Repair process of magnesium alloy casting by He-Ar mixed gas TIG welding

-

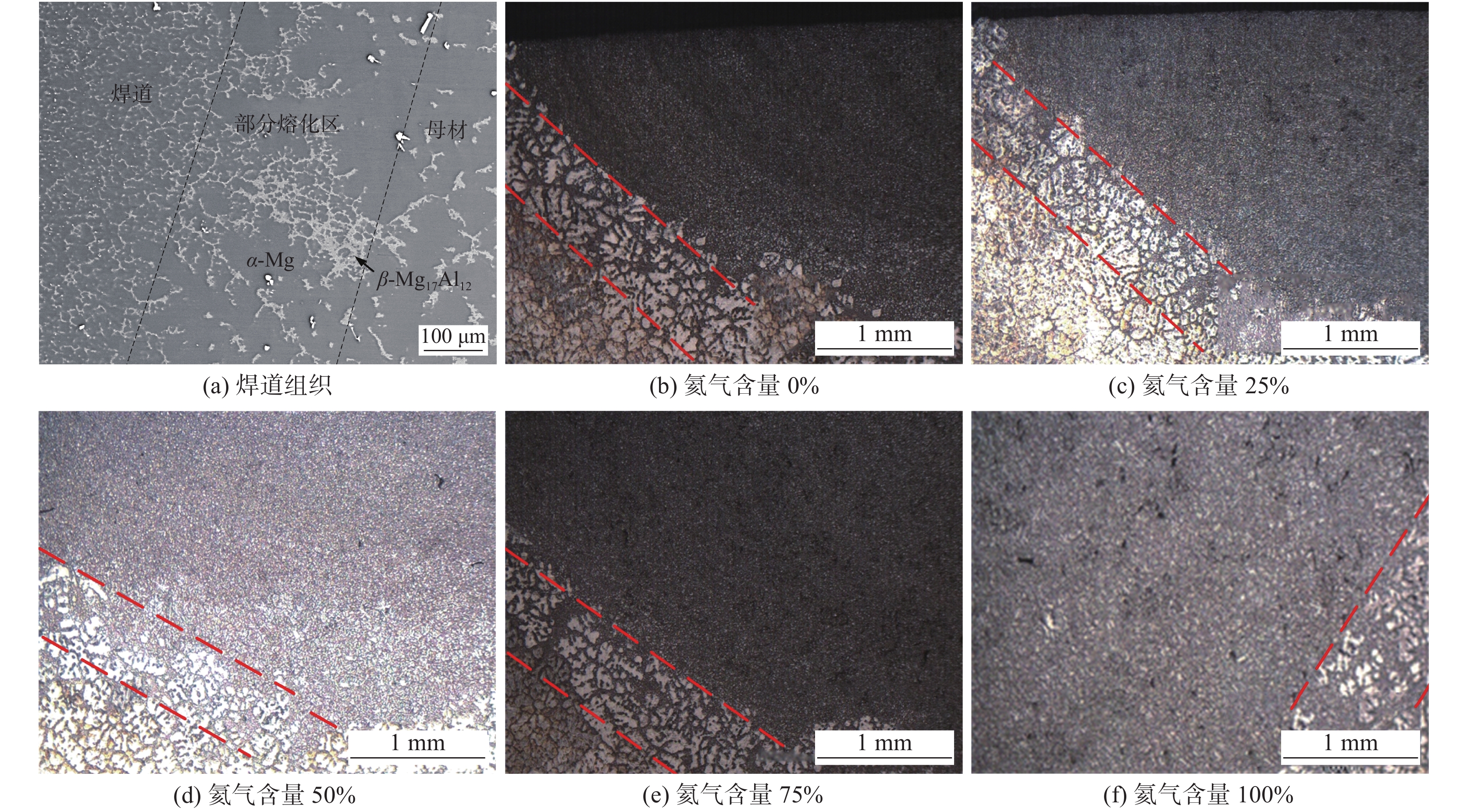

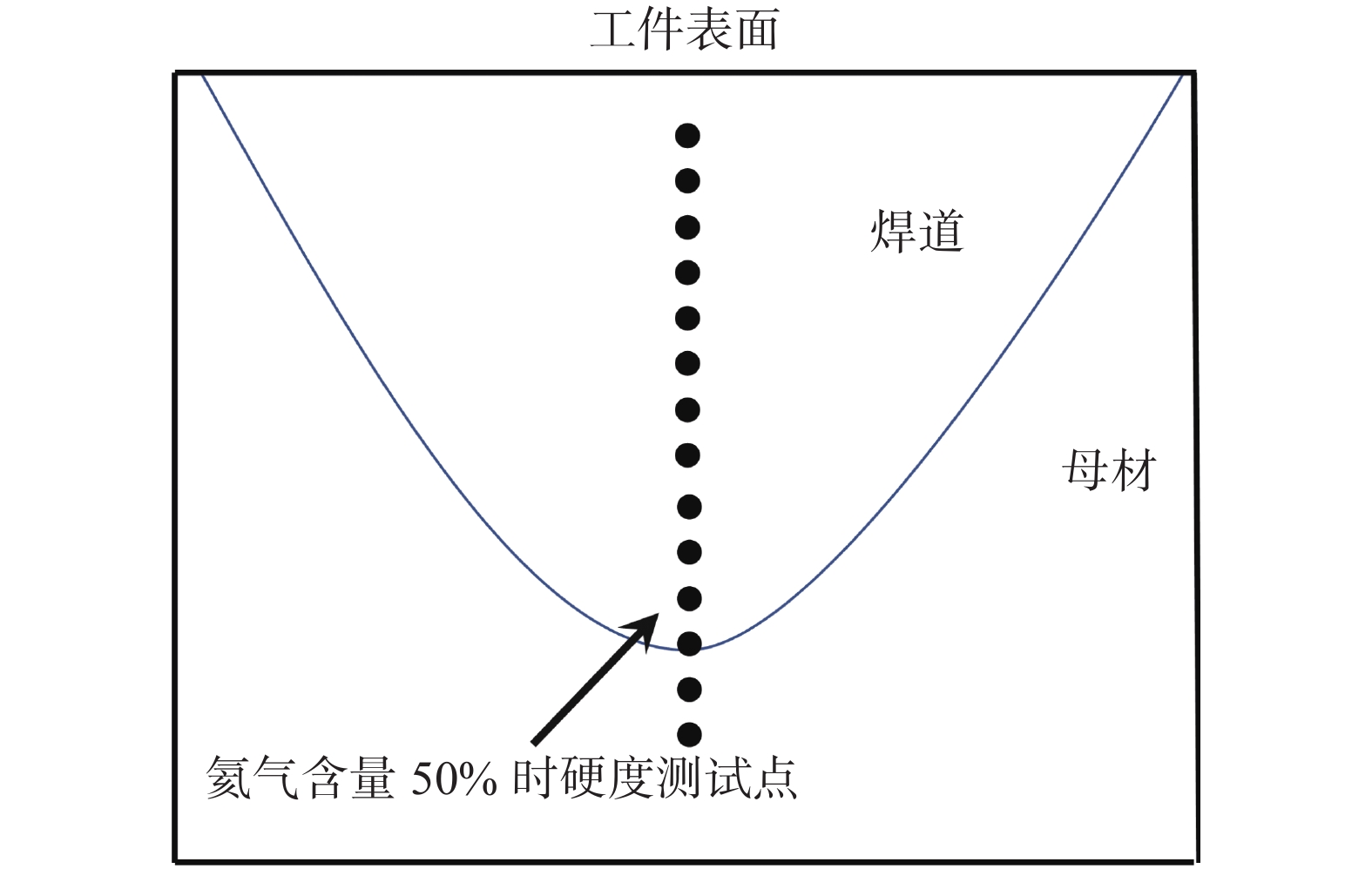

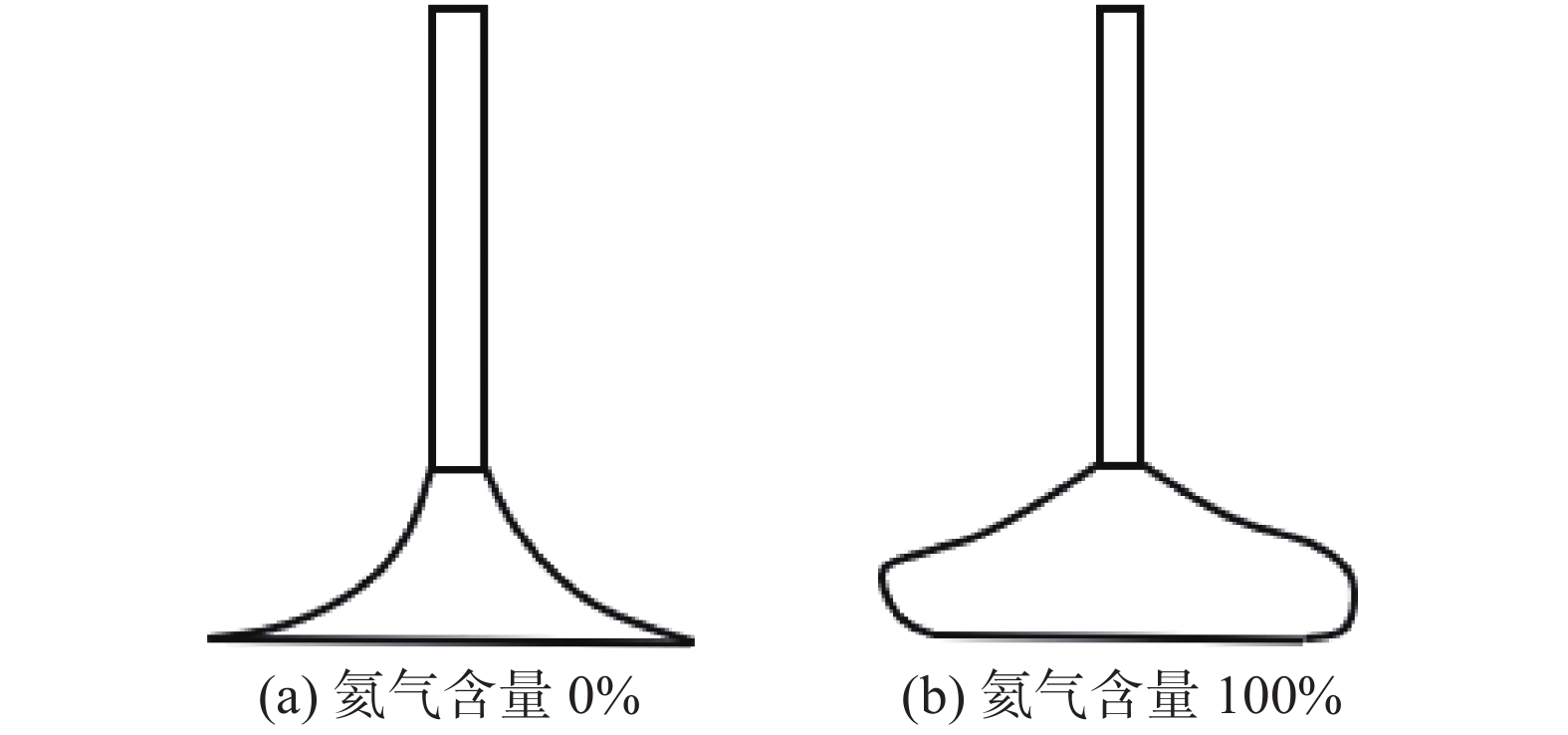

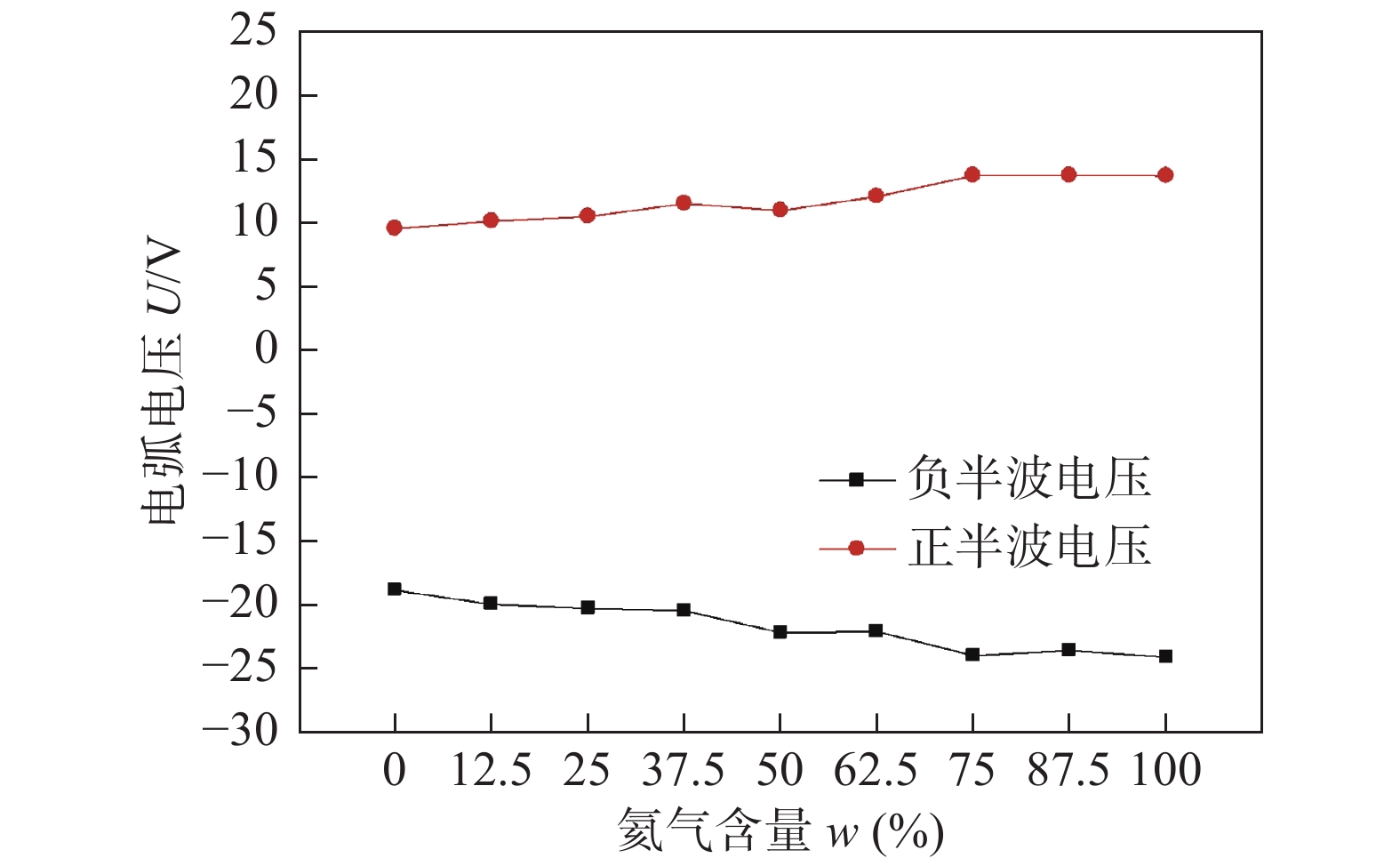

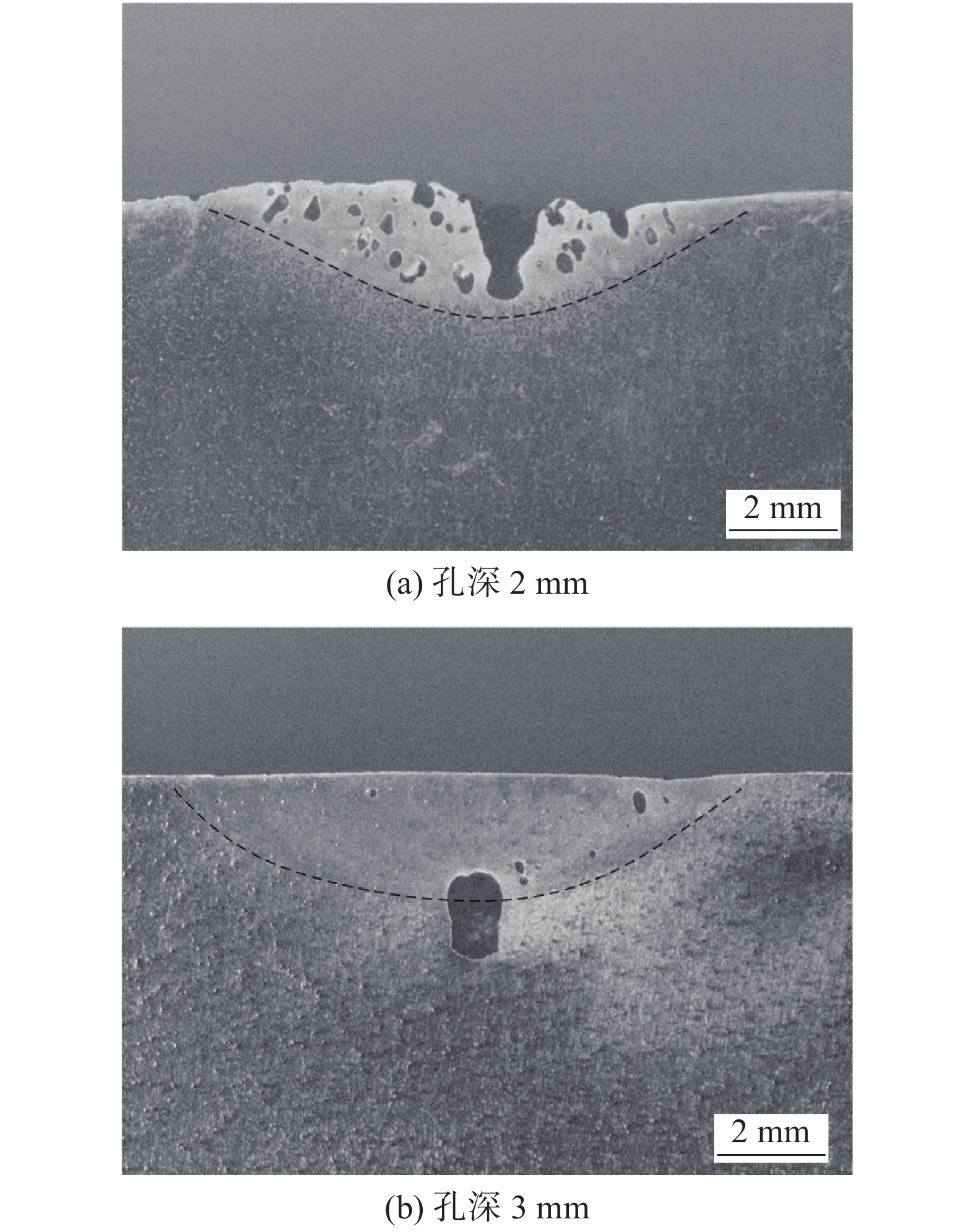

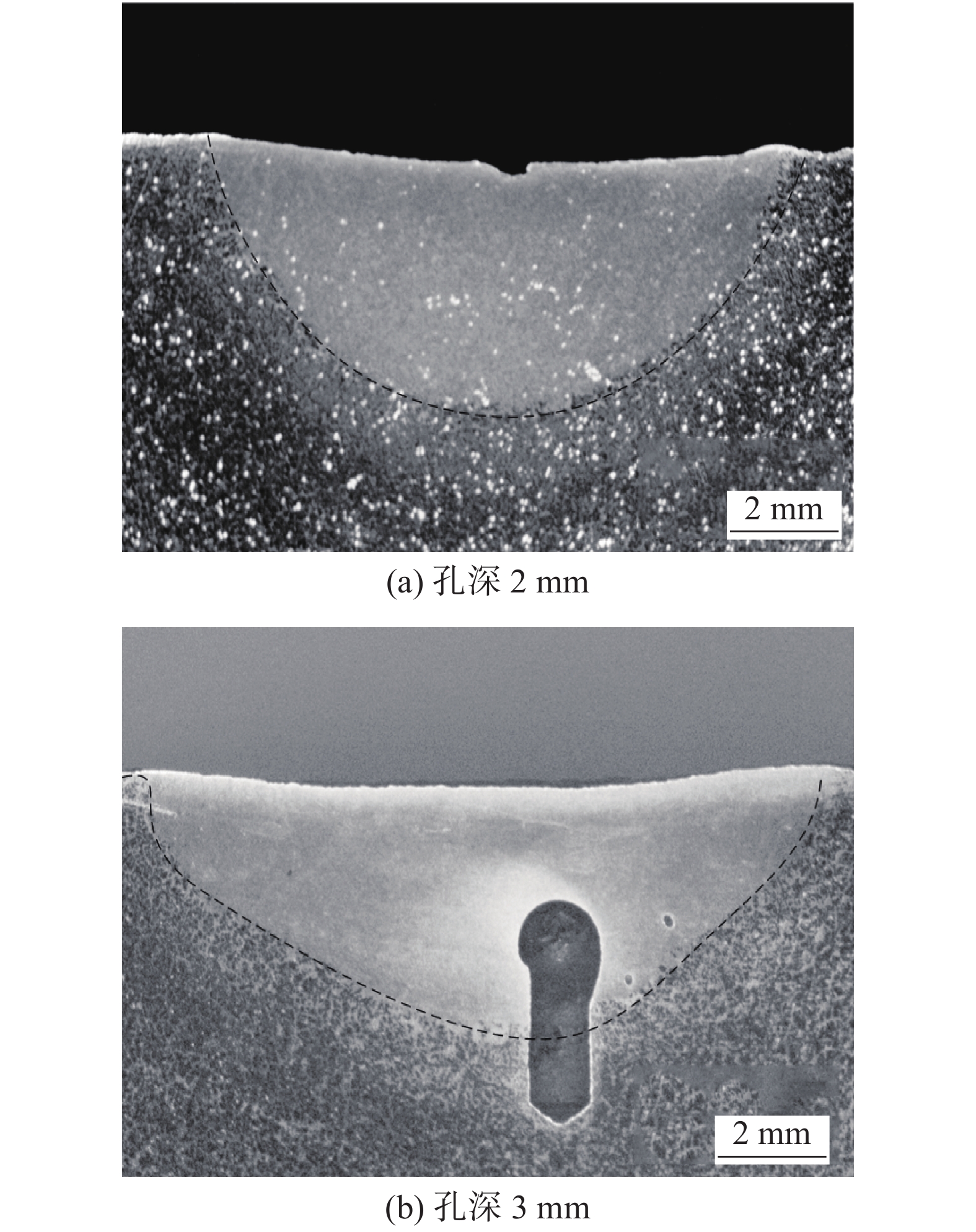

摘要: 镁合金因其较高的比强度而在诸多领域发挥重要的减重作用,且多为铸造构件,但镁合金铸件的缺陷问题成为制造瓶颈. 对镁合金铸件修复工艺进行研究,采用非熔化极惰性气体保护焊(TIG焊)探究此工艺下不同保护气体对TIG焊修复焊道的成形、组织特征及性能的影响,并通过不同氦-氩含量的保护气体下TIG焊电弧形态及电弧电压的研究,分析氦气含量对修复焊道熔深的影响. 结果表明,调整镁合金铸件TIG焊修复工艺保护气体中的氦气比例,会改善焊道形貌;增加保护气体中的氦气比例,将有效提高焊道熔深和深宽比;保护气体中氦气含量的改变对修复焊道组织、硬度无显著影响. 模拟缺陷修复试验结果表明,镁合金铸件氦-氩保护TIG修复工艺可以满足铸件浅层缺陷修复需求,增加保护气体中氦气含量可提高熔深,提高此工艺的适用性.Abstract: Magnesium alloy plays an important role in weight-loss because of its high specific strength, most of magnesium alloy components are casting. The defects of magnesium alloy castings become a manufacturing bottleneck issue. The repair process of magnesium alloy castings by tungsten inert gas (TIG) welding was studied, the effects of protect gas on the form, microstructure and properties of TIG repair beads were examined. The effects of helium content on the penetrations of welding beads were analyzed through the arc shape and arc voltage of TIG welding under different helium content. The results showed that the form of the weld bead could be improved by changing the helium content, the penetration and the penetration to width ratio could be improved by increasing the helium content, with no obvious effect on the microstructure and the hardness. The results of the simulating defect repair experiments showed that, the He-Ar mixed gas TIG welding repair process could repair shallow defects of magnesium alloy castings, increasing the helium content in the protect gas could increase the penetration and the suitability of this repair process.

-

Keywords:

- magnesium casting /

- defects repair /

- helium /

- arc characteristics

-

-

表 1 焊接工艺参数

Table 1 Welding process parameters

焊接电流I/A 焊接速度v/(mm·s−1) 电弧长度a/mm 保护气体流量Q/(L·min−1) 钨极伸出长度l/mm 160 4 1.5 14 11 -

[1] Mo N, Tan Q, Bermingham M J, et al. Current development of creep-resistant magnesium cast alloys: A review[J]. Materials & Design, 2018: 422 − 442.

[2] Alizadeh R, Mahmudi R, Ngan A H, et al. Microstructural stability and grain growth kinetics in an extruded fine-grained Mg-Gd-Y-Zr alloy[J]. Journal of Materials Science, 2015, 50(14): 4940 − 4951. doi: 10.1007/s10853-015-9041-x

[3] Nie J F, Shin K S, Zeng Z R. Microstructure, deformation, and property of wrought magnesium alloys[J]. Metallurgical and Materials Transactions A, 2020, 51(12): 6045 − 6109. doi: 10.1007/s11661-020-05974-z

[4] 蔡森, 董宇, 张晓东, 等. 差压铸造大型复杂航空用ZM5镁合金壳体铸件研究[J]. 铸造, 2016, 65(9): 847 − 850, 854. doi: 10.3969/j.issn.1001-4977.2016.09.001 Cai Sen, Dong Yu, Zhang Xiaodong, et al. Research on large complicated magnesium alloy aerial shell castings by differential pressure casting technology[J]. Foundry, 2016, 65(9): 847 − 850, 854. doi: 10.3969/j.issn.1001-4977.2016.09.001

[5] Adamiec J. Repairing the WE43 magnesium cast alloys[J]. Solid State Phenomena, 2011, 176: 99 − 106. doi: 10.4028/www.scientific.net/SSP.176.99

[6] Adamiec J. The quantitative assessment of the fracture profile of magnesium alloy QE22 welded joint[J]. Solid State Phenomena, 2013, 197: 215 − 220. doi: 10.4028/www.scientific.net/SSP.197.215

[7] 侯慧鹏, 田象军, 刘栋, 等. 氩弧焊修复激光成形TC11钛合金组织及高周疲劳性能[J]. 焊接学报, 2016, 37(8): 9 − 12. Hou Huipeng, Tian Xiangjun, Liu Dong, et al. Microstructure and high-cycle fatigue properties of laser melting deposited TC11 titanium alloy repaired by tungsten argon arc welding[J]. Transactions of the China Welding Institution, 2016, 37(8): 9 − 12.

[8] Kadoi K, Murakami A, Shinozaki K, et al. Crack repair welding by CMT brazing using low melting point filler wire for long-term used steam turbine cases of Cr-Mo-V cast steels[J]. Materials Science and Engineering A, 2016, 666: 11 − 18.

[9] 赵红星, 王国庆, 宋建岭, 等. 氦弧与氩弧电弧特性对比研究[J]. 机械工程学报, 2018, 54(8): 137 − 143. doi: 10.3901/JME.2018.08.137 Zhao Hongxing, Wang Guoqing, Song Jianling, et al. Comparative research of helium and argon arc characters[J]. Journal of Mechanical Engineering, 2018, 54(8): 137 − 143. doi: 10.3901/JME.2018.08.137

[10] Dai H, Shen X, Wang H. Study on the arc pressure of TIG welding under the condition of Ar-Ar and Ar-He supply alternately[J]. Results in Physics, 2018, 10: 917 − 922. doi: 10.1016/j.rinp.2018.08.015

[11] Tanaka M, Tashiro S, Satoh T, et al. Influence of shielding gas composition on arc properties in TIG welding[J]. Science and Technology of Welding and Joining, 2008, 13(3): 225 − 231. doi: 10.1179/174329308X283929

-

期刊类型引用(3)

1. 张明军,李晨希,邹江林,程波,张健,仝永刚,胡永乐,陈根余. AZ31B镁合金功率调制环形光斑光纤激光焊接试验研究. 机械工程学报. 2025(02): 151-161 .  百度学术

百度学术

2. 刘坤,李洁,王浩,简思捷. 镁合金焊接凝固裂纹敏感性评价及晶间液相回填规律分析. 焊接学报. 2023(09): 9-15+129 .  本站查看

本站查看

3. 焦婧,黄金鑫,张志凯. 论带复杂油路类镁合金铸件的清理方法. 世界有色金属. 2022(23): 175-177 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: