Imprint characteristics extracted from images in resistance spot welding of high strength steels and relationship with welding quality

-

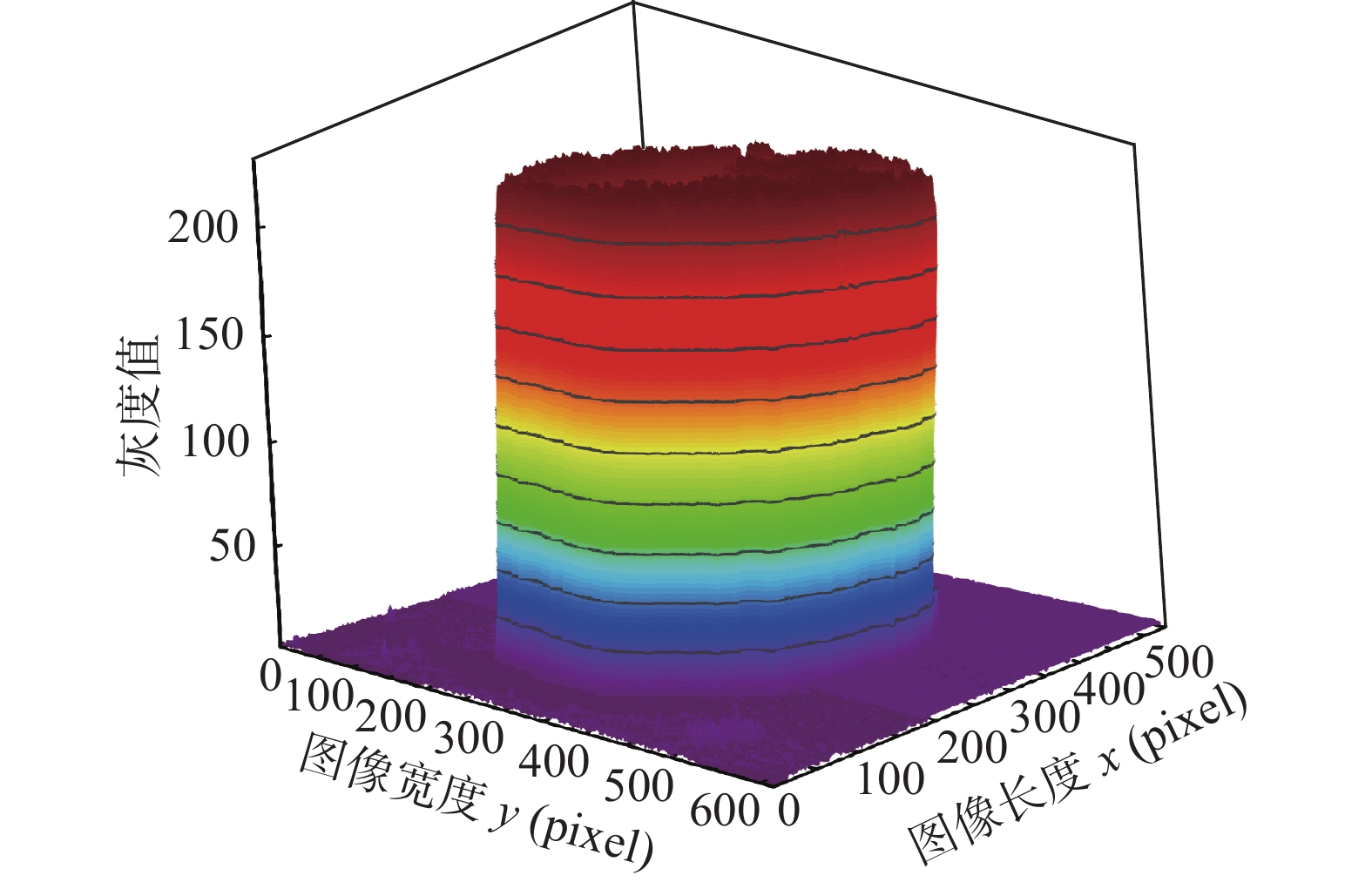

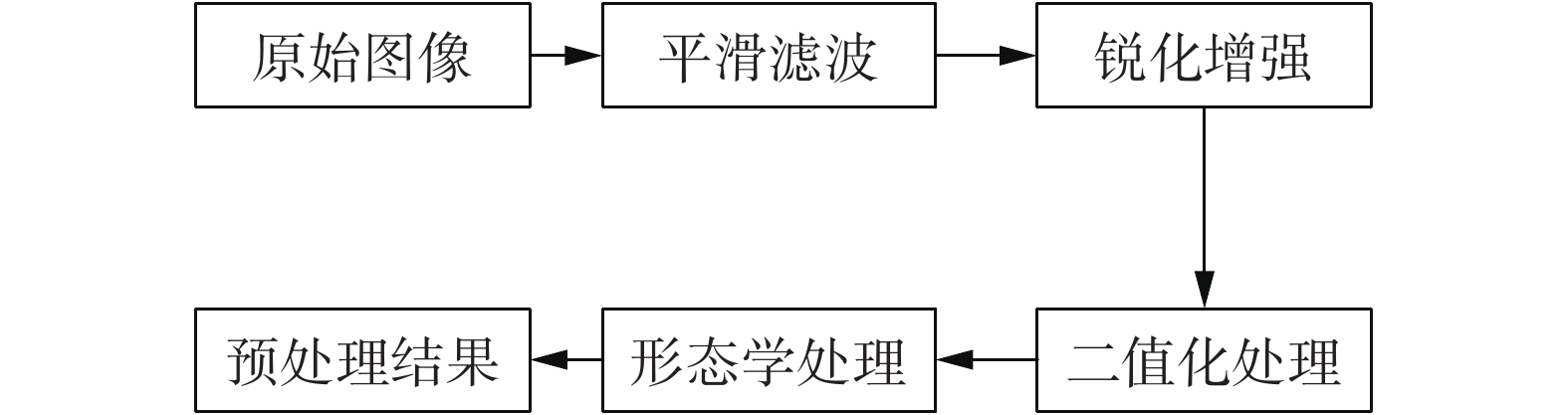

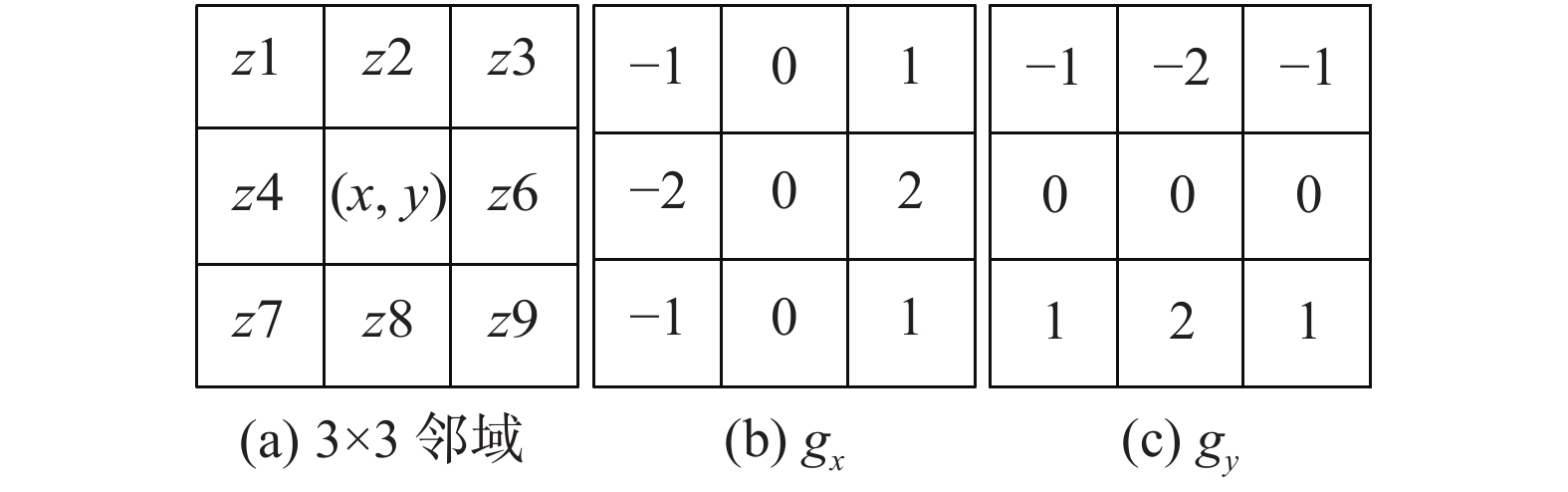

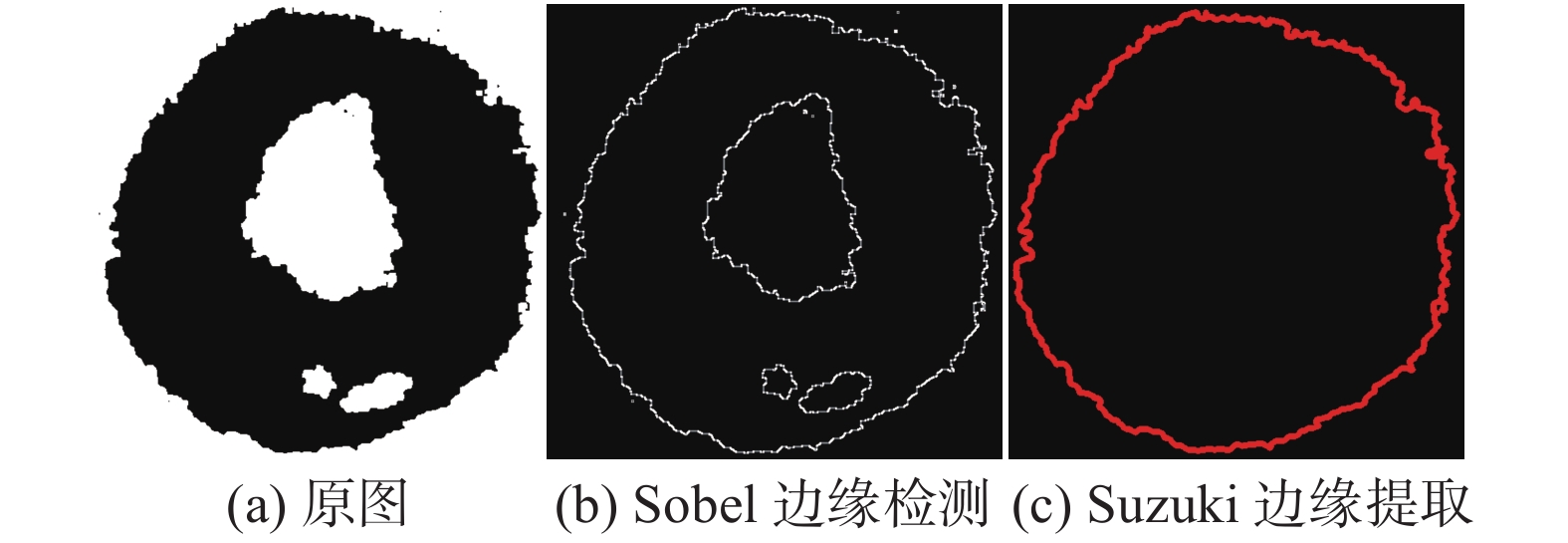

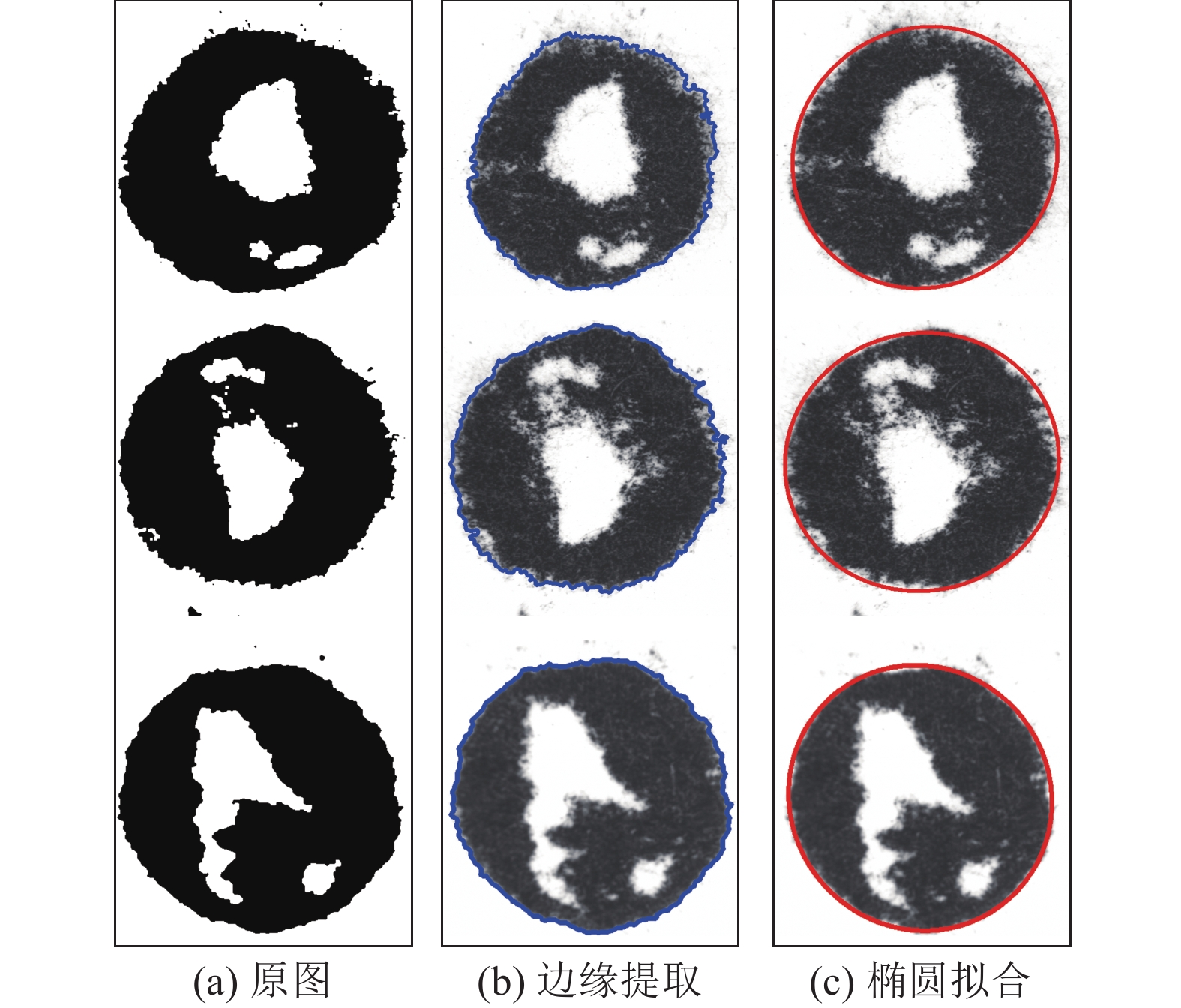

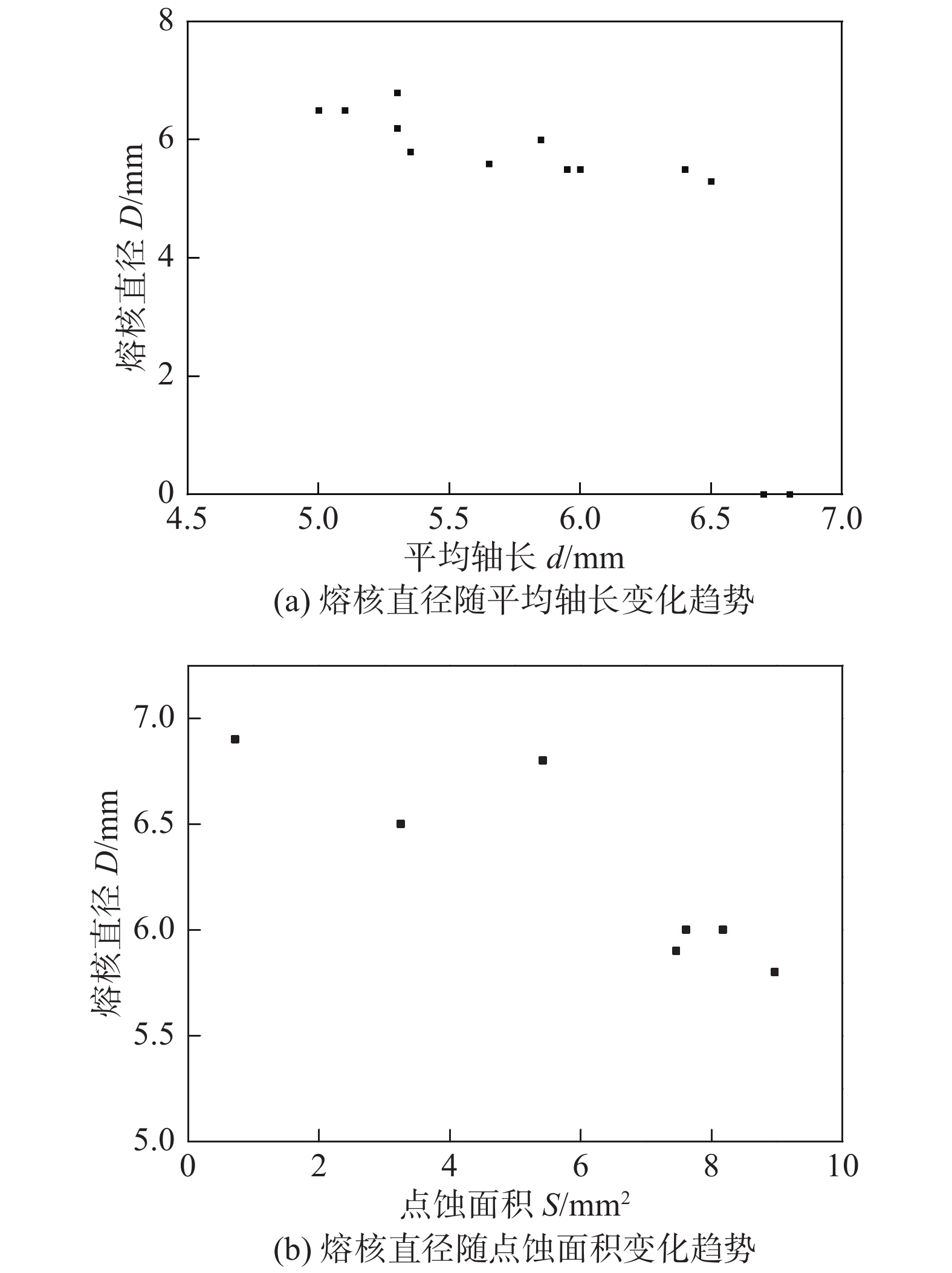

摘要: 高强钢以其优良的性能广泛应用于工业生产,但在点焊过程中,高强钢的点焊特征难以提取,评价焊点质量较为困难. 电极压痕是焊点表面形貌与电极端面的直接反映,压痕图像中同时包含着焊点与电极磨损信息. 通过图像处理与识别的方法对压痕进行轮廓边缘检测与识别,采用椭圆拟合的方法提取压痕特征参数. 对压痕特征参数与焊点熔核直径进行分析,研究各个特征对焊点质量的影响. 结果表明,椭圆拟合的压痕轮廓能够近似代替实际轮廓,压痕特征中提取的平均轴长和点蚀面积与焊点质量之间呈显著的负相关性.Abstract: High strength steel is widely used in industrial production because of its excellent properties. However, it is difficult to extract the welding characteristics of high strength steel and evaluate the quality of resistance spot welding. Electrode imprint is a direct reflection of the surface morphology of the spot welding and the end face of the electrode. Imprint image contains both spot welding information and electrode wear information. Through image processing and recognition, the contour edge of imprint image is detected and recognized, and the imprint characteristics parameters are extracted by ellipse fitting method. The imprint characteristic parameters and nugget diameter were analyzed, and the influence of each characteristic on spot welding quality was studied. The results show that the imprint contour fitted by ellipse can approximately replace the actual contour. There is a significant negative correlation between the average axial length and pitting area extracted from imprint characteristics and spot weld quality.

-

Keywords:

- weld quality /

- edge detection /

- image processing /

- electrode imprint

-

0. 序言

磁脉冲焊接作为一种新型的高能率焊接技术,与爆炸焊接类似,焊接过程产生射流,可清除待焊界面氧化膜,属于固态焊接,焊接过程热量低,可以有效避免或减少异种材料界面处脆性金属间化合物的产生,在汽车、航空航天和电力装备制造领域被广泛应用[1-3].

集磁器是磁脉冲焊接中的工具,它对焊接过程中磁场分布和磁压力有重要影响,能够显著提高焊接效率,有效减少线圈的负荷,提高线圈使用寿命[4-5]. 利用集磁器可以将磁力线集中在有效工作区域周围,提高磁脉冲焊接工艺的效率[6]. 集磁器的有效面积越大,均匀力面积越大,磁压量越小,压力随着集磁器相对直径的增大而减小[7-8]. Yan等人[9]研发了一种新型的多焊缝集磁器,并进行数值模拟和实验研究. 结果表明,采用多缝集磁器的磁脉冲焊接系统可以显著改善5052铝合金管的圆形变形均匀性. Kumar等人[10]研究了3种集磁器的几何形状对复合棒塑性变形的影响,为集磁器的设计提供了依据.

在现有的集磁器类型中,截面为梯形的常规集磁器,其结构简单,便于制作,应用广泛,垂直型集磁器和曲线型集磁器的应用较少[6,11-13]. 然而,现有的研究都针对于磁脉冲焊接的过程,对于磁脉冲焊接线圈和集磁器进行了大量的设计和研究,都集中在放电装置的放电电压和能量等电路参数,和点焊集磁器和板件焊接集磁器等集磁器种类的设计之上[14-15]. 集磁器仅仅承担改善磁场分布的作用,却忽略了对集磁器本身性能的研究.

文中基于ANSYS仿真平台对常规型集磁器、垂直型集磁器和曲线型集磁器(根据集磁器截面分类)进行仿真分析. 研究了集磁器作用下磁场的分布和相同电路参数下集磁器对管件所受电磁力的影响,通过电磁缩径的模拟验证仿真得到的磁压力分布,对最优结构进行磁脉冲焊接验证.

1. 磁脉冲焊接理论分析

磁脉冲焊接主要分为两个模块,即充电模块和放电模块,磁脉冲焊接示意图,如图1所示. 在充电阶段中,交流电源通过变压器对电容器组进行充电. 放电阶段,存储在电容器中的能量以高频震荡衰减的电流形式释放到线圈中,在周围产生瞬态变化的磁场,集磁器表面产生与线圈内相反的感应电流,由集磁器外表面流向内表面. 此时,在管件和集磁器之间会产生二次磁场,工件中会产生与线圈电流方向相反的感应电流,使得工件在磁场中受到电磁力的作用,发生变形并与目标工件碰撞,从而到达焊接的目的.

磁脉冲焊接放电过程中电路等效于RLC电路,其对应的放电过程为震荡放电过程. 通过基尔霍夫电压定律得到方程为

$$ \left\{ \begin{gathered} - {u_C} + {u_R} + {u_L} = 0 \\ LC\frac{{{{\text{d}}^2}{u_c}}}{{{\text{d}}{t^2}}} + RC\frac{{{\text{d}}{u_c}}}{{{\text{d}}t}} + {u_c} = 0 \\ \end{gathered} \right. $$ (1) 式中:uC为电容器电压;uR为电阻电压;uL为电感电压;R为电路的总电阻;L为电路的总电感;C为电容器组的电容;t为放电时间.

根据相关的初始条件,流入线圈的电流为

$$ \left\{ \begin{gathered} i = \frac{{{U_0}}}{{\omega L}}{e^{ - \lambda t}}\sin (\omega t) \\ \lambda = \frac{R}{{2L}},{\omega ^2} = \frac{1}{{LC}} - {\left(\frac{R}{{2L}}\right)^2} \\ \end{gathered} \right. $$ (2) 式中:电路电流为i,峰值为U0/ωL;λ为电流的衰减系数;ω为电流的角频率,ω取2πf;f为放电电流频率.

焊接过程中作用在工件上的体积力F可由电流密度J和磁通量密度B确定,即

$$ {{\boldsymbol{F}}} = {{\boldsymbol{J}}} \times {{\boldsymbol{B}}} $$ (3) 对于管件所受洛伦兹力,作用在管状工件上的径向力Fr为

$$ {F_r} = - \frac{1}{2}{\mu _0}\frac{{\partial ({H^2})}}{{{\partial _r}}} $$ (4) 在有限元软件中,电磁力以压力的形式作为载荷进行添加,因此这些体积力作用于工件可以转换为磁压力p,工件壁上两点之间的压力差可以通过对距离上的作用力进行积分来确定. 作用于管状工件总体压力为

$$ \left\{\begin{array}{c} p(r, t)=\dfrac{1}{2} \mu\left(H_g^2(t)-H_\delta^2(t)\right) \\ \delta=\dfrac{1}{\sqrt{\mu \pi f \gamma}} \end{array}\right. $$ (5) 式中:Hg为工件和线圈之间的磁场强度;Hδ为工件感应电流的深度磁场强度;δ为趋肤深度的大小;γ为电导率的大小.

如果趋肤深度相对于工件厚度较小,则穿透磁场往往被忽略. 如果壁厚至少等于趋肤深度的1.5倍,这种简化是可以接受的. 通过计算可得放电频率在18 kHz,趋肤深度为0.63 mm,管件厚度为1 mm. 考虑铝合金对应变速率敏感,本构方程采用Johnson-Cook来描述工件的塑性变形行为,由于焊接过程中温度变化不显著,忽略温度后的方程为

$$ \sigma = ({R_{{\mathrm{el}}}} + B{\varepsilon ^n})\left(1 + \ln \frac{{\dot \varepsilon }}{{{{\dot \varepsilon }_0}}}\right) $$ (6) 式中:σ为应力;ε为应变;$ \dot{\varepsilon} $为应变速率;$ \dot{\varepsilon}_{0} $为参考应变率;Rel为材料的屈服强度;B为强度硬化系数;n为硬化指数;C为应变速率常数. 材料1060Al和T2Cu的Johnson-Cook材料参数模型参数如表1所示.

表 1 Johnson-Cook材料模型参数Table 1. The Johnson-Cook material model parameters材料 屈服强度

Rel/MPa强度硬化系数

B应变速率常数

C硬化指数

n1060Al 100 182.3 0.01987 0.34 T2Cu 90 292.0 0.02500 0.31 2. 磁脉冲焊接集磁器结构

焊接结构示意图,如图2所示. 管件磁脉冲焊接集磁器分为常规集磁器,垂直型集磁器和曲线型集磁器,如图2(a)所示. 常规集磁器通过更改角度α来改变截面形状;垂直型集磁器改变侧边长l来改变结构;曲线型集磁器11号结构是与内壁相切的圆弧,其α角也是直角,12号结构是过斜壁中垂线的圆弧,集磁器结构尺寸如表2所示.

表 2 集磁器结构编号和尺寸Table 2. Fieldshaper structure number and size类型 编号 角度α/(°) 边长l/mm 常规型 1 20 31.8 2 30 27.0 3 40 21.1 4 50 13.2 5 60 1.0 垂直型 6 90 2.0 7 90 10.0 8 90 18.0 9 90 26.0 10 90 32.0 曲线型 11 90 2.0 12 104 2.0 图2(b)为磁脉冲焊接模型尺寸,集磁器内外径分别为28 mm和108 mm,线圈由单匝实心的矩形铜线圈组成,该线圈与集磁器共同作用,产生电磁场和电磁力,用于与1060Al和T2Cu的焊接. 外管和内管是外径分别为26 mm和21 mm,厚度分别为1 mm和2 mm,两者间径向间隙为1.5 mm,同轴置于集磁器内,集磁器与外管径向间隙为1 mm. 铜管的厚度略大于铝管,用于保证碰撞时的稳定性.表3所示为材料的仿真参数.

表 3 材料仿真参数Table 3. Material simulation parameters结构 材料 密度ρ/(kg·m−3) 杨氏模量E/Gpa 泊松比μ 电导率γ/(107S·m−1) 线圈 CuCrZr 8930 117 0.34 4.52 集磁器 CuCrZr 8930 117 0.34 4.52 铝管 1060Al 2700 70 0.33 3.53 铜管 T2Cu 8960 110 0.35 5.71 3. 数值模拟

3.1 电磁场模拟

文中使用了Maxwell和workbench软件对集磁器集磁性能进行有限元分析,在Maxwell中分析了电磁场,整个模拟过程中电容的大小为150 μF,电阻为20 mΩ,电感为200 nH,放电周期在110 μs左右. 结构场使用了workbench软件,将电磁场中的电磁力以压力的形式导入到结构场中,用于研究集磁器结构的强度和铝管电磁缩颈变形.

集磁器工作原理,如图3所示. 图3(a)为5号结构磁脉冲焊接数值模拟模型,图3(b)为模型俯视图. 图3(a)中空气域为模拟边界条件;集磁器工作时表面磁感应强度主要分布在内外侧,斜面的磁感应强度非常小,如图3(c)所示;图3(d)为集磁器工作时的表面电流密度流从缝隙处流入内表面,再由缝隙流向外表面,流向内表面时,随着截面面积的减小,电流密度越来越大,实现集磁的作用,解释了集磁器的工作原理.

放电过程中线圈内产生的震荡衰减的电流波形,如图4所示. 放电周期在110 μs左右. 磁脉冲焊接的实际焊接过程在25 μs左右,3类集磁器在放电过程中线圈电流波形几乎一致,可见改变集磁器的截面形状并不会明显改变放电回路的参数,对线圈与集磁器之间的互感系数影响较小. 垂直型集磁器和曲线型集磁器相比常规的集磁器结构电流波形差异较小,由此可见,通过改变集磁器截面形状来优化其性能的方案是可行的.

分别在焊接模型中管件的周向取4个点M1,M2,M3和M4,观察集磁器对磁感应强度分布的影响观测点和截线示意图,如图5所示. 为了探究集磁器的性能,将磁场强度可视化,绘制二维截线,该截线从坐标轴原点由内向外沿x轴延伸,穿过铝管、铜管和集磁器,长度为54 mm,截线位置如图5所示. 铝管周向4个点的磁感应强度随时间变化,如图6所示. 由于集磁器缝隙的存在,M1处的整体磁感应强度低于其余3点. M2和M4在管件两侧,具有对称性,两者的磁感应强度曲线几乎一致. M3与集磁器缝隙相对,该处的磁场强度最大.

二维截线上磁感应强度分布,如图7所示. 图7(a)为编号5的集磁器,在20 μs时的磁感应强度,图7(a)中DE段为集磁器和铝管的间隙,E点为集磁器的内表面,该位置的磁场强度最大,随着距离线圈越来越远,磁通强度缓慢下降;CD段为铝管所在位置,D点为铝管外表面,由于表面存在趋肤效应,管件的磁感应强度由外向内急速下降;由于铝管对磁场的屏蔽作用,BC段和AB段的铜管几乎不受磁场影响,铜管不受电磁力作用,从而保证焊接过程的稳定性. 在20 μs时,集磁器结构11在点M3位置的磁通密度大小为28.76 T,比5号结构磁通密度 25.64 T高12%,5号结构和9号结构的磁通密度强度相近,两者在性能上十分相近.

图7(b)为常规型集磁器结构截线上磁感应强度的分布,常规集磁器1号结构的磁感应强度最小, 5号结构最大,常规型集磁器随着角度α的增大,性能越来越好;垂直型集磁器由于其角度α为90°,当其侧边l与常规集磁器相近时,其整体的性能均优于常规型集磁器,如图7(c)所示,这是由于其截面变化速度快,使得感应电流快速汇聚. 常规型集磁器和垂直型集磁器性能均随着侧边l的增大而逐渐的减小;图7(d)中11号结构由于其α角度为0,其磁感应强度略大于12号结构.

放电时间为15 μs时的电磁力的分布,如图8所示. 为了便于直观的看清铝管电磁力的大小,将所有结构模拟的电磁力的标尺统一. 由图8云图可以直观的看出铝管所受的电磁力集中在集磁器内侧位置,其宽度与集磁器内壁高度一致,铝管所受电磁力的大小与磁感应强度大小一致. 通过分析可知,集磁器结构性能与角度α成正比,和侧边长度l成反比. 传统的集磁器结构中,5号结构性能最好;垂直型集磁器中除去侧边长度l较大的10号结构,其性能均较好;曲线型集磁器中,结构11最优.

3.2 结构场模拟

根据3.1小节可以得知集磁器结构性能的差异. 但是,集磁器在焊接过程中除了承担汇聚磁场的功能之外也是电磁力的直接承担者,所以集磁器在增强集磁性能的同时也要能保持结构强度. 考虑到这一因素,综合集磁器的性能,选择结构5,9,11号集磁器进行结构强度的模拟. 在Maxwell和Workbench软件在进行电磁场和结构场耦合计算时,电磁力以压力的形式作为载荷施加在集磁器内壁上,整个焊接过程中所受到350 MPa的最大压力,因此在集磁器的内壁施加350 MPa的压力来模拟磁脉冲焊接时的反作用力,法向施加在集磁器内壁,整个作用过程为25 μs,为了贴近实际焊接情况,在集磁器外侧表面添加约束来模拟实际焊接时的加固层.

图9展示的是集磁器的形变大小,3种集磁器结构强度在整体上没有太大差距,都是由内向外变形,磁器狭缝的最内侧宽度都大于原始宽度. 结构9和结构11集磁器狭缝宽度大小接近. 结构5和结构11狭缝的变形由内侧到外侧缓慢减少,结构9由于截面变化较大,高度垂直下降,外侧强度高,因此形变集中在内侧. 常规集磁器5号结构的变形量相比其他两种结构少20%,

通过上述分析可知3种集磁器狭缝的最外侧的变形基本相等,集磁器的整体结构强度接近;而内侧区域是集磁器内边缘附近区域,凹形集磁器的圆弧形状的切点和垂直型集磁器的直角在狭缝区域内,两种集磁器的α角度均为0,相较于常规集磁器,在这一位置的强度较低,同时考虑集磁器工作原理,狭缝两侧感应电流在狭缝位置聚集,所以在放电瞬间,凹形集磁器和垂直型在狭缝位置受到比常规形集磁器更强的电磁斥力作用,使得狭缝位置的形变更大. 除狭缝位置外,3种集磁器的变形程度相差不多.

为了更详细地研究不同集磁器结构对磁脉冲焊接的影响,选择编号5和11的结构进行管件的磁脉冲电磁缩径成形仿真,通过管件的形变量来判断结构的优劣,缩径成形管件长为50 mm. 磁脉冲管件缩径成形云图,如图10所示. 在结构5的作用下,感应电流汇聚更加集中,使得铝管所受径向电磁力更大,由图10可以清晰的看出,结构11下的铝管变形量远大于结构5,最大变形量比结构5多24.9%. 由于集磁器缝隙处管件所受电磁力较小,集磁器狭缝处管件受到挤压,向外侧发生反向变形,可以通过增加集磁器缝隙的方法来增加周向变形的均匀性. 结构11铝管碰撞发生塑性变形的过程,如图11所示. 0 ~ 6 μs为放电初始阶段,管件所受电磁力未达到塑性变形标准. 6 ~ 12 μs管件发生塑性变形,变形从管件端部开始,向中间移动,碰撞12 μs以后开始发生,最终完成整个焊接过程,由此可见,曲线型集磁器的应用是可行的.

4. 结论

(1)集磁器工作原理是利用结构内外侧的高度差,实现感应电流的汇聚,达到改善磁场分布的作用;

(2)集磁器改善磁场分布的性能主要受角度α和侧边l的影响. 当角度达到90°,侧边长度较小时性能最好,此时,狭缝截面的形状会影响集磁器的性能;

(3)11号结构集磁器相比5号结构集磁器,结构强度相当,但同样的参数下,11号结构下铝管缩径变形量时比常规5号结构集磁器多24.9%,并且能够实现良好的焊接效果.

-

表 1 焊接工艺参数

Table 1 Welding parameters

厚度

δ/mm电流

I/kA时间

T(cycle)电极力

F1/kN水冷流量

q/(L·min−1)0.8 10 10 2.2 8 1.5 11 18 4.3 8 表 2 拟合参数与实际参数误差分析表

Table 2 Error table of fitted and actual parameters

样本号 CB(pixel) C(pixel) EB(pixel) E(pixel) fe(%) ae(%) 1 68052 71952 66727 72999 1.46 −1.95 2 92518 105656 90313 105944 0.27 −2.38 3 88185 113235 86966 113587 0.31 −1.38 4 77589 115641 76085 115956 0.27 −1.94 5 90372 127984 88529 129302 1.03 −2.04 6 106734 139384 103446 140878 1.07 −3.08 7 109772 145838 107258 147366 1.05 −2.29 8 122812 158875 120196 159532 0.41 −2.13 9 117724 159088 114032 160043 0.60 −3.14 10 122310 158223 119829 159563 0.85 −2.03 表 3 特征参数a, b, EB, S与d之间相关性分析

Table 3 Correlation analysis table between characteristic parameters a, b, EB, S and d

参数 EB a b E S d EB 1 0.917 0.933 0.941 0.663 0.928 a 0.917 1 0.988 0.994 0.898 0.997 b 0.933 0.988 1 0.996 0.878 0.997 E 0.941 0.994 0.996 1 0.878 0.998 S 0.663 0.898 0.878 0.878 1 0.890 d 0.928 0.997 0.997 0.998 0.890 1 表 4 d、S与D的相关系数表

Table 4 d, S and D correlation coefficient table

参数 d S D −0.841 −0.884 -

[1] 张旭强, 陈关龙, 张延松. 热镀锌高强钢点焊的电极磨损机理分析[J]. 焊接学报, 2009, 30(11): 41 − 43. doi: 10.3321/j.issn:0253-360X.2009.11.011 Zhang Xuqiang, Chen Guanlong, Zhang Yansong. Experimental study on electrode wear mechanism in resistance spot welding of high strength hot galvanization steels[J]. Transactions of the China Welding Institution, 2009, 30(11): 41 − 43. doi: 10.3321/j.issn:0253-360X.2009.11.011

[2] 张旭强, 张延松, 刘衍聪. 热镀锌高强钢点焊的电极磨损对焊点质量的影响[J]. 焊接学报, 2009, 30(10): 5 − 8. Zhang Xuqiang, Zhang Yansong, Liu Yancong. Effects of electrode wear on weld quality of hot galvanization steel with high strength in resistance spot welding[J]. Transactions of the China Weld-ing Institution, 2009, 30(10): 5 − 8.

[3] 石强, 张旭强, 孔祥顺, 等. 点蚀对镀锌高强钢点焊熔核形成的影响[J]. 电焊机, 2017, 47(2): 5 − 8. Shi Qiang, Zhang Xuqiang, Kong Xiangshun, et al. Effect of electrode pitting on nugget formation in resistance spot welding of galvanization high strength steel[J]. Electric Welding Machine, 2017, 47(2): 5 − 8.

[4] Manladan S M, Yusof F, Ramesh S, et al. A review on resistance spot welding of aluminum alloys[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1−4): 605 − 634. doi: 10.1007/s00170-016-9225-9

[5] Rout A, Deepak B, Biswal B B, et al. An optimal image processing method for simultaneous detection of weld seam position and weld gap in robotic arc welding[J]. International Journal of Manufacturing, Materials and Mechanical Engineering (IJMMME), 2018, 8(1): 37 − 53. doi: 10.4018/IJMMME.2018010103

[6] 于英飞, 朱志明, 孙博文, 等. 焊接电弧图像的边缘检测及其批处理算法[J]. 焊接学报, 2018, 39(10): 17 − 21. Yu Yingfei, Zhu Zhiming, Sun Bowen, et al. Edges detection and batch algorithm for welding arc images[J]. Transactions of the China Welding Institution, 2018, 39(10): 17 − 21.

[7] 李乐乐. 镁合金逆变电阻点焊电极失效研究[D]. 太原: 太原科技大学, 2016. Li Lele. Research on the electrode failure in inverter resistance spot welding of magnesium alloy [D]. Taiyuan: Taiyuan University of Science and Technology, 2016.

[8] Xia Y J, Su Z W, Lou M, et al. Online precision measurement of weld indentation in resistance spot welding using servo gun[J]. IEEE Transactions on Instrumentation and Measurement, 2019, 69(7): 4465 − 4475.

[9] Vinista P, Joe M M. A novel modified sobel algorithm for better edge detection of various images[J]. International Journal of Emerging Technologies in Engineering Research, 2019, 7(3): 26 − 31.

[10] Xu Z, Xu S, Qian C, et al. Accurate ellipse extraction in low-quality images[C]//2019 16th International Conference on Machine Vision Applications (MVA). IEEE, 2019: 1-5.

下载:

下载: