Large diameter hollow stud welding process based on longitudinal magnetic field control

-

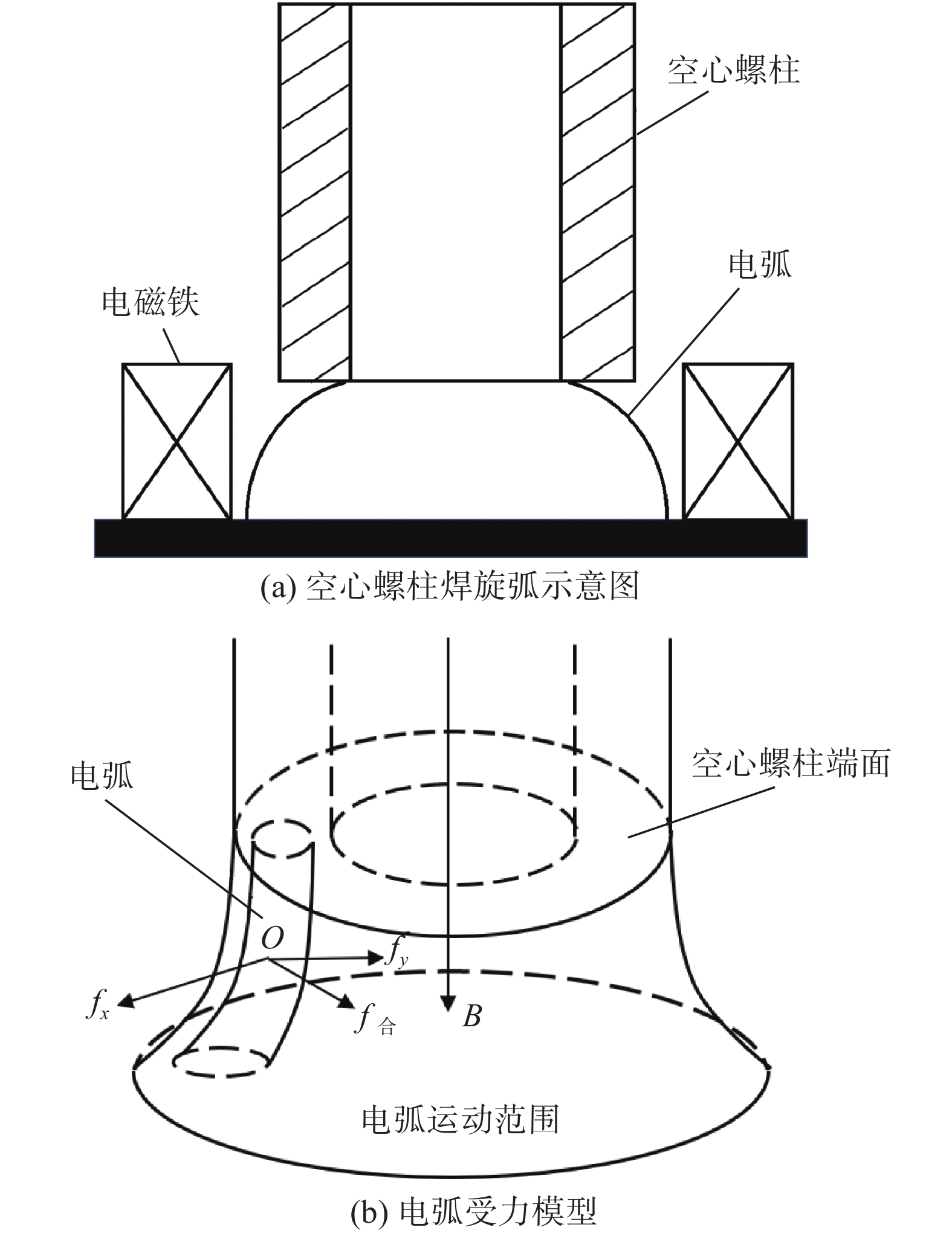

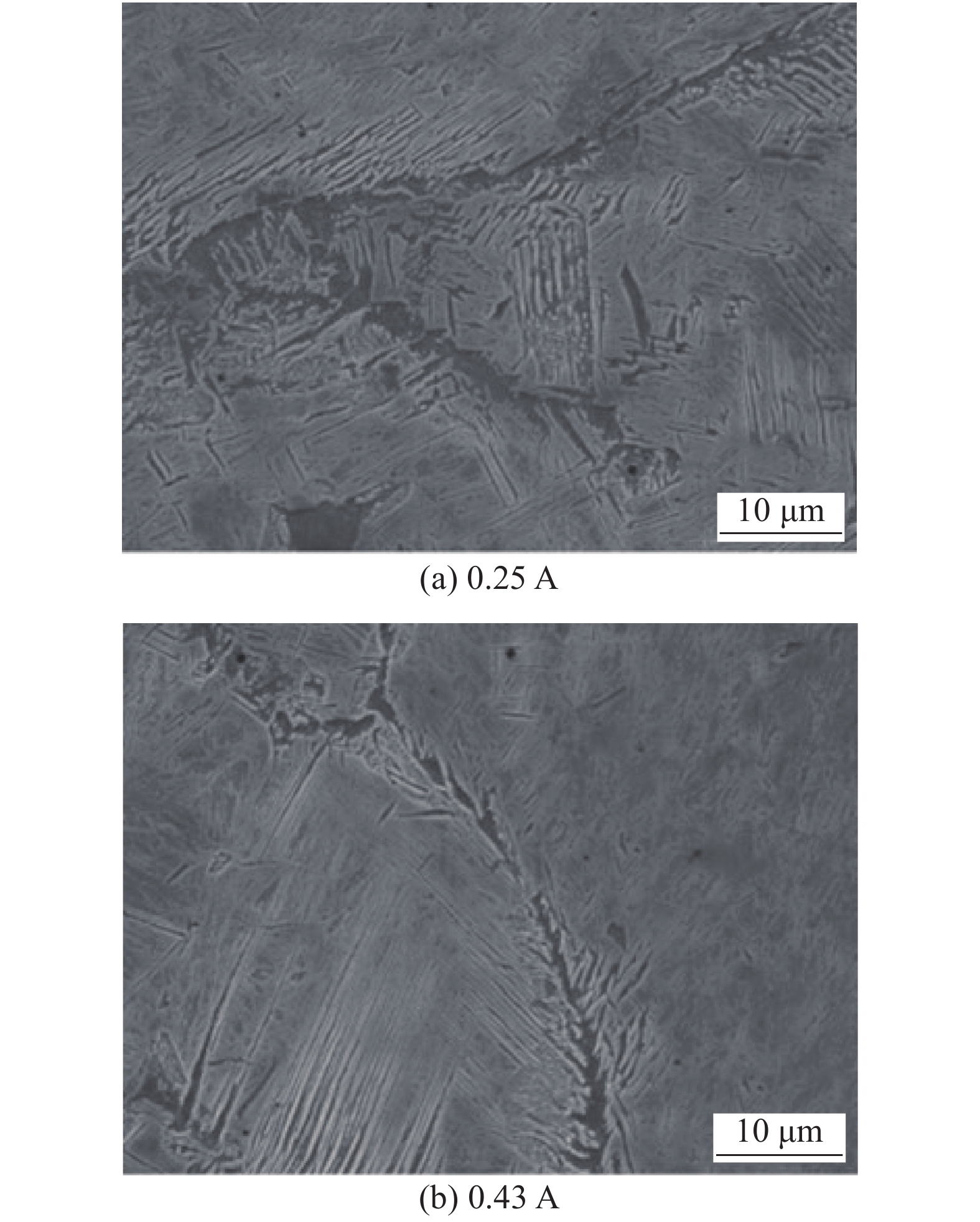

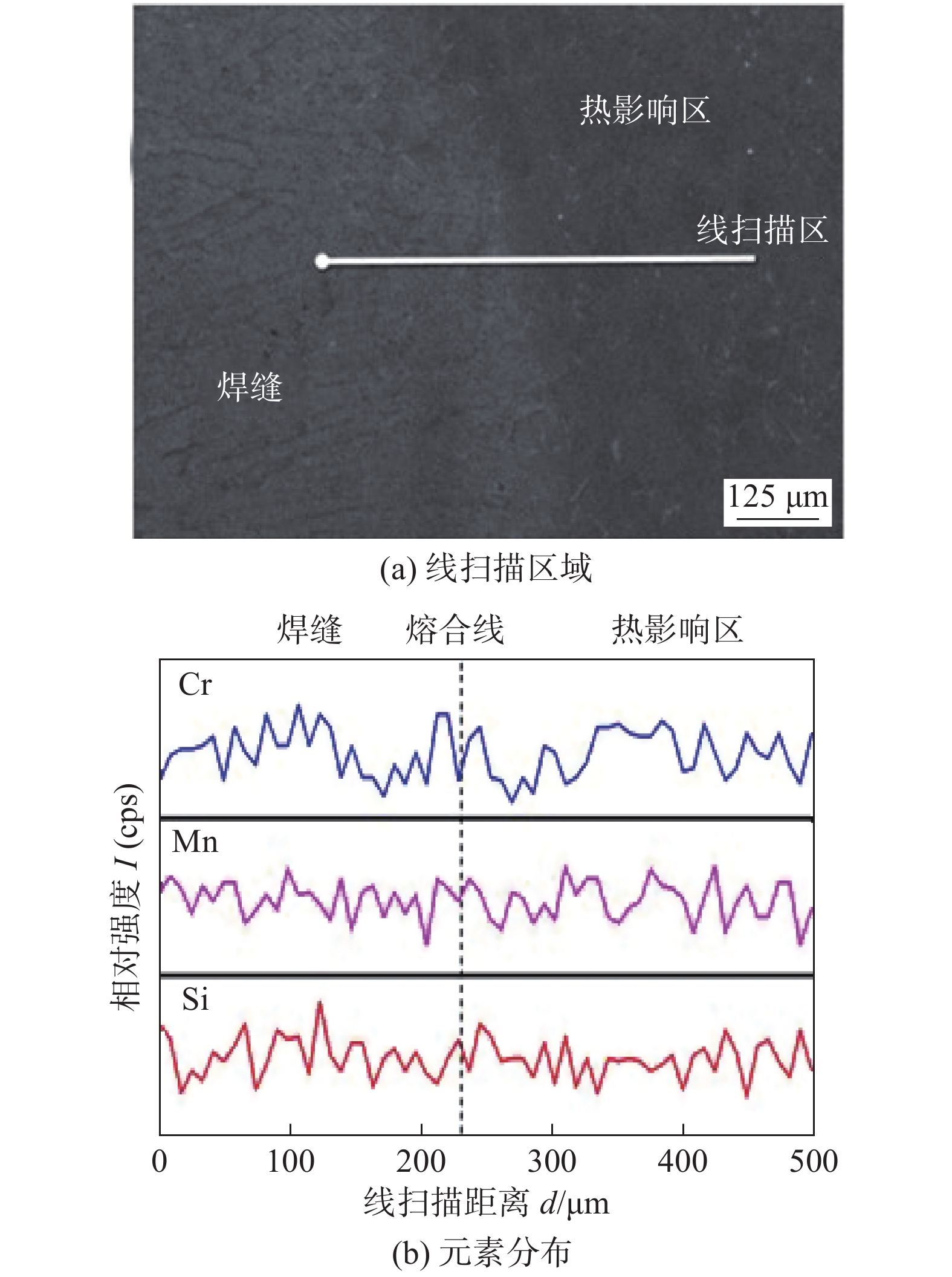

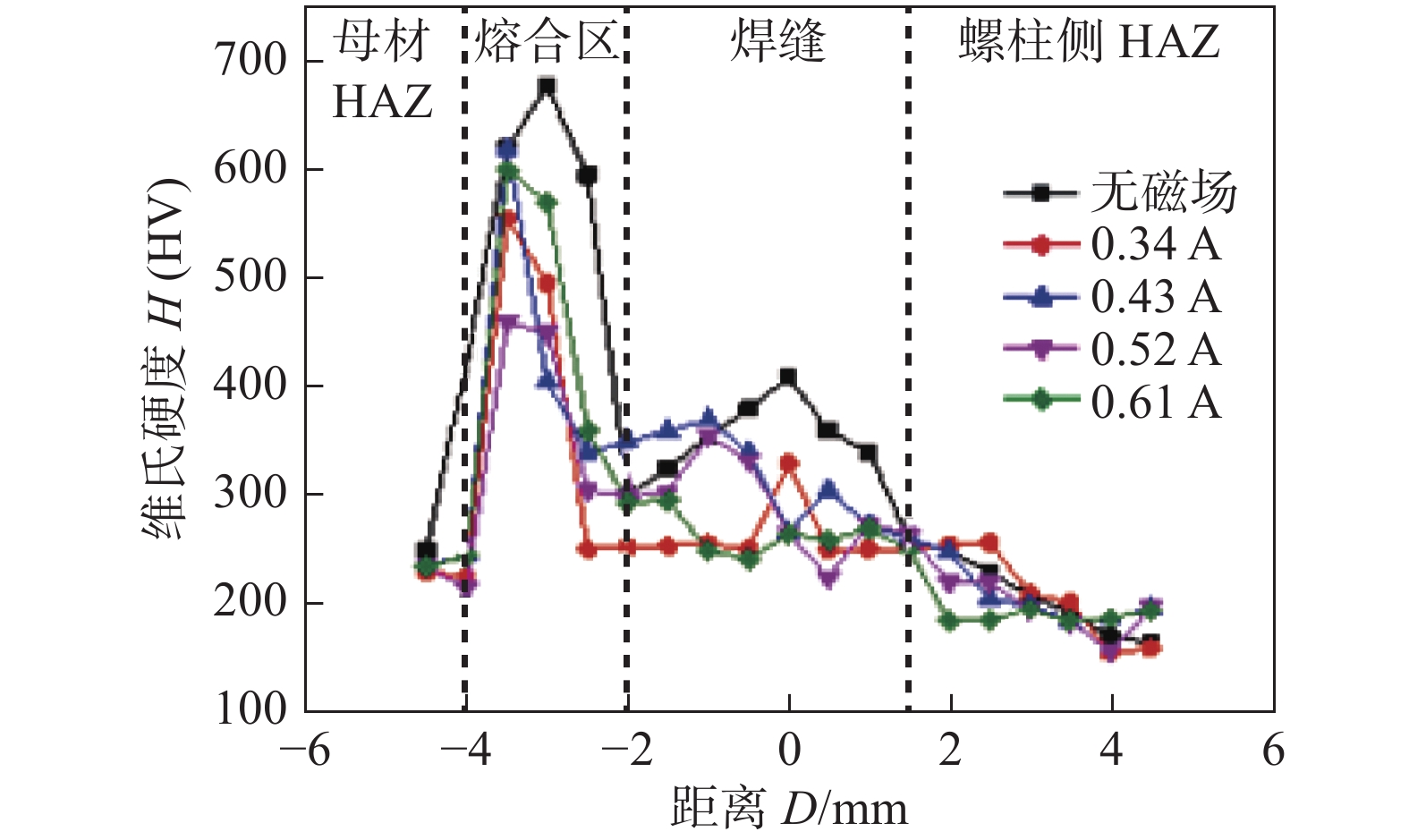

摘要: 采用电弧螺柱焊方法对外径20 mm、内径10 mm的空心螺柱与45钢板材进行焊接,研究了旋弧磁场对接头显微组织特征及力学性能的影响. 结果表明,在纵向旋弧磁场作用下,电弧中电荷受洛伦兹力作用呈螺旋运动,接头外观成形得到改善. 受磁场控制的电弧持续搅拌熔池,改善了焊接热循环条件,影响了熔池凝固结晶过程. 接头中先共析铁素体呈有规律的网状分布,珠光体也变得细化. 接头温度梯度减小使得固态相变时间增长,母材侧热影响区马氏体数量显著下降,热影响区宽度变小. 但旋弧磁场电流过大时焊接过程飞溅倾向明显增大,焊缝中气孔增多. 在焊接时间1 400 ms、焊接电流800 A、旋弧磁场电流0.43 A时,电弧在空心螺柱端面充分燃烧,接头抗剪强度可达到325 MPa.Abstract: The arc stud welding method was used to weld 45 steel plate and hollow stud with outer diameter of 20 mm and inner diameter of 10 mm. Effects of the rotating arc magnetic field on microstructure and mechanical properties were studied. The results show that with the longitudinal rotating arc magnetic field, the charge in the arc moved spirally under the action of Lorentz force, which extended outward to some extent and the appearance of the joint was improved. The thermal cycle condition of joint was improved thanks to the continuous stirring of molten pool by controlled arc, and the solidification and crystallization of molten pool was affected. The proeutectoid ferrite showed a regular network distribution and the pearlite became fine. For the decrease of joint temperature gradient, the solid-state phase transition time increased, the martensite content in the heat affected zone of the parent metal of 45 steel side decreased significantly and the width of HAZ became smaller. When the rotating arc magnetic field current was too large, the spatter tendency increased obviously as well as the porosity in the weld increased. When the welding time of 1 400 ms, the welding current of 800 A and the rotating arc current of 0.43 A, the arc was fully burned at the full end face of the hollow stud, the shear strength of joints can reach 325 MPa.

-

Keywords:

- arc stud welding /

- hollow stud /

- magnetic field /

- arc

-

0. 序言

304不锈钢在室温下具有稳定的奥氏体组织,同时因其具有良好的塑性、韧性、焊接性及成形性而广泛应用于食品、建筑给水及直饮水管道等众多领域[1-4].然而在实际工程应用时,过高的硬度和强度往往会阻碍不锈钢管的二次加工,另外国家标准《GB/T 24593—2018 锅炉和热交换器用奥氏体不锈钢焊接钢管》要求钢管交货状态时的硬度应不大于200 HV. 因此在304奥氏体不锈钢管生产时需添加后续的热处理工艺以提高材料的塑性和韧性,降低其硬度和强度[5].

刘巍等人[6]指出SA213-TP304奥氏体不锈钢弯管经固溶处理后,其形变强化效果得到较大程度消除.周慧等人[7]指出304不锈钢的塑性随着固溶温度升高逐渐增加,而抗拉强度降低比较快.史勤益等人[8]发现将304不锈钢加热至1 050 ℃,保温30 min后,组织为单一的奥氏体,但后续施加水冷获得了较大的内应力,导致其硬度高于空冷,郭国林等人[9]也发现水冷比空冷具有更高的硬度.唐峰等人[10]认为304不锈钢的最佳固溶工艺为加热至1 140 ℃,保温35 min. 由此可见,固溶温度、保温时间及后续的冷却速度会对304不锈钢的微观组织和力学性能产生较大的影响.

304奥氏体不锈钢薄壁管生产线是持续运行的,焊后的固溶处理工艺因此被称为在线固溶处理,由于其保温时间较短,以上文献中的热处理工艺参数均不能在生产线应用.另外,目前大部分企业固溶处理时采用氢气作为保护气,氢气是一种易燃易爆气体,生产时存在一定的安全隐患.同时氢气需要通过氨分解设备制得,设备运行周期长,安全性差,成本较高.因此本文通过将固溶处理保护气更换为纯氩气(纯度99.99%),研究不同固溶温度及冷却速度时不锈钢管焊缝和母材微观组织及力学性能的变化,为企业不锈钢管的生产标准化提供一定的基础数据与理论支撑.

1. 试验方法

试验采用304奥氏体不锈钢作为研究对象,厚度为0.8 mm,该材料的化学成分如表1所示.

表 1 304不锈钢的化学成分(质量分数,%)Table 1. Chemical composition of 304 stainless steelC Mn Cr Ni Si Co Fe 0.054 0.956 18.18 10.21 0.325 0.236 余量 不锈钢带在前期经卷板机逐级卷制成管状,而后焊接成为钢管,其外径为32 mm,焊接工艺为TIG焊,焊接速度为1.30 m/min.后续工艺为固溶处理,该工艺由加热阶段和冷却阶段构成,如图1所示.加热阶段设备包括一台GGC100高频感应加热设备、铜管线圈及水冷循环机.冷却阶段设备由石墨换热器、水管等构成.通过调整高频感应加热设备的功率可以改变固溶处理加热温度,通过调节石墨换热器的进出水流量、管件走出石墨换热器是否冲水来控制固溶处理的冷却速度.

在试验前,固溶处理通道提前10 min通保护气,以保证腔体内无杂质气体残留.测温时将红外测温仪紧贴玻璃管,其位置位于线圈后方,如图1所示. 通过数字显示器读取数值,因此示数仅为加热后的温度. 试验结束后,使用线切割制取试样.经研磨、抛光后,采用硝酸、盐酸、蒸馏水配比为1∶1∶1的稀王水对试样进行腐蚀,之后对金相组织进行观察.

由于硬度是影响管件后续二次加工的重要指标,所以需要对不同试验条件下获得的试样进行硬度测试.试样经抛光后表面无划痕即可进行试验,施加载荷为1 kgf,加载时间为10 s.在不锈钢管生产中存在模具对管件的挤压变形不均匀现象,致使不锈钢管横截面母材硬度不均匀,因此对于整个钢管横截面的母材位置,随机选取30个点进行硬度测试,结果取平均值.而焊接接头区域是钢管结构中最为薄弱的环节,因此还需对焊缝的硬度进行测量.对于焊缝试样,打点位置为距离管件内外表面0.4 mm处,从焊缝中心向两侧每隔0.2 mm打一个点.由于焊缝的对称性,因此焊接接头的硬度分布曲线仅展示其一侧的硬度.

在不锈钢管交货时,为了保证管件的塑韧性符合标准,还需对其进行扩口与压扁试验,其原理如图2所示.在扩口试验时,平稳地对圆锥形顶芯施加力F使其压入试样端部进行扩口,直至达到所要求的外径.在压扁试验时,将焊缝保持在水平位置,控制操纵杆使压板向着固定板方向移动,从而将管件压扁.根据国标《GB/T 242—2007 金属管扩口试验方法》和《GB/T 246—2017 金属材料管压扁试验方法》,试验结束时,在不使用放大镜的情况下观察扩口和压扁的管件,如无可见裂纹,应评定为合格.

2. 试验结果与分析

2.1 氩气保护条件下不同固溶温度对不锈钢管组织及性能的影响

在保护气为纯氩气时,通过调整感应加热设备功率来改变固溶处理温度,固溶温度由890 ℃提高到1 035 ℃.后续冷却条件均为“全开,不加水冷”(即石墨冷却管的阀门开至最大,管件从石墨冷却管出来后不用水冲),试验参数如表2所示.

表 2 固溶处理工艺参数Table 2. Solution treatment process parameters序号 设备功率P/kW 固溶温度T/℃ A/C1 — — A2 505 890 A3 518 930 A4 528 970 A5 536 990 A6 540 1007 A7 557 1035 图3a为不同固溶处理温度时管件横截面母材的平均硬度,发现未采用固溶处理(组别A1)时,管件的平均硬度为211.9 HV,未变形的钢带母材平均硬度为173.1 HV,卷管成形后硬度提高了22.4%.在固溶处理后,管件母材的平均硬度值低于未固溶时的硬度值,且均低于200 HV.但随着固溶温度的提高,管件平均硬度变化不大,这可能是在管件截面取点位置不同导致的.其中组别A4的平均硬度最低,其值为188.7 HV,与未固溶时相比降低了11.0%.因此,使用氩气作为保护气对于降低管件硬度具有一定效果,满足国家标准GB/T 24593—2018的要求.

根据上文测定的不同固溶温度时管件母材平均硬度,选取组别A1(未固溶),A2,A4及A6,对不同固溶温度条件下焊接接头处的硬度进行测定.由于硬度测试位置确定,因此试验结果更能体现固溶温度对不锈钢管硬度的影响.组别A1,A2,A4及A6的硬度分布曲线如图3b所示,分析发现热影响区及母材的硬度值随着固溶温度的提高明显降低.而对于焊缝区,当固溶温度提高时,其硬度值略有降低.

图4和图5中a,b,c为组别A1和A4焊缝区、热影响区与母材的金相组织. 焊缝区中包含等轴晶与柱状晶,中心为等轴晶,柱状晶垂直于熔合线指向焊缝中心.焊缝凝固模式为FA模式[11],在不同固溶处理温度条件下,焊缝区的组织均由奥氏体和沿其晶界分布的骨骼状或者板条状的铁素体[12-13]组成.热影响区和母材均含有一定数量的孪晶.

![]() 图 4 A1组别焊接接头金相组织与SEM图Figure 4. Metallurgical structure and SEM diagram of welded joints in A1 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal

图 4 A1组别焊接接头金相组织与SEM图Figure 4. Metallurgical structure and SEM diagram of welded joints in A1 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal![]() 图 5 A4组别焊接接头金相与SEM图Figure 5. Metallurgical structure and SEM diagram of welded joints in A4 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal

图 5 A4组别焊接接头金相与SEM图Figure 5. Metallurgical structure and SEM diagram of welded joints in A4 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal依据国家标准《GB/T 6394—2017 金属平均晶粒度测定法》,采用直线截点法对焊缝中心、热影响区及母材位置进行晶粒尺寸测量.图6a为不同位置处晶粒的尺寸,分析发现,随着固溶温度的提升,焊缝的晶粒度略有增大,而热影响区与母材位置的晶粒明显增大.与未固溶时相比,组别A4焊缝中心、热影响区及母材的晶粒度分别增大了2.4%、37.5%与28.8%,并且孪晶的量大大减少.

为了进一步确定焊接接头析出相的分布情况,对不同固溶温度条件下的试样进行SEM电子扫描拍摄.图4和图5中 e,f,g为组别A1和A4管件的焊缝区、热影响区与母材的 SEM 扫描图片,分析发现提高固溶处理温度,焊缝区沿奥氏体晶界分布的铁素体变得不连续,其原因是固溶处理后铁素体产生部分溶解.同时在热影响区和母材的晶粒内部与晶界处存在着明显的块状析出物,通过图6b中EDS能谱分析确定块状析出物为(Fe,Cr)23C6[14-15],且固溶处理后热影响区与母材处块状析出物的数量降低.由于钢管在生产线中持续向前运动导致在线固溶处理保温时间较短,固溶处理不充分,在奥氏体晶界和晶粒内部仍存在着少量的块状析出物.

试验结果表明,采用固溶处理工艺时,焊缝区的铁素体变得不连续,产生少量溶解,同时该位置的晶粒度略有增大,两者共同作用导致焊缝区硬度的降低[16].而热影响区的晶粒度明显增大,析出物(Fe,Cr)23C6产生部分固溶,热影响区和母材的硬度降低[17]得比较明显.

2.2 氩气保护条件下不同冷却条件对不锈钢管性能的影响

在A2的加热条件下,通过调整初始冷却条件与最终冷却条件进行不同冷却速度试验,其中初始冷却条件为石墨冷却管进、出水流量,其状态可以是阀门全开和接近关闭.最终冷却条件为管件从石墨冷却管出来是否进行水冷,工艺参数如表3所示.

表 3 固溶处理工艺参数Table 3. Solution treatment process parameters序号 冷却条件 设备功率P/kW 固溶温度T/℃ B1 全开,不加水冷 505 890 B2 全开,加水冷 505 890 B3 接近关闭,不加水冷 505 890 B4 接近关闭,加水冷 505 890 图7为不同冷却条件下管件截面母材平均硬度及焊接接头硬度分布曲线.分析发现,通过调整初始冷却条件与最终冷却条件,管件焊缝区、热影响区及母材的硬度几乎不变.

![]() 图 7 不同冷却条件时硬度分布曲线Figure 7. Hardness distribution curve at different cooling conditions. (a) average hardness of base metal; (b) hardness distribution curve of welded joints at different initial cooling conditions; (c) hardness distribution curve of welded joints at different final cooling conditions

图 7 不同冷却条件时硬度分布曲线Figure 7. Hardness distribution curve at different cooling conditions. (a) average hardness of base metal; (b) hardness distribution curve of welded joints at different initial cooling conditions; (c) hardness distribution curve of welded joints at different final cooling conditions钢管经感应加热后仍需通过较长的透明玻璃导管,之后进入石墨冷却管.而透明玻璃导管较薄,与空气直接接触,因此钢管在进入石墨冷却管前就已经进行了空冷.本试验中冷却条件对管件硬度影响不大,原因可能是在钢管进入石墨冷却管前温度就已快速降低至较低温度,已经达到了薄壁结构件固溶处理要求的空冷冷却条件[18].

2.3 氢气保护条件下不同固溶温度对不锈钢管组织及性能的影响

在304奥氏体不锈钢薄壁管生产流程中,目前大多企业采用氢气作为固溶保护气.为了进一步分析两种不同保护气条件下不锈钢管焊缝和母材的组织、性能差异,开展了氢气保护气条件下不同固溶处理温度试验,试验参数如表4所示.

表 4 固溶处理工艺参数Table 4. Solution treatment process parameters序号 设备功率P/kW 固溶温度T/℃ A/C1 — — C2 530 870 C3 567 980 C4 597 1035 C5 623 1050 C6 633 1083 C7 643 1120 图8a为不同固溶温度条件下管件截面母材的平均硬度,分析发现,在使用氢气作为固溶处理保护气时,管件截面平均硬度也均低于未固溶时的硬度,满足国家标准GB/T 24593—2018的要求.但随着固溶温度的提高,管件平均硬度变化不大,这也可能是在管件截面取点位置不同导致的.其中组别C4的管件母材平均硬度最低,其值为182.7 HV,与未固溶时相比降低了13.8%.组别A/C1(未固溶)、A4(氩气条件下平均硬度最低)和C4(氢气条件下平均硬度最低)的焊接接头硬度分布曲线如图8b所示,可以发现在氢气保护气条件下,进行在线固溶处理后的管件焊缝及母材位置硬度均比未固溶时(A/C1)的样品低. C4组别热影响区与母材的硬度分布曲线与A4较为相似,但A4条件下焊缝区的硬度更大.

根据图9a、9b、9c金相组织图提取晶粒尺寸,如图8c所示.与未固溶时(A/C1)相比,组别C4焊缝中心、热影响区及母材的晶粒度分别增大了3.3%、15.3%和16.2%,并且孪晶的数量大大减少.对该组试样进行SEM电子扫描观察,发现焊缝区中沿晶界分布的铁素体也产生了部分溶解,热影响区和母材区域的块状析出物(Fe,Cr)23C6产生部分固溶.因此氢气保护气条件下进行固溶处理的管件硬度有所降低.此外,C4与A4组别相比,热影响区与母材的硬度分布曲线较为相似,而A4条件下焊缝区的硬度更大.这是因为C4条件下的固溶设备功率及固溶温度高于A4组别,导致C4组别焊缝区的平均晶粒尺寸略大于A4组别.同时,固溶温度的提高有利于铁素体及碳化物的溶解,因此C4条件下焊缝区的硬度低于A4组别.

![]() 图 9 C4组别焊接接头金相与SEM图Figure 9. Metallurgical structure and SEM diagram of welded joints in C4 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal

图 9 C4组别焊接接头金相与SEM图Figure 9. Metallurgical structure and SEM diagram of welded joints in C4 group. (a) metallographic structure of welded zone; (b) metallographic structure of heat-affected zone; (c) metallographic structure of base metal; (d) SEM scanning diagram of welded zone; (e) SEM scanning diagram of heat-affected zone; (f) SEM scanning diagram of base metal2.4 扩口和压扁试验

在不锈钢管固溶处理、定长切割等生产流程完成后,往往需要对其进行二次加工变形,从而达到实际的工程需求,因此要求不锈钢管具有一定的塑韧性. 参考国家标准以及实际生产经验,需对管件进行扩口和压扁试验,以验证钢管的塑韧性,试验原理见小节1. 表5与图10a、10b为扩口和压扁试验结果,发现在进行扩口试验之后,管件均未出现裂纹,扩口率大于厂家要求的14%. 经压扁试验之后,焊缝也未发现任何裂纹.结果表明,在氩气和氢气保护气条件下固溶处理的管件均满足后续加工的塑韧性要求.

表 5 扩口和压扁试验结果Table 5. Results of flaring and flattening test组别 扩口率A(%) 扩口试验结果 压扁试验结果 A/C1 34.37 未出现裂纹 未出现裂纹 A4 37.50 未出现裂纹 未出现裂纹 B4 40.94 未出现裂纹 未出现裂纹 C4 37.50 未出现裂纹 未出现裂纹 结合显微组织、硬度、扩口及压扁试验结果,在氢气和氩气保护气条件下,对奥氏体不锈钢管进行在线固溶处理生产的管件均判定为合格样品.但结合表2 ~ 表4也发现,氩气保护气条件下的最低硬度组别A4比氢气保护气条件下的最低硬度组别C4所使用的加热设备功率降低了11.6%,固溶处理成本显著降低.

3. 结论

(1)采用氩气作为固溶保护气时,在试验温度范围内,提高固溶温度可以降低焊缝及母材的硬度,其中,管件母材平均硬度可降低至188.7 HV,降低了11.0%.而调整冷却条件对焊缝及母材的硬度影响不大.在氢气作为保护气时,平均硬度可降低至182.7 HV,降低了13.8%.

(2)在氢气和氩气保护气条件下固溶处理生产的管件经显微组织观察,硬度、扩口与压扁测试后均判定为合格.

(3)当氩气作为固溶保护气时,最低硬度组别加热设备功率可降低11.6%,同时避免使用氨分解设备来生产氢气.大大降低了生产成本,提高了焊工焊接生产的安全性.

-

图 5 旋弧磁场对空心螺柱焊接头组织的影响

Figure 5. Effects of rotating arc magnetic field on the microstructure of hollow stud welded joints. (a) non-magnetic field stud welding seam; (b) weld microstructure of rotating arc stud welding; (c) non-magnetic field stud welding fusion line; (d) rotating arc stud welding fusion line

表 1 45钢的化学成分(质量分数,%)

Table 1 Chemical compositions of 45 steel

C Si Mn Cr+Ni+Cu P S Fe 0.42~0.50 0.17~0.37 0.5~0.8 0.7 0.035 0.035 余量 表 2 焊接工艺参数及接头抗剪强度

Table 2 Welding process parameters and shear strength of joints

编号 焊接电流

I/A焊接时间

t/ms旋弧电流

I/A抗剪强度

Rτ/MPa1 800 1 400 0 278 2 800 1 400 0.25 302 3 800 1 400 0.43 325 4 800 1 400 0.61 310 -

[1] Harada Y, Sada Y, Kumai S. Dissimilar joining of AA2024 aluminum studs and AZ80 magnesium plates by high-speed solid-state welding[J]. Journal of Materials Processing Technology, 2014, 214(2): 477 − 484. doi: 10.1016/j.jmatprotec.2013.10.005

[2] 王克鸿, 张德库, 薛鹏飞, 等 . 复合热源螺柱焊方法[J]. 焊接学报, 2008, 29(11): 45 − 48. doi: 10.3321/j.issn:0253-360X.2008.11.012 Wang Kehong, Zhang Deku, Xue Pengfei, et al. Compound heat source stud welding method[J]. Transactions of the China Welding Institution, 2008, 29(11): 45 − 48. doi: 10.3321/j.issn:0253-360X.2008.11.012

[3] 顾艳红, 马慧娟, 高辉, 等. 16Mn钢摩擦螺柱焊接头的微观组织与局部腐蚀[J]. 上海交通大学学报, 2017, 51(11): 1348 − 1354. Gu Yanhong, Ma Huijuan, Gao Hui, et al. Microstructure and local corrosion behavior of friction stud welding of 16Mn steel[J]. Journal of Shanghai Jiaotong University, 2017, 51(11): 1348 − 1354.

[4] 高辉, 焦向东, 周灿丰, 等. 基于Abaqus的水下摩擦螺柱焊焊接过程仿真[J]. 焊接学报, 2014, 35(12): 50 − 54. Gao Hui, Jiao Xiangdong, Zhou Canfeng, et al. Simulation of underwater friction stud welding process based on Abaqus[J]. Transactions of the China Welding Institution, 2014, 35(12): 50 − 54.

[5] 王克鸿, 张德库, 郑石雄, 等. 空心螺柱旋弧焊接方法[J]. 焊接学报, 2008, 29(12): 101 − 103. doi: 10.3321/j.issn:0253-360X.2008.12.026 Wang Kehong, Zhang Deku, Zheng Shixiong, et al. Rotating arc welding method of hollow stud[J]. Transactions of the China Welding Institution, 2008, 29(12): 101 − 103. doi: 10.3321/j.issn:0253-360X.2008.12.026

[6] 艾星宇. 纵向磁场与活性剂联合下镁合金焊接接头组织性能的研究[D]. 沈阳: 沈阳工业大学, 2017. Ai Xingyu. Study on microstructure property of magnesium alloy welded joint under the longitudinal magnetic field associated with active agents[D]. Shenyang: Shenyang University of Technology, 2017.

[7] Kamikawa S, Ishii I, Takezawa K, et al. Elastic softening due to the quadrupole interaction and anomalous magnetic phase diagram under the magnetic field in HoRu2Al10[J]. Physical Review B, 2017, 96(15): 155131. doi: 10.1103/PhysRevB.96.155131

[8] Zhang Xun, Zhao Zeyang, Mi Gaoyang, et al. Effect of external longitudinal magnetic field on arc plasma characteristics and droplet transfer during laser-MIG hybrid welding[J]. International Journal of Advanced Manufacturing Technology, 2017, 92(5-8): 2185 − 2195. doi: 10.1007/s00170-017-0293-2

[9] 姚猛. 空心螺柱焊接工程化质量控制研究[D]. 南京: 南京理工大学, 2018. Yao Meng. Study on quality control of hollow stud welding engineering[D]. Nanjing: Nanjing University of Science and Technology, 2018.

[10] Egry I, Ricci E, Novakovic R, et al. Surface tension of liquid metals and alloys recent developments[J]. Advances in Colloid & Interface Science, 2010, 159(2): 198 − 212.

[11] 孙莉, 张腾, 刘晨曦, 等. 单组分活性剂对二氧化碳气体保护焊熔池形态的影响[J]. 天津科技, 2017, 44(6): 29 − 34. doi: 10.3969/j.issn.1006-8945.2017.06.010 Sun Li, Zhang Teng, Liu Chenxi, et al. Effect of single component active flux on weld pool for carbon dioxide welding[J]. Tianjin Science and Technology, 2017, 44(6): 29 − 34. doi: 10.3969/j.issn.1006-8945.2017.06.010

[12] 陈荣. 磁场辅助激光_MIG复合焊接对316L焊缝组织与性能影响的研究[D]. 武汉: 华中科技大学, 2018. Chen Rong. Research on influence of microstructure and properties of 316L welds via magnetic field assisted laser-MIG hybrid welding[D]. Wuhan: Huazhong University of Science and Technology, 2018.

[13] Kohout J. An alternative to the JMAK equation for a better description of phase transformation kinetics[J]. Journal of Materials Science, 2008, 43(4): 1334 − 1339. doi: 10.1007/s10853-007-2255-9

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: