Connection performance of friction element welding between aluminum and high strength steel

-

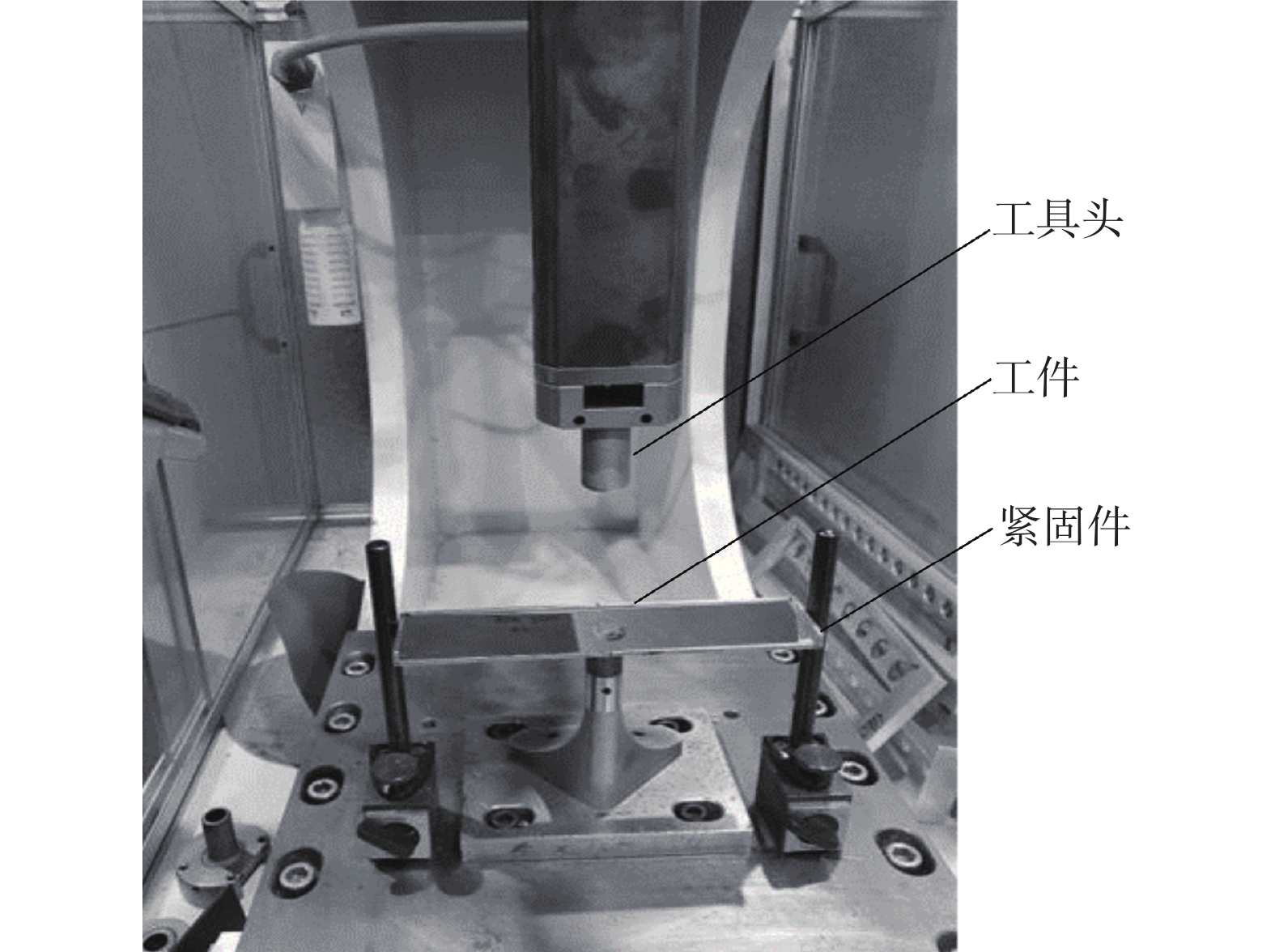

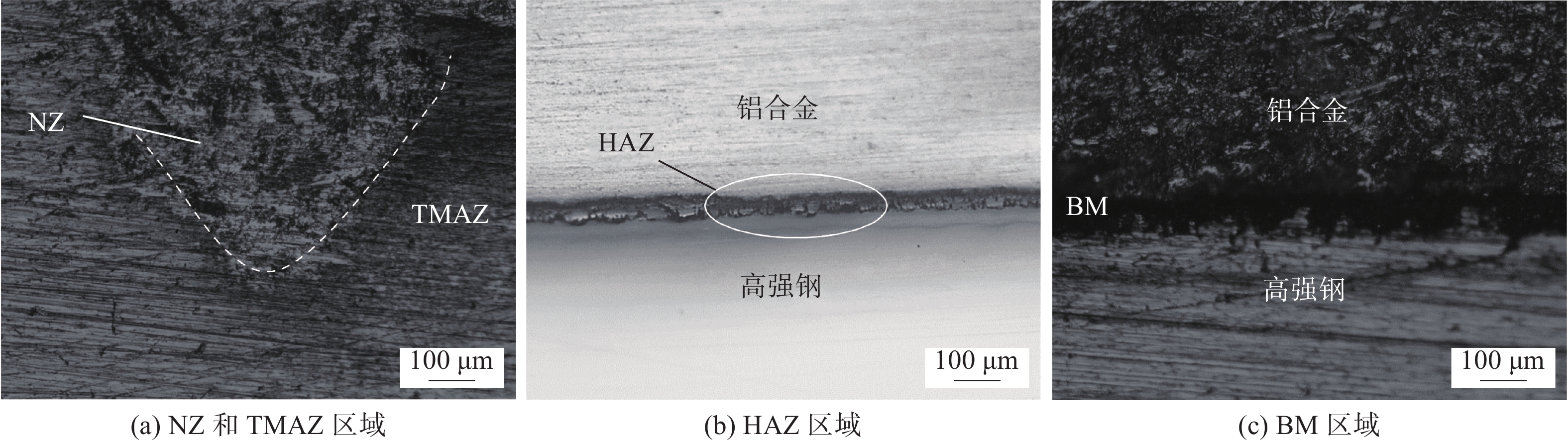

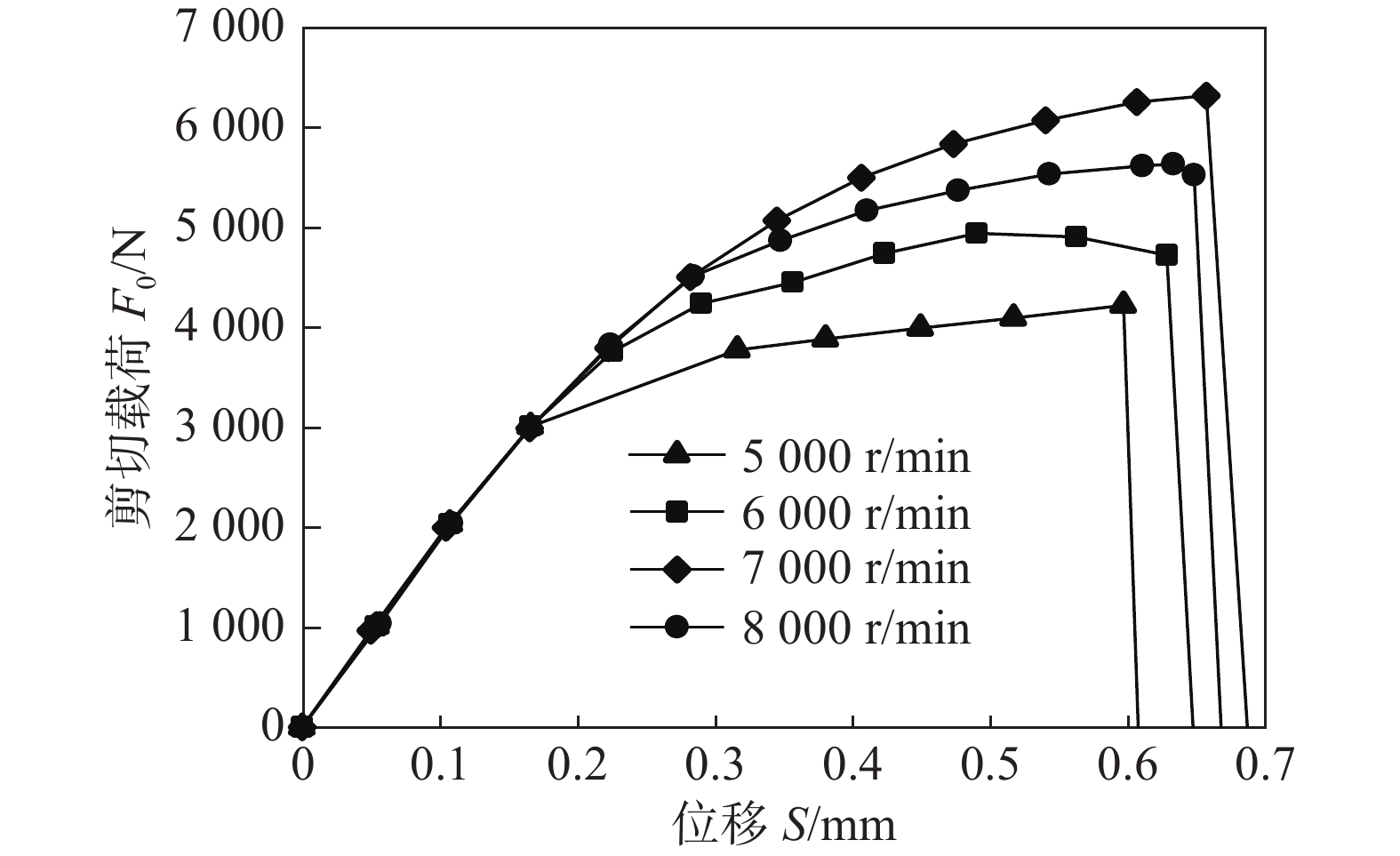

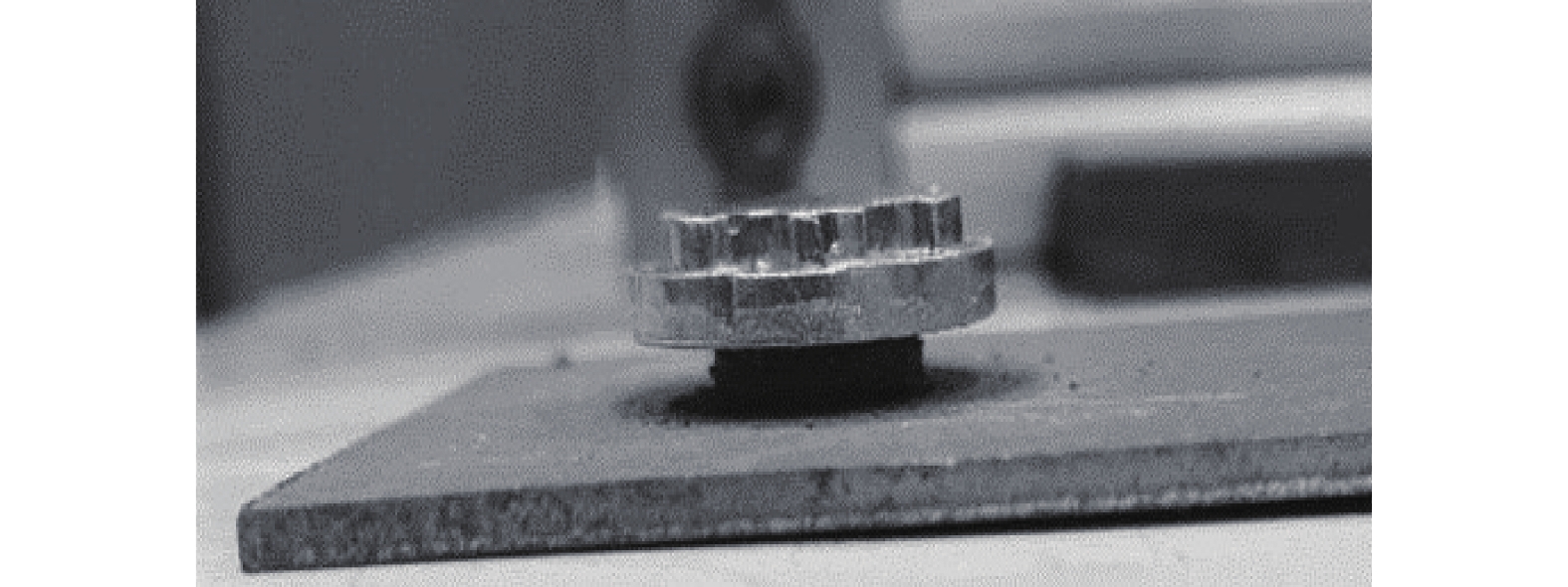

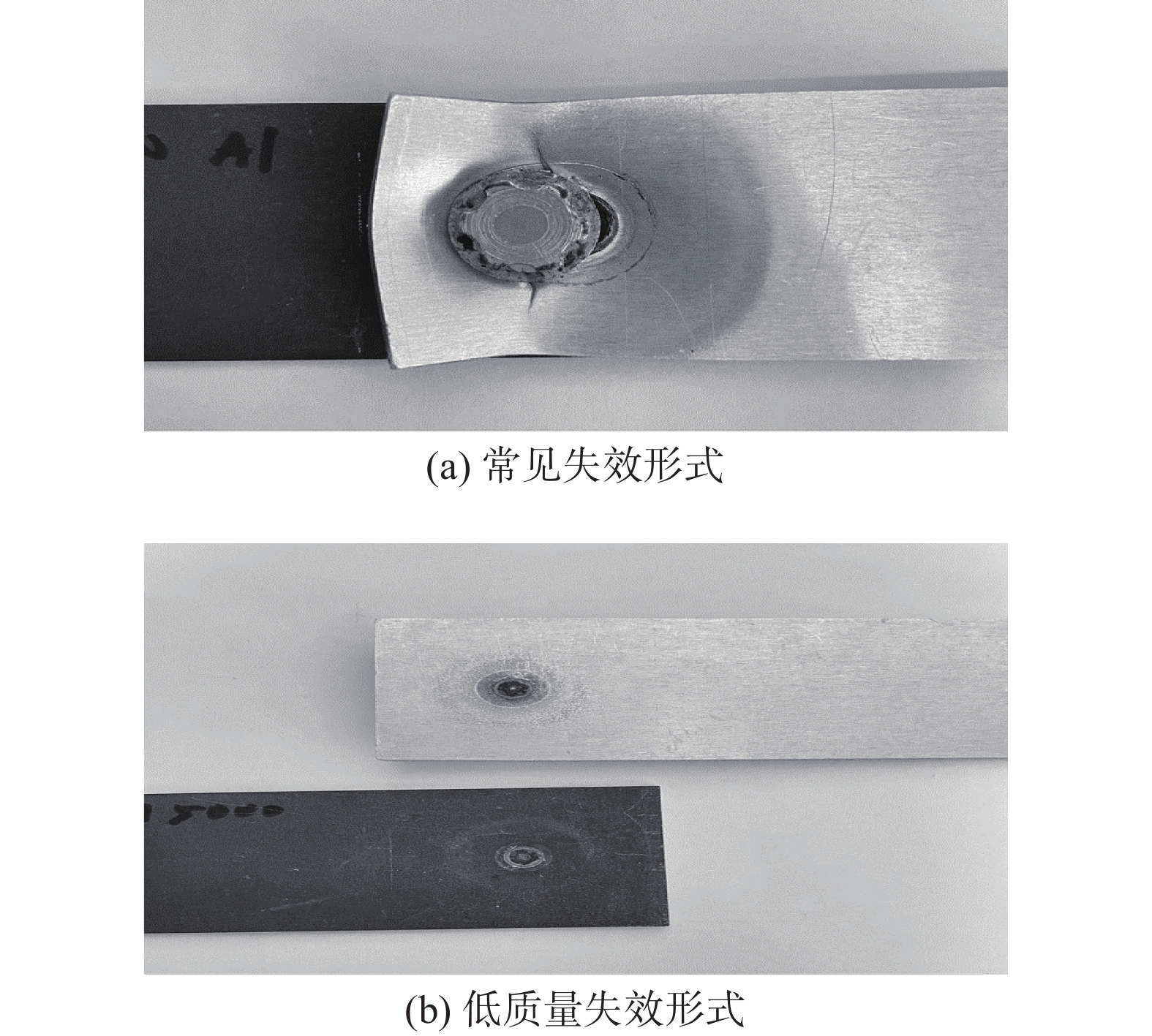

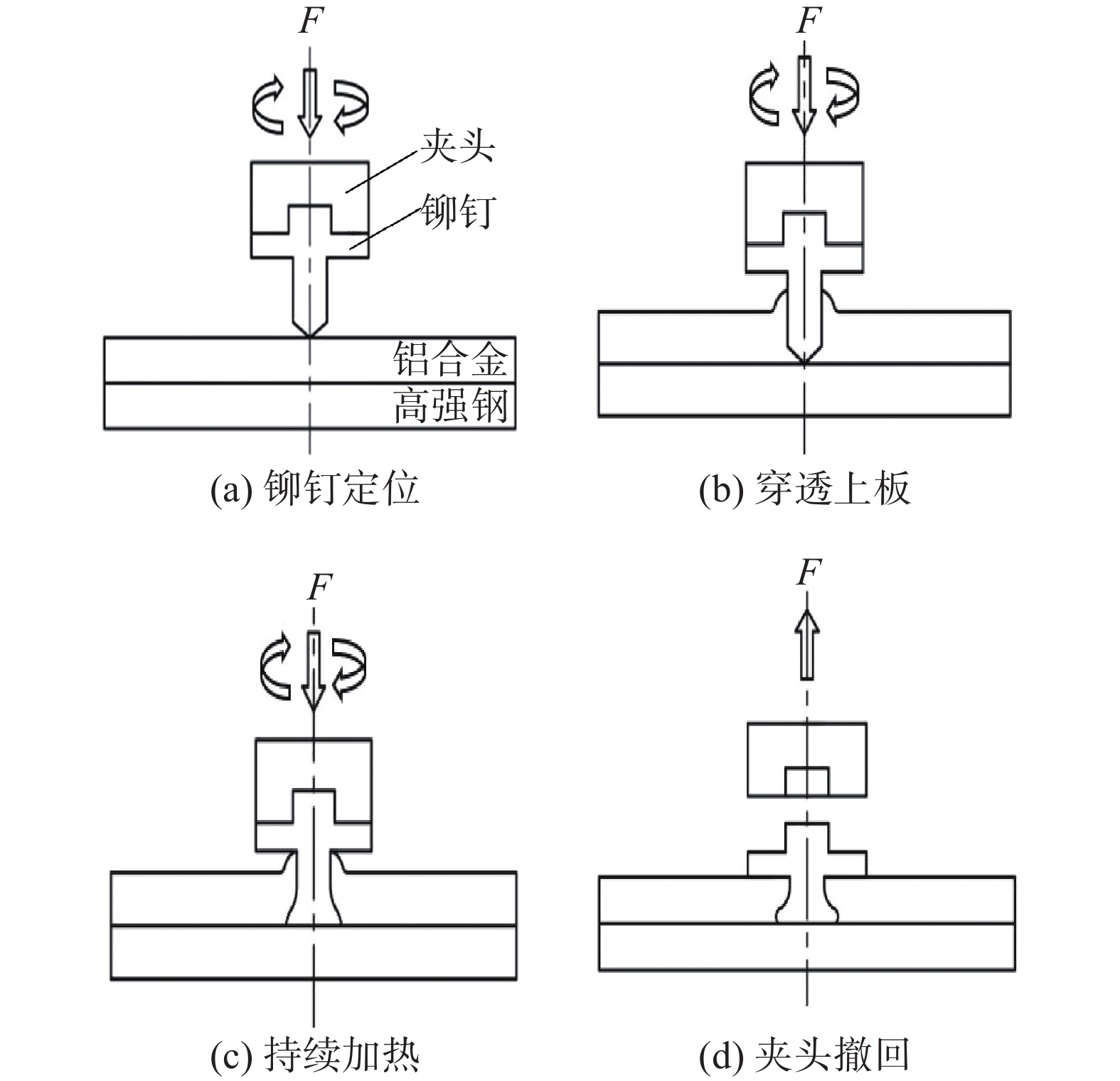

摘要: 为了解决铝合金与高强钢材料之间连接困难的问题,保证铝合金与高强钢之间的连接质量,采用摩擦塞铆焊工艺实现了6061-T6铝合金和DP1470高强钢的连接,并通过对接头宏观形貌和微观组织特征的观察、接头力学性能的测试以及接头失效形式的对比,研究了摩擦塞铆焊所获接头连接性能的变化规律. 结果表明,转速是影响焊接质量的重要因素. 在焊接试验过程中,转速控制范围为5000 ~ 8000 r/min,接头的抗拉强度随转速的增加先升高后降低,当转速达到7000 r/min时,接头所承受的剪切载荷最大,可以达到6.3 kN,此时得到的接头表面平整,无明显孔洞、裂纹等缺陷. 铝合金板材在接头处发生断裂失效时,接头所能承受载荷相对较大,焊接质量较高. 因此,铝合金和高强钢能够通过摩擦塞铆焊工艺实现高质量连接.Abstract: In order to find out the difficulty of the bonding between aluminum alloy and high strength steel material, ensured the high quality bonding between them, friction element welding was used to implement the bonding between 6061-T6 aluminum alloy and high strength steel DP1470. By observed the macro morphology and microstructure of the joint, tested the joint mechanical properties and compared the joint failure forms, the variation law of bonding performance of joint obtained by friction element welding was studied. The results show that rotating speed is an important factor affecting the welding quality. During the welding test, the speed control range is 5000−8000 r/min. The tensile strength of the joint will increase at first and then decrease with the increase of the rotating speed. When the rotating speed reaches 7000 r/min, the shear load of the joint can reach 6.3 kN, the surface of the joints are flat without cracks and pores. When the failure mode of the joint is the fracture failure which occurs on the aluminum alloy plates at the joint, the tensile strength of the joint will increase higher and the welding quality will be better. Therefore, aluminum alloy and high strength steel can achieve high-quality joining through friction element welding.

-

Keywords:

- aluminum alloy /

- high strength steel /

- friction element welding /

- mechanical property /

- failure form

-

-

-

[1] 马潇天, 闫德俊, 孟祥晨, 等. 铝/钢搅拌摩擦焊金属间化合物调控研究进展[J]. 焊接学报, 2020, 41(7): 1 − 11. doi: 10.12073/j.hjxb.20200617001 Ma Xiaotian, Yan Dejun, Meng Xiangchen, et al. Progress on the control of intermetallic compounds in aluminum/steel friction stir welding[J]. Transactions of the China Welding Institution, 2020, 41(7): 1 − 11. doi: 10.12073/j.hjxb.20200617001

[2] 黄健康, 何翠翠, 石玗, 等. 铝/钢异种金属焊接接头界面Al-Fe金属间化合物生成及其热力学分析[J]. 吉林大学学报(工学版), 2014, 44(4): 1037 − 1041. Huang Jiankang, He Cuicui, Shi Yu, et al. Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminum and galvanized steel[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(4): 1037 − 1041.

[3] Booth G, Olivier C, Westgate S, et al. Self-piercing riveted joints and resistance spot welded joints in steel and aluminium[C]//International Body Engineering Conference & Exposition. SAE Technical Paper, 2000: 268.

[4] Sønstabø J K, Holmstrøm P H, Morin D, et al. Macroscopic strength and failure properties of flow drill screw connections[J]. Journal of Materials Processing Technology, 2015, 222: 1 − 12. doi: 10.1016/j.jmatprotec.2015.02.031

[5] 贺地求, 刘杭琪, 赖瑞林. MS1400/DP980钢的电阻点焊的工艺性能分析[J]. 焊接学报, 2018, 39(4): 104 − 108. doi: 10.12073/j.hjxb.2018390105 He Diqiu, Liu Hangqi, Lai Ruilin. Analysis on resistance spot welding process performance of MS1400 and DP980[J]. Transactions of the China Welding Institution, 2018, 39(4): 104 − 108. doi: 10.12073/j.hjxb.2018390105

[6] Gibson B T, Lammlein D H, Prater T J, et al. Friction stir welding: Process, automation, and control[J]. Journal of Manufacturing Processes, 2014, 16(1): 56 − 73. doi: 10.1016/j.jmapro.2013.04.002

[7] Taban E, Gould J E, Lippold J C. Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: Properties and microstructural characterization[J]. Materials and Design, 2010, 31(5): 2305 − 2311. doi: 10.1016/j.matdes.2009.12.010

[8] 王希靖, 张亚州, 李经纬, 等. 铝/镀锌钢搅拌摩擦铆焊接头组织与力学性能[J]. 材料科学与工艺, 2015, 23(2): 103 − 108. doi: 10.11951/j.issn.1005-0299.20150218 Wang Xijing, Zhang Yazhou, Li Jingwei, et al. Microstructure and mechanical properties of friction stir rivet welding joint between aluminum and galvanized steel[J]. Materials Science and Technology, 2015, 23(2): 103 − 108. doi: 10.11951/j.issn.1005-0299.20150218

[9] Kimapong K, Watanabe T. Lap joint of A5083 aluminum alloy and SS400 steel by friction stir welding[J]. Materials Transactions, 2005, 46(4): 835 − 841. doi: 10.2320/matertrans.46.835

[10] Xian Xirui, Ma Yunwu, Shan He, et al. Single-sided joining of aluminum alloys using friction self-piercing riveting (F-SPR) process[J]. Journal of Manufacturing Processes, 2019, 38: 319 − 327. doi: 10.1016/j.jmapro.2019.01.037

[11] 黄体方. 铝/钢铆接辅助搅拌摩擦焊接头界面行为及承载特性分析[D]. 哈尔滨: 哈尔滨工业大学, 2017. Huang Tifang. Interfacial behavior and mechanical properties analysis of Al/steel joint by riveting assisted friction stir welding [D]. Harbin: Harbin Institute of Technology, 2017.

[12] Skovron J D, Ruszkiewicz B J, Mears L, et al. Investigation of the cleaning and welding steps from the friction element welding process[C]//International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2017, 50725: 1−14.

[13] Oliveira J P, Ponder K, Brizes E, et al. Combining resistance spot welding and friction element welding for dissimilar joining of aluminum to high strength steels[J]. Journal of Materials Processing Technology, 2019, 273: 116192. doi: 10.1016/j.jmatprotec.2019.04.018

[14] 林健, 赵海峰, 雷永平, 等. 钢铝搅拌摩擦焊搭接接头的机械结合与冶金结合方式[J]. 机械工程学报, 2015, 51(16): 106 − 112. doi: 10.3901/JME.2015.16.106 Lin Jian, Zhao Haifeng, Lei Yongping, et al. Mechanical and metallurgical bonding in friction stir welding joint of steel-aluminum dissimilar materials[J]. Journal of Mechanical Engineering, 2015, 51(16): 106 − 112. doi: 10.3901/JME.2015.16.106

[15] Khodir S A, Shibayanagi T, Naka M. Microstructure and mechanical properties of friction stir welded AA2024-T3 aluminum alloy[J]. Materials Transactions, 2006, 47(1): 185 − 193. doi: 10.2320/matertrans.47.185

[16] Cederqvist L, Reynolds A P. Factors affecting the properties of friction stir welded aluminum lap joints[J]. Welding Journal, 2001, 80(12): 281 − 287.

[17] 江超, 陈辉, 车小莉, 等. 高速列车 A6005A 铝合金焊接接头断裂韧性研究[J]. 材料科学与工艺, 2013, 21(2): 55 − 60. doi: 10.11951/j.issn.1005-0299.20130210 Jiang Chao, Chen Hui, Che Xiaoli, et al. Fracture toughness of welded joints of A6005A aluminum alloy for high speed train[J]. Materials Science &Technology, 2013, 21(2): 55 − 60. doi: 10.11951/j.issn.1005-0299.20130210

-

期刊类型引用(4)

1. 向剑,蒋立君,谭江峰,刘学刚,乔明伟,胡兴. Q355T型接头焊缝尺寸设计及承载能力研究. 新技术新工艺. 2025(02): 48-53 .  百度学术

百度学术

2. 陈建春. 角焊缝强度计算与焊脚尺寸分析. 焊接技术. 2020(04): 17-19 .  百度学术

百度学术

3. 张涛,王志宇,李晓磊. T形接头钢板焊接残余应力试验研究. 建筑结构学报. 2018(S2): 128-134 .  百度学术

百度学术

4. 孔祥明,吉伯海,傅中秋,陈祥. 正交异性钢桥面板焊缝疲劳应力影响因素分析. 交通科学与工程. 2017(03): 10-17 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: