Study on low-cycle fatigue property of 12Cr/30Cr2Ni4MoV heterogeneous joint

-

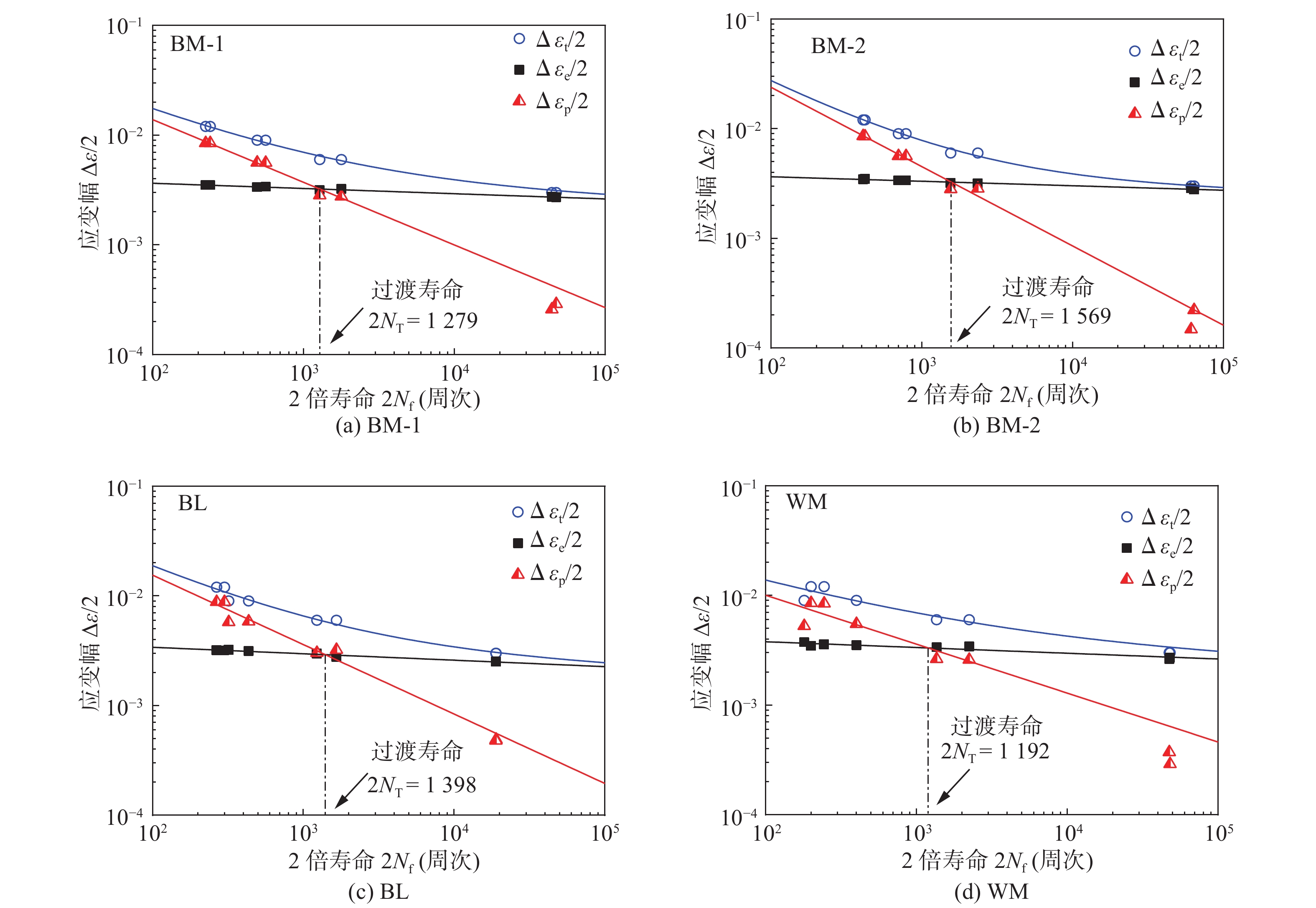

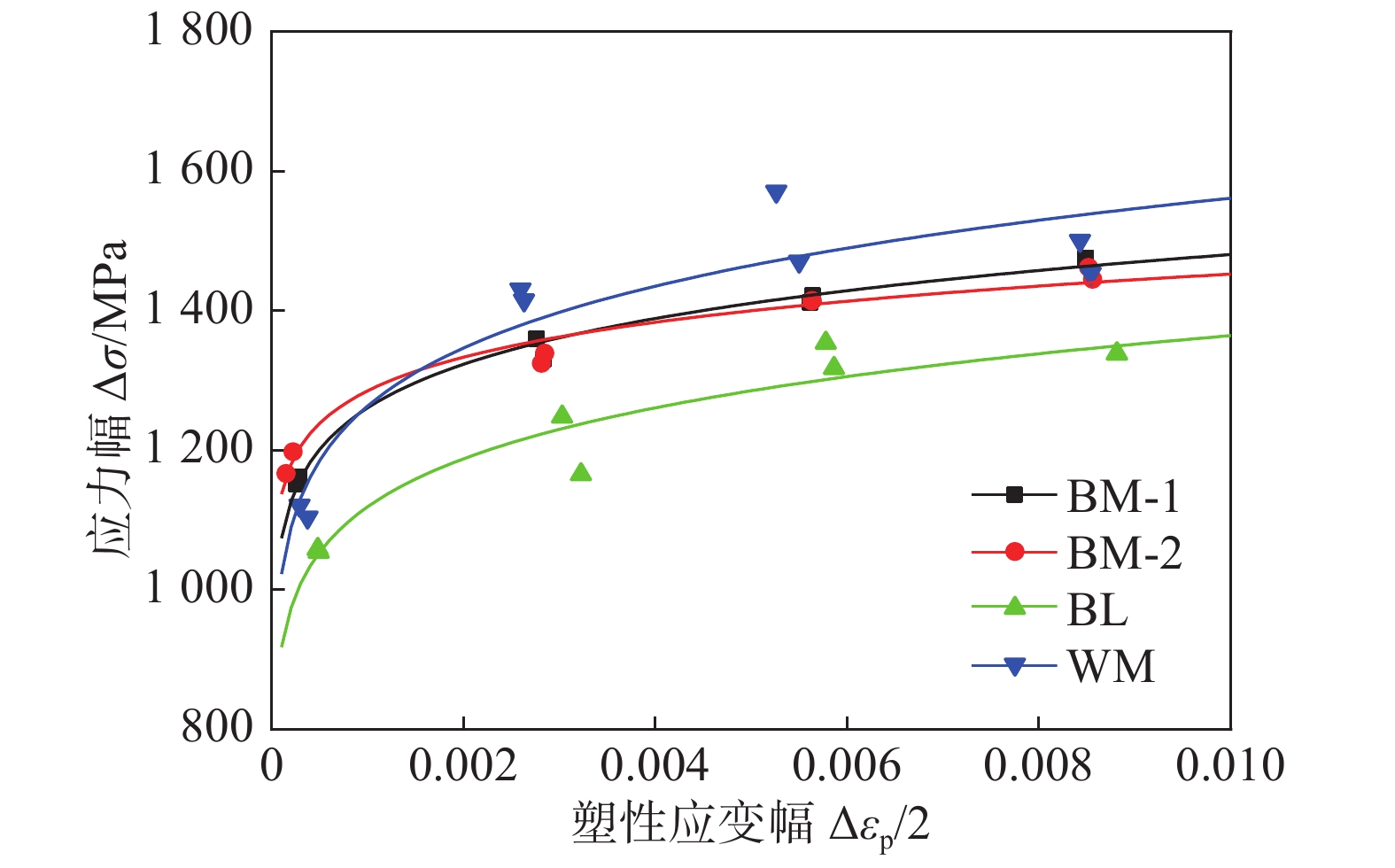

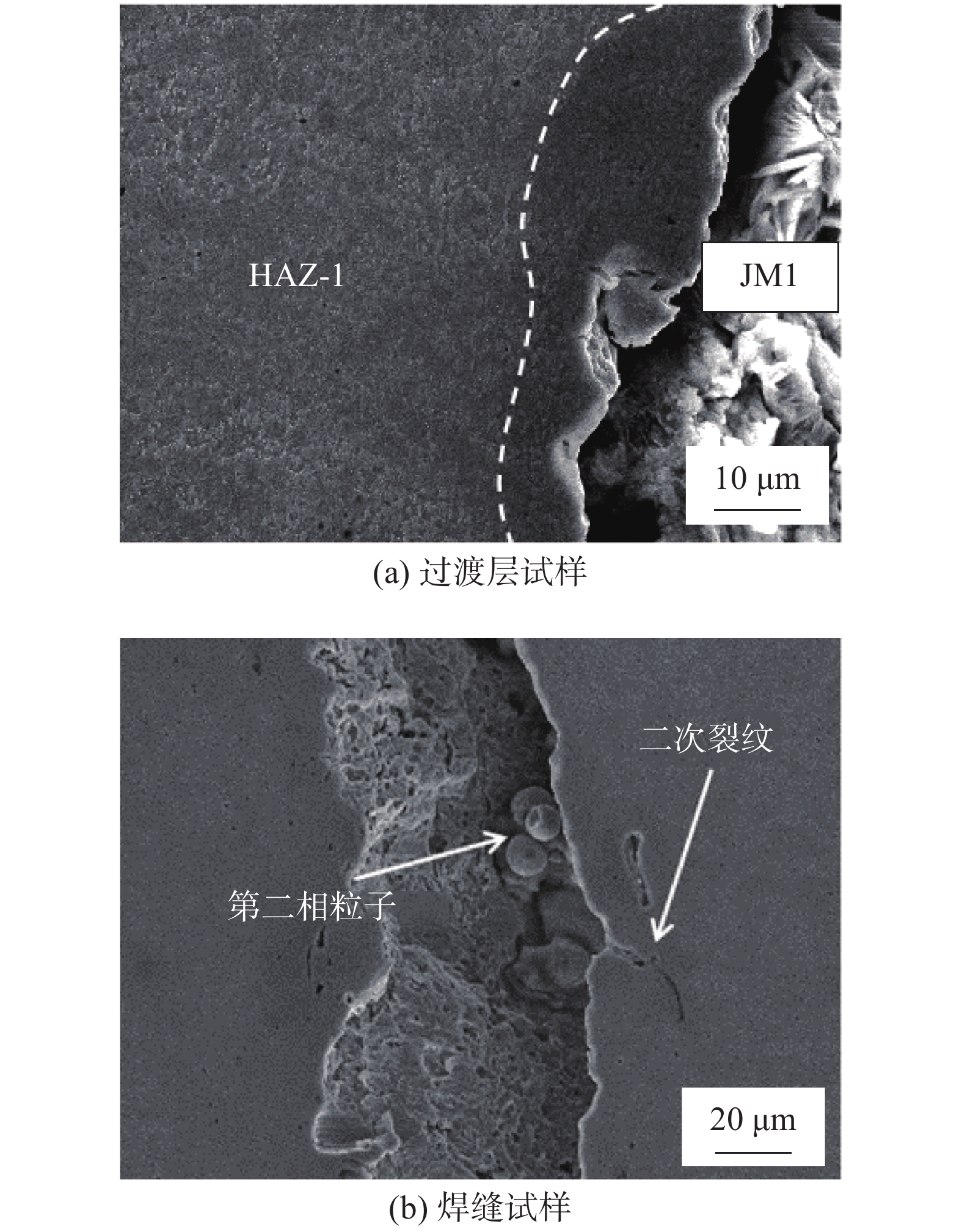

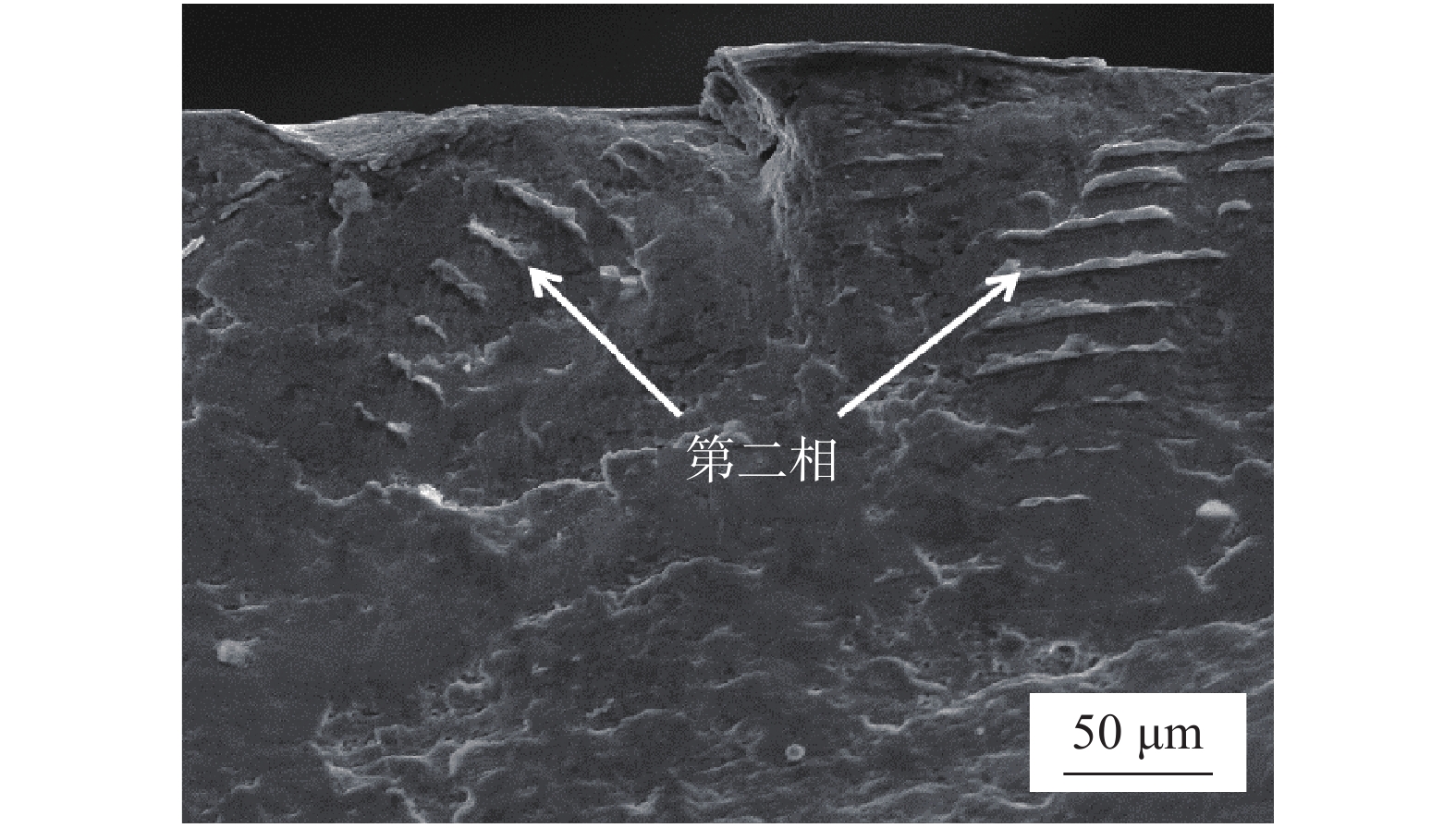

摘要: 文中研究了12Cr/30Cr2Ni4MoV异质焊接接头的显微组织、显微硬度和室温低周疲劳性能. 结果表明,母材12Cr的显微组织是板条状回火马氏体,母材30Cr2Ni4MoV是板条状回火马氏体和粒状回火贝氏体,过渡层和焊缝的显微组织为粒状回火贝氏体,且焊缝由柱状晶区与等轴晶区交替构成. 30Cr2Ni4MoV比12Cr有更高的显微硬度,过渡层的硬度最低,热影响区的显微硬度梯度变化. 12Cr,30Cr2Ni4MoV和过渡层的低周疲劳性能表现为循环软化特征,焊缝循环初期硬化随后软化;过渡层的疲劳过渡寿命最高;12Cr与过渡层之间的熔合界面是整个异质焊接接头低周疲劳最薄弱环节;焊缝柱状晶区的晶界或亚晶界分布的第二相粒子与基体的不协调变性,容易萌生疲劳裂纹.Abstract: In this article, the microstructure, micro-hardness and low-cycle fatigue property of a 12Cr/30Cr2Ni4MoV welded joint have been studied. The results show that the microstructure of the 12Cr is lath tempered martensite, 30Cr2Ni4MoV is lath tempered martensite and granular tempered bainite. The microstructure of the buttering layer (BL) and weld metal (WM) is granular tempered bainite. WM is composed of columnar grain regions and equiaxed grain regions alternately. 30Cr2Ni4MoV has higher micro-hardness than 12Cr, and the BL is the lowest. Micro-hardness in the heat-affected zone (HAZ) is gradient change. 12Cr, 30Cr2Ni4MoV and BL show cyclic softening characteristics, while WM has initial cycle hardening and subsequent cyclic softening characteristics. BL has the highest fatigue transition life; the 12Cr/BL interface is the weakest link of the low-cycle fatigue of the entire heterogeneous welded joint. The second phase particles distributed in the grain boundary or sub-grain boundary of the columnar grains have uncoordinated deformation with the matrix of WM, which result in the initiation of fatigue cracks in second phase

-

Keywords:

- heterogeneous welding joint /

- low-cycle fatigue /

- microstructure /

- micro-hardness

-

-

表 1 母材、过渡层和焊缝的化学成分 (质量分数,%)

Table 1 Chemical component of BMs, BL and WM

区域 C Si Cr Ni Mo V Mn Nb BM-1 0.16 0.07 11.00 0.70 1.35 0.20 0.70 0.070 BM-2 0.37 0.12 2.05 3.82 0.62 0.16 0.43 — BL 0.10 0.14 2.30 — 1.04 0.28 0.42 0.034 WM 0.10 0.55 0.50 2.60 0.55 — 1.80 — 表 2 低周疲劳参数

Table 2 Low-cycle fatigue parameters

区域 应变疲劳极限

Δεt(%)疲劳强度系数

σf′/MPa疲劳强度指数

b疲劳延性系数

εf′疲劳延性指数

c过渡寿命

2NT循环强度系数

K′/MPa应变硬化指数

n′BM-1 0.23 953 −0.047 61 0.192 19 −0.571 13 1279 1020.78 0.069 75 BM-2 0.19 924 −0.040 93 0.664 69 −0.722 96 1569 927.70 0.053 14 BL 0.18 937 −0.058 81 0.285 80 −0.633 23 1398 1014.21 0.086 10 WM 0.29 1010 −0.052 42 0.078 17 −0.446 05 1192 1192.48 0.091 96 表 3 焊缝疲劳断口上第二相的EDS结果 (质量分数,%)

Table 3 EDS results of second phase on fatigue fracture of WM

元素 C V Cr Mn Fe Ni Mo 总量 测试1 16.35 0.78 4.57 0.00 75.00 1.06 2.24 100.00 测试2 47.78 0.54 3.08 0.00 47.14 0.64 0.82 100.00 -

[1] 朱明亮, 轩福贞, 梅林波. 汽轮机高、低压一体化转子材料及性能的研究进展[J]. 动力工程, 2008, 28(5): 664 − 671. Zhu Mingliang, Xuan Fuzhen, Mei Linbo. Progression of investigation on high-low-pressure combined rotor materials and properties of the steam turbine[J]. Journal of Power Engineering, 2008, 28(5): 664 − 671.

[2] 庞庆, 彭建强, 孙秀萍. 高参数大容量汽轮机焊接转子[J]. 汽轮机技术, 2014, 56(6): 478 − 480. doi: 10.3969/j.issn.1001-5884.2014.06.024 Pang Qing, Peng Jianqiang, Sun Xiuping. Welded rotor for large power rating steam turbine with high steam parameters[J]. Turbine Technology, 2014, 56(6): 478 − 480. doi: 10.3969/j.issn.1001-5884.2014.06.024

[3] Timo D P, Designing turbine components for low-cycle fatigue[C]//International Conference on Thermal Stress and Thermal Fatigue, Berkeley, USA, 1969: 453 − 469.

[4] Liu X. Investigation on mechanical properties of 9%Cr-CrMoV dissimilar steels welded joint[J]. Materials Engineering and Performance, 2015, 24(4): 1434 − 1440. doi: 10.1007/s11665-015-1428-y

[5] Wu Q J, Lu F, Cui H, et al. Role of butter layer in low-cycle fatigue behavior of modified 9Cr and CrMoV dissimilar rotor welded joint[J]. Materials and Design, 2014, 59: 165 − 175. doi: 10.1016/j.matdes.2014.02.022

[6] 杨百勋, 丁玲玲, 田晓, 等. FB2转子钢低周疲劳断口分析[J]. 中国电力, 2018, 51(11): 20 − 25. Yang Baixun, Ding Lingling, Tian Xiao. Analysis of the fracture morphology of FB2 under low-cycle fatigue[J]. Electric Power, 2018, 51(11): 20 − 25.

[7] 张建勋. 金属焊接性能的不均匀性及其尺度效应研究[J]. 电焊机, 2008, 39(1): 24 − 29. Zhang Jianxun. Unevenness of metal welding performance and its scale effect study[J]. Electric Welding Machine, 2008, 39(1): 24 − 29.

[8] Wang W K, Liu Y, Zhang Q B, et al. Microstructure and local mechanical properties of a dissimilar metal welded joint with buttering layer in steam turbine rotor[J]. Materials Science & Engineering: A, 2019, 747: 244 − 254.

[9] Tan L, Zhang J X, Zhuang D, et al. Influences of lumped passes on welding residual stress of a thick-walled nuclear rotor steel pipe by multipass narrow gap welding[J]. Nuclear Engineering and Design, 2014, 273: 47 − 57.

[10] Manson S S, Behavior of materials under conditions of thermal stress[C]//Washington, USA: National Advisory Committee for Aeronautics, 1953: 1 − 105.

[11] Coffin L F. A study of the effects of cyclic thermal stresses on a ductile metal[J], Trans. ASTM, 1954, 76: 931.

[12] Zhou H W , He Y Z , Zhang H , et al. Influence of dynamic strain aging pre-treatment on the low-cycle fatigue behavior of modified 9Cr–1Mo steel[J]. International Journal of Fatigue, 2013, 47(FEB.): 83 − 89.

[13] 郑修麟, 张钢柱. 应变疲劳公式的探讨[J]. 西北工业大学学报, 1984(2): 223 − 229. Zheng Xiulin, Zhang Gangzhu. On fatigue formula under strain cycling[J]. Journal of Northwestern Polytechnical University, 1984(2): 223 − 229.

[14] Ramberg W, Osgood W R. Description of stress-strain curves by three parameters[C]//Technical note no. 902, National Advisory Committee on Aeronautics, 1943: 1 − 6.

[15] 师田田, 周晓, 沈寅忠. 11%Cr铁素体/马氏体钢蠕变前后的析出相研究[J]. 金属热处理, 2018, 43(7): 1 − 6. Shi Tiantian, Zhou Xiao, Shen Yanzhong. Precipitate phases in 11%Cr ferritic/martensitic steel before and after creep[J]. Heat Treatment of Metals, 2018, 43(7): 1 − 6.

-

期刊类型引用(1)

1. 王文安. 铝合金焊接头的软化及改善措施分析. 中国设备工程. 2021(12): 73-74 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: