Three-dimensional measurement of post-weld surface based on grating projection

-

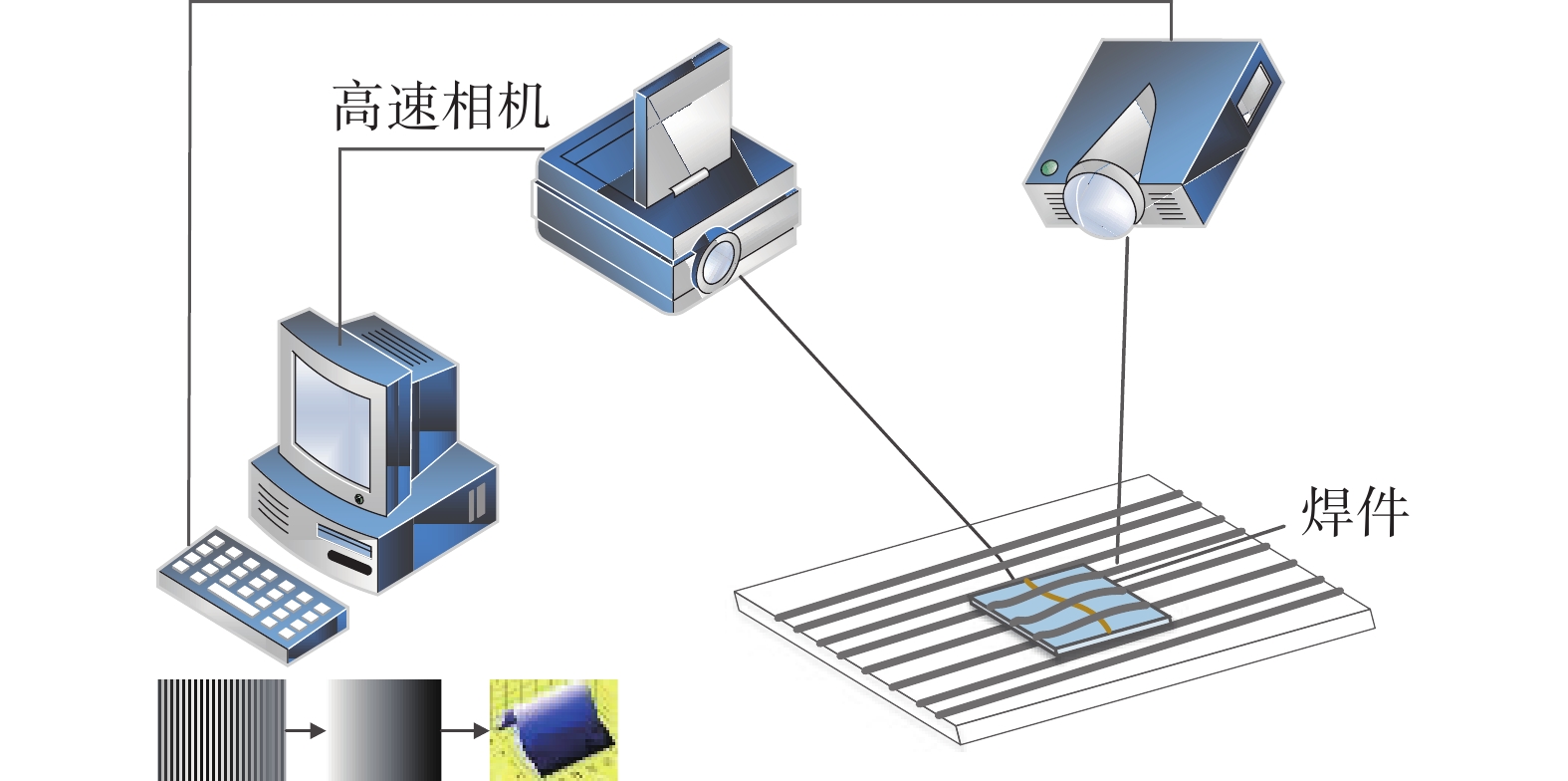

摘要: 焊缝表面三维轮廓是评价焊后焊缝质量的重要指标,针对常用线结构光扫描进行焊缝测量时无法兼顾测量速度与精度等问题,设计并搭建了一种基于面结构光光栅投影的焊缝三维轮廓测量系统. 首先,通过数字光处理(digital light processing,DLP)投影仪向焊缝表面投射面结构光光栅条纹图像,摄像机获取变形调制条纹,利用四步相移法结合多频外差时域解相算法准确地实现了变形光栅条纹相位主值的解算和相位的展开.然后,利用平面靶标结合精密平移台获取空间点阵列的方法实现了对模型参数的标定,该标定方法精度高、可操作性强、结构稳定.最后,采用空间相位映射模型实现焊缝相位信息到高度信息的转换,实现焊缝三维轮廓的测量.结果表明,该测量方法能很好的表现焊缝细节信息,测量结果准确,测量精度能达到0.0968 mm,可以为焊后焊缝外观检测与评价提供可靠数据.Abstract: The three-dimensional contour of the weld surface is an important index to evaluate the quality of the weld. In response to the problem that the measurement speed and accuracy cannot be balanced when the weld is measured by the commonly used line structured light scanning, a weld three-dimensional profile measurement system based on the surface structured light grating projection is designed and built. Firstly, the grating fringe is projected onto the weld through a digital light processing(DLP) projector, and the camera acquires the deformation modulation fringe. The phase of the deformed grating fringe is accurately calculated and unwrapped by using the four-step phase-shifting method combined with the multi-frequency heterodyne time-domain phase-resolving algorithm. Then, using a planar target combined with a high precision moving platform to obtain space coordinate data to calibrate the model parameters. The calibration method has high precision, strong operability and stable structure. Finally, the spatial phase mapping model is used to convert the phase information of the weld to the height information, and the measurement of the three-dimensional profile of the weld is realized. The test results show that this measurement method can well represent the detailed information of the weld, the measurement results are accurate, and the measurement accuracy can reach 0.096 8 mm, which can provide reliable data for the appearance inspection and evaluation of the post-weld.

-

-

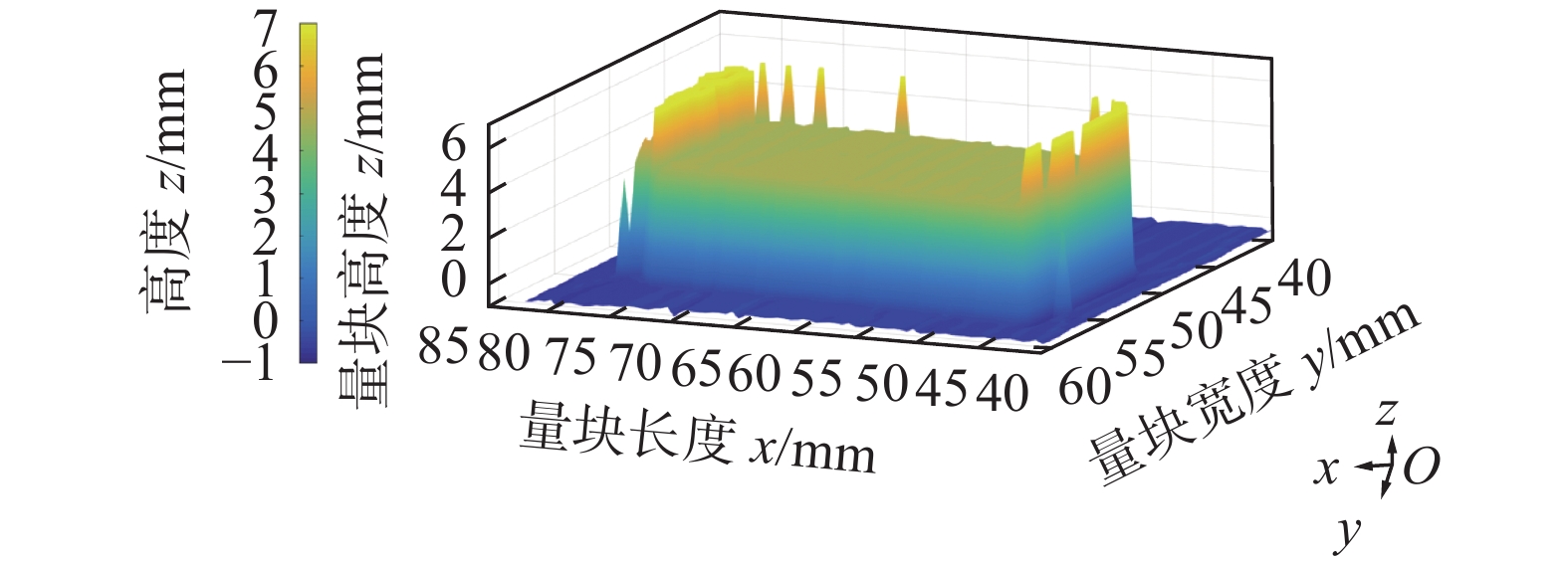

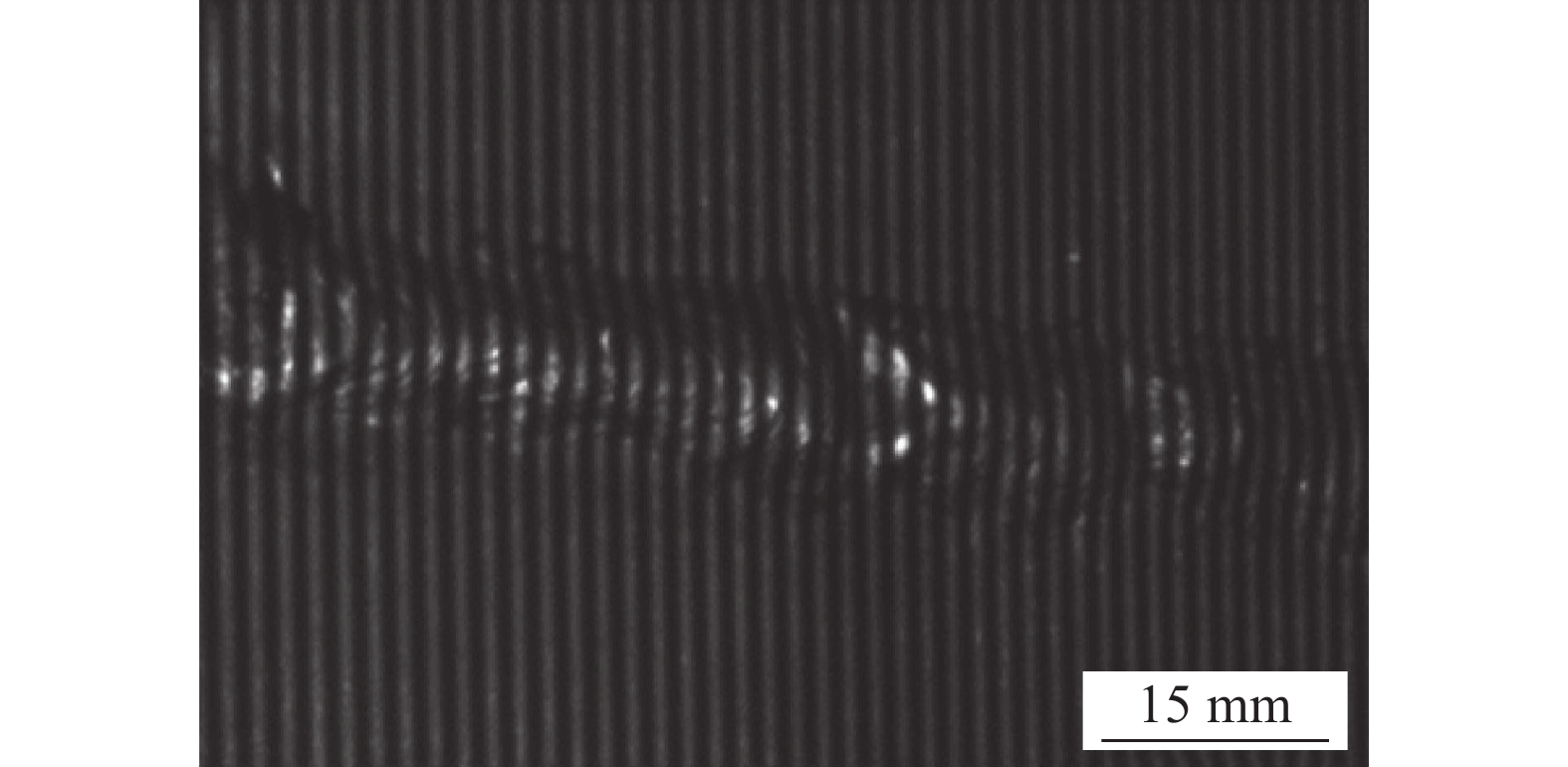

图 11 焊缝三维测量结果

Figure 11. 3D measurement results of welding seam.(a) results of workpiece 1 with three frequency heterodyne method; (b) results of workpiece 1 with branch cutting method; (c) results of workpiece 2 by three frequency heterodyne method; (d) results of workpiece 2 with branch cutting method

表 1 模型参数

Table 1 Model parameters

$ {p_i} $ $ {q_i} $ $ {r_i} $ 1245.56

−5.121770628

0.006729067

−0.00000289

−0.534082009

0.001769769

−0.00000146

−0.0000131

0.0000000202

−0.000000000627

−1.557448492

0.004277788

−0.00000259

0.000586622

−0.000000972

0.00000000907

0.000635451

−0.000000674

−0.000000162

−0.0000000495−2470.71

11.28448568

−0.017017439

0.00000842

0.589600969

−0.001643752

0.00000149

−0.0000196

0.000000024

0.00000000394

4.139785184

−0.012510248

0.00000931

−0.000603428

0.00000109

0.00000000779

−0.002287981

0.00000341

0.000000195

0.0000004164683.44

−23.02690587

0.03843155

−0.0000217

0.014012346

−0.0000564

0.00000005

0.0000135

−0.0000000185

0.00000000112

−7.670646446

0.025792839

−0.0000221

0.000000366

0.00000000464

−0.0000000098

0.004336764

−0.00000746

−0.00000000206

−0.000000839表 2 量块表面某点高度值

Table 2 Height value of a certain point of gauge block

量块长度x/mm 量块宽度y/mm 量块高度z/mm 45.655

45.113

55.112

60.220

65.138

68.78650.370

55.640

55.463

55.381

55.308

49.9975.019

4.923

4.939

5.010

4.939

4.978表 3 焊件焊缝表面某点高度值

Table 3 Height value of a certain point of welding seam

焊件

编号检测位置

编号焊缝检

验尺值

h/mm系统检测值

h0/mm误差

δ/mm1 1 5.2 5.121 0.079 2 4.8 4.716 0.084 3 4.7 4.828 0.128 4 4.8 4.879 0.079 5 5.1 5.013 0.087 2 1 5.5 5.571 0.071 2 3.4 3.482 0.082 3 4.6 4.487 0.113 4 4.9 4.993 0.093 5 4.8 4.917 0.117 -

[1] 伏喜斌, 林三宝, 杨春利, 等. 基于激光视觉传感的焊后检测技术研究综述[J]. 焊接, 2007(6): 24 − 27. doi: 10.3969/j.issn.1001-1382.2007.06.006 Fu Xibin, Lin Sanbao, Yang Chunli, et al. Summary of research on post-weld inspection technology based on laser vision Sensor[J]. Welding & Joining, 2007(6): 24 − 27. doi: 10.3969/j.issn.1001-1382.2007.06.006

[2] Li Yan, Hu Miao, Wang Taiyong. Visual inspection of weld surface quality[J]. Journal of Intelligent & Fuzzy Systems, 2020, 39(4): 1 − 10.

[3] 周兆逸, 张亚南, 王肖锋, 等. 基于改正二维主成分分析的焊缝表面缺陷检测[J]. 焊接学报, 2021, 42(11): 70 − 76. Zhou Zhaoyi, Zhang Yanan, Wang Xiaofeng, et al. Weld surface defect detection based on improved two-dimensional principal component analysis[J]. Transactions of the China Welding Institution, 2021, 42(11): 70 − 76.

[4] Qi Jiyang, Li Jinyan. Feature extraction of welding defect base-don machine vision[J]. China Welding, 2019, 28(1): 56 − 62.

[5] 樊丁,胡桉得,黄健康,等. 基于改进卷积神经网络的管焊缝X射线图像缺陷识别方法[J]. 焊接学报, 2020, 41(1): 7 − 11. Fan Ding, Hu Ande, Huang Jiankang, et al. X-ray image defect re-cognition method for pipe weld based on improved convolutional neural network[J]. Transactions of the China Welding Institution, 2020, 41(1): 7 − 11.

[6] Chi D Z, Gang T. Defect detection method based on 2D entropy image segmentation[J]. China Welding, 2020, 29(1): 45 − 49.

[7] 王睿, 胡云雷, 刘卫朋, 等. 基于边缘AI的焊缝X射线图像缺陷检测[J]. 焊接学报, 2022, 43(1): 79 − 84. Wang Rui, Hu Yunlei, Liu Weipeng, et al. Defect detection of weld X-ray image based on edge AI[J]. Transactions of the China Welding Institution, 2022, 43(1): 79 − 84.

[8] 杨鹏程, 高向东, 林少铎, 等. 焊缝表面缺陷激光扫描三维重构测量[J]. 焊接学报, 2020, 41(3): 59 − 63. Yang Pengcheng, Gao Xiangdong, Lin Shaoduo, et al. Laser scanning three-dimensional reconstruction measurement of weld surface defects[J]. Transactions of the China Welding Institution, 2020, 41(3): 59 − 63.

[9] 杨军涛, 李志勇, 范力予, 等. 基于线激光扫描的焊缝表面缺陷检测系统[J]. 焊接, 2016(2): 19 − 23. doi: 10.3969/j.issn.1001-1382.2016.02.006 Yang Juntao, Li Zhiyong, Fan Liyu, et al. Surface defect detection system of welding seam based on line laser scanning[J]. Welding & Joining, 2016(2): 19 − 23. doi: 10.3969/j.issn.1001-1382.2016.02.006

[10] Xue Bin, Ma Shufang, Chu Huihui, et al. Research on weld quality detection method based on machine vision and computer image processing[J]. IOP Conference Series:Materials Science and Engineering, 2019, 631(5): 052031 − 1 − 7. doi: 10.1088/1757-899X/631/5/052031

[11] 王仁荣, 赵力伟, 郑劲豹, 等. 基于LABVIEW的焊缝表面缺陷智能检测系统研究[J]. 焊接技术, 2018, 47(11): 54 − 57. Wang Renrong, Zhao Liwei, Zheng Jinbao, et al. Research on the intelligent inspection system for weld surface defects based on LABVIEW[J]. Welding Technology, 2018, 47(11): 54 − 57.

[12] Han Yanqing, Fan Junfeng,Yang Xiaozhong. A structured lightvision sensor for on-line weld bead measurement and weld qual-ity inspection[J]. The International Journal of Advanced Manufac-turing Technology, 2020, 106(5): 2065 − 2078.

[13] Zhang Qican, Han Yu, wu Yingshan. Comparison and combina-tion of three spatial phase unwrapping algorithms[J]. Optical Re-view, 2019, 26(4): 380 − 390.

[14] Wang Le, Song Lei, Zhong Lijun, et al. Multi-frequency hetero-dyne phase shift technology in 3-D measurement[J]. Advanced Materials Research, 2013, 2586(774-776): 1582 − 1585.

-

期刊类型引用(2)

1. 张超,周猛兵,崔雷,陶欣,王军,王伟,刘永长. 9Cr-1.5W-0.15Ta耐热钢搅拌摩擦焊焊缝组织和冲击性能分析. 焊接学报. 2024(04): 36-42+131 .  本站查看

本站查看

2. 王猛,张立平,赵琳瑜,吴军,熊然,蒙永胜,李军红. 增材制造和锻造TC11钛合金激光焊接头组织与力学性能. 焊接学报. 2023(10): 102-110+138-139 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: