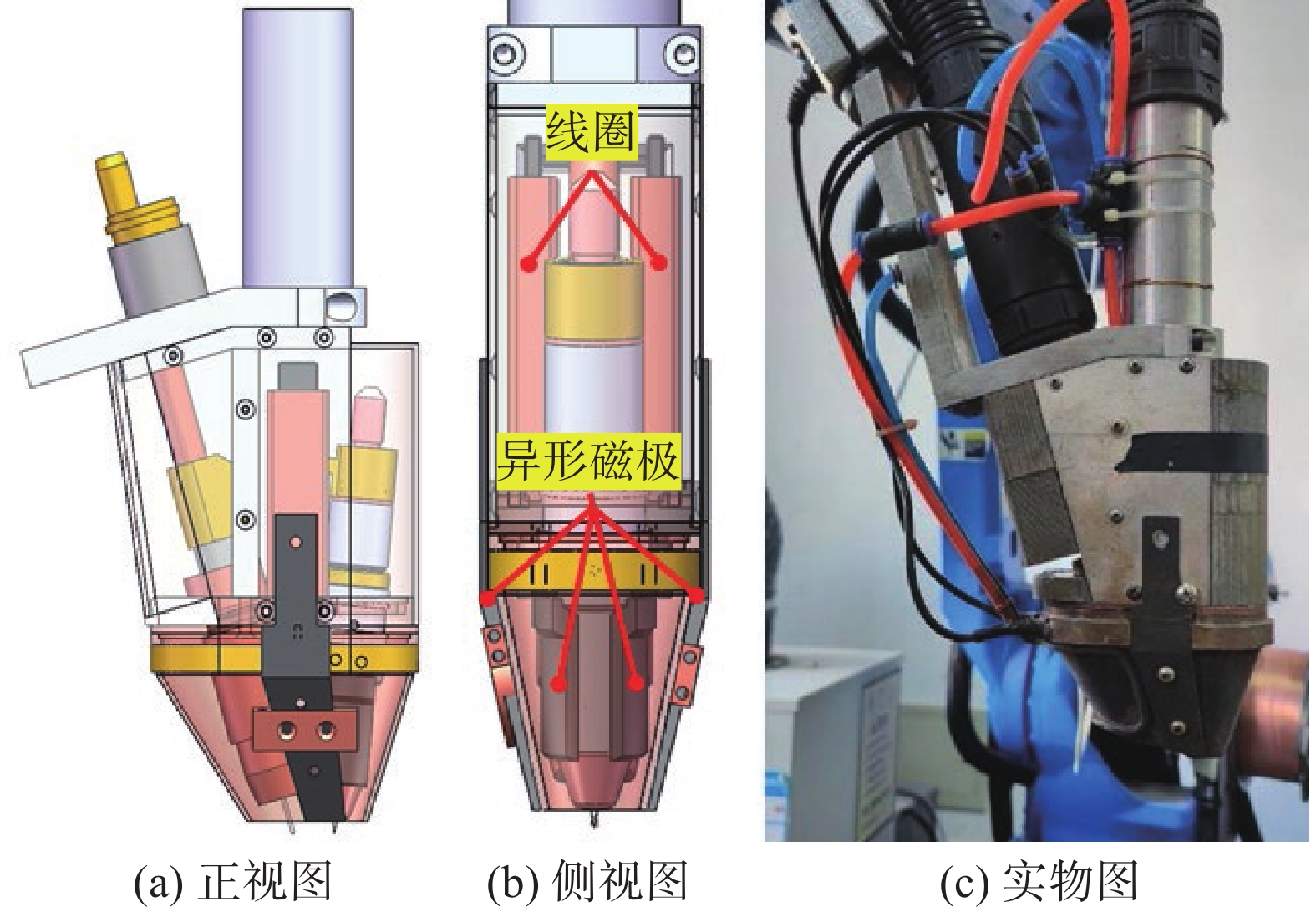

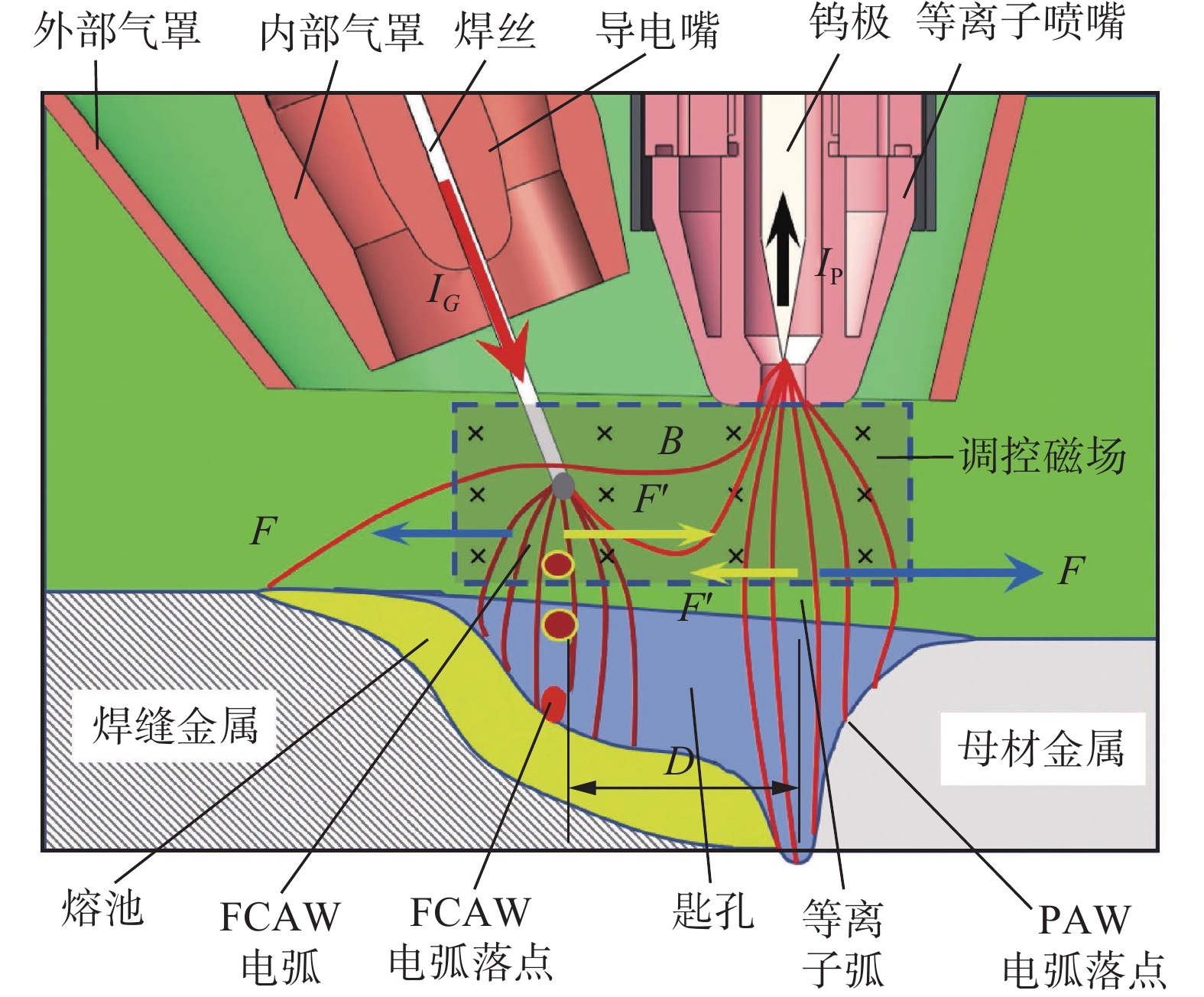

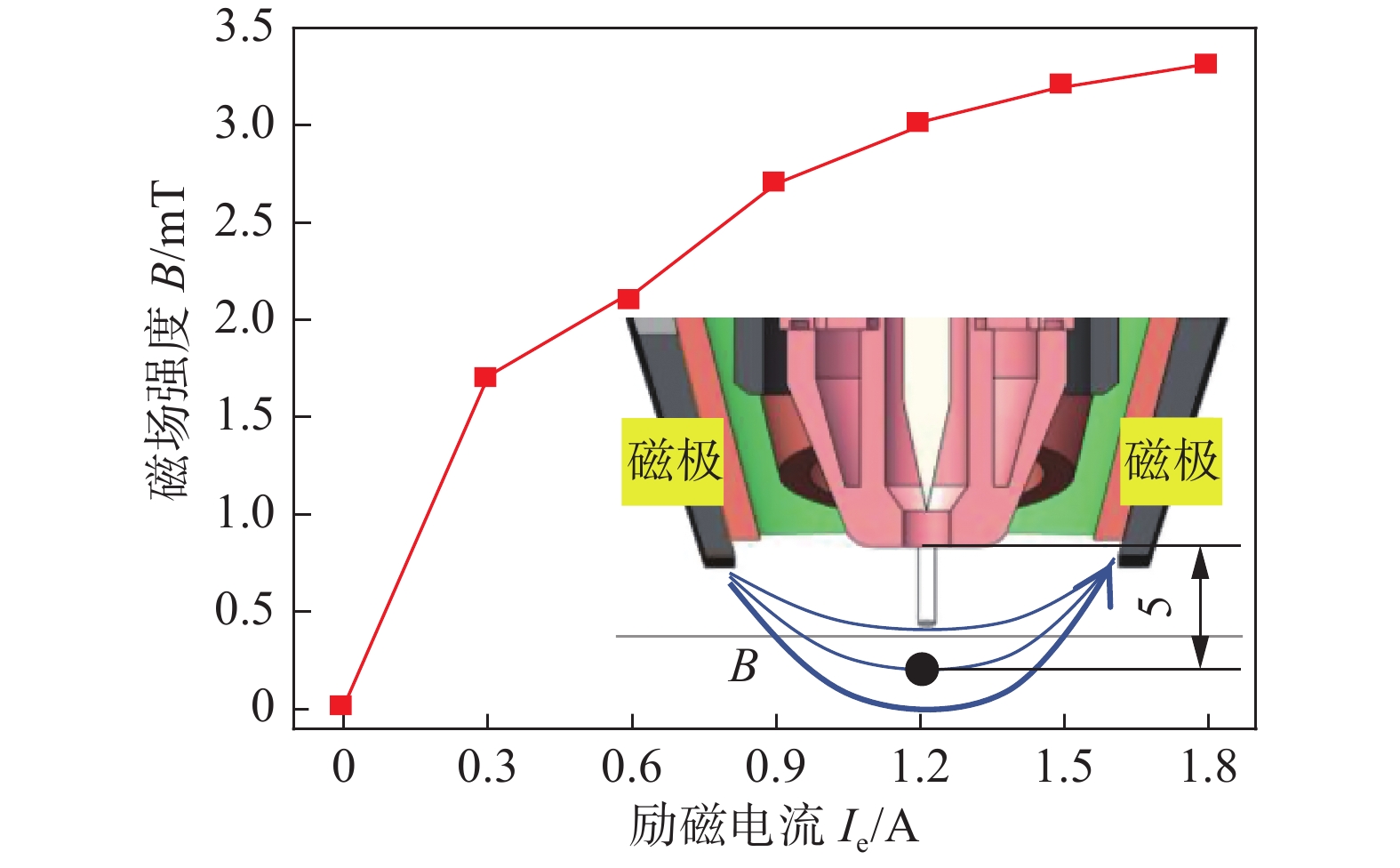

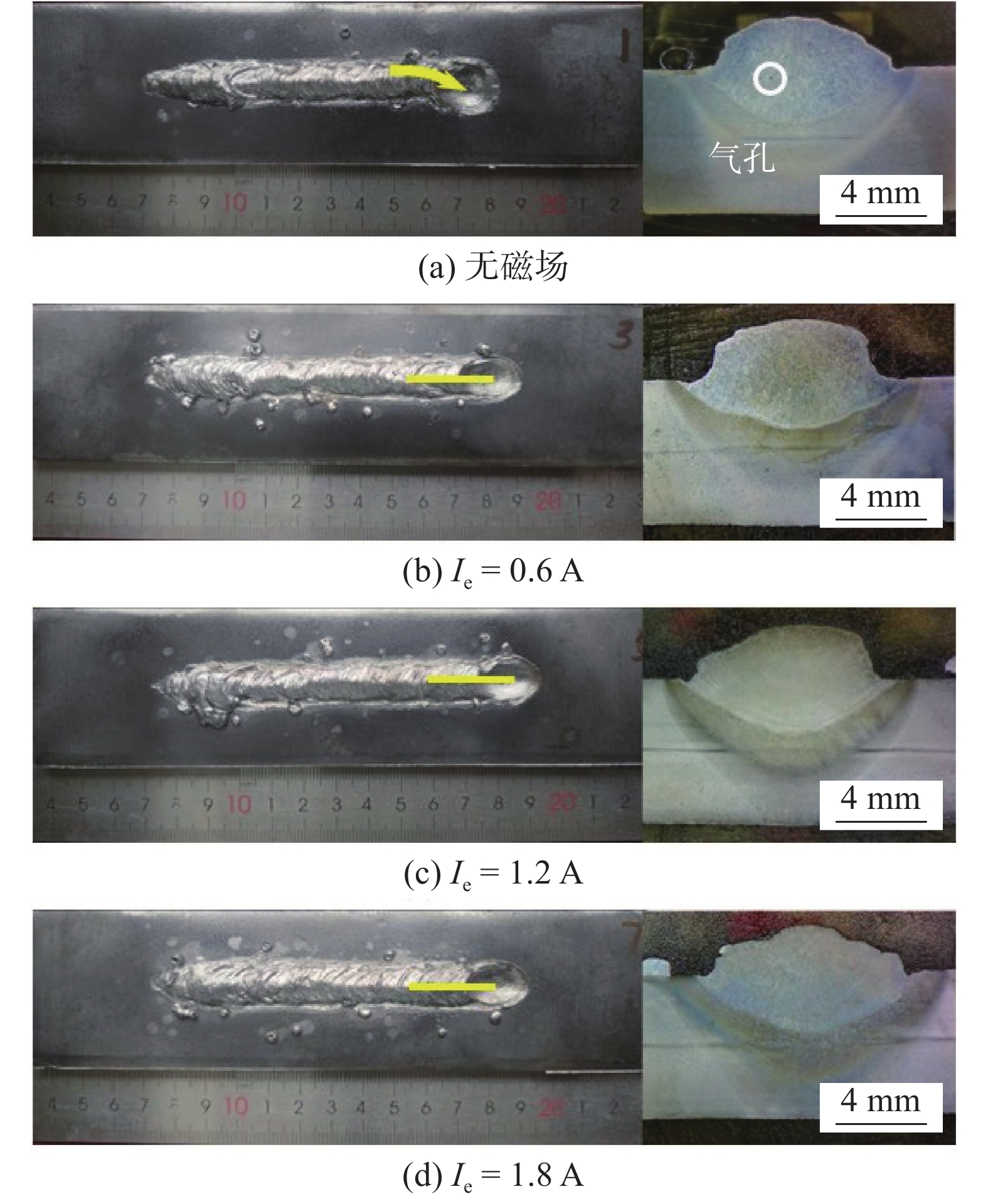

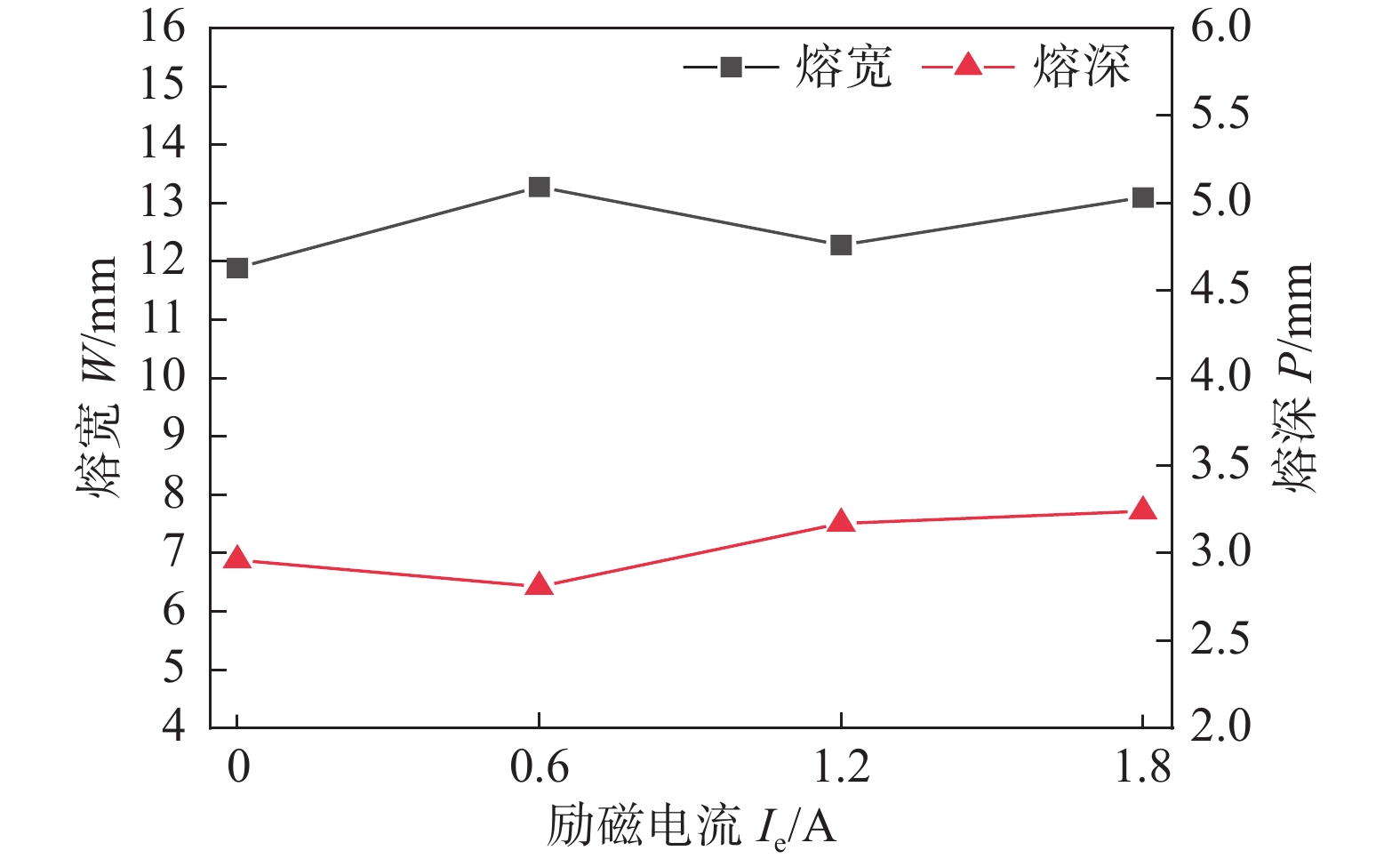

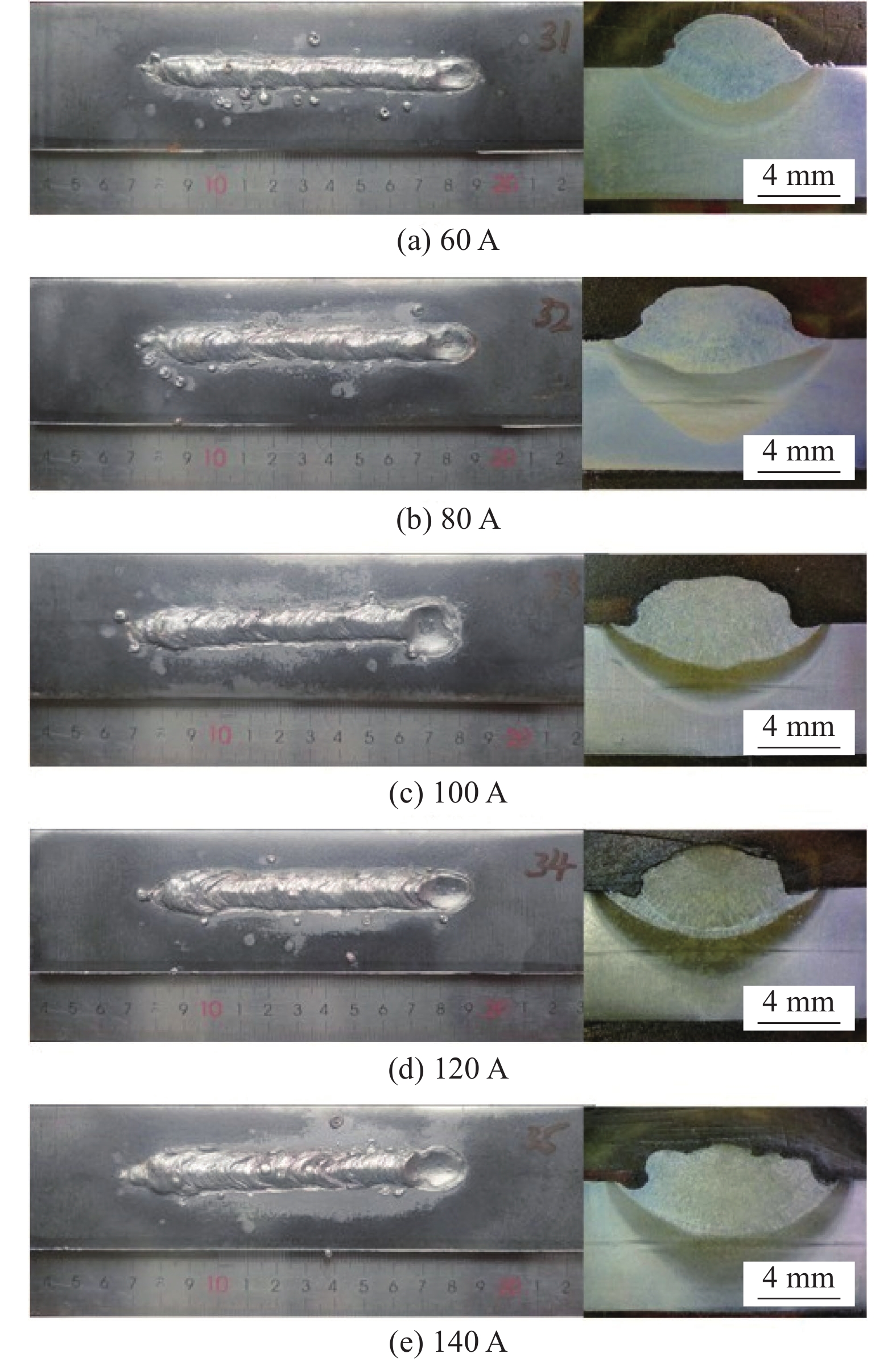

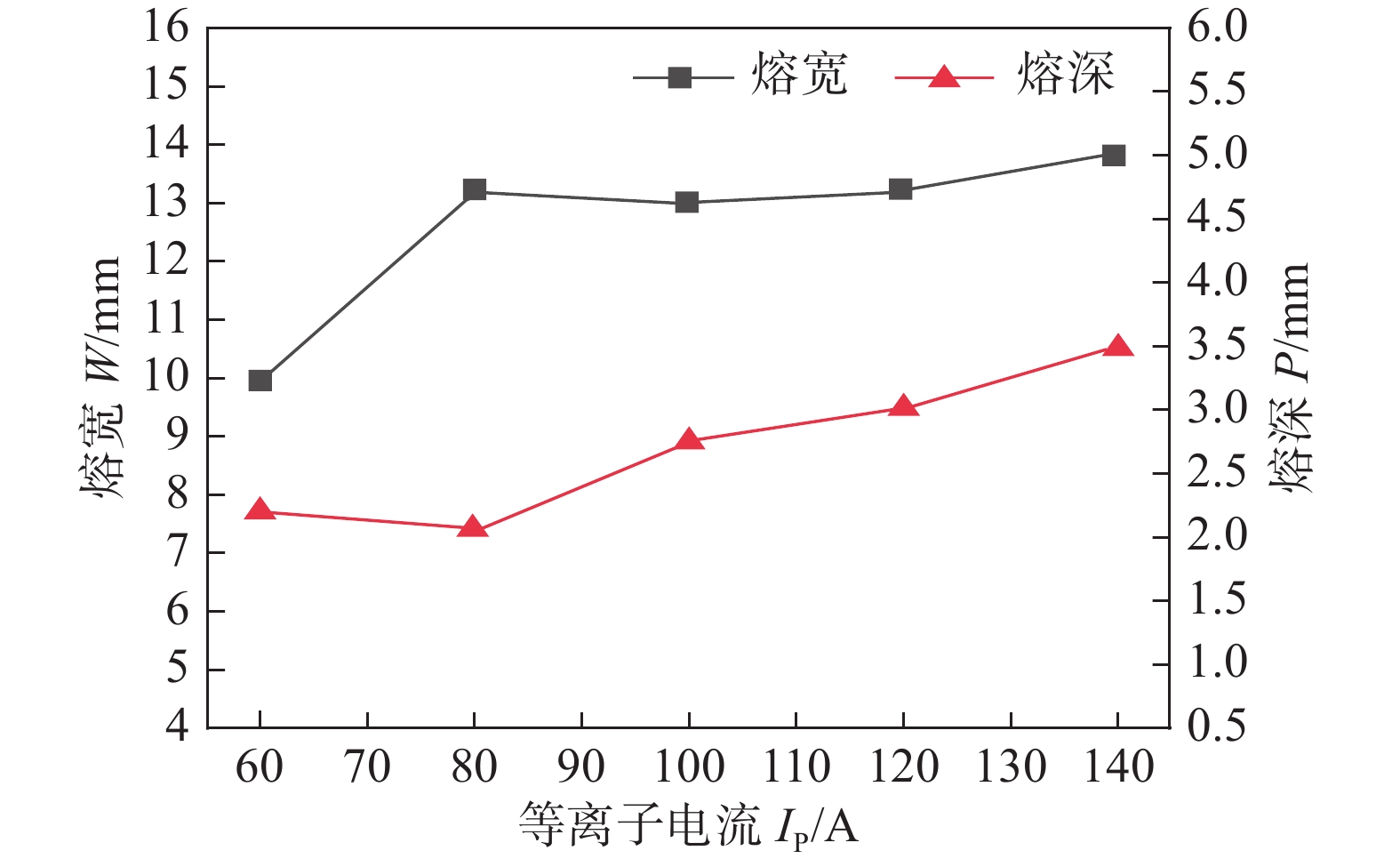

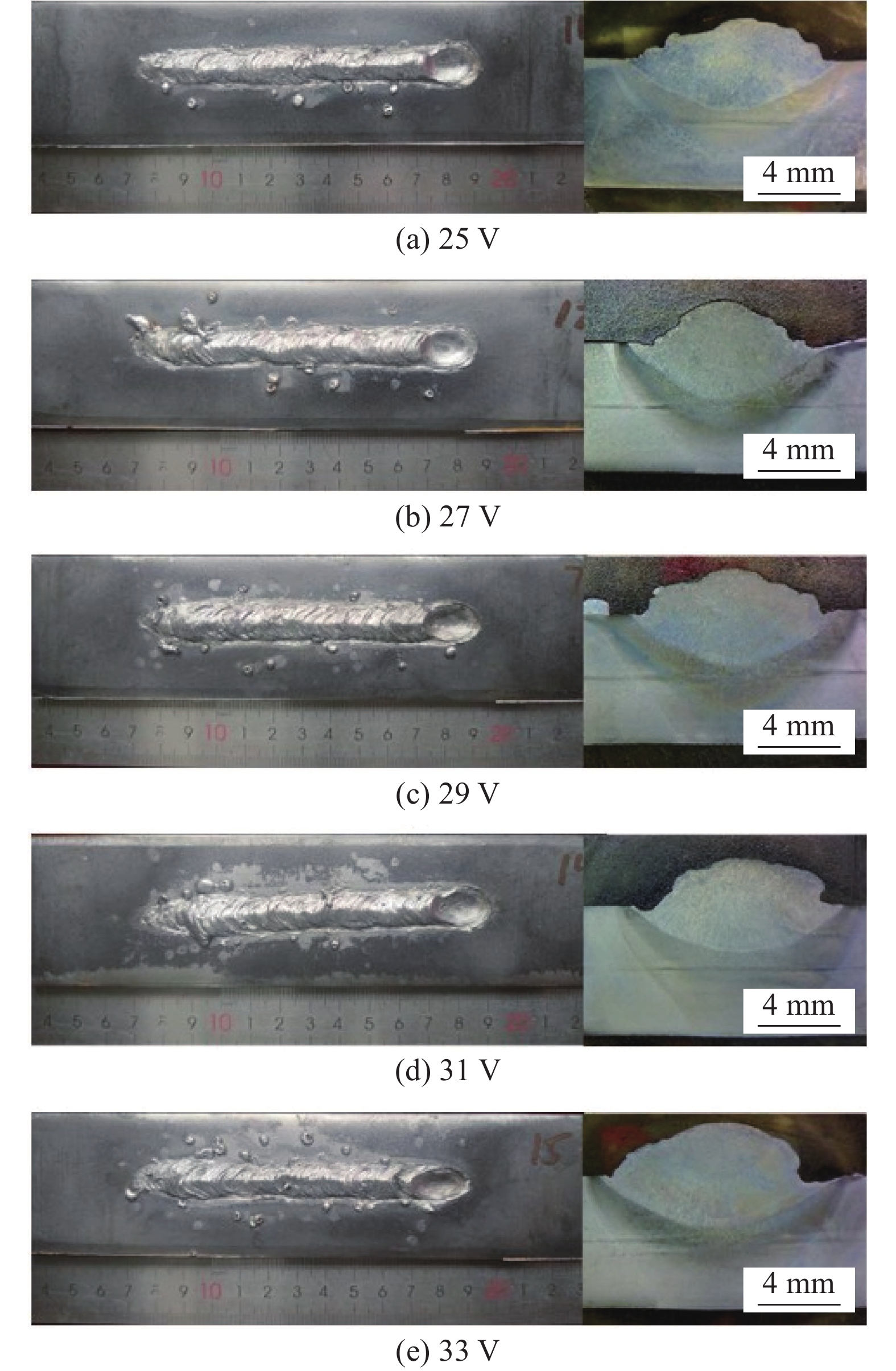

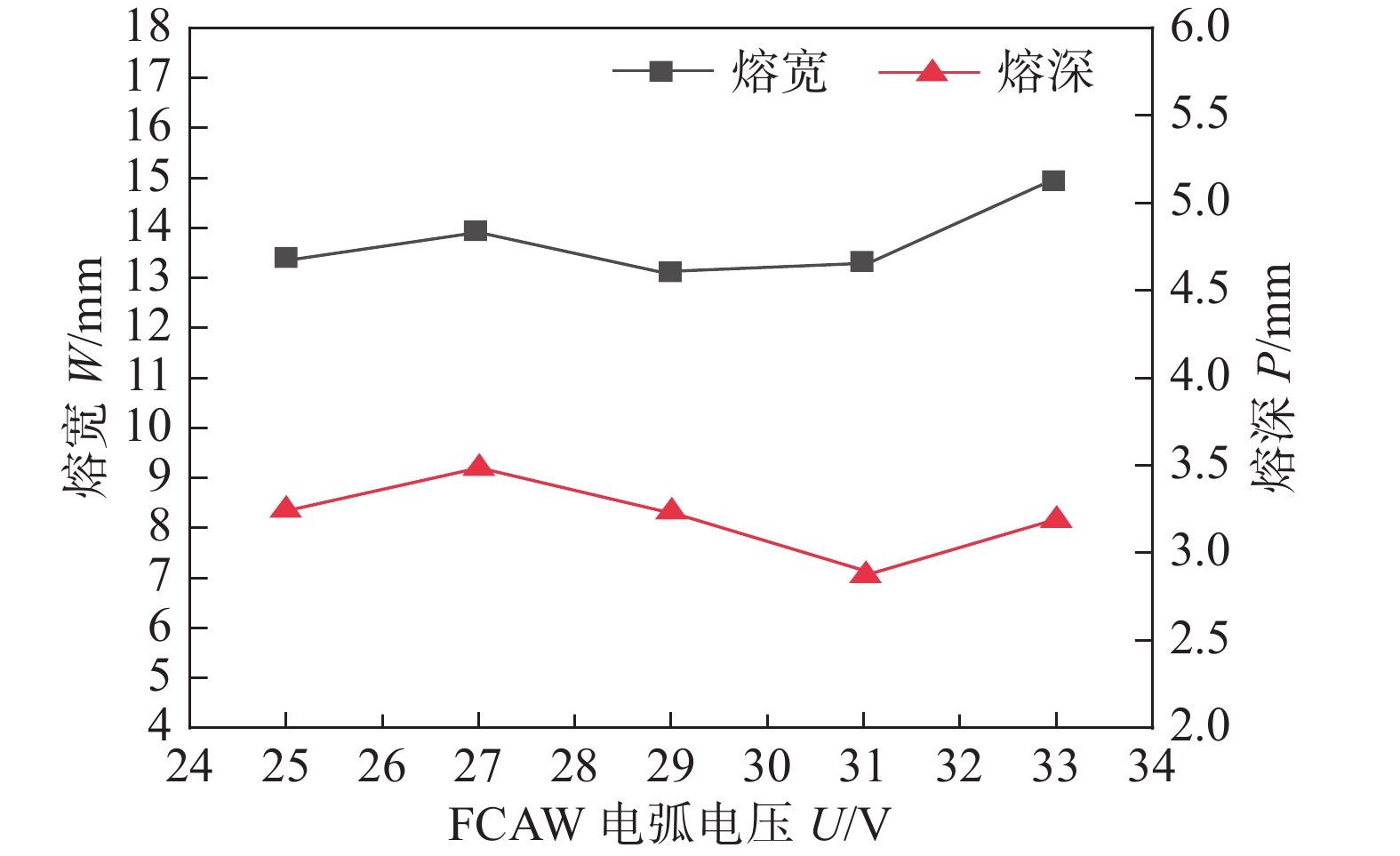

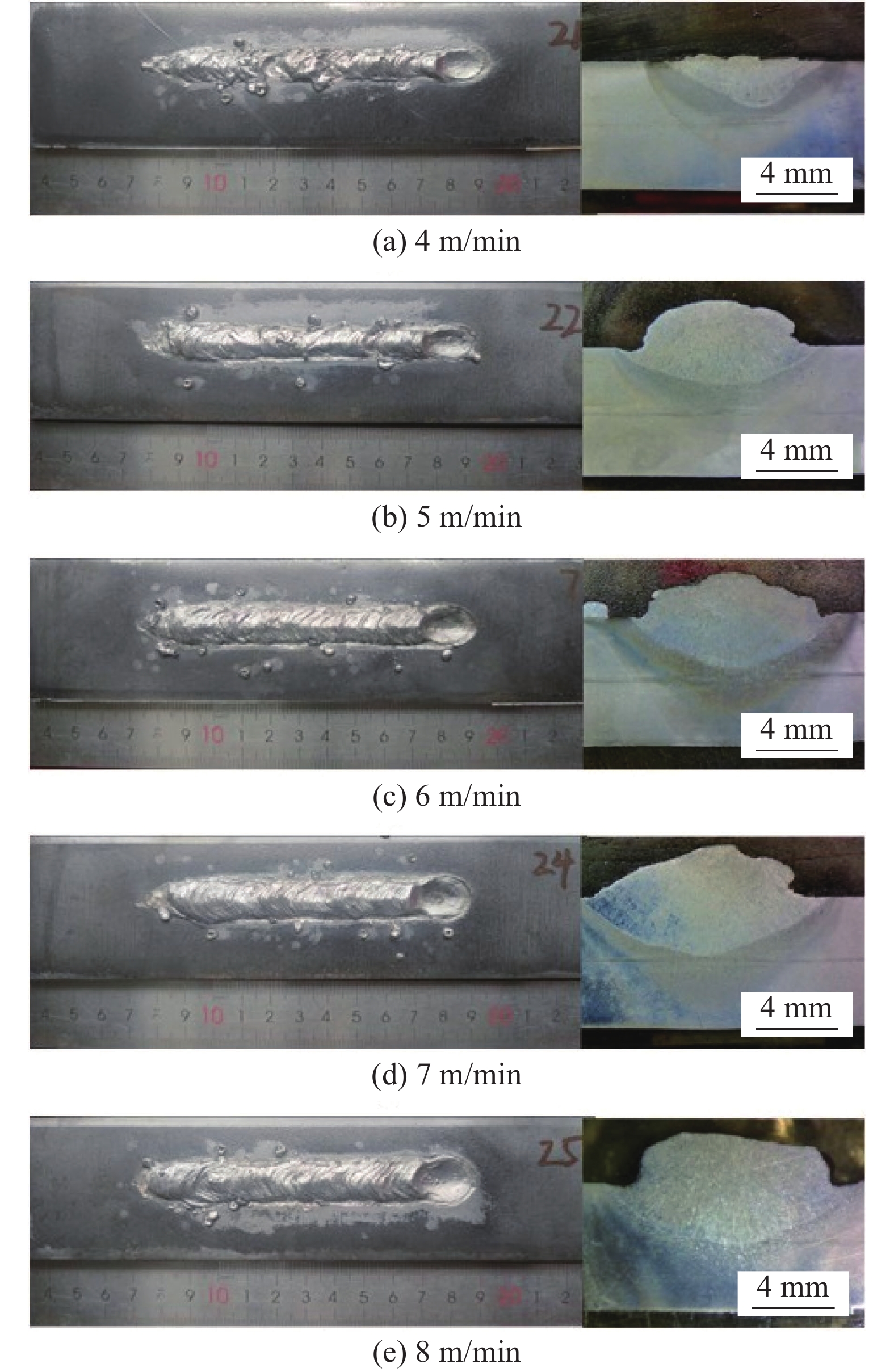

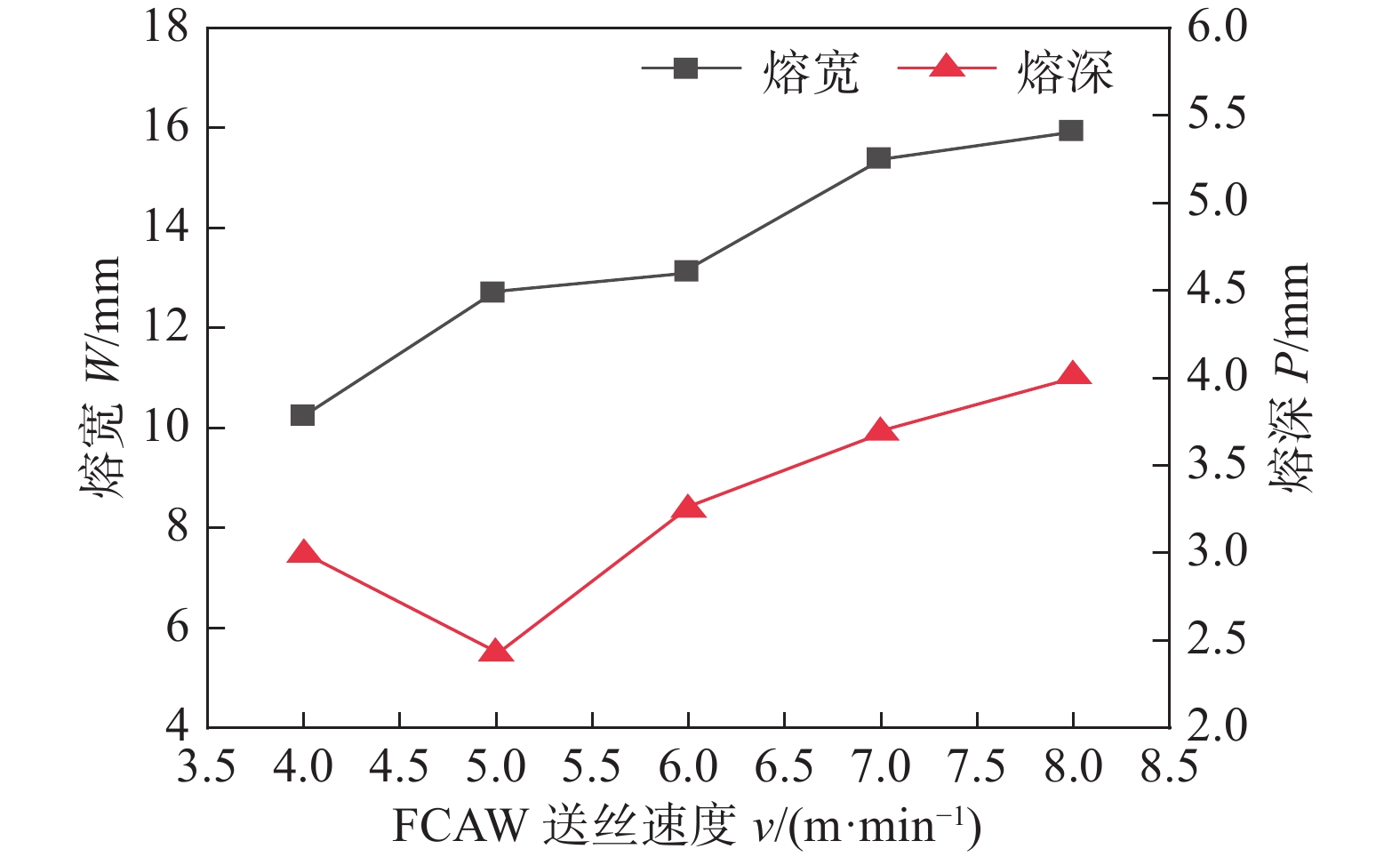

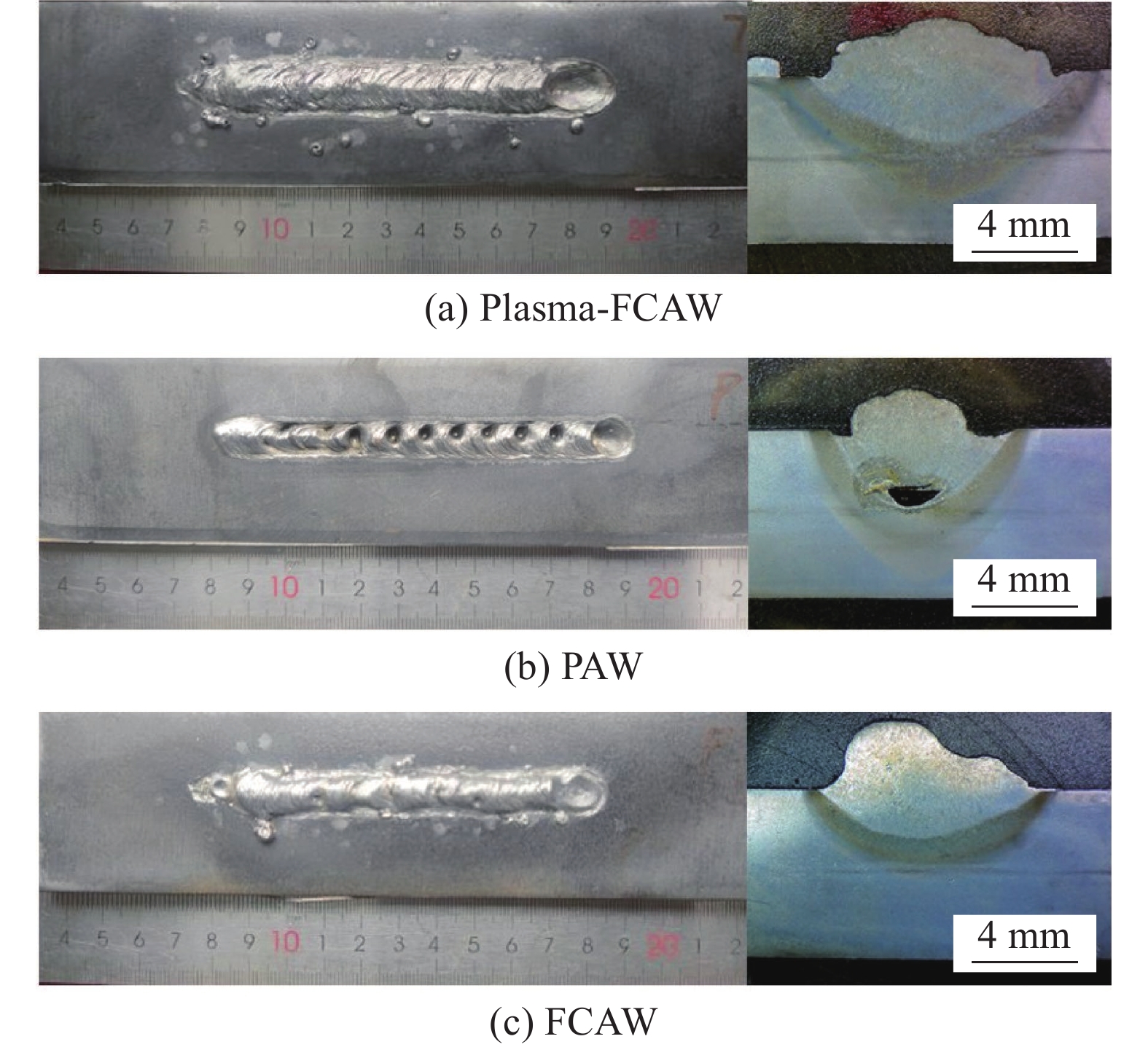

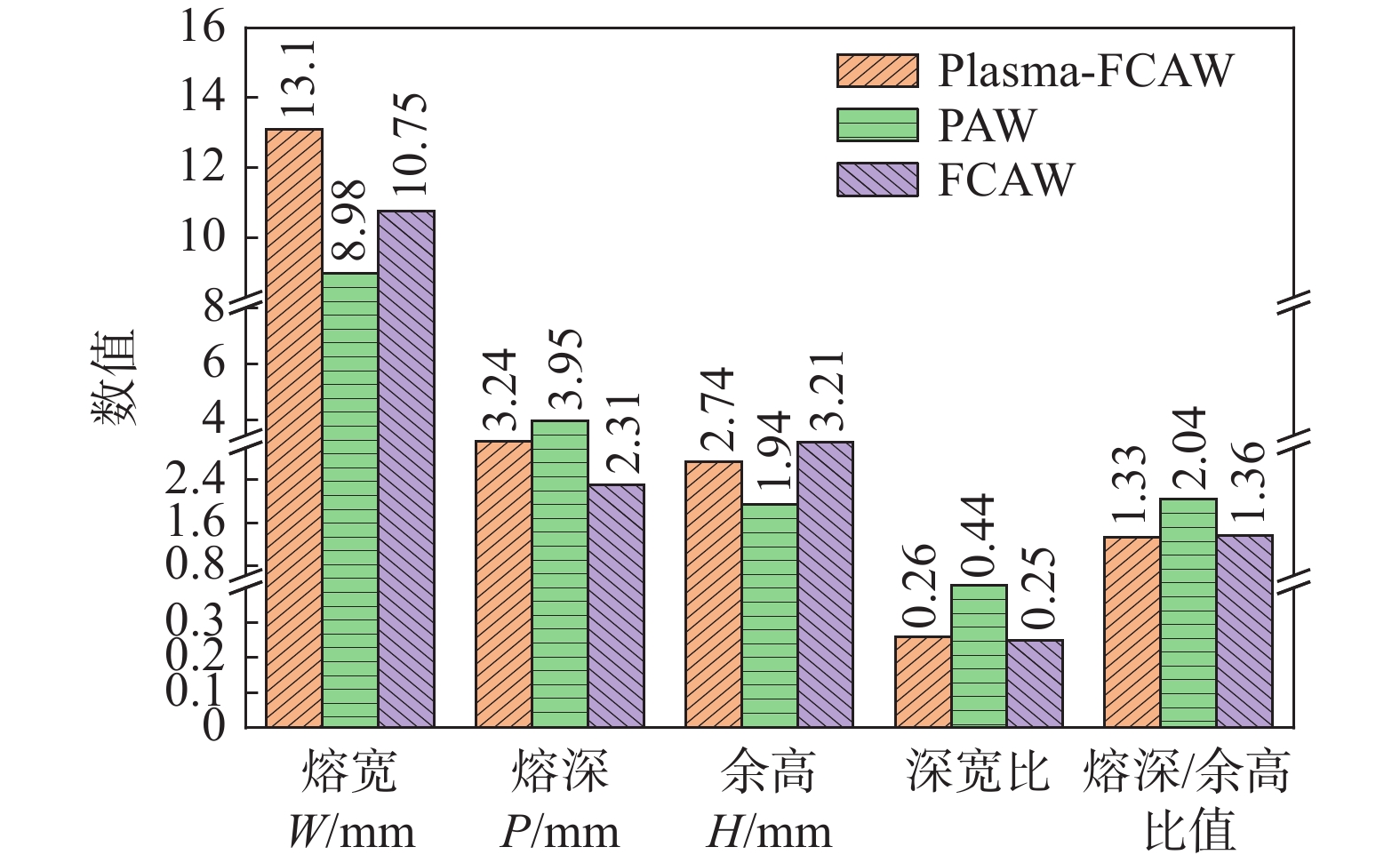

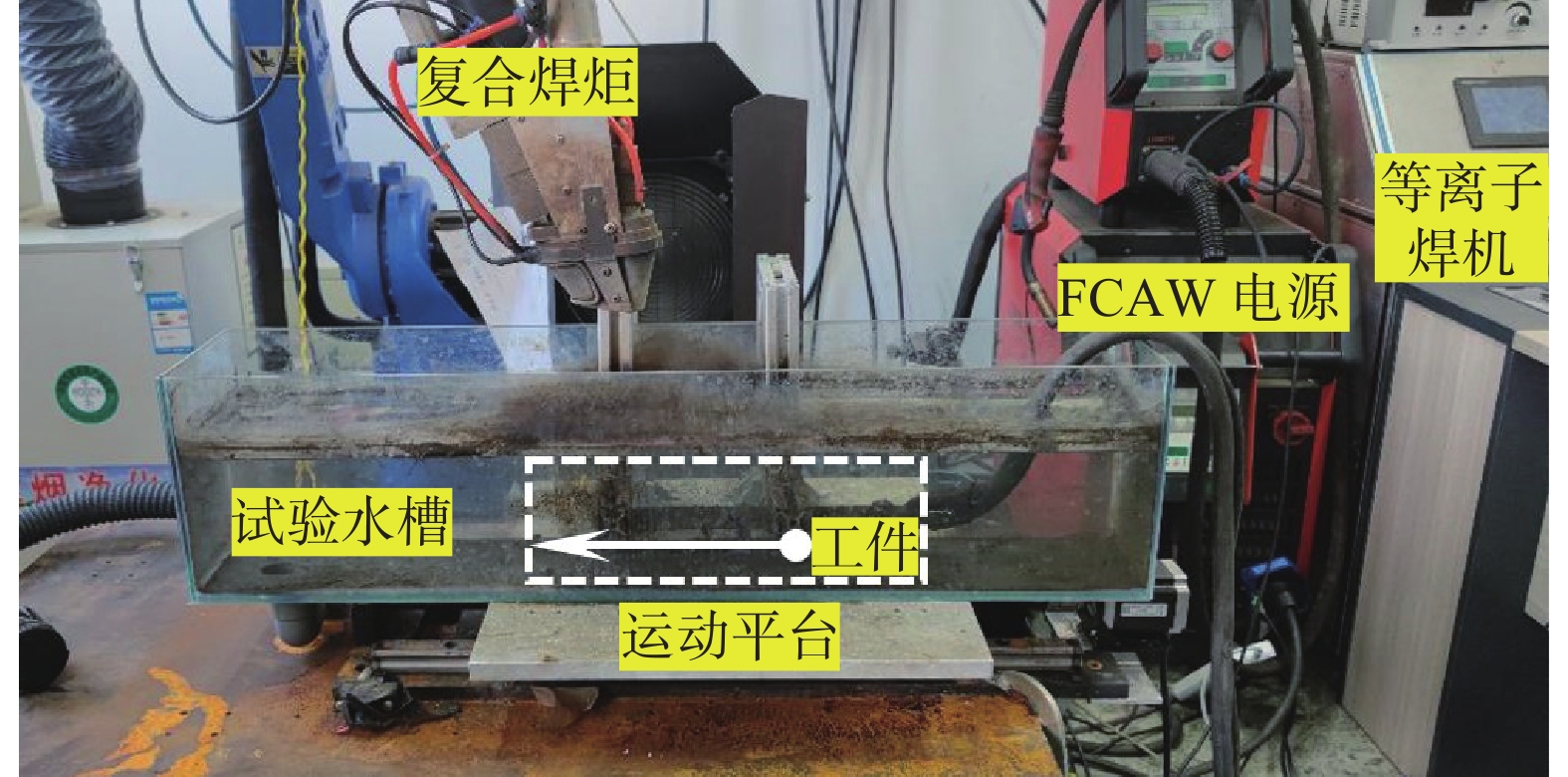

摘要: 磁控等离子-药芯焊丝电弧复合焊(plasma-flux cored arc welding,Plasma-FCAW)作为一种新型水下高效焊接方法被提出,通过特殊焊炬结构设计实现了两种独立焊接工艺的优势互补. 针对复合焊接工艺中由于电源极性不同引起的电弧排斥问题,设计了外部磁场用于调控两个电弧间的耦合程度,并研究了主要工艺参数对Q355B钢水下焊缝成形及其截面几何特征的影响. 结果表明,施加的外部磁场能够有效改善复合焊接过程及焊缝成形的稳定性;药芯焊丝电弧焊(flux cored arc welding,FCAW)电压对水下复合焊接过程稳定性具有显著影响;等离子电流和FCAW电弧电压对焊缝熔深影响较大且等离子电流与熔深间呈近似线性关系;相比于水下FCAW工艺,复合焊工艺焊接熔深提升超过40%,具有更高的焊接效率和焊接稳定性.

-

关键词:

- Plasma-FCAW /

- 水下复合焊 /

- 旁轴复合 /

- 磁场调控 /

- 焊缝成形

Abstract: Magnetically controlled plasma-FCAW hybrid welding technology is proposed as a new efficient underwater welding method. The advantages of the two independent welding processes are complementary through the unique welding torch structure design. An external magnetic field was designed by regulating the coupling degree between two arcs for the problem of arc repulsion caused by different polarity of power supply in hybrid welding process to solve. The influence of main process parameters on the weld forming and section geometry characteristics of Q355B steel was studied. The results show that the external magnetic field can effectively improve the stability of the hybrid welding process and weld forming. FCAW voltage greatly influences the stability of the underwater hybrid welding process. Plasma welding current and FCAW voltage greatly influence weld penetration, and the plasma current has an approximately linear relationship with weld penetration. Compared with the underwater FCAW process, the welding depth of the hybrid welding process is increased by more than 40%, with higher welding efficiency and welding stability. -

-

表 1 焊接工艺试验参数

Table 1 Welding process parameters

试验

序号励磁电流

IM /A等离子电流

IP /AFCAW工艺参数 电弧电压

U/V送丝速度

v/(m·min−1)1 0 ~ 1.8 100 29 6 2 1.8 60 ~ 140 29 6 3 1.8 100 25 ~ 33 6 4 1.8 100 29 4 ~ 8 -

[1] Han L, Wu X, Chen G, et al. Local dry underwater welding of 304 stainless steel based on a microdrain cover[J]. Journal of Materials Processing Technology, 2019, 268: 47 − 53. doi: 10.1016/j.jmatprotec.2018.12.029

[2] Barnabas S G, Rajakarunakaran S, Pandian G S, et al. Review on enhancement techniques necessary for the improvement of underwater welding[J]. Materials Today:Proceedings, 2021, 45: 1191 − 1195. doi: 10.1016/j.matpr.2020.03.725

[3] Chen J, Wen Z, Jia CB, et al. The mechanisms of underwater wet flux-cored arc welding assisted by ultrasonic frequency pulse high-current[J]. Journal of Materials Processing Technology, 2022, 304: 117567. doi: 10.1016/j.jmatprotec.2022.117567

[4] Xu C S, Guo N, Zhang X, et al. Influence of welding speed on weld pool dynamics and welding quality in underwater wet FCAW[J]. Journal of Manufacturing Processes, 2020, 55: 381 − 388. doi: 10.1016/j.jmapro.2020.03.046

[5] 徐鲁宁, 殷树言, 卢振洋, 等. 提高焊丝熔敷率的试验研究[J]. 焊接, 2001(3): 16 − 18. doi: 10.3969/j.issn.1001-1382.2001.03.006 Xu Luning, Yin Shuyan, Lu Zhenyang, et al. Study on enhancing wire depoition rates[J]. Welding & Joining, 2001(3): 16 − 18. doi: 10.3969/j.issn.1001-1382.2001.03.006

[6] Putri E D W S, Surojo E, Budiana E P, et al. Current research and recommended development on fatigue behavior of underwater welded steel[J]. Procedia Structural Integrity, 2020, 27: 54 − 61. doi: 10.1016/j.prostr.2020.07.008

[7] 杜永鹏, 郭宁, 吴程皞, 等. 焊缝余高变异系数在水下湿法焊接质量评估过程中的应用[J]. 焊接学报, 2020, 41(2): 24 − 27. doi: 10.12073/j.hjxb.20190917001 Du Yongpeng, Guo Ning, Wu Chenghao, et al. Study on the application of the weld reinforcement variation coefficient in underwater wet welding quality evaluation[J]. Transaction of the China Welding Institution, 2020, 41(2): 24 − 27. doi: 10.12073/j.hjxb.20190917001

[8] Draugeiates R, Bouaifi B, Bartzsch J. Investigations on underwater welding by the plasma Mig method[C]//The Second International Offshore and Polar Engineering Conference. OnePetro, San Francisco, USA, 1992: 199 − 207.

[9] Zhang H T, Dai XY, Feng J C, et al. Preliminary investigation on real-time induction heating-assisted underwater wet welding[J]. Welding Journal, 2015, 94(1): 8s − 15s.

[10] 王建峰, 孙清洁, 马江坤, 等. 超声振动辅助E40钢水下湿法焊接组织与性能[J]. 焊接学报, 2018, 39(4): 1 − 5. doi: 10.12073/j.hjxb.2018390084 Wang Jianfeng, Sun Qingjie, Ma Jiangkun, et al. Microstructure and mechanical properties of underwater wet welded joint of E40 ship plate steel subjected to ultrasonic vibration[J]. Transaction of the China Welding Institution, 2018, 39(4): 1 − 5. doi: 10.12073/j.hjxb.2018390084

[11] Yu J, Wang B, Zhang H T, et al. Characteristics of magnetic field assisting plasma GMAW-P[J]. Welding Journal, 2020, 99(1): 25 − 38. doi: 10.29391/2020.99.003

[12] 陈姬, 宗然, 武传松, 等. TIG-MIG复合焊电弧间相互作用对焊接过程的影响[J]. 机械工程学报, 2016, 52(6): 59 − 64. doi: 10.3901/JME.2016.06.059 Chen Ji, Zong Ran, Wu Chuansong, et al. Influence of arcs interaction on TIG-MIG hybrid welding process[J]. Journal of Mechanical Engneering, 2016, 52(6): 59 − 64. doi: 10.3901/JME.2016.06.059

-

期刊类型引用(2)

1. 张超,周猛兵,崔雷,陶欣,王军,王伟,刘永长. 9Cr-1.5W-0.15Ta耐热钢搅拌摩擦焊焊缝组织和冲击性能分析. 焊接学报. 2024(04): 36-42+131 .  本站查看

本站查看

2. 王猛,张立平,赵琳瑜,吴军,熊然,蒙永胜,李军红. 增材制造和锻造TC11钛合金激光焊接头组织与力学性能. 焊接学报. 2023(10): 102-110+138-139 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: