Analysis of arc and weld pool characteristics in direct current added-pulsed TIG welding process

-

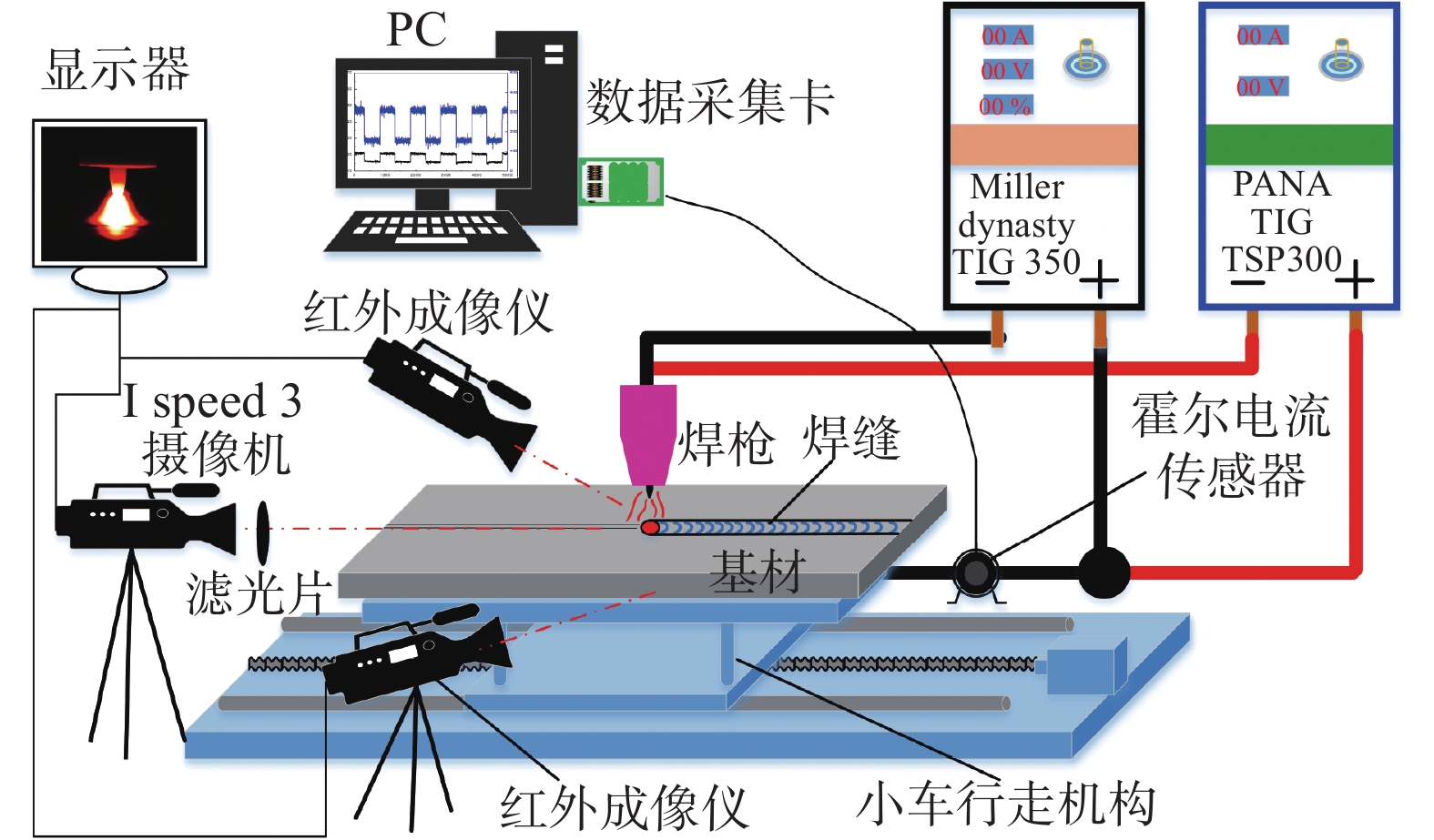

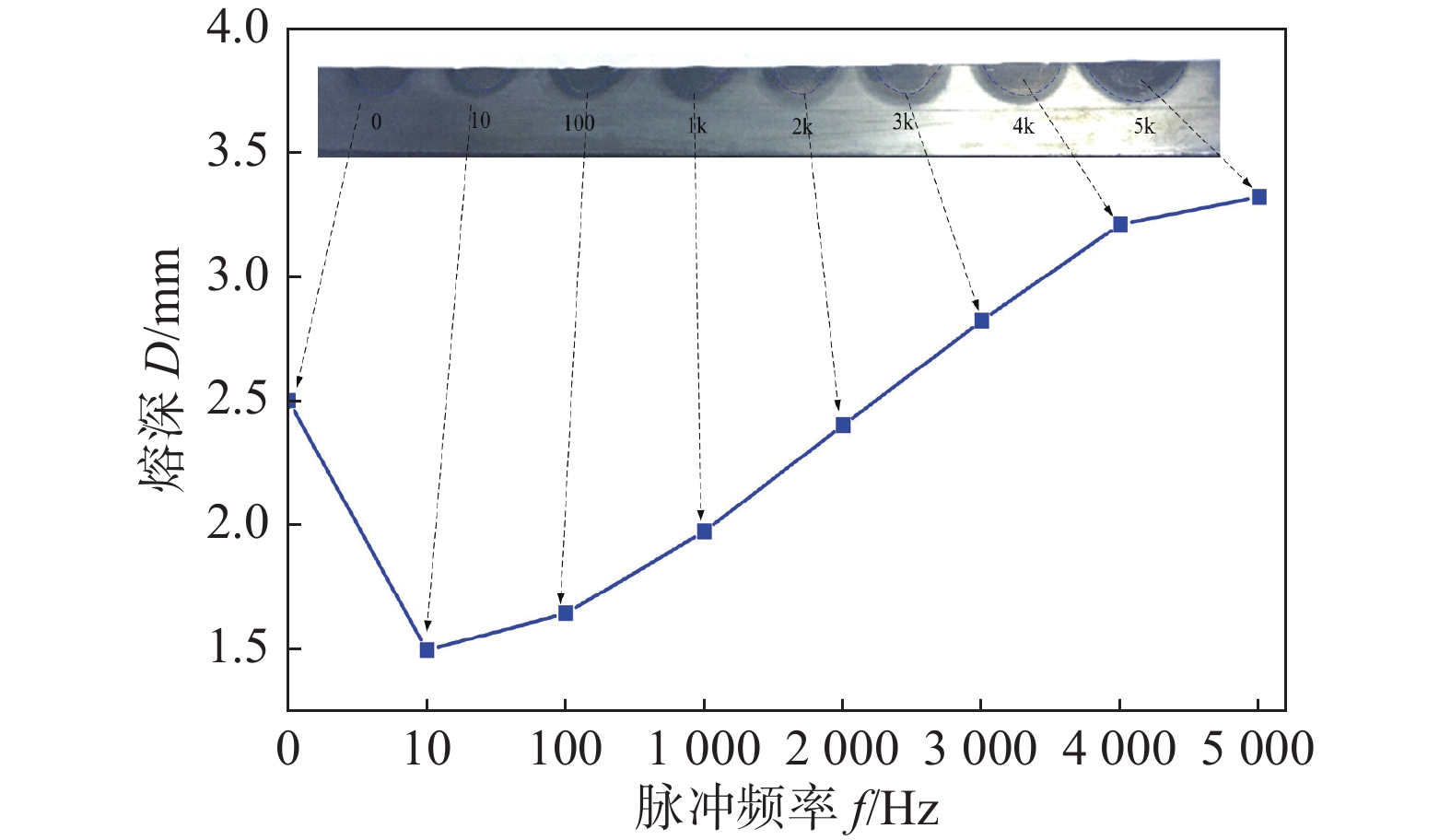

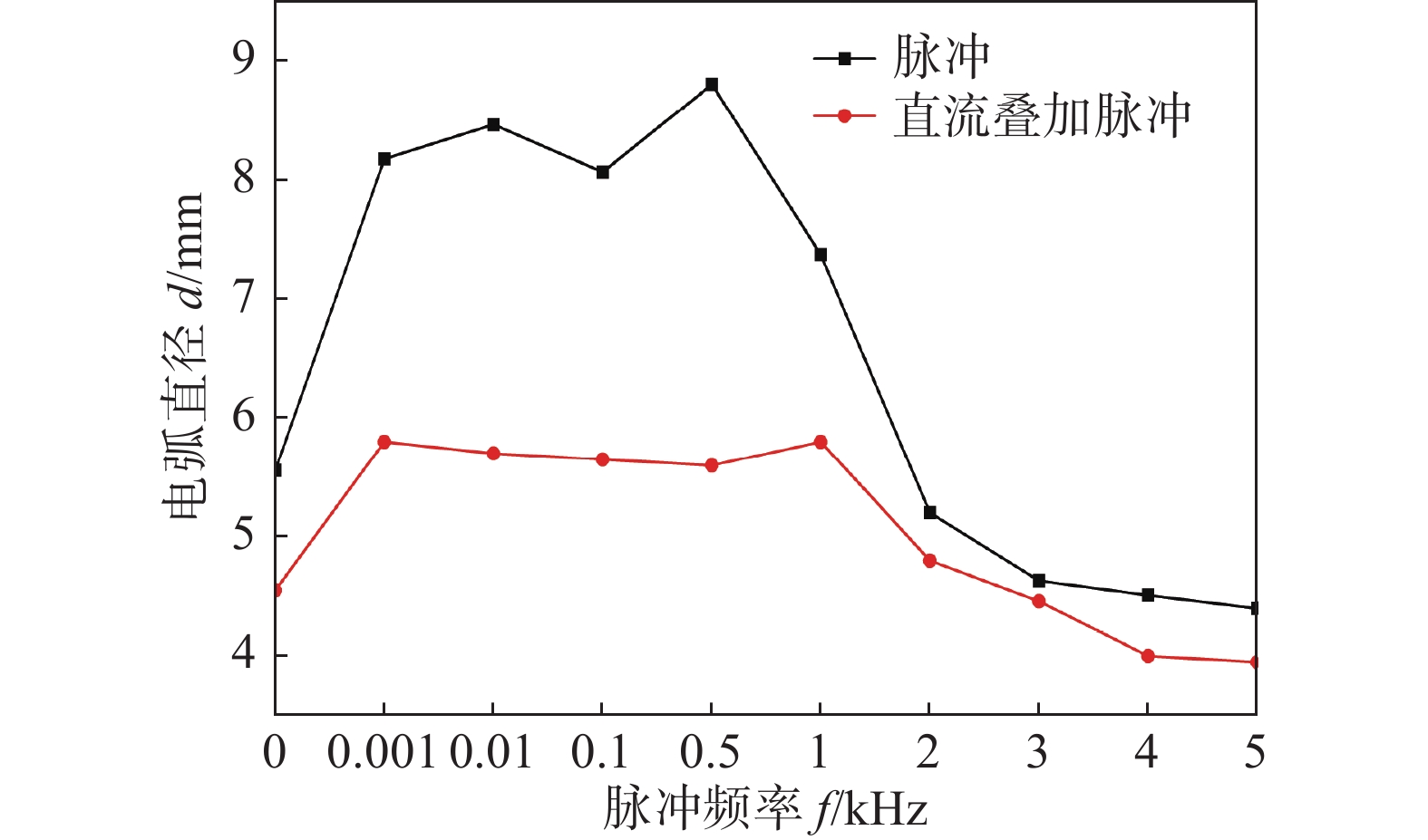

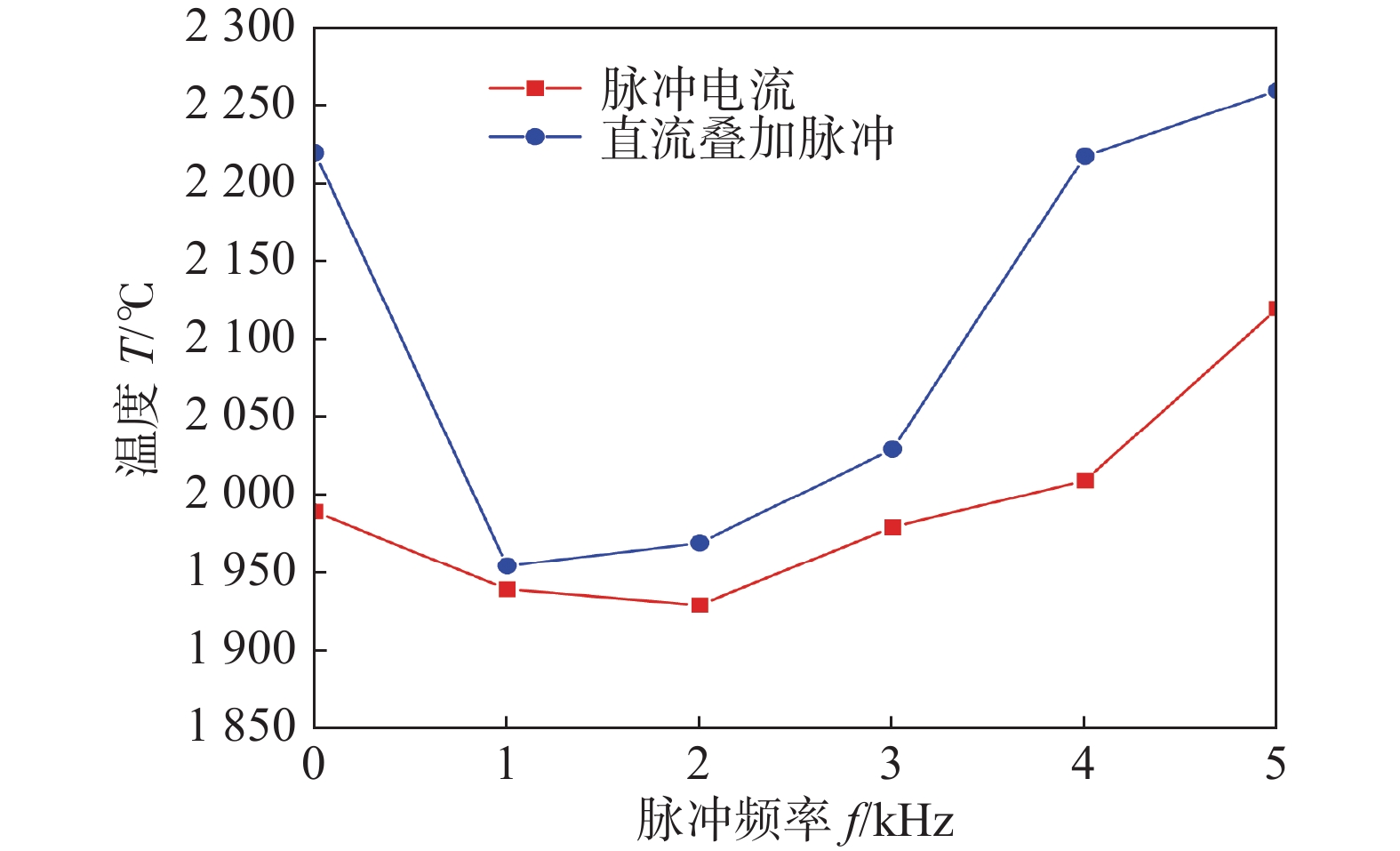

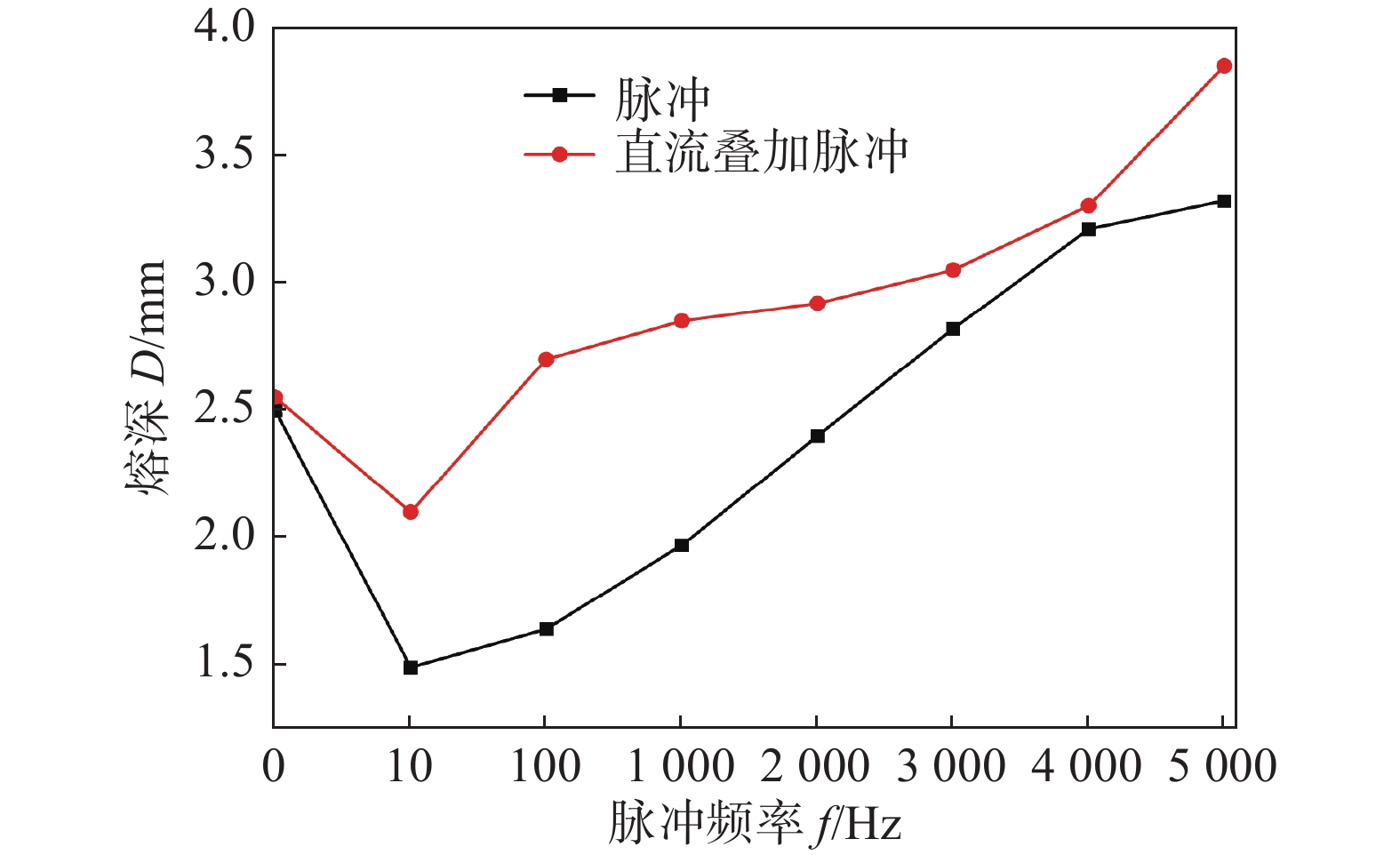

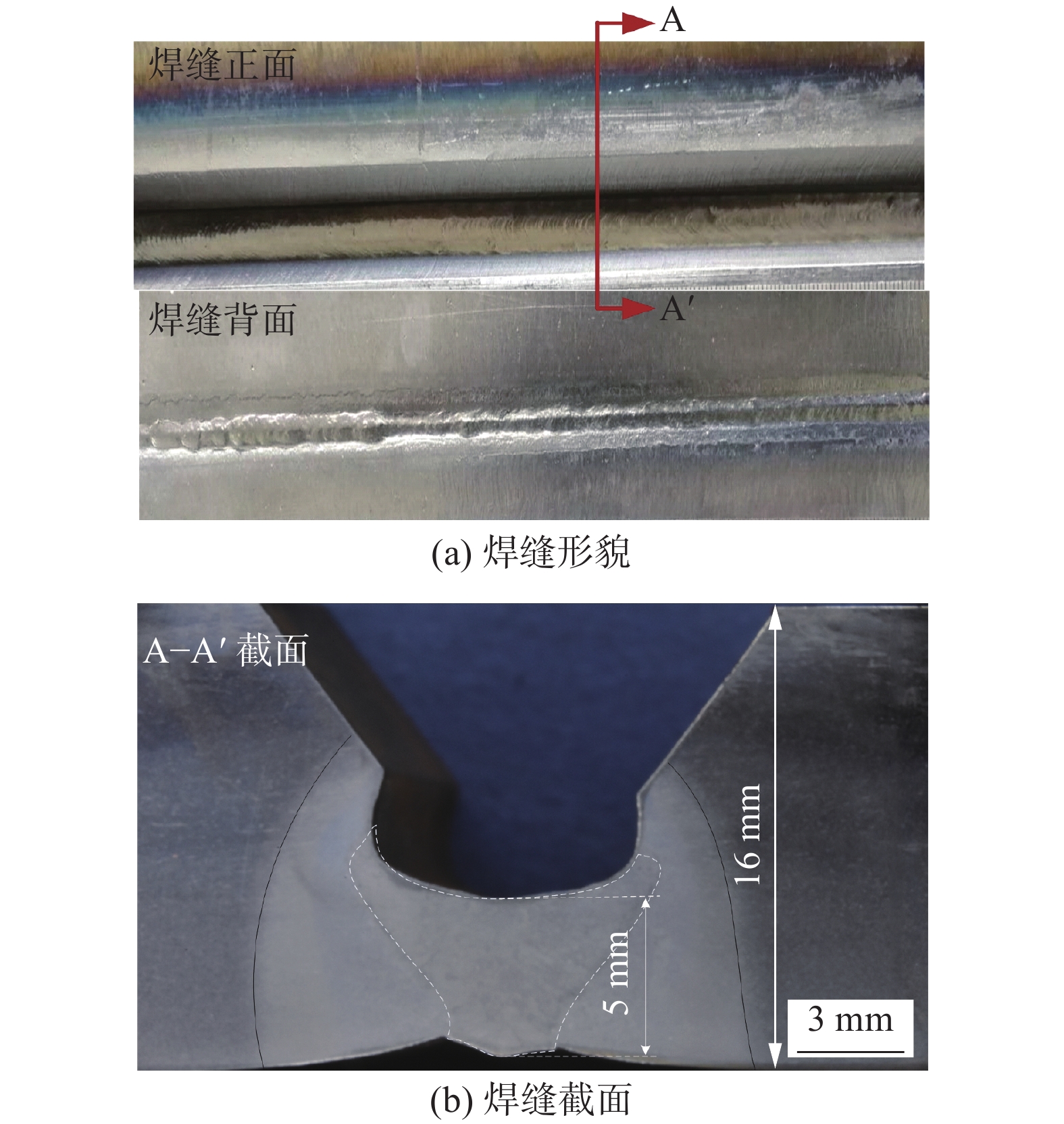

摘要: 针对乏燃料后处理溶解器腐蚀裂纹等缺陷的快速、一次性、可靠焊接修复工程技术需求,提出一种直流叠加脉冲型TIG深熔焊接方法,在10和16 mm厚304不锈钢板上进行了系列平板堆焊工艺试验. 以电弧-熔池特性变化为研究对象,对比分析脉冲电流作用和直流叠加脉冲型电流作用的电弧行为、熔池流动行为及温度场的变化规律,探讨了直流叠加至脉冲电流波形的焊缝熔深增加机理. 结果表明,高频脉冲电流使电弧产生电磁收缩效应,且电弧被压缩程度及焊缝熔深与脉冲频率(1 ~ 5 kHz)成正相关;叠加直流的高频脉冲电弧具有更高的电流、能量密度,进一步提高了熔池表面液态金属温度及增加了熔池电磁搅拌力使熔池流动加剧、对流换热充分、熔池热惯性作用增强,进而使焊缝熔深增加. 试验验证了该方法能够实现5 mm厚304不锈钢板对接可靠的单面焊双面成形.Abstract: In view of the technical requirements for rapid and reliable automatic welding repairment of defects such as corrosion cracks in the dissolver for spent fuel reprocessing, a direct current added-high-frequency pulsedd tungsten inert gas arc welding method was developed in this paper, and a series of bead on plate welding experiments with 10 and 16 mm thick plate were performed. Taking the variations of arc-weld pool characteristic as the research object, the arc characteristic, and the flow behavior and the temperature field evolution of weld pool of pulsedd TIG with adding direct current and without were compared, respectively. The mechanism of increasing weld penetration was discussed. The results show that the high-frequency pulsed current makes the arc to produce electromagnetic contraction, and the compressed degree and the weld penetration positively correlates to the pulsed frequency (1 ~ 5 kHz); the reason of the penetration increase in the direct current added- high-frequency pulsed welding process is that the direct current added pulsed arc increases the arc current and energy density and rises the surface liquid metal temperature of weld pool, and increases the electromagnetic stirring force of the molten pool to improve the flow intensify of molten pool, sufficient convection heat exchange, and enhances the thermal inertia of the molten pool, finally. This method is able to reliably realize the one-sided welding and back formation of the butt joint of 5 mm thick stainless-steel plates.

-

0. 序言

传统Sn-Pb钎料因熔点低(183 ℃)、成本低、润湿性优良等优点,作为互连材料广泛应用于微电子行业中,然而长期使用过程中发现,铅会对人类身体健康和居住环境造成严重威胁[1]. Sn-Ag-Cu钎料合金因其优异的润湿性、可靠性和力学性能而被广泛应用于替代Sn-Pb钎料[2],其熔点远高于Sn-37Pb共晶钎料的183 ℃,这会因热膨胀系数(CTE)差异导致基板和芯片在高温回流下发生翘曲,因此Sn-Ag-Cu钎料不能应用于需低温焊接的热敏元件. 为了解决热应力引起的翘曲问题,提高产品可靠性,亟需开发替代Sn-Pb钎料的低温无铅钎料体系,以应用于电子封装领域[2]. Sn-Bi钎料合金体系(共晶Sn-58Bi钎料熔点为139 ℃),因其熔点低、抗蠕变性能好、硬度高等优点成为低温钎料体系代表,被广泛关注与开发利用[3-4].

对于电子封装互连结构,芯片工作时产生的大量焦耳热首先通过微焊点向外界环境进行传导,导致互连焊点内形成温度梯度,引发金属原子热迁移行为,显著影响脆性界面金属间化合物相的生长行为,进而影响器件服役可靠性. Qiao等人[5]研究了150 ℃下Cu/Sn-3.0Ag-0.5Cu/Cu微焊点在1 000 ℃/cm温度梯度下的界面反应行为,发现在Cu原子扩散速率较快的微焊点中,冷、热两端界面IMC呈现非对称性生长,且随时间延长,热端铜基体溶解加重,Cu原子向冷端迁移的现象也更明显,导致IMC非对称性生长更加显著;Shen等人[6]研究了平均温度为88.95 ℃时,Cu/Sn-58Bi/Cu微焊点在1 309 ℃/cm温度梯度下的热迁移行为,发现Bi原子会向焊点冷端迁移,且随时间延长,Bi原子迁移量增加,当热迁移至200 h时,在冷端出现了连续的Bi层. 界面处脆性Bi相的偏聚及粗化会严重影响微焊点的可靠性,限制Sn-Bi钎料的进一步应用. 因此,研究微焊点中Bi原子的热迁移行为及其对界面反应行为的影响,为促进Sn-Bi钎料的应用开发及提高器件可靠性具有重要意义.

文中针对Cu/Sn-58Bi/Cu微焊点,设置不同的温度梯度,分析回流及时效时的原子迁移行为及其对界面反应行为的影响,以期获得温度梯度和时间对原子迁移及界面反应的影响规律,据此提出原子迁移对界面反应行为影响的机制,为提高低温互连焊点可靠性提供理论指导.

1. 试验方法

试验采用99.95%(质量分数)的铜块作为金属基体,以共晶Sn-58Bi为钎料,制备Cu/Sn-58Bi/Cu微焊点,试验装置示意图如图1所示,具体步骤如下. 首先,准备两个尺寸为10 mm × 10 mm × 10 mm的铜金属块,将每个面磨抛后浸入酒精中进行超声清洗,并吹干;然后,在铜块待焊表面均匀涂覆一薄层松香助焊剂,采用直径100 μm的不锈钢丝控制间距,并采用如图1(a)所示方式进行夹持;随后,对待焊结构进行预热,并立即浸入温度为180 ℃的熔融钎料合金中进行钎焊,钎焊10 s后迅速取出焊块并浸入水中冷却;最后,将焊块切割、磨抛后制得初始微焊点,如图1(b)所示.

将初始微焊点用导热硅脂贴于散热片上,然后将散热片垂直固定于热台上进行温度梯度试验,如图1(c)所示,在试验过程中采用热电偶测量微焊点两端的温度. 此外,利用ANSYS软件对Cu/Sn-58Bi/Cu微焊点内部温度分布进行了模拟,结果如图2所示. 模拟时设置Sn-58Bi钎料的热导率为19 W/(m·℃),密度为8.7 g/cm3,铜的热导率为400 W/(m·℃),密度为8.9 g/cm3,模拟结果与热电偶测量值基本吻合. 表1为具体试验条件.

表 1 Cu/Sn-58Bi/Cu微焊点温度梯度下试验条件Table 1. Experimental conditions for temperature gradient of Cu/Sn-58Bi/Cu solder试验

条件焊点高度

H/μm平均温度

T/℃反应时间

t/h温度梯度

△T/(℃·cm−1)时效 100 110 100,200,400 1 000,1 300,1 500 回流 100 180 0.083,0.25,0.5,1 1 000 使用配备有电子背散射衍射(EBSD,X-Max50)的扫描电子显微镜(SEM,IT800-SHL)对初始微焊点进行晶粒取向表征,利用场发射电子探针(EPMA,JXA-8530F PLUS)观测在温度梯度下回流及时效后微焊点界面微观组织形貌及元素分布.

2. 试验结果与讨论

常温下,体心四方晶体结构(body-centered tetragonal structure,a = b = 5.83 Å,c = 3.18 Å)的β-Sn[7-10],使含有限个β-Sn晶粒的微焊点表现出强烈的扩散各向异性,当锡晶粒c轴与温度梯度方向平行时,原子扩散速度快,而二者相互垂直时原子扩散速度慢[9]. 当焊点中锡晶粒呈现择优取向,会影响原子迁移行为及界面反应行为. 已知Bi原子为菱形六面体结构(rhombic hexahedron structure,a = b = 4.55 Å,c = 11.86 Å)[10-11],c轴的扩散系数大于a/b轴,导致Bi原子也存在显著的各向异性[12]. 对初始微焊点晶粒取向进行观测,以确定焊点中Sn和Bi晶粒是否存在择优取向是必要的. 图3为Cu/Sn-58Bi/Cu初始微焊点中局部微观组织及晶粒取向图,由图3(a)的SEM图可以观察到焊点内Sn-58Bi为Sn和Bi两相均匀交错的共晶组织. 通过图3(b)中EBSD晶粒取向图可以观察到,Sn和Bi晶粒均没有明显的择优取向特征. 图3(d)是Bi相的晶粒取向图,可以进一步观察到Bi晶粒没有择优取向,因此Bi晶粒取向不会对热迁移结果产生影响,这与Chen等人[12]试验结果一致.

图4为Cu/Sn-58Bi/Cu微焊点在1 000 ℃/cm温度梯度下回流后的微观组织形貌,图中下界面为热端,上界面为冷端. 在此温度梯度下回流5 min后,冷、热两端IMC为非对称性生长的扇贝状Cu6Sn5,冷端IMC厚度明显高于热端,如图4(a)所示. 已知当焊点内温度梯度达到Cu原子热迁移门槛值后,热端铜基体便会溶解,Cu原子会向冷端持续迁移并在冷端与Sn原子反应生成界面Cu6Sn5,反应式为

$ 6{\rm{Cu}} + 5{\rm{Sn}} \to {\rm{Cu}}_6{\rm{Sn}}_5 $ ,使冷端IMC厚度远大于热端,然而,该温度梯度并不能使Bi原子发生迁移,因此Bi原子没有表现出明显的迁移行为. 当回流时间延长至15 min时,界面IMC的非对称生长现象相对5 min时更加明显,如图4(b)所示. 随着热迁移时间的延长及界面化合物与固态钎料界面能的降低,Cu6Sn5晶粒更倾向于沿Cu6Sn5与铜基体错配度低的方向生长,因此冷端界面Cu6Sn5 IMC由扇贝状转变为棱柱状[13-14],同时冷、热两端IMC非对称性生长更加明显. 与图4(c)中回流30 min类似,回流60 min后Cu原子通量继续增多,非对称性生长更加明显,如图4(d)所示. 由此可知,在1 000 ℃/cm温度梯度下回流,即可引发Cu原子迁移,但并未引发Bi原子热迁移.原子热迁移门槛值与温度相关[15],不同温度下原子热迁移门槛值不同. 时效过程中原子的热迁移行为是影响微焊点可靠性的关键因素,因此有必要分析时效(焊点平均温度为110 ℃)过程中的原子热迁移行为及界面反应行为. 图5为1 000 ℃/cm温度梯度下时效不同时间后微观组织,可以看到,在温度梯度下时效后,冷、热两端IMC厚度非常接近,说明在此温度梯度下时效时,Cu/Sn-58Bi/Cu焊点中没有发生明显的Cu原子定向迁移,这与电迁移研究结果一致[12]. 此外,也并未观察到Bi原子的热迁移现象,说明在此条件下也并未触发Bi原子的热迁移行为. 然而,当热迁移时间延长至200 h和400 h时,发现了Bi相的明显粗化和界面IMC层的增厚. 综上,在110 ℃时效时,1 000 ℃/cm的温度梯度并不会引发Cu原子和Bi原子的热迁移.

为了进一步探究引起Bi原子热迁移的临界温度梯度,对时效(焊点平均温度为110 ℃)过程中,不同温度梯度下微焊点的微观组织演变进行分析. 采用温度梯度分别为0 ℃/cm(等温),1 000 ℃/cm,1 300 ℃/cm和1 500 ℃/cm. 由图6中焊点在不同温度梯度下时效100 h后的截面图可知,时效后两侧界面IMC均为对称生长的层状Cu6Sn5. 此外,在温度梯度为0 ℃/cm(等温)时,Sn-58Bi钎料呈共晶状均匀分布; 温度梯度为1 300 ℃/cm时,Bi相在冷端偏聚不明显,但当温度梯度增加到1 500 ℃/cm时,Bi相在冷端明显偏聚,且迁移至冷端的Bi原子会挤压Sn原子,导致Sn原子向相反方向迁移,即从冷端迁移至热端,在热端出现了Sn相的偏聚[6]. 由此可得,引起Bi原子热迁移的温度梯度为1 300 ~ 1 500 ℃/cm,这与文献中报道的引发Bi原子热迁移的温度梯度(1 308 ℃/cm)相一致[6]. 为了更直观地观察此现象,对不同温度梯度下时效后的焊点截面进行了面扫分析,试验结果见图7和图8所示.

为更加明确触发Bi原子热迁移的温度梯度门槛值,将微焊点在温度梯度下的时效时间由100 h延长至200 h,试验结果如图9所示. 由图可知,当温度梯度为0 ℃/cm和1 000 ℃/cm时,界面处仍未出现Bi相的偏聚,即未发生明显的Bi原子迁移,但IMC厚度相较100 h有所增加. 当温度梯度达到1 500 ℃/cm时,可以发现在冷端出现了明显的Bi相偏聚,相对应的,热端出现了Sn相的偏聚. 将温度梯度下时效时间延长至400 h,界面IMC厚度继续增加,但仍表现为对称性生长,如图10所示. 当温度梯度为1 300 ℃/cm和1 500 ℃/cm时,冷端均出现了明显的Bi相偏聚,形成了连续的Bi层,温度梯度为1 500 ℃/cm时冷端Bi相偏聚最为明显,同时热端Sn相偏聚也更加明显.

综上所述,引起Bi原子迁移的临界温度梯度在1 300 ℃/cm左右,且随着温度梯度下时效时间的延长,Bi原子的迁移现象更加明显. 图11是不同温度梯度下时效时Bi原子迁移情况示意图. 已知Bi原子在β-Sn中的扩散速率D = 1 × 10−11.5 cm2/s[16],远大于Bi的自扩散速率D = 5.76 × 10−17 cm2/s[17]. 因此,温度梯度足够大时,Bi原子会进行热迁移,迁移路径如图11(c)和图11(d)所示,随着Bi原子自扩散和在Sn相中的快速扩散,Bi原子便逐步从热端迁移至冷端,从而在冷端界面出现明显的Bi相偏聚现象,热端呈现Sn相偏聚.

在Cu/Sn/Cu微焊点中,热端Cu原子在温度梯度驱动下会向冷端迁移,并在冷端界面生成界面IMC[4],因此时效后冷、热两端界面IMC呈非对称性生长. 然而,文中的Cu/Sn-58Bi/Cu微焊点在温度梯度下时效后,两端界面IMC几乎呈现对称性生长. 机理分析认为,因网状结构Bi相的阻挡作用,抑制了热端Cu原子向冷端迁移,热端Cu基体溶解的大部分Cu原子会聚集在热端界面处(图12中①位置,图中

${J}^{{\rm{Cu}}}_{{\rm{TM}}}$ 为Cu原子沿路径的扩散通量),与热端界面Sn原子结合,形成热端界面IMC. 仅有少量Cu原子在温度梯度驱动作用下,会沿Sn相由热端向冷端慢慢扩散(图12中②位置). 然而,即使Cu原子迁移至冷端界面,因冷端Bi相的偏聚,也不会与Sn反应形成冷端界面IMC,生成冷端界面IMC的Cu原子通量必然来自于冷端铜基体溶解. 因此,Cu/Sn-58Bi/Cu微焊点在温度梯度下时效时两侧界面IMC几乎呈现对称性生长.3. 结论

(1) 初始Cu/Sn-58Bi/Cu微焊点中,Sn及Bi相均不存在择优取向晶粒组织,取向分布杂乱且随机,不会产生原子扩散各向异性.

(2) 温度梯度下回流时,Cu/Sn-58Bi/Cu微焊点中大量Cu原子由热端迁移至冷端,并在冷端界面生成IMC,导致冷、热两端界面IMC呈现非对称性生长,该现象随着回流时间的延长更加明显,与此同时,未发现明显的Bi原子热迁移行为.

(3) 温度梯度下时效时,因Bi相网状结构对Cu原子热迁移的抑制作用,冷、热两端界面IMC几乎呈现对称性生长. 温度梯度较小时,并未出现Bi原子迁移现象;而当温度梯度超过1 300 ℃/cm时,Bi原子由热端迁移至冷端,并在冷端界面处偏聚,形成连续的层状富集相,且随着温度梯度的增加和热迁移时间的延长这种偏聚更加明显.

-

图 4 不同频率的电流电压波形和直流叠加脉冲电流波形

Figure 4. Arc current and voltage waveform with different pulse frequency and DC-added pulsed current waveform. (a) voltage/current waveform with 10 Hz; (b) direct current waveform; (c) voltage/current waveform with 1 000 Hz; (d) pulsed current waveform with 10 Hz; (e) voltage/current waveform with 5 000 Hz; (f) current waveform of Fig.4b added Fig.4d

表 1 脉冲TIG焊接参数

Table 1 Pulsed TIG welding parameters

序号 频率

f / kHz峰值电流

Ip / A基值电流

Ib / A占空比

δ(%)等效电流

IE / A1 0 150 — — 150 2 1 212 10 50 150 3 2 212 10 50 150 4 3 212 10 50 150 5 4 212 10 50 150 6 5 212 10 50 150 表 2 直流叠加脉冲型TIG焊接参数

Table 2 Direct current added pulsed TIG welding parameters

序号 脉冲电流参数 直流 等效电流 频率

f /kHz峰值

Ip / A基值

Ib / A占空比

δ(%)I /A IE / A 7 0 100 — — 50 150 8 1 141 7 50 50 150 9 2 141 7 50 50 150 10 3 141 7 50 50 150 11 4 141 7 50 50 150 12 5 141 7 50 50 150 -

[1] 张瀛, 王桂敏, 戴文博, 等. 我国乏燃料后处理项目公众沟通策略研究[J]. 核安全, 2021, 19(6): 86 − 92. Zhang Ying, Wang Guimin, Dai Wenbo, et al. Research on public communication strategy of spent fuel reprocessing project in China[J]. Nuclear Safety, 2021, 19(6): 86 − 92.

[2] 叶国安, 郑卫芳, 何辉, 等. 我国核燃料后处理技术现状和发展[J]. 原子能科学技术, 2020, 54(S1): 75 − 83. Ye Guoan, Zheng Weifang, He Hui, et al. Status and development of technology on reprocessing spent nuclear fuel in China[J]. Atomic Energy Science and Technology, 2020, 54(S1): 75 − 83.

[3] Wu X. On residual stress analysis and microstructural evolution for stainless steel type 304 spent nuclear fuel canisters weld joint: Numerical and experimental studies[J]. Journal of Nuclear Materials, 2020, 534: 152131 − 152142. doi: 10.1016/j.jnucmat.2020.152131

[4] 李春凯, 席保龙, 石玗, 等. 氟化物活性TIG焊电弧特征的光谱分析[J]. 焊接学报, 2021, 42(8): 54 − 58. doi: 10.12073/j.hjxb.20210201002 Li Chunkai, Xi Baolong, Shi Yu, et al. Spectral analysis of A-TIG welding arc with fluorides activating flux[J]. Transactions of the China Welding Institution, 2021, 42(8): 54 − 58. doi: 10.12073/j.hjxb.20210201002

[5] Sahoo A, Tripathy S. Improvement in depth of weld penetration during TIG, activated-TIG, and pulsed TIG welding: a review[J]. International Journal of Manufacturing, Materials, and Mechanical Engineering, 2021, 11(2): 68 − 86. doi: 10.4018/IJMMME.2021040105

[6] Cui S, Liu Z, Fang Y, et al. Keyhole process in K-TIG welding on 4 mm thick 304 stainless steel[J]. Journal of Materials Processing Technology, 2017, 243: 217 − 228. doi: 10.1016/j.jmatprotec.2016.12.027

[7] Shang L, Zu M, Xing C, et al. Influence of cusp magnetic field configuration on K-TIG welding arc penetration behavior[J]. Journal of Manufacturing Processes, 2020, 53: 229 − 237. doi: 10.1016/j.jmapro.2020.02.027

[8] 韩晓辉, 赵延强, 杨晓益, 等. 不锈钢激光-MAG复合焊接头成型规律及性能[J]. 西南交通大学学报, 2017, 52(5): 956 − 961. doi: 10.3969/j.issn.0258-2724.2017.05.016 Han Xiaohui, Zhao Yanqiang, Yang Xiaoyi, et al. Forming rules and performances of laser-MAG hybrid welding joints of SUS301L-MT stainless steel[J]. Journal of Southwest Jiaotong University, 2017, 52(5): 956 − 961. doi: 10.3969/j.issn.0258-2724.2017.05.016

[9] Han Y, Han J, Chen Y, et al. Stability of fiber laser-MIG hybrid welding of high strength aluminum alloy[J]. China Welding, 2021, 30(3): 7 − 11.

[10] 齐铂金, 许海鹰, 张伟. 0Crl8Ni9Ti超音频脉冲TIG焊接头组织与性能[J]. 北京航空航天大学学报, 2009, 35(2): 132 − 136. Qi Bojin, Xu Haiying, Zhang Wei. Microstructure and property analysis of 0Cr18Ni9Ti joints welded by ultra-sonic pulse tungsten-inert-gas welding technology[J]. Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(2): 132 − 136.

[11] 齐铂金, 杨舟, 杨明轩, 等. 超高频脉冲GTAW工艺特性分析[J]. 机械工程学报, 2016, 52(2): 26 − 32. doi: 10.3901/JME.2016.02.026 Qi Bojin, Yang Zhou, Yang Mingxuan, et al. Analysis on characteristic of ultra-high frequency pulsed gas tungsten arc welding process[J]. Journal of Mechanical Engineering, 2016, 52(2): 26 − 32. doi: 10.3901/JME.2016.02.026

[12] Yang M, Zheng H, Li L, et al. Arc shape characteristics with ultra -high-frequency pulsed arc welding[J]. Applied Sciences, 2017, 7(1): 45 − 51. doi: 10.3390/app7010045

[13] 赵家瑞, 张选明. 高频脉冲TIG焊电弧的阳极行为[J]. 焊接学报, 1992, 13(1): 59 − 66. Zhao Jiarui, Zhang Xuanming. Anode behavior of high frequency pulse TIG welding arc[J]. Transactions of the China Welding Institution, 1992, 13(1): 59 − 66.

[14] Zheng H, Qi B, Yang M. Dynamic analysis of the ultrasonic -frequency pulsed GMAW metal transfer process[J]. Journal of Manufacturing Processes, 2021, 62(9-12): 283 − 290.

-

期刊类型引用(1)

1. 孙磊,王文昊,王静,虞佳鑫,张亮,姜加伟. 等温时效对Cu-Sn IMC焊点的组织与性能影响. 焊接学报. 2025(03): 82-88 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: