Analysis on manufacturing process for thin-walled circular structure based on wire and arc additive manufacturing

-

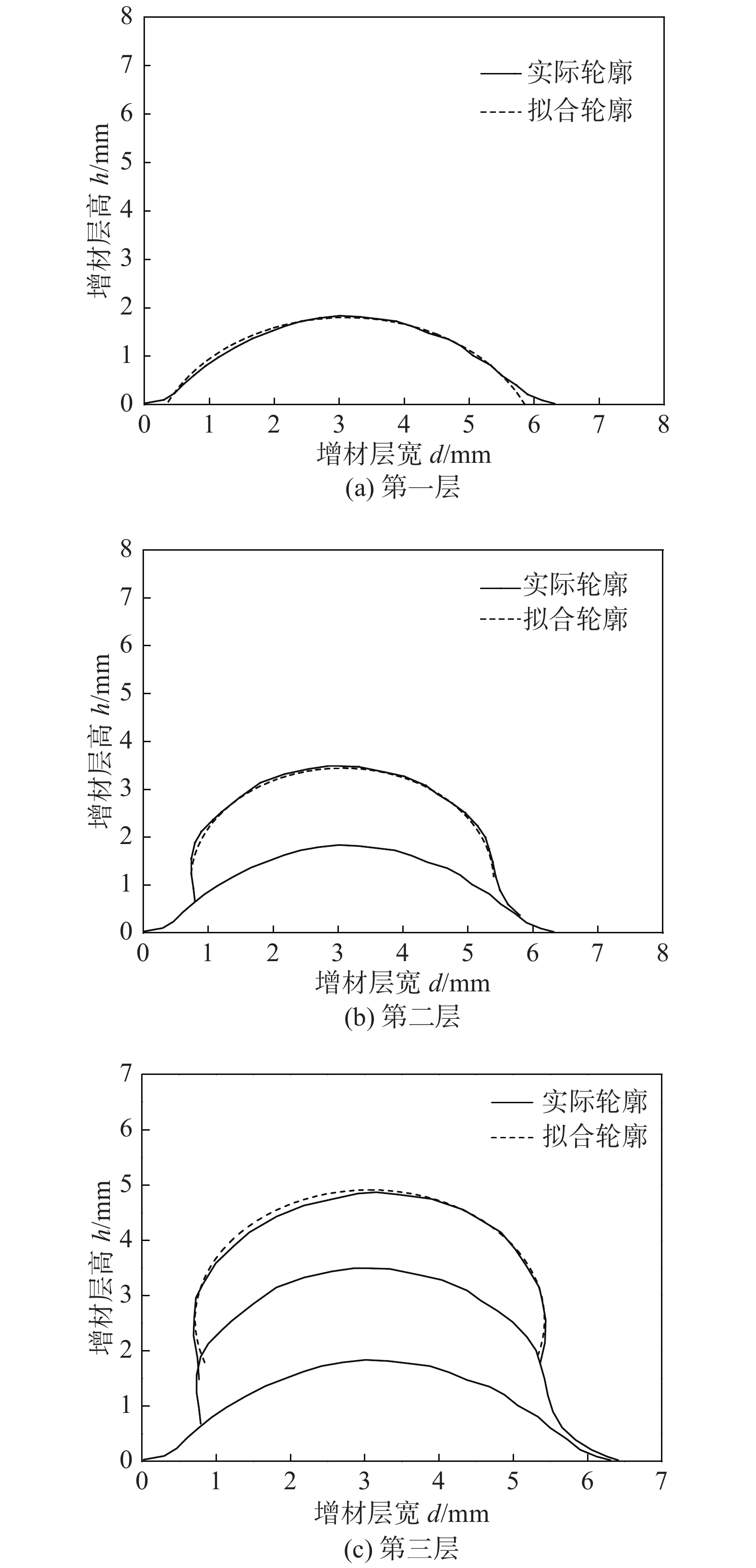

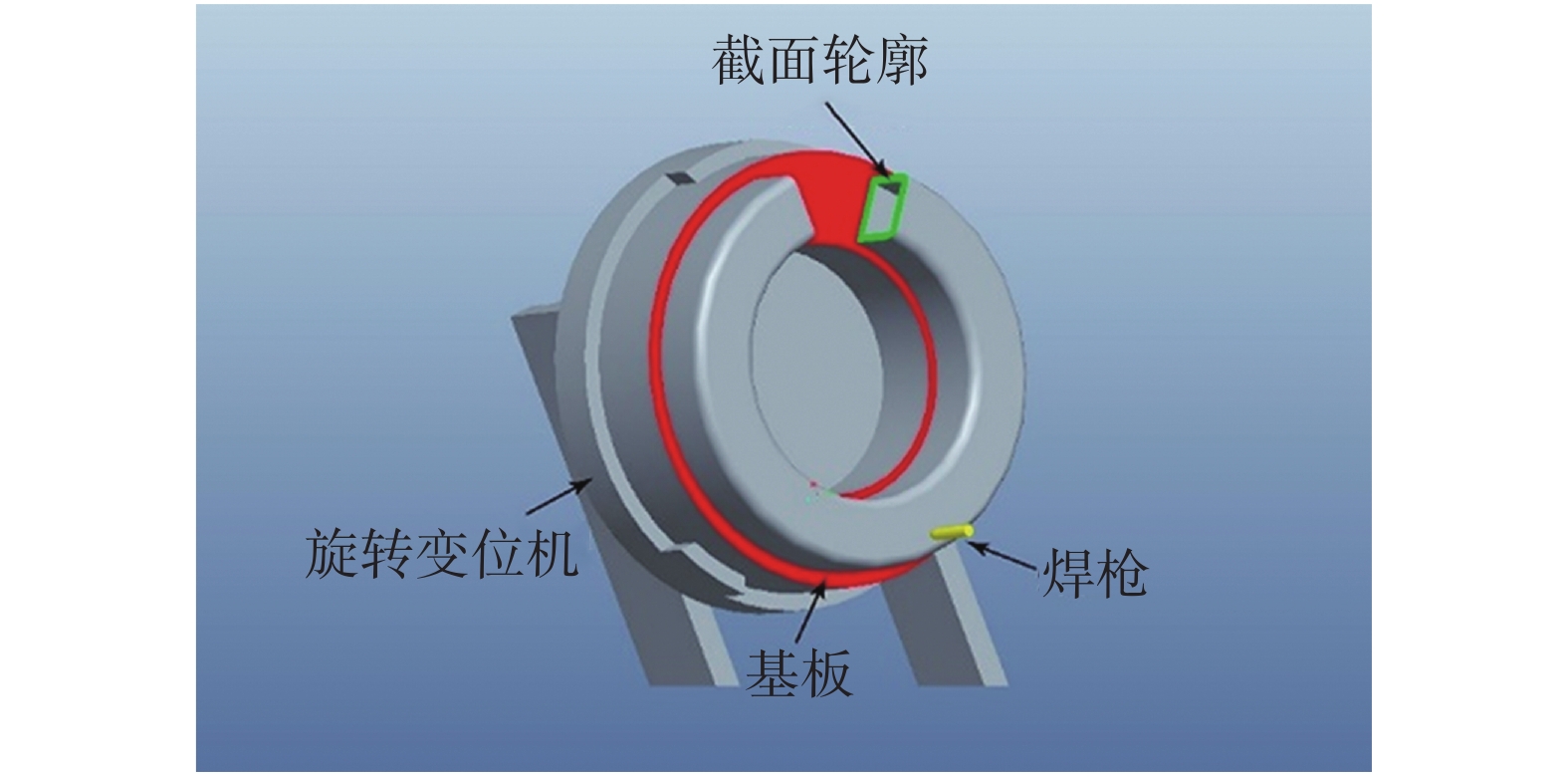

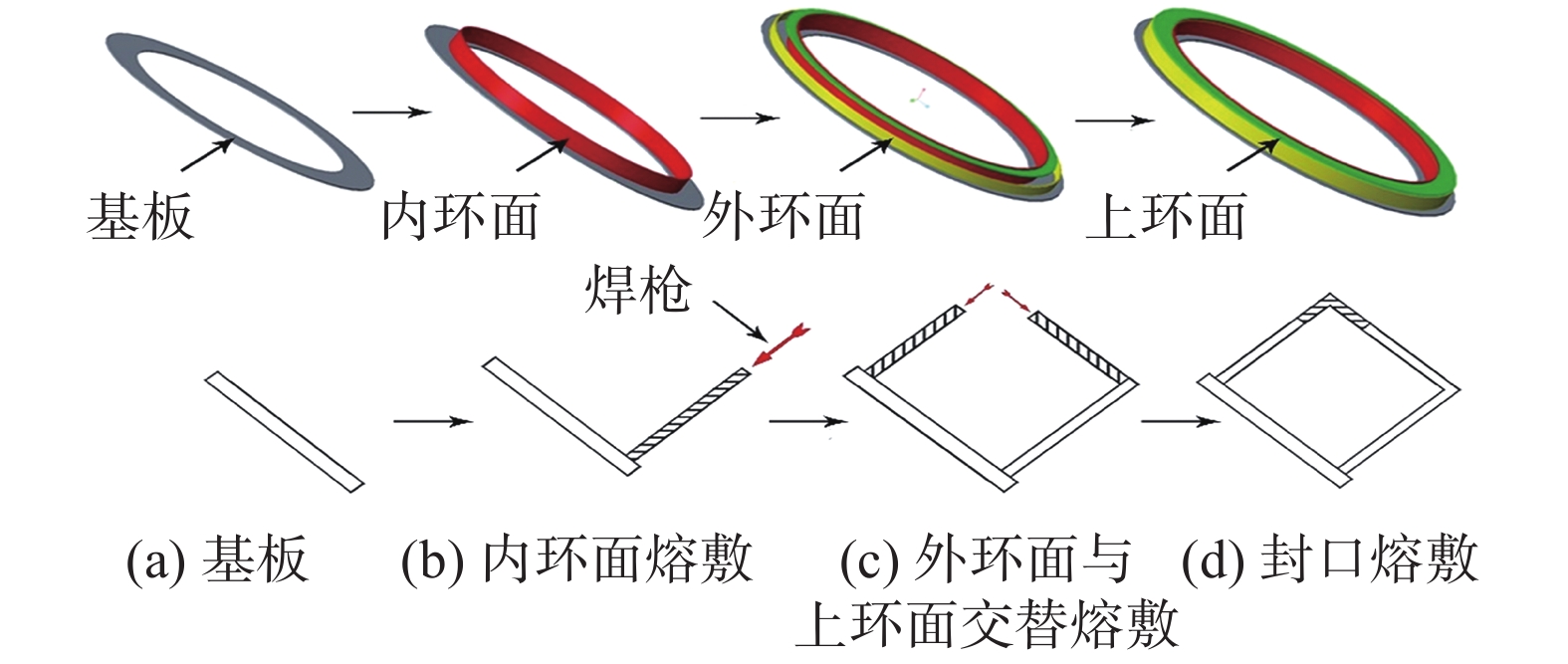

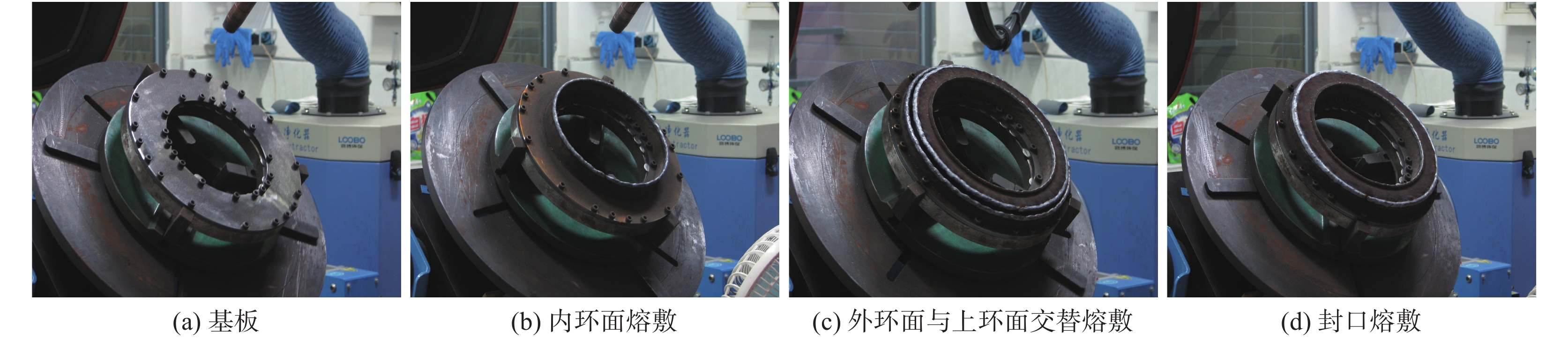

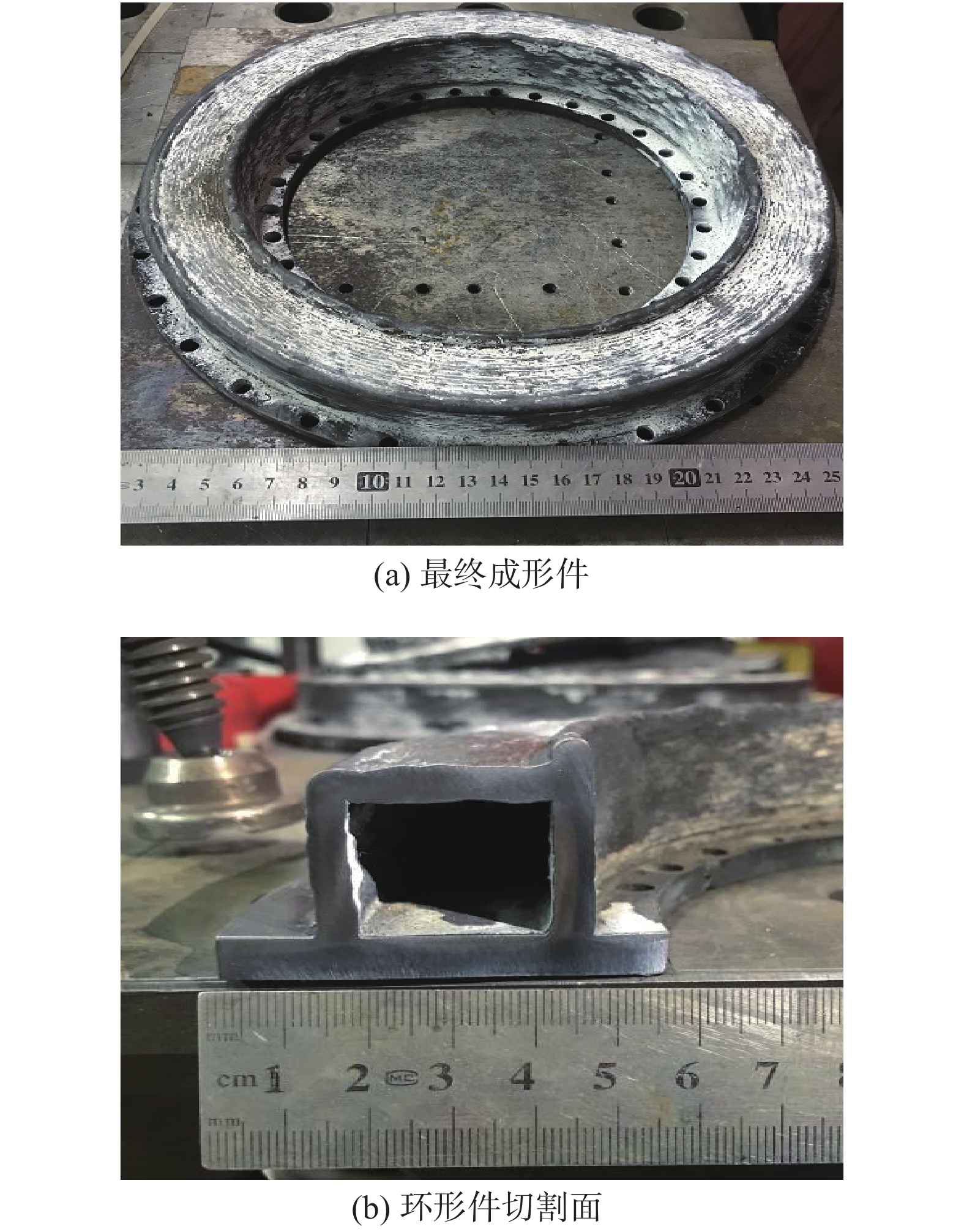

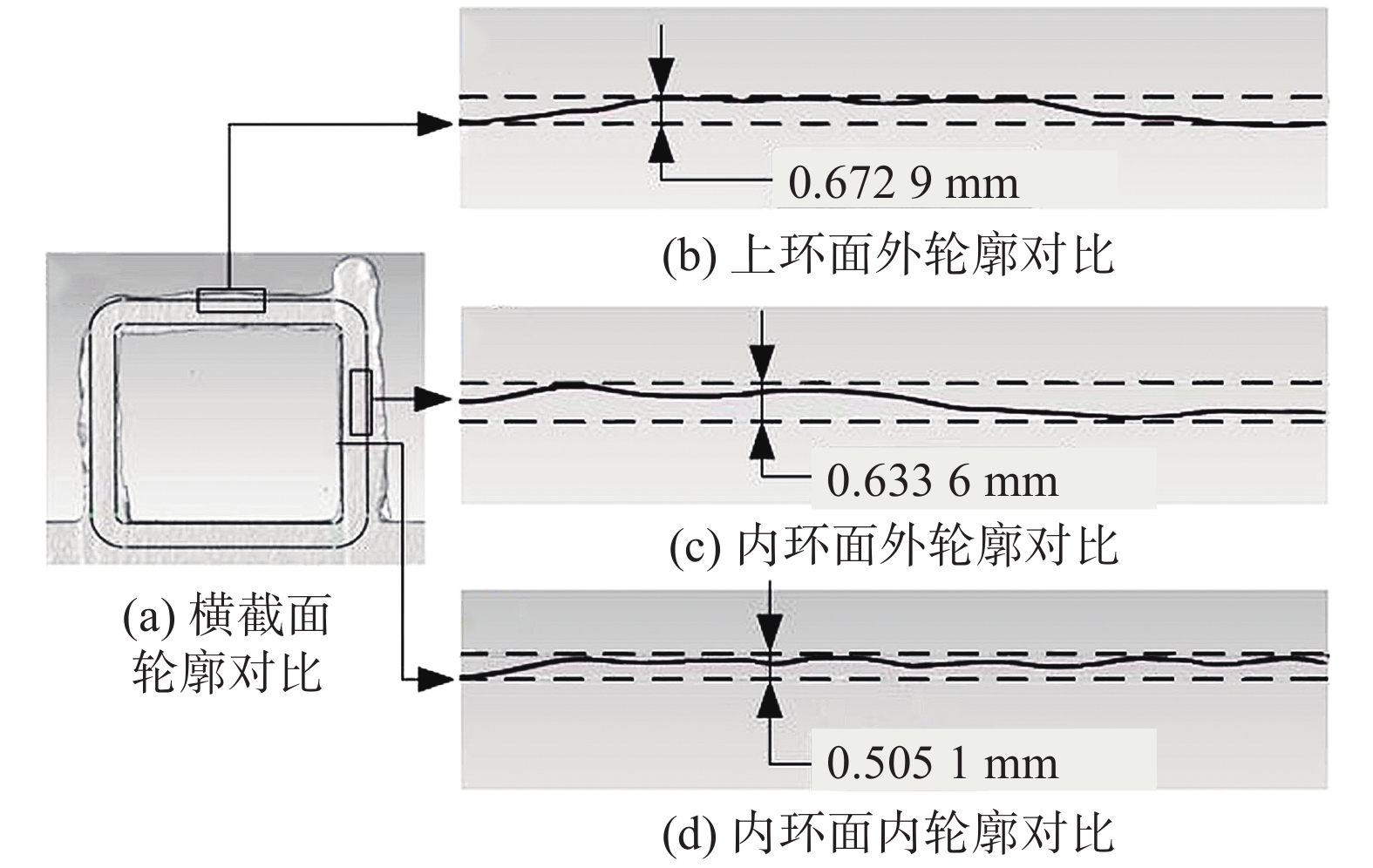

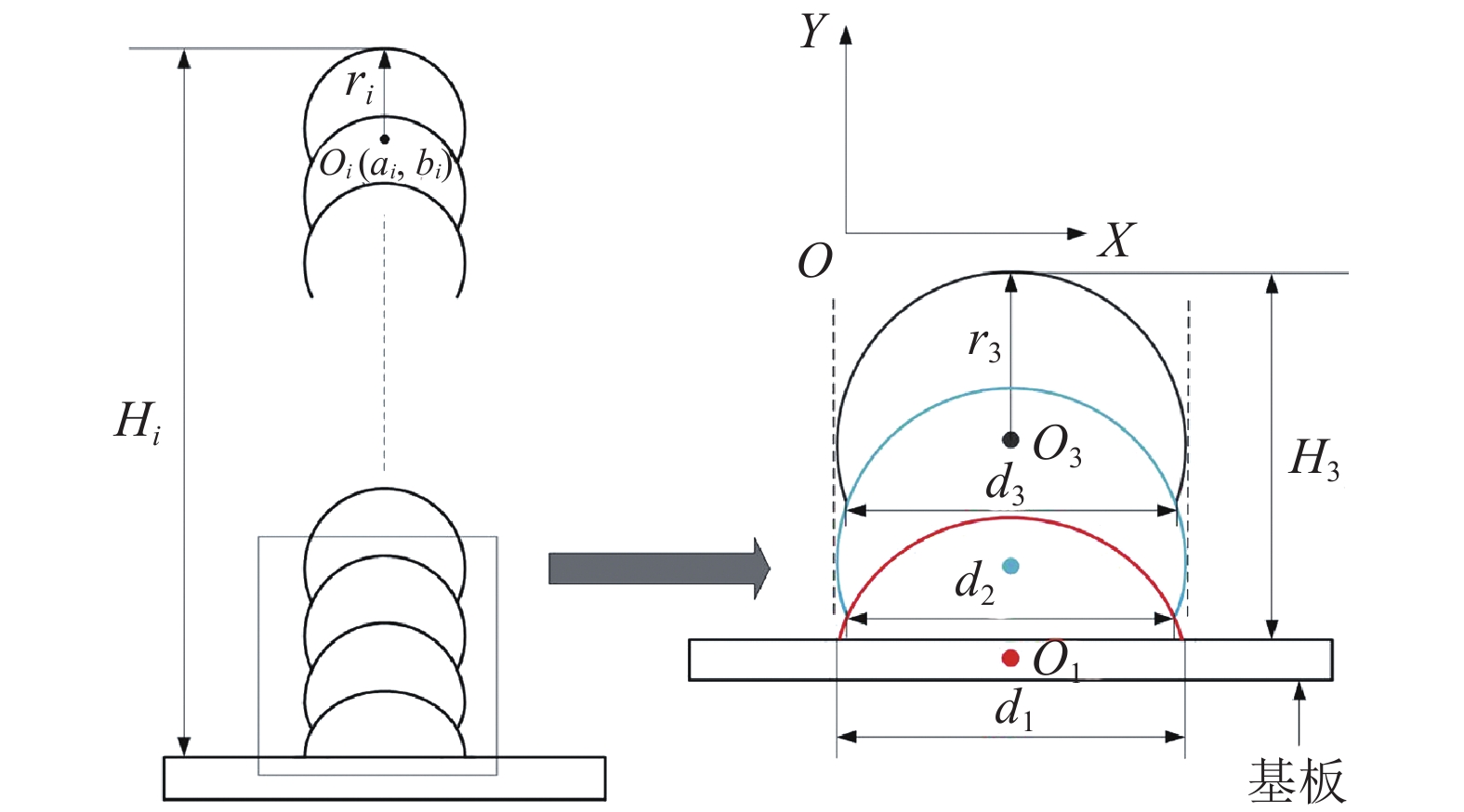

摘要: 基于冷金属过渡技术,研究了全封闭薄壁中空环形件的电弧增材制造工艺. 首先在单层单道熔敷层圆弧形截面轮廓的基础上推导了单道多层熔敷层的叠加数学模型;其次建立了可根据薄壁结构尺寸获取合理工艺参数的等体积电弧增材模型,最后通过试验数据验证了模型的可靠性. 基于该模型,建立了工艺参数(送丝速度、电弧移动速度)与成形件尺寸之间的关系,在优化的增材工艺下成形出了外观质量良好的薄壁中空环形工件,并将成形件扫描得到的实际轮廓与理论轮廓进行对比,验证了叠加模型和等体积增材模型的准确性以及工艺的可行性.Abstract: Enclosed thin-walled circular structure was studied by CMT technology based WAAM. The overlaying mathematical model for single-pass multi-layer is firstly constructed on the basis of circular arc profile of single-pass single-layer; then an equal-volume melting metal for each layer was proposed and applied for actual manufacturing process and testified the feasibility. On account of the aforementioned model, the process parameters corresponding to the size of the thin-walled structure were also established and used for fabricating the parts. The enclosed thin-walled circular structure with fairly high appearance was obtained under the optimized process parameters. The scanned outline profile was also compared to the theoretical outline, and the results showed a good match between them.

-

-

表 1 不同送丝速度下焊道理论轮廓与实际轮廓对比

Table 1 Comparison of theoretical and practical contours of weld bead at different wire feeding speeds

送丝速度v1/(m·min−1) 实际r2/mm 理论r2/mm 理论H2/mm 实际H2/mm 理论r3/mm 实际r3/mm 理论H3/mm 实际H3/mm 2.5 2.20 2.07 2.93 3.16 2.07 1.92 4.46 4.48 3.0 2.76 2.35 3.19 3.48 2.35 2.38 4.99 4.84 3.5 3.05 2.64 3.57 3.71 2.64 2.74 5.30 5.10 4.0 3.16 2.80 3.85 3.90 2.80 2.75 5.67 5.73 表 2 焊丝与基板主要化学成分(质量分数,%)

Table 2 Composition of welding wires and substrate

材料 C Si Mn Cu Cr Ni Mo Fe ER70-G 0.08 0.57 1.66 — 0.2 1.41 0.47 余量 Q550 $ \leqslant $ 0.18$ \leqslant $ 0.551.00 ~ 1.60 — — — — 余量 表 3 上环面增材层数与所用增材电弧工艺

Table 3 Number of additive layers on the upper ring surface and the additive arc process used

增材层数 送丝速度v1/(m·min−1) 热源移动速度v2/(mm·s−1) 理论高度h1/mm 实际高度h2/mm 误差率ε(%) 1 3.0 5.77 2.24 2.36 5.36 2 3.1 5.90 4.34 4.42 1.84 3 3.1 6.02 6.35 6.50 2.36 4 3.2 6.13 8.36 8.52 1.91 5 3.2 6.25 10.37 10.48 1.06 6 3.3 6.36 12.38 12.46 0.65 7 3.4 6.47 14.39 14.62 1.60 8 3.4 6.59 16.40 16.48 0.49 9 3.5 6.70 18.41 18.68 1.47 10 3.5 6.82 20.42 20.66 1.18 11 3.6 6.93 22.43 22.58 0.67 12 3.7 7.04 24.44 24.66 0.09 13 3.7 7.16 26.45 26.72 1.02 14 3.7 7.27 28.46 28.88 1.48 -

[1] Champagne V, Jacob A, Dindl F, et al. Cold spray and WAAM methods for manufacturing gun barrels: United State: 10281227[P]. 2019-07-05.

[2] 姚祥宏, 周琦, 王克鸿, 等. 基于焊道尺寸控制的电弧增材成形高氮奥氏体不锈钢与316L不锈钢交织结构[J]. 材料工程, 2020, 48(1): 54 − 60. Yao Xianghong, Zhou Qi, Wang Kehong, et al. Mix structure of high nitrogen austenitic stainless steel and 316L stainless steel formed by wire and arc additive manufacturing based on size controlling of beads[J]. Journal of Materials Engineering, 2020, 48(1): 54 − 60.

[3] 郭龙龙, 贺雨田, 鞠录岩, 等. 脉冲TIG增材制造技术研究进展[J]. 材料工程, 2018, 46(12): 10 − 17. doi: 10.11868/j.issn.1001-4381.2018.000267 Guo Longlong, He Yutian, Ju Luyan, et al. Progress in additive manufacturing technique based on pulsed TIG[J]. Journal of Materials Engineering, 2018, 46(12): 10 − 17. doi: 10.11868/j.issn.1001-4381.2018.000267

[4] Baufeld B, Biest O, Gault R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties[J]. Materials & Design, 2010, 31(1): 106 − 111.

[5] Thomas L, Akshay J, Yash J, et al. Concurrent geometry- and material-based process identification and optimization for robotic CMT-based wire arc additive manufacturing[J]. Materials & Design, 2020, 194: 108841.

[6] Wu B, Pan Z, Ding D, et al. A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement[J]. Journal of Manufacturing Processes, 2018, 35:127–139.

[7] 李天旭. 典型薄壁结构件CMT电弧增材制造成型技术研究[D]. 天津: 天津工业大学, 2019. Li Tianxu. Research on CMT arc additive manufacturing technology of typical thin-walled structural parts[D]. Tianjin: Tianjin University of Technology, 2019.

[8] 赵昀, 卢振洋, 陈树君, 等. 薄壁结构冷金属过渡增材制造工艺优化[J]. 西安交通大学学报, 2019, 53(8): 82 − 89. Zhao Yun, Lu Zhenyang, Chen Shujun, et al. Optimization of manufacturing process for thin-walled structures based on cold metal transfer[J]. Journal of Xi’an Jiaotong University, 2019, 53(8): 82 − 89.

[9] 刘勇. CMT电弧熔丝增材制造304不锈钢组织和性能研究[D]. 沈阳: 沈阳工业大学, 2018. Liu Yong. Research on microstructure and mechanical property of 304 stainless steel by CMT arc additive manufacturing[D]. Shenyang: Shenyang University of Technology, 2018.

[10] Yuan L, Pan Z, Ding D, et al. Investigation of humping phenomenon for the multi-directional robotic wire and arc additive manufacturing[J]. Robotics and Computer-Integrated Manufacturing, 2020, 63: 101916.

[11] 莫非, 李佳蒙. 浅析CMT技术在铝合金电弧增材制造中的应用[J]. 现代制造技术与装备, 2019(8): 107 − 113. doi: 10.3969/j.issn.1673-5587.2019.08.050 Mo Fei, Li Jiameng. Application of CMT technology in aluminum alloy arc addition manufacturing[J]. Modern Manufacturing Technology and Equipment, 2019(8): 107 − 113. doi: 10.3969/j.issn.1673-5587.2019.08.050

[12] Yuan L, Pan Z, Ding D, et al. Fabrication of metallic parts with overhanging structures using the robotic wire arc additive manufacturing[J]. Journal of Manufacturing Processes, 2021, 63: 24 − 34.

[13] 王天琪, 杨壮, 李亮玉, 等. 悬空特征结构件电弧增材制造成形及算法优化[J]. 焊接学报, 2019, 40(12): 78 − 82. Wang Tianqi, Yang Zhuang, Li Liangyu, et al. Research on forming and welding technology of thick wall structure arc added material manufacturing[J]. Transactions of the China Welding Institution, 2019, 40(12): 78 − 82.

[14] 张兆栋, 曾庆文, 刘黎明, 等. 铝合金激光诱导MIG电弧增材制造成形尺寸规律[J]. 焊接学报, 2019, 40(8): 7 − 12. Zhang Zhaodong, Zeng Qinwen, Liu Liming, et al. Forming regularity of aluminum alloy formed by laser induced MIG arc additive manufacturing[J]. Transactions of the China Welding Institution, 2019, 40(8): 7 − 12.

[15] Cao Y, Zhu S, Liang X, et al. Overla-pping model of beads and curve fitting of bead section for rapid manufacturing by robotic MAG welding process[J]. Robotics and Computer-Integra-ted Manufacturing, 2011, 27(3): 641 − 645. doi: 10.1016/j.rcim.2010.11.002

-

期刊类型引用(1)

1. 王守明,高振坤,陈建华,丁韦,许蕊,刘国庆,谭锦红. U71Mn钢闪光-摩擦复合焊接头组织及性能研究. 金属加工(热加工). 2025(04): 67-73+78 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: