Effect of Zn on the shear properties of Sn0.5Ag0.7Cu/Cu joints and the microstructure of aging joints

-

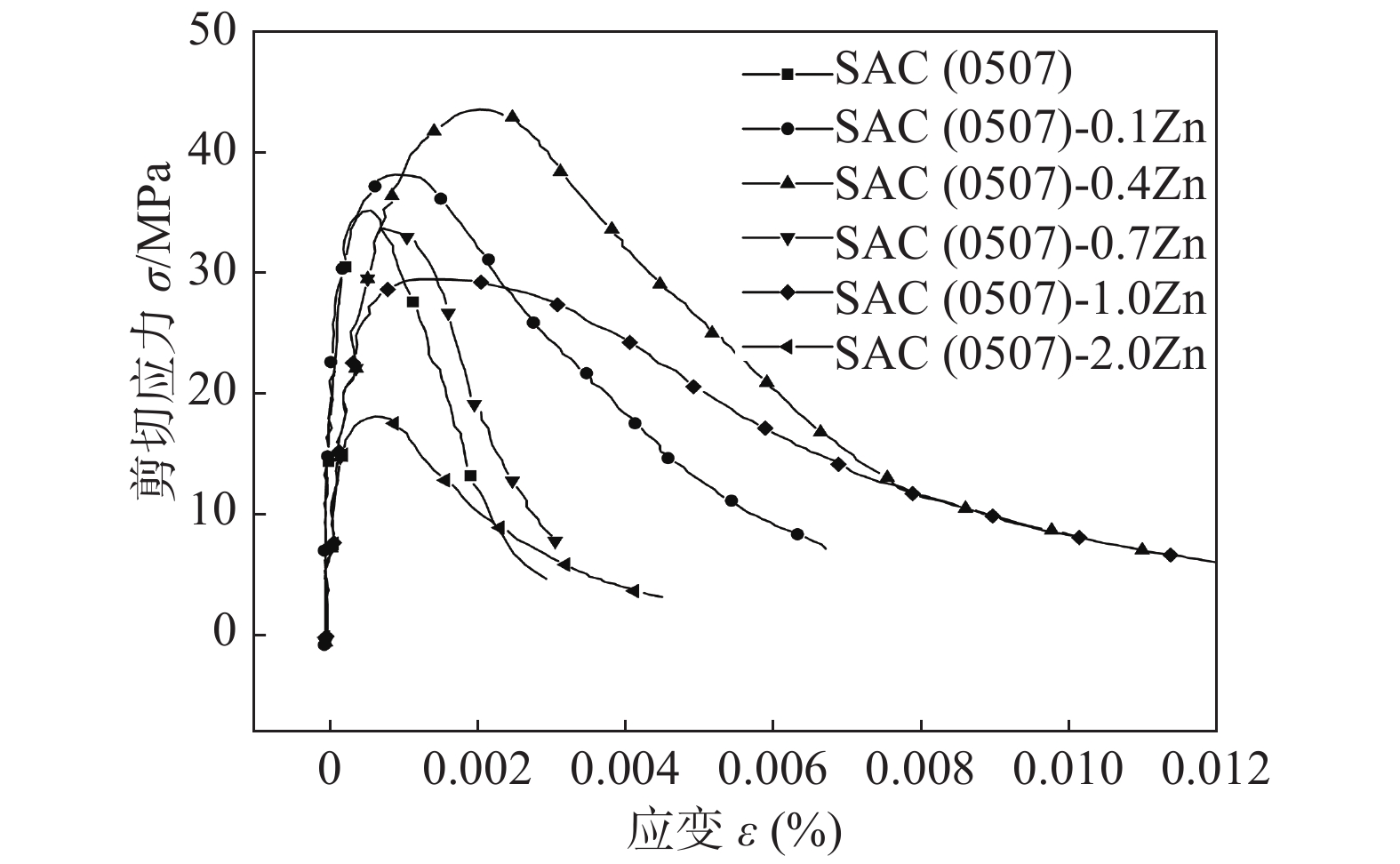

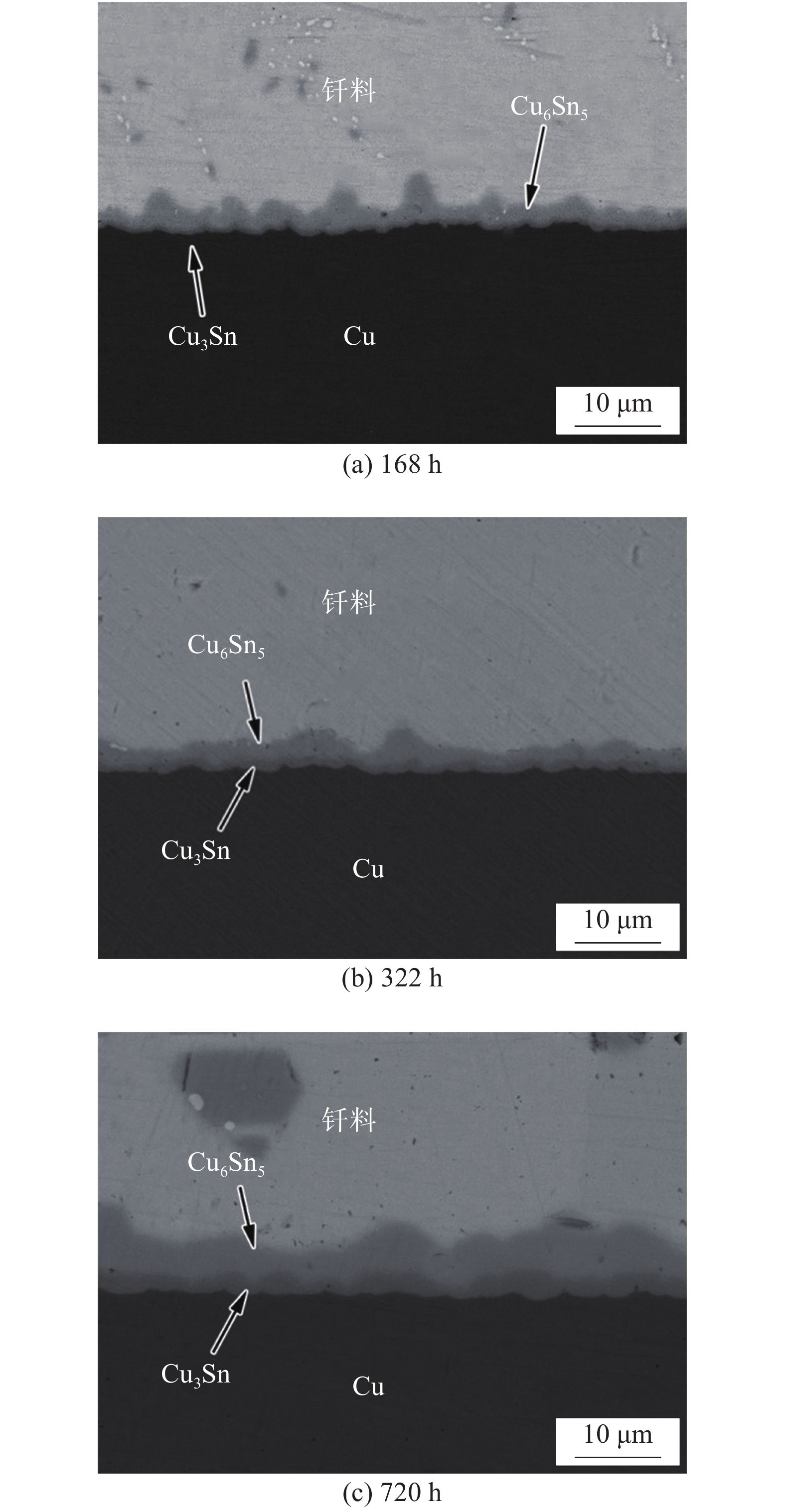

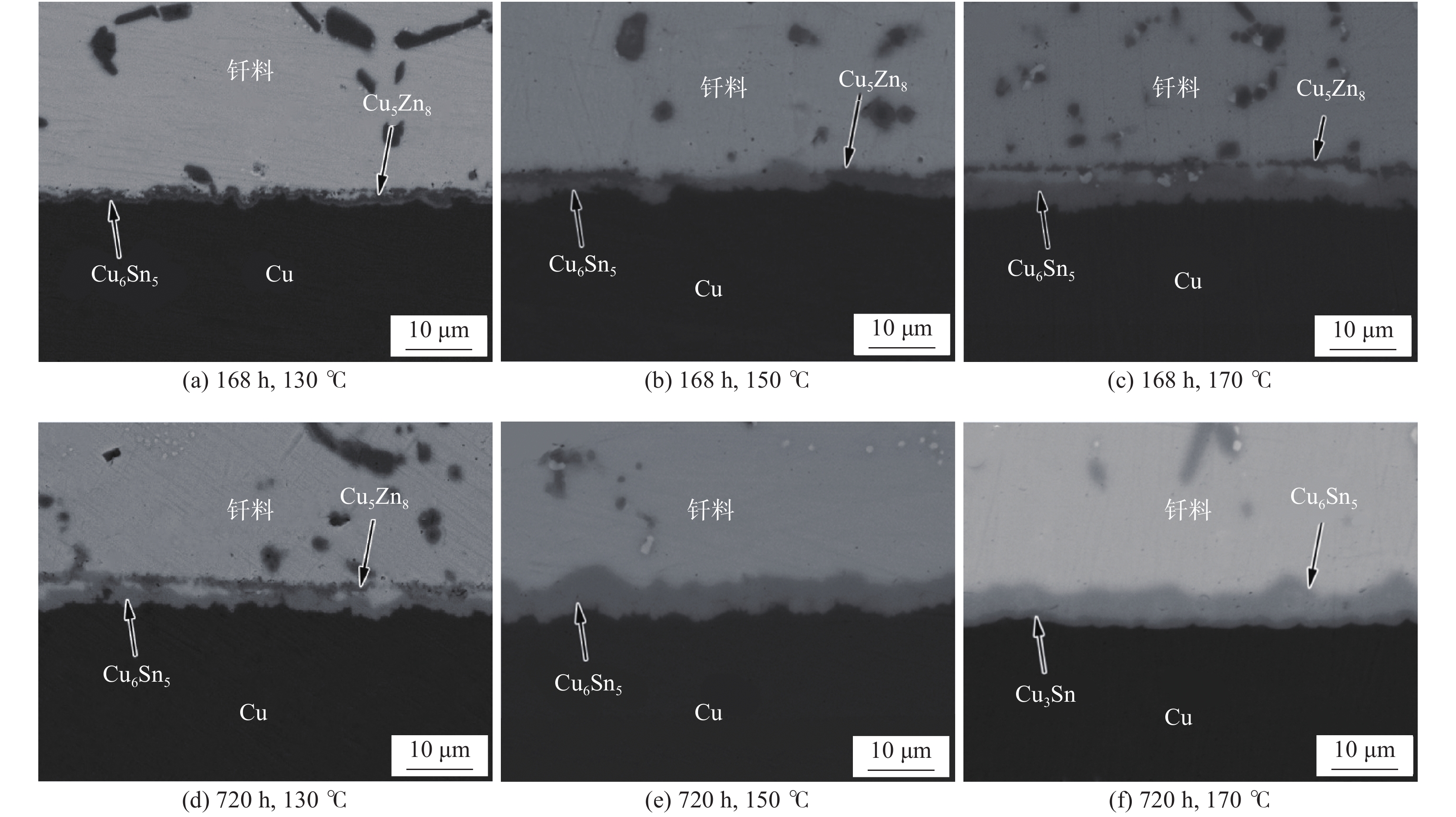

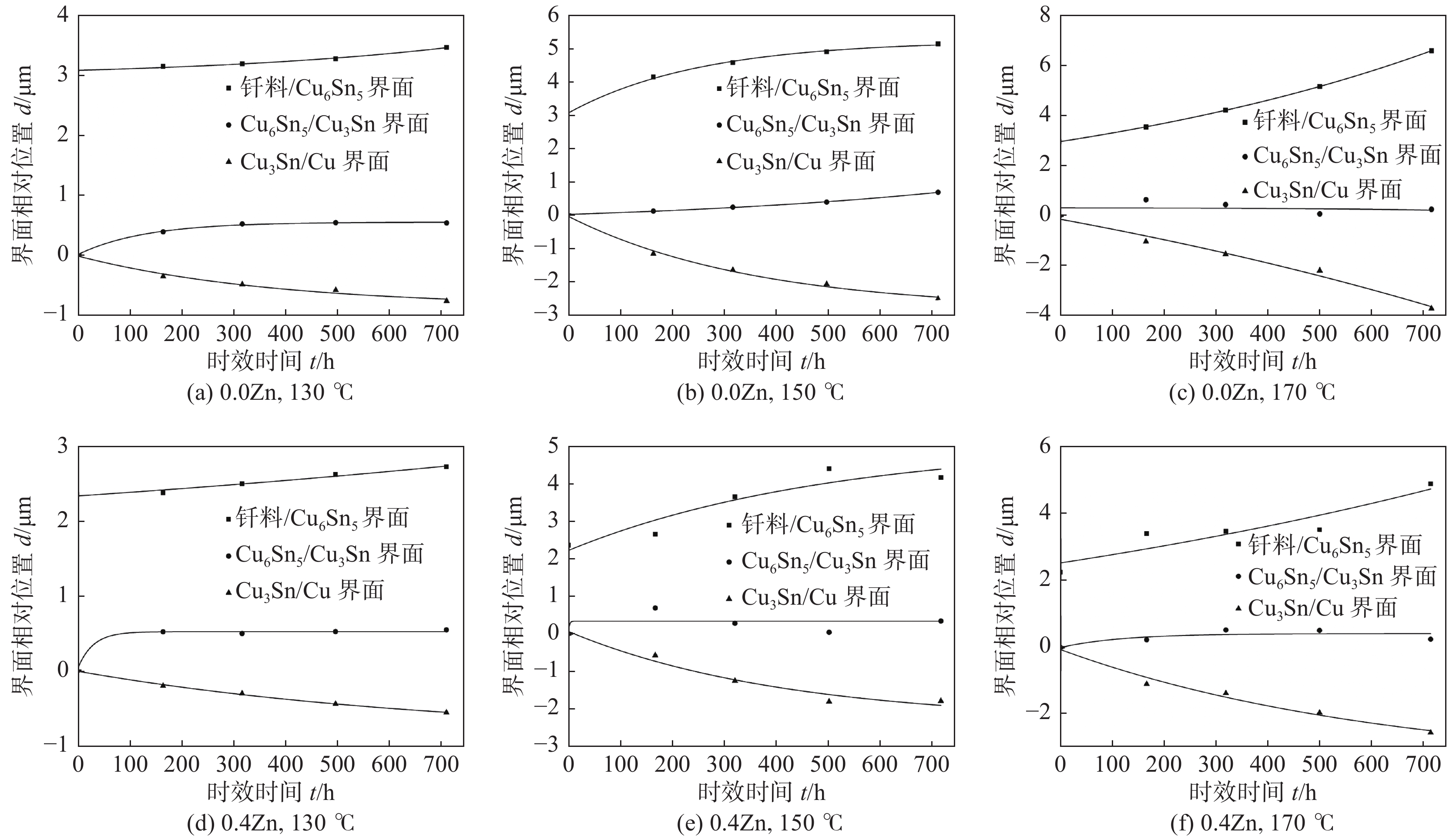

摘要: 为了改善Sn0.5Ag0.7Cu/Cu接头组织结构和力学性能,通过在Sn0.5Ag0.7Cu钎料中添加Zn元素,以Sn0.5Ag0.7Cu-xZn (x=0, 0.1, 0.4, 0.7, 1)钎料合金对紫铜基板进行了熔钎焊试验,并对接头进行微观组织及力学性能分析. 结果表明,改变了接头结合界面处金属间化合物(intermetallic compound,IMC)组织结构,增强了接头剪切断裂的韧性断裂特征,提高了接头抗剪强度. 当Zn元素的加入量为0.4% (质量分数)时,接头抗剪强度达到最高的47.81 MPa. 添加Zn元素等温时效处理后,对接头中IMC层的生长有着抑制作用,并且随着时效温度的提高和时效时间的延长,脆性层Cu5Zn8会破碎直至消失,因此在改善接头结合界面处IMC组织性能的同时,不会改变其组成和结构.Abstract: In order to improve the microstructure and mechanical properties of the Sn0.5Ag0.7Cu/Cu joint, by adding Zn element to the Sn0.5Ag0.7Cu solder, changed the intermetallic compound (intermetallic compound, IMC) structure at the joint interface, and the joint shear is strengthened. The ductile fracture characteristics of shear fracture improve the joint shear strength.When the addition of Zn element is 0.4%, the joint shear strength reaches the highest 47.81 MPa.The solder joint of Sn0.5Ag0.7Cu-xZn(x=0, 0.1, 0.4, 0.7, 1) /Cu was studied, the result shows that the addition of Zn element has an inhibitory effect on the growth of the IMC layer in the joint after isothermal aging treatment, and with the increase of aging temperature and aging time, the brittle layer Cu5Zn8. It will break until it disappears, so it will not change its composition and structure while improving the performance of the IMC at the joint interface.

-

Keywords:

- bonding interface /

- diffusion /

- intermetallic compound /

- aging

-

0. 序言

碳纤维增强热塑性材料(carbon fiber reinforced thermoplastic composite,CFRTP)以其高强度、耐蚀、耐热等特点被广泛应用于航空航天、轨道交通等领域,同样铝合金因其轻量化、强度高的特点在这些领域中应用也较为广泛,因此CFRTP与铝合金的连接成为不可避免的问题,由于两种材料性能差异较大,CFRTP与铝合金的有效连接存在一定难度. 激光焊以其能量集中、热影响区小的特点在CFRTP和铝合金连接方面具有明显的优势[1-3].

激光焊接过程中的界面温度至关重要,温度场分布直接影响着接触界面的树脂熔化情况. 因此通过仿真手段分析异种材料激光焊接过程中的温度场演化规律对于实际焊接工艺摸索具有重要的指导意义. 目前在异种材料焊接的仿真方面,王强等人[4-8]均采用ANSYS软件以高斯面热源模型作为激光热源模型,主要对不锈钢和以PPS为基的碳纤维材料的焊接温度场进行研究,用来预测工艺参数对温度场的影响;贾少辉[9]对CFRTP(PA树脂为基体)/铝合金的激光搅拌焊接试验及温度场做出了研究分析,利用有限元法预测分析了激光搅拌焊接过程中的温度场;李云[10]构建刻蚀6061铝合金与CFPEEK激光连接过程有限元模型,开展激光连接过程温度场仿真研究;Hussein等人[11]对PMMA/不锈钢激光焊接过程进行了数值模拟,计算模拟结果和实际测量结果基本吻合;黄创[12]利用ANSYS软件建立了钛合金与碳纤维聚合物材料的激光焊接温度场有限元模型,研究了激光功率、焊接速度及离焦量等工艺参数对焊接温度场的影响规律;黄怡洁[13]通过不锈钢与聚合物材料激光焊接的有限元模型,对焊接过程中的温度场进行,数值模拟分析,一定程度上揭示了连接机理;景若木等人[14]利用ABAQUS软件对钛合金和CFPEEK激光焊接温度场进行模拟,获得了钛合金\CFPEEK连接的工艺窗口. 而关于以PA66树脂为基体的碳纤维增强复合材料的激光焊接仿真鲜有报道,且涉及到的工艺参数较少.

文中以高速列车轻量化需求为背景,以6061铝合金和CF/PA66树脂基碳纤维增强复合材料为研究对象,通过试验和数值模拟相结合的手段,利用SYSWELD有限元软件对6061铝合金和CF/PA66激光焊接温度场进行模拟,研究激光功率、焊接速度、搭接宽度、冷却条件、工装导热条件对接头温度场演化的影响规律.

1. 有限元数值模拟模型

6061铝合金和CF/PA66材料搭接激光焊接原理如图1所示,激光照射到铝合金表面,在高密度能量的作用下形成熔池,热量通过热传导的方式传递到6061铝合金和CF/PA66接触界面,使CF/PA66表面树脂熔化,最后在压力的作用下与铝合金表面有效贴合.

针对铝合金/CFRTP搭接构件建立几何模型,铝合金板尺寸为150 mm × 50 mm × 1.5 mm,CFRTP板尺寸为50 mm × 25 mm × 3 mm,如图2所示.

对6061铝合金/CFRTP搭接构件的几何模型进行网格划分,考虑到计算效率和计算时间,在保证计算结果不失真的情况下,对于网格数量进行优化,网格划分结果如图3所示,对CFRTP板上距离界面0.5mm以内区域的网格进行细分,铝合金板上搭接区域内的网格划分密集,搭接区域外的网格划分稀疏,且距离焊缝越远,网格越稀疏,最小网格尺寸为0.25 mm × 0.18 mm × 0.05 mm,最大网格尺寸为3.2 mm × 1.5 mm × 0.5 mm.

为考虑搭接宽度对接头温度场的影响,建立不同搭接宽度的有限元模型,如图4所示,a为焊缝中心至铝合金板端部距离,b为焊缝中心至CFRTP板端部距离,a默认为15 mm.

热源模型的选取直接关系着激光焊接模拟的准确性,结合前期试验结果,选用“高斯面热源 + 指数旋转抛物线体热源”的复合热源模型[15],即

$$ \begin{gathered} Q \cdot \eta = {Q_s} + {Q_v} \\ {q_s}\left( {x,y} \right) = \frac{{\alpha {Q_s}}}{{{\text{π}} R_0^2}}\exp \left[ { - \frac{{\alpha \left( {{x^2} + {y^2}} \right)}}{{R_0^2}}} \right] \\ {q_v}\left( {x,y,{\textit{z}}} \right) = \frac{{27{Q_v}}}{{2{\text{π}} HR_0^2}}\exp \left( {\frac{{ - 3{\textit{z}}}}{H}} \right)\exp \left[ {\frac{{ - 3H\left( {{x^2} + {y^2}} \right)}}{{\left( {H - {\textit{z}}} \right)R_0^2}}} \right] \\ \end{gathered} $$ (1) 式中:Q为激光焊接时的总功率,qs和qv分别表示高斯面热源和指数旋转抛物线体热源的热流密度,

$ \eta $ 表示热效率,Qs和Qv分别表示两种热源模型的有效功率,$ \alpha $ 表示能量集中系数,R0表示指数旋转抛物线体热源的开口半径,H表示旋转体高度.在激光焊接过程中,铝合金在激光热源的作用下升温,其热物理性能参数随温度的升高发生改变,这一情况在焊接仿真过程中也应考虑,6061铝合金材料的热物理性能参数如图5所示[10].

文中采用的CFRTP材料是以PA66树脂为基体,30%短棒碳纤维为增强相通过注塑工艺形成的,该材料在厚度方向上的热导率小于其他两个方向,且假设CFRTP材料的热物理性能参数不随温度发生改变,热物理性能参数如表1所示[16].

表 1 CFRTP热物性参数Table 1. Thermal properties of CFRTP材料 比热c/(J∙kg−1∙K−1) 热导率λ/(W∙m−1∙K−1) PA66 1.672 0.2 CF 1.76 6.5 为考虑工装导热情况对激光焊接过程中搭接接头温度场的影响,将工装夹具简化为焊缝两侧添加导热块的有限元网格模型,如图6所示,导热块长度为25 mm,分布于焊道两侧,内侧间距为10 mm,导热块材质分别为导热性能优良的T2紫铜[17]、与铝板材质相同的6061铝合金、导热性能一般的Q345钢[18],3种材料的热导率如表2所示.

表 2 3种材料热导率 (W∙m−1∙K−1)Table 2. Thermal conductivity of three materials温度T/℃ T2 6061 Q345 25 397 154 46 100 380 158 46 200 367 163 45 300 355 164 43 400 349 167 41 500 345 170 38 为考虑冷却方式对焊接过程中接头温度场的影响情况,设定两种散热方式;一种是工件外表面与空气辐射和自然对流换热,另一种是铝合金板下表面搭接区域之外强制水冷,如图7所示,空冷换热系数为29 W/m2·℃),水冷换热系数取1 800 W/(m2·℃)[19].

为研究激光功率、焊接速度、搭接宽度、冷却条件和工装导热条件对6061铝合金和CFRTP搭接激光焊接温度场的影响,分别进行不同工艺参数下构件的有限元仿真,工艺参数如表3所示.

表 3 工艺参数Table 3. Welding parameters序号 激光功率

P/W焊接速度

v/(mm∙s−1)搭接宽度

d/mm冷却

条件导热 1 400 5 25 空冷 无 2 450 5 25 空冷 无 3 500 5 25 空冷 无 4 550 5 25 空冷 无 5 600 5 25 空冷 无 6 500 3 25 空冷 无 7 500 5 25 空冷 无 8 500 7 25 空冷 无 9 500 9 25 空冷 无 10 500 11 25 空冷 无 11 500 13 25 空冷 无 12 500 5 30 空冷 无 13 500 5 35 空冷 无 14 500 5 25 水冷 无 15 500 5 25 空冷 T2 16 500 5 25 空冷 6061 17 500 5 25 空冷 Q345 2. 模型验证

2.1 试验材料与激光参数

6061铝合金板和CFRTP板尺寸分别为150 mm × 50 mm × 1.5 mm和50 mm × 25 mm × 3 mm,试验前将CFRTP板放在超声波清洗机中用丙酮进行清洗,然后放入烘干箱中进行烘干,激光焊接试验采用IPG公司YLS-6000光纤激光器,为避免激光反射至光路,将激光枪头前倾10°,焊接过程中采用25 L/min的氩气作为保护气体,激光功率为500 W,焊接速度为5 mm/s,离焦量为 + 10 mm.

2.2 试验结果及模拟结果

选用与2.1中相同的工艺参数进行6061铝合金和CFRTP板搭接激光焊数值模拟,图8为6061铝合金和CFRTP激光焊接试验结果与热源参数校核后的仿真结果对比,左侧为激光焊接铝合金焊缝横截面宏观形貌,右侧为相同工艺参数下的仿真结果,由于6061铝合金熔点为650 ℃,因此将仿真结果中温度高于650 ℃的区域作为熔池区域,可以看出,数值模拟获得的熔池形态与实际焊缝横截面形态基本吻合,计算得到的熔宽和熔深结果与实际焊缝熔宽熔深基本一致.

图9为焊接时间4.26 s时焊缝横截面的温度场云图,可以看出,铝合金和CFRTP界面处的等温线更为密集,温度梯度较大,且由于PA66的热导率远小于6061铝合金,高温区域在CFRTP侧的厚度较小;提取路径1上各节点的温度,如图10所示,温度随着距离起始点位移大小的增大而降低,由于两种材料的热物性差异巨大,因此曲线在界面处存在拐点,CFRTP材料熔化深度约为0.265 mm,且界面处温度超过PA66数值的分解温度,分解区宽度约为0.104 mm. 图11为路径1上Z = 0 mm、Z = 1.5 mm、Z = 1.7 mm处的温度随时间的变化曲线,可以看出,距离铝合金上表面越远,最高温度越低,且Z = 0 mm、Z = 1.5 mm处温度达到最大值时,Z = 1.7 mm处温度还未达到最大值,滞后时间约为0.3 s.

图12为CFRTP表面实际熔化宽度与仿真计算结果的对比,可以看出,二者趋势基本相近,CFRTP熔化宽度沿焊接方向逐渐增大,中后部位置的熔化情况存在差异,可能是由于试验条件下铝合金下表面与CFRTP上表面搭接部分未能完全接触;从温度场云图中也可发现,CFRTP表面存在一定宽度的分解区域.

3. 结果和分析

3.1 激光功率的影响

为分析激光功率对搭接界面处熔化和分解情况的影响规律,提取不同激光功率作用下的搭接界面处的温度场分布云图,如图13所示,可以发现,CFRTP表面熔化区域和分解区域均沿焊接方向逐渐增大,且随着激光功率的逐渐增大,搭接界面熔化区域和分解区域逐渐增大,当激光功率增大到600 W时,CFRTP表面整个搭接区域基本熔化.

图14为不同激光功率下CFRTP搭接位置熔化深度、分解深度、分解深度占熔化深度比例的对比图,可以发现,随着激光功率的增加,CFRTP熔化深度和分解深度逐渐增加,且分解深度在整个熔化深度中所占比例逐渐增大,当激光功率为400 W时,CFRTP中间位置熔化深度和分解深度较小,分别为0.2 mm和0.03 mm,分解深度在整个熔化深度中所占比例仅为15%,在整个焊接接头的有效连接区域中PA66树脂基分解量较小,当激光功率为600 W时,CFRTP中间位置熔化深度和分解深度分别达到0.41 mm和0.18 mm,分解深度在整个熔化深度中所占比例达到43.9%,在整个焊接接头的有效连接区域中PA66树脂基分解量较大,焊接过程中,接头爆裂风险较高.

3.2 焊接速度的影响

为分析焊接速度对搭接界面熔化和分解行为的影响规律,提取不同焊接速度下CFRTP上表面温度场云图,如图15所示,虚线左侧为搭接区域,可以发现,当焊接速度为3 mm/s时,基本整个搭接区域表面温度都超过PA66树脂的熔化温度,且搭接表面上大部分区域温度超过PA66分解温度,随着焊接速度的增加,CFRTP搭接表面熔化区域和分解区域逐渐减小,当焊接速度增加到13 mm/s时,熔化宽度仅为4.45 mm,分解区域不再贯穿整个搭接区域.

图16为不同焊接速度CFRTP搭接区域熔化深度、分解深度以及分解深度占比的对比图,可以看出,该位置CFRTP熔化深度和分解深度均随着焊接速度的增大而减小,且整个熔化深度中分解深度所占比例随焊接速度的增大而减小,由39.2%降低为5.4%,这说明增加焊接速度能显著减小PA66树脂熔化区域深度内分解区域占比;相反,采用较低的焊接速度,虽然能够增加PA66树脂的熔化深度,但熔化深度内PA66树脂分解所占比例也相应增加.

3.3 搭接宽度的影响

为分析搭接宽度对搭接界面熔化和分解行为的影响规律,提取不同搭接宽度下CFRTP上表面温度场云图,虚线左侧为搭接区域,如图17所示,可以看出,不同搭接区域下CFRTP表面温度分布情况基本一致,表面PA66树脂熔化宽度和分解宽度基本一致,尤其是在a区域(焊缝中心至铝合金板端部)内温度场基本一致;当搭接宽度超过25 mm之后,b区域(焊缝中心至CFRTP端部)温度场分布也基本一致,这说明在搭接宽度超过该工艺参数下的CFRTP最大熔化宽度后,搭接宽度对CFRTP表面熔化宽度和分解宽度几乎没有影响.

3.4 冷却条件的影响

为分析冷却条件对搭接界面熔化和分解行为的影响规律,提取两种冷却条件下CFRTP上表面温度场云图,虚线左侧为搭接区域,如图18所示,可以看出,水冷条件下CFRTP上表面熔化宽度显著缩小,且熔化区域关于焊缝中心几乎对称,这说明在水冷条件下下,CFRTP上表面焊缝两侧温度分布基本一致,区域A过热、散热慢的情况得到明显改善;对于PA66分解区域,水冷条件下PA66分解区域并没有明显减小,熔化区域内的有效连接区域占比减小.

3.5 导热条件的影响

图19为不同导热块下CFRTP搭接界面温度场云图,可以看出,添加导热块之后,CFRTP上表面熔化宽度和分解宽度显著减小,且焊缝两侧熔化区域不对称的情况基本消失,这说明添加导热块可以改善CFRTP上表面温度分布不对称,缩小CFRTP上表面过热区域,当导热块为T2紫铜时,熔化宽度和分解宽度相较于其它两种材质更窄,这主要是由于T2紫铜热导率明显高于其它两种材质,在焊接过程中导热能力更强.

测量和计算不同导热条件下的CFRTP熔化深度、分解深度和分解深度占比,如表4所示,可以看出,添加导热块之后,CFRTP熔化深度、分解深度和分解深度占比显著降低,特别是当导热块材质为T2紫铜时,相比于无导热块,熔化深度降低超过50%,分解深度降低超过90%;导热块热导率越高,降低幅度越大. 这说明添加导热块能够降低CFRTP材料中PA66树脂熔化量,导热性能越好,降低幅度越大.

表 4 不同导热条件下CFRTP熔化情况Table 4. Melting condition of CFRTP at different thermal conductivity condition导热条件 熔化深度

H1/mm分解深度

H2/mm分解深度占比

A(%)无导热块 0.31 0.11 35.5 T2 0.15 0.01 6.7 6061 0.18 0.03 16.7 Q345 0.19 0.04 21.1 提取距CFRTP上表面0.05 mm厚度处的温度循环曲线,如图20所示,可以看出,添加导热块可以降低该深度处温度,增大冷却速度,缩短该处区域在PA66熔化和分解温度之上停留时间,且导热块的导热性能越好,效果越明显,这说明添加导热块同样可以降低焊接过程中CFRTP材料内部温度,加快PA66树脂的冷却凝固过程,改善PA66树脂的分解情况.

4. 结论

(1) 建立了6061铝合金和CFRTP搭接激光焊接的有限元仿真模型,通过试验验证了其准确性,并分析焊接过程中铝合金和CFRTP温度变化规律.

(2) 激光功率越大,搭接区域PA66树脂的熔化深度和分解深度均随激光功率的增大而增加.

(3) 焊接速度越大,搭接区域PA66树脂的熔化宽度、分解宽度、熔化深度和分解深度随焊接速度的增大而减小,且焊接速度越快,处于熔化温度和分解温度之上停留时间越短.

(4) 同种工艺参数下,界面树脂的有效熔化宽度一定,材料搭接尺寸对树脂有效熔化宽度几乎没有影响;水冷条件能够降低搭接区域中PA66树脂熔化和分解量.

(5) 添加导热块能够显著增大搭接面冷却速度,缩小表面过热区域,且导热块材质热导率越高,效果越显著;添加导热块之后,搭接面PA66树脂的熔化量也显著减少.

-

-

[1] Bradley E, Handwerker C A, Bath J, et al. Lead-free electronics: iNEMI projects lead to successful manufacturing[C]//Reliability & Maintainability Symposium. IEEE, 2007: 1-15.

[2] Fazal M A, Liyana N K, Saeed Rubaiee, et al. A critical review on performance, microstructure and corrosion resistance of Pb-free solders[J]. Measurement, 2019, 134: 897 − 907. doi: 10.1016/j.measurement.2018.12.051

[3] Guang Ren, Maurice N Collins, Jeff Punch, et al. Pb-free solder—microstructural, material reliability, and failure relationships[M]. Handbook of Materials Failure Analysis, 2020.

[4] Yang L, Quan S, Liu C, et al. Aging resistance of the Sn-Ag-Cu solder joints doped with Mo nanoparticles[J]. Materials Letters, 2019, 253(15): 191 − 194.

[5] 贾九红, 姚戴锋, 田红春, 等. 钎焊耦合高温波导杆技术测厚可靠性研究[J]. 压力容器, 2021, 38(2): 7 − 13. doi: 10.3969/j.issn.1001-4837.2021.02.002 Jia Jiuhong, Yao Daifeng, Tian Hongchun, et al. Study on the reliability of the thickness measurement of brazing coupled high temperature waveguide rod technology[J]. Pressure Vessel Technology, 2021, 38(2): 7 − 13. doi: 10.3969/j.issn.1001-4837.2021.02.002

[6] Chou T T, Song R W, Chen W Y, et al. Enhancement of the mechanical strength of Sn-3.0Ag-0.5Cu/Ni joints via doping minor Ni into solder alloy[J]. Materials Letters, 2019, 235(15): 180 − 183.

[7] Zhang Min, Xu Huanrui, Wang Gang, et al. Effect of Ga on microstructure and properties of Sn-Zn-Bi solder for photovoltaic ribbon[J]. China Welding, 2019, 28(4): 1 − 7.

[8] 隋然, 林巧力. SnAgCu-xTi在单晶硅表面的润湿行为[J]. 焊接学报, 2020, 41(4): 90 − 96. doi: 10.12073/j.hjxb.20191122001 Sui Ran, Lin Qiaoli. Wetting behavior of SnAgCu-xTi on the surface of single crystal silicon[J]. Transactions of the China Welding Institution, 2020, 41(4): 90 − 96. doi: 10.12073/j.hjxb.20191122001

[9] 姜楠, 张亮, 刘志权, 等. FCBGA器件SnAgCu焊点的热冲击可靠性分析[J]. 焊接学报, 2019, 40(9): 39 − 42. Jiang Nan, Zhang Liang, Liu Zhiquan, et al. Thermal shock reliability analysis of SnAgCu solder joints for FCBGA devices[J]. Transactions of the China Welding Institution, 2019, 40(9): 39 − 42.

[10] Yee-Wen Y, William Y, Chu-Hsuan W, et al. Study of interfacial reactions between lead-free solders and Cu-xZn alloys[J]. Journal of Electronic Materials, 2018, 48(13): 170 − 181.

[11] Wang S, Yao Y, Wang W. Microstructure and size effect of interfacial intermetallic on fracture toughness of Sn3.0Ag0.5Cu solder interconnects[J]. Engineering Fracture Mechanics, 2018, 202(15): 259 − 274.

[12] Kunwar A, Shang S, Raback P, et al. Heat and mass transfer effects of laser soldering on growth behavior of interfacial intermetallic compounds in Sn/Cu and Sn-3.5Ag0.5/Cu joints[J]. Microelectronics Reliability, 2018, 80: 55 − 67. doi: 10.1016/j.microrel.2017.11.016

[13] Ali B, Sabri M F M, Said S M, et al. Microstructural and tensile properties of Fe and Bi added Sn-1Ag-0.5Cu solder alloy under high temperature environment[J]. Microelectronics Reliability, 2018, 82: 171 − 178. doi: 10.1016/j.microrel.2018.01.015

[14] Shang S, Wang Y, Wang Y, et al. Enhancement of hardness of bulk solder by doping Cu nanoparticles at the interface of Sn/Cu solder joint[J]. Microelectronic Engineering, 2019, 208(1): 47 − 53.

[15] Gusak A M, Tu K N. Kinetic theory of flux-driven ripening[J]. Physical Review B, 2002, 66(11): 115403. doi: 10.1103/PhysRevB.66.115403

[16] 杨扬. Sn基钎料/Cu界面柯肯达尔空洞机理研究[D]. 上海: 上海交通大学, 2012. Yang Yang. Study on the Kirkendall void mechanism of Sn-based solder/Cu interface[D]. Shanghai: Shanghai Jiao Tong University, 2012.

[17] Paul A. The Kirkendall effect in solid state diffusion[D]. Eindhoven: Technical University of Eindhoven, 2004.

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: