Analysis of CMT Advanced+P welding-brazing characteristics of 7075/TC4 dissimilar metals

-

摘要: 基于CMT Advanced+P焊接方法,以ER5356铝合金焊丝对7075铝合金和TC4钛合金组成的搭接接头进行熔钎焊试验,并对接头进行微观组织及力学性能分析. 结果表明,焊接接头主要由焊缝区、铝合金侧热影响区和钎焊界面区组成;焊缝区主要是等轴晶;铝合金侧热影响区的晶粒表现出轧制特性,并在晶界附近析出大量金属间化合物;钎焊界面区存在由钛侧向焊缝区进行生长的锯齿状金属间化合物层,该化合物层厚度1 ~ 2.5 μm,主要由Al-Ti金属间化合物组成;接头拉伸后断裂位置位于铝合金侧热影响区附近,断裂类型属于混合断裂,最高抗剪强度达到293.1 MPa.Abstract: Based on CMT advanced + P welding method, the welding-brazing test of 7075 aluminum alloy and TC4 titanium alloy lap joint was carried out using ER5356 filler metal. The microstructure and mechanical properties of the joint were analyzed. The results showed that the welded joint was composed of weld zone, heat affected zone and brazing interface zone. The weld zone was mainly composed of equiaxed grains. The grains in the heat affected zone of aluminum alloy showed rolling characteristics, and a certain amount of intermetallic compounds were precipitated near the grain boundary. In the brazing interface area, there existed a serration-shaped intermetallic compound layer growing from the lateral weld area of titanium. The thickness of the compound layer was 1 ~ 2.5 μm and mainly composed of Al-Ti intermetallic compounds. The fracture location of the joint was near the heat affected zone of the aluminum alloy, and the tensile fracture type was mixed fracture, with the maximum shear strength of 293.1 MPa.

-

Keywords:

- aluminum alloy /

- titanium alloy /

- cold metal transfer /

- welding-brazing

-

0. 序言

铝合金具有重量轻、成本低、高比强度等特点,钛合金具有低密度、高比强度、抗腐蚀性能优良等特点,使得这两种金属在航空航天、交通运输领域得到了广泛的应用[1]. TC4钛合金和7系铝合金在航空领域应用十分广泛,TC4钛合金多用于飞机蒙皮的制造[2],7系铝合金广泛使用在飞机的机翼结构中[3]. 国内研制的C919、空客研制的A380、波音公司研制的7XXX等系列飞机大量应用了铝/钛复合结构[4-5].

铝与钛的物理化学性能相差较大,焊接铝和钛的最大问题是产生Al-Ti金属间化合物,严重的降低接头的力学性能[6]. 针对铝钛焊接的难点,国内外学者的研究主要集中在5系[7]和6系[8]铝合金与钛合金的连接. 相比于5系和6系铝合金,7系铝合金的合金元素含量更高,焊后接头软化更严重,焊接7系铝合金和钛合金具有更大的挑战性,所以目前关于7系铝合金与钛合金连接的研究较少. 有学者采用扩散焊[9]和电子束焊[10]的方式来实现7075铝合金和钛合金异种金属的连接,由于扩散焊和电子束焊存在设备复杂且投资大、焊前准备工序繁琐、焊接过程需要真空环境等特点,限制了其在实际生产中的应用.

Fronius公司于2010年对CMT (冷金属过渡)焊接技术进行发展,开发出CMT Advanced (变极性冷金属过渡)技术和CMT Advanced+P (焊丝负极性的冷金属过渡+脉冲)技术. 由于变极性CMT存在EN (焊丝负极性)阶段,使其比传统CMT具有更好的间隙搭桥能力、更低的热输入、更高的熔覆效率[11-12]. CMT Advanced+P技术将变极性CMT的优势与脉冲熔化极气体保护焊的优势进行结合,使其具有更精确的热输入控制、极佳的间隙搭桥能力、更高的熔覆效率等优点. 故文中基于CMT Advanced+P焊接方法,进行7075铝合金与TC4钛合金的熔钎焊试验,为实际生产中焊接7系铝合金与钛合金提供新的思路和方法.

1. 试验方法

试验材料为100 mm × 50 mm × 1 mm的TC4钛合金、100 mm × 50 mm × 2 mm的7075铝合金(T6)以及直径为1.2 mm的ER5356焊丝,试验所用材料的主要化学成分如表1、表2所示.

焊接电源使用奥地利Fronius公司生产的CMT Advanced 4000. 图1为CMT Advanced+P技术的电流波形参数示意图. 完整的CMT Advanced+P焊接过程包括EN-CMT (焊丝负极性冷金属过渡)阶段和脉冲阶段两部分. 整个EN-CMT过程包括燃弧阶段和短路阶段,其中燃弧阶段又包括峰值阶段和基值阶段. 脉冲过程包含脉冲峰值阶段和脉冲基值阶段. EN-CMT与脉冲的波形比例可以通过焊接电源的控制面板进行设置.

表 1 钛合金的化学成分含量(质量分数,%)Table 1. Chemical composition of titanium alloyAl V Fe C N O H Ti 6 4 < 0.3 < 0.08 < 0.05 < 0.2 < 0.015 余量 表 2 铝合金及焊丝的化学成分含量(质量分数,%)Table 2. Chemical composition of aluminum alloy and welding wire元素 Si Fe Cu Mn Mg Cr Zn Ti Al 7075 0.4 0.5 2.0 0.3 2.5 0.2 5.8 0.20 余量 ER5356 0.25 0.4 0.1 0.05 5 0.1 0.1 0.1 余量 施焊前用物理和化学方法将母材表面的氧化膜和油污清除干净,焊接工艺参数如表3所示,由FANUC M-10iA/12 焊接机器人进行施焊. 接头形式采用钛合金在下,铝合金在上的搭接形式,搭接宽度15 mm,搭接间隙0.5 mm,焊丝向钛合金一侧偏移1.2 mm,焊枪与焊接方向夹角约110 °,焊丝伸出长度13 mm,保护气体为流量17 L/min的高纯氩气.

表 3 焊接工艺参数Table 3. Welding parameters送丝速度

ν/(m·min−1)焊接速度

ν/(cm·min−1)EN-CMT与

P比例电弧电压

U/V焊接电流

I/A6 38 3∶5 13.8 96 焊后在焊缝垂直方向截取金相试样,对试样进行打磨、抛光后用扫描电子显微镜观察其微观组织形貌,利用X射线衍射仪对焊接接头进行XRD分析,利用能谱仪对接头中微观组织的成分进行分析. 用Dix-Keller试剂对抛光后的金相试样进行化学腐蚀,腐蚀时间为3 min,再用4%的硝酸酒精溶液进行中和,中和时间为3 min,最后用光学显微镜和扫描电子显微镜观察其微观组织. 沿垂直焊缝方向取85 mm × 10 mm的条形拉伸试样,拉伸试样如图2所示. 用DDL300电子万能试验机对拉伸试样进行拉伸试验,拉伸速率为0.8 mm/min,并用扫描电子显微镜观察其拉伸后的断口.

2. 试验结果与分析

2.1 焊缝成形与宏观形貌

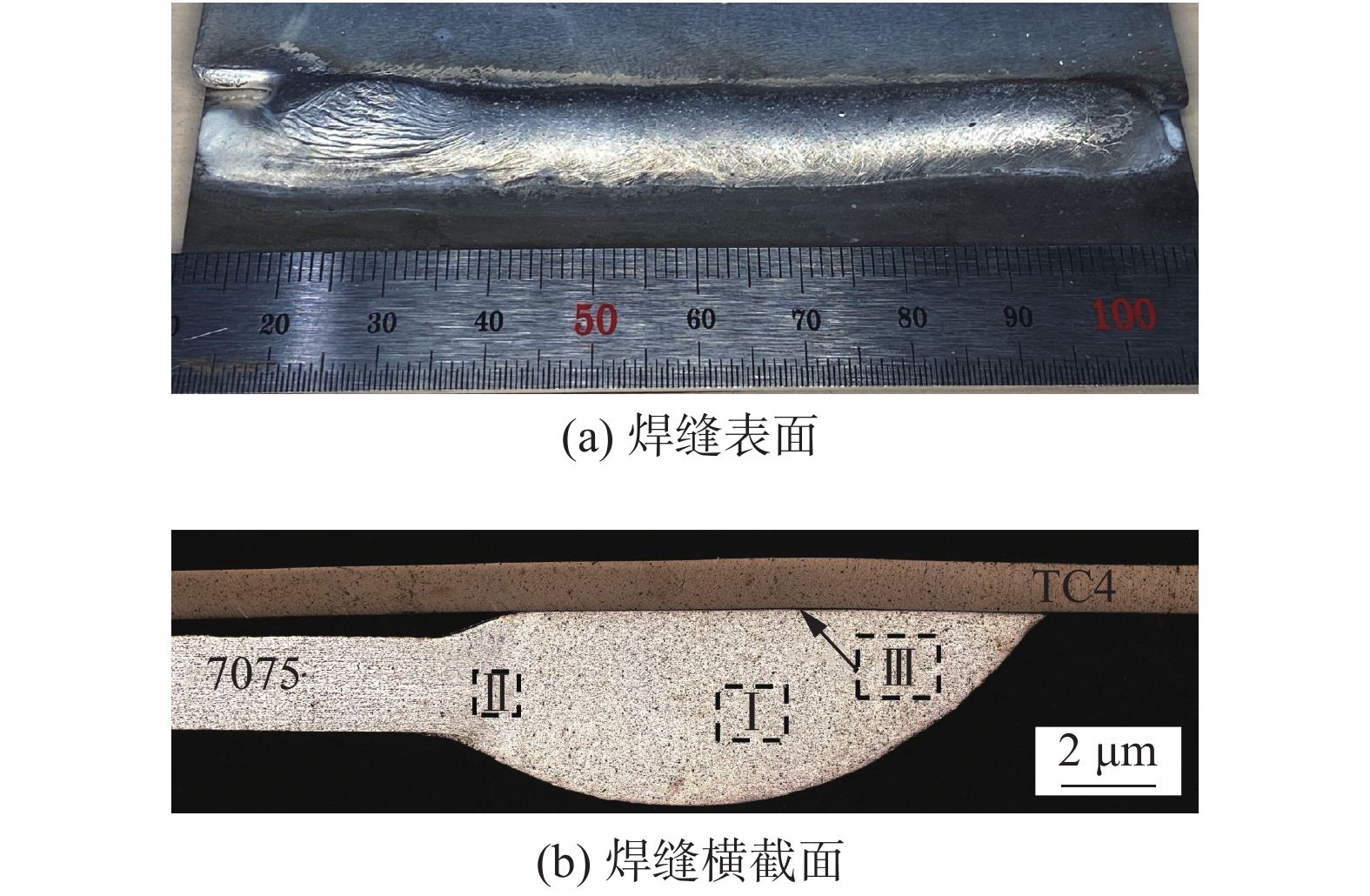

通过表3所示的焊接工艺可以获得外观优良的焊接接头,其宏观形貌如图3. 由图3a焊缝表面可得:焊缝连续且表面成形良好,没有裂纹、气孔等缺陷产生. 由图3b焊缝横截面观察到:铝/钛搭接接头的焊缝横截面主要由焊缝区(Ⅰ)、铝合金侧热影响区(Ⅱ)和钎焊界面区(Ⅲ)组成,靠近7075铝合金一侧的接头表现出熔化焊的特征,热影响区与焊缝区存在明显的交界,靠近钛合金一侧的接头则主要表现出钎焊的特性,钛合金几乎不发生熔化,焊缝金属在钛合金母材上的润湿性良好.

2.2 显微组织分析

图4为搭接接头腐蚀后的微观形貌. 图4a为图3b中焊缝区腐蚀后的微观形貌,图5为未腐蚀的微观形貌. 图5a为图3b中焊缝区未腐蚀状态的微观形貌. 由图4观察到:焊缝区主要由等轴晶组成,同时在该区存在一定数量的条棒状化合物. 由于铝合金的导热性远高于钛合金,焊接过程的散热主要由铝合金进行,焊缝区距离铝合金一侧存在一段距离,在冷却过程中液相焊缝区金属的温度梯度趋于缓和,同时由于焊缝区合金元素含量较高,冷却过程中先生成的金属间化合物与部分晶粒受电弧力和熔滴冲击力的作用发生破碎并分散到焊缝中,促进非自发形核,所以在焊缝区易于形成等轴晶.

由图5a未腐蚀的焊缝区微观形貌可以观察到,焊缝区存在链状的、条棒状的化合物,对图中所示的A,B,C,D 4处位置进行EDS能谱分析,结果如表4所示. 位于晶界附近的A处主要含有Mg、Al元素,该处可能由Al-Mg化合物和α-Al固溶体组成. B处含有Al 98.35和Mg 1.65,该处为α-Al固溶体,固溶少量的Mg元素,可知该位置为基体. C处的条棒状化合物主要含Al和Ti元素,其中铝原子与钛原子的比例小于3,并且大于2,推测该处主要由TiAl3相和TiAl相组成. 根据D处的元素组成,该处存在由Al,Mg,Cu,Zn元素组成的各种金属间化合物和α-Al固溶体. 对焊缝区进行XRD分析,结果如图6a,6b所示,焊缝区除了存在α-Al固溶体,还存在的金属间化合物有CuZn,Cu5Zn8,Al6CuMg4,Al0.56Mg0.44,TiAl3. 焊缝区的成分组成与焊接过程的热输入形式、焊接材料、施焊条件等因素密切相关. 焊接过程中脉冲阶段的熔滴冲击力和整个过程的电弧力会对熔池产生强烈的搅拌作用,使得熔化的7075铝合金和TC4钛合金母材的组成元素分布在焊缝中,焊缝中的Zn和Cu元素主要来源于铝合金母材,Mg元素主要来源于焊丝和铝合金母材,所以在焊缝中形成了由Al,Ti组成的金属间化合物和由Al,Mg,Cu,Zn组成的金属间化合物,又由于焊缝金属的冷却过程为非平衡凝固过程,所以金属间化合物的分布呈现不均匀的状态.

表 4 EDS能谱分析(原子分数,%)Table 4. EDS energy spectrum analysis位置 Al Mg Zn Cu Ti 可能的生成相 A 95.05 5.71 0.25 0.00 0.00 α-Al固溶体 + 少量Al-Mg化合物 B 98.35 1.65 0.00 0.00 0.00 α-Al固溶体 C 71.02 0.61 0.10 0.00 28.26 TiAl3 + 少量TiAl D 66.76 22.30 5.07 5.88 0.00 α-Al固溶体 + CuZn + Al6CuMg4 + Al-Mg化合物 E 63.39 16.41 10.67 9.54 0.00 α-Al固溶体 + CuZn + Al6CuMg4 + MgZn2 +

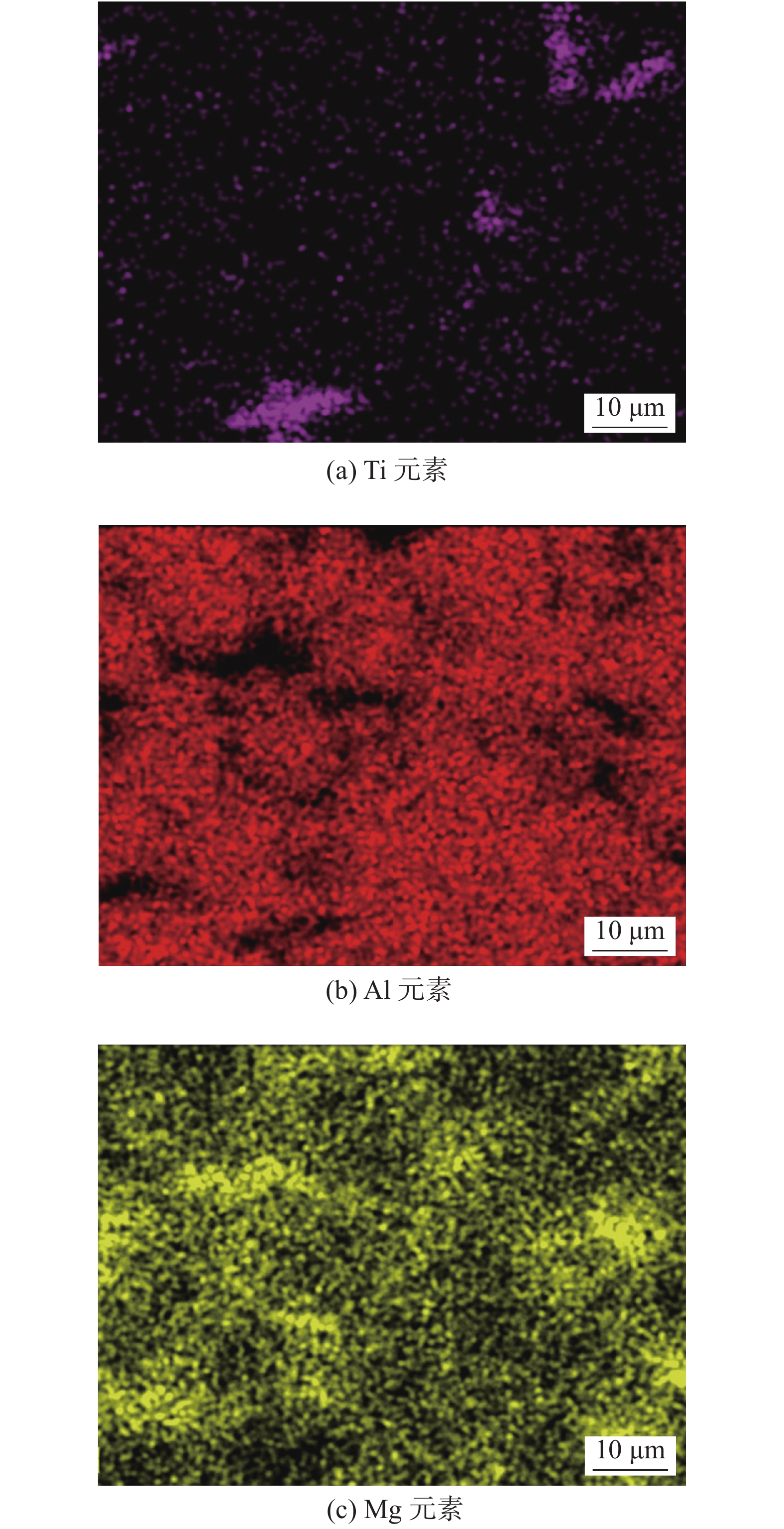

Al-Mg化合物F 71.88 0.24 0.20 0.01 27.67 TiAl3相 + 少量TiAl相 图7为图5a的面扫描分析结果,将图7与图5a进行比较分析,图7c的结果表明:Mg元素在晶界附近的浓度明显偏高,存在聚集现象,同时这种聚集现象并不稳定,有的晶界附近浓度高,有的晶界附近浓度低. 图7a所示的Ti元素的分布情况与图5a中条棒状化合物的分布相吻合,进一步验证了焊缝区不均匀分布的条棒状化合物主要是Al-Ti金属间化合物.

图4b为图3b中铝合金侧热影响区腐蚀后的微观形貌,图中所标的虚线近似为熔合线. 由图4b观察到:位于熔合线右侧的热影响区出现再结晶现象,存在一定数量的等轴晶,但总体上依然表现为轧制态特性,在晶内及晶界附近有明显的析出物. 图5b和图5c为图3b中铝合金侧热影响区未腐蚀状态的微观形貌,析出物的形貌主要呈现出层片状和球状,对图5c中E处层片状析出物进行EDS能谱分析,结果如表4所示. E处析出物可能存在CuZn,Al6CuMg4,MgZn2,Al-Mg化合物和α-Al固溶体.

对热影响区进行XRD分析,结果如图6c所示,热影响区存在的相有CuZn,Cu5Zn8,Mg2Al3,Al3.892Cu6.108,Al6CuMg4和α-Al固溶体. 由于受焊接热循环的作用,热影响区部分区域的峰值温度会处在共晶温度以上,此时铝合金母材中细小、弥散分布的析出物会与α-Al固溶体发生共晶反应的逆反应,这些液化后的析出物会在随后的再冷却过程中又重新沿晶界网状析出或者在晶内呈球状析出. 晶界附近脆性的网状金属间化合物会显著降低该处的力学性能,从而使该区域成为接头的薄弱环节.

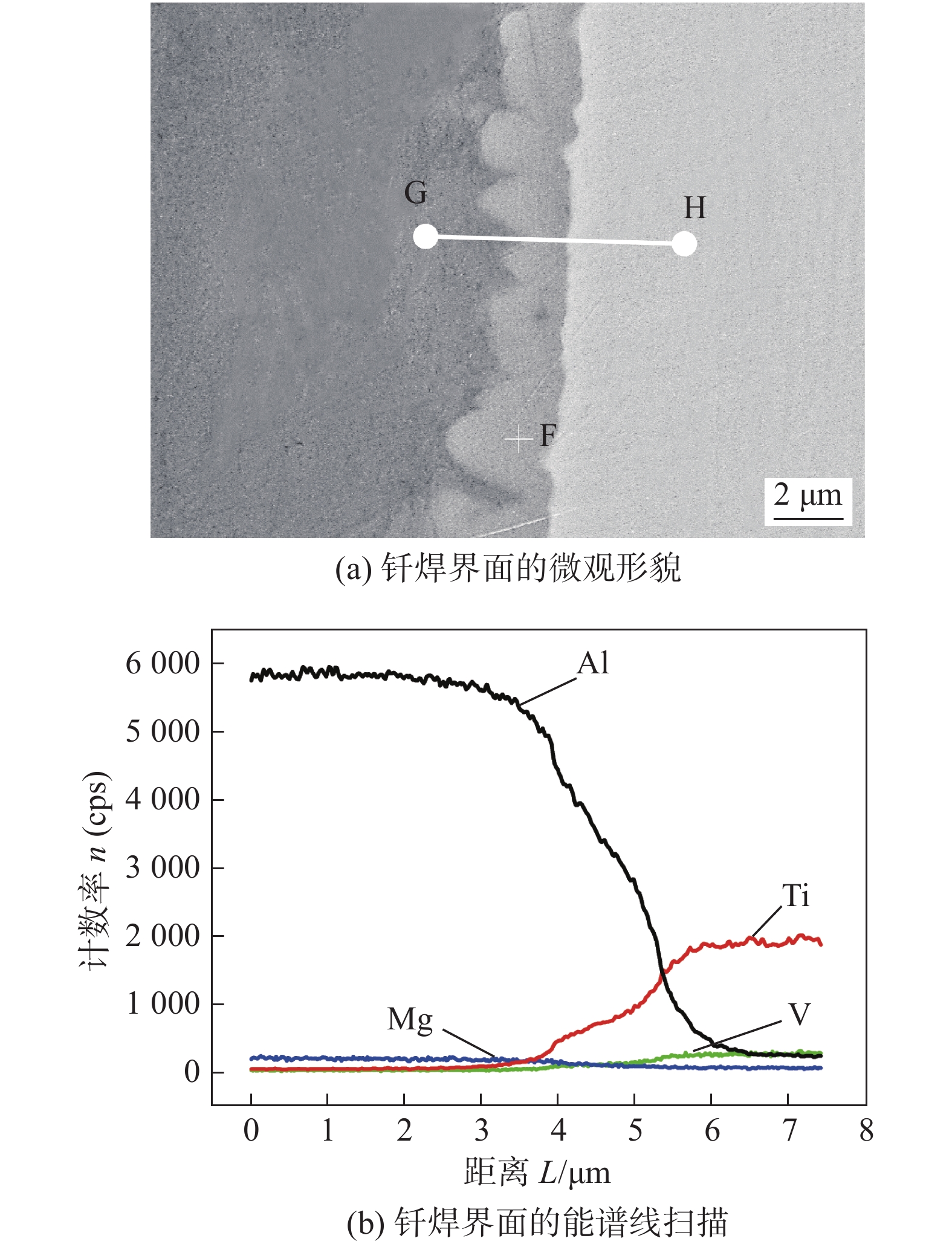

图8为钎焊界面的微观形貌及能谱扫描. 图8a为图3b中钎焊界面区的放大. 由图8a观察到:在焊缝和钛合金之间形成了一层金属间化合物层,其厚度1 ~ 2.5 μm,金属间化合物由钛合金向焊缝区进行生长,化合物层呈现出锯齿状的微观形貌特征. 沿图8a中G-H路径进行EDS线扫描分析,G-H路径是由焊缝区指向钛合金母材的线段,线扫描的结果如图8b. 由V,Mg,Ti,Al元素的线扫描结果得出:界面附近V原子、Mg原子、Ti原子和Al原子均发生了扩散,元素的扩散为生成金属间化合物提供了条件,其中变化最明显的元素为Al和Ti元素,化合物层距离钛合金母材一侧越近,Al原子含量越低,而Ti原子含量则越高.

界面微观特征的主要形成原因:在液相冷却过程中,沿着垂直于钎焊界面指向焊缝的方向,Ti原子的含量逐渐降低,根据Al-Ti二元相图,随着Ti原子含量的下降其液相的熔点也会逐渐降低,金属间化合物先在Ti原子含量高的区域发生凝固,金属间化合物由钛合金侧向焊缝内部不断进行生长,又由于TiAl3相是一种有序结构,存在择优生长的取向[13]. 对图8a中F处进行EDS能谱分析,结果如表4所示. F处主要为TiAl3相和TiAl相. 根据图8b,在紧邻钛合金母材的钎焊界面层中,存在 Ti 原子含量高于Al原子含量的区域,该区域存在Ti3Al相. 钎焊界面层主要由脆硬的Al-Ti金属间化合物组成,脆硬的界面层往往容易成为裂纹源,所以该区为接头的另一个薄弱环节.

2.3 力学性能与断口分析

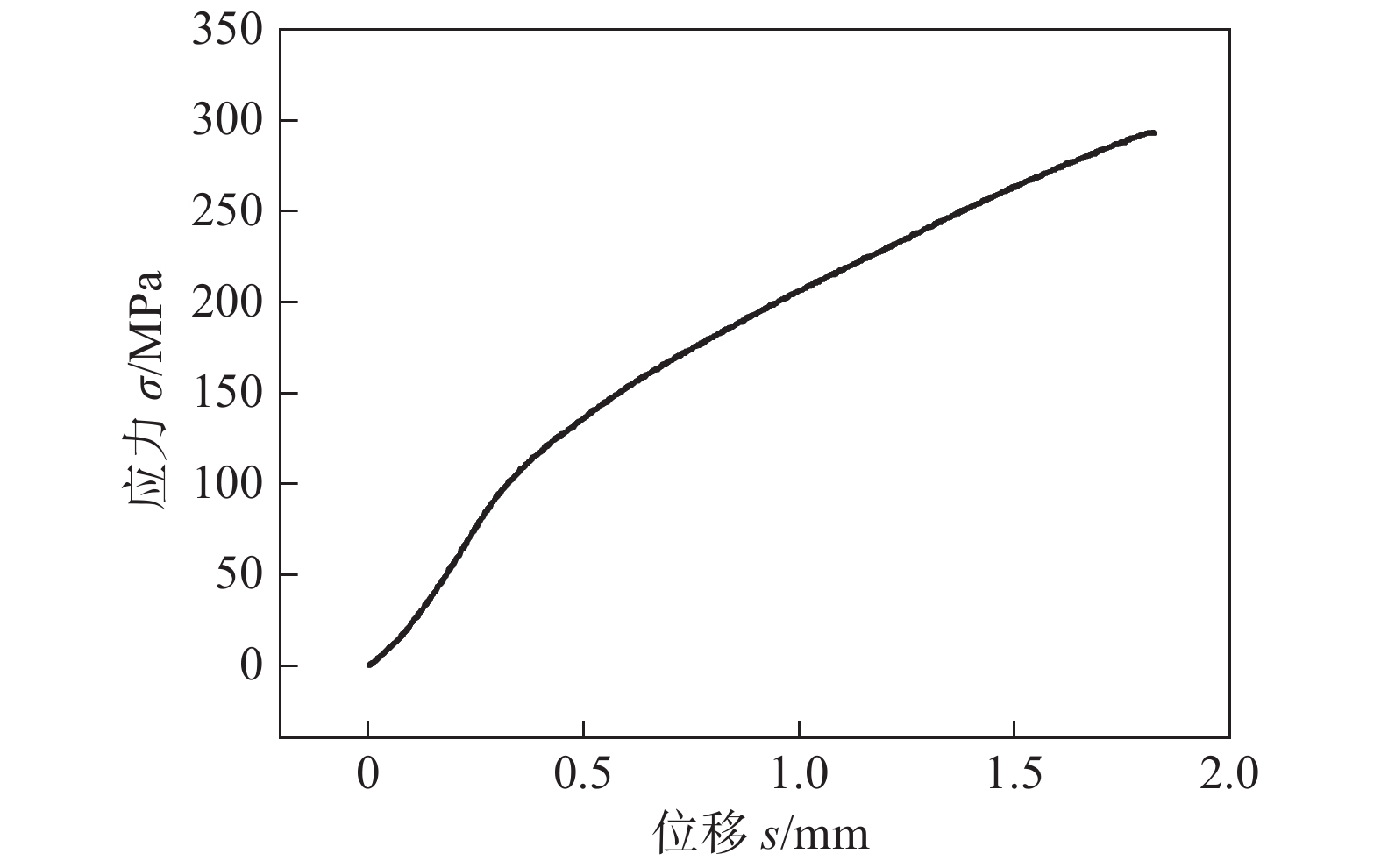

对铝/钛熔钎焊接头进行拉伸试验,图9为焊接接头的应力-位移曲线. 由图9可得:接头的最高抗剪强度可达293.1 MPa. 接头拉伸断裂后的断裂位置如图10a所示,接头断裂位置位于铝合金一侧的热影响区附近,熔焊侧的热影响区为接头的最薄弱环节,同时在断口附近可以观察到一定的缩颈.

用扫描电子显微镜对接头拉伸后的断口进行显微分析,结果如图10b,10c. 断口的微观形貌中存在沿晶脆性开裂的特征,也存在大小不一的韧窝、微孔和撕裂棱. 断口的微观特征表明:接头整体表现为混合断裂的特征,断裂方式存在沿晶脆性开裂和穿晶开裂两种,其中穿晶开裂的断裂模式主要为准解理断裂和微孔聚集性断裂,但以准解理断裂为主;图10c中撕裂棱存在的区域韧性较差,韧窝和微孔存在的区域韧性较好,同时在韧窝底部可以观察到第二相粒子.

3. 结论

(1) 采用Advaced CMT+P的新型焊接方法可以实现高质量的7075/TC4搭接接头的连接. 焊后接头表现出熔钎焊的特性,铝合金侧呈现典型的熔焊特征,钛合金侧呈现钎焊的特征. 接头主要由焊缝区、铝合金侧热影响区和钎焊界面区组成.

(2) 焊缝区的组成相有:α-Al固溶体、Al-Mg化合物、Al-Ti化合物、Cu-Zn化合物、Al-Mg-Cu化合物,同时Al-Ti化合物在焊缝区主要以条棒状的形式存在. 铝合金侧热影响区发生明显的晶界和晶内析出,析出物主要是由Al,Mg,Cu和Zn元素组成的各种金属间化合物,并且晶界析出物以层片状的形式存在. 钎焊界面层由Al-Ti金属间化合物组成,其厚度为1 ~ 2.5 μm,由钛合金母材向焊缝区进行生长,呈现锯齿状的形貌特征.

(3) 在拉剪载荷的作用下,熔钎焊接头的最大抗剪强度为293.1 MPa,具有良好的力学性能. 接头断裂位置位于铝合金侧的热影响区附近,断口处存在一定的缩颈,断口微观形貌可以观察到沿晶脆性开裂、韧窝、微孔和撕裂棱等微观特征,断裂类型属于混合断裂.

-

表 1 钛合金的化学成分含量(质量分数,%)

Table 1 Chemical composition of titanium alloy

Al V Fe C N O H Ti 6 4 < 0.3 < 0.08 < 0.05 < 0.2 < 0.015 余量 表 2 铝合金及焊丝的化学成分含量(质量分数,%)

Table 2 Chemical composition of aluminum alloy and welding wire

元素 Si Fe Cu Mn Mg Cr Zn Ti Al 7075 0.4 0.5 2.0 0.3 2.5 0.2 5.8 0.20 余量 ER5356 0.25 0.4 0.1 0.05 5 0.1 0.1 0.1 余量 表 3 焊接工艺参数

Table 3 Welding parameters

送丝速度

ν/(m·min−1)焊接速度

ν/(cm·min−1)EN-CMT与

P比例电弧电压

U/V焊接电流

I/A6 38 3∶5 13.8 96 表 4 EDS能谱分析(原子分数,%)

Table 4 EDS energy spectrum analysis

位置 Al Mg Zn Cu Ti 可能的生成相 A 95.05 5.71 0.25 0.00 0.00 α-Al固溶体 + 少量Al-Mg化合物 B 98.35 1.65 0.00 0.00 0.00 α-Al固溶体 C 71.02 0.61 0.10 0.00 28.26 TiAl3 + 少量TiAl D 66.76 22.30 5.07 5.88 0.00 α-Al固溶体 + CuZn + Al6CuMg4 + Al-Mg化合物 E 63.39 16.41 10.67 9.54 0.00 α-Al固溶体 + CuZn + Al6CuMg4 + MgZn2 +

Al-Mg化合物F 71.88 0.24 0.20 0.01 27.67 TiAl3相 + 少量TiAl相 -

[1] Sun Q J, Li J Z, Liu Y B, et al. Microstructural characterization and mechanical properties of Al/Ti joint welded by CMT method-Assisted hybrid magnetic field[J]. Materials & Design, 2017, 116(2): 316 − 324.

[2] 刘全明, 张朝晖, 刘世锋, 等. 钛合金在航空航天及武器装备领域的应用与发展[J]. 钢铁研究学报, 2015, 27(3): 1 − 4. Liu Quanming, Zhang Zhaohui, Liu Shifeng, et al. Application and development of titanium alloy in aerospace and military hardware[J]. Journal of Iron and Steel Research, 2015, 27(3): 1 − 4.

[3] 吴一雷, 李永伟, 强俊, 等. 超高强度铝合金的发展与应用[J]. 航空材料学报, 1994(1): 49 − 55. Wu Yilei, Li Yongwei, Qiang Jun, et al. Development and application of supper-high strength aluminum alloys[J]. Journal of Aeronautical Materials, 1994(1): 49 − 55.

[4] Zhang, X, Chen Y, Hu Z. Recent advances in the development of aerospace materials[J]. Progress in Aerospace Ences, 2018, 97(2): 22 − 34.

[5] 庄敏. C919用了哪些新材料[J]. 大飞机, 2017(8): 34 − 37. doi: 10.3969/j.issn.2095-3399.2017.08.007 Zhuang Min. What new materials are used in C919[J]. Jetliner, 2017(8): 34 − 37. doi: 10.3969/j.issn.2095-3399.2017.08.007

[6] Jiang S, Li S. Formation mechanism and growth law of diffusion solution zone between Al/Ti liquid/solid interface[J]. Rare Metal Materials & Engineering, 2011, 40(6): 983 − 986.

[7] Zhang Y, Huang J, Ye Z, et al. An investigation on butt joints of Ti6Al4V and 5A06 using MIG/TIG double-side arc welding-brazing[J]. Journal of Manufacturing Processes, 2017, 27(6): 221 − 225.

[8] Miao Y, Ma Z, Yang X, et al. Experimental study on microstructure and mechanical properties of AA6061/Ti-6Al-4V joints made by bypass-current MIG welding-brazing[J]. Journal of Materials Processing Technology, 2018, 260: 104 − 111. doi: 10.1016/j.jmatprotec.2018.05.019

[9] Rajakumar S, Balasubramanian V. Diffusion bonding of titanium and AA 7075 aluminum alloy dissimilar joints—process modeling and optimization using desirability approach[J]. International Journal of Advanced Manufacturing Technology, 2016, 82(1−4): 1095 − 1112.

[10] Yarong W, Yang Y, Wenhua T. Effect of welding parameters on Al/Ti joint property in electron beam welding-brazing[J]. China Welding, 2016, 25(4): 27 − 33.

[11] Guojin L, Peilei Z, Xi W, et al. Gap bridging of 6061 aluminum alloy joints welded by variable-polarity cold metal transfer[J]. Journal of Materials Processing Technology, 2018, 255: 927 − 935. doi: 10.1016/j.jmatprotec.2018.01.004

[12] 汪殿龙, 张志洋, 梁志敏, 等. 交流CMT动态电弧特征及熔滴过渡行为分析[J]. 焊接学报, 2014, 35(3): 6 − 10. Wang Dianlong, Zhang Zhiyang, Liang Zhimin, et al. Analysis of dynamic arc characteristics and melt transfer behavior of AC CMT[J]. Transactions of the China Welding Institution, 2014, 35(3): 6 − 10.

[13] 倪加明, 李俐群, 陈彦宾, 等. 铝/钛异种合金激光熔钎焊接头特性[J]. 中国有色金属学报, 2007, 17(4): 617 − 622. doi: 10.3321/j.issn:1004-0609.2007.04.020 Ni Jiaming, Li Liqun, Chen Yanbin, et al. Characteristics of laser welding-brazing joint of Al/Ti dissimilar alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 617 − 622. doi: 10.3321/j.issn:1004-0609.2007.04.020

-

期刊类型引用(6)

1. 王鑫,赵津嫚,王倩,武佳璇,周子烨. 工艺参数对电弧增材制造工件的影响. 河北冶金. 2024(02): 32-38 .  百度学术

百度学术

2. 尹孝辉,朱正英,陈凯,陈子航,孟威. 22MnB5/6061异种金属CMT+A+P熔钎焊界面特征及性能研究. 过程工程学报. 2023(07): 1073-1080 .  百度学术

百度学术

3. 刘德运,沈元勋,李秀朋,李云月,赵明远. 钛合金与铝合金异种金属钎焊及熔钎焊研究进展. 焊接. 2023(12): 50-57 .  百度学术

百度学术

4. 王博,龙伟民,娄银斌,邓建峰,关绍康,费文潘,王水庆,张雷. 钎剂复合4047钎料组织及钎焊性能分析. 稀有金属材料与工程. 2022(05): 1919-1925 .  百度学术

百度学术

5. 魏小红,刘瑞君,肖梦智,路超. 厚板钛合金等离子-钨极氩弧复合焊接接头组织与性能. 焊接. 2022(10): 32-36 .  百度学术

百度学术

6. 常敬欢,曹睿,闫英杰. 钛合金/不锈钢冷金属过渡焊接头组织及性能. 焊接学报. 2021(06): 44-51+99 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: