Analysis of mechanical properties and application effect of over-matching lap angle weld joint

-

摘要: 采用等匹配和高匹配焊材完成了高钢级B型套筒修复高钢级管道的试验研究. 结果表明,等匹配焊接和高匹配焊接的角焊缝焊接接头都具有良好的拉伸强度和冲击韧性,高匹配焊接接头熔覆金属的冲击韧性略低于等匹配,其焊接接头延展性略差;施焊后等匹配搭接角焊缝未发现焊接缺陷,焊接接头维氏硬度最大值为293 HV10,出现在角焊缝外表面与套筒搭接焊缝处;高匹配搭接角焊缝出现了起源于角焊缝外表面层的横向裂纹,且该焊接接头硬度整体偏高,最大值出现在外表面中心位置焊缝处,为403 HV10,与裂纹起裂位置对应,其产生原因与焊接过程中不同部位熔池金属冷却速率有关,尤其是外表面盖面焊处冷却速度较快,外壁层硬度值异常偏高,萌生裂纹.因此建议搭接角焊缝焊接焊材选择时,在不影响密封和承载前提下,可尝试降低焊缝匹配强度等级.Abstract: The experimental analysis of repairing high-grade steel pipeline with high-grade B-type sleeves is completed by using matching and over-matching welding materials. The results show that the fillet weld joints of matching welding and over-matching welding have good tensile strength and impact toughness. The impact toughness of cladding metal of over-matching welded joint is slightly lower than that of matching, and the ductility of welded joint is slightly poor. No welding defects were found in the matching lap fillet weld after welding. The maximum Vickers hardness of the welded joint was 293 HV10, which appeared at the lap weld between the outer surface of the fillet weld and the sleeve. The transverse crack originated from the outer surface layer of the fillet weld appeared in the high match lap fillet weld, and the hardness of the welded joint is generally high. The maximum value appears at the weld at the center of the outer surface, with a value of 403 HV10, which corresponds to the crack initiation position. The reason is related to the cooling rate of molten pool metal in different parts during the welding process, especially the cooling rate at the welding place of the outer surface cover is fast, the hardness value of the outer wall layer is abnormally high, and cracks are initiated. Therefore, it is suggested that when selecting welding materials for lap fillet weld, try to reduce the matching strength grade of the weld without affecting the sealing and bearing.

-

Keywords:

- over-matching /

- lap angle weld joint /

- B-type sleeve /

- transverse crack

-

0. 序言

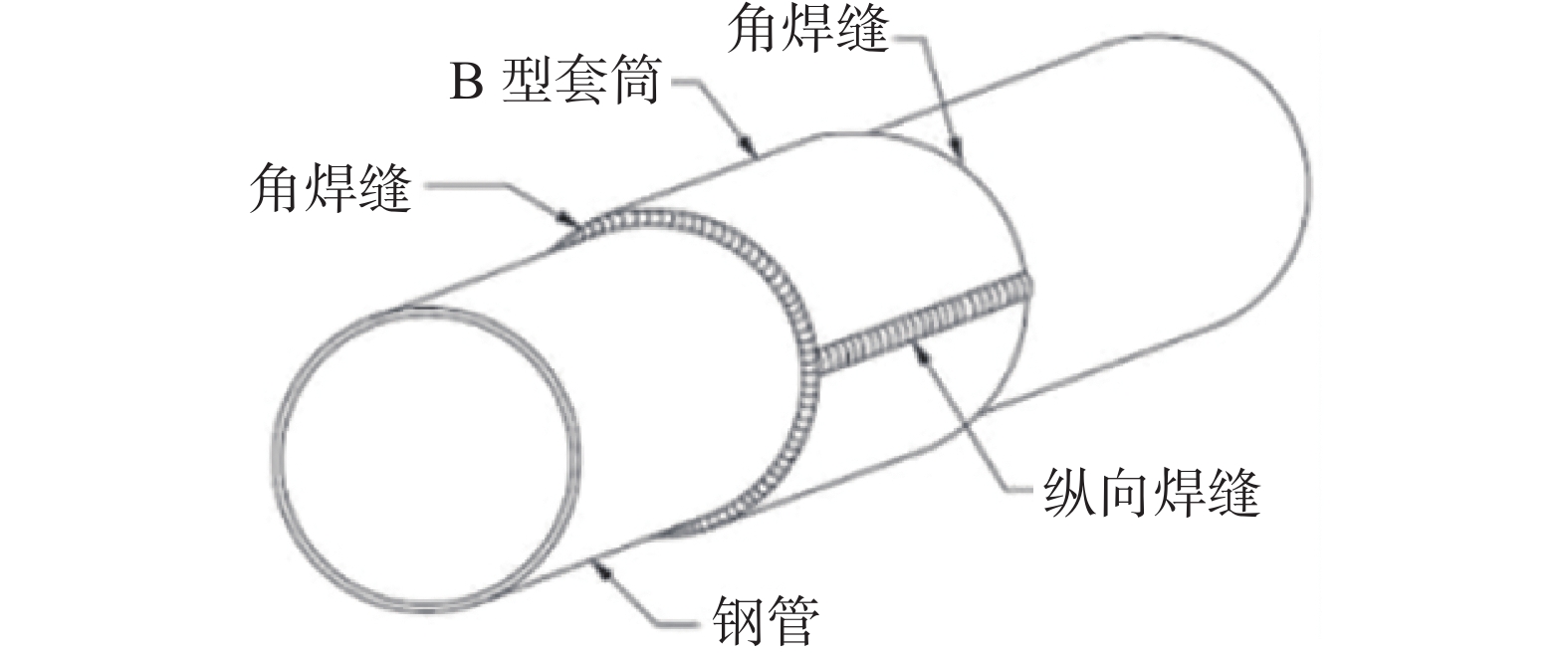

B型套筒修复技术作为重要的在役焊接修复手段,能够保证管道输送的连续进行,减少对环境破坏,缩短修复周期,降低修复费用,具有广阔发展前景[1-2].B型套筒安装须焊接完成两条对接纵向焊缝和两条环形搭接角焊缝,其中,角焊缝搭接着钢管和B型套筒,其焊接质量直接影响到B型套筒修复的密封性和承压能力[3-8]. 目前,现场使用的低强度级别B型套筒壁厚甚至达到50 ~ 60 mm,造成套筒安装焊接劳动强度过高,焊接质量难以保障,为了实现高钢级管道环焊缝的有效修复,高强度级别薄壁B型套筒有着大量的应用需求,其配套焊材选择和焊接工艺亟待改进,尤其是焊材选择的强度不匹配程度必然会影响焊接接头的力学性能及承载能力,目前关于对接环焊缝的强度匹配研究较多[9-12],而关于搭接角焊缝的强度匹配则较少报道. 文中开展等匹配和高匹配搭接角焊缝焊接接头的 试验研究,通过对比试验掌握高匹配搭接角焊缝焊接接头的力学性能及应用效果,指导搭接角焊缝焊接材料选择及焊接质量控制.

1. 试验方法

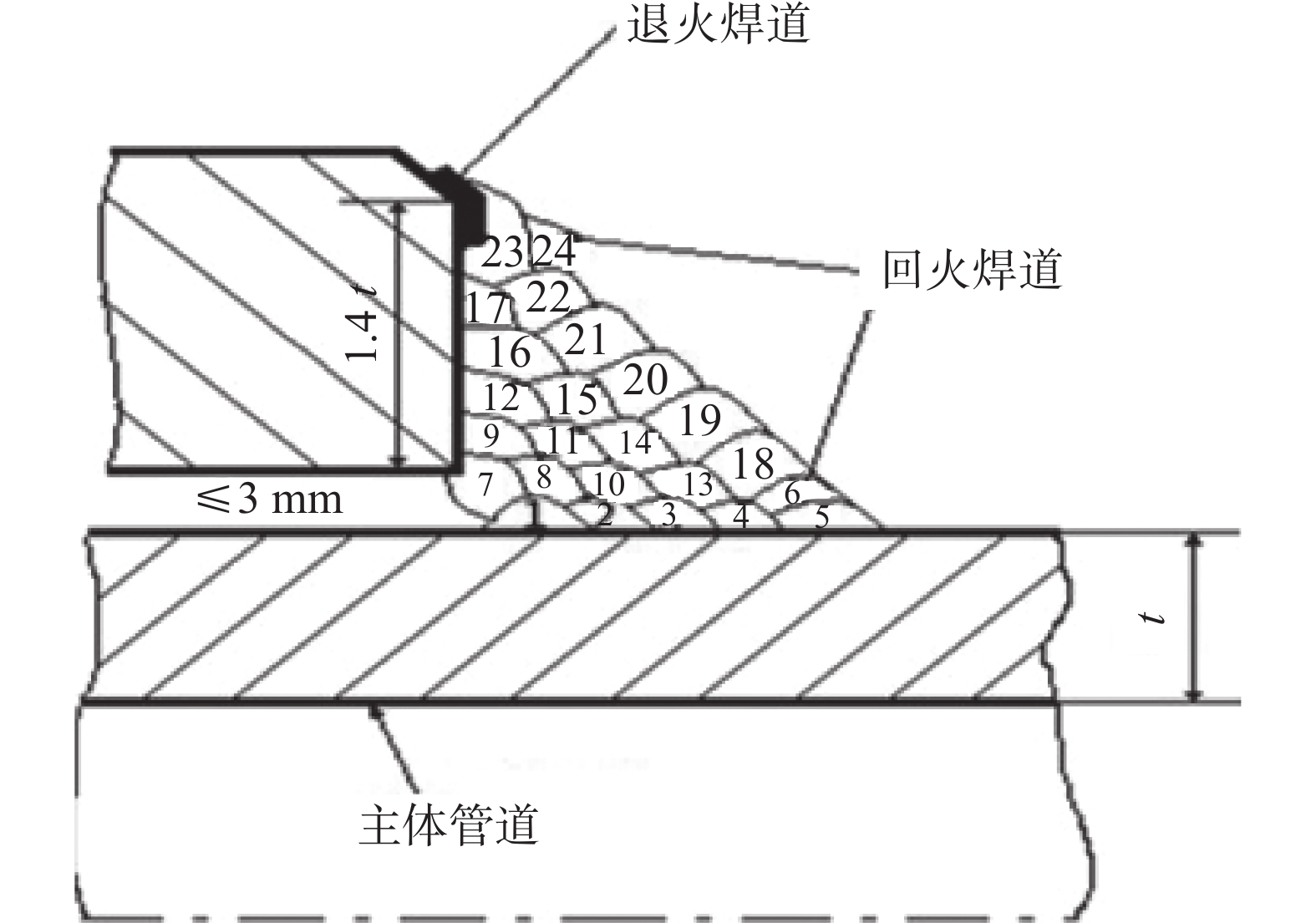

图1为B型套筒安装示意图. 试验选用一根外径1 016 mm、壁厚12.8 mm X80螺旋缝钢管作为待修复钢管,并选用相同强度级别的X80钢级B型套筒对钢管进行焊接修复,同时,选取四川大西洋焊接材料股份有限公司生产的CHE707Ni和CHE607Ni 2种焊条进行焊接试验,其实物水平分别接近X90和X70.试验用钢管、套筒及焊条熔覆金属的化学成分如表1表示.

表 1 试验用钢及焊条熔覆金属化学成分(质量分数,%)Table 1. Chemical composition of molten steel and electrode for test材料 C Si Mn P S Cr Mo Ni Nb V Ti Cu Fe X80钢管 0.049 0.19 1.80 0.007 2 0.002 3 0.31 0.24 0.008 4 0.088 0.006 3 0.012 0.012 余量 X80套筒 0.048 0.20 1.67 0.007 5 0.001 6 0.16 0.12 0.19 0.064 0.004 8 0.014 0.02 余量 CHE707Ni 0.067 0.34 1.45 0.020 0.010 — 0.30 1.70 — — — — 余量 CHE607Ni 0.080 0.50 1.50 0.019 0.011 — 0.35 0.90 — — — — 余量 采用焊条电弧焊进行角焊缝焊接,角焊缝焊接接头形式及焊接顺序如图2所示,焊接工艺参数如表2所示. 采用直流反接方法,管道倾斜45°进行全方位焊接,焊接顺序是由12点位置下向焊接至6点位置,整个焊接过程采用火焰加热方法进行预热,预热温度应不低于80 ℃.

采用UTM5305型的材料试验机按照标准GB/T 228.1—2010《金属材料 拉伸试验 第1部分:室温试验方法》进行拉伸试验. 沿角焊缝环向在其焊缝金属中心处取样,试样为棒状试样,标距段直径为6.25 mm,标距段长度为25 mm. 采用PSW750型冲击试验机按照标准GB/T 229—2007《金属材料 夏比摆锤冲击试验方法》进行冲击韧性试验. 沿角焊缝环向在其焊缝金属中心处取样,加工夏比V形缺口冲击试样,试样尺寸为55 mm × 10 mm × 10 mm. 依据标准GB/T 13298—2015《金属显微组织检验方法》分别在等匹配焊接接头和高匹配搭接角焊缝处取样进行金相分析. 依据标准GB/T 4340.1—2009《金属材料 维氏硬度试验 第1部分:试验方法》在金相试样上进行维氏硬度试验,测试角焊缝处焊缝及热影响区维氏硬度,并绘制硬度分布云图. 硬度试验中加载载荷为9.8 N.

表 2 焊接材料工艺参数Table 2. Welding process parameters材料 强度匹配 焊条直径d/mm 电弧电压U/V 焊接电流I/A 焊接速度v/(cm·min−1) 套筒长度L/mm 套筒壁厚t/mm CHE707Ni 高匹配 3.2 22 ~ 28 80 ~ 110 6 ~ 15 600 26.4 CHE607Ni 等匹配 3.2 22 ~ 28 80 ~ 110 6 ~ 15 600 20.0 2. 试验结果

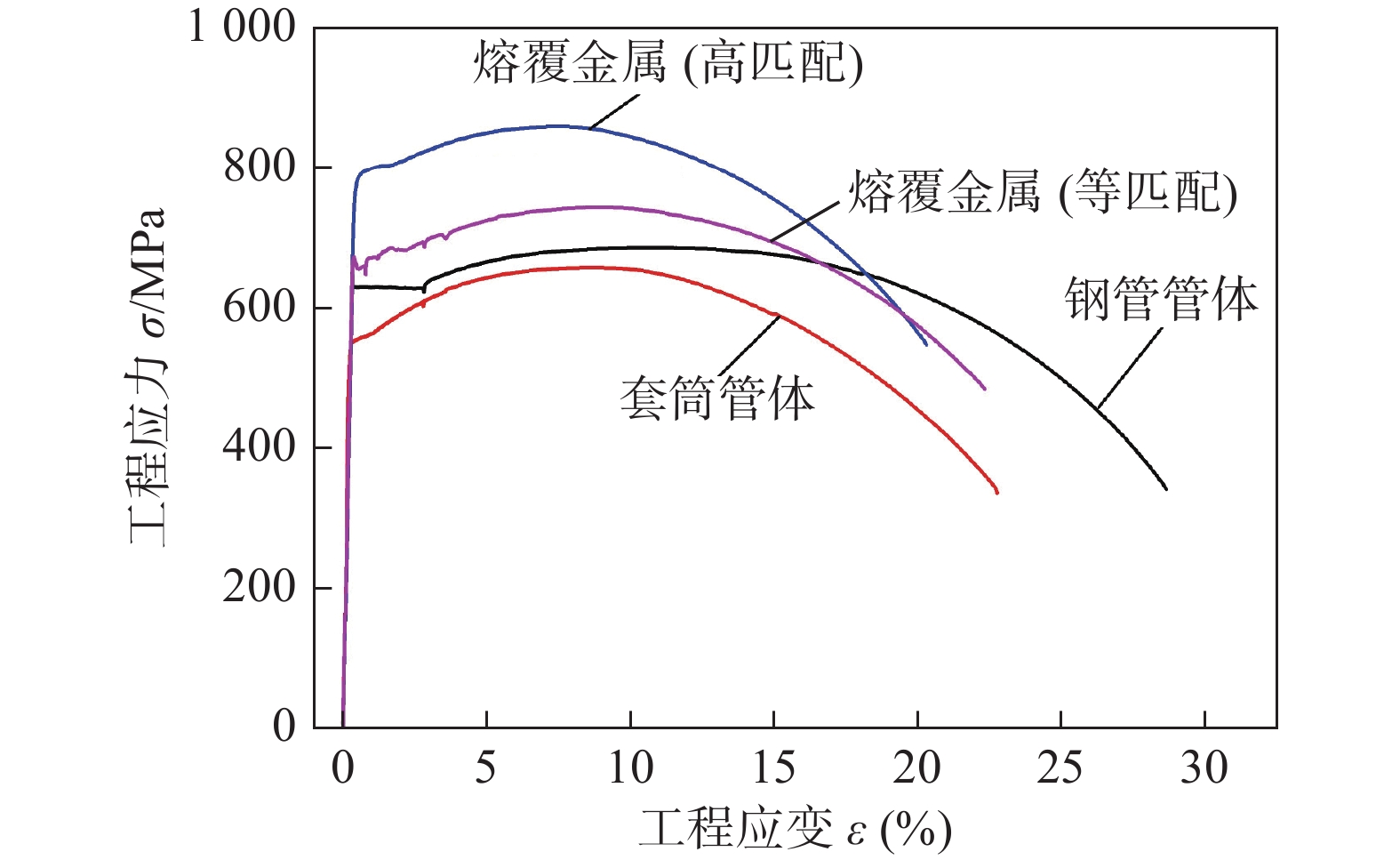

2.1 拉伸试验

采用焊接接头所用焊接材料的抗拉强度和钢材抗拉强度的比值定义强度匹配比,并且将强度匹配比小于1、等于1和大于1的情况分别称为低匹配、等匹配和高匹配. 拉伸试验结果如图3所示,断后伸长率主要反映整体变形阶段的塑性变形能力,均匀延伸率反映了均匀变形阶段的塑性变形能力.待修复钢管管体屈服强度为639 MPa,抗拉强度为682 MPa,屈强比为0.94,断后伸长率为28.5%,均匀延伸率为10.5%,拉伸曲线存在明显屈服平台;套筒的屈服强度为556 MPa,抗拉强度为659 MPa,屈强比0.84,断后伸长率为22.5%,均匀延伸率为8.5%. 选用CHE607Ni焊接材料施焊的等匹配焊接接头熔敷金属屈服强度为657 MPa,抗拉强度为744 MPa,强度略高于钢管和套筒,屈强比为0.88,断后伸长率为22.5%,均匀延伸率为9.0%,延展性变化不大;选用CHE707Ni焊接材料施焊的高匹配焊接接头熔敷金属屈服强度为792 MPa,抗拉强度为841 MPa,强度明显高于钢管和套筒,屈强比为0.91,断后伸长率为20.5%,均匀延伸率为7.5%,延展性最差.

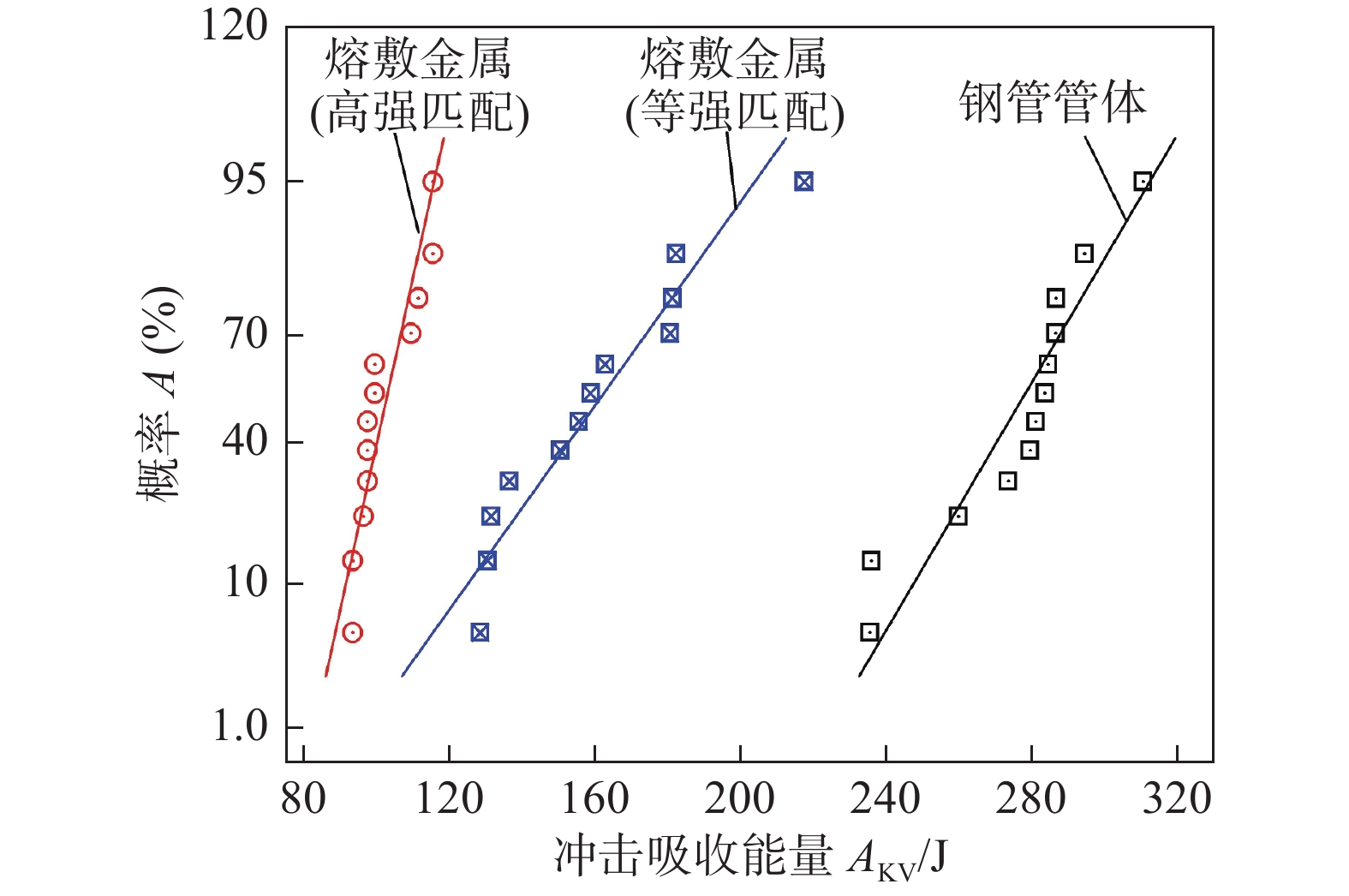

2.2 冲击韧性试验

图4为冲击韧性试验结果. 采用正态概率纸对数据进行统计分析,待修复钢管管体的夏比冲击吸收能量分布在235 ~ 310 J范围,平均值为275 J,标准偏差为22.2,具有良好的韧性;等匹配焊接接头熔敷金属的夏比冲击能量分布在128 ~ 217 J范围,平均值为159 J,标准偏差为27.0,冲击韧性低于待修复钢管,且数值分布较为分散;高匹配焊接接头熔敷金属的夏比冲击能量分布在93 ~ 115 J范围,平均值为102 J,标准偏差为8.3,冲击韧性相较其他数值最低,但数值分布更为集中.

2.3 缺陷检测及电镜分析

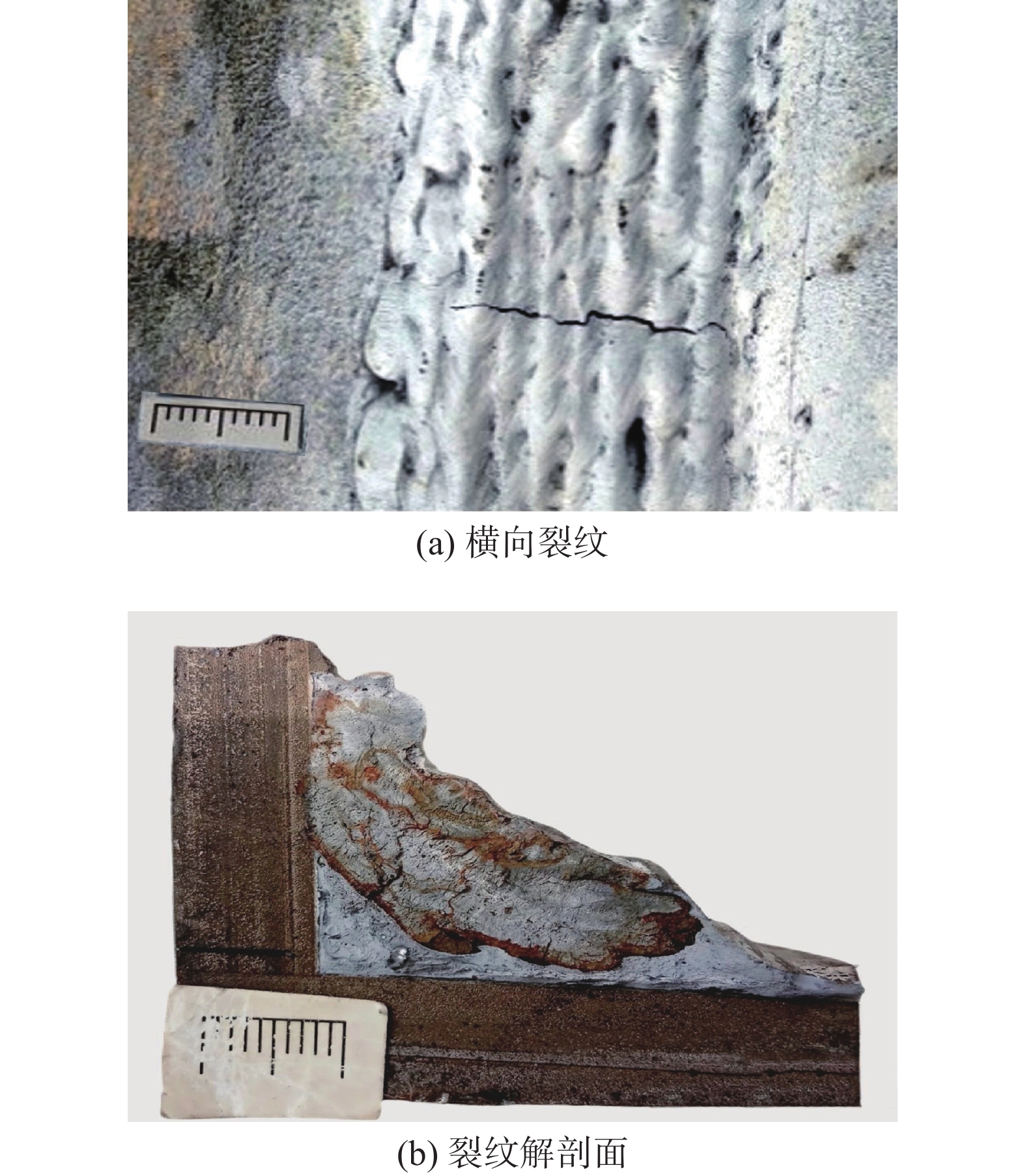

对角焊缝进行磁粉检测时发现高匹配搭接角焊缝出现了横向裂纹,裂纹及沿裂纹所在界面解剖后断口形貌如图5所示,裂纹面存在轻微锈蚀.

对角焊缝裂纹面进行电镜观察,如图6所示,焊缝裂纹均起源于角焊缝的外表面层,源区沿柱状晶呈放射状由外向内壁层方向扩展,准解离扩展方式反复向前推进,整个断口较为粗糙,断口上存在较多的小气孔,局部扩展区呈浅韧窝形貌.

2.4 低倍形貌观察及硬度试验

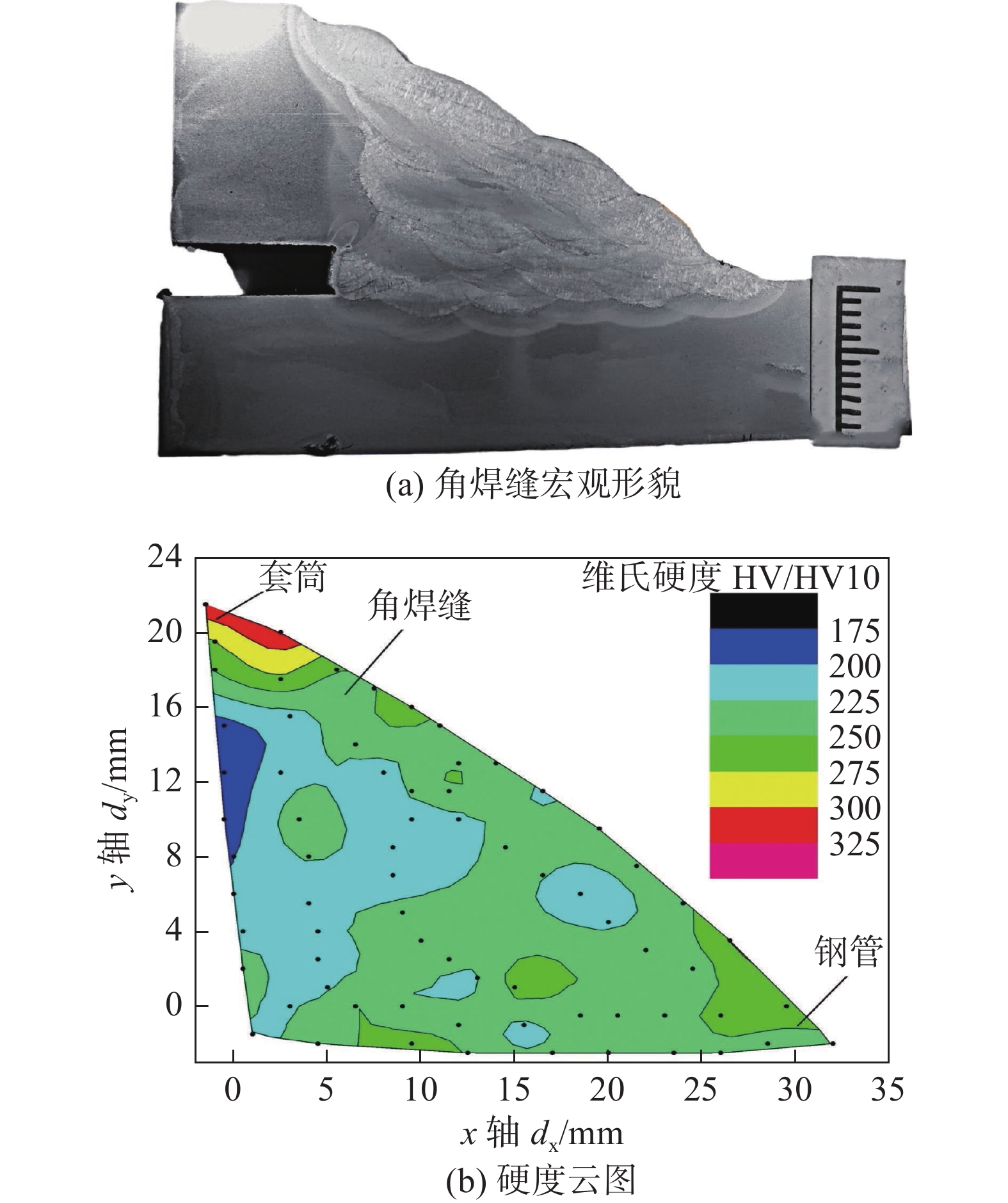

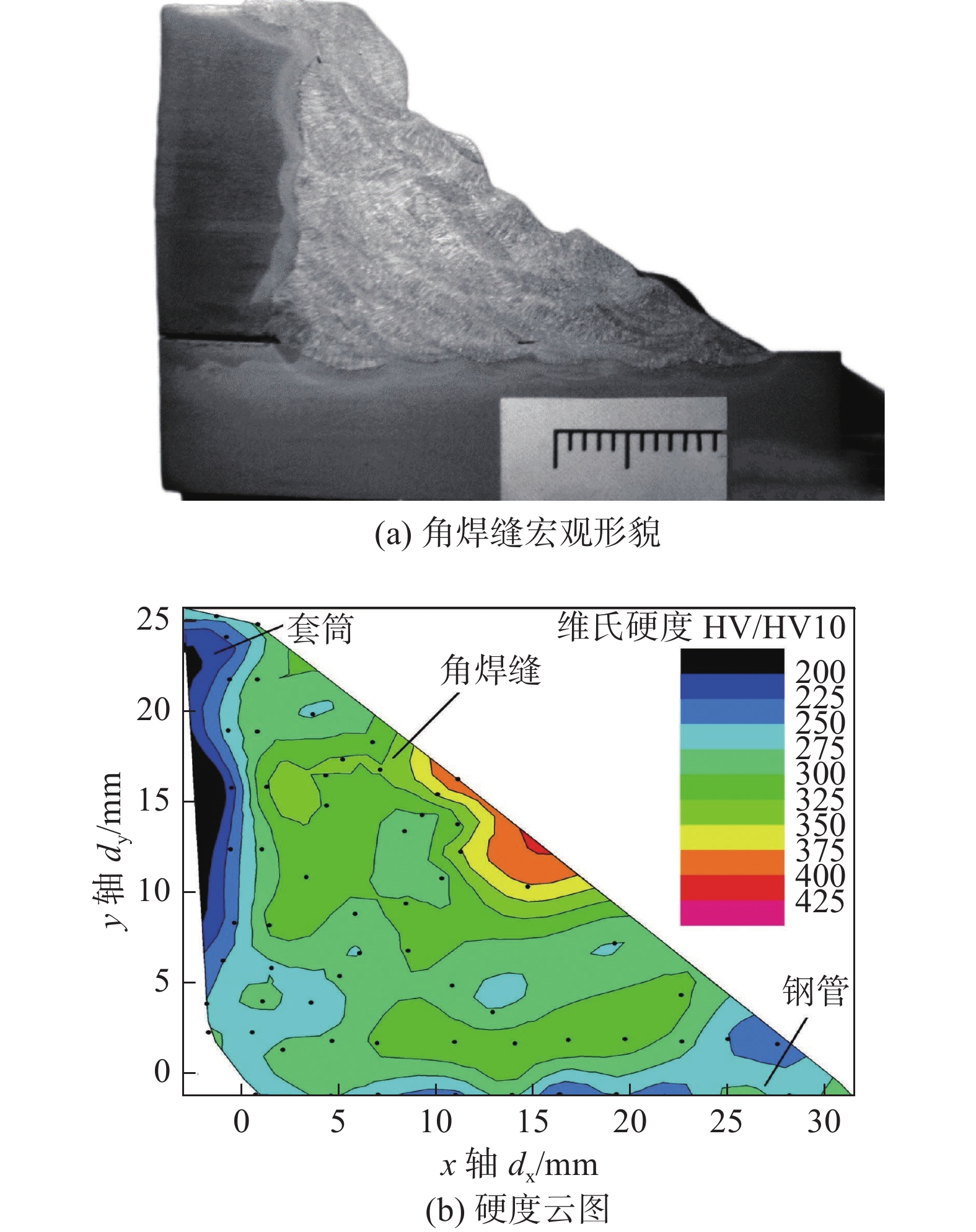

图7为等匹配搭接角焊缝宏观形貌和硬度云图,图8为高匹配搭接角焊缝宏观形貌和硬度云图. 图7所示焊缝及热影响区维氏硬度分布在179 ~ 293 HV10范围,平均值为227 HV10,标准偏差为24.3,角焊缝外表面与套筒搭接处焊缝硬度出现最高值. 图8所示焊缝及热影响区维氏硬度分布在207 ~ 403 HV10范围,平均值为285 HV10,标准偏差为38.1,角焊缝整体硬度偏高,尤其是外表面中心位置焊缝硬度出现异常峰值.

3. 讨论及分析

试验选用X80钢级B型套筒修复X80钢管,待修复钢管及选用的B型套筒具有良好的拉伸强度和冲击韧性;并选用管道专用细晶粒钢焊条(CHE607Ni)施焊角焊缝实现等匹配焊接,选用低氢钠型药皮的低合金钢船用焊条(CHE707Ni)施焊角焊缝实现高匹配焊接.相较待修复钢管,选用CHE607Ni焊材施焊的等匹配焊接接头熔敷金属实测拉伸强度接近待修复钢管,冲击韧性低于待修复钢管且数值分布较为分散;而选用CHE707Ni焊材施焊的高匹配焊接接头熔敷金属拉伸强度明显高于待修复钢管,且延展性较差,冲击韧性较低但数值分布更为集中.总体而言,等匹配焊接和高匹配焊接的焊接接头具有良好的拉伸强度和冲击韧性,高匹配焊接的焊接接头延展性较差.后续开展了修复结构件的静水压验证试验,其试验压力为1.5倍的设计压力,发现B型套筒修复件未发现泄漏.

对施焊完成的角焊缝进行磁粉检测,高匹配搭接角焊缝出现了横向裂纹,其扩展方向与管道受力荷载相关性关系不大,推测其形成与其焊缝内应力偏大相关,并且焊缝裂纹均起源于角焊缝的外表面层,源区沿柱状晶呈放射状由外向内壁层方向扩展,准解离扩展方式反复向前推进,整个断口较为粗糙,断口上存在较多的小气孔,局部扩展区呈浅韧窝形貌.通过进一步的低倍形貌检查及硬度测试,等匹配搭接角焊缝维氏硬度最大值为293 HV10,出现在角焊缝外表面与套筒搭接焊缝处,然而,高匹配搭接角焊缝维氏硬度整体偏高,与焊缝熔敷金属合金含量偏高有关,测得维氏硬度最大值为403 HV10,出现在外表面中心位置焊缝处,与横向裂纹起裂位置相对应,其产生原因与焊接过程中不同部位熔池金属冷却速率有关,尤其是外表面盖面焊焊接时冷却速度较快,造成外壁层硬度值异常偏高,进一步造成裂纹产生.因此建议搭接角焊缝焊接焊材选择时,在不影响密封和承载前提下,可尝试降低焊缝匹配强度等级.

4. 结论

(1)高匹配搭接角焊缝焊接接头仍具有良好的拉伸强度和冲击韧性,其冲击韧性和延展性略低于等匹配焊接.

(2)高匹配搭接角焊缝出现了起源于角焊缝外表面层的横向裂纹,且该焊接接头硬度整体高于等匹配焊接,硬度最大值出现在外表面中心位置焊缝处,数值为403 HV10,与裂纹起裂位置对应,其产生原因应与焊接过程中不同部位熔池金属冷却速率有关.

-

表 1 试验用钢及焊条熔覆金属化学成分(质量分数,%)

Table 1 Chemical composition of molten steel and electrode for test

材料 C Si Mn P S Cr Mo Ni Nb V Ti Cu Fe X80钢管 0.049 0.19 1.80 0.007 2 0.002 3 0.31 0.24 0.008 4 0.088 0.006 3 0.012 0.012 余量 X80套筒 0.048 0.20 1.67 0.007 5 0.001 6 0.16 0.12 0.19 0.064 0.004 8 0.014 0.02 余量 CHE707Ni 0.067 0.34 1.45 0.020 0.010 — 0.30 1.70 — — — — 余量 CHE607Ni 0.080 0.50 1.50 0.019 0.011 — 0.35 0.90 — — — — 余量 表 2 焊接材料工艺参数

Table 2 Welding process parameters

材料 强度匹配 焊条直径d/mm 电弧电压U/V 焊接电流I/A 焊接速度v/(cm·min−1) 套筒长度L/mm 套筒壁厚t/mm CHE707Ni 高匹配 3.2 22 ~ 28 80 ~ 110 6 ~ 15 600 26.4 CHE607Ni 等匹配 3.2 22 ~ 28 80 ~ 110 6 ~ 15 600 20.0 -

[1] Crapps J M, Yue X, Berlin R A, et al. Strain-based pipeline repair via type B sleeve[J]. International Journal of Offshore and Polar Engineering, 2018, 28(3): 280 − 286.

[2] Amori K E, Hussain M N, Hilal H B. Thermal analysis of in-service welding process for pipeline[J]. Journal of Petroleum Research and Studies, 2019, 9(1): 1 − 20.

[3] Amori K E, Hussain M N, Hilal H B. Experimental investigation of pipeline in-service welding process[J]. Journal of Petroleum Research and Studies, 2018, 8(1): 18 − 28.

[4] Cui B, Yan P, Du Q, et al. The welding application of high strength steels used in engineering machinery[J]. China Welding, 2021, 30(1): 57 − 64.

[5] Cheng Z, Long W, Xue S, et al. Research on the influence mechanism of brazing seam geometry on gas pores in brazed joints[J]. China Welding, 2020, 29(4): 13 − 18.

[6] Farzadi A, Sanaei S. Analysis of failure caused by in-service welding in an X52 gas pipeline[J]. Journal of Welding Science and Technology of Iran, 2018, 3(2): 9 − 19.

[7] 严春妍, 易思, 张浩, 等. S355钢激光-MIG复合焊接头显微组织和残余应力[J]. 焊接学报, 2020, 41(6): 12 − 18. doi: 10.12073/j.hjxb.20191014001 Yan Chunyan, Yi Si, Zhang Hao, et al. Investigation of micro-structure and stress in laser-MIG hybrid welded S355 steel plates[J]. Transactions of the China Welding Institution, 2020, 41(6): 12 − 18. doi: 10.12073/j.hjxb.20191014001

[8] 滕彬, 李小宇, 雷振, 等. 低合金高强钢激光-电弧复合热源焊接冷裂纹敏感性分析[J]. 焊接学报, 2010, 31(11): 61 − 64. Teng Bin, Li Xiaoyu, Lei Zhen, et al. Analysis on cold crack sens-itivity of low alloy high strength steel weld by laser-arc hybrid welding[J]. Transactions of the China welding institution, 2010, 31(11): 61 − 64.

[9] Qiao L, Han T, Wang H T, et al. Microscopic study on mechanical properties of different microregions during in-service welding[C]. Materials Science Forum, 2019, 944: 841 − 853.

[10] Dunđer M, Vuherer T, Samardžić I, et al. Analysis of heat-affected zone microstructures of steel P92 after welding and after post-weld heat treatment[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9): 3801 − 3812.

[11] Song W, Sun X, Liu X, et al. Strength mismatch effect on residual stress of high strength steel butt-welded joints[J]. Procedia Structural Integrity, 2021, 33: 795 − 801. doi: 10.1016/j.prostr.2021.10.088

[12] Ran M M, Sun F F, Li G Q, et al. Experimental study on the behavior of mismatched butt welded joints of high strength steel[J]. Journal of Constructional Steel Research, 2019, 153: 196 − 208. doi: 10.1016/j.jcsr.2018.10.003

下载:

下载: