Influences of preheating temperatures on the microstructures and mechanical properties of GTA additive manufactured TiAl based alloy

-

摘要: 高温结构材料TiAl金属间化合物的可加工性较差,复杂结构成形技术难度大,制造成本高. 电弧增材可以实现TiAl基合金的原位低成本柔性制造,但制造过程中仍需注意裂纹控制问题. 预热处理通过改善组织可以有效抑制裂纹产生. 文中以Ti6Al4V与ER1100纯铝焊丝作为原材料,在200 ,300,450 ℃的预热温度下利用TIG焊原位合成了铝含量为50% (原子分数)的TiAl基合金,考察了不同预热温度下TIG电弧增材制造的钛铝合金的组织与力学性能. 结果表明,随着预热温度的增加,构件的顶部与中部区域逐渐在γ/α2层片团的晶界析出更多的块状γ相,底部组织变化不明显. 预热温度的增加使得合金中γ相增多而α2相减少,导致合金室温硬度减少. 同时,弥散分布的块状γ相的增多,使得构件的压缩性能提升,当预热温度为450 ℃时,构件抗压强度与压缩率最高.Abstract: High-temperature structural material TiAl based alloy has poor machinability. It is challenging to fabricate complex structures. And the processing cost is relatively high. GTA arc additive manufacturing is a promising technology to synthesis TiAl based alloy in situ with increased flexibility and low cost. However, crack control is still essential during fabrication. Preheating is effective in avoiding cracking during additive manufacturing. In this work, the Ti6Al4V and ER1100 wires are used as feedstock to fabricate TiAl based alloy in situ with an aluminum content of 50 at%. Preheating temperatures of 200, 300, 450 ℃ are used to investigate the influences on the microstructures and mechanical properties of the fabricated specimen. Results show that, with the preheating temperature increasing, more bulk γ phases precipitate on the boundaries of γ/α2 lamellar clusters in the top and middle region of the specimen, while the influences on the microstructures at the bottom are not significant. The proportion of α2 decreases with the preheating temperature, leading to a diminishing hardness. At the same time, the percentage of bulk-like γ phases increases, which results in the promotion of compressive properties. When the preheating temperature is set at 450 ℃, the fabricated specimen shows the highest compressive strength and compression ratio.

-

0. 序言

以电弧作为热源的增材制造技术,近几年正受到人们的关注,该技术具有设备成本低、沉积效率高、丝材利用率高、尺寸限制少、整体制造周期短等优点,还具备原位复合制造以及大尺寸零件成形的能力[1] . 国内外学者利用电弧增材制造技术先后针对钛合金[2]、镍基高温合金[3]、铝合金[4]及金属间化合物[5-7]进行了相关研究.

以TiAl金属间化合物为基体的合金具有低密度、抗氧化的特点以及优异的高温力学性能[8-9],耐蚀性和抗氧化性均优于钛合金,是一种适合于600~1000 ℃应用的有潜力的高温结构材料,有望应用于下一代高性能航空发动机中[10-11] . 传统的材料加工和成形手段对这种材料的适应性很差,容易造成开裂,制造复杂形状的TiAl结构件工艺复杂且成本高. 近年来国内外学者对TiAl金属间化合物的增材制造技术进行了初步地研究,但大多研究方法为激光增材制造[12-14]和电子束熔化沉积技术[15-16].

TiAl合金中裂纹的产生往往源于两个因素:第一,组织中生成了脆硬相;第二,构件内部存在足够大的内应力. 电弧增材制造获得的TiAl合金构件的组织主要是γ(TiAl)相与α2(Ti3Al)相,且组织形态主要为γ/α2片层,其中α2相在室温下为脆性相. 不同的预热温度对构件的组织特征会产生一定的影响,通过优化预热温度可以改善合金内部的组织特征,减少脆性相的生成,从组织调控的角度控制裂纹的生成. Ma等人[17-19]开展了TiAl金属间化合物的TIG电弧增材制造,采用400 ℃的预热温度制得无裂纹的γ-TiAl金属间化合物. Cai等人[20]利用双侧不同角度送丝的TOP-TIG焊接方法,采用450 ℃的预热温度成功制备了TiAl合金. 然而,不同预热温度下电弧增材所获得TiAl合金的组织及性能特性还少有研究,预热对裂纹的抑制机理还缺少较为完善的理论支撑.

在此背景下,文中考察不同预热温度下电弧增材制造的TiAl合金的组织与性能,阐述预热温度对合金组织的影响,并基于组织分析揭示力学性能变化规律,揭示组织的优化对抑制裂纹及提升性能的作用,最终建立预热工艺、组织与性能之间的关系.

1. 试验方法

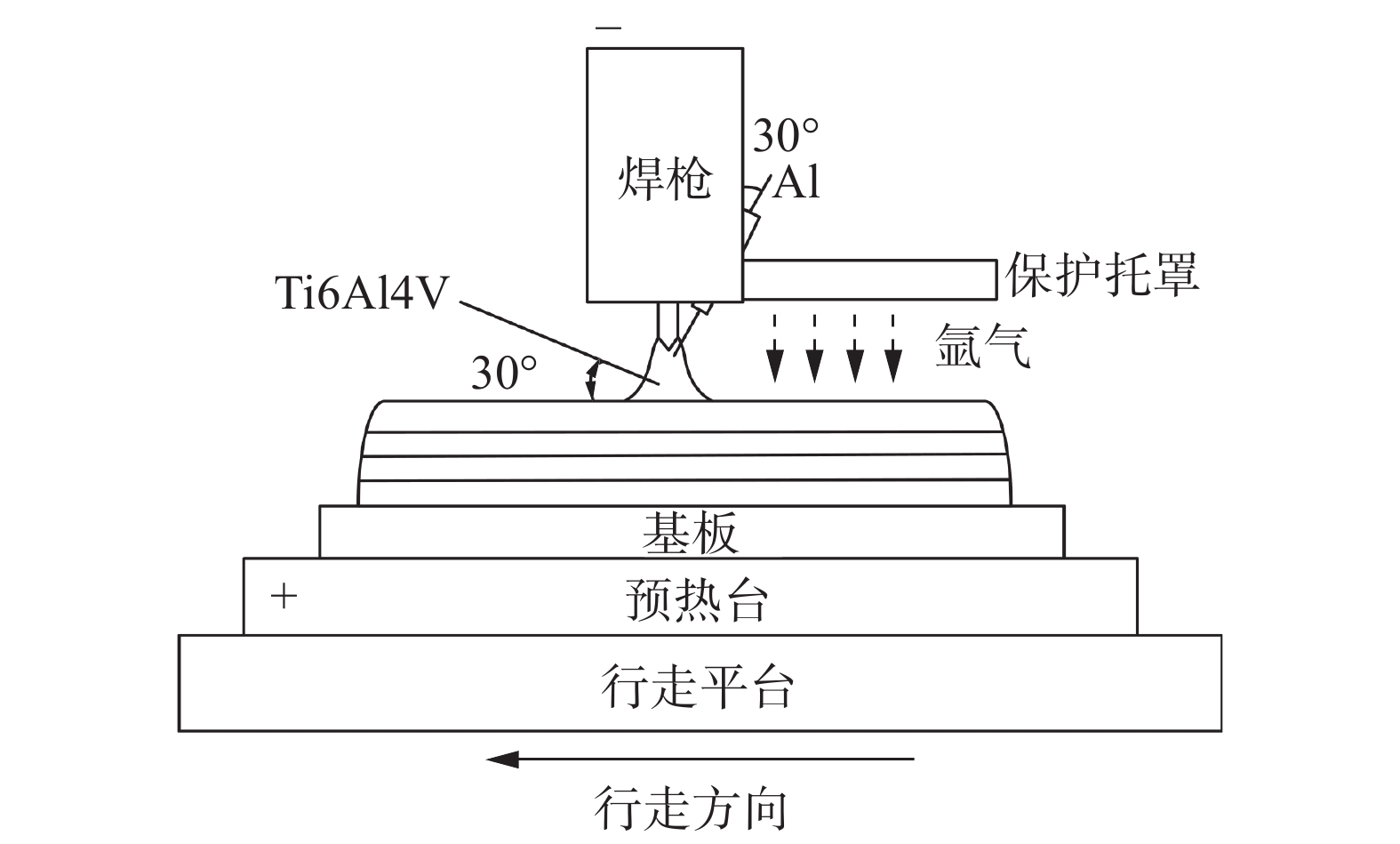

使用的沉积原材料为直径1.2 mm的Ti6Al4V焊丝和ER1100纯铝焊丝,如图1所示,增材工艺使用双侧不同角度送丝的双丝TIG焊工艺,两根焊丝分别由两台送丝机独立送进,在一个电弧加热下熔化沉积,电源采用直流正接. 经前期试验论证[20],增材过程中选择Ti6Al4V焊丝从电弧前方以与基板呈30°角送进,而纯铝焊丝从电弧后方以与焊枪轴线呈30°角送进. 主要试验参数如表1所示,设计TiAl合金成分组成为Al含量为50% (原子分数),为考察不同预热温度的影响,选取三组不同的预热温度进行试验:200,300和450 ℃.

表 1 主要沉积参数Table 1. Main depositing parameters焊接电流

I/ATi6Al4V送丝速度

vST/(m·min−1)Al送丝速度

vSA/(m·min−1)弧长

La/mm扫描速度

v/(mm·min−1)120 0.7 0.481 6 3.5 100 采用电火花线切割截取增材试样,经过金相砂纸研磨后抛光,最后采用HNO3∶HF∶H2O = 1∶1∶8的Kroll试剂腐蚀30 s,采用光学显微镜(OLYMPUS-SZX21)进行观察. 利用扫描电镜(SEM)对微观组织进行观察,试样腐蚀10 s后,在Quanta 200 FEG场发射扫描电镜下进行观察,利用X射线能谱分析(EDS)进行成分测定. 利用X射线衍射(XRD)技术确定TiAl合金中相组成,并定性判断相含量,制样过程主要是利用线切割在待考察位置截取10 mm × 10 mm × 5 mm的块状试样,经砂纸研磨得到表面清洁的样品,使用Empyrean智能X射线衍射仪进行测量,其中步进宽度设定为2°,步进时间为0.5 s,测量角度范围为10°~90°. 利用电子背散射衍射技术(EBSD)分析晶粒大小,其中电解抛光液为体积含量35%正丁醇 + 60%甲醇 + 5%高氯酸,电解电压25 V,温度−30 ℃,抛光时间40 s.

测试构件显微硬度与压缩性能,采用HVS-1000型显微硬度计测量维氏硬度,选用载荷0.2 kg,加载时间与保载时间均为10 s,测3点取平均值,测量间距为1 mm. 如图2a所示,沿构件横截面中心线由底部逐点测试到顶部. 依据GB/T 7314—2017《金属材料室温压缩测试方法》,采用Instron 5569电子万能实验机对增材试样进行压缩性能测试,试样为直径4 mm、长度6 mm的圆棒,取样方式如图2b所示,加载速率为0.36 mm/min,在圆棒两端加入石墨利用其润滑作用减少压头与压缩试样间的摩擦.

2. 试验结果与讨论

2.1 预热温度对增材构件中裂纹生成的影响

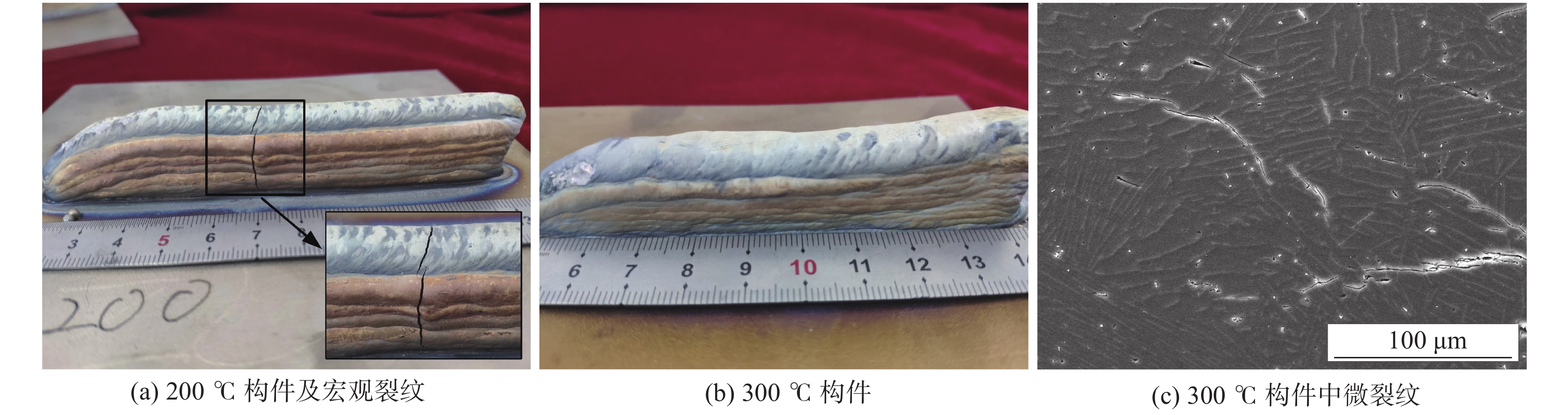

前期研究表明[20],当预热温度达到450 ℃时,可获无裂纹的TiAl合金构件. 如图3所示为预热温度200和300 ℃下沉积获得的TiAl合金构件,可见当预热温度为200 ℃时,构件中存在从底部到顶部的贯穿性裂纹,预热温度为300 ℃时,没有宏观裂纹. 但是,预热温度为300 ℃时,构件的底部区域存在微观裂纹(图3c).

2.2 预热温度对沉积态TiAl合金组织的影响

电弧增材构件由上到下主要分为顶部、中部、底部3个主要区域.图4所示为不同预热温度下增材构件不同区域的显微组织,可以看出,随着预热温度从200 ℃增加到450 ℃,顶部组织的γ/α2片层结构中逐渐析出块状γ相,且体积增大. 中部区域基本没有树枝晶特征,由片层结构和γ相构成. 当预热温度较低时,γ相弥散的点状分布,随着预热温度升高γ相的体积分数增多,同时趋向于块状分布. 预热温度的改变对于底部区域的组织影响不大,三者底部区域全部由尺寸粗大的α2晶粒伴随着晶内析出的γ片层构成.

![]() 图 4 不同预热温度下TiAl沉积件不同位置的微观组织Figure 4. Microstructure of the different regions of the as-fabricated TiAl under different preheating temperatures. (a) 200 ℃ top region; (b) 300 ℃ top region; (c) 450 ℃ top region; (d) 200 ℃ middle region; (e) 300 ℃ middle region;(f) 450 ℃ middle region; (g) 200 ℃ bottom region; (h) 300 ℃ bottom region; (i) 450 ℃ bottom region

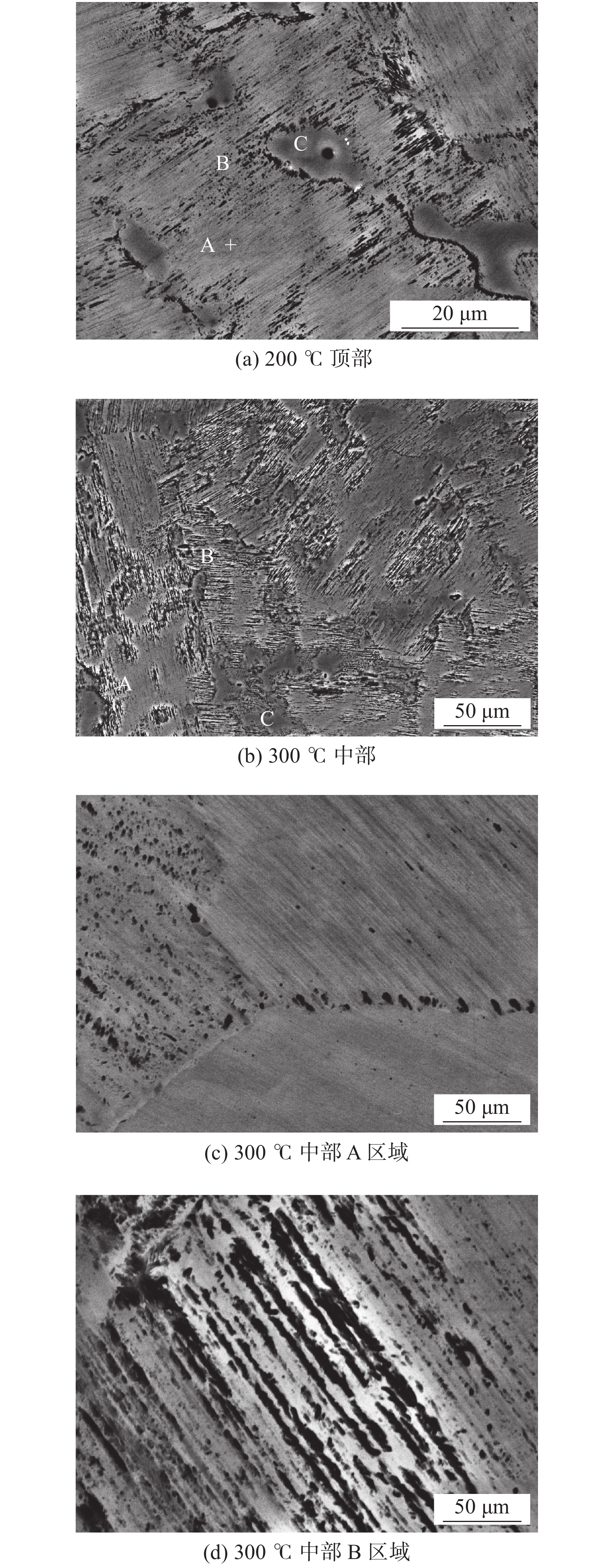

图 4 不同预热温度下TiAl沉积件不同位置的微观组织Figure 4. Microstructure of the different regions of the as-fabricated TiAl under different preheating temperatures. (a) 200 ℃ top region; (b) 300 ℃ top region; (c) 450 ℃ top region; (d) 200 ℃ middle region; (e) 300 ℃ middle region;(f) 450 ℃ middle region; (g) 200 ℃ bottom region; (h) 300 ℃ bottom region; (i) 450 ℃ bottom region图5为顶部和中部区域的扫描电镜获取的图像,可见这两个区域主要包含浅灰色的基体相A,带有黑色衬度的组织B,以及深灰色块状相C. 对典型组织进行EDS分析,结果如表2所示,可知A与B区域位置为γ/α2片层组织,C区域为典型的块状γ相,且该块状组织分布在层片团的晶界处. 由图5c,5d对比可以看出,B区域为粗化后的γ/α2片层,其片层间距明显大于A区域,这是由于中部区域经历长时间的热作用,部分不稳定的层片组织发生不连续粗化导致的. 不连续粗化[21]是一种仅对成分调整而晶体结构不变的晶界迁移反应,其通过不断的消耗原始片层将高密度的细层片组织转化为粗层片组织,该反应常常发生在存在α2和γ层片台阶的层片团晶界处,片层组织的热稳定性差,容易发生晶界迁移的不连续粗化,粗化后的片层组织Al元素含量偏高[22].

表 2 SEM图像中不同区域元素成分(原子分数,%)Table 2. Composition of the different regions in SEM images位置 区域 Ti Al V 相 顶部区域 A 53.81 44.73 1.46 γ + α2 B 49.33 49.07 1.61 γ + α2 C 44.17 54.01 1.82 γ 中部区域 A 52 46.66 1.34 γ + α2 B 49.32 49.42 1.26 γ + α2 C 43.25 55.38 1.37 γ 为了研究预热温度对显微偏析的影响,对不同预热温度下得到的典型区域进行了微观线扫描分析. 如图6所示,可以看出三者在层片组织区域元素分布均匀,而在层片团晶界处Al的原子含量突增,而Ti的原子含量减少,这证明了在层片团晶界处存在Al元素的偏析,导致析出了块状的γ相. 对比层片团晶界处的Ti,Al元素含量差异,可以看出随着基板预热温度的升高,层片区域和晶界处的成分差异减小,说明预热温度的升高对于显微偏析有抑制作用.

对不同构件的中部区域进行XRD分析以研究预热温度对于相组成与相含量的影响,如图7所示. 可见,随着预热温度的升高,γ相的含量越来越多,α2相的含量越来越少. 尤其(201)晶面对应的α2相衍射峰强度越来越低,(002)和(200)晶面对应的γ相衍射峰强度越来越高,同时450 ℃沉积件出现了(222)晶面对应的γ相衍射峰. 分析认为,β相为一种高温稳定相,基板预热温度的升高有利于提高β相的稳定性,因此会抑制L + β→α的包晶反应;同时α→β + γ的共析反应对于冷却速度的敏感度高,随着基板预热温度的升高,冷却速率变慢,促进了α→β + γ共析反应,因此γ相的含量随着预热温度的升高而升高.

利用EBSD考察晶粒大小,由图8可以看出随着基板预热温度的增加,晶粒的尺寸也随之增加. 晶粒的尺寸主要是由于材料的冷却速率决定的,冷却速率越快,晶粒尺寸越细小. 随着基板预热温度的增加,沉积件的冷却速率逐渐减少,高温的存在时间延长,因此晶粒长大.

2.3 预热温度对沉积态TiAl合金力学性能的影响

预热温度对合金的微观组织有较为明显的影响,而组织特征将影响最终的力学性能,图9a为不同预热温度下构件横截面硬度分布,可见硬度值为顶部和底部较高,中部较低,机械混合区最低. 取硬度平均值如图9b所示,可以看出随着预热温度的升高,平均硬度降低. 硬度的降低可以从相含量以及晶粒尺寸变化的角度来解释,由组织表征分析可知,随着预热温度的升高,γ相含量增加,α2相含量减少. 室温下γ相的硬度比α2相的硬度小. 同时随着基板预热温度的升高,晶粒的平均尺寸增加,由Hall-Patch公式知晶粒尺寸越大,材料的硬度越低. 因此随着预热温度的升高,合金的室温硬度逐渐降低.

压缩性能测试结果如图10所示. 随着基板预热温度的升高,TiAl合金的抗压强度与压缩率都变大,450 ℃的沉积件压缩性能最好,抗压强度与压缩率分别为1779 MPa和26.5 %. 这个现象可归因于两个因素:一是随着基板预热温度的升高,γ相的含量越来越多,γ相属于面心正方结构,滑移系的数量远超密排六方的α2相,因此随着γ相的增多、α2相的减少,TiAl合金的塑性越来越好. 二是当预热温度为200和300 ℃时,表面或者内部有缺陷裂纹的存在,该缺陷对合金的力学性能有极不利影响,因此随着预热温度的升高,TiAl合金的抗压强度、压缩率都升高.

综合上述分析可知,随着预热温度的升高,沉积合金构件中弥散的块状γ相逐渐增多,由于室温下γ相塑性优于α2相,使得在一定程度上构件的塑性增加. 组织的变化使得构件的力学性能得到改善,塑性的提升在一定程度上降低了裂纹的生成倾向,所以提高预热温度后构件的裂纹逐渐减少直至消失.

3. 结论

(1) 预热温度为200 ℃时,构件出现可见的宏观贯穿性裂纹;预热温度为300 ℃时,构件底部存在微观裂纹;预热温度为450 ℃时,构件无裂纹.

(2) 预热温度的改变使得构件顶部与中部区域组织形态发生变化,随预热温度的升高,块状γ相逐渐更多地从γ/α2层片团晶界析出. 而底部组织无明显变化,均为等轴α2晶伴随着晶内析出的γ层片.

(3) 随预热温度的升高,构件中γ相增加而α2相减少,且晶粒尺寸增加.

(4) 合金硬度随预热温度升高而降低,抗压强度与压缩率均随预热温度升高而升高.

-

图 4 不同预热温度下TiAl沉积件不同位置的微观组织

Figure 4. Microstructure of the different regions of the as-fabricated TiAl under different preheating temperatures. (a) 200 ℃ top region; (b) 300 ℃ top region; (c) 450 ℃ top region; (d) 200 ℃ middle region; (e) 300 ℃ middle region;(f) 450 ℃ middle region; (g) 200 ℃ bottom region; (h) 300 ℃ bottom region; (i) 450 ℃ bottom region

表 1 主要沉积参数

Table 1 Main depositing parameters

焊接电流

I/ATi6Al4V送丝速度

vST/(m·min−1)Al送丝速度

vSA/(m·min−1)弧长

La/mm扫描速度

v/(mm·min−1)120 0.7 0.481 6 3.5 100 表 2 SEM图像中不同区域元素成分(原子分数,%)

Table 2 Composition of the different regions in SEM images

位置 区域 Ti Al V 相 顶部区域 A 53.81 44.73 1.46 γ + α2 B 49.33 49.07 1.61 γ + α2 C 44.17 54.01 1.82 γ 中部区域 A 52 46.66 1.34 γ + α2 B 49.32 49.42 1.26 γ + α2 C 43.25 55.38 1.37 γ -

[1] Cunningham C R, Flynn J M, Shokrani A, et al. Invited review article: strategies and processes for high quality wire arc additive manufacturing[J]. Additive Manufacturing, 2018, 22: 672 − 686. doi: 10.1016/j.addma.2018.06.020

[2] 张帅锋, 吕逸帆, 魏正英, 等. 基于CMT的电弧熔丝增材Ti-6Al-3Nb-2Zr-1Mo合金的组织与性能[J]. 焊接学报, 2021, 42(2): 56 − 62. Zhang Shuaifeng, Lv Yifan, Wei Zhengying, et al. Microstructures and mechanical properties of Ti-6Al-3Nb-2Zr-1Mo alloy fabricated by CMT-wire arc additive manufacturing[J]. Transactions of the China Welding Institution, 2021, 42(2): 56 − 62.

[3] 贾志宏, 万晓慧, 郭德伦. 超高频电弧增材制造GH4169合金热处理组织[J]. 焊接学报, 2019, 40(12): 154 − 160. Jia Zhihong, Wan Xiaohui, Guo Delun. Study on heat-treated microstructure of GH4169 superalloy deposited by UHFP-GTAW[J]. Transactions of the China Welding Institution, 2019, 40(12): 154 − 160.

[4] Bai J Y, Yang C L, Lin S B, et al. Mechanical properties of 2219-Al components produced by additive manufacturing with TIG[J]. International Journal of Advanced Manufacturing Technology, 2015, 86: 479 − 485.

[5] Shen C, Pan Z X, Cuiuri D, et al. Influences of postproduction heat treatment on Fe3Al-based iron aluminide fabricated using the wire-arc additive manufacturing process[J]. International Journal of Advanced Manufacturing Technology, 2018, 97(1-4): 335 − 344. doi: 10.1007/s00170-018-1954-5

[6] Dong B S, Pan Z X, Shen C, et al. Fabrication of copper-rich Cu-Al alloy using the wire-arc additive manufacturing process[J]. Metallurgical and Materials Transactions B, 2017, 48(6): 3143 − 3151. doi: 10.1007/s11663-017-1071-0

[7] 李健. Ni-Al金属间化合物的电弧增材制造技术基础研究[D]. 武汉: 华中科技大学, 2018. Li Jian. Fundamental study on wire and arc additive manufacturing of Ni-Al intermetallic compounds[D]. Wuhan: Huazhong University of Science and Technology, 2018.

[8] Nochovnaya N A, Panin P V, Kochetkov A S, et al. Modern refractory alloys based on titanium gamma-aluminide: Prospects of development and application[J]. Metal Science and Heat Treatment, 2014, 56(7−8): 364 − 367. doi: 10.1007/s11041-014-9763-4

[9] Zhu H L, Maruyama K, Seo D Y, et al. Interfacial strengthening by soft phase in lamellar microstructure of TiAl alloys[J]. Applied Physics Letters, 2007, 90: 171925. doi: 10.1063/1.2733600

[10] Kothari K, Radhakrishnan R, Wereley N M. Advances in gamma titanium aluminides and their manufacturing techniques[J]. Progress in Aerospace Sciences, 2012, 55: 1 − 16. doi: 10.1016/j.paerosci.2012.04.001

[11] Wu X. Review of alloy and process development of TiAl alloys[J]. Intermetallics, 2006, 14(10): 1114 − 1122.

[12] Qu H P, Li P, Zhang S Q, et al. The effects of heat treatment on the microstructure and mechanical property of laser melting deposition γ-TiAl intermetallic alloys[J]. Materials & Design, 2010, 31(4): 2201 − 2210.

[13] Qu H P, Li P, Zhang S Q, et al. Microstructure and mechanical property of laser melting deposition (LMD) Ti/TiAl structural gradient material[J]. Materials & Design, 2010, 31(1): 574 − 582.

[14] Li W, Liu J, Zhou Y, et al. Effect of laser scanning speed on a Ti-45Al-2Cr-5Nb alloy processed by selective laser melting: Microstructure, phase and mechanical properties[J]. Journal of Alloys and Compounds, 2016, 688: 626 − 636. doi: 10.1016/j.jallcom.2016.07.206

[15] Murr L E, Gaytan S M, Ceylan A, et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting[J]. Acta Materialia, 2010, 58(5): 1887 − 1894. doi: 10.1016/j.actamat.2009.11.032

[16] Yue H Y, Chen Y Y, Wang X P, et al. Microstructure, texture and tensile properties of Ti-47Al-2Cr-2Nb alloy produced by selective electron beam melting[J]. Journal of Alloys and Compounds, 2018, 776: 450 − 459.

[17] Ma Y, Cuiuri D, Hoye N, et al. The effect of location on the microstructure and mechanical properties of titanium aluminides produced by additive layer manufacturing using in-situ alloying and gas tungsten arc welding[J]. Materials Science and Engineering: A, 2015, 631: 230 − 240. doi: 10.1016/j.msea.2015.02.051

[18] Ma Y, Cuiuri D, Shen C, et al. Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding[J]. Additive Manufacturing, 2015, 8: 71 − 77. doi: 10.1016/j.addma.2015.08.001

[19] Ma Y, Cuiuri D, Li H J, et al. The effect of postproduction heat treatment on γ-TiAl alloys produced by the GTAW-based additive manufacturing process[J]. Materials Sciense and Engineening: A, 2016, 657: 86 − 95. doi: 10.1016/j.msea.2016.01.060

[20] Cai X Y, Dong B L, Yin X L. Wire arc additive manufacturing of titanium aluminide alloys using two-wire TOP-TIG welding: Processing, microstructures, and mechanical properties[J]. Additive Manufacturing, 2020, 35: 101344. doi: 10.1016/j.addma.2020.101344

[21] 汪小平, 郑运荣. TiAl基合金中的不连续粗化转变[J]. 材料工程, 2000, 7: 20 − 23. doi: 10.3969/j.issn.1001-4381.2000.01.005 Wang Xiaoping, Zheng Yunrong. Discontinuous coarsening transformations in TiAl based alloys[J]. Journal of Materials Engineering, 2000, 7: 20 − 23. doi: 10.3969/j.issn.1001-4381.2000.01.005

[22] 方璐. 全片层高Nb-TiAl合金显微组织热稳定性研究[D]. 北京: 北京科技大学, 2017. Fang Lu. Investigation on the thermal stabilities of microstructure in fully lamellar high Nb containing TiAl alloys[D]. Beijing: University of Science and Technology Beijing, 2017.

-

期刊类型引用(8)

1. 李敬勇,李超然,徐育烺,钱鹏. 层间温度对CMT电弧增材制造2Cr13不锈钢薄壁件成形及组织和性能影响. 焊接. 2024(02): 43-50 .  百度学术

百度学术

2. 赵昀,梁乐,孙宏伟,陈卫彬,张本顺. 层间冷却对电弧增材制造钛合金构件性能的影响. 焊接. 2024(02): 26-30 .  百度学术

百度学术

3. 王林,华学明,沈忱,张跃龙,李芳,周雯露,丁煜瀚. 等离子电弧双丝增材制造Ti-48Al合金组织特征. 焊接学报. 2024(02): 1-6+129 .  本站查看

本站查看

4. 张栩菁,魏艳红,赵文勇,龙金卫,刘仁培. 电弧增材制造控形改性技术研究进展. 机械制造文摘(焊接分册). 2022(01): 1-13 .  百度学术

百度学术

5. 蔡笑宇,董博伦,王俊哲,林三宝. 热处理对GTA增材制造TiAl合金组织与性能的调控. 焊接学报. 2022(03): 7-12+113 .  本站查看

本站查看

6. 奥妮,何子昂,吴圣川,彭鑫,吴正凯,张振先,祝弘滨. 激光增材制造AlSi10Mg合金的力学性能研究进展. 焊接学报. 2022(09): 1-19+113 .  本站查看

本站查看

7. 王鑫,陈玉勇,孔凡涛. 氧和氮对TiAl合金精密热成形显微组织和力学性能的影响. 精密成形工程. 2022(11): 199-209 .  百度学术

百度学术

8. 倪永谦,王猛,杜心伟,刘仁培,魏艳红. 基于遗传算法优化的电弧增材再制造焊道尺寸预测模型. 机械制造文摘(焊接分册). 2021(06): 15-20 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: