Prediction and optimization of tensile strength of 7A52 aluminum alloy friction stir welding joints based on response surface methodology

-

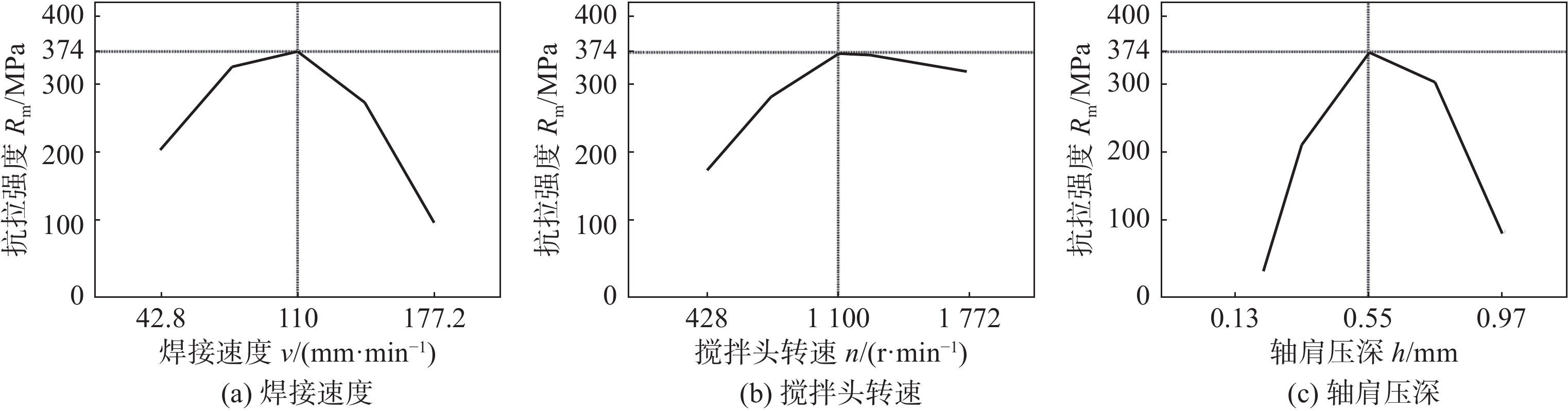

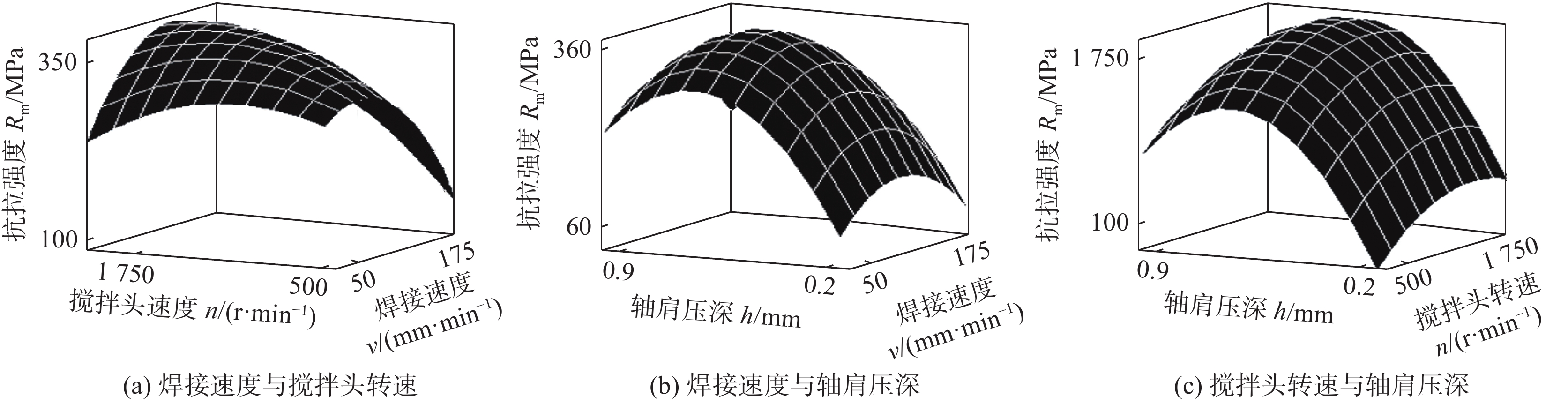

摘要: 为了研究7A52铝合金搅拌摩擦焊的焊接速度、搅拌头转速及轴肩压深对接头抗拉强度的影响,采用响应面法的中心复合试验设计法设计20组试验,并建立抗拉强度响应函数关系式. 为了验证响应函数关系式的精确性,通过方差分析和回归分析确定该回归模型为显性,相关性系数R2的偏差为3.17%. 通过单一焊接参数因素和双因素焊接参数对抗拉强度的影响分析,进一步验证了模型的准确性,最后通过拉伸试验验证. 结果表明,基于响应面法拟合的搅拌摩擦焊焊接速度、搅拌头转速及轴肩压深与接头抗拉强度响应函数关系式能精确的预算不同焊接参数组合所对应的接头抗拉强度,并获得接头最佳参数组合为焊接速度110 mm/min、搅拌头转速1 436 r/min和轴肩压深0.55 mm,得到最大预测抗拉强度为380 MPa.Abstract: In order to study the effects of welding speed, stirring head rotation speed and pressure deep of shaft shoulder on tensile strength of 7A52 aluminum alloy friction stir welding. 20 groups of tests were designed by response surface methodology based on central composite test design, and response function relationship were established. In order to verify the accuracy of the response function relationship, variance analysis and regression analysis were used to determine the dominance of the regression model, and the deviation of correlation coefficient R2 was only 3.17%. The accuracy of the model was verified by analyzing the influence of single welding parameter and double welding parameter on tensile strength. Finally, the model was verified by tensile test. The results show that the joint tensile strength can be predicated based on response function relationship of response surface methodology fitting, and the best combination of welding parameter (welding speed 110 mm/min, stirring head rotation speed 1 436 r/min, pressure deep of shaft shoulder 0.55 mm) was gained. The maximum predication tensile strength was 380 MPa.

-

0. 序言

Q355B低合金钢凭借其强度高、塑性和韧性好等特点,被广泛应用于桥梁、船舶、轨道列车转向架等关键结构[1]. 在这些结构中,主要承载结构部件均经焊接而成,并在服役过程中承受着复杂的载荷条件. 而焊接接头在交变载荷条件下往往发生疲劳失效,继而成为整个结构中最薄弱的环节[2]. 因此,评估焊接结构的疲劳寿命至关重要,而焊接接头的应力状态以及相应的裂纹扩展路径更是成为了学者们关注的焦点. 评估焊接接头疲劳寿命最常用的方法有名义应力法、结构应力法等,这些方法对焊根失效问题均存在一定的局限性,准确评估疲劳寿命困难较大. 这是由于当焊根处起裂失效时,根部存在严重的应力集中,裂纹的扩展路径为焊缝区,疲劳寿命主要为焊缝区裂纹的扩展寿命,且扩展角度不同,扩展寿命不同. 当焊根处的宏观裂纹被监测到时,剩余疲劳寿命往往已不足20%[3-4],因此,准确获得根部裂纹扩展角度是评估焊根失效疲劳寿命的关键,也是结构设计中最重要的环节.

针对以上问题,Wang等人[5]采用最大周向应力准则(MCS法)模拟裂纹扩展,即裂纹垂直于最大周向应力方向从裂纹尖端开始沿径向扩展,故可以将周向应力(σθθ)达到最大时的角度作为裂纹扩展的角度. 王苹等人[3]在Xing等人[6]的基础上,针对十字接头承载角焊缝提出了有效结构应力法(ETS法). 该方法认为不同的扩展角度对应于不同的有效结构应力,其中最大有效结构应力所对应的角度即为裂纹扩展的角度. 上述两种方法均基于有限元数值模拟计算,其中MCS法具有网格敏感性,不同的网格密度有不同的结果,获得结果的精度依赖于划分网格的精密程度;相较之下,ETS法具有网格不敏感性的优点.

针对T形接头承载角焊缝根部疲劳失效问题,提出了一种新的预测裂纹扩展角度的方法——等效应力强度因子法(KEQ法). 该方法只需简单的受力分析计算即可得到根部裂纹扩展的角度,无须进行有限元模拟,可有效地避免建模时网格精度造成的误差. 为验证KEQ法的有效性和精准性,以Q355B低合金钢液压挖掘机动臂和斗杆结构中的T形接头为研究对象,从实际受力情况出发,进行了弯曲疲劳试验,测量了此接头焊根处裂纹的扩展角度. 建立了有限元模型,对KEQ法进行了验证,并与MCS法、ETS法进行了对比分析. 该研究为求解应力强度因子提供了简便途径,同时为预测T形接头角焊缝根部裂纹扩展角度问题提供了新的方法.

1. 试验方法

1.1 试验材料

文中选用工程机械领域常用的Q355B低合金钢,采用CO2气体保护焊制备T形接头,所用焊丝为ER50-6 实芯焊丝,直径为1.6 mm. 焊接工艺参数如表1所示.母材和焊丝的化学成分如表2所 示.T形接头疲劳试件取样及接头具体尺寸如图1所示. 疲劳试件经线切割、铣削加工,无加工痕迹残留,以确保疲劳试件与实际失效情况相符,由焊缝根部起裂.

表 1 焊接工艺参数Table 1. Welding processing parameters电弧电压

U/V焊接电流

I/A气体流量

Q/(L·min−1)焊接速度

v/(mm·s−1)22 200 20 5 表 2 母材及焊丝的化学成分(质量分数,%)Table 2. Chemical compositions of base metal and welding wire材料 C Si Mn S P Fe Q355B 0.20 0.25 0.60 0.04 0.02 余量 ER50-6 0.12 1.05 1.60 0.03 0.01 余量 1.2 疲劳试验

弯曲疲劳试验采用GPS300型高频疲劳试验机,其最大载荷为300 kN,试件装夹如图2所示. 弯曲疲劳试验应力比R设定为0.5,选用3个应力范围Δσ进行测试,分别为80,115 和150 MPa,每个应力范围测试6个试件.

1.3 焊接接头根部裂纹扩展角度的测量

疲劳试件失效断裂后,垂直于焊缝切取55 mm × 50 mm × 20 mm的金相试样,使用砂纸依次打磨至1000号后机械抛光至表面光亮,再使用4%硝酸+96%酒精(体积分数)的试剂进行腐蚀. 处理后的试样用于焊根处剖面的观察以及裂纹扩展角度的测量.

2. 等效应力强度因子法

裂纹尖端应力场存在奇异性,具有无法直接通过应力来反映裂纹尖端的受力特性[7]. 断裂力学理论认为应力强度因子(K)反映了裂纹尖端附近应力强弱程度,裂纹会沿着K最大的方向扩展,可通过计算最大应力强度因子间接得到裂纹扩展角度.

计算K有多种方法,如:借助数学分析的复变函数法及权函数法[8],近似计算的边界配置法[9]及有限元法,利用试验标定的柔度标定法[10]等.

对于从根部起裂的T形接头,应力强度因子手册中没有直接的公式计算K,根据BS 7910:2019 Guide to methods for assessing the acceptability of flaws in metallic structures可采用有限长板条公式进行推导,经有限元模拟验证,使用此方法计算出的解析解误差较小.

图3为有限长板条受力示意图. 根据应力强度因子手册,宽度为b的有限长板条,有一长度为a的单边裂纹,受单向均匀拉伸作用,如图3a所示,其应力强度因子KⅠ为

$$ {K}_{{\rm{I}}}={F}_{1}{\sigma }_{1}\sqrt{{\text{π}} a} $$ (1) 式中:σ1为板所受拉应力;F1为有关a和b的函数,即

$$ \begin{split} {F_1} =& 1.12 - 0.231\left( {\frac{\,a\,}{\,b\,}} \right) + 10.55{\left( {\frac{\,a\,}{\,b\,}} \right)^2}-\\ &21.72{\left( {\frac{\,a\,}{\,b\,}} \right)^3}{\text{ + }}30.39{\left( {\frac{\,a\,}{\,b\,}} \right)^4} \end{split} $$ (2) 作用在裂纹长度为a、宽度为b的有限长板条的单位厚度弯曲力矩M,如图3b所示,其应力强度因子KⅠ为

$$ {K}_{{\rm{I}}}={F}_{2}{\sigma }_{2}\sqrt{{\text{π}} a} $$ (3) $$ {\sigma }_{2}\text=\frac{6M}{{b}^{2}} $$ (4) 式中:σ2为板所受弯曲应力;F2为有关a和b的函数,即

$$ \begin{split} {F_2} = &1.122 - 1.40\left( {\frac{\,a\,}{\,b\,}} \right) + 7.33{\left( {\frac{\,a\,}{\,b\,}} \right)^2}-\\ &13.08{\left( {\frac{\,a\,}{\,b\,}} \right)^3}{\text{ + }}14.0{\left( {\frac{\,a\,}{\,b\,}} \right)^4} \end{split}$$ (5) 在含裂纹长度为a的有限长板条裂纹嘴上作用一对单位厚度的集中切向力q,如图3c所示,其应力强度因子KⅡ为

$$ {K}_{{\text{Ⅱ}}}={F}_{3}\frac{2}{\sqrt{{\text{π}} a}}q $$ (6) 式中:F3为有关a和b的函数,即

$$ {F_3} = \dfrac{{1.3 - 0.65\left( {\dfrac{\,a\,}{\,b\,}} \right) + 0.37{{\left( {\dfrac{\,a\,}{\,b\,}} \right)}^2} - 0.28{{\left( {\dfrac{\,a\,}{\,b\,}} \right)}^3}}}{{\sqrt {1 - \dfrac{\,a\,}{\,b\,}} }} $$ (7) 许多承受单轴载荷的结构部件包含随机定向的缺陷或裂纹,这些缺陷/裂纹经历混合模式的应力状态. 混合模式疲劳裂纹的一个特征是它们通常以非自相似的方式扩展[11],即当受到混合模式加载条件时,裂纹会改变扩展方向. 对于研究中承受弯曲载荷F的T形接头,焊根处未焊透可被视为初始裂纹缺陷,当承受弯曲疲劳载荷时,裂纹将沿着一定的角度进行扩展,定义扩展角度为θ. 因采用有限长板条公式进行推导,故规定等效平板的上下平面垂直于裂纹扩展面. 根据力的平移定理以及参考应力强度因子手册,将外力F平移至等效板边会产生附加弯矩M1, 将外力F分解为轴向力Fsinθ,切向力Fcosθ,并将切向力Fcosθ平移至裂纹尖端产生附加弯矩M2,受力分析如图4所示.

$$ {\sigma _1}{\text{ = }}\frac{{F\sin \theta }}{{w{t'}}} $$ (8) $$ Q_1 = \frac{{F\cos \theta }}{{{w}}} $$ (9) $$ M = {M_1} + {M_2} = F{{\text{d}}_1} + Fd\cos \theta $$ (10) $$ {\sigma _2}{\text{ = }}\frac{{6M}}{{{{w}}{{{t}}}^{'2}}} $$ (11) 式中:σ1为轴向力F sinθ产生的轴向应力; σ2为弯矩M产生的弯曲应力;Q1为单位厚度下的剪切力;d为力作用的距离,140 mm;w为取样长度,200 mm; d1为F移动的水平距离;t′为等效的有限长板条宽度;d1与t′的大小都与θ有关.

焊缝尺寸放大图如图5所示,将未焊透长度a视为初始裂纹的长度,a0为裂纹面上的等效初始裂纹长度. t′由等效初始裂纹长度a0与焊喉长度L两部分组成.

$$ {a_0} = a\cos \theta = ({t_2} - p)\cos \theta $$ (12) $$ L = \frac{{\left( {p + {{{s}}_1}} \right)\sin \alpha }}{{\sin \left( {\alpha + \theta } \right)}} $$ (13) $$ {t}'={a}_{0}+L $$ (14) $$ \alpha {\text{ = }}\arctan \left( {\frac{{{{{s}}_2}}}{{{s_1}}}} \right) $$ (15) 式中:α为焊脚角度.将上述等效关系,如图6所示,带入式(1) ~ 式(15),求出KⅠ, KⅡ.

KEQ法包含Ⅰ型与Ⅱ型两种应力强度因子,在工程结构中,Ⅰ型裂纹是引起构件疲劳失效的主导因素,Ⅰ型应力强度因子KⅠ对裂纹扩展的影响要大于Ⅱ型应力强度因子KⅡ,所以要考虑等效应力强度因子对裂纹扩展的影响,Zhang等人[12]提出的等效应力强度因子为

$$ {K}_{\text{eq}}={\left({K}_{{\text{Ⅰ}}}^{4}+8{K}_{{\text{Ⅱ}}}^{4}\right)}^{0.25} $$ (16) KEQ法中包含扩展角度θ,因此求出0° ~ 90° 中Keq的最大值,即可获得裂纹扩展角度.

3. 结果分析与讨论

3.1 KEQ法有限元模拟验证

通过式(16)计算出KEQ最大值为25.6°. 为验证KEQ法计算等效应力强度因子的准确性,对T形接头采用ABAQUS进行有限元模拟. 模型中单元为二次单元,采用二维平面应变分析,裂纹扩展角度设置为25.6°,应力范围设置为80 MPa,如图7所示. 建立不同裂纹长度的模型,分别计算Keq,并与由KEQ 法求得的Keq进行对比分析,如表3所示. 从表3可以看出,采用KEQ法求出的应力强度因子与有限元模拟的最大误差小于4%,验证了KEQ法等效过程的正确性.

表 3 不同裂纹长度下Keq对比分析Table 3. Analysis of Keq under different crack lengths等效初始

裂纹长度

a/mm应力强度因子

K/(MPa·mm−1/2)误差e(%) KEQ 法 模拟验证 a0 + 0.1 193.09 194.48 −0.93 a0 + 0.2 195.27 199.48 −2.38 a0 + 0.5 201.81 197.36 2.00 a0 + 1 212.72 207.26 2.43 a0 + 2 234.87 226.18 3.74 a0 + 4 282.54 283.16 −0.25 a0 + 6 339.12 337.24 0.55 a0 + 10 511.88 515.18 −0.64 为了进一步验证KEQ法的准确性,分别建立不同的未熔透深度a以及不同扩展角度θ的模型,计算Keq,并与KEQ法求得的Keq进行对比分析,如表4所示. 从表4可以看出,采用KEQ法求出的Keq与有限元模拟的最大误差小于5%,进一步验证了KEQ法等效过程的正确性.

表 4 a0 + 4 mm裂纹长度下Keq对比分析Table 4. Analysis of Keq at crack length of a0 + 4 mm未焊透长度

a/mm裂纹扩展

角度θ/(°)应力强度因子

K/(MPa·mm−1/2)误差e(%) KEQ 法 模拟验证 0.1 25.6 174.83 181.74 3.95 1 25.6 193.50 199.70 3.20 3 25.6 239.62 229.72 4.31 5 25.6 282.54 283.16 −0.25 8 25.6 361.90 360.81 −0.30 5 10 256.92 270.16 −4.90 5 20 282.87 278.35 −1.60 5 60 207.11 205.10 −0.97 3.2 疲劳试验及评估结果

图8为不同应力水平下裂纹扩展角度测量结果.从图8可知,Δσ = 80 MPa时,扩展角度为24°;Δσ = 115 MPa时为23.6°;Δσ = 150 MPa时为24.2°. 3个应力水平下裂纹扩展角度相差较小,均约为24°.

采用上文所述的3种方法分别计算裂纹扩展角度,在弹性范围内,其不受应力水平大小的影响,裂纹扩展角度均相同. 图9为Δσ = 80 MPa时不同测试方法下裂纹扩展角度曲线. 从图9可以看出,3种方法均呈现先上升后下降的趋势,即分别存在确定的角度使得Keq,σθθ,RETS达到最大值,对比结果如表5所示. KEQ法计算出Keq的最大值对应的角度为25.6°,采用最大周向应力法计算出的裂纹扩展角度为25.9°,采用有效结构应力法计算的裂纹扩展角度为32.2°,与实际裂纹扩展角度对比,KEQ法与MCS法误差都较小,但MCS法需要进行有限元模拟,具有网格敏感性,需要划分较为精密的网格. 因ETS法误差较大,故其适用于十字接头承载角焊缝,对于承受弯曲载荷的T形接头适用性具有局限性. 综上所述,KEQ法在无需进行有限元模拟的基础上仍具有较高的精度,适合预测承受弯曲疲劳载荷下的T形接头焊根裂纹扩展角度.

表 5 不同测试方法下裂纹扩展角度的对比Table 5. Comparison of crack propagation angle under different test methods测试方法 裂纹扩展角度θ/(°) 误差e(%) KEQ法 25.6 6.67 MCS法 25.9 7.92 ETS法 32.2 34.17 试验测试 24.0 — 4. 结论

(1)分别建立不同裂纹长度、未熔透深度、裂纹扩展角度的有限元模型计算Keq,与基于受力分析计算的KEQ法进行对比验证,最大误差小于5%.

(2) KEQ法预测T形接头承受弯曲载荷时角焊缝根部失效裂纹扩展角度,计算结果为25.6°,与疲劳试验结果相比较,误差为6.67%.

(3) MCS法与ETS法求解出的裂纹扩展角度分别为25.9°和32.2°,相较于疲劳试验结果,误差为7.92%,34.17%.

(4)经比较,KEQ法预测T形接头承载角焊缝根部裂纹扩展角度因只需要简单的力学分析,无需进行有限元模拟,最为简便,且误差较小.

-

表 1 7A52铝合金的化学成分(质量分数,%)

Table 1 Chemical compositions of 7A52 aluminum alloy

Zr Zn Mg Fe Mn Si Cr Cu Al 0.12 4.2 2.3 0.33 0.31 0.24 0.23 0.13 余量 表 2 焊接工艺参数

Table 2 Welding parameter

焊接速度

v/(mm·min−1)转速

n/(r·min−1)轴肩压深

h/mm60 ~ 200 600 ~ 2 500 0.3 ~ 0.8 表 3 基于CCD试验设计的FSW接头抗拉强度

Table 3 Results of tensile strength of FSW joints based on CCD

因素 实际焊接参数 标准化焊接参数 抗拉强度

Rm/MPa焊接速度v/(mm·min−1) 转速n/(r·min−1) 轴肩压深h/mm 焊接速度X1 转速X2 轴肩压深X3 1 70 700 0.3 −1 −1 −1 275.10 2 70 700 0.8 −1 −1 1 328.92 3 70 1500 0.3 −1 1 −1 251.61 4 70 1500 0.8 −1 1 1 305.43 5 150 700 0.3 1 −1 −1 167.58 6 150 700 0.8 1 −1 1 221.40 7 150 1500 0.3 1 1 −1 247.96 8 150 1 500 0.8 1 1 1 301.77 9 42.73 1 100 0.55 −1.68 0 0 267.45 10 177.27 1 100 0.55 1.68 0 0 266.72 11 110 427.28 0.55 0 −1.68 0 260.62 12 110 1 772.72 0.55 0 1.68 0 371.91 13 110 1 100 0.13 0 0 −1.68 141.16 14 110 1 100 0.97 0 0 1.68 231.66 15 110 1 100 0.55 0 0 0 368.89 16 110 1 100 0.55 0 0 0 378.68 17 110 1 100 0.55 0 0 0 348.72 18 110 1 100 0.55 0 0 0 388.89 19 110 1 100 0.55 0 0 0 375.59 20 110 1 100 0.55 0 0 0 386.58 表 4 标准条件下回归系数及P值

Table 4 Coefficients and their P values in coded condition

项目 预测系数 误差e F值 Prob > F值 X1 −16.371 1 6.236 805 6.890 166 0.025 4 X2 22.035 61 6.236 805 12.483 19 0.005 4 X3 26.907 62 6.236 805 18.613 42 0.001 5 X12 −35.301 9 6.071 366 33.808 2 0.000 2 X1 X2 25.966 25 8.148 775 10.153 92 0.009 7 X1 X3 −0.001 25 8.148 775 2.356 53 0.999 9 X22 −17.914 1 6.071 366 8.705 962 0.014 5 X2X3 −0.001 25 8.148 775 2.354 33 0.999 9 X32 −63.824 9 6.071 366 110.511 3 < 0.000 1 表 5 模型的方差分析结果

Table 5 Results of ANOVA test

项目 自由度 f 平方和 SS 均方值 MS F值 Prob > F值 X1 1 3 660.20 3660.20 8.268 0.014 X2 1 6 631.33 6631.33 14.980 0.002 X3 1 9 887.83 9887.83 22.336 0.001 X12 1 17 959.60 17959.60 40.570 <0 X1X2 1 5 393.97 5393.97 12.185 0.005 X22 1 4 624.78 4624.78 10.447 0.007 X32 1 58 705.87 58705.87 132.614 <0 模型 7 97 667.90 13952.56 31.518 <0 表 6 模型预测值与试验值比较

Table 6 Comparison of model predicted value and experimental value

因素 转速

n/(r·min−1)焊接速度

v/(mm·min−1)轴肩压深

h/mm抗拉强度Rm/MPa 误差e(%) 预测值 试验值 预测值 1100 110 0.55 374 369 1.33 优化值 1436 110 0.55 380 377 0.79 -

[1] 陈芙蓉, 贾翠玲. 7A52铝合金焊接及其接头表面纳米化研究现状[J]. 华东交通大学学报, 2019, 36(1): 1 − 11. Chen Furong, Jia Cuiling. Review on 7A52 aluminum alloy welding and its welded joint surface nanocrystallization[J]. Journal of East China Jiaotong University, 2019, 36(1): 1 − 11.

[2] Jia Y, Qin Y, Ou Y, Wang K, et al. The influence of microstructural heterogeneity on mechanical properties of friction stir welded joints of T6-treated Al-Zn-Mg alloy 7A52[J]. Metals, 2018, 8: 527 − 538. doi: 10.3390/met8070527

[3] Eivani A R, Vafaeenezhad H, Jafarian H R, et al. A novel approach to determine residual stress field during FSW of AZ91 Mg alloy using combined smoothed particle hydrodynamics/ neuro-fuzzy computations and ultrasonic testing[J]. Journal of Magnesium and Alloys, 2021, 9(4): 1304 − 1328. doi: 10.1016/j.jma.2020.11.018

[4] 赵军军, 张平, 王卫欣, 等. 7A52铝合金搅拌摩擦焊的焊缝成形[J]. 焊接学报, 2005, 26(5): 61 − 64. doi: 10.3321/j.issn:0253-360X.2005.05.016 Zhao Junjun, Zhang Ping, Wang Weixin, et al. Weldbead shaping of friction stir welded 7A52 aluminum Alloy[J]. Transactions of the China Welding Institution, 2005, 26(5): 61 − 64. doi: 10.3321/j.issn:0253-360X.2005.05.016

[5] Su H, Wu C S. Numerical simulation for the optimization of polygonal pin profiles in friction stir welding of aluminum[J]. Acta Metallurgica Sinica(English Letters), 2021, 34(8): 1065 − 1078. doi: 10.1007/s40195-021-01198-1

[6] Chen D G, Liu J H, Ma Z H, et al. Microstructure and properties of welding joints of 7A52 aluminum alloy by the friction stir welding[J]. Applied Mechanics and Materials, 2014, 2948: 292 − 296.

[7] 刘红伟, 周琦, 朱军, 等. 7A52铝合金厚板搅拌摩擦焊接头性能研究[J]. 兵器材料科学与工程, 2006, 29(3): 57 − 60. doi: 10.3969/j.issn.1004-244X.2006.03.016 Liu Hongwei, Zhou Qi, Zhu Jun, et al. Research on joint properties of 7A52 aluminum alloy thick plate by friction stir welding[J]. Ordnance Material Science and Engineering, 2006, 29(3): 57 − 60. doi: 10.3969/j.issn.1004-244X.2006.03.016

[8] 周鹏展, 钟掘, 贺地求. 7A52铝合金厚板搅拌摩擦焊[J]. 中国有色金属学报, 2006, 16(6): 964 − 969. doi: 10.3321/j.issn:1004-0609.2006.06.006 Zhou Pengzhan, Zhong Jue, He Diqiu. Friction-stir welding on thick plate of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 964 − 969. doi: 10.3321/j.issn:1004-0609.2006.06.006

[9] Sivabalan S, Sridhar R, Parthiban A, et al. Experimental investigations of mechanical behavior of friction stir welding on aluminium alloy 6063[J]. Materials Today:Proceedings, 2021, 37(2): 1678 − 1684.

[10] 郝利新,贾瑞灵,张慧霞,等. 微弧氧化膜对7A52铝合金搅拌摩擦焊接头腐蚀不均匀性的影响[J]. 焊接学报, 2019, 40(3): 145 − 150. Hao Lixin, Jia Ruiling, Zhang Huixia, et al. Influence of micro-arc oxidation film on corrosion of inhomogeneity of 7A52 aluminum alloy friction stir welding joint[J]. Transactions of the China Welding Institution, 2019, 40(3): 145 − 150.

[11] Yuvaraj K P, Ashoka V P, Boopathiraja K P. Optimization of process parameters on friction stir welding of AA7075-T651 and AA6061 joint using response surface methodology[J]. Materials Research Express, 2019, 6(9): 6558 − 6578.

[12] Thanatkij S, Rapeepan P, Kanchana S, et al. Combined response surface method and modified differential evolution for parameter optimization of friction stir welding[J]. Processes, 2020, 8: 1080 − 1102. doi: 10.3390/pr8091080

[13] Wasif S, Salman H, Ahmad W, et al. Predicting the tensile strength, impact toughness, and hardness of friction stir-welded AA6061-T6using response surface methodology[J]. International Journal of Advanced Manufacturing Technology, 2016, 87: 1765 − 1781. doi: 10.1007/s00170-016-8565-9

[14] Ramachandran K K, Murugan N, Kumar S S. Performance analysis of dissimilar friction stir welded aluminium alloy AA5052 and HSLA steel butt joints using response surface method[J]. International Journal of Advanced Manufacturing Technology, 2016, 86: 2373 − 2392. doi: 10.1007/s00170-016-8337-6

-

期刊类型引用(3)

1. 张明军,李晨希,邹江林,程波,张健,仝永刚,胡永乐,陈根余. AZ31B镁合金功率调制环形光斑光纤激光焊接试验研究. 机械工程学报. 2025(02): 151-161 .  百度学术

百度学术

2. 刘坤,李洁,王浩,简思捷. 镁合金焊接凝固裂纹敏感性评价及晶间液相回填规律分析. 焊接学报. 2023(09): 9-15+129 .  本站查看

本站查看

3. 焦婧,黄金鑫,张志凯. 论带复杂油路类镁合金铸件的清理方法. 世界有色金属. 2022(23): 175-177 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: